engine BMW M6 CONVERTIBLE 2012 Workshop Manual

[x] Cancel search | Manufacturer: BMW, Model Year: 2012, Model line: M6 CONVERTIBLE, Model: BMW M6 CONVERTIBLE 2012Pages: 297, PDF Size: 12.09 MB

Page 238 of 297

RefuelingVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehicle,

e. g., because of the selected optional equip‐

ment or country variant. This also applies for

safety-related functions and systems.

General information Refuel promptly

Refuel no later than at a range of

30 miles/50 km, or operation of the engine is not

ensured and damage may occur.◀

Fuel cap

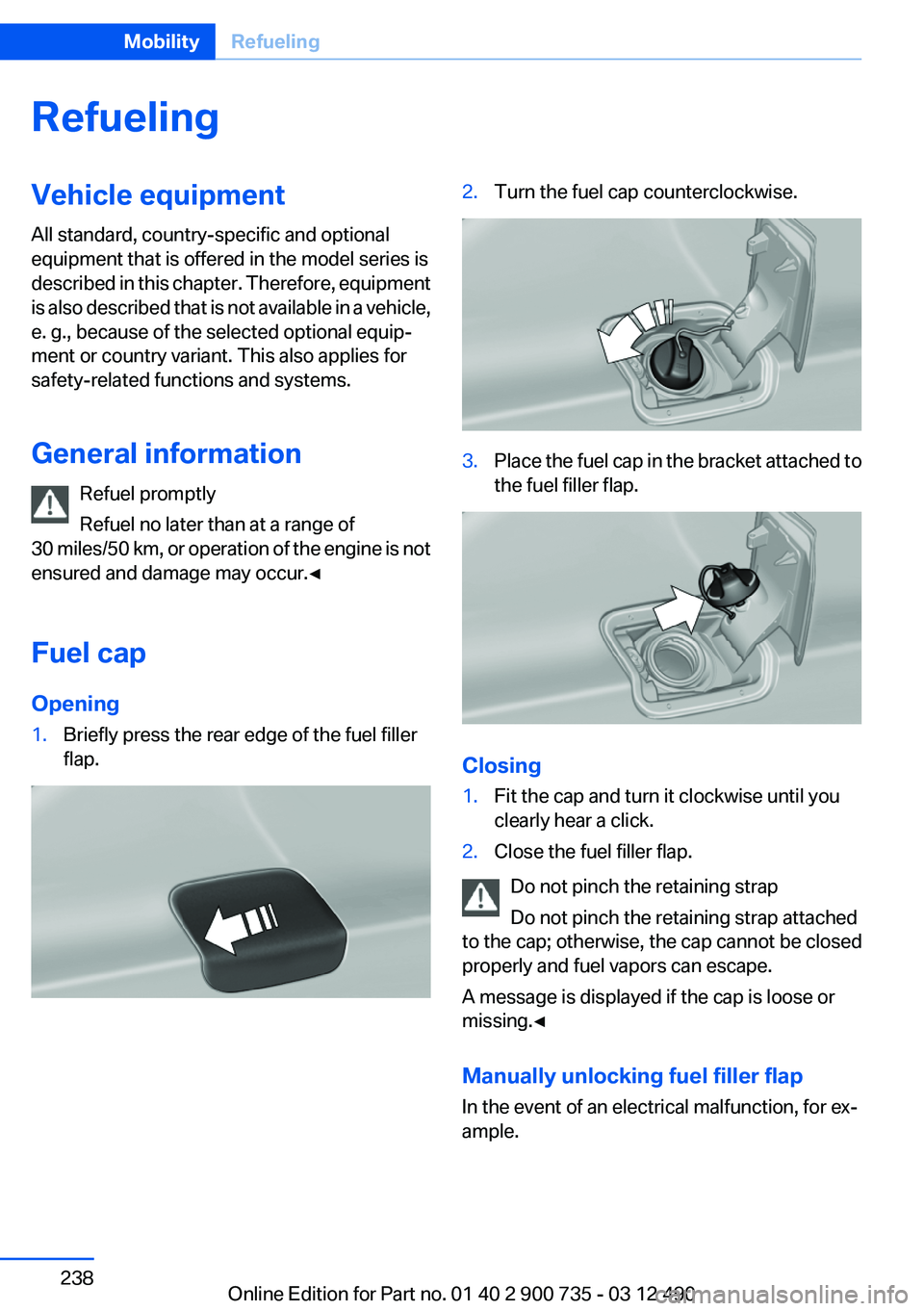

Opening1.Briefly press the rear edge of the fuel filler

flap.2.Turn the fuel cap counterclockwise.3.Place the fuel cap in the bracket attached to

the fuel filler flap.

