BMW M3 1992 E36 Workshop Manual

Manufacturer: BMW, Model Year: 1992, Model line: M3, Model: BMW M3 1992 E36Pages: 759

Page 101 of 759

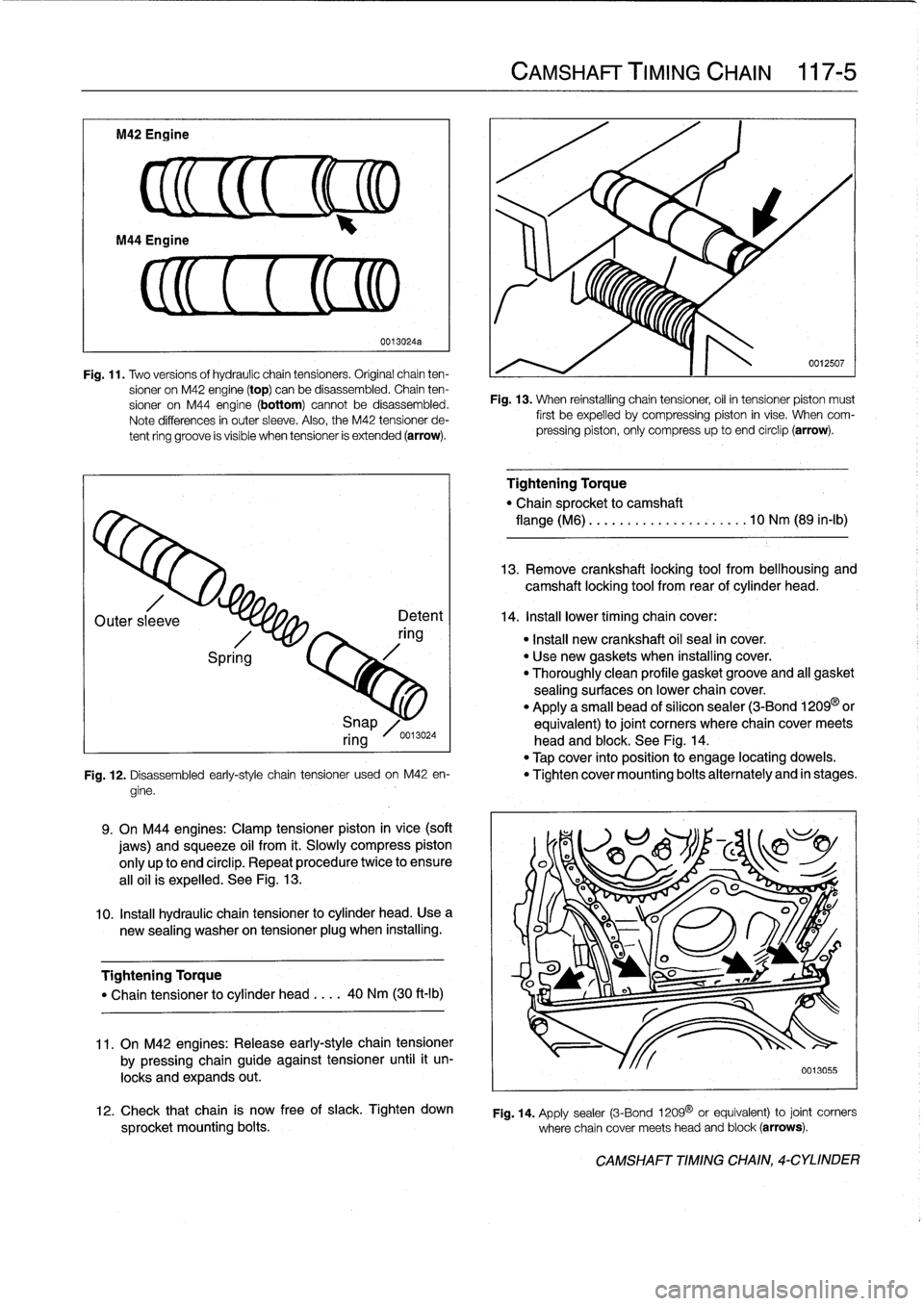

M42

Engine

CL

(EM

Fig

.

11

.

Two

versionsof

hydraulic

chaintensioners

.

Original

chain

ten-

sioner

on

M42

engine

(top)

canbe

disassembled

.

Chain

ten-

sioner

on

M44

engine

(bottom)

cannot

be

disassembled

.

Note

differences

in

outer

sleeve

.

Also,

the

M42

tensioner

de-

tent

ring

groove

is

visible

when

tensioner

is

extended

(arrow)

.

Outer

sleeve

Spring

0013024a

Detent

ring

9

.

On

M44

engines

:

Clamp

tensioner

piston

in

vice

(soft

jaws)

and

squeeze

oil

from

it

.

Slowly

compress

piston

only

up

to

end

círclip

.

Repeat

procedure

twice

to

ensure

al¡oil

is

expelled

.

See

Fig

.

13

.

10

.

Insta¡¡

hydraulic

chain

tensioner

lo

cylinder

head

.

Usea

new

sealing

washer

on

tensionerplug

when

installing

.

Tightening

Torque

"

Chain

tensioner

to

cylinder

head

....

40

Nm

(30

ft-Ib)

11

.

On

M42

engines

:

Release

early-style

chain

tensioner

by

pressing

chain

guide

against

tensioner

until

it

un-

locks

and

expands

out

.

CAMSHAFT

TIMING

CHAIN

117-

5

0012507

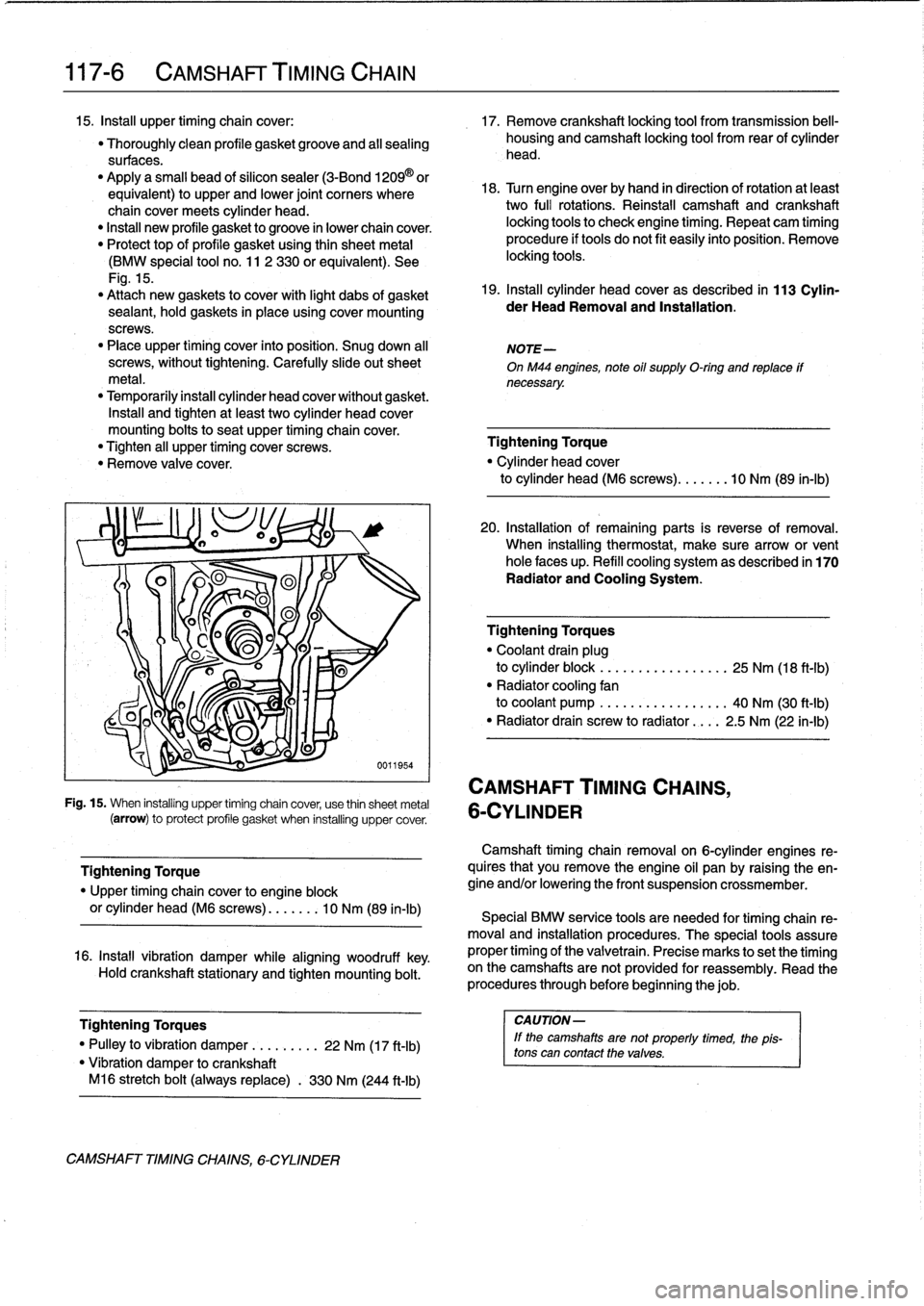

Fig

.

