AC line BMW 540i 2001 E39 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2001, Model line: 540i, Model: BMW 540i 2001 E39Pages: 1002

Page 792 of 1002

Downloaded from www.Manualslib.com manuals search engine

1 Brakes

- Remove precharge pump mounting bracket fasteners and re-

move pump.

- Installation is reverse of removal, noting the following:

Be sure to replace rubber pump mounts if damaged

01

worn.

Bleed brakes as described earlier.

Tightening torque Brake line

to precharge pump 18 Nrn (13 ft-lb)

DSC pressure sensor (1 999 - 2002 models)

On 1999 and later DSC systems, the DSC pressure sensor is

screwed into the DSC hydraulic unit (right rear of engine com-

partment).

WARNING-

* €39 cars require special BMW service equipment to prop-

erly bleed the brakes. Removal of the

DSCpressure sensor

is not recommended unless this equipment is available. For

safety reasons, the brake system on cars with ABS must be

bled using the procedures described in this repair group.

Switch off ignition and remove

key to male sure brake

system cannot be activated.

- Disconnect electrical harness connector at switch.

- Use BMW special tool 34 5 160 to remove and install sensor.

Inspect threads and sealing surfaces for damage.

* Work quicltly to avoid excessive brake fluid leakage.

Tightening torque

Pressure sensor

to hydraulic 19 Nrn (14ft-lb)

unit

- Reconnect harness connector

- Bleed front brakes as described earlier.

- Press on brakes and check for leaks at sensor.

- Turn on ignition and firmly depress brake pedal. Check that

DSC warning light does not come on.

Page 794 of 1002

Downloaded from www.Manualslib.com manuals search engine

340-32

Brakes

The procedure for removing the ABS I ASC or ABS I DSC hy-

draulic unit is similar for all models. The unit is located at the

right rear of the engine compartment.

- Using a clean syringe, empty brake fluid reservoir.

CAUTION-

Brake fluid is highly corrosive and dangerous to the environ-

ment. Dispose of it

properiw

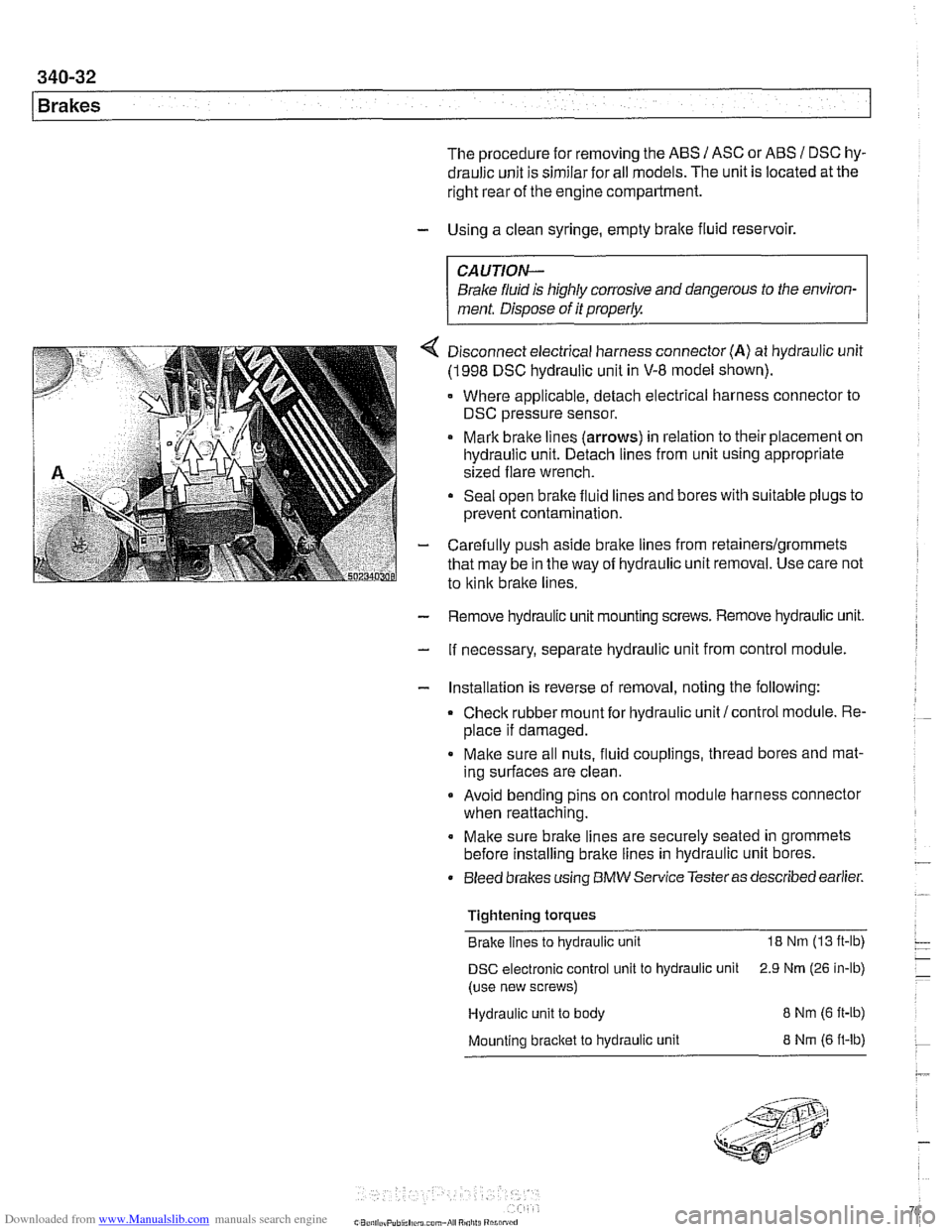

4 Disconnect electrical harness connector (A) at hydraulic unit

(1998 DSC hydraulic unit in V-8 model shown).