Closing

1.Fit the cap and turn it clockwise until you

clearly hear a click.2.Close the fuel filler flap.

Do not pinch the retaining strap

Do not pinch the retaining strap attached

to the cap; otherwise, the cap cannot be closed

properly and fuel vapors can escape.

A message is displayed if the cap is loose or

missing.◀

Manually unlocking fuel filler flap

In the event of an electrical malfunction, for ex‐

ample.

Seite 238MobilityRefueling238

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 240 of 297

FuelVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehicle,

e. g., because of the selected optional equip‐

ment or country variant. This also applies for

safety-related functions and systems.

Fuel quality

Fuels that are marked on the gas pump as con‐

taining metal must not be used.

Refuel only with unleaded gasoline with‐

out metallic additives.

Do not refuel with any leaded gasoline or gaso‐

line with metallic additives, e. g. manganese or

iron, or permanent damage to the catalytic con‐

verter and other components.◀

Do not refuel with ethanol

Do not refuel with E85, i.e., fuel with an

ethanol content of 85 %, or with Flex Fuel, as this

would damage the engine and fuel supply sys‐

tem.◀

Required fuel

Super premium gasoline/AKI 93

This gasoline is highly recommended.

Gasoline with lower AKI

However, you may also use gasoline with less

AKI.

The minimum AKI Rating is 91.

If you use gasoline with this minimum AKI Rat‐

ing, the engine may produce knocking sounds

when starting at high outside temperatures.

This has no effect on the engine life.Minimum fuel grade

Do not use any gasoline below the mini‐

mum fuel grade as this may impair engine per‐

formance.◀

Use high-quality brands

Field experience has indicated significant differ‐

ences in fuel quality: volatility, composition, ad‐

ditives, etc., among gasolines offered for sale in

the United States and Canada.

Fuels containing up to and including 10 % etha‐

nol or other oxygenates with up to 2.8 % oxygen

by weight, that is, 15 % MTBE or 3 % methanol

plus an equivalent amount of co-solvent, will not

void the applicable warranties with respect to

defects in materials or workmanship.

Minimum fuel grade

The use of poor-quality fuels may result in

driveability, starting and stalling problems es‐

pecially under certain environmental conditions

such as high ambient temperature and high al‐

titude.

Should you encounter driveability problems

which you suspect could be related to the fuel

you are using, we recommend that you respond

by switching to a recognized high-quality brand

such as gasoline that is advertised as Top Tier

Detergent Gasoline.