13

.

When

reinstalling

chain

tensiones,

oil

in

tensioner

piston

must

first

be

expelled

by

compressing

piston

in

vise

.

When

com-

pressing

piston,

only

compress

up

to

and

circlip

(arrow)

.

Tightening

Torque

"

Chain

sprocket

lo

camshaft

flange

(M6)

..

.

..

.............

.

..

10

Nm

(89

in-lb)

13

.

Remove

crankshaft

locking

tool

from

bellhousing

and

camshaft

locking

tool

from

rear

of

cylinder

head

.

14

.

Install

lower

timingchain

cover

:

"

Insta¡¡

new

crankshaft

oil

seal

in

cover

.

"

Use

new

gaskets

when

installing

cover

.

"

Thoroughly

clean

profile

gasketgroove

and

all

gasket

sealing

surfaces

on

lowerchaincover

.

"

Apply

a

small

bead

of

silicon

sealer

(3-Bond

1209

or

Snap

equivalent)

lo

joint

corners

where

chaincover

meets

ring

0013024

head

and

block

.

See

Fig

.

14

.

"

Tap

cover

into

position

to

engage

locating

dowels

.

Fig

.

12

.

Disassembled

early-style

chain

tensioner

usadon

M42

en-

"

Tighten

cover

mounting

bolts

alternately

and

in

stages

.

gine

.

12

.

Check

that

chain

is

now

free

of

siack

.

Tighten

down

sprocket

mounting

bolts

.

where

chain

cover

meets

head

and

block

(arrows)

.

Fig

.

14

.

Apply

sealer

(3-Bond

1209

0

or

equivalent)

to

joint

corners

CAMSHAFT

TIMING

CHAIN,

4-CYLINDER

Page 102 of 759

117-

6

CAMSHAFT

TIMING

CHAIN

15

.

Insta¡¡

upper

timing

chaincover

:

17

.

Remove

crankshaft

locking

tool

from

transmission

bell-

"

Thoroughly

clean

profile

gasketgroove

and

all

sealing

housing

and

camshaft

locking

tool

from

rear

of

cylinder

surfaces

.

head

.

"

Applya

small

bead

ofsilicon

sealer

(3-Bond

1209®

or

equivalent)

to

upper

and

lower

joint

comers

where

18

.

Turn

engine

over

by

hand

in

direction

of

rotation

at

least

chaincover

meets

cylinder

head

.

two

full

rotations

.

Reinstall

camshaft

and

crankshaft

"

Insta¡¡

new

profile

gasket

to

groove

in

lowerchain

cover

.

locking

tools

to

check

engine

timing

.

Repeat

cam

timing

"

Protect

top

of

profile

gasket

using

thin

sheetmetal

procedure

if

tools

do

not

fit

easily

into

position

.

Remove

(BMW

special

tool

no

.

11

2

330

or

equivalent)

.

See

locking

tools

.

Fig

.

15

.

"

Attach

new

gaskets

to

cover

with

light

dabs

of

gasket

19

.

Install

cylinder

head

cover

as

described

in

113

Cylin-

sealant,

hold

gaskets

in

placeusing

cover

mounting

der

HeadRemoval

and

Installation

.

screws

.

"

Place

upper

timing

cover

into

position

.

Snug

down

al¡

NOTE-

screws,

without

tightening

.

Carefully

slide

out

sheet

OnM44

engines,

note

oil

supply

O-ring

and

replace

ff

metal

.

necessary

.

"

Temporarily

install

cylinder

head

cover

without

gasket

.

Insta¡¡

and

tighten

at

least

two

cylinder

head

cover

mounting

bolts

to

seat

upper

timing

chaincover

.

"

Tighten

all

upper

timing

cover

screws

.

Tightening

Torque

"

Remove

valve

cover

.

"

Cylinder

head

cover

to

cylinder

head

(M6

screws)

...

..

.

.

10

Nm

(89

ín-Ib)

-

CAMSHAFT

TIMING

CHAINS,

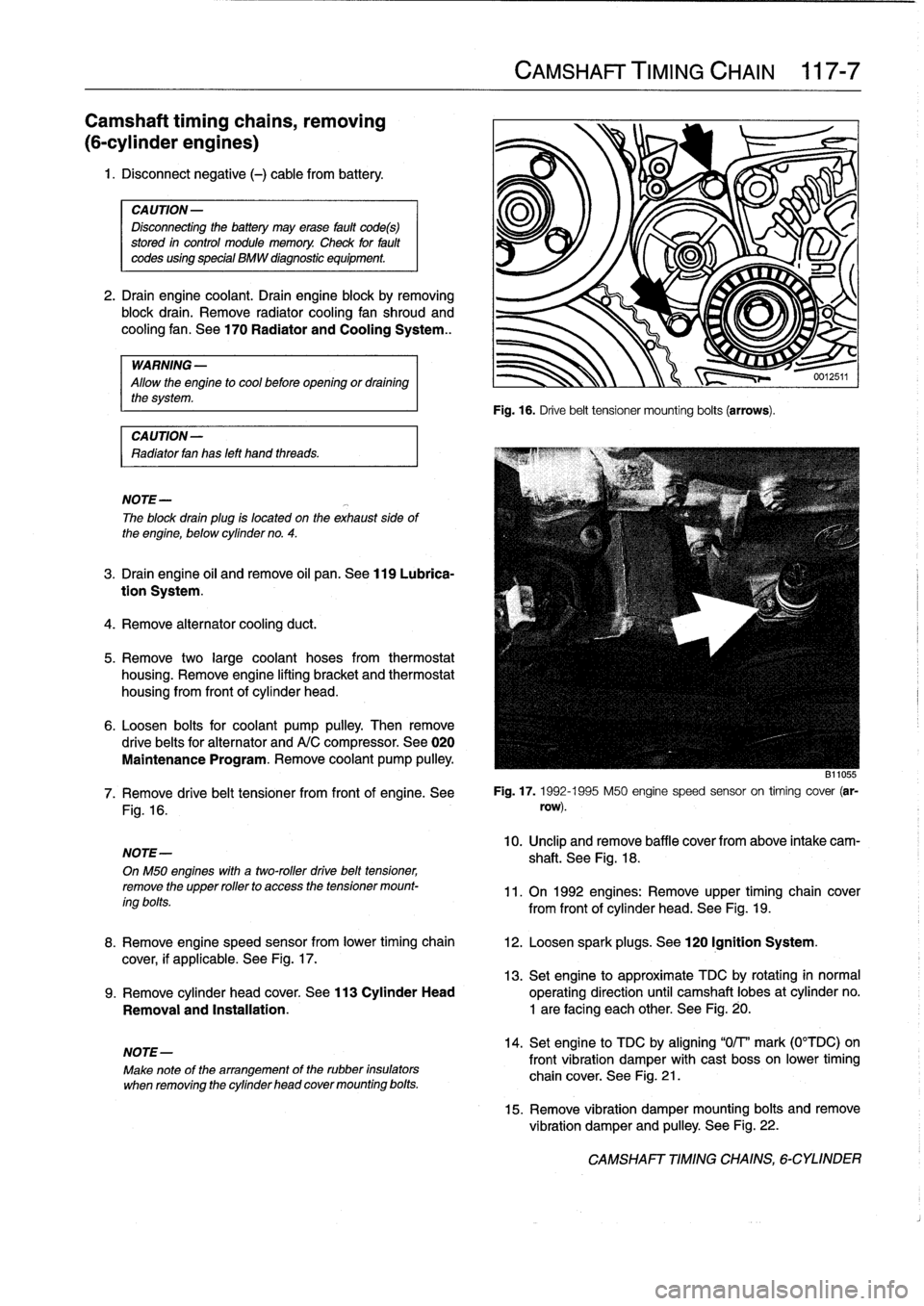

Fig

.

15

.

When

installing

upper

timing

chain

cover,

use

thin

sheetmetal

6-CYLINDER

(arrow)

to

protect

profile

gasket

when

installing

uppercover

.

Tightening

Torque

"

Upper

timing

chaincover

to

engine

block

or

cylinder

head

(M6

screws)

....

.

..

10

Nm

(89

in-lb)

16

.

Install

vibration

damper

while

aligning

woodruff

key

.

Hold

crankshaft

stationary

and

tighten

mounting

bolt

.

Tightening

Torques

I

CAUTION-

"

Pulley

to

vibration

damper

..

.

.

.

....

22

Nm

(17

ft-Ib)

lf

the

camshaftsare

not

properly

timed,

the

1

pis-

tons

can

contact

thevalves

.

"

Vibration

damper

tocrankshaft

M16

stretch

bolt

(always

replace)

.

