AC line BMW 540i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 540i, Model: BMW 540i 2001 E39Pages: 1002

Page 769 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Warnings and cautions

WARNING-

. E39 cars require special BMWsen/ice equipment toprop-

erly bleed the brake hydraulic system. See Bleeding

Brakes for additional information.

Semi-metallic and metallic brake friction materials in

brake pads or shoes may produce dangerous dust.

Brake fluid is poisonous, corrosive and dangerous to

the environment. Wear safety glasses and rubber

gloves when worliing with

bralie fluid. Do not siphon

brake fluid with your mouth. Dispose of brake fluid

properly

Do not reuse self-locking nuts, bolts or fasteners. They

are designed to be used only once and may fail if re-

used. Always replace them with new self-locliing fas-

teners.

CAUTlOI\C

Immediately clean bralie fluid spilled on painted surfaces

and wash with water, as

bralie fluid will remove paint.

Always use new brake fluid from a fresh, unopened

container.

Brake fluid will absorb moisture from the air.

This can lead to corrosion problems in the

braking sys-

tem, and will also lower the fluid boiling point.

. Plug open lines and brake fluid ports to prevent con-

tamination.

Only tighten brake hoses on front wheels

with wheels

in straight ahead position.

If carrying out electric welding

worlc, be sure to discon-

nect electrical harness connector from electronic con-

trol module.

Do not expose electronic control modules to high sus-

tained heat, such as in a paint drying booth. Maximum

heat exposure:-95°C (203

OF) for short periods of time-

85'C (185°F) for Ions periods of time (approx. 2 hours)

Page 770 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-8

1 Brakes

Brake bleeding is usually done for one of two reasons: either

to replace old brake fluid as part of routine maintenance or to

expel trapped air in the system that resulted

from opening the

brake hydraulic system during repairs.

Read the

Warnings listed below before beginning the bleed-

ing procedure an on any

E39 car. If air enters the ACS or DSC

hydraulic unit, the factory BMW Service Tester MUST be

used in conjunction with a bralte pressure bleeder before the

vehicle is driven.

The BMW

ServiceTester (DISpluslGT1iMoDiC) must be

used to bleed the braltes if:

Any hydraulic brake system components are replaced, in-

cluding bralte lines.

Air has enter the

ABSIASC or ABSlDSC hydraulic unit.

WARNING -

* The ASC and DSC systems use electronic controls and a

sophisticated hydraulic unit Once air enters the hydraulic

unit, it is very difficult to remove using traditional methods.

For this reason, pressure

brake bleeding should be done

in conjunction with the BMW

Sewice Tester (DIS-

plus/GTl/MoDiC). The tester electrically cycles the hy-

draulic unit solenoids in the hydraulic unit while

pressurized brake fluid is forced through the system.

When flushing the brake fluid from the system, use ex-

treme care to not let the

brale fluid reservoir run dry If

air enters the hydraulic unit, the BMW Service Tester

MUST be used to bleed the brale system before the

vehicle is driven.

Always use new brake fluid from an unopened container. It is

important to bleed the entire system when any part of the hy-

draulic system has been opened. Be sure to have the special

equipment needed before beginning the job.

When bleeding the

braltes, start atthe wheel farthest from the

master cylinder and progress in the following order:

right rear brake

left rear brake

* right front brake

left front brake

Page 777 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-1 5

Brakes

- Remainder of installation is reverse of removal.

- Clean brake caliper mounting bolts (7 mm Allen). Replace

ones which are not in perfect condition. Do not grease.

Top up brake fluid to MAX marking.

- Before driving car, pump bralte pedal several times so that

brake pads contact brake rotors.

Check that brake fluid level is correct. Top up if necessary.

Hold ignition key for at least

30 seconds in accessory po-

sition without starting engine. This clears any fault codes in

memory and turns off brake pad warning light.

Tightening torques Brake caliper to pad carrier

(7 mm Allen)

Front caliper

30 Nm (22 It-lb)

- Rear caliper 28 Nm (21 It-lb)

Road wheel to hub

120i 10 Nm (89i7 ft-lb)

