lock BMW MOTORRAD K 1200 R 2007 Rider's Manual (in English)

[x] Cancel search | Manufacturer: BMW MOTORRAD, Model Year: 2007, Model line: K 1200 R, Model: BMW MOTORRAD K 1200 R 2007Pages: 168, PDF Size: 2.85 MB

Page 105 of 168

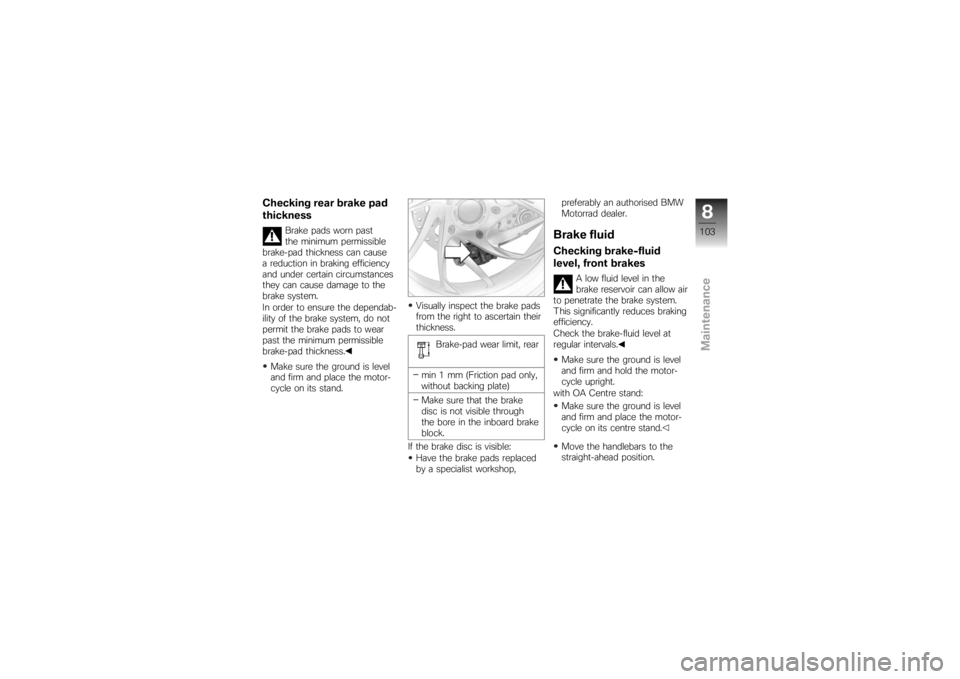

Checking rear brake pad

thickness

Brake pads worn past

the minimum permissible

brake-pad thickness can cause

a reduction in braking efficiency

and under certain circumstances

they can cause damage to the

brake system.

In order to ensure the dependab-

ility of the brake system, do not

permit the brake pads to wear

past the minimum permissible

brake-pad thickness.

Make sure the ground is level

and firm and place the motor-

cycle on its stand. Visually inspect the brake pads

from the right to ascertain their

thickness.

Brake-pad wear limit, rear

min 1 mm (Friction pad only,

without backing plate)

Make sure that the brake

disc is not visible through

the bore in the inboard brake

block.

If the brake disc is visible: Have the brake pads replaced

by a specialist workshop, preferably an authorised BMW

Motorrad dealer.

Brake fluidChecking brake-fluid

level, front brakes

A low fluid level in the

brake reservoir can allow air

to penetrate the brake system.

This significantly reduces braking

efficiency.

Check the brake-fluid level at

regular intervals.

Make sure the ground is level

and firm and hold the motor-

cycle upright.

with OA Centre stand:

Make sure the ground is level

and firm and place the motor-

cycle on its centre stand.

Move the handlebars to the

straight-ahead position.