330

Nm

(244

ft-Ib)

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

20

.

Installation

of

remaining

parts

is

reverse

of

removal

.

When

installing

thermostat,

make

sure

arrow

or

vent

hole

faces

up

.

Refill

cooling

system

as

described

in

170

Radiator

and

Cooling

System

.

Tighteníng

Torques

"

Coolant

drain

plug

to

cylinder

block

.

..

.

.

.

...

.

..

.....

25

Nm

(18

ft-Ib)

"

Radiator

cooling

fan

to

coolant

pump

.

..

.

...

...

..

.....

40

Nm

(30

ft-Ib)

"

Radiator

drain

screw

to

radiator

....

2

.5

Nm

(22

in-lb)

Camshaft

timing

chainremovalon

6-cylinder

engines

re-

quires

that

you

Rmove

the

engine

oil

pan

by

raising

the

en-

gine

and/or

lowering

the

front

suspension

crossmember

.

Special

BMW

service

tools

are

needed

for

timing

chain

re-

moval

and

installation

procedures

.

The

special

tools

assure

proper

timing

of

the

valvetrain

.

Precise

marks

to

setthe

timing

on

the

camshafts

arenot

provided

for

reassembly

.

Read

the

procedures

through

before

beginning

thejob

.

Page 103 of 759

Camshaft

timing

chains,

removing

(6-cylinder

engines)

1

.

Disconnect

negative

(-)

cable

from

battery

.

CA

UTION-

Disconnecting

the

battery

may

erase

fault

codes)

stored

in

control

module

memory

.

Check

for

fault

codes

using

special

BMW

diagnostic

equipment

.

2

.

Drain

engine

coolant

.

Drain

engine

block

by

removing

block

drain

.

Remove

radiator

cooling

fan

shroud

and

cooling

fan

.

See170

Radiator

and

Cooling

System

.

.

WARNING

-

Allow

the

engine

to

cool

before

openingor

draining

the

system

.

CAUTION-

Radiator

fan

has

left

hand

threads

.

NOTE-

The

block

drain

plug

is

located

on

the

exhaust

side

of

the

engine,

below

cylinder

no

.

4

.

3

.

Drain

engine

oíl

andremove

oil

pan

.

See

119

Lubrica-

tion

System

.

4

.

Remove

alternator

cooling

duct

.

5

.

Remove

two

large

coolant

hoses

from

thermostat

housing

.

Remove

engine

lifting

bracket

and

thermostat

housing

from

front

of

cylinder

head

.

6

.

Loosen

bolts

for

coolant

pump

pulley

.

Then

remove

drive

belts

for

alternator

andA/C

compressor

.

See

020

Maintenance

Program

.

Remove

coolant

pump

pulley

.

Fig

.

16

.

NOTE-

OnM50

engines

with

a

two-roller

drive

belt

tensioner,

remove

the

upper

rollerto

access

thetensioner

mount-

ing

bolts

.

NOTE-

Make

note

of

the

arrangement

of

the

rubber

insulators

when

removing

the

cylinder

head

cover

mounting

bolts

.

CAMSHAFT

TIMING

CHAIN

117-

7

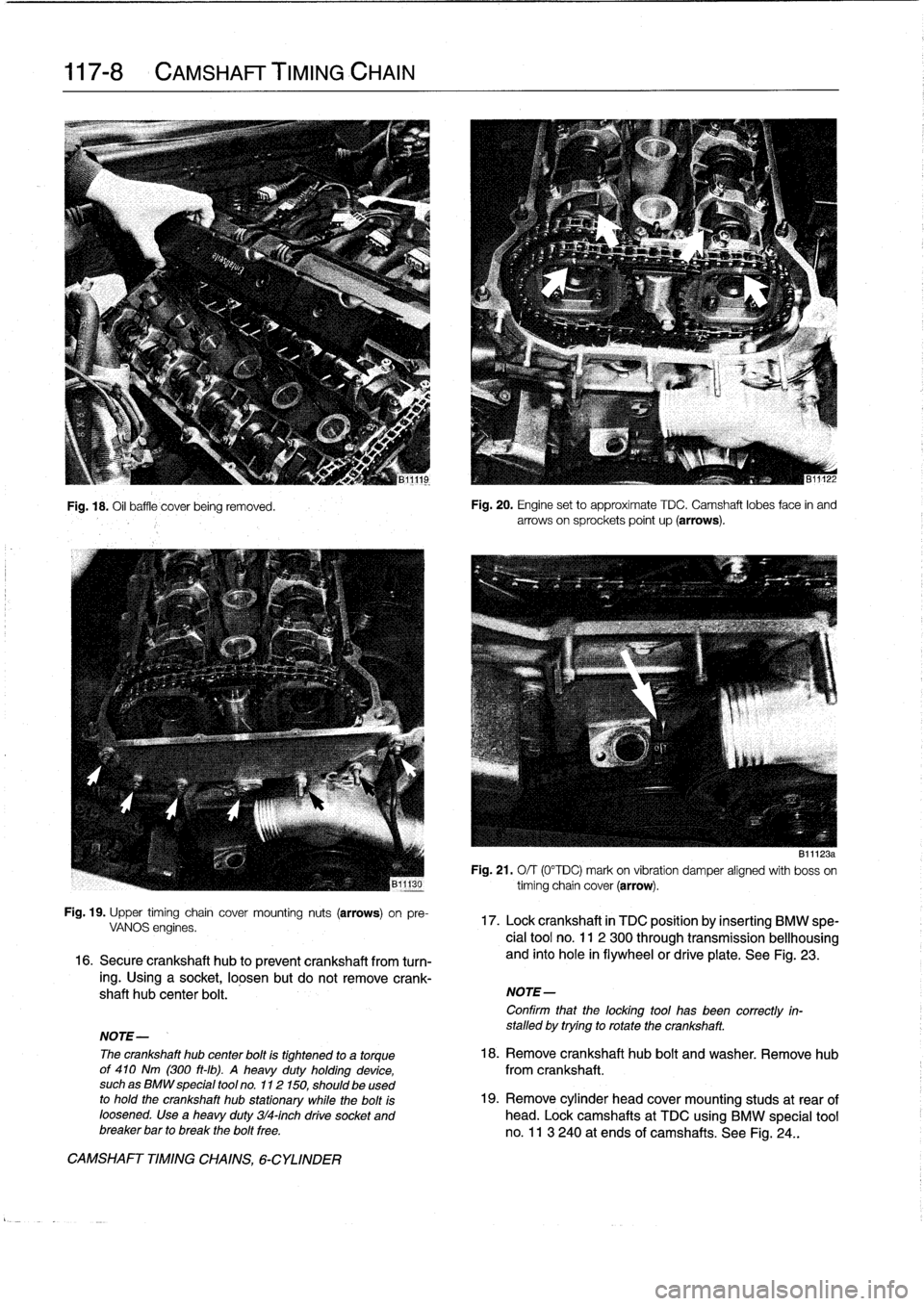

Fig

.

16

.

Drive

belt

tensioner

mounting

bolts

(arrows)

.

B11055

7

.

Remove

drive

belt

tensioner

from

front

of

engine

.

See

Fig

.

17

.

1992-1995

M50

engine

speed

sensor

on

timing

cover

(ar-

row)

.

10

.

Unclip

andremove

baffle

cover

from

above

intake

cam-

shaft

.

See

Fig

.

18

.

11

.

On

1992

engines

:

Remove

upper

timing

chain

cover

from

front

of

cylinder

head

.

See

Fig

.

19

.

8

.

Remove

engine

speed

sensor

from

lower

timing

chain

12

.

Loosen

spark

plugs

.

See

120

Ignition

System

.

cover,

if

applicable

.

See

Fig

.

17

.

13

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

9

.

Remove

cylinder

head

cover

.

See

113

Cylinder

Head

operating

direction

until

camshaft

lobes

at

cylinder

no

.

Removal

and

Installatíon

.

1

are

facing

each

other

.

See

Fig

.

20

.

14

.

Set

engine

to

TDC

by

aligning

"0/T'

mark

(0°TDC)on

front

vibration

damper

with

cast

bosson

lower

timing

chain

cover

.

See

Fig

.

21

.

15

.

Remove

vibration

damper

mounting

bolts

and

remove

vibration

damper

and

pulley

.

See

Fig

.

22

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

Page 104 of 759

117-

8

CAMSHAFT

TIMING

CHAIN

Fig

.

18

.

Oil

baffle'

cover

being

removed

.

Fig

.

19

.

Upper

timing

chaincover

mounting

nuts

(arrows)

on

pre-

VANOS

engines

.

16

.

Secure

crankshaft

hub

to

prevent

crankshaft

from

turn-

ing

.

Using

a

socket,

loosen

but

do

not

remove

crank-

shaft

hub

center

bolt

.

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

Fig

.

20

.

Engine

set

to

approximate

TDC

.

Camshaft

lobes

face

in

and

arrows

on

sprockets

point

up

(arrows)

.