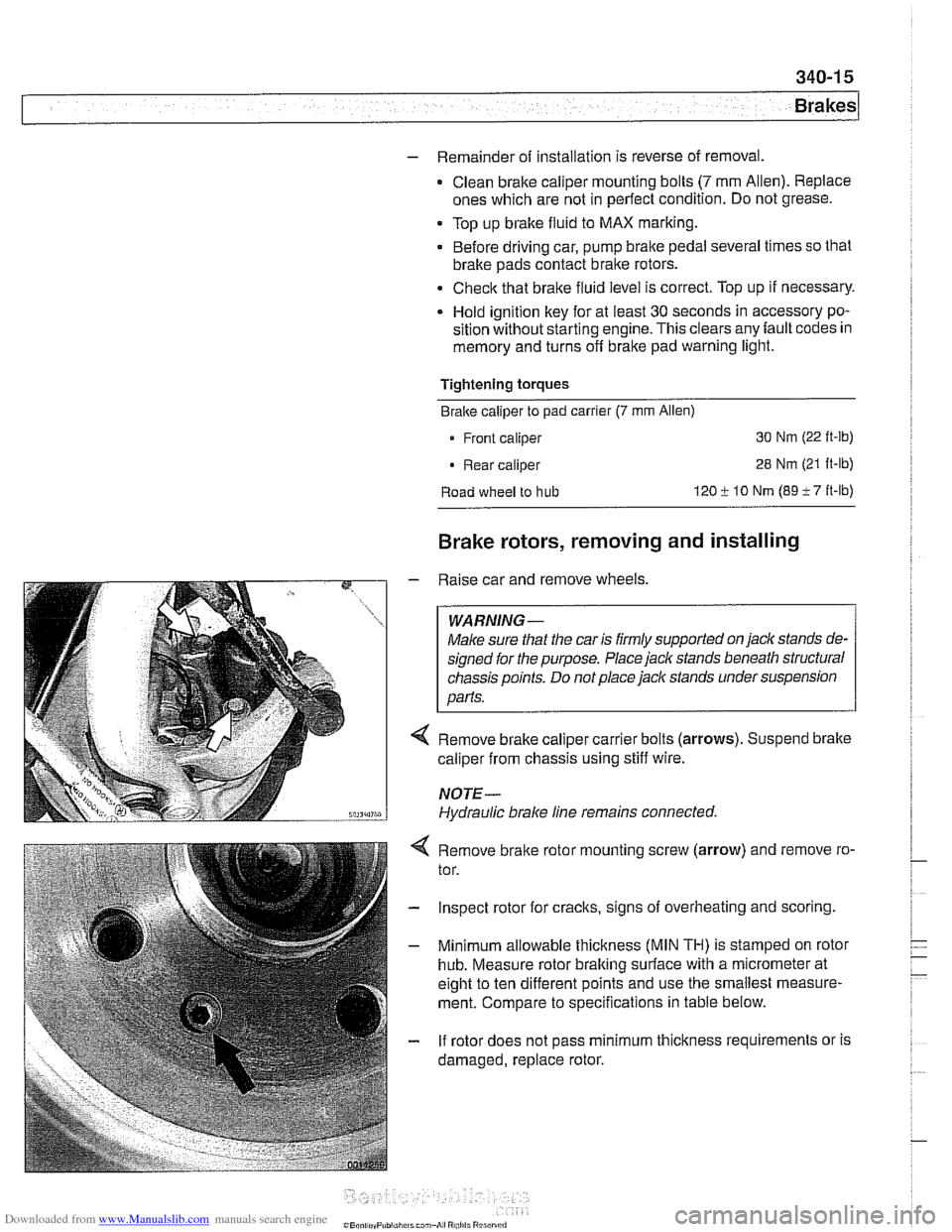

Brake rotors, removing and installing

- Raise car and remove wheels

WARNING-

Male sure that the car is firmly supported on jack stands de-

signed for the purpose. Place jack stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

Remove brake caliper carrier bolts (arrows). Suspend brake

caliper from chassis using stiff wire.

NOTE-

Hydraulic brake line remains connected.

4 Remove bralte rotor mounting screw (arrow) and remove ro-

tor.

- Inspect rotor for cracks, signs of overheating and scoring.

- Minimum allowable thickness (MIN TH) is stamped on rotor

hub. Measure rotor braking surface with a micrometer at

eight to ten different points and use the smallest measure-

ment. Compare to specifications in table below.

- If rotor does not pass minimum thickness requirements or is

damaged, replace rotor.

Page 779 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

Master cylinder, removing and installing

CAUTlOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it properly.