Where applicable, detach electrical harness connector to

DSC pressure sensor.

Mark brake lines

(arrows) in relation to their placement on

hydraulic unit. Detach lines from unit using appropriate

sized flare wrench.

Seal open brake fluid lines and bores with suitable plugs to

prevent contamination.

- Carefully push aside brake lines from retainerslgrommets

that may be in the way of hydraulic unit removal. Use care not

to

kink brake lines.

- Remove hydraulic unit mounting screws. Remove hydraulic unit.

- If necessary, separate hydraulic unit from control module.

- Installation is reverse of removal, noting the following:

Check rubber mount for hydraulic unit/control module. Re-

place if damaged.

Make sure all nuts, fluid couplings, thread bores and mat-

ing surfaces are clean.

Avoid bending pins on control module harness connector

when reattaching.

Make sure brake lines are securely seated in grommets

before installing brake lines in hydraulic unit bores.

Bleed brakes using

BMW Service Testeras described earlier.

Tightening torques Brake lines to hydraulic unit

18 Nm (13 ft-lb)

DSC electronic control unit to hydraulic unit 2.9 Nrn (26 in-lb)

(use new screws)

Hydraulic unit to body

8 Nm (6 ft-ib)

Mounting bracket to hydraulic unit 8 Nrn (6 ft-lb)

Page 808 of 1002

Downloaded from www.Manualslib.com manuals search engine

[Fenders, Engine Hood

This repair group covers replacement of the front fenders and

removal and installation of the engine hood.

NOJE-

The body is painted at the factory affer assembly Realign-

ment of body panels may expose unpainted metal. Paint all

exposed metal once the work is complete.

Special tools

Most body repairs can be performed using regular automotive

service tools. Some BMW special tools are required to set

body pieces into the

service positions.

Front fender, removing and installing

- Raise front of vehicle and remove wheel

WARNING-

Make sure that the car is firmly supported on jack stands de-

signed for the purpose.

Placejaclr stands beneath structural

chassis points. Do not place jack stands under suspension

parts.

- Raise hood to service position. See Hood, raising to ser-

vice position.