B1

1123a

Fig

.

21

.

O/

T

(0°TDC)

mark

on

vibration

damper

aligned

with

boss

on

timing

chain

cover

(arrow)

.

17

.

Lock

crankshaft

in

TDC

position

by

inserting

BMW

spe-

cial

tool

no

.

11

2

300

through

transmissionbellhousing

and

into

hole

in

flywheelor

drive

plate

.

See

Fig

.

23

.

NOTE-

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotate

the

crankshaft

.

NOTE-

The

crankshaft

hub

center

bolt

is

tightened

to

a

torque

18

.

Remove

crankshaft

hub

bolt

and

washer

.

Remove

hub

of

410

Nm

(300

ft-ib)

.

A

heavy

duty

holding

device,

from

crankshaft

.

suchas

BMW

special

tool

no

.

112150,

should

be

used

to

hold

the

crankshaft

hub

stationary

while

the

bolt

is

19

.

Remove

cylinder

head

cover

mounting

studs

at

rear

of

loosened

.

Use

a

heavy

duty

314-inch

drive

socket

and

head

.

Lock

camshafts

at

TDC

using

BMW

special

tool

breaker

bar

to

break

the

bolt

free

.

no

.

11

3

240

at

ends

of

camshafts

.

See

Fig

.

24

.

.

Page 105 of 759

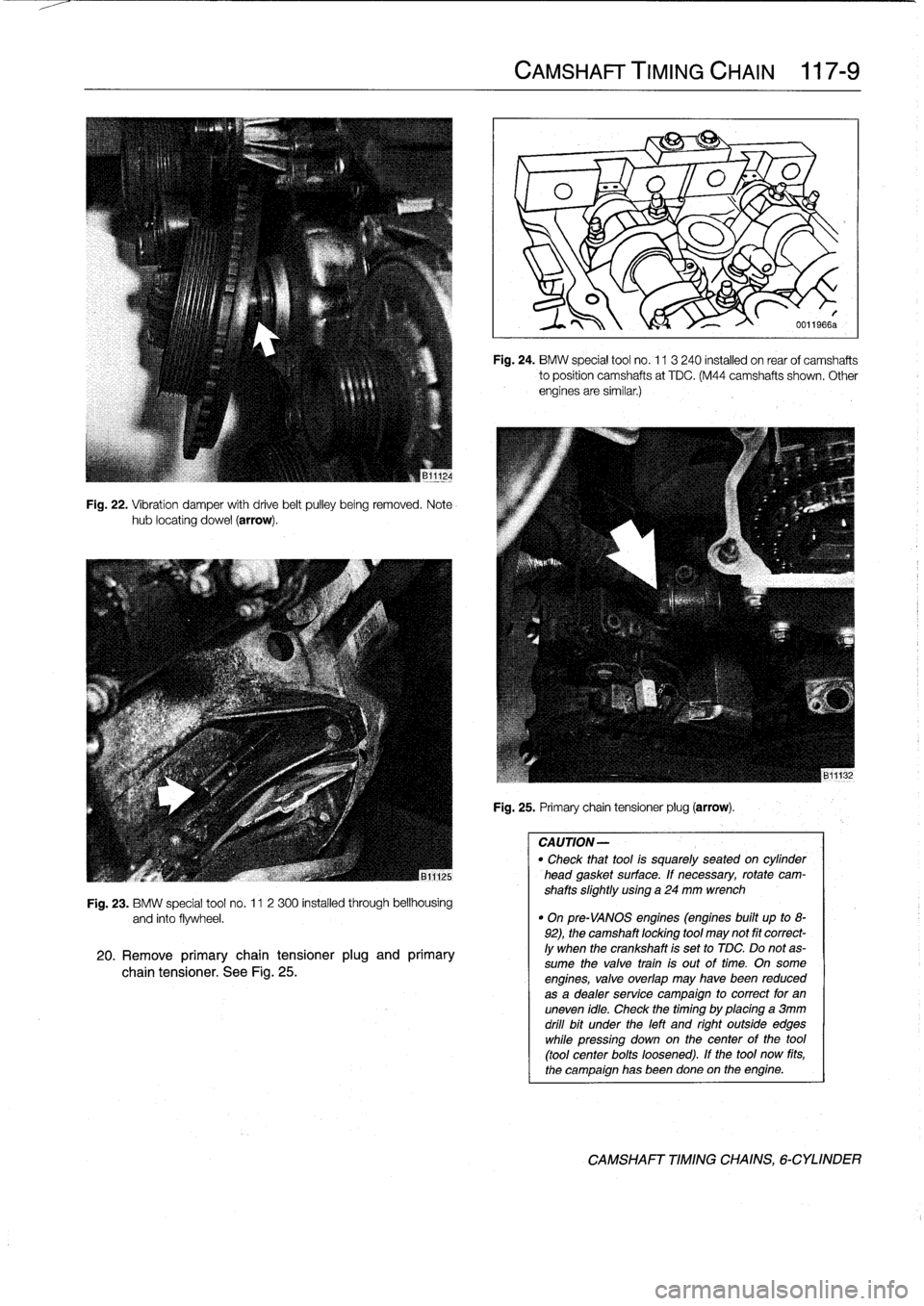

Fig

.

22

.

Vibration

damper

with

drive

belt

pulley

being

removed

.

Notehub

locating

dowel

(arrow)

.

Fig

.

23

.

BMW

special

tool

no

.

11

2

300

installed

through

bellhousing

and

into

flywheel

.

20

.

Remove

primary

chain

tensioner

plug

and

primary

chain

tensioner

.

See

Fig

.

25

.

CAMSHAFT

TIMING

CHAIN

117-

9

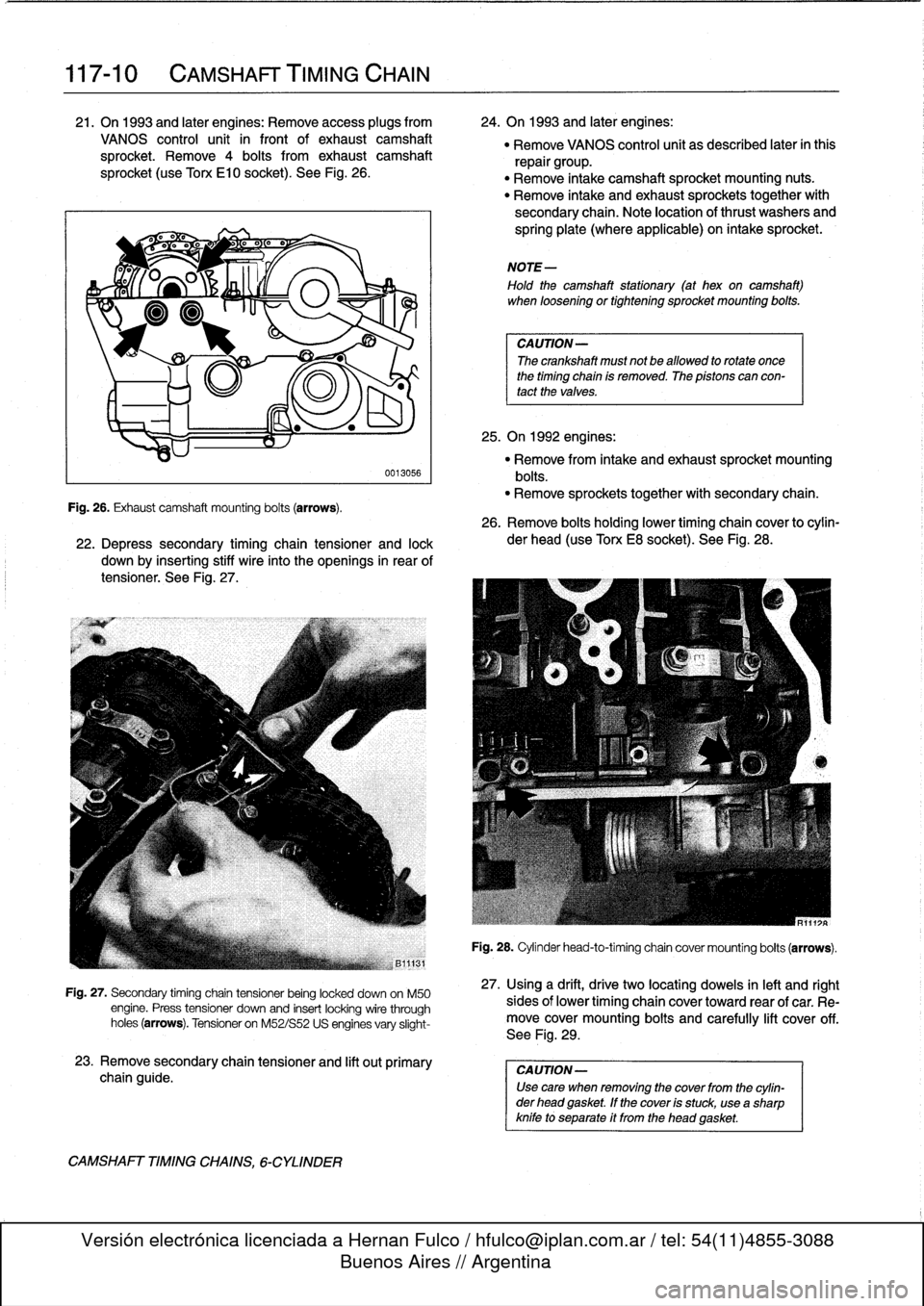

Fig

.