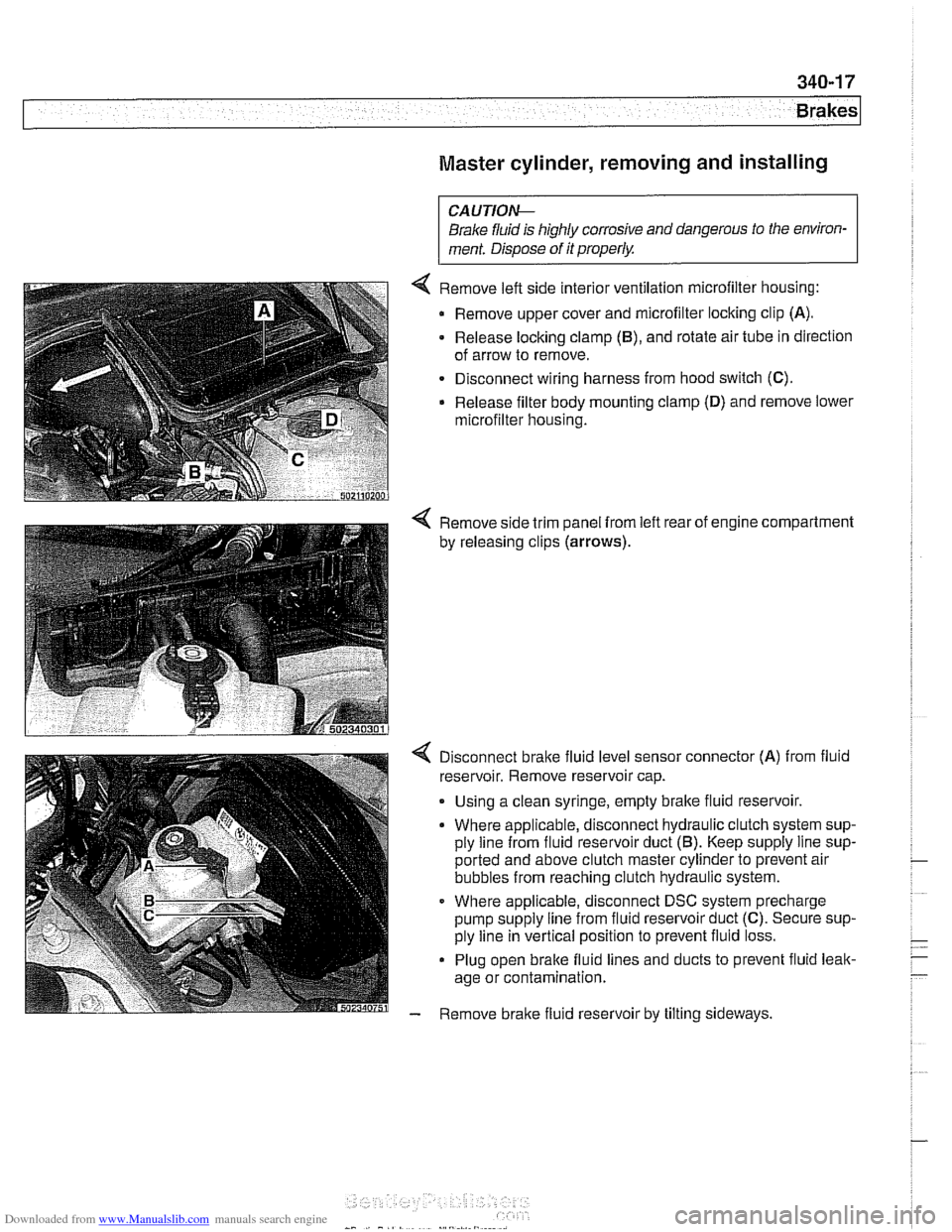

4 Remove left side interior ventilation microfilter housing:

Remove upper cover and microfilter locking clip

(A).

- Release locking clamp (B), and rotate air tube in direction

of arrow to remove.

Disconnect wiring harness from hood switch

(C).

Release filter body mounting clamp (D) and remove lower

microfilter housing.

4 Remove side trim panel from left rear of engine compartment

by releasing clips

(arrows).

4 Disconnect bralte fluid level sensor connector (A) from fluid

reservoir. Remove reservoir cap.

. Using a clean syringe, empty bralte fluid reservoir.

Where applicable, disconnect hydraulic clutch system sup-

ply line from fluid reservoir duct

(5). Keep supply line sup-

ported and above clutch master cylinder to prevent air

bubbles from reaching clutch hydraulic system.

Where applicable, disconnect DSC system precharge

pump supply line from fluid reservoir duct

(C). Secure sup-

ply line in vertical position to prevent fluid loss.

Plug open brake fluid lines and ducts to prevent fluid leak-

age or contamination.

- Remove brake fluid reservoir by tilting sideways.

Page 780 of 1002

Downloaded from www.Manualslib.com manuals search engine

.- -

Brakes

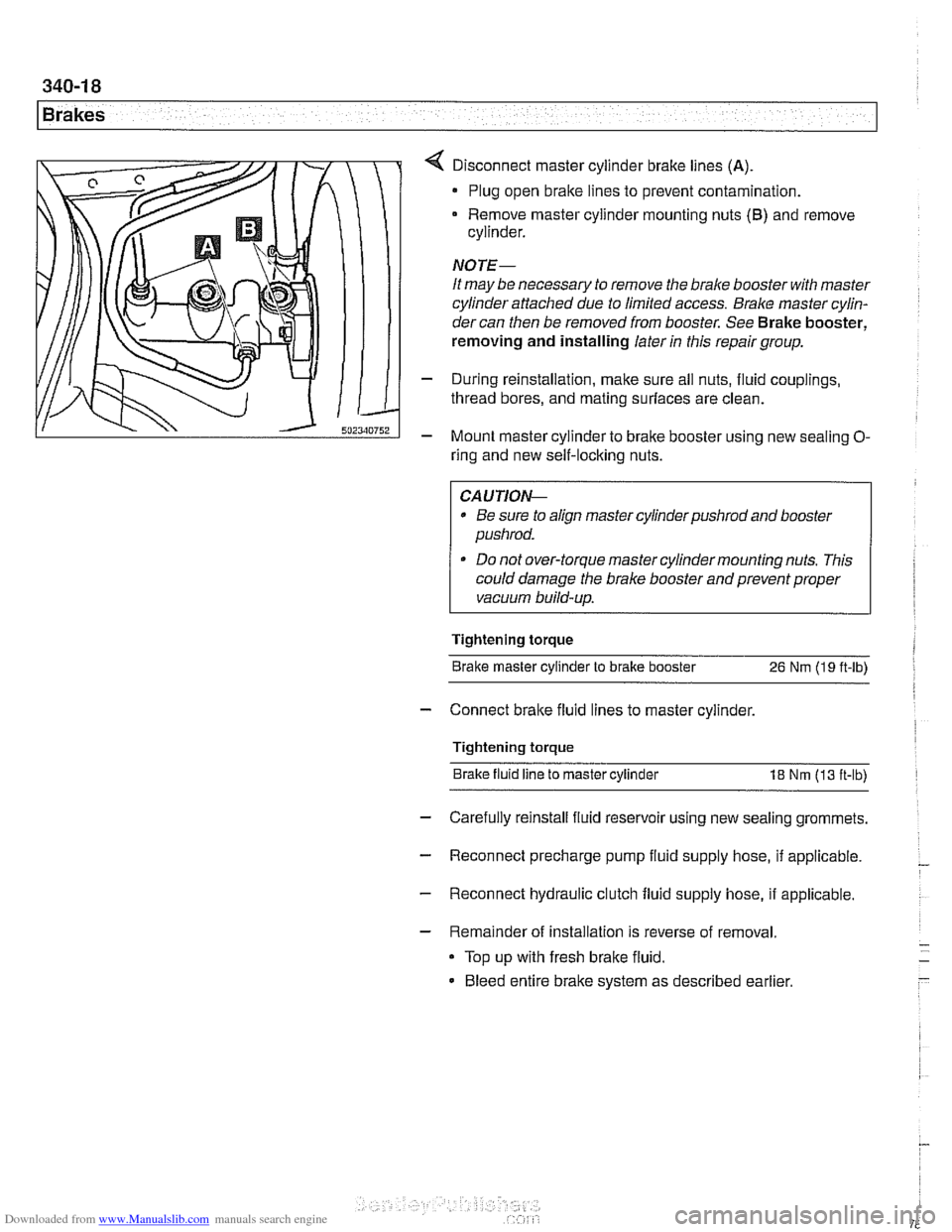

Disconnect master cylinder brake lines (A)