Failure to comply with these recommendations

may result in unscheduled maintenance.◀Seite 240MobilityFuel240

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 248 of 297

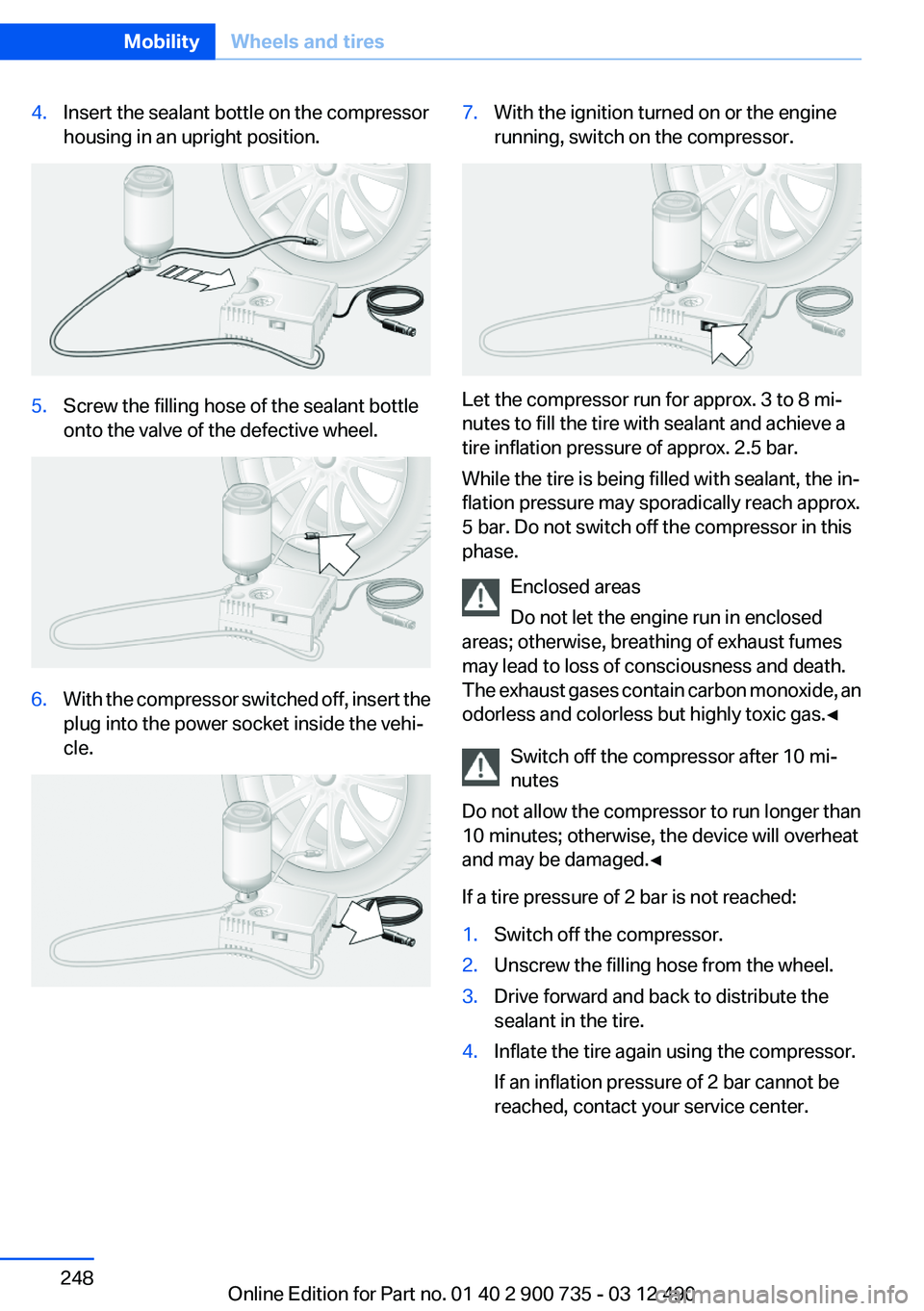

4.Insert the sealant bottle on the compressor

housing in an upright position.5.Screw the filling hose of the sealant bottle

onto the valve of the defective wheel.6.With the compressor switched off, insert the

plug into the power socket inside the vehi‐

cle.7.With the ignition turned on or the engine

running, switch on the compressor.

Let the compressor run for approx. 3 to 8 mi‐

nutes to fill the tire with sealant and achieve a

tire inflation pressure of approx. 2.5 bar.

While the tire is being filled with sealant, the in‐

flation pressure may sporadically reach approx.

5 bar. Do not switch off the compressor in this

phase.

Enclosed areas

Do not let the engine run in enclosed

areas; otherwise, breathing of exhaust fumes

may lead to loss of consciousness and death.

The exhaust gases contain carbon monoxide, an

odorless and colorless but highly toxic gas.◀

Switch off the compressor after 10 mi‐

nutes

Do not allow the compressor to run longer than

10 minutes; otherwise, the device will overheat

and may be damaged.◀

If a tire pressure of 2 bar is not reached:

1.Switch off the compressor.2.Unscrew the filling hose from the wheel.3.Drive forward and back to distribute the

sealant in the tire.4.Inflate the tire again using the compressor.

If an inflation pressure of 2 bar cannot be

reached, contact your service center.Seite 248MobilityWheels and tires248

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 249 of 297

Stowing the Mobility System1.Unscrew the filling hose of the sealant bottle

from the wheel.2.Unscrew the compressor connection hose

from the sealant bottle.3.Connect the sealant bottle filling hose that

was previously connected to the valve to the

vacant connector on the sealant bottle.

This prevents left-over sealant from escap‐

ing from the bottle.4.Wrap the empty sealant bottle in suitable

material to avoid dirtying the cargo area.5.Stow the Mobility System back in the vehi‐

cle.

Distributing the sealant

Immediately drive approx. to ensure that the

sealant is evenly distributed in the tire.

Do not exceed a speed of .

Do not drop below if possible.

Correcting the tire inflation pressure

1.Stop at a suitable location.2.Screw the connection hose of the compres‐

sor directly onto the tire valve.3.Insert the connector into the power socket

in the vehicle interior.4.Correct the tire inflation pressure to 2.5 bar.▷Increase pressure: with the ignition

turned on or the engine running, switch

on the compressor.▷To reduce the pressure: press the but‐

ton on the compressor.

Continuing the trip

Do not exceed the maximum permissible speed

of 50 mph/80 km/h.

Reinitialize the Flat Tire Monitor, refer to

page 101.

Reinitialize the Tire Pressure Monitor, refer to

page 99.

Replace the defective tire and the sealant bottle

of the Mobility System as soon as possible.

Snow chains

Fine-link snow chains

Only certain types of fine-link snow chains have

been tested by the manufacturer of your vehicle,

classified as road-safe and recommended.

Consult your service center for more informa‐

tion.

Use

Use only in pairs on the rear wheels, equipped

with the tires of the following size:

255/40 R 19

Follow the chain manufacturer's instructions.