24

.

BMW

special

tool

no

.

113

240

installed

on

rear

of

camshafts

to

position

camshafts

at

TDC

.

(M44

camshafts

shown

.

Other

engines

are

similar

.)

Fig

.

25

.

Primary

chain

tensioner

plug

(arrow)

.

CAUTION-

"

Check

thattool

is

squarely

seated

on

cytinder

head

gasket

surface

.

If

necessary,

rotate

cam-

shafts

slightly

using

a

24

mm

wrench

"

On

pre-VANOS

engines

(engines

built

up

to

8-

92),

the

camshaft

locking

tool

may

not

fit

correct-

ly

when

the

crankshaft

is

set

to

TDC

.

Do

notas-

sume

the

valve

train

is

out

oftime

.

On

some

engines,

valve

overlap

may

havebeen

reduced

as

a

dealer

service

campaign

to

correct

for

an

uneven

idle

.

Check

thetiming

by

placing

a

3mm

drill

bit

under

the

left

and

right

outside

edges

while

pressíng

down

on

thecenter

of

the

tool

(tool

center

bolts

loosened)

.

If

the

tool

now

fits,

the

campaign

has

beendone

on

the

engine

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

Page 106 of 759

117-

1

0

CAMSHAFT

TIMING

CHAIN

21

.

On

1993

and

lates

engines

:

Remove

access

plugs

from

24

.

On

1993

and

later

engines

:

VANOS

control

unit

in

front

of

exhaust

camshaft

"

Remove

VANOS

control

unit

as

described

laterinthis

sprocket

.

Remove

4

bolts

from

exhaust

camshaft

repair

group

.

sprocket

(useTono

El0

socket)

.

See

Fig

.

26

.

"

Remove

intake

camshaft

sprocket

mounting

nuts

.

"

Remove

intake

and

exhaust

sprockets

together

with

secondary

chain

.

Note

location

of

thrust

washers

and

spring

plate

(where

applicable)

on

intake

sprocket

.

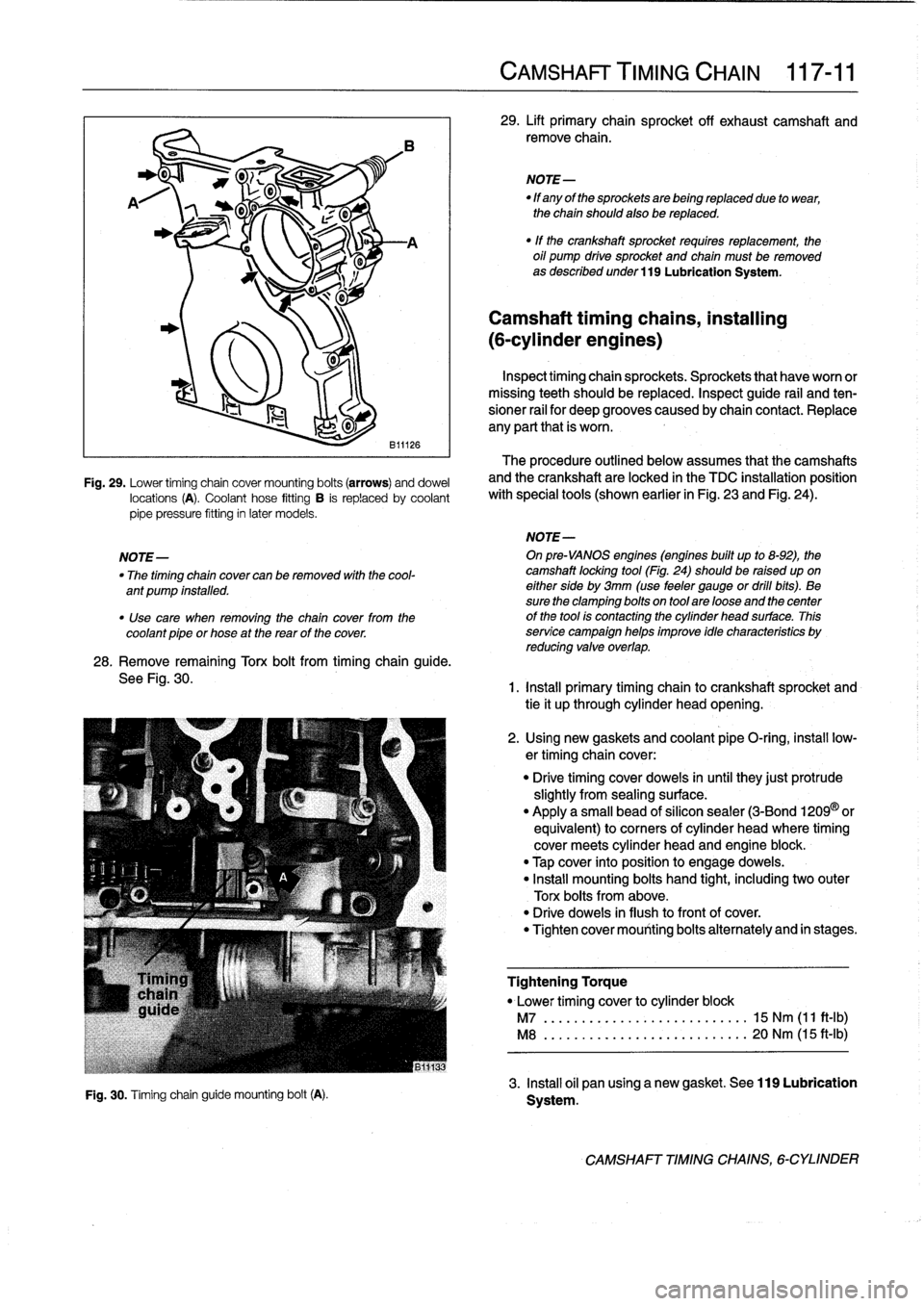

Fig

.

26

.

Exhaust

camshaftmounting

bolts

(arrows)

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

0013056

22

.

Depress

secondary

timing

chain

tensiones

and

lock

down

by

inserting

stiff

wire

into

the

openings

in

rear

of

tensioner

.

See

Fig

.

27

.

Fig

.

27

.

Secondary

timing

chaintensioner

being

locked

down

on

M50

engine

.

Press

tensioner

downand

insert

locking

wire

through

holes(arrows)

.

Tensioner

on

M52/S52

US

engines

vary

slight-

23

.

Remove

secondary

chain

tensioner

and

lift

out

primary

chain

guide

.

NOTE-

Hold

the

camshaft

stationary

(at

hex

on

camshaft)

when

loosening

ortightening

sprocket

mounting

boits

.

CAUTION-

The

crankshaft

must

not

be

allowed

to

rotate

once

the

timing

chain

is

removed

.

The

pistons

can

con-

tact

the

valves

.

25

.

On

1992

engines

:

"

Remove

from

intake

and

exhaust

sprocket

mounting

bolts

.

"

Remove

sprockets

together

with

secondary

chain

.

26

.

Remove

bolts

holding

lower

timing

chain

cover

to

cylin-

der

head

(use

Torx

E8

socket)

.

See

Fig

.

28

.

MR111:

R

Fig

.

28

.

Cylinderhead-to-timingchain

covermounting

bolts

(arrows)

.

27

.

Using

a

drift,

drive

two

locatiog

dowels

in

left

and

right

sides

of

lower

timing

chaincover

toward

rear

of

car

.

Re-

move

covermounting

boits

and

carefully

lift

cover

off

.

See

Fig

.

29

.

CA

UTION-

Use

care

when

removing

the

cover

from

the

cylin-

der

head

gasket

.

If

the

cover

is

stuck,

useasharp

knife

to

separate

it

from

the

head

gasket

.