Plug open brake lines to prevent contamination.

Remove master cylinder mounting nuts

(6) and remove

cylinder.

NOTE-

It may be necessary to remove the brake booster with master

cylinder attached due to limited access.

Bralce master cylin-

dercan then be removed from booster. See Brake booster,

removing and installing later

in this repair group.

- During reinstallation, make sure all nuts, fluid couplings,

thread bores, and mating surfaces are clean.

- Mount master cylinder to bralte booster using new sealing O-

ring and new self-locking nuts.

CAUTIOI\C

* Be sure to align master cylinderpushrod and booster

pushrod.

* Do not over-torque master cylinder mounting nuts. This

could damage the brake booster and prevent proper

vacuum build-up.

Tightening torque Brake master cylinder to brake booster

26 Nm (19 ft-lb)

- Connect bralte fluid lines to master cylinder.

Tightening torque Brake fluid line to master cylinder

18 Nm (13 ft-lb)

- Carefully reinstall fluid reservoir using new sealing grommets.

- Reconnect precharge pump fluid supply hose, if applicable. -

- Reconnect hydraulic clutch fluid supply hose, if applicable.

- Remainder of installation is reverse of removal.

Top up with fresh brake fluid.

Bleed entire brake system as described earlier

Page 781 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

The brake booster is mounted to the bulkhead on driver's side

of the engine compartment, directly behind the brake master

cylinder. Intake manifold vacuum acts on a large diaphragm

in the brake booster to reduce brake pedal effort.

Brake booster check valve

The checlc valve in the bralte booster vacuum line prevents

contamination from engine backfires and other sources from

entering the bralte booster.

Location of

check valve varies, depending on year and mod-

el.

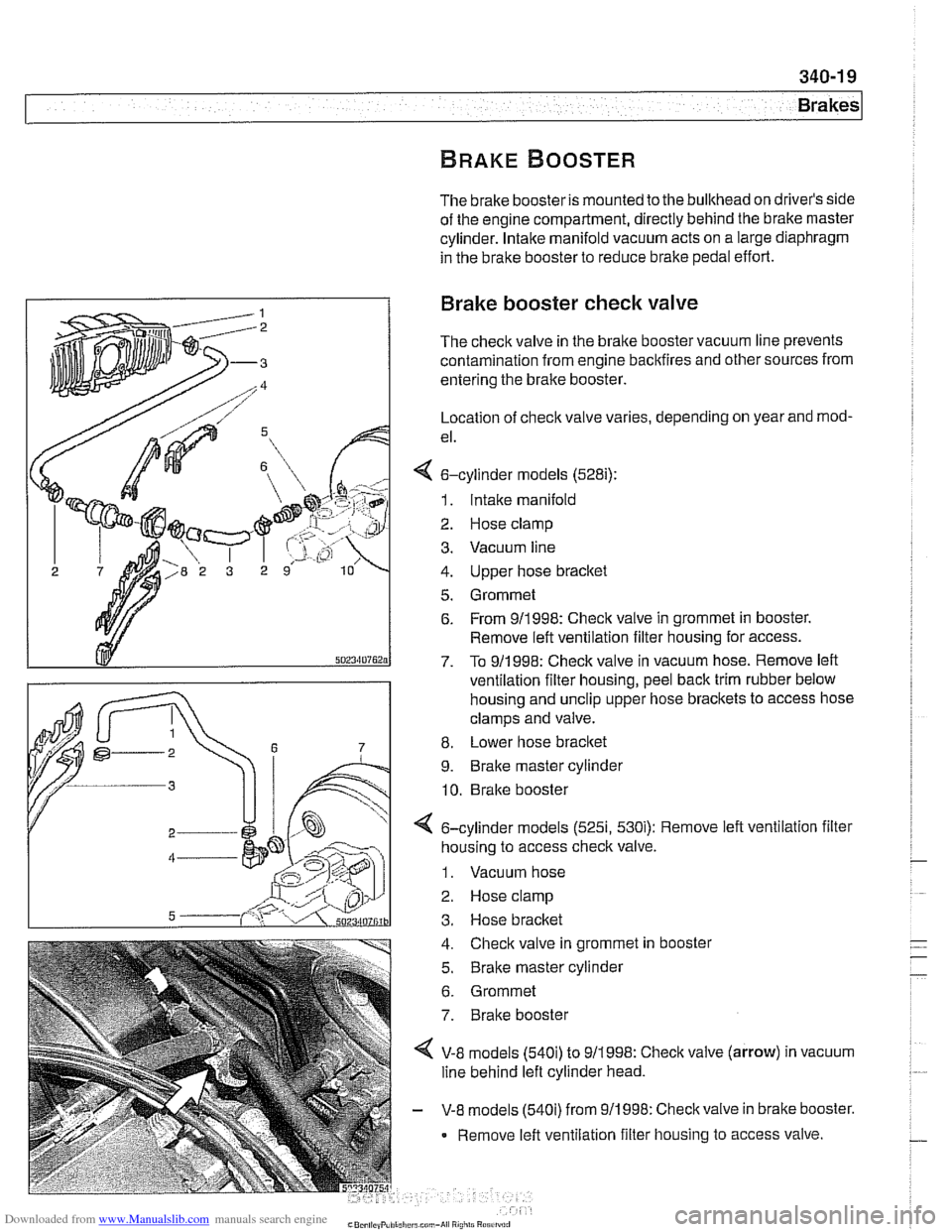

4 6-cylinder models (528i):