Make sure that the snow chains are always suf‐

ficiently tight. Retighten as needed according to

the chain manufacturer's instructions.

Do not initialize the Flat Tire Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

Do not initialize the Tire Pressure Monitor after

mounting snow chains, as doing so may result

in incorrect readings.

When driving with snow chains, if necessary

briefly activate M Dynamic Mode.

Maximum speed with snow chains

Do not exceed a speed of 30 mph/50 km/h when

using snow chains.Seite 249Wheels and tiresMobility249

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 250 of 297

Engine compartmentVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipmentis also described that is not available in a vehicle,

e. g., because of the selected optional equip‐

ment or country variant. This also applies for

safety-related functions and systems.

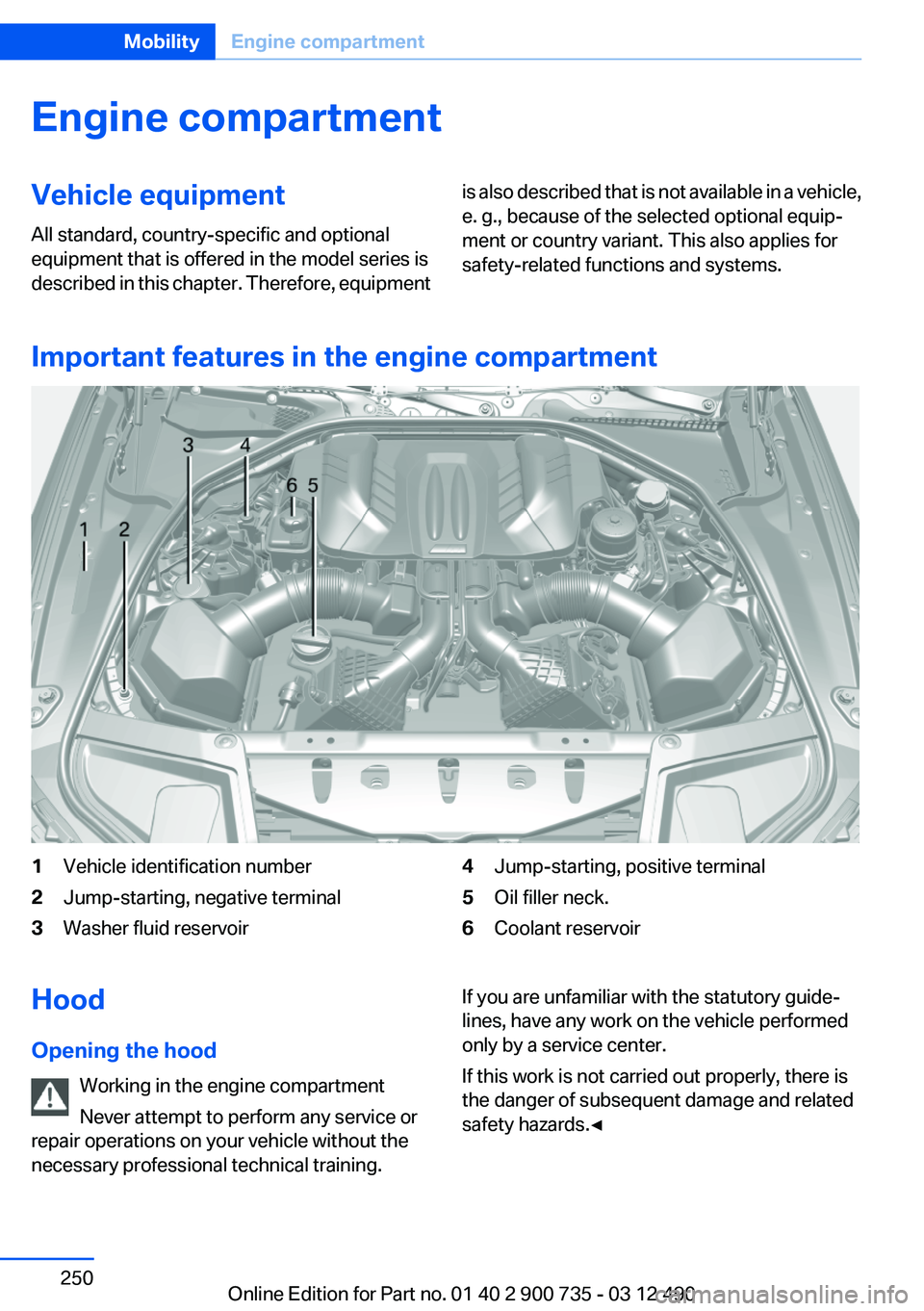

Important features in the engine compartment

1Vehicle identification number2Jump-starting, negative terminal3Washer fluid reservoir4Jump-starting, positive terminal5Oil filler neck.6Coolant reservoirHood

Opening the hood Working in the engine compartment

Never attempt to perform any service or

repair operations on your vehicle without the

necessary professional technical training.If you are unfamiliar with the statutory guide‐

lines, have any work on the vehicle performed

only by a service center.