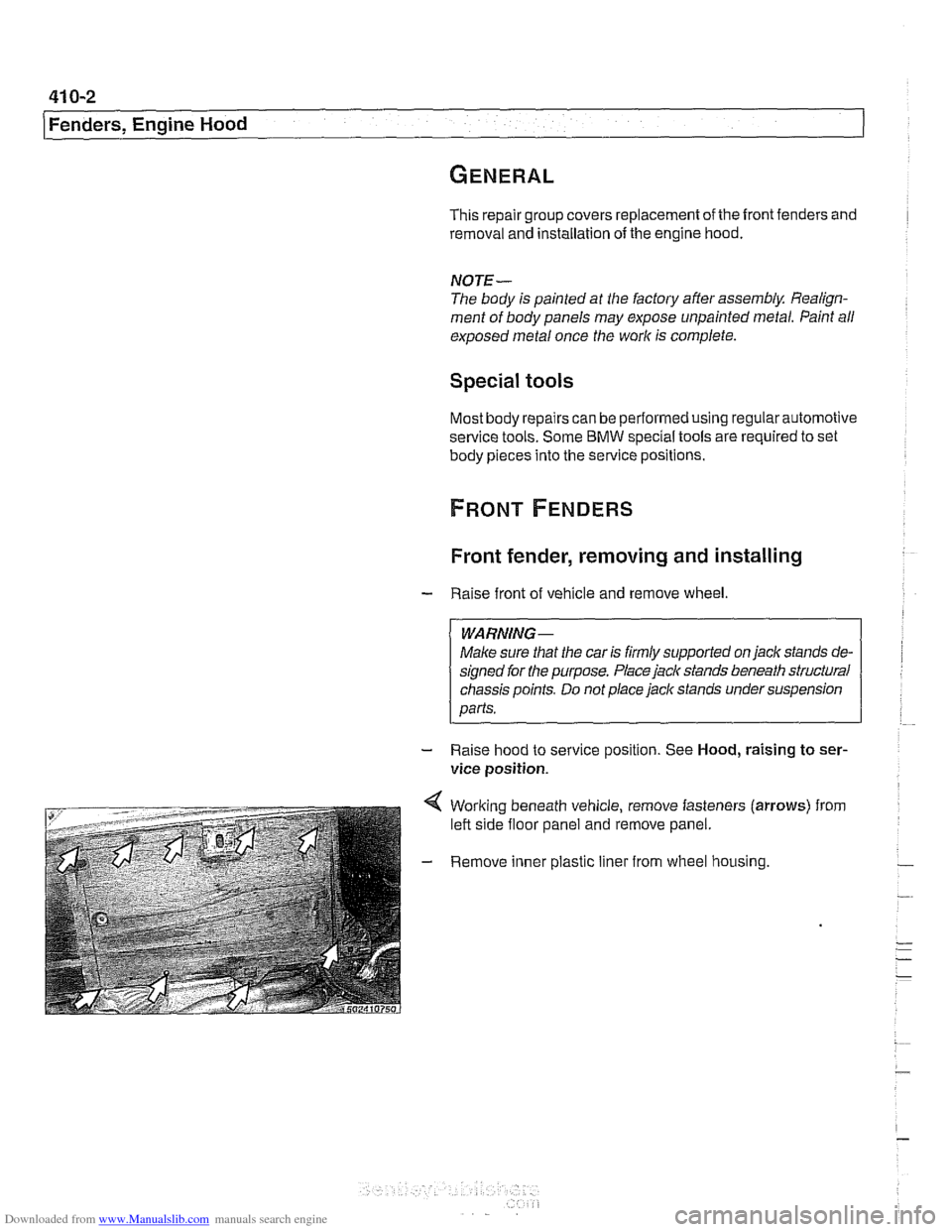

4 Working beneath vehicle, remove fasteners (arrows) from

left side floor panel and remove panel.

- Remove inner plastic liner from wheel housing.

Page 830 of 1002

Downloaded from www.Manualslib.com manuals search engine

41 2-2

Trunk Lid, Tailgate

This repair group covers trunk lid and tailgate removal and in-

stallation. Also included here are replacement proceduresfor

the gas-charged support struts that hold the trunk lid or tail-

gate in the open position.

NO JE -

The body is painted at the factory after assembly. Realign-

ment of body panels may expose unpainted metal. Paint all

exposed metal once the

work is complete.

Trunk lid, removing and installing

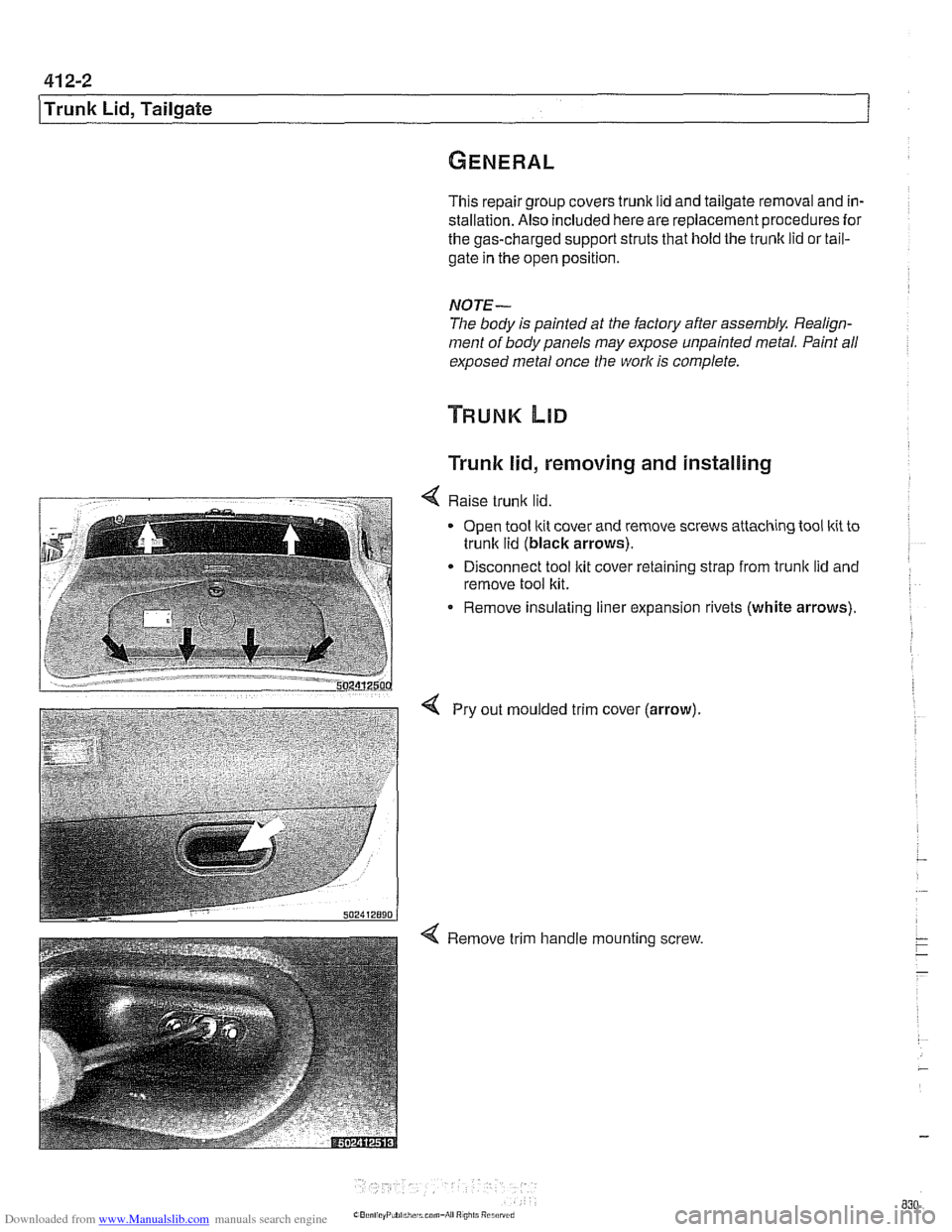

4 Raise trunlc lid.

Open tool ltit cover and remove screws attaching tool kit to

trunlc lid (black arrows).