1. Intake manifold

2 Hose clamp

3. Vacuum line

4. Upper hose bracket

5. Grommet 6. From 911998: Check valve in grommet in booster.

Remove left ventilation filter housing for access.

7. To 911 998: Check valve in vacuum hose. Remove left

ventilation filter housing, peel back trim rubber below

housing and

unclip upper hose brackets to access hose

clamps and valve.

8. Lower hose

bracket

9. Brake master cylinder

10. Brake booster

< 6-cylinder models (525i, 530i): Remove left ventilation filter

housing to access

checlc valve.

1. Vacuum hose

2. Hose clamp

3. Hose bracket

4. Check valve in grommet in booster

5.

Braite master cylinder

6. Grommet

7. Brake booster

4 V-8 models (540i) to 911998: Check valve (arrow) in vacuum

line behind left cylinder head.

- V-8 models (540i) from 911998: Checkvalve in brake booster.

Remove left ventilation filter housing to access valve.

Page 782 of 1002

Downloaded from www.Manualslib.com manuals search engine

Brakes

- Pump brake pedal a few times to reduce vacuum in brake

booster. This makes removal of

check valve easier.

- Remove or loosen hose clamp(s) at check valve.

- Disconnect hoses. Remove valve to test or replace.

NOTE-

If valve is pressed into grommet in vacuum booster, pry it out

carefully.

- Reinstall valve using new hose clamps

NOTE-

Install the valve so that the molded arrow is pointing toward

the intake manifold.

Brake booster, removing and installing

CAUTIO&

All E39 vehicles sold in the USA are equipped with Antiloclc

Braking System (ABS) and either Automatic Stability Control

(ASC) or Dynamic Stability Control (DSC). In order for the

bralchg and stability controls to work properk if brake fluid

lines are disconnected and reconnected,

male sure that the

brake system is bled by an authorized BMW dealer or other

qualified repair facility using the BMW Service Tester: See

Brake Bleeding earlier in this group.

- Disconnect negative (-) cable from battery.

I CAUTION- I

Prior to disconnecting the battery read the battery discon-

nection cautions given in

001 General Cautions and

I Warnings. I

- Remove bralte master cylinder as described earlier.

