check engine BMW M3 1998 E36 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 1998, Model line: M3, Model: BMW M3 1998 E36Pages: 759

Page 423 of 759

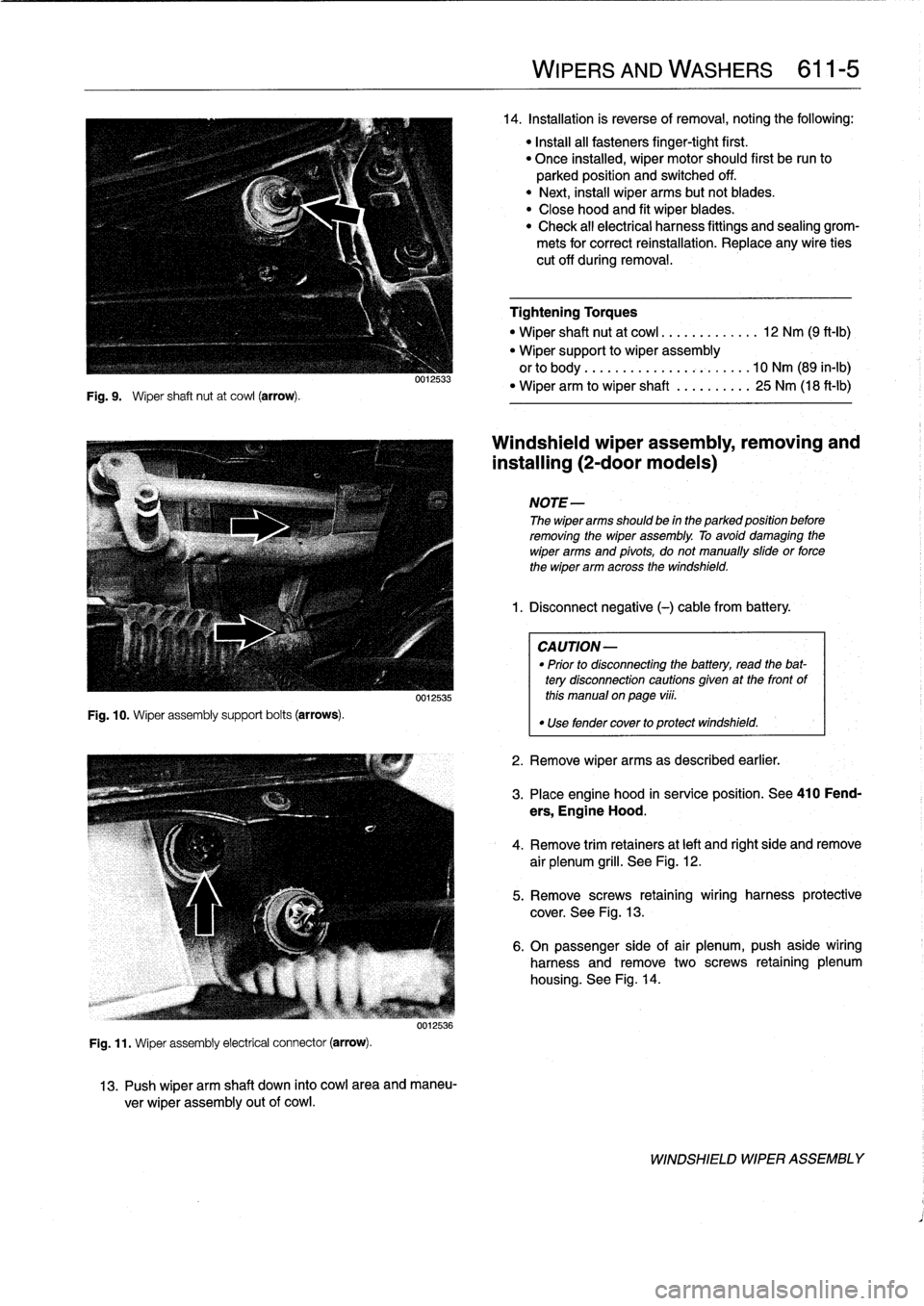

Fig

.

9

.

Wiper

shaft

nut

at

cowl

(arrow)

.

Fig

.

10

.

Wiper

assembly

support

bolts

(arrows)

.

0012533

0012535

Fig

.

11

.

Wiper

assembly

electrical

connector

(arrow)

.

0012536

13

.

Push

wiper

arm

shaft

down

into

cowl

area

and

maneu-

ver

wiper

assembly

out

of

cowl

.

WIPERS

AND

WASHERS

611-

5

14

.

Installation

is

reverse

of

removal,noting

the

following

:

"

Install

all

fasteners

finger-tight

first

.

"

Once

installed,

wiper

motor

should

first

be

run

to

parked

position

and

switched

off

.

"

Next,

instaf

wiper

arms

butnotblades

.

"

Close

hood

and

fit

wiper

blades

.

"

Check

all

electrical

harness

fittings

and

sealing

grom-

mets

for

correct

reinstallation

.

Replace

any

wire

ties

cut

off

during

removal

.

Tightening

Torques

"

Wiper

shaft

nut

at

cowl

.............

12

Nm

(9

ft-Ib)

"

Wiper

support

to

wiper

assembly

orto

body

..

..

..

.

...............

10

Nm

(89

in-lb)

"

Wiper

arm

to

wiper

shaft

..........

25

Nm

(18

ft-lb)

Windshieldwiper

assembly,

removing

and

installing

(2-door

modeis)

NOTE-

The

wiper

arms

should

be

in

the

parked

position

before

removing

the

wiper

assembly

.

To

avoid

damaging

the

wiper

arms

and

pivots,

donotmanually

sidde

or

force

the

wiper

arm

across

the

windshield

.

1

.

Disconnect

negative

(-)cablefrom

battery

.

CAUTION-

"

Prior

to

disconnectiog

the

battery,

read

the

bat-

tery

disconnection

cautionsgiven

at

the

front

of

this

manual

on

page

viii

.

"

Use

fendercover

to

protect

windshield

.

2

.

Remove

wiper

arms

as

described

earlier

.

3

.

Place

engine

hood

in

service

position

.

See410

Fend-

ers,

Engine

Hood

.

4

.

Remove

trim

retainers

at

left

and

right

side

and

remove

air

plenum

grill

.

See

Fig

.

12

.

5

.

Remove

screws

retaining

wiring

harness

protective

cover

.

See

Fig

.

13

.

6

.

On

passenger

side

of

air

plenum,push

aside

wiring

harness

and

remove

two

screws

retaining

plenum

housing

.

See

Fig

.

14

.