8103zMaintenance

Page 119 of 168

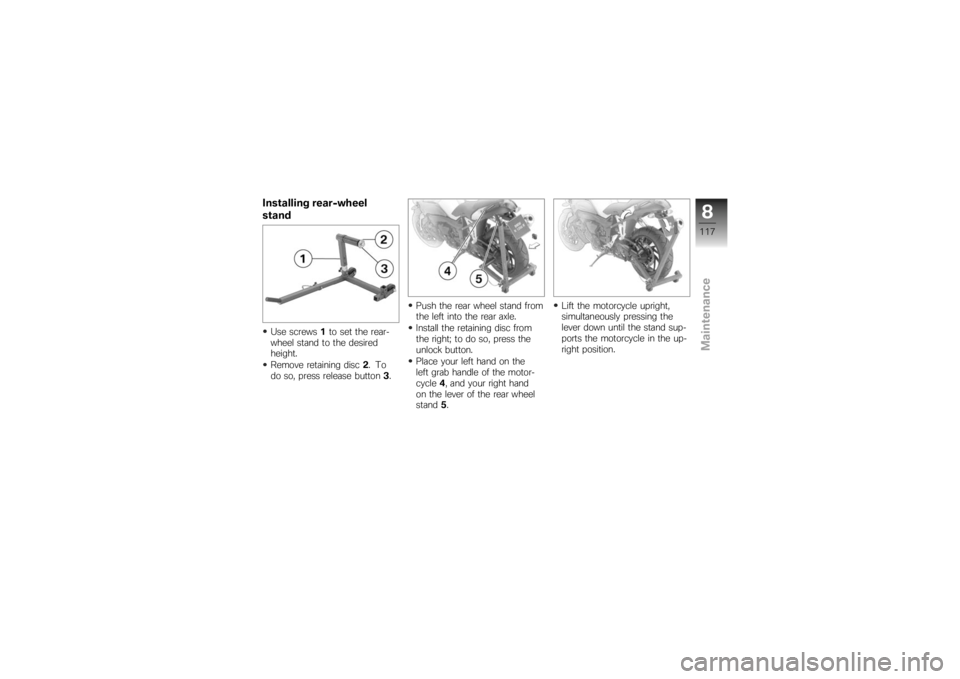

Installing rear-wheel

standUse screws1to set the rear-

wheel stand to the desired

height.

Remove retaining disc 2.To

do so, press release button 3. Push the rear wheel stand from

the left into the rear axle.

Install the retaining disc from

the right; to do so, press the

unlock button.

Place your left hand on the

left grab handle of the motor-

cycle

4, and your right hand

on the lever of the rear wheel

stand 5. Lift the motorcycle upright,

simultaneously pressing the

lever down until the stand sup-

ports the motorcycle in the up-

right position.