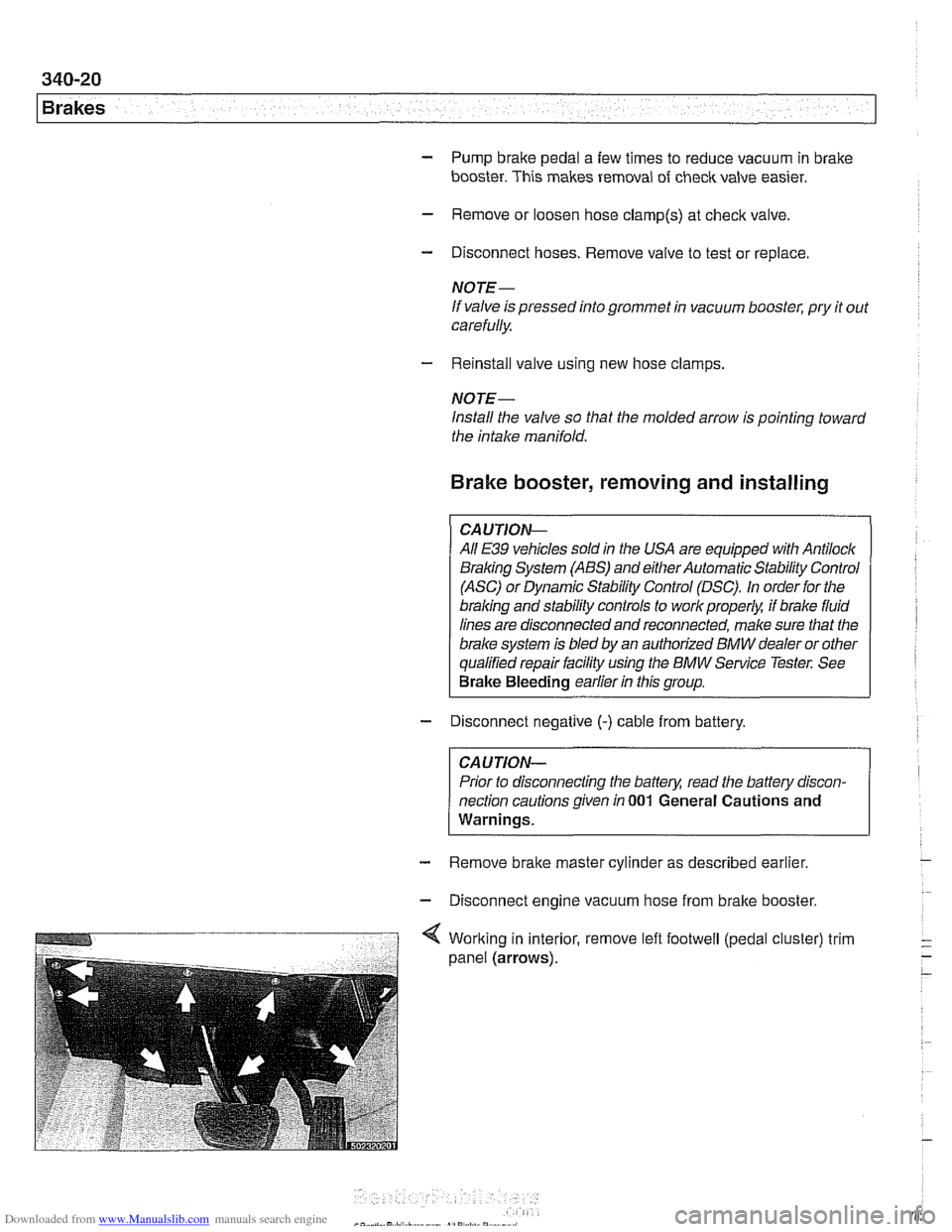

- Disconnect engine vacuum hose from bralte booster.

Page 783 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

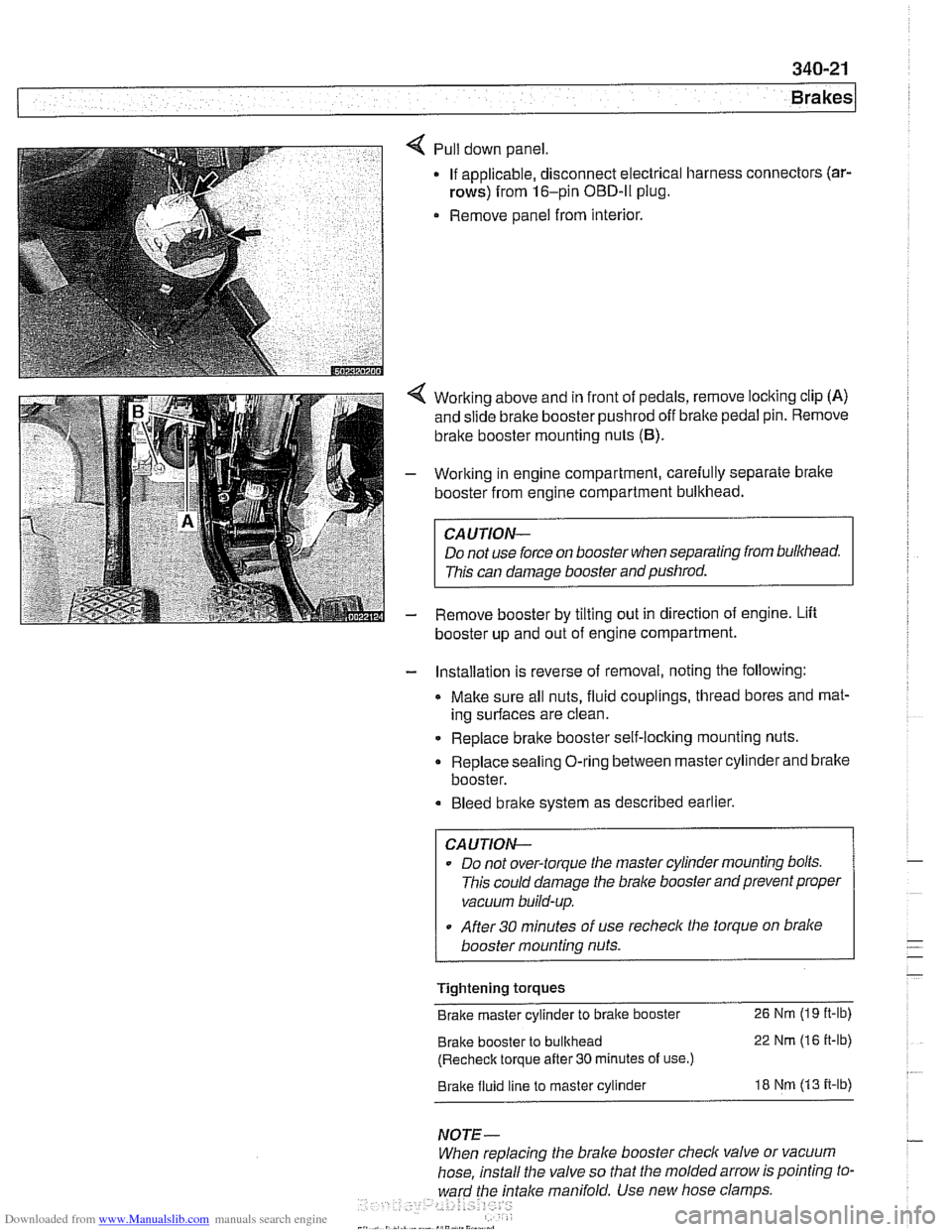

Pull down panel

If applicable, disconnect electrical harness

rows) from 16-pin OBD-ll plug.

Remove panel from interior. connectors

(ar-

Working

above and in front of pedals, remove locking clip (A)

and slide brake booster pushrod off bralte pedal pin. Remove

brake booster mounting nuts

(6).

Working in engine compartment, carefully separate bralte

booster from engine compartment bulkhead.

CAUTION-

Do not use force on booster when separating from bulkhead.

This can damage booster and pushrod.

Remove booster by tilting out in direction of engine. Lift

booster up and out of engine compartment.