WINDSHIELD

WIPER

ASSEMBLY

Page 425 of 759

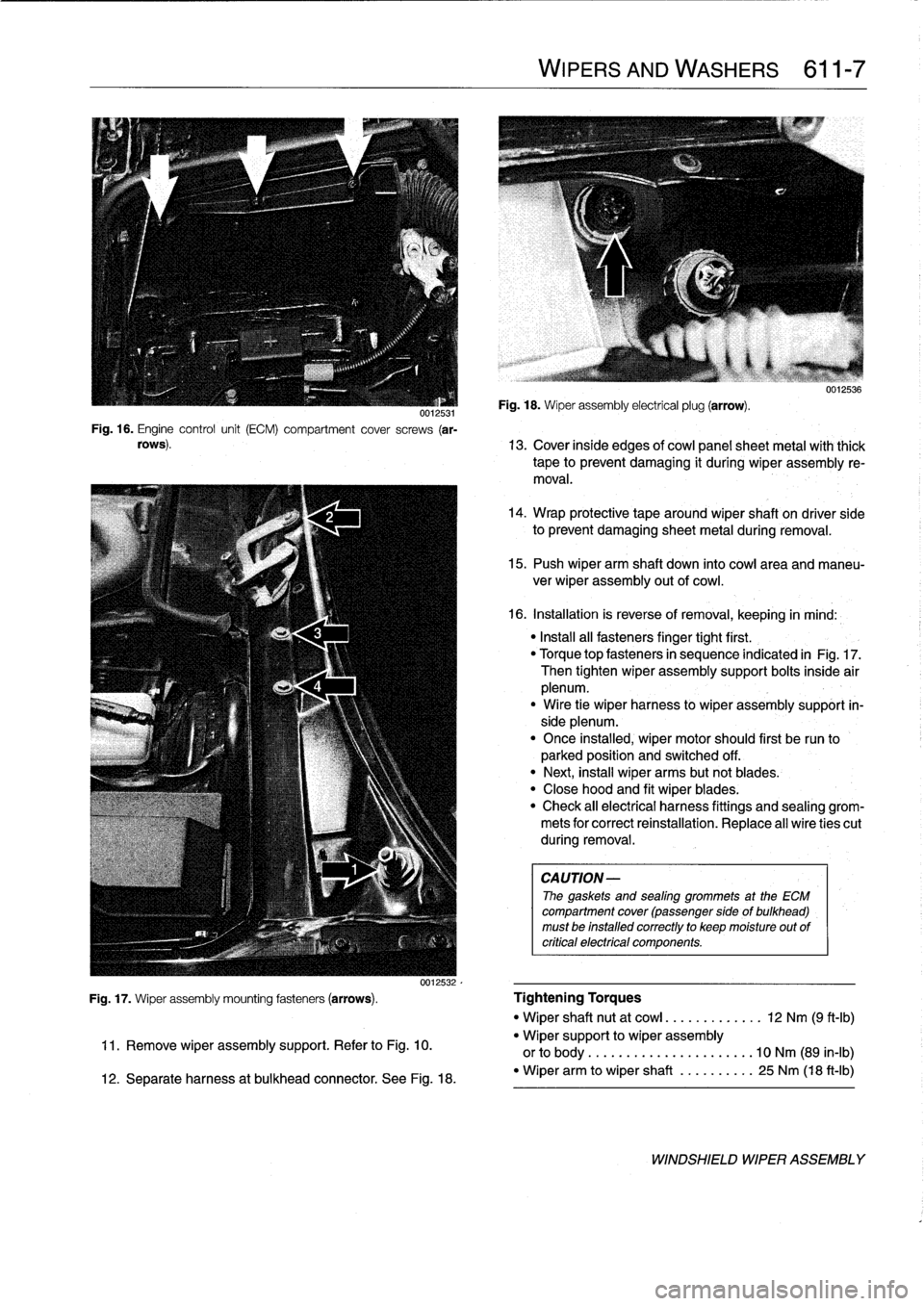

0012531Fig

.

16

.

Engine

control

unit

(ECM)

compartment

cover

screws

(ar-

rows)

.

WIPERS

AND

WASHERS

611-

7

Fig

.

18

.

Wiper

assembly

electrical

plug

(arrow)

.

uu1zbs6

13

.

Cover

inside

edges

of

cowi

panelsheet

metal

with

thick

tape

to

prevent

damaging

it

during

wiper

assembly

re-

moval

.

14

.

Wrap

protective

tape

around

wiper

shaft

on

driver

side

to

prevent

damaging

sheet

metal

during

removal

.

15

.

Push

wiper

arm

shaft

down

into

cowiarea

and

maneu-

ver

wiper

assembly

outof

cowi

.

16

.

Installation

is

reverse

of

removal,

keeping

in

mind

:

"

Install

all

fasteners

finger

tight

first

.

"

Torque

topfasteners

in

sequence

indicated

in

Fig

.

17

.

Then

tighten

wiper

assembly

support

bolts

inside

air

plenum

.

"

Wire

tie

wiper

harness

lo

wiper

assembly

support

in-

side

plenum

.

"

Once

installed

;

wiper

motor

should

first

be

run

to

parked

position

and

switched

off

.

"

Next,

insta¡¡

wiper

arms

butnot

blades

.

"

Close

hood

and

fit

wiper

blades

:

"

Check

all

electrical

harness

fittings

and

sealing

grom-

mets

for

correct

reinstallation

.

Replace

al]

wire

ties

cut

during

removal

.

CAUTION-

The

gaskets

and

sealing

grommets

at

the

ECM

compartment

cover

(passenger

sideof

bulkhead)

must

be

installed

correctly

to

keep

moisture

out

of

critica¡

electrical

componente

.

Fig

.

17

.

Wiper

assembly

mounting

fasteners

(arrows)

.

Tightening

Torques

"

Wiper

shaft

nut

at

cowi

..

.

.

..

.......

12

Nm

(9

ft-Ib)

11

.

Remove

wiper

assembly

support

.

Refer

to

Fig

.

10

.

"

Wiper

support

to

wiper

assembly

or

to

body

.........

...

..........

10

Nm

(89

in-lb)

12

.

Separate

harness

at

bulkhead

connector

.

See

Fig

.

18

.

-

Wiper

arm

to

wiper

shaft

..........

25

Nm

(18

ft-Ib)

WINDSHIELD

WIPER

ASSEMBLY

Page 427 of 759

WINDSHIELD

CLEANING

SYSTEM

Washer

f

luid

reservoir,

replacing

1

.

Open

hood

and

siphon

out

washer

fluid

reservoir

.

The

windshieldcleaning

system

includes

the

spray

nozzles

in

the

engine

hood,

the

washer

fluid

pump,

and

the

washer

flu-

id

reservoir

in

the

front

passenger

side

of

the

engine

compart-

ment

.

The

windshield

spray

nozzles

can

be

aimed

by

using

asew-

ing

need1e

or

a

similar

diameter

stiff

piece

of

wire

.

Windshield

spray

nozzle,

removing

and

installing

1

.

Open

hood

andremove

hood

insulating

pad

retaining

clips

until

bottom

of

nozzle

canbe

fully

accessed

.

See

410

Fenders,

Engine

Hood

.

2

.

Carefully

disconnect

hose

from

nozzle

.

Disconnect

har-

ness

connectors

for

nozzleheater

.

3

.

Push

nozzleout

of

hood

.

See

Fig

.

21

.

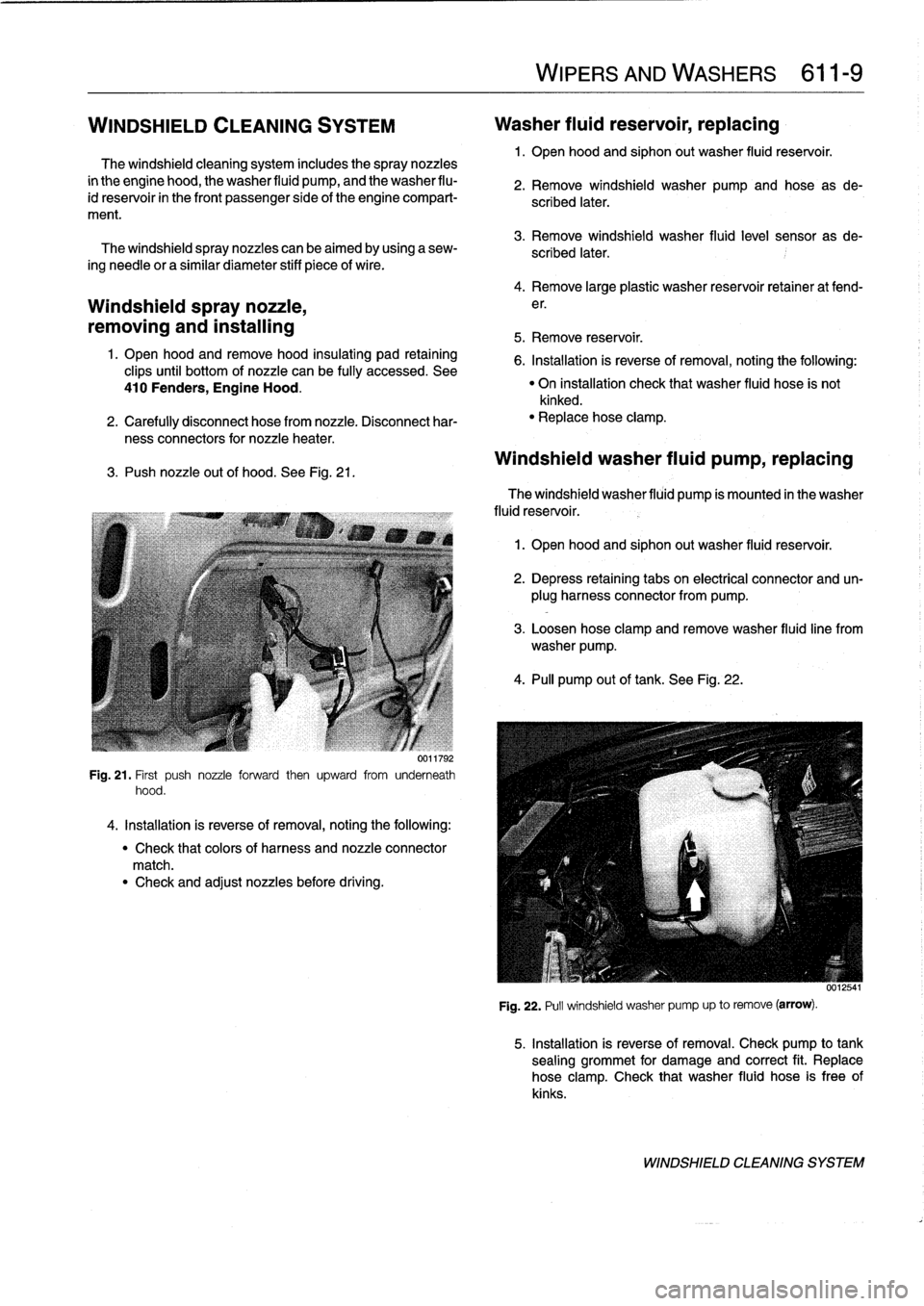

Fig

.