8117zMaintenance

Page 121 of 168

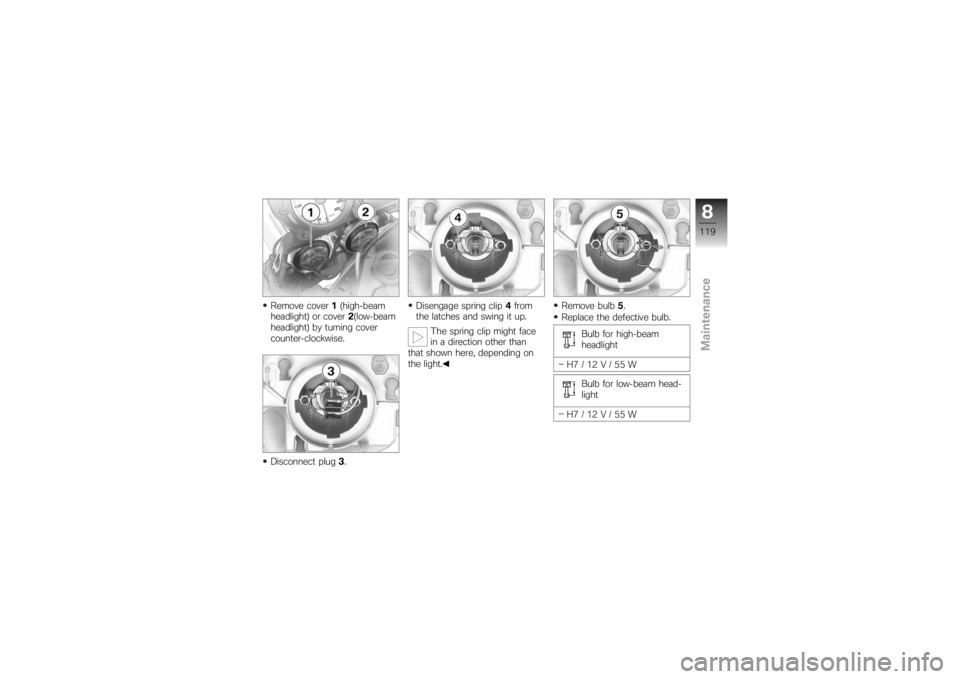

Remove cover1(high-beam

headlight) or cover 2(low-beam

headlight) by turning cover

counter-clockwise.

Disconnect plug 3. Disengage spring clip

4from

the latches and swing it up.

The spring clip might face

in a direction other than

that shown here, depending on

the light. Remove bulb

5.

Replace the defective bulb.

Bulb for high-beam

headlight

H7/12V/55W Bulb for low-beam head-

light

H7/12V/55W

8119zMaintenance

Page 122 of 168

Install bulb5. When installing,

make sure that tab 6is point-

ing up.

Engage spring retainer 4in the

catches. Connect plug

3.

Install cover 1(high-beam

headlight) or cover 2(low-beam

headlight) by turning cover

clockwise.

Replacing parking-light

bulb

If it is not standing firmly,

the motorcycle could topple

in the course of the operations

described below.

Always make sure that the

motorcycle is stable and firmly

supported.

Make sure the ground is level

and firm and place the motor-

cycle on its stand.

Switch off the ignition.

8120zMaintenance

Page 123 of 168

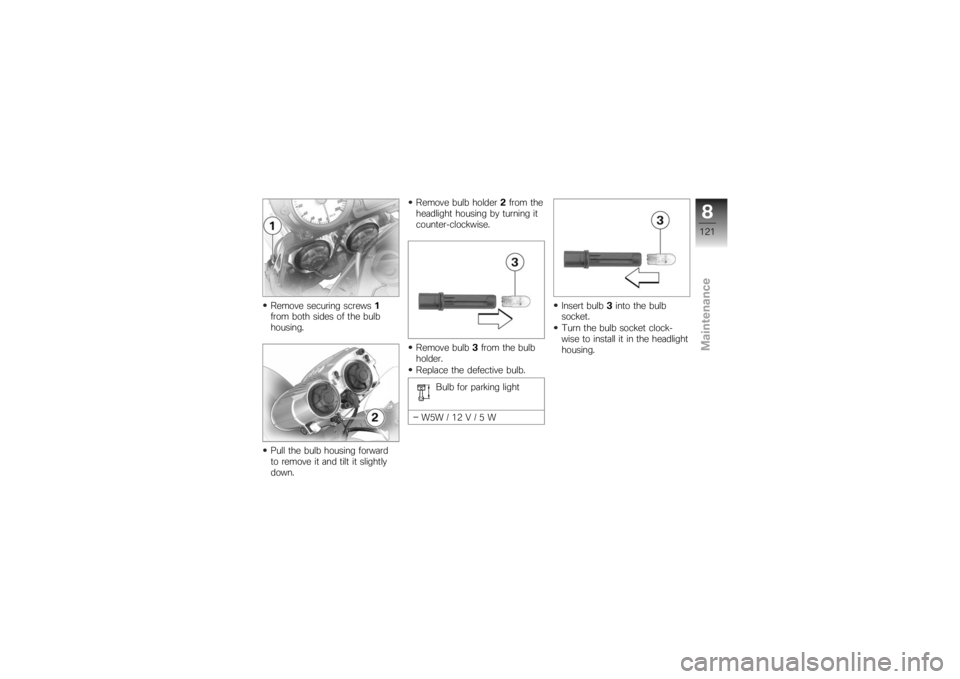

Remove securing screws1

from both sides of the bulb

housing.