Page 107 of 759

9)

B11126

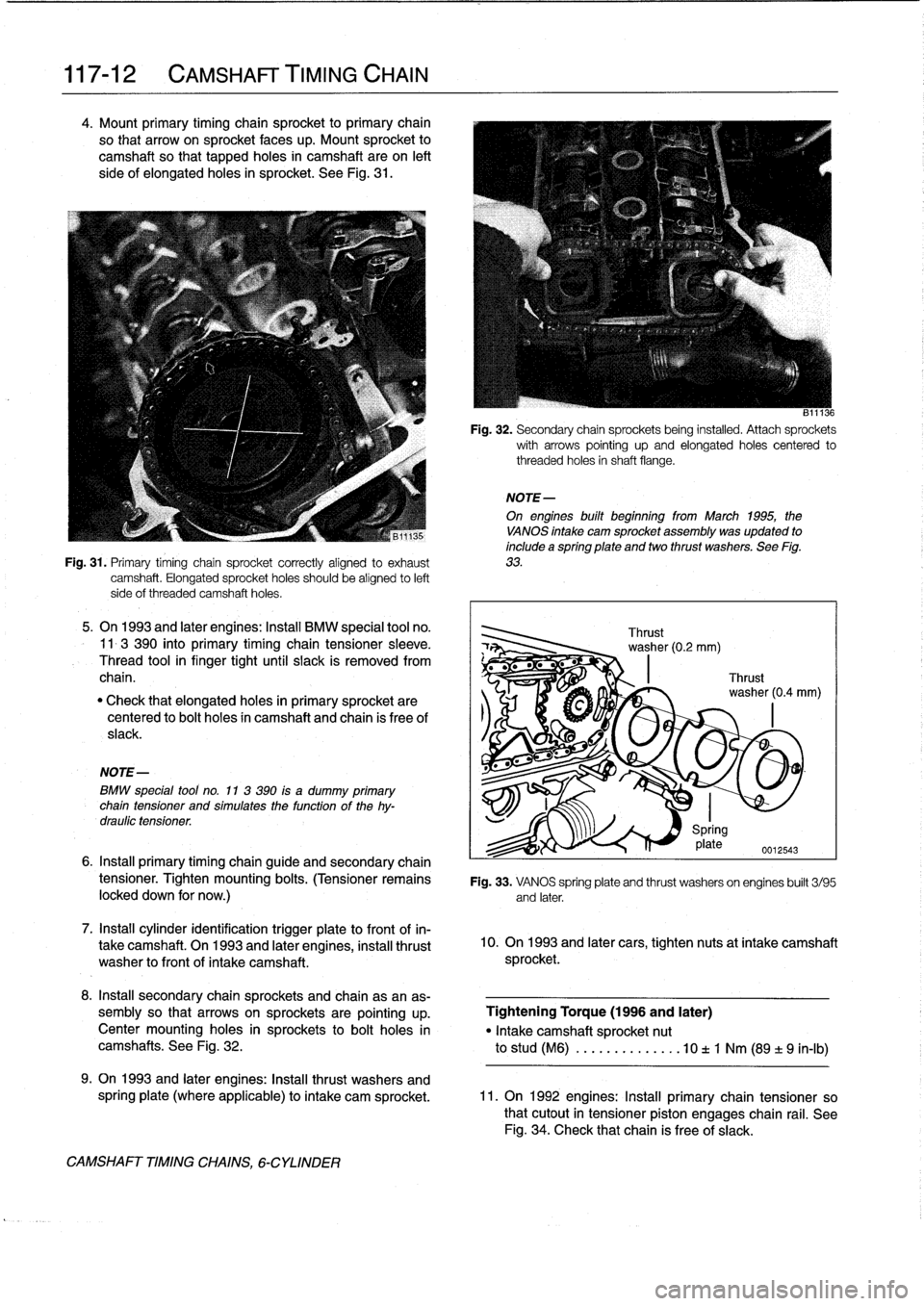

Fig

.

29

.

Lower

timing

chain

cover

mounting

bolts

(arrows)

anddowel

locations

(A)

.

Coolant

hose

fitting

B

is

replaced

by

coolant

pipe

pressure

fitting

in

later

models

.

28

.

Remove

remaining

Torx

bolt

from

timing

chain

guide

.

See

Fig

.

30

.

Fig

.

30

.

Timing

chainguide

mounting

bolt(A)

.

CAMSHAFT

TIMING

CHAIN

117-

11

29

.

Lift

primary

chain

sprocket

off

exhaust

camshaft

and

remove

chain

.

NOTE-

"

If

any

of

the

sprockets

are

being

replaced

due

to

wear,

the

chain

should

also

be

replaced

.

"

If

the

crankshaft

sprocket

requires

replacement,

the

oil

pump

drive

sprocket

and

chain

must

be

removed

as

described

under

119

Lubrication

System

.

Camshaft

timing

chains,

installing

(6-cylinder

engines)

Inspecttiming

chainsprockets

.

Sprockets

that

haveworn

or

missing

teeth

should

be

replaced

.

Inspect

guide

rail

and

ten-

sioner

rail

for

deep

grooves

caused

by

chain

contact

.

Replace

any

parí

that

is

worn

.

The

procedure

outlined

below

assumes

that

the

camshafts

and

the

crankshaft

are

locked

in

the

TDC

installation

position

with

special

tools

(shown

earlier

in

Fig

.

23

and

Fig

.

24)

.

NOTE-

NOTE-

On

pre-VANOS

engines

(engines

built

up

to

8-92),

the

"

The

timing

chain

cover

can

be

removed

with

the

cool-

camshaft

locking

tool

(Fig

.

24)should

be

raised

upon

ant

pump

installed

.

eitherside

by

3mm

(use

feeler

gauge

or

dril¡

bits)

.

Be

sure

the

clamping

bolts

on

tool

are

loose

and

thecenter

"

Use

care

when

removing

the

chain

cover

from

the

of

the

tool

is

contacting

the

cylinder

head

surface

.

This

coolant

pipe

or

hose

at

the

rearof

the

cover

.

service

campaign

helps

improve

idle

characteristics

by

reducing

valve

overlap

.

1

.

Install

primary

timing

chain

to

crankshaft

sprocket

and

tie

it

up

through

cylinder

head

opening

.

2

.

Using

new

gaskets

and

coolant

pipe

O-ring

;

insta¡¡

low-

ertiming

chain

cover

:

"

Drive

timing

cover

doweis

inuntil

they

just

protrude

slightly

from

sealing

surface

.

"

Apply

a

small

bead

of

silicon

sealer

(3-Bond

1209

©

or

equivalent)

to

corners

of

cylinder

head

where

timing

cover

meets

cylinder

head

and

engine

block

.

"

Tap

cover

into

position

to

engage

doweis

.

"

Install

mounting

bolts

hand

tight,

including

two

outer

Torx

bolts

from

above

.

"

Drive

doweis

in

flush

to

front

of

cover

.

"

Tighten

cover

mounting

bolts

alternately

and

in

stages

.

Tightening

Torque

"

Lower

timing

cover

to

cylinder

block

M7

................

...

..

.

.....

15

Nm

(11

ft-Ib)

M8

.............

.

.

...

.........

20

Nm

(15

ft-Ib)

3

.

Insta¡¡

oil

pan

using

a

new

gasket

.

See

119

Lubrication

Systern

.

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

Page 108 of 759

117-

1

2

CAMSHAFT

TIMING

CHAIN

4

.

Mount

primary

timing

chain

sprocket

to

primary

chain

so

that

arrowon

sprocket

faces

up

.

Mount

sprocket

to

camshaftso

that

tapped

holes

in

camshaftare

on

left

side

of

elongated

holes

in

sprocket

.

See

Fig

.

31

.

NOTE-

On

engines

built

beginning

from

March

1995,

the

VANOS

intake

cam

sprocket

assembly

was

updated

to

ínclude

a

spring

plate

and

two

thrust

washers

.

See

Fig

.

Fig

.

31

.

Primary

timing

chain

sprocket

correctly

alignedto

exhaust

33

.

camshaft

.

Elongated

sprocket

holes

should

be

aligned

to

left

side

of

threaded

camshaft

holes

.

5

.

On

1993

and

later

engines

:Install

BMW

special

tool

no

.

11-3

390

into

primary

timíng

chain

tensionersleeve

.

Thread

toolin

finger

tight

until

slack

is

removed

from

chain

.

"

Check

that

elongatedholes

in

primary

sprocket

are

centered

to

bolt

holes

in

camshaft

and

chain

is

free

of

slack

.

NOTE-

BMW

special

tool

no

.

11

3

390

ís

a

dummy

primary

chaín

tensioner

and

simulatesthe

function

of

the

hy-

draulic

tensíoner

.

7

.

Install

cylinder

identification

trigger

píate

to

front

of

in-

take

camshaft

.

On

1993

and

later

engines,

instanthrust

washer

tofrontof

intake

camshaft

.

CAMSHAFT

TIMING

CHAINS,

6-CYLINDER

B11136

Fig

.

32

.

Secondary

chain

sprockets

being

installed

.

Attach

sprockets

with

arrows

pointing

up

and

elongated

holes

centered

to

threaded

holes

in

shaft

flange

.

6

.

Install

primary

timing

chainguide

and

secondary

chain

tensioner

.

Tighten

mounting

bolts

.

(Tensioner

remains

Fig

.

33

.

VANOS

spring

plate

and

thrust

washers

on

engines

built

3/95locked

down

for

now

.)

and

later

.

10

.

On

1993

and

later

cars,

tighten

nuts

at

intake

camshaft

sprocket

.

8

.