Disconnect tool ltit cover retaining strap from

trunk lid and

remove tool kit.

Remove insulating liner expansion rivets (white arrows).

4 Pry out moulded trim cover (arrow).

Page 831 of 1002

Downloaded from www.Manualslib.com manuals search engine

Trunk Lid, Tailgate

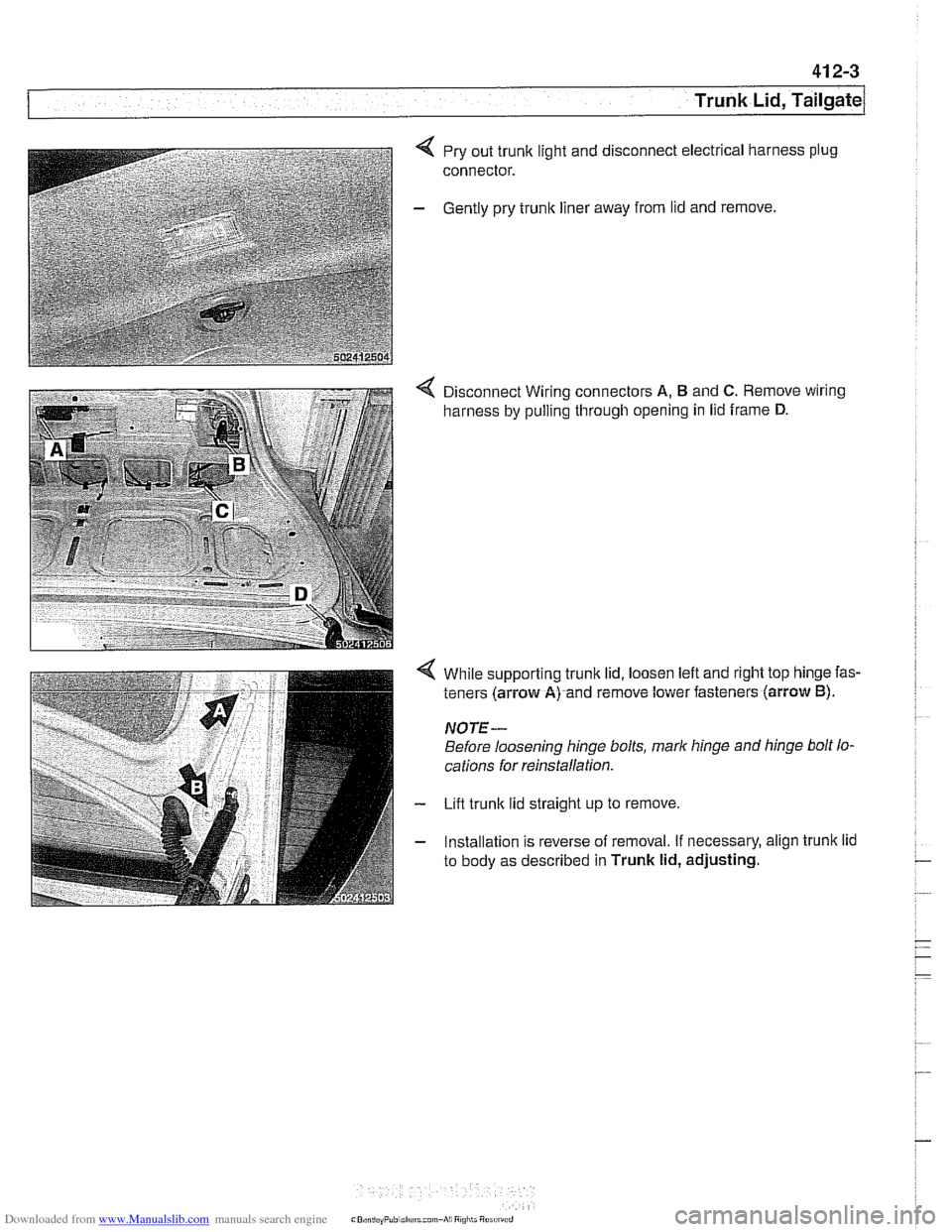

4 Pry out trunk light and disconnect electrical harness plug

connector.

- Gently pry trunk liner away from lid and remove.

4 Disconnect Wiring connectors A, B and C. Remove wiring

harness by pulling through opening in lid frame

D.

While supporting trunk lid, loosen left and right top hinge fas-

teners (arrow

A) and remove lower fasteners (arrow B).

NOTE-

Before loosening hinge bolts, mark hinge and hinge bolt lo-

cations for

reins~alla~on

Lift trunk lid straight up to remove.

Installation is reverse of removal. If necessary, align trunk lid

to body as described in

Trunk lid, adjusting.