Pull the bulb housing forward

to remove it and tilt it slightly

down. Remove bulb holder

2from the

headlight housing by turning it

counter-clockwise.

Remove bulb 3from the bulb

holder.

Replace the defective bulb.

Bulb for parking light

W5W / 12 V / 5 W Insert bulb

3into the bulb

socket.

Turn the bulb socket clock-

wise to install it in the headlight

housing.

8121zMaintenance

Page 125 of 168

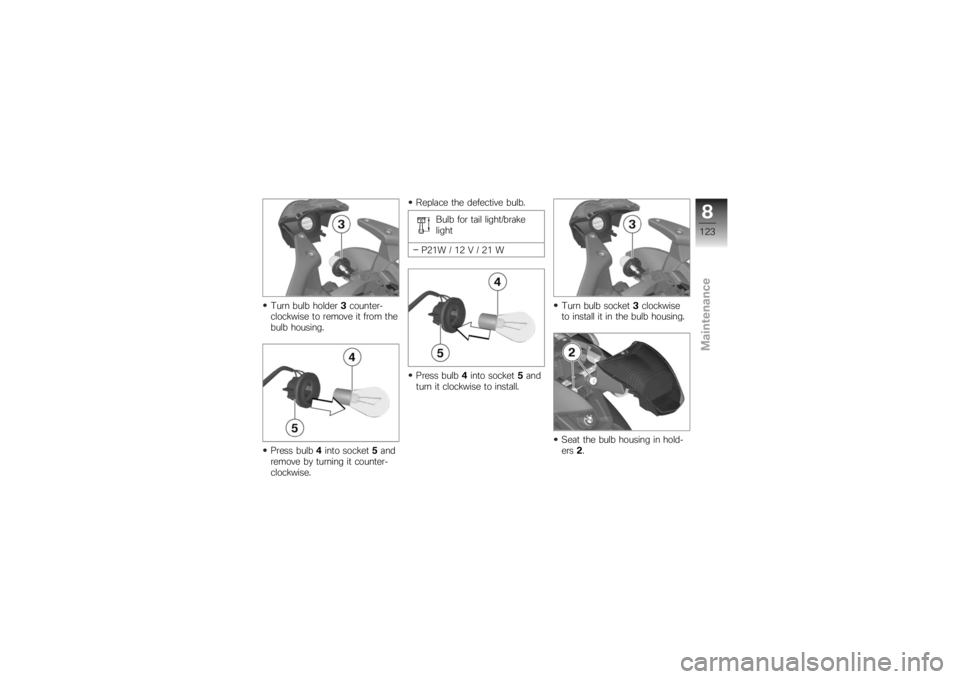

Turn bulb holder3counter-

clockwise to remove it from the

bulb housing.

Press bulb 4into socket 5and

remove by turning it counter-

clockwise. Replace the defective bulb.

Bulb for tail light/brake

light

P21W / 12 V / 21 W

Press bulb 4into socket 5and

turn it clockwise to install. Turn bulb socket

3clockwise

to install it in the bulb housing.

Seat the bulb housing in hold-

ers 2.