Insta¡¡

secondary

chainsprockets

and

chain

asan

as-

sembly

so

that

arrows

on

sprockets

are

pointing

up

.

Tightening

Torque

(1996

and

later)

Centermounting

holes

in

sprockets

tobolt

holes

in

"

Intake

camshaft

sprocket

nut

camshafts

.

See

Fig

.

32

.

to

stud

(M6)

.............

.10t

1

Nm

(89

±9

in-lb)

9

.

On

1993

and

later

engines

:

Insta¡¡

thrust

washers

and

spring

plate

(where

applicable)

to

intake

cam

sprocket

.

11

.

On

1992

engines

:

Insta¡¡

primary

chain

tensioner

so

that

cutout

in

tensioner

piston

engages

chain

rail

.

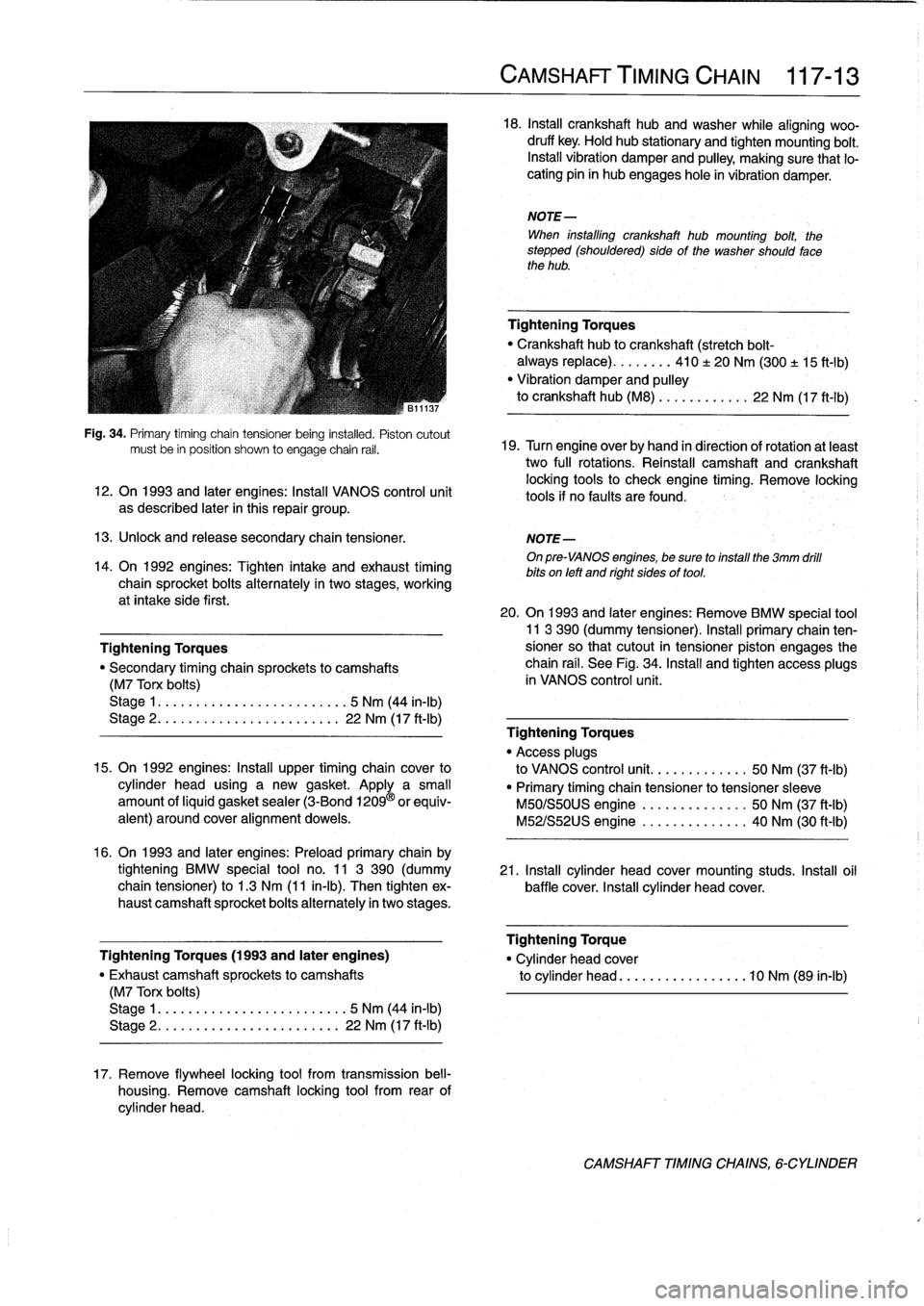

See

Fig

.

34

.

Check

that

chain

is

free

of

slack

.

Page 109 of 759

Fig

.

34

.

Primary

timíng

chain

tensioner

being

instafed

.

Pistoncutout

mustbe

in

position

shown

to

engage

chain

rail

.

12

.

On

1993

and

later

engines

:

Install

VANOS

control

unit

as

described

later

in

this

repair

group

.

13

.

Unlock

and

release

secondary

chaintensioner

.

NOTE-

On

pre-VANOS

engines,

be

sure

toinstall

the

3mm

drill

bits

on

left

and

right

sides

of

tool

.

14

.

On

1992

engines

:

Tighten

intake

and

exhaust

timing

chain

sprocket

bolts

alternately

in

two

stages,

working

at

intake

side

first

.

Tightening

Torques

"

Secondary

timing

chaira

sprockets

to

camshafts

(M7

Torx

bolts)

Stage

1

....

.

.

.

...

...............

5

Nm

(44

in-lb)

Stage

2

..

.

.

.

.

.

.

................

22

Nm

(17

ft-Ib)

15

.

On

1992

engines

:

Install

upper

timing

chaincover

to

cylinder

head

using

a

new

gasket

.

Apply

a

small

amount

ofliquid

gasket

sealer

(3-Bond

1209

®

orequiv-

alent)

around

coveralignment

dowels

.

16

.

On

1993

and

later

engines

:

Preloadprimary

chain

by

tightening

BMW

special

tool

no

.

11

3

390

(dummy

21

.

Install

cylinder

head

cover

mounting

studs

.

Insta¡¡

oil

chain

tensioner)

to

1

.3

Nm

(11

in-lb)

.

Then

tighten

ex-

baffle

cover

.

Install

cylinder

head

cover

.

haust

camshaft

sprocket

bolts

alternately

in

twostages

.

Tightening

Torques

(1993

and

later

engines)

"

Exhaust

camshaft

sprockets

to

camshafts

(M7

Torx

bolts)

Stage

1

..

...

..

..

................

5

Nm

(44

in-lb)

Stage

2

.....

.

.

...

..............

22

Nm

(17

ft-Ib)

17

.

Remove

flywheel

locking

tool

from

transmission

bell-

housing

.

Remove

camshaft

locking

tool

from

rear

of

cylinder

head

.

CAMSHAFT'TIMING

CHAIN

117-

1

3

18

.

Insta¡¡

crankshaft

hubandwasher

while

aligning

woo-

druff

key

.

Hold

hub

stationary

and

tighten

mounting

bolt

.

Install

vibration

damper

and

pulley,

making

sure

that

lo-

cating

pin

in

hub

engages

hole

in

vibration

damper

.

NOTE-

When

installing

crankshaft

hub

mounting

bolt,

the

stepped

(shouldered)

sideof

the

washer

should

fase

the

hub

.

Tightening

Torques

Crankshaft

hub

to

crankshaft

(stretch

bolt-

always

replace)

........

410

±

20

Nm

(300

±

15

ft-1b)

"

Vibration

damper

and

pulley

to

crankshaft

hub

(M8)

...

..

.

..

....

22

Nm

(17

ft-Ib)

19

.

Turn

engine

over

by

hand

in

direction

of

rotation

atleast

two

full

rotations

.

Reinstall

camshaft

and

crankshaft

locking

tools

to

check

engine

timing

.

Remove

locking

tools

if

no

faults

are

found

.

20

.

On

1993

and

later

engines

:

Remove

BMW

special

tool11

3

390

(dummy

tensioner)

.

Install

primary

chain

ten-sioner

so

that

cutout

in

tensioner

piston

engages

the

chain

rail

.

See

Fig

.

34

.

Install

and

tighten

access

plugs

in

VANOS

control

unit

.

Tightening

Torques

"

Access

plugs

to

VANOS

control

unit

..........

.

..

50

Nm

(37

ft-Ib)

"

Primary

timing

chain

tensioner

to

tensioner

sleeve

M50/S50US

engine

.......

.

..

..

.

.

50

Nm

(37

ft-Ib)

M52/S52US

engine

..........

..

.

.

40

Nm

(30

ft-Ib)

Tightening

Torque

"

Cylinder

head

cover

to

cylinder

head

............

...

.

.10

Nm

(89

in-lb)

CAMSHAFT

TIMINGCHAINS,

6-CYLINDER

Page 110 of 759

117-

1

4

CAMSHAFT

TIMING

CHAIN

22

.