If this work is not carried out properly, there is

the danger of subsequent damage and related

safety hazards.◀Seite 250MobilityEngine compartment250

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 251 of 297

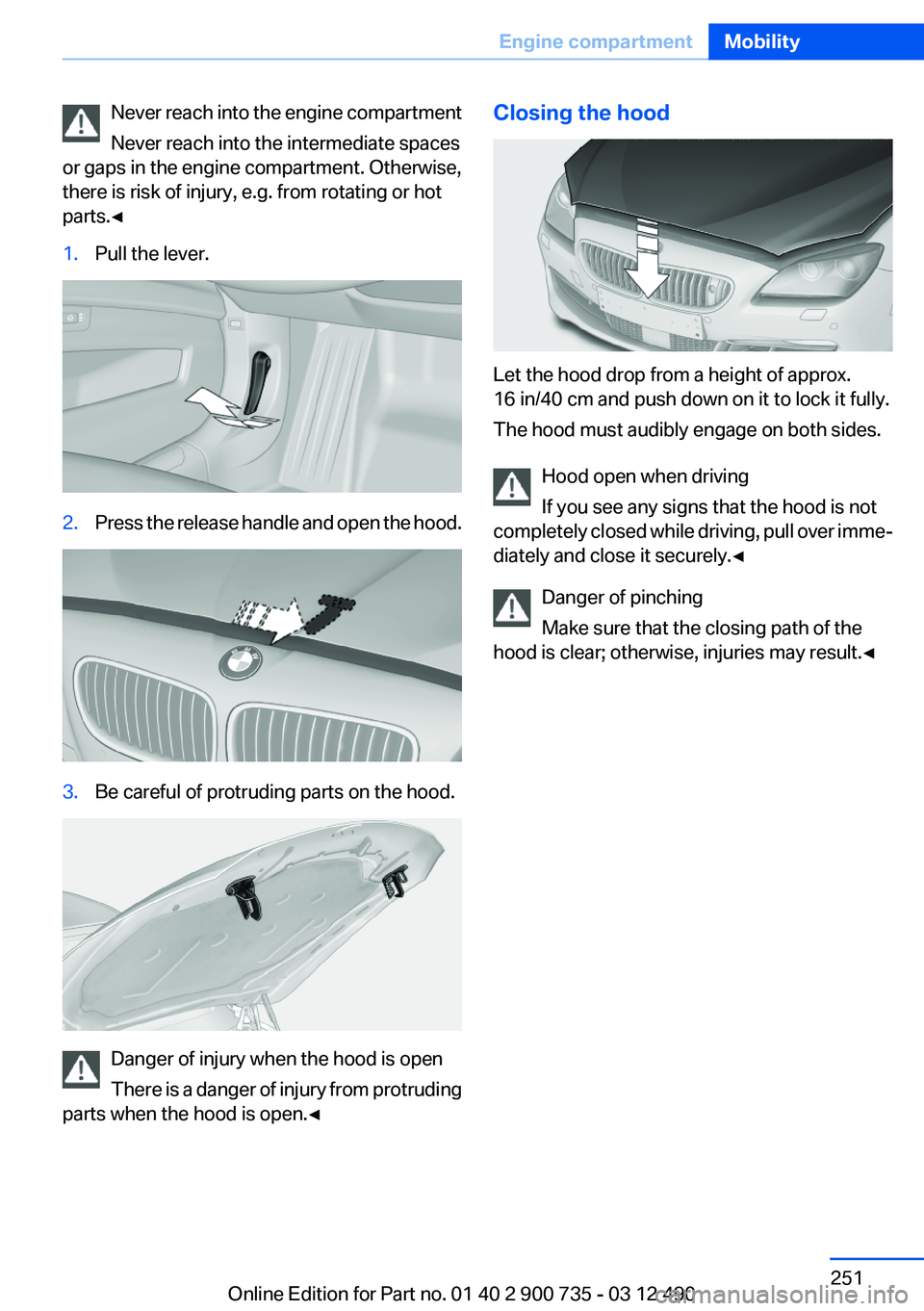

Never reach into the engine compartment

Never reach into the intermediate spaces

or gaps in the engine compartment. Otherwise,

there is risk of injury, e.g. from rotating or hot

parts.◀1.Pull the lever.2.Press the release handle and open the hood.3.Be careful of protruding parts on the hood.

Danger of injury when the hood is open

There is a danger of injury from protruding

parts when the hood is open.◀

Closing the hood

Let the hood drop from a height of approx.