Page 919 of 1002

Downloaded from www.Manualslib.com manuals search engine

51 5-25

Central Lockina and ~nti-~heftl

1

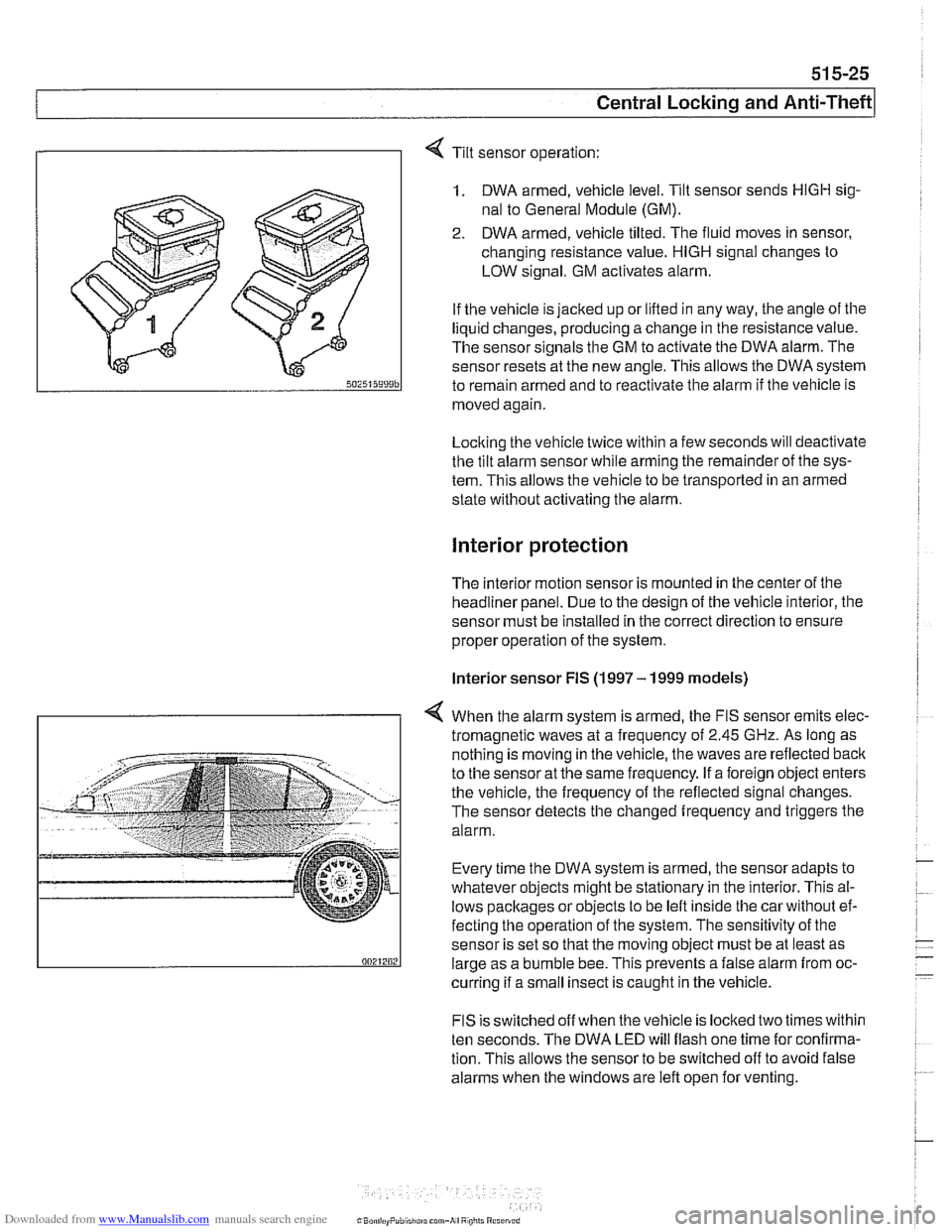

Tilt sensor operation:

1. DWA armed, vehicle level. Tilt sensor sends HlGH sig-

nal to General Module (GM).

2. DWA armed, vehicle tilted. The fluid moves in sensor,

changing resistance value.

HlGH signal changes to

LOW signal. GM activates alarm.

If the vehicle is jacked up or lifted in any way, the angle of the

liquid changes, producing a change in the resistance value.

The sensor signals the GM to activate the DWA alarm. The

sensor resets at the new angle.

This allows the DWA system

to remain armed and to reactivate the alarm if tlie vehicle is

moved again

Locking the vehicle twice within a few seconds will deactivate

the tilt alarm sensor while arming tlie remainder of the sys-

tem. This allows the vehicle to be transported in an armed

state without activating tlie alarm.

Interior protection

The interior motion sensor is mounted in the center of the

headliner panel. Due to the design of the vehicle interior, the

sensor must be installed in the correct direction to ensure

proper operation of the system.

lnterior sensor FIS (1997 - 1999 models)

4 When the alarm system is armed, the FIS sensor emits elec-

tromagnetic waves at

a frequency of 2.45 GHz. As long as

nothing is moving in the vehicle, the waves are reflected

baclc

to the sensor at the same frequency. If a foreign object enters

the vehicle, the frequency of the reflected signal changes.

The sensor detects the changed frequency and triggers the

alarm.

Every time the DWA system is armed, the sensor adapts to

whatever objects might be stationary in the interior. This al-

lows pacltages or objects to be left inside tlie car without ef-

fecting the operation of the system. The sensitivity of the

sensor is set so that the moving object must be at least as

large as a bumble bee. This prevents a false alarm from oc-

curring if a small insect is caught in the vehicle.