Installation

of

remaining

parts

is

reverse

of

removal,

When

theengine

is

running,

the

piston

housing

is

supplied

noting

the

following

:

with

pressurized

engine

oil

.

At

idie,

the

solenoid

isin

the

off

"

When

installing

thermostat,

make

sure

arrow

or

vent

position

(de-energized)

and

valve

timing

is

maintained

in

the

hole

faces

up,

if

applicable

.

normal

position

:

When

the

solenoid

is

energized,

the

gear

cup

"

Refill

cooling

systemas

described

in

170

Radiator

piston

moves

forward

to

advance

the

camshaftby

a

maximum

and

Coming

System

.

of

12

.5

.

"

Install

oil

pan

as

described

in

119

Lubrication

Sys-

tem

.

"

Fill

engine

with

oil

and

install

a

new

oil

filter

as

de-

scribed

in

020

Maintenance

Program

.

"

Insta¡¡

ground

wires

at

cylinder

head

cover

mounting

studs

and

at

front

of

cylinder

head

and

thermostat

housing,

where

applicable

.

VANOS

system

operation,

testing

Tightening

Torques

There

are3

special

tools

required

to

check

VANOS

opera-

"

Coolant

drain

plugto

cylinder

block

.

.

25

Nm

(18

ft-Ib)

tion

;

an

electricaltest

lead

(BMW

special

tool

no

.

12

6

410),

an

"

Radiator

cooling

fan

to

coolant

pump

.

40

Nm

(30

ft-Ib)

air

line

fitting

(BMW

special

tool

no

.

11

3

450),

and

a

crank-

"

Radiator

drain

screw

to

radiator

...

.

2

.5

Nm

(22

in-Ib)

shaft

TDC

locking

tool

(BMW

special

tool

no

.

112

300)

.

"

Upper

timing

chaincover

to

cylinder

head

The

test

leal

is

used

to

power

the

solenoid,

simulating

the

M6

nut

...

.....

.............

..

.

10

Nm

(89

in-lb)

ground

signal

from

the

DME

control

unit

.

The

air

line

fitting

M8

bolt

.....

....

.

.

.............

22

Nm

(17

ft-Ib)

takes

the

place

of

the

oil

supply

line

fitting

to

simulate

oil

Ares-

"

VANOS

control

unit

to

cylinder

head

sure

.

The

locking

tool

positions

and

locks

the

crankshaft

at

M6

nut

.........

..

..

.

..........

10

Nm

(89

in-lb)

TDC,

cylinder

no

.

l.

M8

bolt

........

...

.............

22

Nm

(17

ft-Ib)

"

VANOS

oil

supply

pipe

to

VANOS

control

unit

1

.

Remove

alternator

cooling

air

duct

.

banjo

bolt

.......

..

..

.

..........

32

Nm

(24

ft-Ib)

VANOS

(VARIABLE

VALVE

TIMING)

3

.

Remove

top

plastic

enginecovers

.

Disconnect

ignition

coil

harness

connectors

fromcofs

.

Remove

ignition

1993

and

later

6-cylinder

engines

are

equipped

with

a

vari-

coils

.

able

valve

timing

system

called

VANOS

.

This

system

is

con-

trolled

by

the

engine

management

system

and

dynamically

4

.

Remove

cylinder

head

cover

mounting

bolts

and

re-

adjusts

intake

camshaft

timing

based

on

engine

load,

engine

move

cylinder

head

cover

.

Unclip

andremove

oil

baffle

speed

and

engine

temperature

.

cover

from

above

intake

camshaft

.

See

113

Cylinder

Head

Removal

and

installation

.

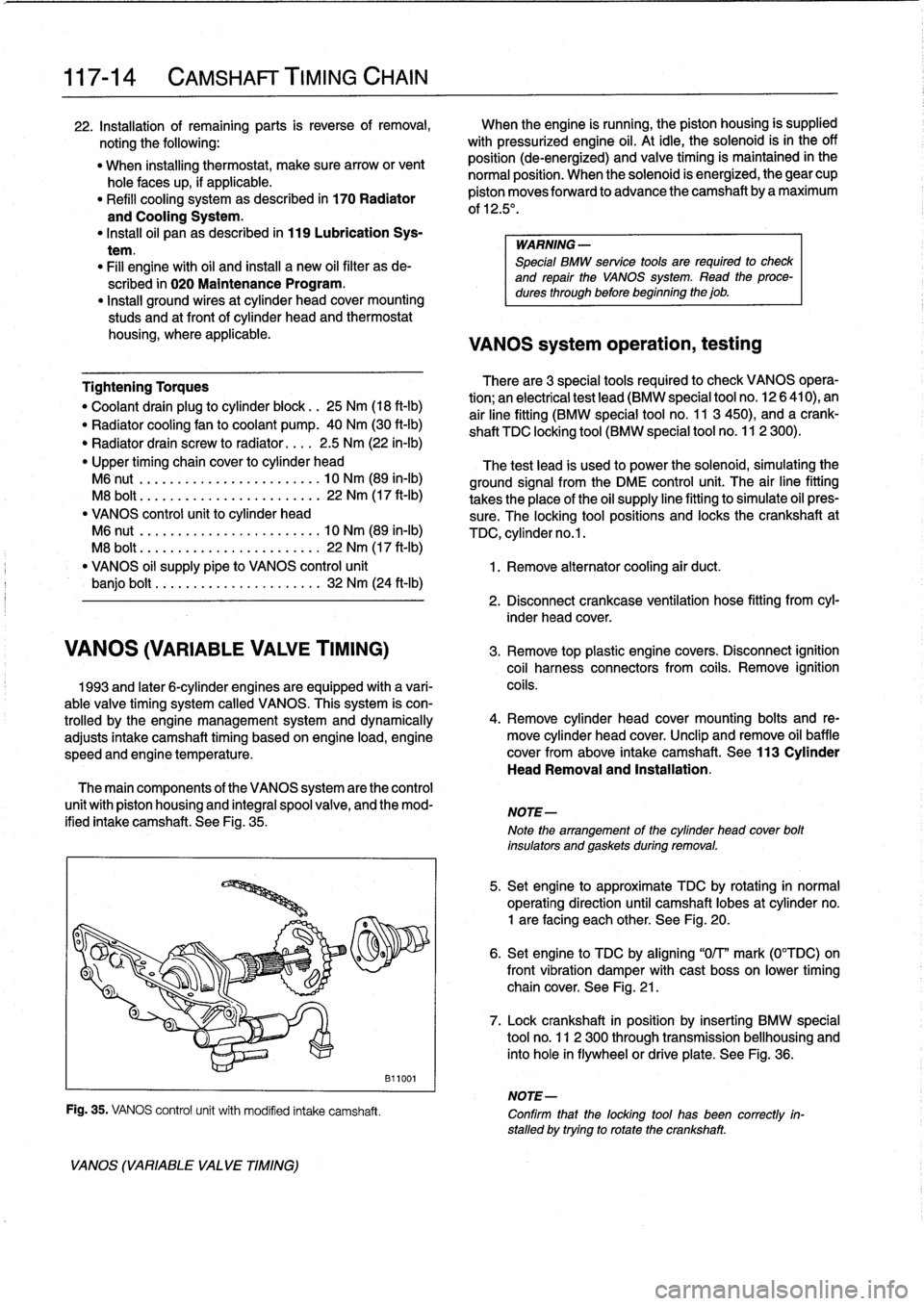

The

main

components

of

the

VANOS

system

are

the

control

unit

with

piston

housing

and

integral

spool

valve,

and

the

mod-

ified

intake

camshaft

.

See

Fig

.

35

.

VANOS

(VARIABLE

VA

LVE

TIMING)

Fig

.

35

.

VANOS

control

unit

with

modified

intake

camshaft

.

B11001

WARNING

-

Special

BMW

service

tools

are

required

to

check

and

repair

the

VANOS

System

.

Read

theproce-

dures

through

before

beginning

the

job

.

2

.

Disconnect

crankcase

ventilation

hose

fitting

from

cyl-

inder

head

cover

.

NOTE-

Note

the

arrangement

of

the

cylinder

head

cover

bolt

insulators

and

gaskets

during

removal

.

5

.

Set

engine

to

approximate

TDC

by

rotating

in

normal

operating

direction

until

camshaft

lobes

at

cylinder

no

.

1

are

facing

each

other

.

See

Fig

.

20

.

6

.

Set

engine

to

TDC

by

aligning

"0/T"

mark

(0°TDC)on

front

vibration

damper

withcast

boss

on

lower

timing

chain

cover

.

See

Fig

.

21

.

7

.

Lock

crankshaft

in

position

by

inserting

BMW

special

tool

no

.

11

2

300

through

transmission

bellhousing

and

into

hole

in

flywheelor

driveplate

.

See

Fig

.

36

.

NOTE-

Confirm

that

the

locking

tool

has

been

correctly

in-

stalled

by

trying

to

rotatethe

crankshaft

.