8123zMaintenance

Page 126 of 168

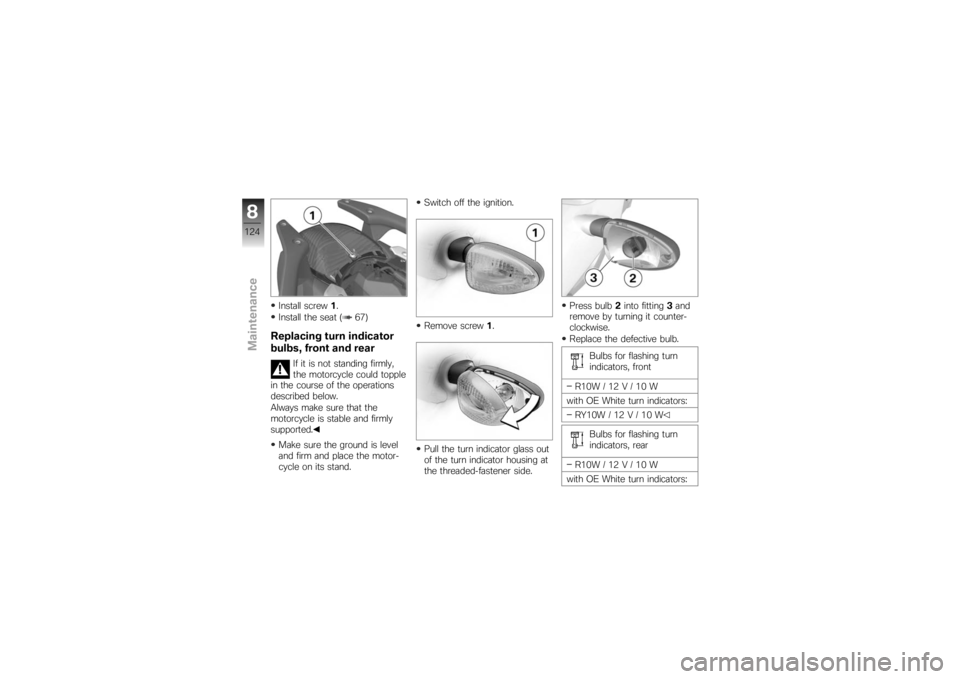

Install screw1.

Install the seat ( 67)Replacing turn indicator

bulbs, front and rear

If it is not standing firmly,

the motorcycle could topple

in the course of the operations

described below.

Always make sure that the

motorcycle is stable and firmly

supported.

Make sure the ground is level

and firm and place the motor-

cycle on its stand. Switch off the ignition.

Remove screw

1.

Pull the turn indicator glass out

of the turn indicator housing at

the threaded-fastener side. Press bulb

2into fitting 3and

remove by turning it counter-

clockwise.

Replace the defective bulb.

Bulbs for flashing turn

indicators, front

R10W / 12 V / 10 W

with OE White turn indicators: RY10W / 12 V / 10 W

Bulbs for flashing turn

indicators, rear

R10W / 12 V / 10 W

with OE White turn indicators:

8124zMaintenance

Page 127 of 168

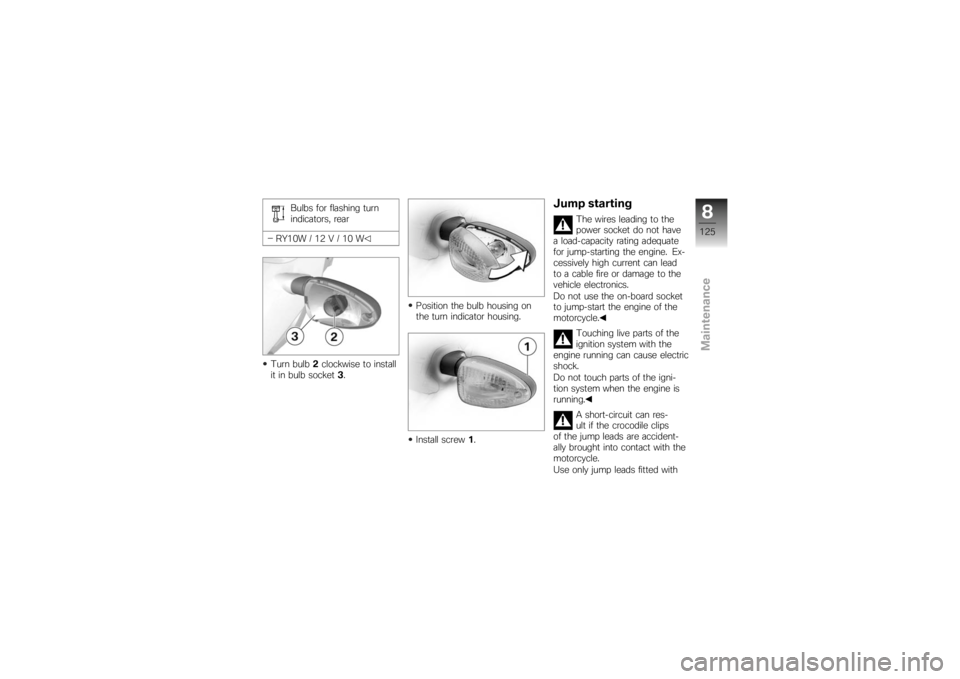

Bulbs for flashing turn

indicators, rear

RY10W / 12 V / 10 W

Turn bulb 2clockwise to install

it in bulb socket 3. Position the bulb housing on

the turn indicator housing.