21

.

First

push

nozzle

forward

then

upward

from

underneath

hood

.

4

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

Check

that

colors

of

harness

and

nozzle

connector

match

.

"

Check

and

adjust

nozzles

before

driving

.

WIPERSAND

WASHERS

611-

9

2

.

Remove

windshield

washer

pump

and

hose

as

de-

scribed

later

.

3

.

Remove

windshield

washer

fluid

level

sensor

as

de-

scribed

later

.

4

.

Remove

large

plastic

washer

reservoir

retainer

at

fend-

e

r

.

5

.

Remove

reservoir

.

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

"

On

installation

check

that

washer

fluid

hose

is

not

kinked

.

"

Replacehose

clamp

.

Windshield

washer

fluid

pump,

replacing

The

windshield

washer

fluid

pump

ís

mounted

in

the

washer

fluid

reservoir

.

1

.

Open

hood

and

siphon

out

washer

fluid

reservoir

.

2

.

Depress

retaining

tabs

on

electrical

connector

and

un-

plug

harness

connector

from

pump

.

3

.

Loosen

hose

clamp

and

remove

washer

fluidline

from

washer

pump

.

4

.

PA

pump

out

of

tank

.

See

Fig

.

22

.

Fig

.

22

.

Pull

windshield

washer

pump

up

to

remove

(arrow)

.

5

.

Installation

is

reverse

of

removal

.

Check

pump

to

tank

sealing

grommet

for

damage

and

correct

fit

.

Replace

hose

clamp

.

Check

that

washer

fluid

hose

is

free

of

kinks

.

WINDSHIELD

CLEANING

SYSTEM

Page 438 of 759

620-2

INSTRUMENTS

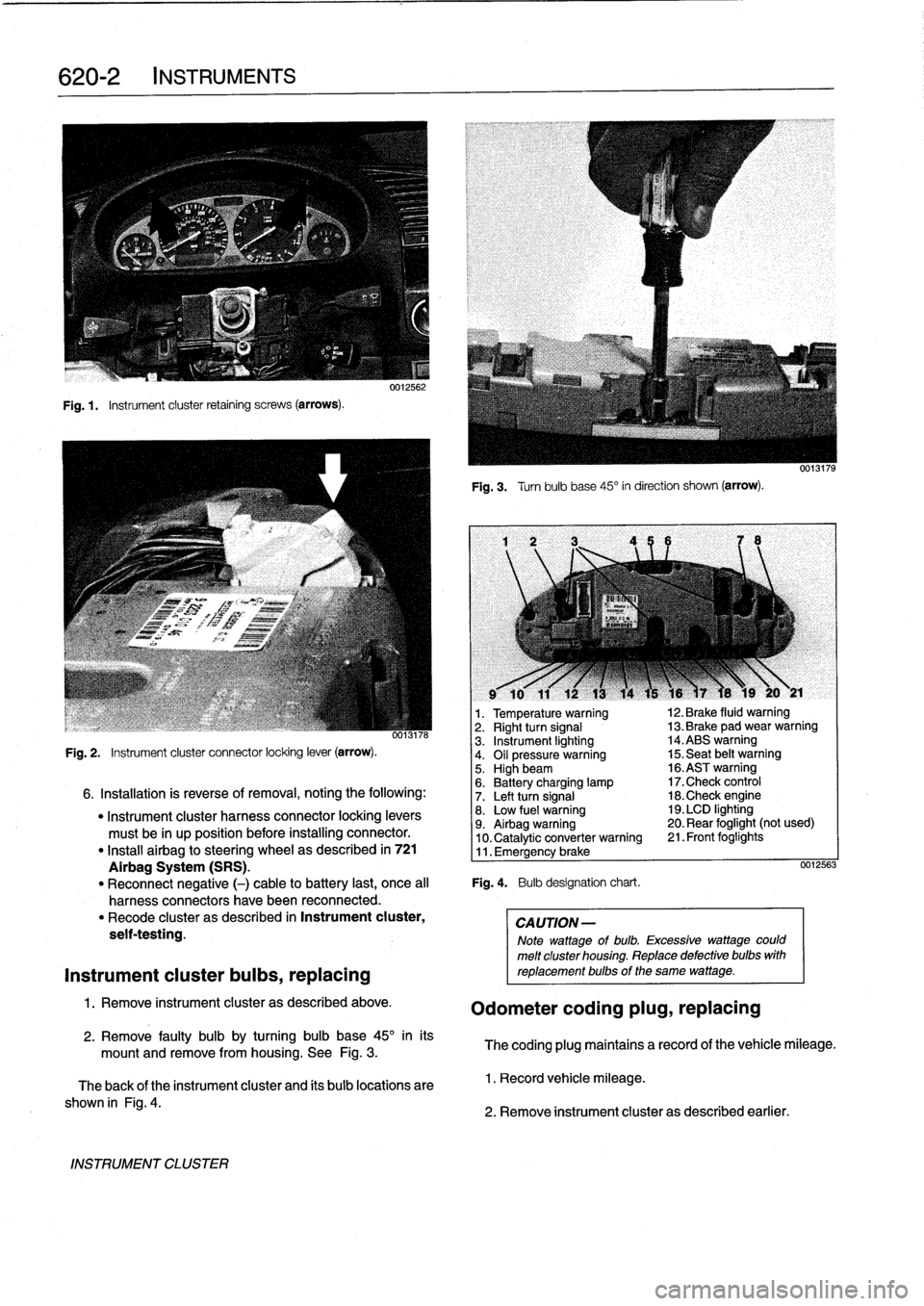

Fig

.1.

Instrument

cluster

retaining

screws

(arrows)

.

INSTRUMENT

CLUSTER

0012562

Fig

.

3

.

Turnbulb

base

45°

in

direction

shown

(arrow)

.

l

v

w

r

v

9

10

11

12

13

14

15

16

)7

18

19

20

y

21

1

.

Temperature

warning

12

.

Brake

fluid

warning

oo13n6

2

.

Right

turn

signal

13

.

Brake

pad

wear

warning

3

.

Instrument

lighting

14

.ABS

warning

Fig

.

2

.

Instrument

cluster

connector

locking

lever

(arrow)

.

4

.

Oil

pressure

warning

15

.

Seat

belt

warning5

.

Highbeam

16

.ASTwarning

6

.

Battery

charging

lamp

17

.Check

control

6

.

Installation

is

reverse

of

removal,

noting

the

following

:

7

.

Left

turn

signal

18

.Check

engine

"

Instrument

cluster

harness

connector

locking

levers

8

.

Low

fuel

warning

19

.

LCD

lighting

must

be

in

up

position

before

installing

connector

.

9

.

Airbag

warning

20

.

Rear

foglight

(not

used)

10

.

Catalytic

converter

warning

21

.

Front

foglights

"

Install

airbag

to

steering

wheel

as

described

in

721

11

.

Emergency

brake

Airbag

System

(SRS)

.

0012563

"

Reconnect

negative

(-)

cable

to

battery

last,

once

al¡

Fig

.

4

.

Bulb

designation

chart

.

harness

connectors

have

been

reconnected

.

"

Recode

cluster

as

described

in

Instrument

cluster,

CAUTION-

seif-testing

.

Note

wattage

of

bulb

.

Excessive

wattage

could

melt

cluster

housing

.

Replace

defective

bulbs

with

Instrument

cluster

bulbs,

replacing

reptacementbulbs

of

the

same

wattage

.

1

.

Remove

instrument

cluster

as

described

above

.

Odometer

coding

plug,

replacing

2

.

Remove

faulty

bulb

by

turning

bulb

base

45°

inits

mount

and

remove

from

housing

.

See

Fig

.

3

.

The

coding

plug

maintains

a

record

of

thevehicle

mileage

.

The

back

of

the

instrument

cluster

and

its

bulb

locations

are

1

.

Record

vehicle

mileage

.

shown

in

Fig

.

4

.

2

.

Remove

instrument

cluster

as

described

earlier

.

Page 441 of 759

FRONT

LIGHTING

.

...........

.

....

.

.

.

.

630-1

Headlight

buib,

replacing

............

.

.

.

.

630-1

Headlight

assembly,

removing

and

installing

.......

.

....

.

.

.

.

630-2

Foglight

assembly,

removing

and

installing

..

630-3

Front

turn

signal

assembly,

removing

and

installing

.....

.

.

.

........

630-4

GENERAL

The

headlight

and

foglight

assemblies

usehalogen

bulbs

.

To

ensure

the

longevity

of

halogen

bulbs,

the

bulb

glass

should

not

be

handied

.