16 in/40 cm and push down on it to lock it fully.

The hood must audibly engage on both sides.

Hood open when driving

If you see any signs that the hood is not

completely closed while driving, pull over imme‐

diately and close it securely.◀

Danger of pinching

Make sure that the closing path of the

hood is clear; otherwise, injuries may result.◀

Seite 251Engine compartmentMobility251

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 252 of 297

Engine oilVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehicle,

e. g., because of the selected optional equip‐

ment or country variant. This also applies for

safety-related functions and systems.

General information

The engine oil consumption is dependent on the

driving style and driving conditions.

Therefore, regularly check the engine oil level

after refueling.

Checking the oil level

The concept

The oil level is monitored electronically during

driving and shown on the Control Display.

If the oil level reaches the minimum level, a

check control message is displayed.

Displaying the oil level1."Vehicle Info"2."Vehicle status"3. "Engine oil level"

Possible messages

▷"Engine oil level OK"▷"Engine oil at minimum. Add 1 quart of

engine oil!"

When the display appears in the instrument

cluster, add 1 US quart/liter of oil within the

next 125 miles/200 km.▷"Engine oil level below minimum. Add 1

quart!"Immediately add 1 US quart/liter of oil.

Detailed measurement

Requirements:

▷Vehicle is on a level road and the engine is

running at operating temperature.▷Double-clutch transmission: Selector lever

in transmission position N and accelerator

not depressed.

In order to perform a detailed measurement of

the engine oil level:

1."Vehicle Info"2."Vehicle status"3. "Measure engine oil level"4."Start measurement"

The oil level is checked and displayed via a scale.

During the detailed measurement, the idle

speed is increased somewhat.

Duration: approx. 1 minute.