- Installation is reverse of removal, noting the following:

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Replace bralte booster self-locking mounting nuts.

Replace sealing O-ring between master cylinder and bralte

booster.

Bleed bralte system as described earlier.

CAUTION--

Do not over-torque tlie master cylinder mounting bolts.

This could damage the

bralce booster and prevent proper

vacuum build-up.

After

30 minutes of use recheclc the torque on bralce

booster mounting nuts.

Tightening torques

Brake master cylinder to brake booster

26 Nm (19 it-lb)

Brake booster to bulkhead 22 Nm (16 it-lb)

(Recheck torque after

30 minutes of use.)

Brake fluid line to master cylinder 18 Nm (13 it-lb)

NOTE-

When replacing the brake booster check valve or vacuum

hose, install the valve so that the molded arrow is pointing to-

ward the

fntalce manifold. Use new hose clamps

Page 788 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

ABS COMPONENT REPLACEMENT

CA UTIOW-

If the tires on the car are of different makes, the ABS/trac-

tion controlsystem may overreact. Only fit tires of the same

make and treadpattern.

In adverse conditions, such as trying to rock the car out

of deep snow or other soft surface, or when snow

chains are fitted, it is advisable to switch off traction

control and allow

tlie car driveline to operate conven-

tionally.

All E39 vehicles are equipped with

Antilock Braking System

(ABS). Early production models featured ABS with Automatic

Stability Control (ABS

I ASC). Later models came equipped

with ABS and Dynamic Stability Control (ABS

/ DSC). This

manual will refer to these systems as ABS. ASC or DSC will

be specified when necessary.

For ABS system and component descriptions, see

300 Sus-

pension, Steering and Brakes-General.

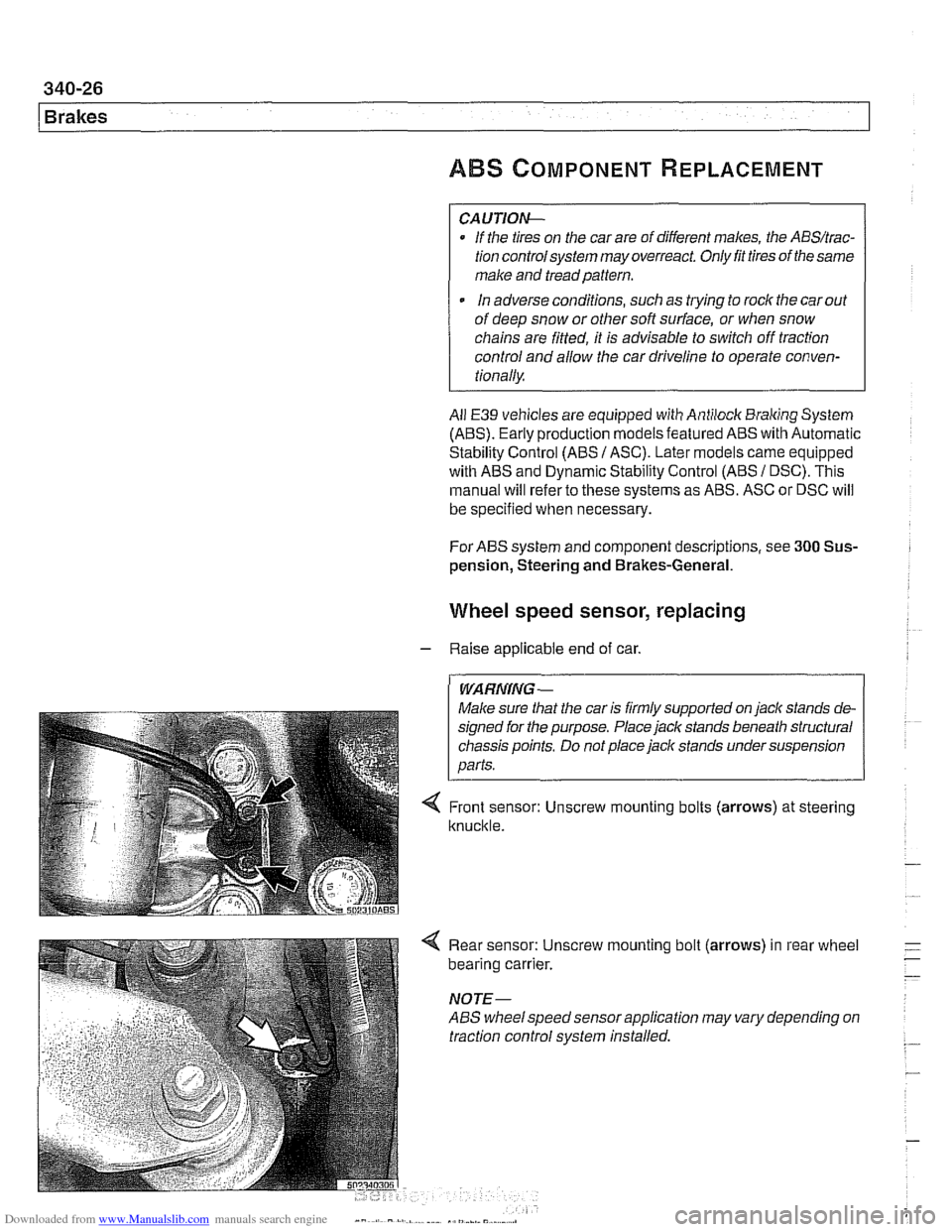

Wheel speed sensor, replacing

- Raise applicable end of car.