Dirt

and

skin

oíls

may

cause

a

bulbto

fail

prematurely

.

If

necessarywipe

bulb

using

a

clean

cloth

dampened

with

rubbing

alcohol

.

NOTE-

Use

only

original

equipment

replacement

bulbs

.

Non-

original

equipment

bulbs

may

cause

false

failure

read-

ings

on

the

check

control

display

(where

applicable)

.

WARNING

-

INhenworking

on

electrical

systems,

remove

the

fuse

protecting

the

circuit

under

repair

.

See

610

Electrical

Component

Locations

.

FRONT

LIGHTING

Headlight

bulb,

replacing

1

.

Open

engine

hood

.

2

.

Working

in

back

of

headlight

assembly,grasp

rear

of

bulbsocket

(harnessconnector)

and

turn

counterclock-

wise

90°

.

Pull

bulb

out

of

headlight

assembly

.

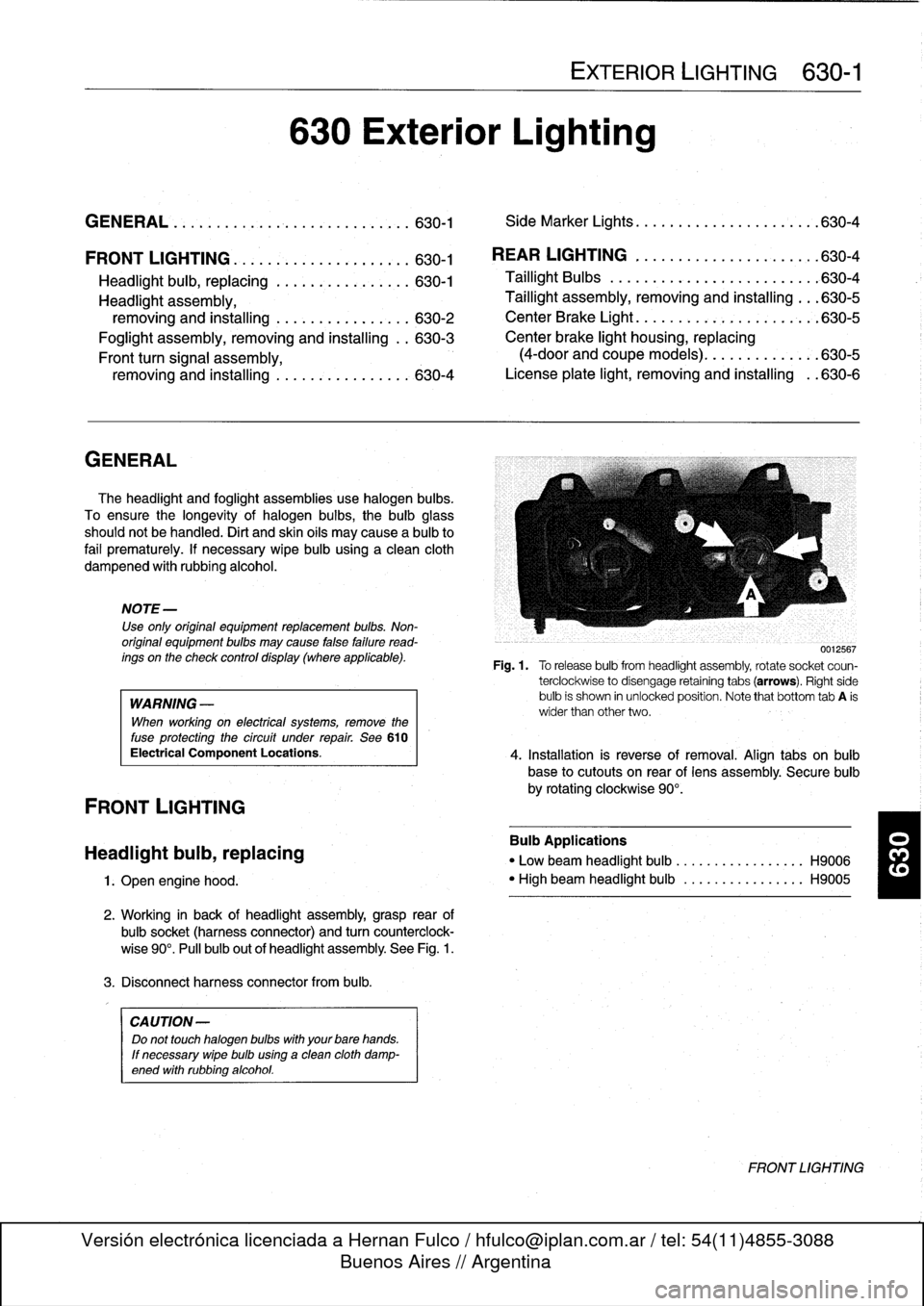

See

Fig

.

1

.

3

.

Disconnect

harness

connector

from

bulb

.

CA

UTION-

Do

not

touch

halogen

bubs

with

yourbare

hands

.

If

necessary

wipe

bulb

using

a

clean

cloth

damp-

ened

with

rubbing

alcohol

.

630

Exterior

Lighting

EXTERIOR

LIGHTING

630-1

GENERAL

.

.

.

.

...

.

................

.

.

.

.

630-1

Side

Marker

Lights

.......

.

.

.

.

.

.......

.

..

630-4

REAR

LIGHTING

.

......

.

.

.

.

.

.

.

...

.

.

.

..

630-4

Taillight

Bulbs

..........

.

.

.

.

.

.....

.

.

.

.

.

630-4

Taillight

assembly,

removing

and

installing

.

.

.

630-5

CenterBrake

Light

.......

.

.

.

.

.

.

.

.

.

.

.

.

.

.

.

630-5

Center

brake

light

housing,

replacing

(4-door

and

coupe

models)

.

.

.

.

.......

.

.

.630-5

License

plate

light,

removingand

installing

.

.630-6

0012567

Fig

.1.

Torelease

bulbfrom

headlight

assembly,

rotate

socket

coun-

terclockwise

to

disengage

retaining

tabs

(arrows)

.

Right

side

bulb

is

shown

in

unlocked

position

.

Note

that

bottom

tab

A

is

wider

than

other

two

.

4

.

Installation

is

reverse

of

removal

.

Align

tabs

on

bulb

base

to

cutouts

on

rear

of

lens

assembly

.

Secure

bulb

by

rotating

clockwise

90°

.

Bulb

Applications

"

Low

beam

headlight

bulb

...

.

..

..

.........

H9006

"

High

beam

headlight

bulb

..

.

..

..

.........

H9005

FRONT

LIGHTING

Page 480 of 759

721-

4

AIRBAG

SYSTEM

(SRS)

CAUTION-

A

new

contact

ring

is

held

in

center

position

with

a

screw

.

This

locking

device

must

be

removed

after

contact

ring

is

installed

on

steering

wheel

.

See

Fig

.

4

.

Latercars

(1994

on)

:

"

Connect

ground

lead

at

contact

ring

.

"

When

installing

a

new

contact

ring

from

BMW,

remove

locking

pin

after

installing

contact

ring

to

steering

wheel

.

See

Fig

.

5

.