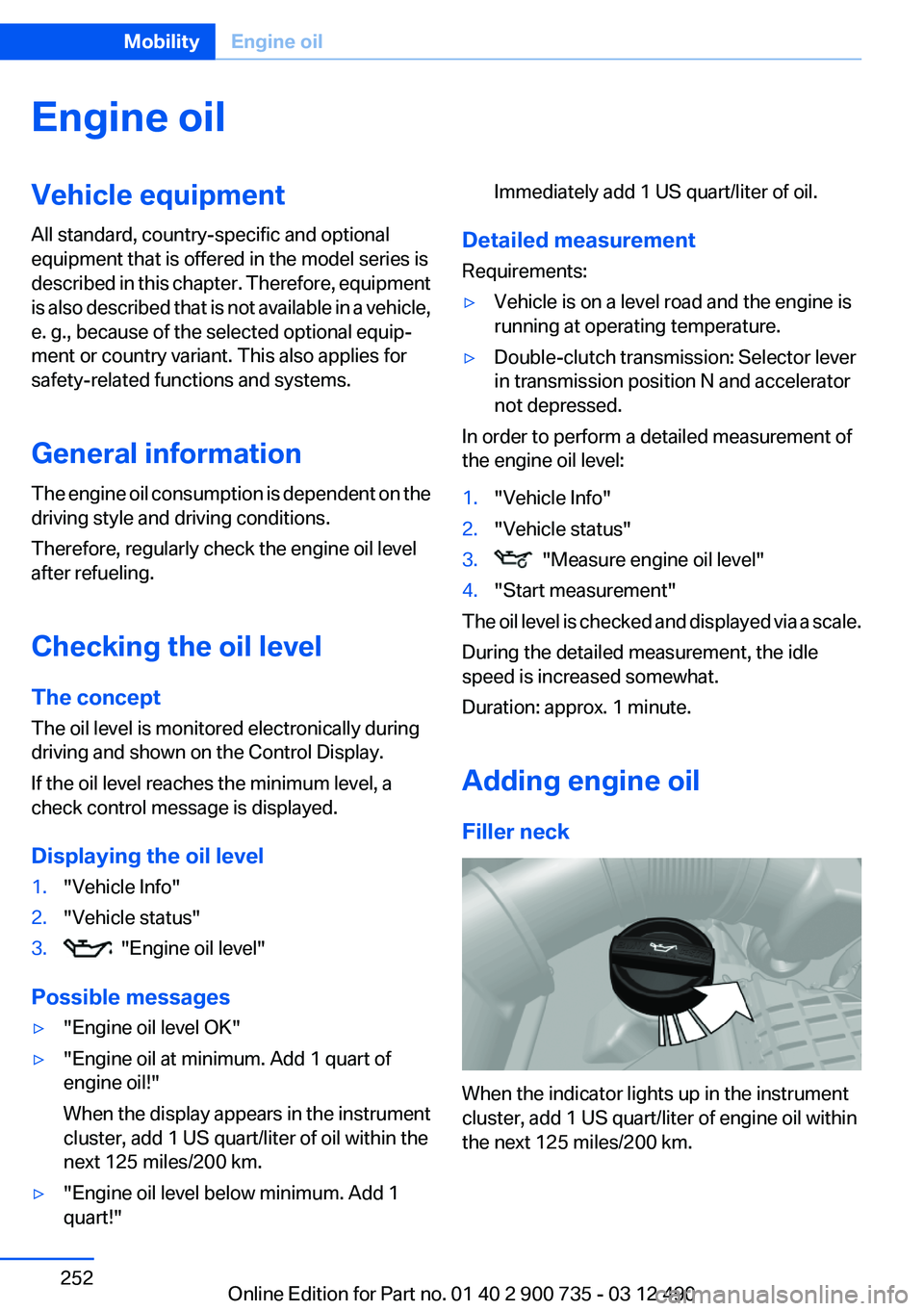

Adding engine oil

Filler neck

When the indicator lights up in the instrument

cluster, add 1 US quart/liter of engine oil within

the next 125 miles/200 km.

Seite 252MobilityEngine oil252

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 253 of 297

Protect children

Keep oil, grease, etc., out of reach of chil‐

dren and heed the warnings on the containers

to prevent health risks.◀

Oil types for refilling

Notes No oil additives

Oil additives may lead to engine damage. ◀

Viscosity grades for engine oils

When selecting an engine oil, ensure that

the engine oil belongs to the viscosity grade

SAE 0W-30 or SAE 0W-40 or malfunctions or

engine damage may occur.

Alternatively, also engine oils with viscosity

grades SAE 5W-30 or SAE 5W-40 may be

used.◀

The engine oil quality is critical for the life of the

engine.

Some types of oils in some cases are not avail‐

able in all countries.

Approved oil typesSpecificationACEA A3/B4API SK/CF or superior grade specification

Additional information about the approved

types of oils can be requested from the service

center.

Alternative oil types

If the approved engine oils are not available, up

to 1 US quart/liter of an oil with the following

specification can be added:

SpecificationACEA A3/B3API SK or superior grade specification

Low ambient temperatures

From the factory, types of oil are used for the

vehicle that can be employed in practically all

ambient temperatures.

However, if the vehicle is used for a longer period

at temperatures below -4 ℉/-20 ℃, ask the serv‐

ice center about suitable types of oil.

Oil change

An oil change should be carried out by your

service center only.

Seite 253Engine oilMobility253

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 254 of 297

CoolantVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehicle,

e. g., because of the selected optional equip‐

ment or country variant. This also applies for

safety-related functions and systems.

General information Danger of burns from hot engine

Do not open the cooling system while the

engine is hot; otherwise, escaping coolant may

cause burns.◀

Suitable additives

Only use suitable additives; otherwise, en‐

gine damage may occur. The additives are

harmful to your health.◀

Coolant consists of water and additives.