FIS is switched off when the vehicle is locked two times within

ten seconds. The DWA LED will flash one time for confirma-

tion. This allows the sensor to be switched off to avoid false

alarms when the windows are left open for venting.

Page 930 of 1002

Downloaded from www.Manualslib.com manuals search engine

540-2

Sunroof

This repair group covers the slide-tilt sunroof assembly.

There are two types of sunroof panels available: steel

01

glass. Service procedures are different for each type.

Component locations, initialization, sunroof panel replace-

ment, and sunroof height adjustment are covered. Replace-

ment of the cable assembly or frame require that the

headliner be removed. Removal and repair of the sunroof as-

sembly and othercomponents inside the roof cavity is beyond

the scope of this manual.

When the sunroof is set to the vent position (rear of panel up),

the inside headliner moves rearward approximately

120 mm

(4.7 in) This provides cabin ventilation with less wind noise. A

water channel is incorporated into the sunroof assembly. It

automatically rises when the sunroof panel is in the vent posi-

tion and prevents water from entering the interior during brak-

ing.

Sunroof electronic controls, initializing

- Initialize the sunroof in the following situations:

Malfunctions

such as lack of one-touch function, lack of

comfort openinglclosing or lack of safety (anti-trapping)

features.

If sunroof motor has been removed and reinstalled.

If power supply to the sunroof has been interrupted.

If repairs have been performed on the slideltilt mechanism.

NOTE -

The initialization sequence is dependent on the software ver-

sion of

tlie sunroof module (in the sunroof drive unit).

I WARNING -

I There is no anti-trapping protection during initialization. I

Page 932 of 1002

Downloaded from www.Manualslib.com manuals search engine

-.

Sunroof

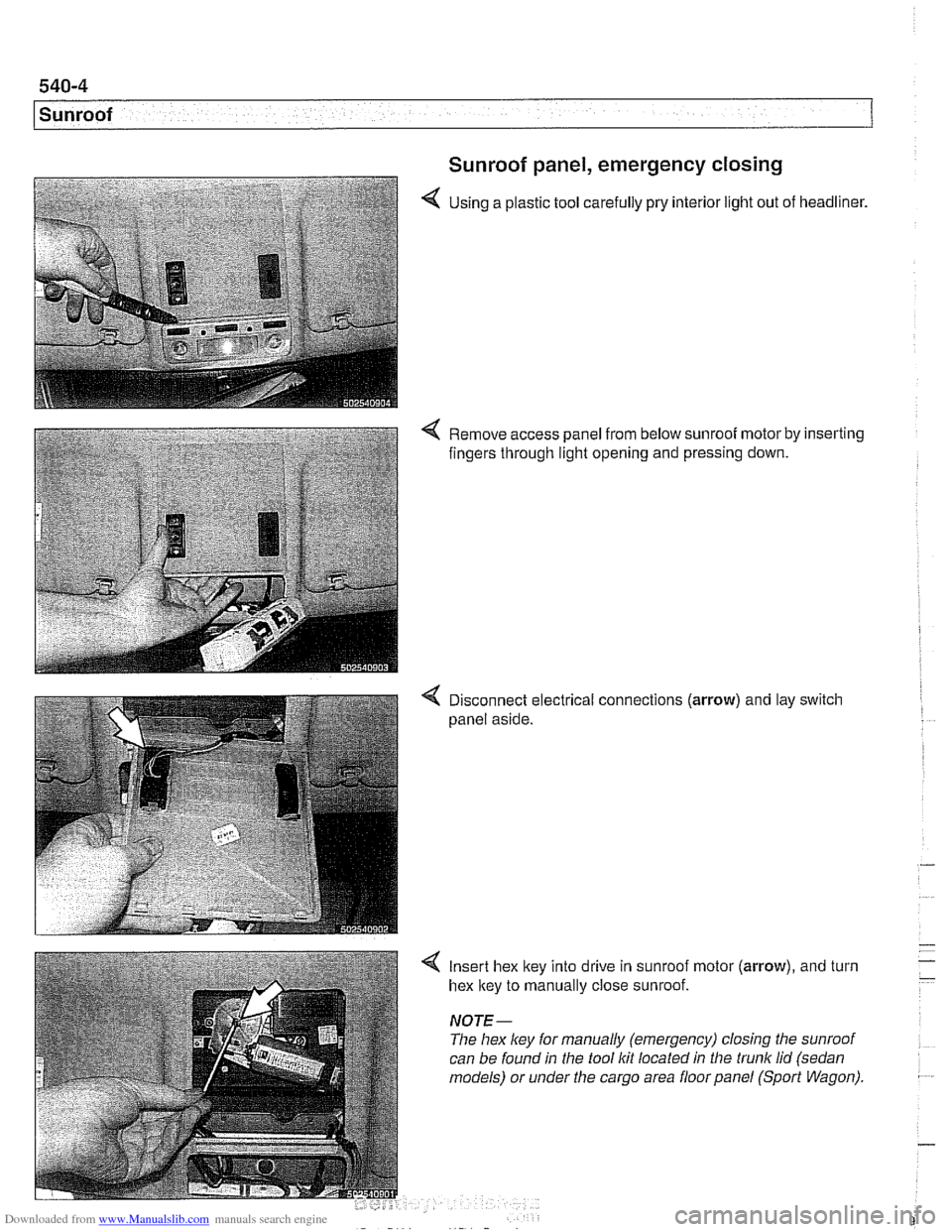

Sunroof panel, emergency closing

4 Using a plastic tool carefully pry interior light out of headliner.

4 Remove access panel from below sunroof motor by inserting

fingers through light opening and pressing down.