Airbag

crash

sensor,

replacing

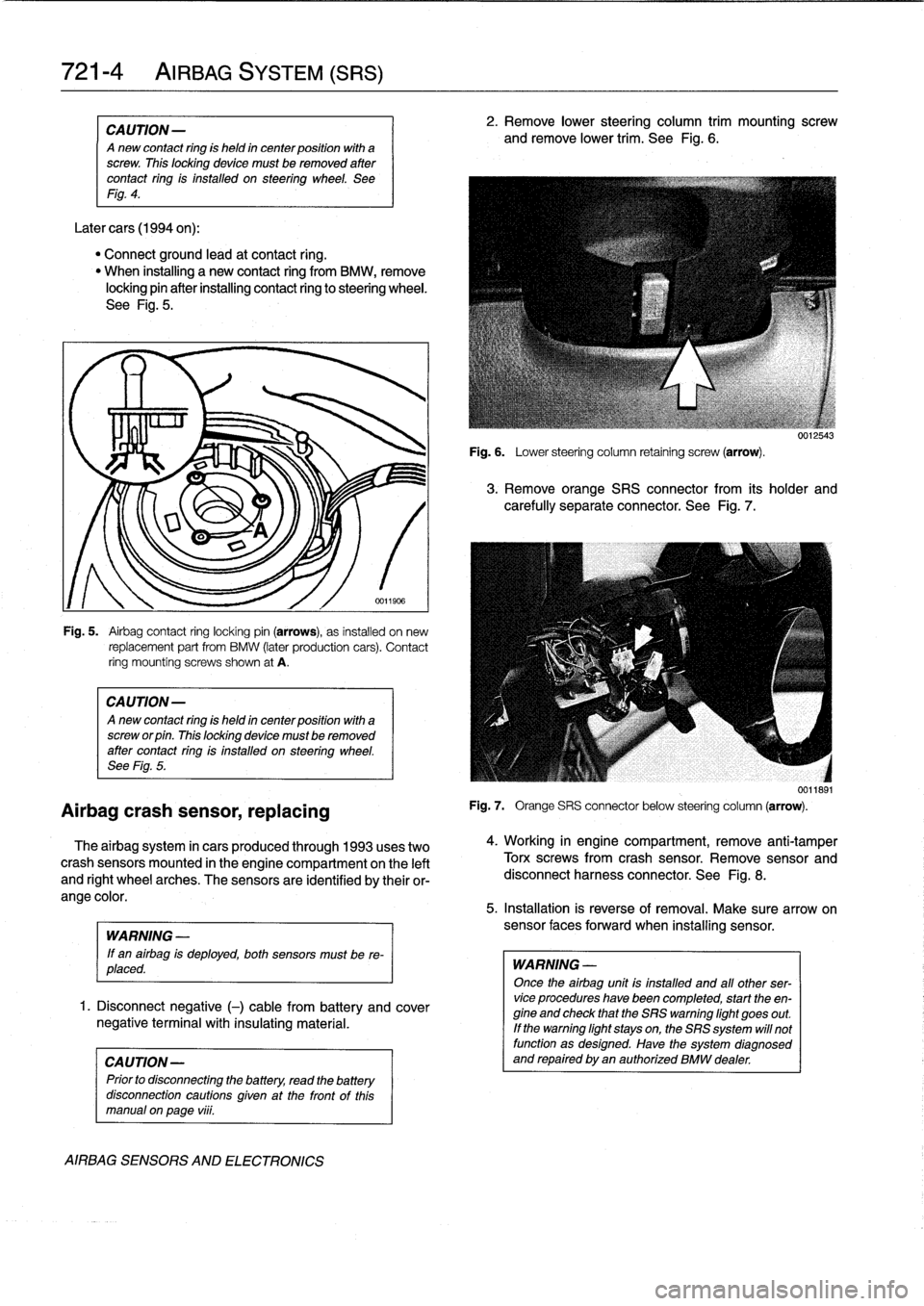

Fig

.

5

.

Airbag

contact

ring

locking

pin

(arrows),

as

installed

on

new

replacement

part

from

BMW

(later

production

cars)

.

Contact

ring

mountíng

screws

shown

at

A

.

CAUTION-

Anew

contact

ring

is

held

in

center

position

with

a

screw

or

pin

.

This

locking

device

mustbe

removed

after

contact

ring

is

installed

on

steering

wheel

.

See

Fig

.

5

.

The

airbag

system

in

cars

produced

through

1993

uses

two

crash

sensors

mounted

in

the

engine

compartment

on

the

left

and

right

wheel

arches

.

The

sensors

are

identified

by

their

or-

ange

color

.

WARNING

-

If

en

airbag

is

deployed,

both

sensors

must

be

re-

placed

.

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

negative

terminal

with

insulating

material

.

CAUTION-

Prior

to

disconnectiog

the

battery,

read

the

battery

disconnection

cautíons

given

at

the

front

of

thls

manual

on

page

viii

.

AIRBAG

SENSORS

AND

ELECTRONICS

2

.

Remove

lower

steering

column

trim

mounting

screw

and

remove

lower

trim

.

See

Fig

.

6

.

Fig

.

6

.

Lower

steering

column

retaining

screw

(arrow)

.

3

.

Remove

orange

SRS

connector

from

its

holder

and

carefully

separate

connector

.

See

Fig

.

7

.

Fig

.

7

.

Orange

SRS

connector

below

steering

column

(arrow)

.

4

.

Working

in

engine

compartment,

remove

anti-tamper

Torx

screwsfrom

crash

sensor

.

Remove

sensor

and

disconnect

harness

connector

.

See

Fig

.

8

.

5

.

Installation

is

reverse

of

removal

.

Make

sure

arrow

on

sensor

faces

forward

when

installing

sensor

.

WARNING

-

Once

the

airbag

unit

is

installed

and

all

other

ser-vice

procedures

have

been

completed,

start

the

en-

gine

and

check

that

the

SRS

warning

light

goes

out

.

If

the

warning

light

stays

on,the

SRS

system

will

not

function

as

designed

.

Have

the

system

diagnosed

and

repaired

byen

authorized

BMW

dealer

.

0012543

0011891

Page 482 of 759

721-

6

AIRBAG

SYSTEM

(SRS)

5

.

Carefully

lift

airbag

unit

off

steering

wheel

and

discon-

6

.

Installation

is

reverse

of

removal

.

Tighten

right

side

nect

orange

harness

connector

from

rear

of

airbag

unit

.

screw

on

airbag

first

(as

viewedfrom

driver's

seat),

See

Fig

.

10

.

then

left

side

screw

.

NOTE-

NOTE-

In

some

models,

theairbag

electrical

connection

to

the

If

there

is

no

electrical

harness

connector

between

the

steering

wheel

isvia

aplug

in

back

of

the

airbag

unit

.

airbag

and

the

steering

wheel,

be

sure

to

fit

the

push

There

is

no

wire

harness

to

disconnect

.

in

electrical

plug

in

back

of

the

airbag

finto

the

proper

re-

ceptacle

in

the

steering

wheel

.

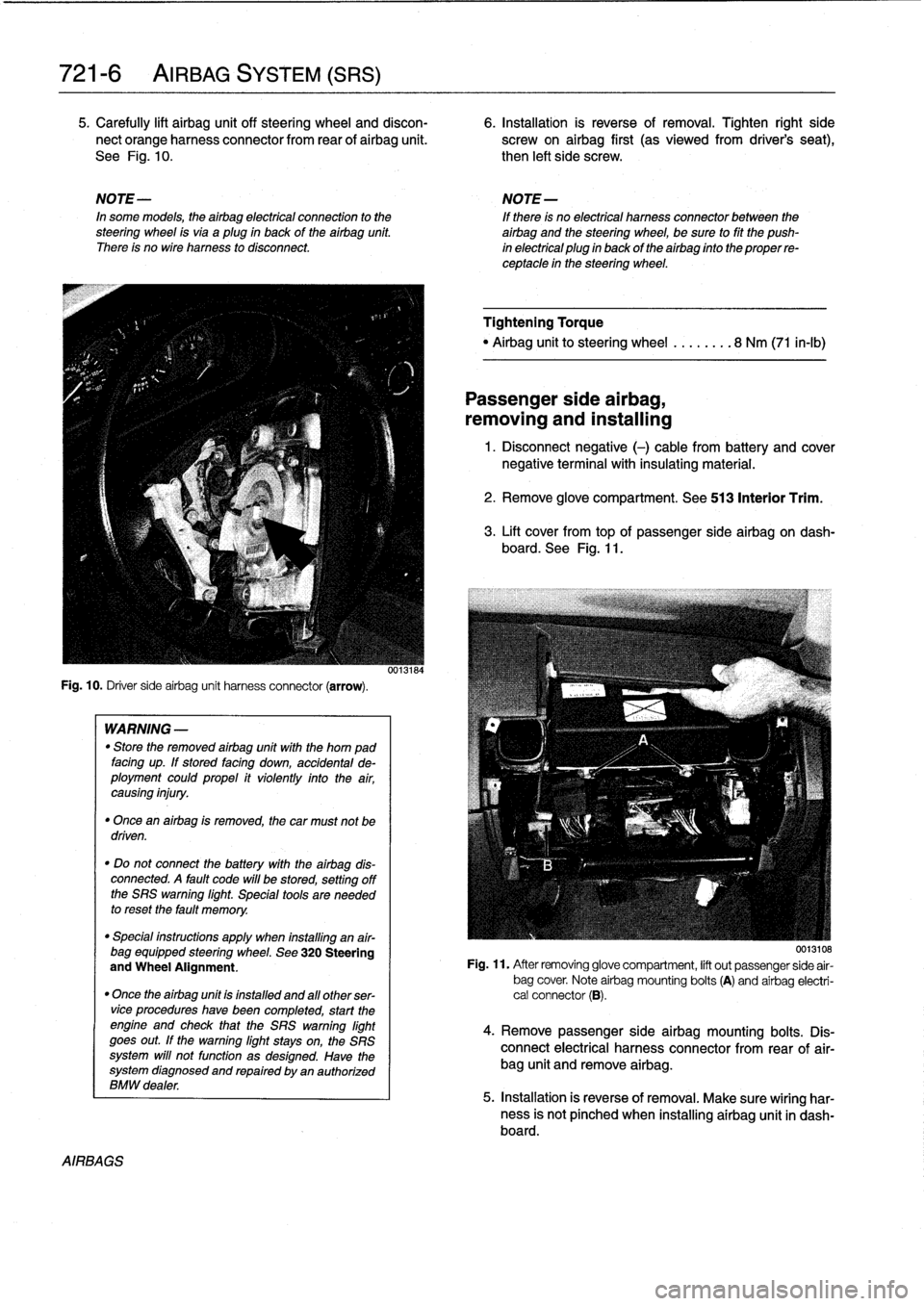

Fig

.