Not all commercially available additives are suit‐

able for your vehicle. Ask your service center for

suitable additives.Coolant level

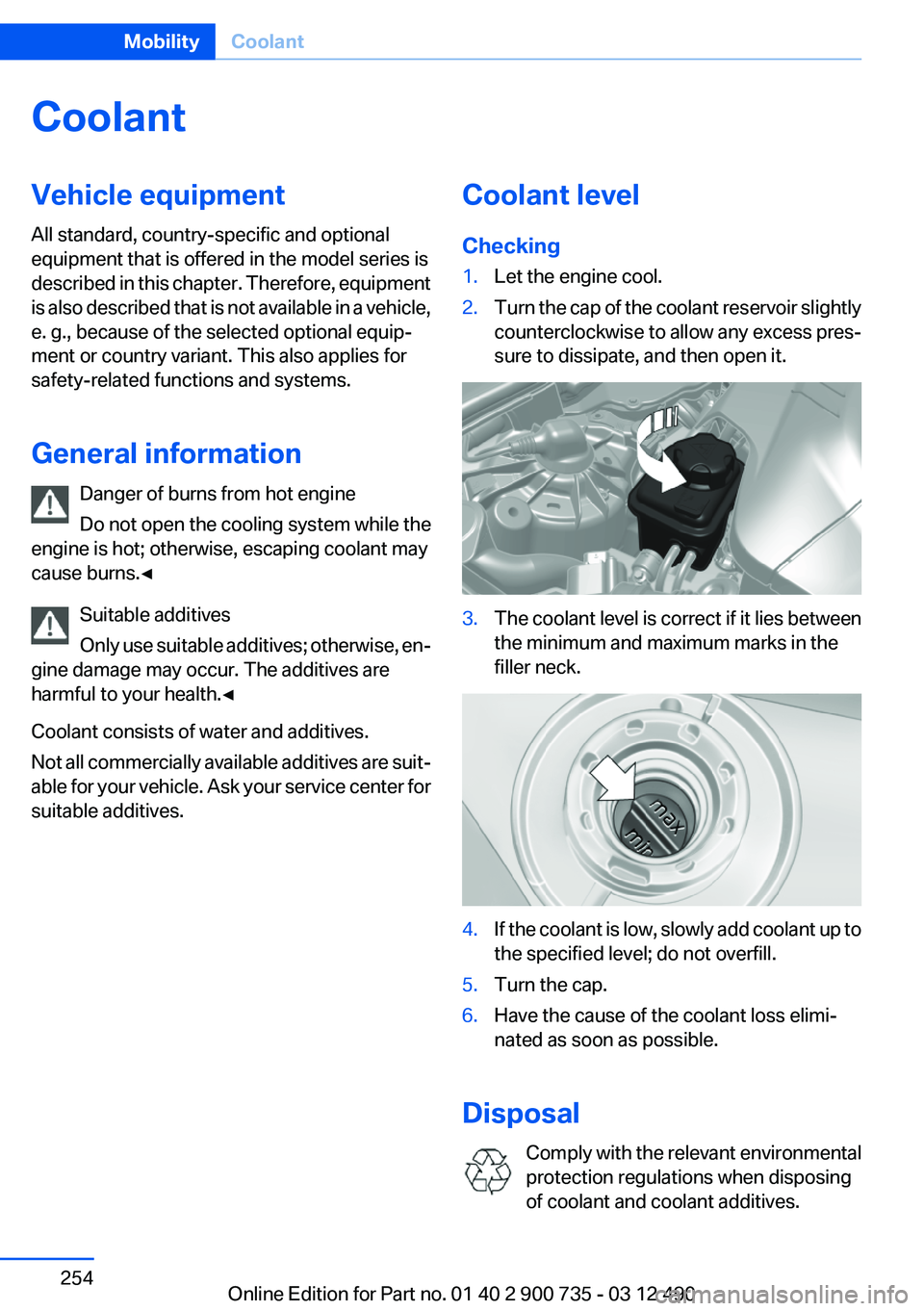

Checking1.Let the engine cool.2.Turn the cap of the coolant reservoir slightly

counterclockwise to allow any excess pres‐

sure to dissipate, and then open it.3.The coolant level is correct if it lies between

the minimum and maximum marks in the

filler neck.4.If the coolant is low, slowly add coolant up to

the specified level; do not overfill.5.Turn the cap.6.Have the cause of the coolant loss elimi‐

nated as soon as possible.

Disposal

Comply with the relevant environmental

protection regulations when disposing

of coolant and coolant additives.

Seite 254MobilityCoolant254

Online Edition for Part no. 01 40 2 900 735 - 03 12 490

Page 255 of 297

MaintenanceVehicle equipment

All standard, country-specific and optional

equipment that is offered in the model series is

described in this chapter. Therefore, equipment

is also described that is not available in a vehicle,

e. g., because of the selected optional equip‐

ment or country variant. This also applies for

safety-related functions and systems.

BMW Maintenance System

The maintenance system directs you to re‐

quired maintenance measures and thereby sup‐

ports you in maintaining road safety and the op‐

erational reliability of the vehicle.

Condition Based Service CBS

Sensors and special algorithms take into ac‐

count the driving conditions of your vehicle.

Based on this, Condition Based Service deter‐

mines the maintenance requirements.

The system makes it possible to adapt the

amount of maintenance you need to your user

profile.

Details on the service requirements, refer to

page 83, can be displayed on the Control Dis‐

play.

Service data in the remote control

Information on the required maintenance is con‐

tinuously stored in the remote control. Your

service center will read out this data and suggest

the right array of service procedures for your ve‐

hicle.

Therefore, hand your service specialist the re‐

mote control that you used most recently.Storage periods

Storage periods during which the vehicle bat‐

tery was disconnected are not taken into ac‐

count.

If this occurs, have a service center update the

time-dependent maintenance procedures,

such as checking brake fluid and, if necessary,

changing the engine oil and the microfilter/acti‐

vated-charcoal filter.

Service and Warranty

Information Booklet for US

models and Warranty and

Service Guide Booklet for

Canadian models

Please consult your Service and Warranty Infor‐

mation Booklet for US models and Warranty and

Service Guide Booklet for Canadian models for

additional information on service requirements.

Maintenance and repair should be performed by

your service center. Make sure to have regular

maintenance procedures recorded in the vehi‐

cle's Service and Warranty Information Booklet

for US models, and in the Warranty and Service

Guide Booklet for Canadian models. These en‐

tries are proof of regular maintenance.Seite 255MaintenanceMobility255

Online Edition for Part no. 01 40 2 900 735 - 03 12 490