Make sure that the car is firmly supported on

jack stands de-

signed for the purpose. Place

jack stands beneath structural

chassis points. Do not place jack stands under suspension

< Front sensor: Unscrew mounting bolts (arrows) at steering

knuckle.

4 Rear sensor: Unscrew mounting bolt (arrows) in rear wheel

bearing carrier.

NOTE-

ABS wheelspeed sensor application may vary depending on

traction control system installed.

Page 791 of 1002

Downloaded from www.Manualslib.com manuals search engine

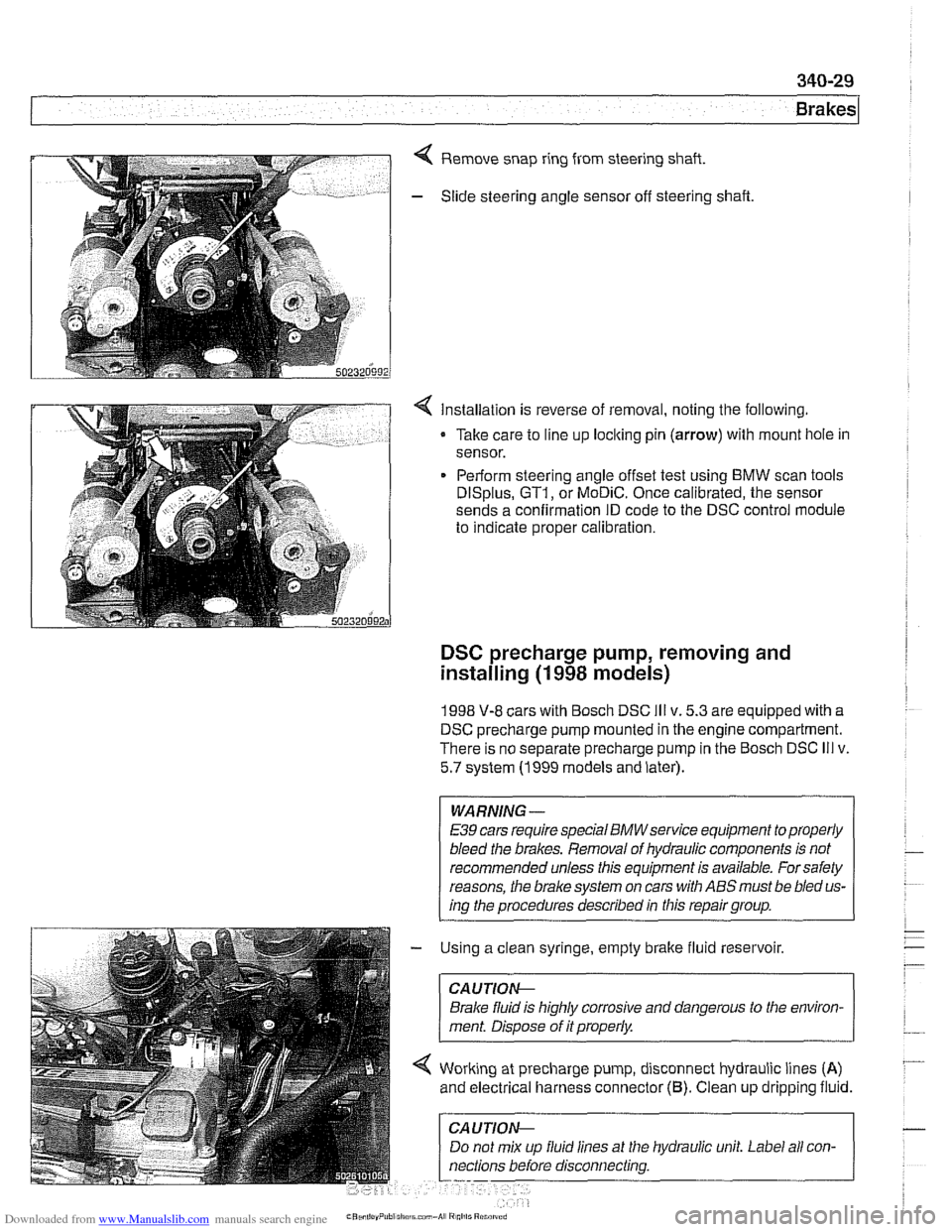

Remove snap ring from steering shaft.

- Slide steering angle sensor off steering shaft

< Installation is reverse of removal, noting the following.

Take care to line up loclting pin

(arrow) with mount hole in

sensor.

Perform steering angle offset test using BMW scan tools

DISplus, GT1, or MoDiC. Once calibrated, the sensor

sends a confirmation ID code to the DSC control module

to indicate proper calibration.

DSC precharge pump, removing and

installing

(1 998 models)

1998 V-8 cars with Bosch DSC Ill v. 5.3 are equipped with a

DSC precharge pump mounted in the engine compartment.

There is no separate precharge pump in the Bosch DSC

Ill v.

5.7 system (1999 models and later).

WARNING-

E39 cars require special BMWservice equipment to properly

bleed the brakes. Removal of hydraulic components is not

recommended unless this equipment is available. For safety

reasons, the

brake system on cars with ABS must be bled us-

ing the procedures described in this repair group.

- Using a clean syringe, empty brake fluid reservoir.

CAUTIOI\C

Brake fluid is highly corrosive and dangerous to the environ-

ment. Disoose of it

orooerlv.

Working at precharge pump, disconnect hydraulic lines (A)

and electrical harness connector (6). Clean up dripping fluid.

hydraulic unit. Label all

con-