10

.

Driver

sideairbag

unit

harness

connector

(arrow)

.

AIRBAGS

WARNING

-

"

Store

the

removed

airbag

unit

with

the

horn

pad

facing

up

.

If

stored

facing

down,

accidental

de-

ployment

couldpropel

it

violently

into

the

air,

causing

injury

.

"

Once

an

airbag

is

removed,

the

car

must

not

be

driven

.

"

Do

not

connect

the

battery

with

the

airbag

dis-

connected

.

A

fault

code

will

be

stored,

setting

off

the

SRS

warning

light

.

Special

tools

are

needed

to

reset

the

fault

memory

.

"

Special

instructions

apply

when

installing

an

air-

bag

equipped

steering

wheel

.

See

320

Steering

and

Wheel

Alignment

.

"

Once

the

airbag

unit

is

installnd

and

all

other

ser-vice

procedureshave

been

completed,

start

the

engíne

and

check

that

the

SRS

warning

light

goes

out

.

If

the

warning

light

stays

on,

the

SRS

system

will

not

function

as

designed

.

Have

the

system

diagnosed

and

repaired

by

an

authorized

BMW

dealer

.

0013184

Tightening

Torque

"

Airbag

unitto

steering

wheel

........

8

Nm

(71

in-lb)

Passenger

side

airbag,

removing

and

installing

1

.

Disconnect

negative

(-)

cable

from

battery

and

cover

negative

terminal

with

insulating

material

.

2

.

Remove

glove

compartment

.

See

513

Interior

Trim

.

3

.

Lift

cover

from

topof

passenger

sideairbag

on

dash-

board

.

See

Fig

.

11

.

0013108

Fig

.

11

.

After

removing

glove

compartment,

lift

out

passenger

side

air-

bag

cover

.

Note

airbag

mounting

bolts

(A)

and

airbag

electri-

cal

connector

(B)

.

4

.

Remove

passenger

sideairbag

mounting

bolts

.

Dis-

connect

electrical

harness

connector

from

rear

of

air-

bag

unit

and

remove

airbag

.

5

.

Installation

is

reverse

of

removal

.

Make

sure

wiring

har-

ness

is

not

pínched

when

installing

airbag

unit

in

dash-board

.

Page 500 of 759

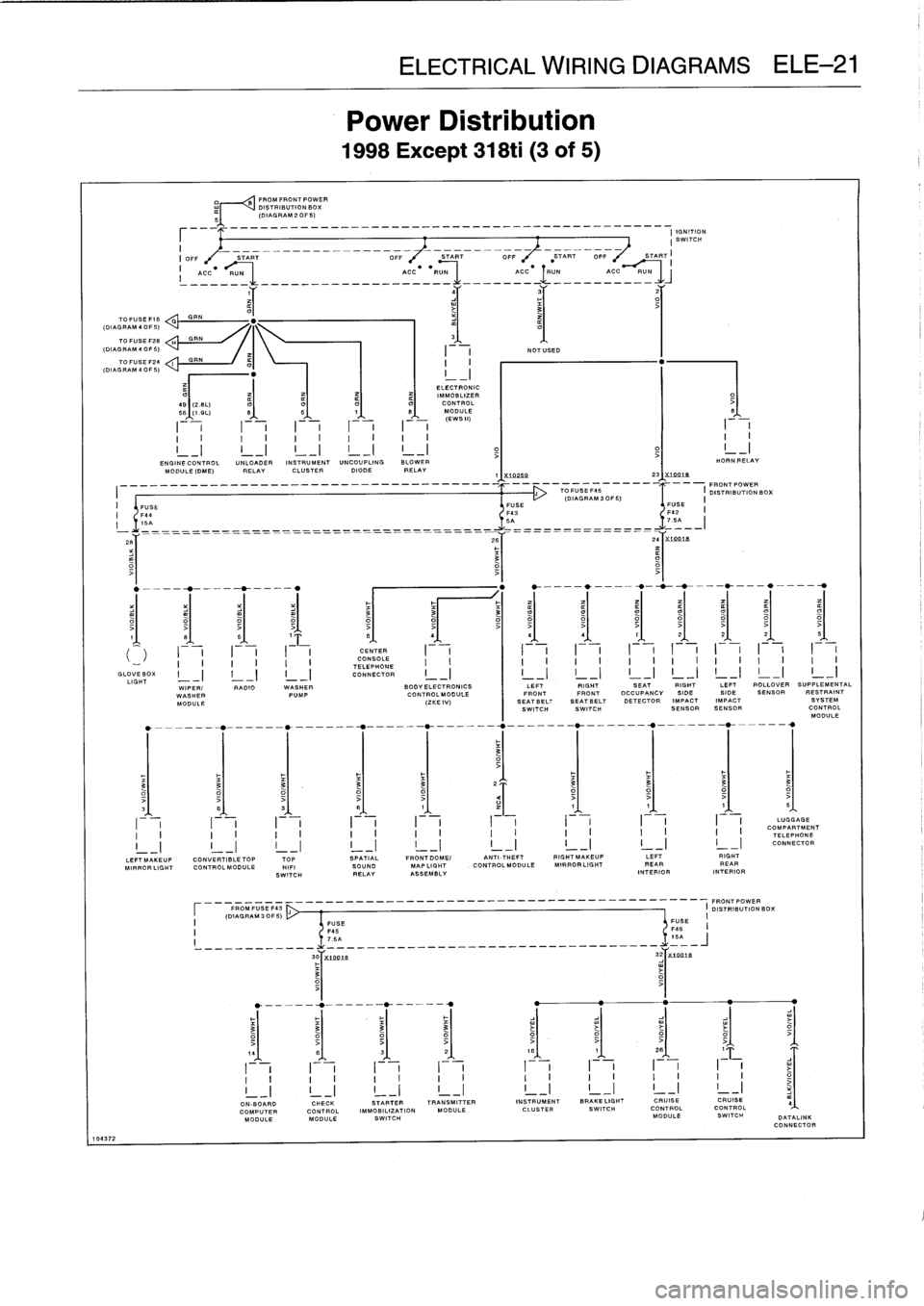

ELE-16

ELECTRICAL

WIRING

DIAGRAMS

88978

TO

FUSE

F16

yDIAGRAM

4

OF

5)

70FU

SEF28

K

GRN

(DIAGRAM

4OF5)

___

--------

_---------------------

______________

I

IGNITION

I

SWITCH

I

_

_

_-_-__-

-----------

I

OFF

START

OFF

START

OFF

START

F,

START

FROM

FRONT

POWER

r

<

DISTRIBUTION

BOX

(DIAGRAM

2OF5)