Install screw

1.

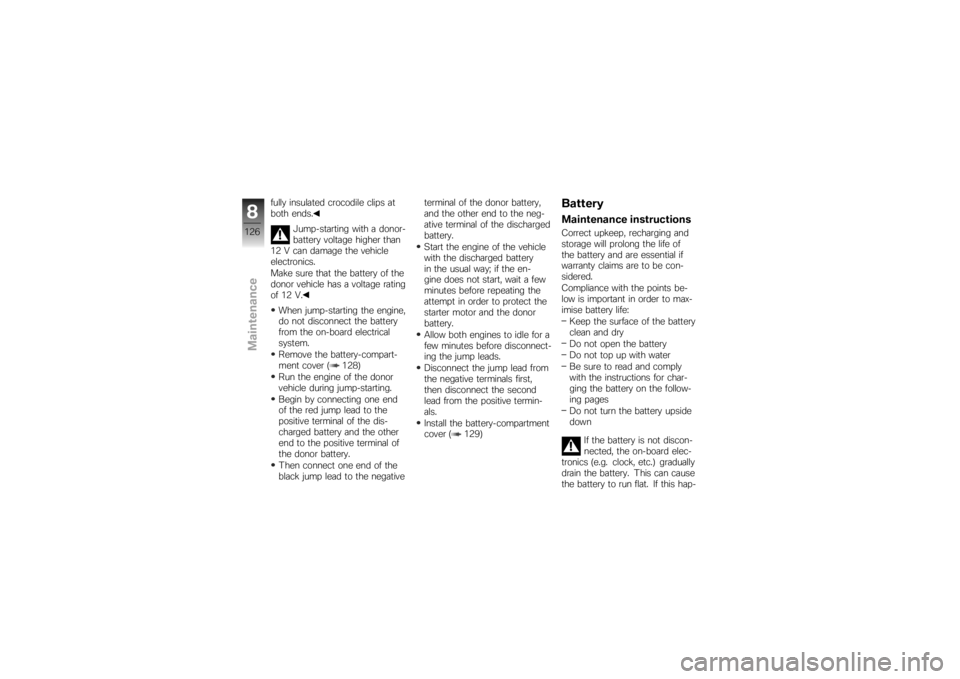

Jump starting

The wires leading to the

power socket do not have

a load-capacity rating adequate

for jump-starting the engine. Ex-

cessively high current can lead

to a cable fire or damage to the

vehicle electronics.

Do not use the on-board socket

to jump-start the engine of the

motorcycle.

Touching live parts of the

ignition system with the

engine running can cause electric

shock.

Do not touch parts of the igni-

tion system when the engine is

running.

A short-circuit can res-

ult if the crocodile clips

of the jump leads are accident-

ally brought into contact with the

motorcycle.

Use only jump leads fitted with

8125zMaintenance

Page 128 of 168

fully insulated crocodile clips at

both ends.Jump-starting with a donor-

battery voltage higher than

12 V can damage the vehicle

electronics.

Make sure that the battery of the

donor vehicle has a voltage rating

of 12 V.

When jump-starting the engine,

do not disconnect the battery

from the on-board electrical

system.

Remove the battery-compart-

ment cover ( 128)

Run the engine of the donor

vehicle during jump-starting.

Begin by connecting one end

of the red jump lead to the

positive terminal of the dis-

charged battery and the other

end to the positive terminal of

the donor battery.

Then connect one end of the

black jump lead to the negative terminal of the donor battery,

and the other end to the neg-

ative terminal of the discharged

battery.