4 Disconnect electrical connections (arrow) and lay switch

panel aside.

4 Insert hex ltey into drive in sunroof motor (arrow), and turn

hex ltey to manually close sunroof.

NOTE-

The hex ley for manually (emergency) closing the sunroof

can be found in the tool

Itit located in the trunk lid (sedan

models) or under the cargo area floor panel (Sport Wagon).

Page 933 of 1002

Downloaded from www.Manualslib.com manuals search engine

Sunroof, adjusting

The sunroof is controlled by a set of cables that move the sun-

roof panel along guide rails when the motor is operated. The

sunroof can be adjusted without removing it from the car.

NOTE-

Be sure to check drains in front corners of sunroof carrier if

water is entering car through headliner.

- The sunroof panel should be adjusted under the following cir-

cumstances:

Sunroof misaligned with roof.

Sunroof does not close squarely.

* Wind noise at high speeds (sunroof closed).

Sunroof has been removed.

For correct sunroof alignment:

Sunroof must be fully closed.

Gap must be even all around edge of sunroof.

Front of sunroof must be flush to

1 mm (0.04 in.) below sur-

face of roof.

. Rear of sunroof must be flush to 1 mm (0.04) above sur-

face of roof.

NOTE-

Use a credit card to measure the gap. The card sllould insert

through the gap with equal resistance all around the perimeter.

Sunroof with steel roof panel, adjusting

- The headliner panel must be disengaged from the drive as-

sembly and moved rearward in order to access the roof panel

attaching screws.

CAUTIOI\C

Sunroof panel must never be moved to open position when . .

I the headliner is disenaaaed. 1

- Start with a fully closed roof panel.

- Remove drive motor access cover. See Sunroof motor, re-

placing.

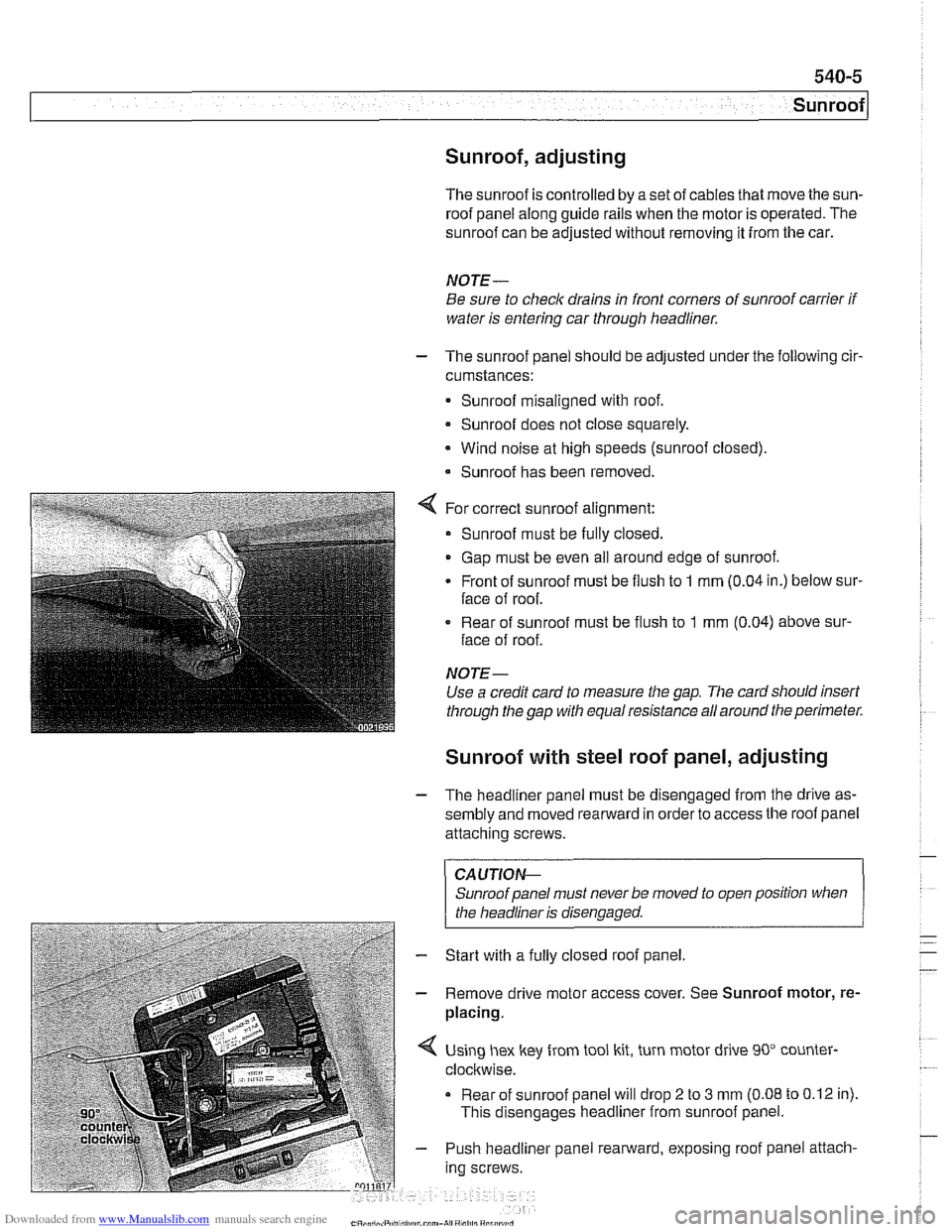

Using hex key from tool kit, turn motor drive 90" counter-

clockwise.