=OC---U-

-_-_---_-__-ACC--RU=

____CC_CC--R=N-

CC-PUN

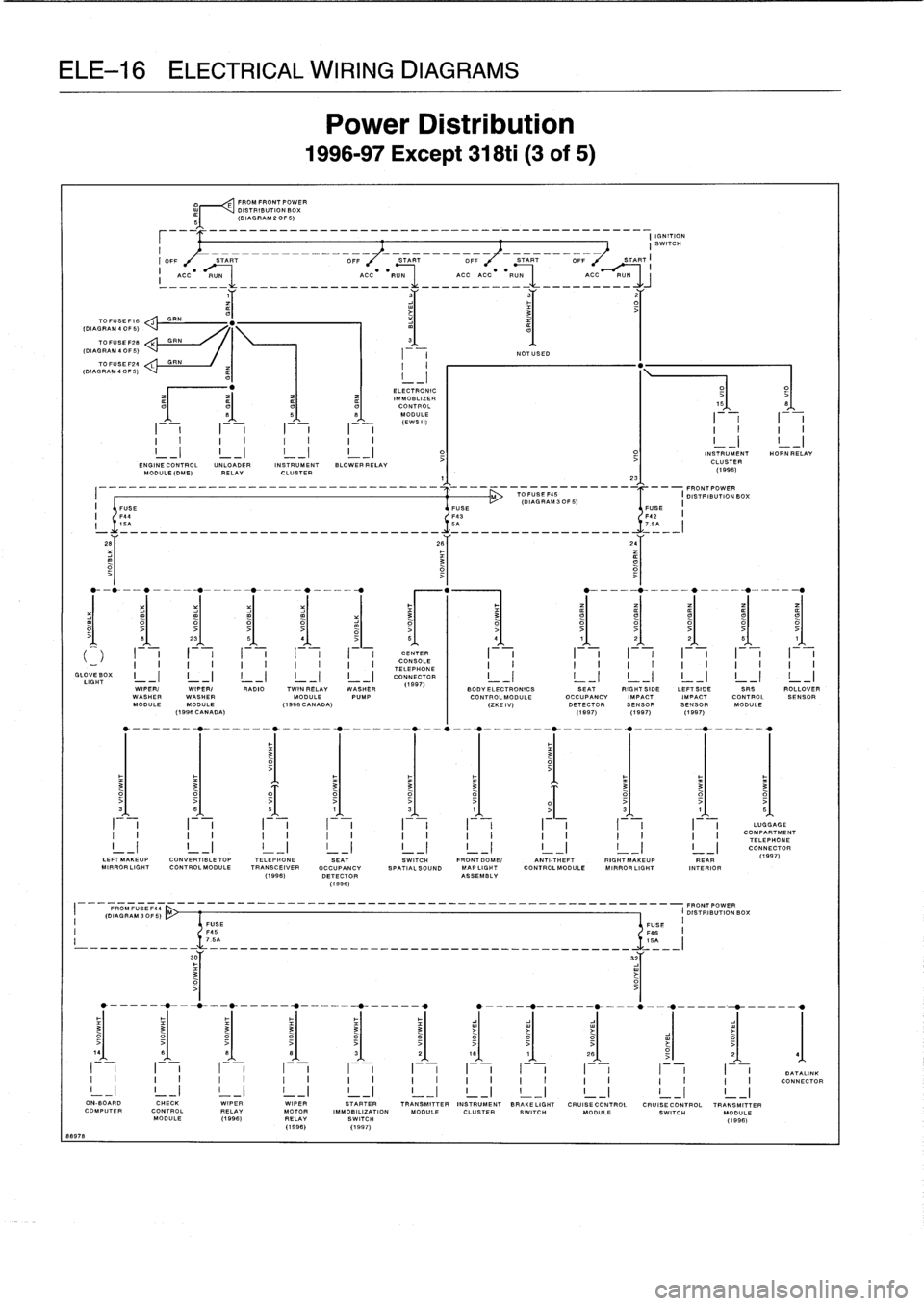

Power

Distribution

1996-97

Except

318ti

(3

of

5)

ELECTRONICIMMOBLIZER

CONTROL

MODULE

(EWS11)

NOTUSED

2_

.

15

t

I

I

II

II

F-,

II

II

I

I

II

I

I

I

I

I

-I

L-1

INSTRUMENT

HORN

RELAY

ENGINECONTROL

UN

LOADER

INSTRUMENT

BLOWERRELAY

CLUSTER

No

DULE(DME)

RELAY

CLUSTER

°_

(1996)

-----

-------

1

1'

--

FRONTPOWER

I

M

TO

1111111

IDISDISTRIBUTION

BOX

(DIAGRAM

3

OF5)

II

FUSE

FUSE

USE

I

1'44

F43

42

I

!

'________________________________

5A

~

_________________

5=

el

231

51

41

51

51

41

1

J

1

2

J

1

2

J

1

5~

1),

1

I

.+

.

1

1

1

CE

.N+

TER

I

I

.+

.

i

I

.

1

I

.

1

I

.

1

1

1

1

1

I

I

II

II

I

I

I

I

CONSOLE

TELEPHONE

GLOVE

BOX

I

-

.

I

I

-

I

I

-)

I

-

I

I

-

I

CONNECTOR

LIGHT

(1987)

WIPER/

WIPER/

RADIO

TWIN

RELAY

WASHERWASHER

WASHER

MODULE

PUMPMODULE

MODULE

(1996

CANADA)

(1996

CANADA)

SEAT

RIGHTSIDE

LEFT

SIDE

SRS

ROLLOVER

OCCUPANCY

IMPACTIMPACT

CONTROLSENSOR

DETECTOR

SENSORSENSOR

MODULE

(1997)(1997)(1997)

O~

31

1~

~

1

31

11

51

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

LUG

AGE

I

I

II

II

I

I

II

I

I

II

II

I

I

COMPARTMENT

TELEPHONE

CONNECTOR

LEF7MAKEUP

CONVERTIBLETOP

TELEPHONE

SEAT

SWITCH

FRONTDOME/

ANTI-THEFT

RIGHTMAKEUP

REAR

(1997)

MI

PROFLIGHT

CONTROLMODULE

TRANSCEIVER

OCCUPANCY

SPATIALSOUND

MAPLIGHT

CONTROLMODULE

MIRROR

LIGHT

INTERIOR

(1996)

DETECTOR

ASSEMBLY

(199fi)

FROMFISE

141

---

(DIAGRAM

30F5)

M

________--_--_________________-_----------------

FRONTPOWER

DISTRIBUTIONBOX

(

FUSE

FUSE

1I

F45

F4fi

I

'S

7

.5A--______________-________________-______

___

30Y

32Y

I

i

F-

,I

iF-

,I

i

I

-

F

-

,

I-

ON-BOAR

CHECK

WIPER

WIPER

STARTER

TRANSMITTER

INSTRUMENT

BRAKELIGHT

CRUISECONTROL

CRUISECONTROL

TRANSMITTER

COMPUTER

CONTROL

RELAY

MOTOR

IMMOBILIZATION

MODULE

CLUSTER

SWITCH

MODULE

SWITCH

MODULE

MODULE

(1996)

RELAY

SWITCH

(1996)

(1998)

(1997)

0

TALINK

CONNECTOR

Page 505 of 759

TOFUSEF16

GGRN

(DIAGRAM

4

OF

5)

TOFUSEF28

HGRN

(DIAL

RAM

4

OF

5)

TOFUSEF24

GRN

(DIAGRAM

4

OF

5)

10437

2

F

-

1I

I

I

I

I

I

I

I

I

I

>

I

I

I

_I

L-1

L

I

D

I

_I

ENGINECONTROL

UNLOADER

INSTRUMENTUNCOUPLING

BLOWERNo

DULE(DME)

RELAY

CLUSTER

DIODE

RELAY

1

I

FUSE

I

F44

I

154

v__-----__---------

a--

_

---____--aaa-r

====

=---~,

.

I--1

I-

I

I,\

I

CONSOLE

I

I

_'

II

I

III

TELEPHONE

I1

GLOVEBOX

I

I

I

CONNECTOR

I

LIGHT

LEFT

RIGHT

SEAT

FIGHT

LEFT

ROLLOVER

SUPPLEMENTAL

FRONTFRONT

OCCUPANCY

SIDESIDE

SENSOR

RESTRAINT

SEATBELT

SEATBELTDETECTOR

IMPACTIMPACT

SYSTEM

SWITCH

SWITCH

SENSOR

SENSOR

CONTROL

MODULE

I

IGNITION

SWITCH

I

OFF

START

OFF

START

OFF

START

OFF

/

START

ACC-__U-

_____________

_

ACC

"

__U_

_____

AC

_-

_____

A

C

____

,

a

FROMFRONTPOWER

DISTRIBUTION

BOX

(DIAGRAM

2

OF

5)

56

ELECTRONICIMMOBLIZER

((

1

.

2

.8

L

(

L)

8

5O

1

8

~

CONTROL

9

MODULE

I

_

_

IF-")

I

1

I

I

I

I

I

I

WIPERI

RADIO

WASHER

BODYELECTRONICS

WASHER

Pump

CONTROL

MODULEMODULE

(ZKE

IV)

61

31

5'

I

I

I

I

I

I

I

II

I

I

I

I

I

I

I

LEFT

MAKEUP

CONVERTIBLETOP

TOP

SPATIAL

FRONTDOME/

ANTITHEFT

T

RIGHT

MAKEUP

LEFT

RIGHT

MIPROFLIGHT

CONTROLMODULEH

I

FI

SOUND

MAPLIGHT

CONTROLMODULE

MIRRORLIGHT

REAR

FEAR

SWTCH

RELAY

ASSEMBLY

INTERIOR

INTERIOR

______

-

-

-

-

-

_____________________________

-_

FRONTPOWER

FROMFUSE

F43

---

I

DISTRIBUTION

BOX

(OIAGRAM30F5)

J

II

FUSE

FUSE

I

F45

146

7

.5

-_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

_

ELECTRICAL

WIRING

DIAGRAMS

ELE-21

Power

Distribution

1998Except

318ti

(3

of

5)

2B

NOTUSED

0259

231X

7Oat8

5I

4151

51

5

;

4

4

1

2

O

16

I

I

I

I

I

I

I

I

I

II

I

I

I

I

I

f

I

I

I

ON-BOARD

CHECK

STARTER

TRANSMITTER

INSTRUMENT

BRAKE

LISHT

COMPUTERCONTROL

IMMOBILIZATION

MODULE

CLUSTER

SWITCH

MODULE

MODULE

SWITCH

---

-

-

------

--

FRONT

POWER

TOFUSEF45

I

DISTRIBUTION

BOX

'DIAGRAM

S

CPS)