Start the engine of the vehicle

with the discharged battery

in the usual way; if the en-

gine does not start, wait a few

minutes before repeating the

attempt in order to protect the

starter motor and the donor

battery.

Allow both engines to idle for a

few minutes before disconnect-

ing the jump leads.

Disconnect the jump lead from

the negative terminals first,

then disconnect the second

lead from the positive termin-

als.

Install the battery-compartment

cover ( 129)

BatteryMaintenance instructionsCorrect upkeep, recharging and

storage will prolong the life of

the battery and are essential if

warranty claims are to be con-

sidered.

Compliance with the points be-

low is important in order to max-

imise battery life:

Keep the surface of the battery

clean and dry

Do not open the battery

Do not top up with water

Be sure to read and comply

with the instructions for char-

ging the battery on the follow-

ing pages

Do not turn the battery upside

down

If the battery is not discon-

nected, the on-board elec-

tronics (e.g. clock, etc.) gradually

drain the battery. This can cause

the battery to run flat. If this hap-

8126zMaintenance

Page 132 of 168

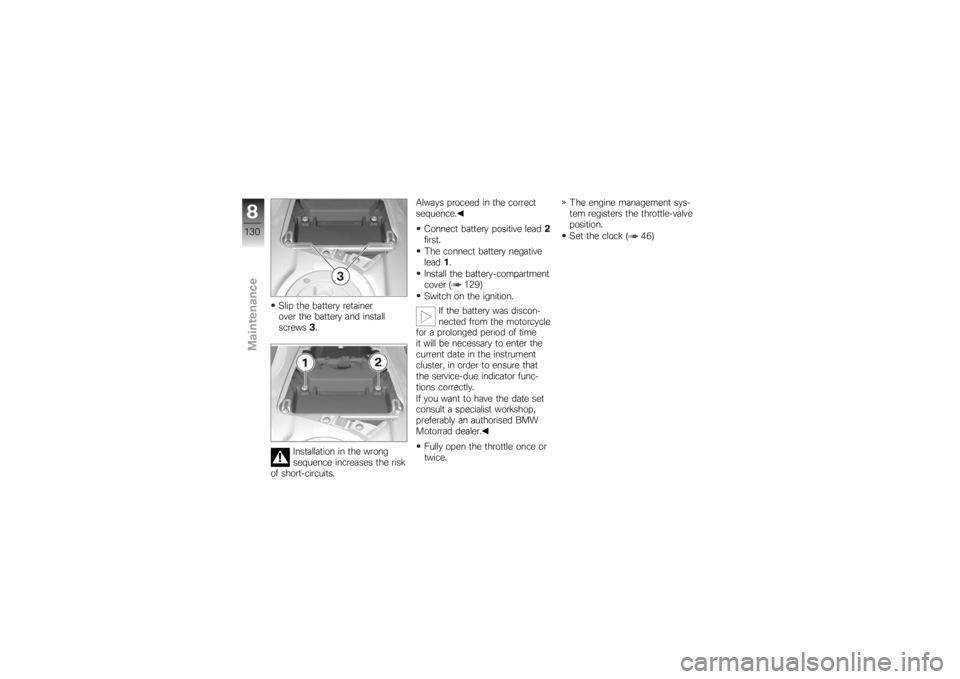

Slip the battery retainer

over the battery and install

screws3.

Installation in the wrong

sequence increases the risk

of short-circuits. Always proceed in the correct

sequence.

Connect battery positive lead 2

first.

The connect battery negative

lead 1.

Install the battery-compartment

cover ( 129)

Switch on the ignition.

If the battery was discon-

nected from the motorcycle

for a prolonged period of time

it will be necessary to enter the

current date in the instrument

cluster, in order to ensure that

the service-due indicator func-

tions correctly.

If you want to have the date set

consult a specialist workshop,

preferably an authorised BMW

Motorrad dealer.

Fully open the throttle once or

twice. The engine management sys-

tem registers the throttle-valve

position.

Set the clock ( 46)

8130zMaintenance