Rear of sunroof panel will drop

2 to 3 mm (0.08 to 0.12 in).

This disengages headliner from sunroof panel.

- Push headliner panel rearward, exposing roof panel attach-

ing screws.

Page 934 of 1002

Downloaded from www.Manualslib.com manuals search engine

l Sunroof

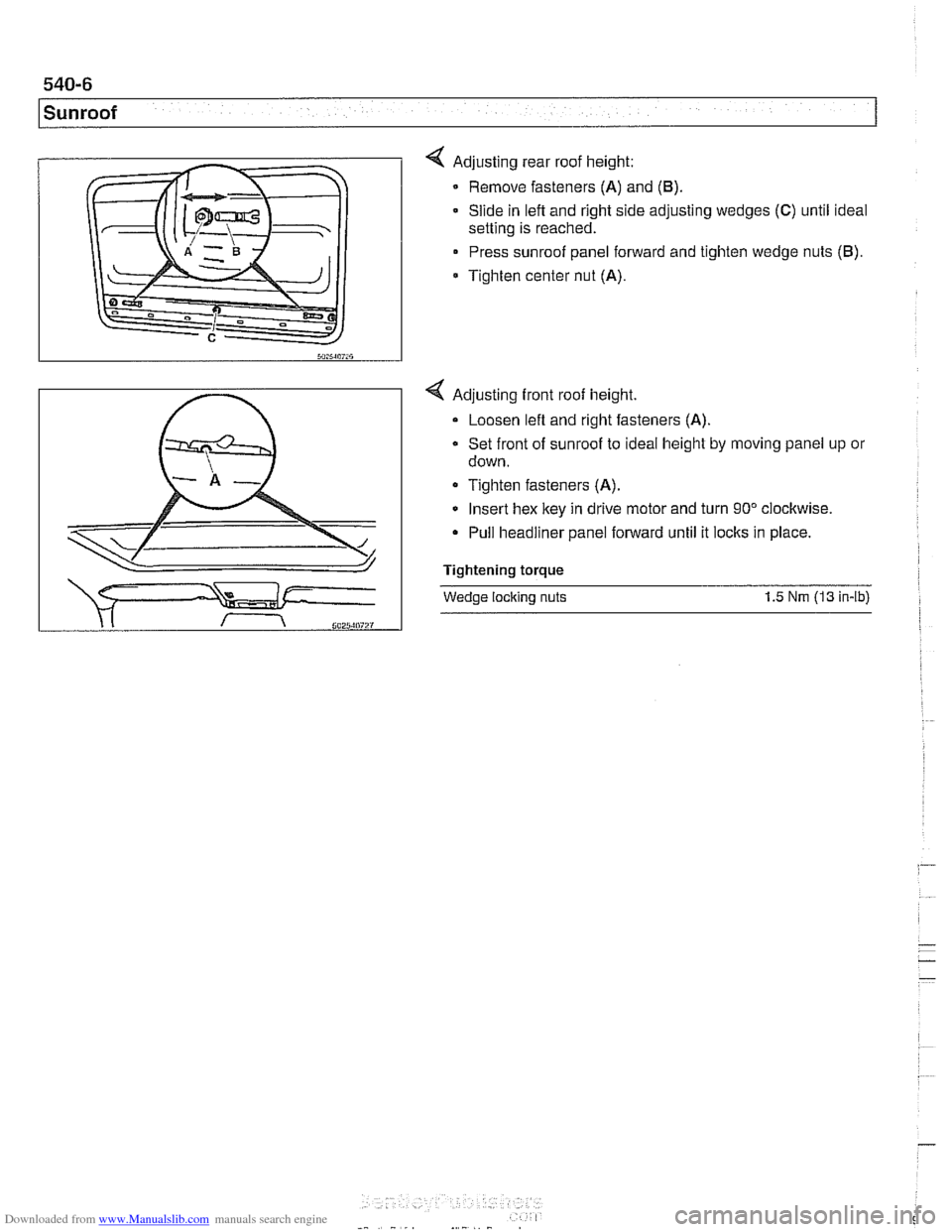

4 Adjusting rear roof height:

Remove fasteners

(A) and (6)

Slide in left and right side adjusting wedges (C) until ideal

setting is reached.

Press sunroof panel forward and tighten wedge nuts

(6).

* Tighten center nut (A).

4 Adjusting front roof height.

Loosen lefl and right fasteners

(A)

Set front of sunroof to ideal height by moving panel up or

down.

Tighten fasteners

(A).

Insert hex key in drive motor and turn 90" clockwise.

Pull headliner panel forward until it locks in place.

Tightening torque

Wedge locking nuts 1.5 Nm (1 3 in-lb)