FUSE

"

FUSE

HORN

RELAY

CRUISECRUISE

CONTROLCONTROL

MODULE

SWITCH

I

I

I

I

I

II

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

II

II

II

LUGGAGECOMPARTMENT

II

II

II

TELEPHONE

CONNECTOR

DATALINK

CONNECTOR

Page 532 of 759

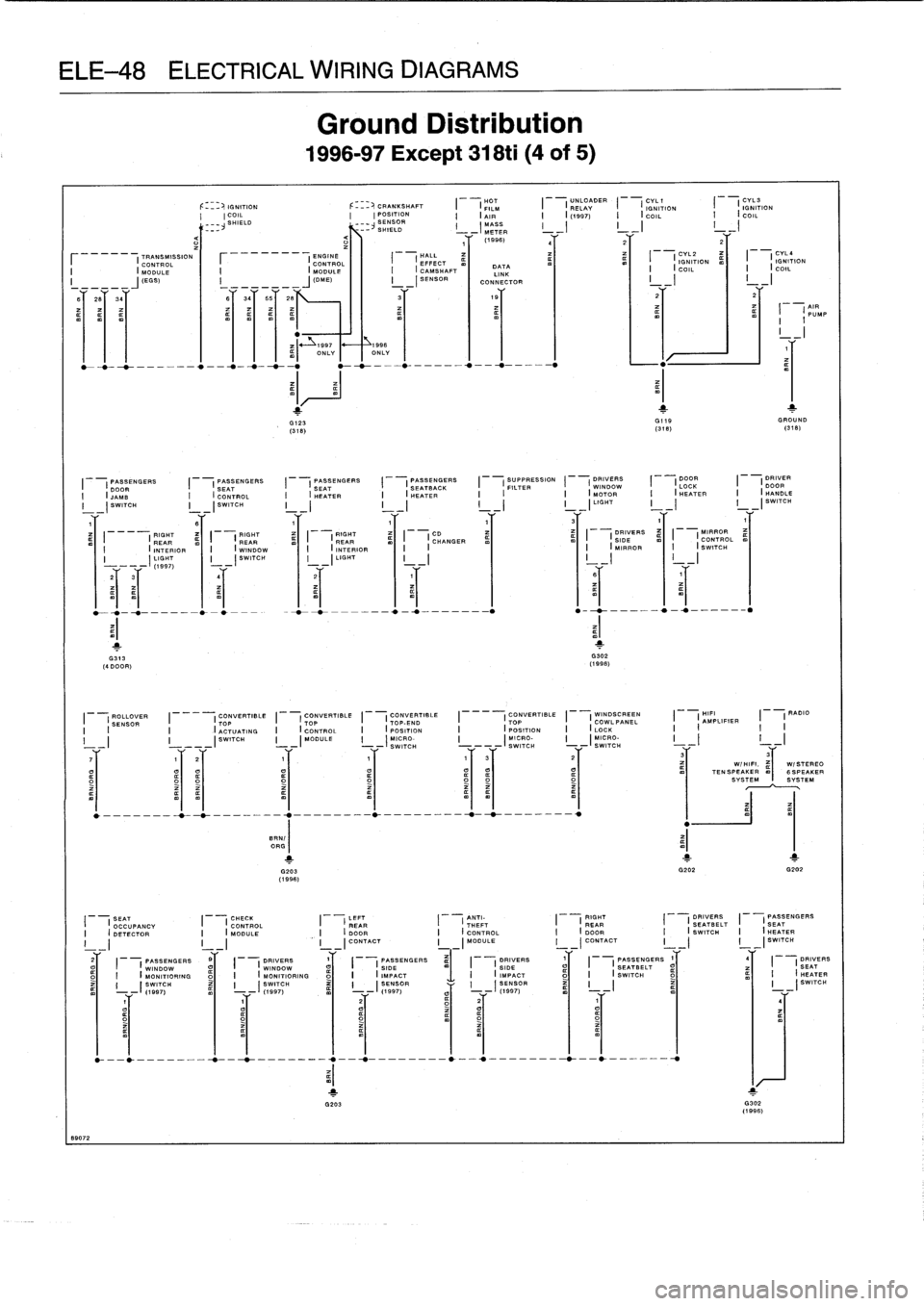

ELE-48

ELECTRICAL

WIRING

DIAGRAMS

TRANSMISSION

r

I

ENGINE

(HALL

CON

TROL

I

CONTROL

I_

(

I

EFFECT

I

(

MODULE

I

(

MODULE

I

(

CAMSHAFT

I

_____y

_

I

11"S)

1

--

j

(DIE)

I

(SENSOR

B'f

28

y_

1

..'r

BY

3ar

BET

26

~

3

8907

2

PASSENGERS

PASSENGERSPASSENGERS

PASSENGERS

SUPPRESSION

DRIVERS

DOOR

DRIVER

I

(DOOR

I

(

SEAT

I

(SEAT

I

I

SEATBACK

I

(

FILTER

I

(

WINDOW

I

(

LOCK

I

(

DOOR

I

(JAMB

I

(CONTROL

I

(HEATER

I

(HEATER

II

I

(MOTOR

I

(HEATER

I

(HANDLE

RIGHT

RIGHT

RIGHT

CD

I---

m

I

-

I_

i

II

REAR

REAR

REAR

CHANGER

(

INTERIOR

I

I

(

WINDOW

ml

I

(

INTERIOR

ml

I

I

1

G313

G302

(4

DOOR)

(1996)

ROLLOVER

CONVERTIBLE

CONVERTIBLECONVERTIBLE

CONVERTIBLE

WINDSCREEN

HIFI

RADIO

I

(

SENSOR

I

---

(

TOP

I

(

TOP

I

(

TOP-END

I

---

(

TOP

I

I

CoWLPANEL

I

(

AMPLIFIER

I

II

I

I

(

ACTUATING

I

I

OONTROL

I

(

POSITION

I

(

POSITION

I

(

LOCK

I

i

I

I

SWITCH

I

-(

MODULE

I

-(

SWITCH

I

,

---(

SWITCH

I

,-(

SWITCH

I

-I

1

-I

IGNITION

F---

CRANKSHAFT

I

(HOT

I

I

UNLOADER

1

'CYL1

IOYL3

COIL

POSITION

FILM

RELAY

IGNITIONIGNITION

I

I

(

AIR

I

(

(1997)

I

(

COIL

I

(

COILCOILSHIELD

_

SENSOR

SHIELD

MASS

METER

S

1

(

I

I

I

I

1

I

___

1

r

(

1996

)

.T

2T

21"

,

.-------

.

.W_-*---___--7-----__-41"

-

----___--0-f---_---7

1

.1

m

SEAT

CHECK

LEFT

ANTI-

RIGHT

DRIVERS

PASSENGERS

I

(

OCCUPANCY

I

(

CONTROL

I

(

REAR

I

(

THEFT

I

(

REAR

I

(

SEATBELT

I

(

SEAT

I

1

DETECTOR

I

(

MODULE

I

(

DOOR

I

(

CONTROL

I

(

DOOR

I

I

SWITCH

I

T

HEATER

1

_I

I

-I

L-1

CONTACT

I

-I

MODULE

I

-I

CONTACT

I

-I

I

_

I

SWITCH

I

PASSENGERS

9

I

'

DRIVERS

4

PASSENGERS

DRIVERS

1

PASSENGERS

1

4

DRIVERS

(

WINDOW

WINDOW

I

(

SIDE

I

(

SIDE

I

(

SEATBELT

I

(

SEA

2

T

I

I

MONITIORING

I

I

MONITIORING

I

(

IMPACT

I

(

IMPACT

I

(

SWITCH

I

(

HEATER

1

(

SWITCH

I-.(

SWITCH

I

V

I

SENSOR

I

v

I

SENSOR

I

5I

I

I

-(

-

(1997)

--

(1997)

--

(1997)

T

--

(1997)

SWITCH

-

Y

Ground

Distribution

1996-97

Except

318ti

(4

of

5)

i

997

__~

1996

m)

ONLYONLY

G123

GI9

GROUND

(318)

(318)

(318)

y

1

1

G203

G202

G202

(1996)

DATA

LINK

CONNECTOR

O

-___-___0_-t--__--_

.,---0__--_---`__

.,-_--_-_-*_--0

.-____-

CYL2

DYLa

I

I

IGNITION

I

I

IGNITION

I

I

m

COIL

l

I

I

COIL

1

'

o~

t

G302

(1996)

1

AIR

I

PUMP

31

3

aIaI¢~

W/HIFI

.

,I

W/STEREOTENSPEAKER6SPEAKER

SYSTEMSYSTEM