torque BMW MOTORRAD K 1200 R 2007 Rider's Manual (in English)

[x] Cancel search | Manufacturer: BMW MOTORRAD, Model Year: 2007, Model line: K 1200 R, Model: BMW MOTORRAD K 1200 R 2007Pages: 168, PDF Size: 2.85 MB

Page 8 of 168

OverviewChapter 2 of this Rider's Manu-

al will provide you with an initial

overview of your motorcycle. All

maintenance and repair work on

the motorcycle is documented in

Chapter 11. This record of the

maintenance work you have had

performed on your motorcycle is

a precondition for generous treat-

ment of goodwill claims.

When the time comes to sell

your BMW, please remember

to hand over this Rider's Manu-

al; it is an important part of the

motorcycle.Abbreviations and

symbols

Indicates warnings that you

must comply with for reas-

ons of your safety and the safety

of others, and to protect your

motorcycle against damage. Specific instructions on

how to operate, control, ad-

just or look after items of equip-

ment on the motorcycle.

Indicates the end of an

item of information.

Instruction.

Result of an activity.

Reference to a page with

more detailed informa-

tion.

Indicates the end of a

passage relating to spe-

cific accessories or items

of equipment.

Tightening torque.

Item of technical data. OE Optional extra

The motorcycles are as-

sembled complete with

all the BMW optional ex-

tras originally ordered.

OA Optional accessory You can obtain option-

al accessories through

your authorised BMW

Motorrad dealer; optional

accessories have to be

retrofitted to the motor-

cycle.

EWS Electronic immobiliser

(Elektronische Wegfahr-

sicherung).

DWA Anti-theft alarm (Diebs-

tahlwarnanlage)

ABS Anti-lock brake system

ASC Automatic Stability Con- trol.

16zGeneral instructions

Page 37 of 168

ASC interventionGeneral warning light quick-

flashes yellow.

ASC symbol appears on

the display.

The ASC has detected a degree

of instability at the rear wheel

and has intervened to reduce

torque. The warning light flashes

for longer than ASC intervention

lasts. This affords the rider visual

feedback on control intervention

even after the critical situation

has been dealt with.

Self-diagnosis not completed ASC symbol flashes.

Self-diagnosis did not complete,

so the ASC function is not avail-

able. The engine must be run-

ning and the motorcycle must

reach a speed of at least 5 km/h

in order for ASC self-diagnosis to

complete. Pull away slowly. Bear in mind

that the ASC function is not

available until self-diagnosis has

completed.

ASC switched off ASC symbol appears on

the display.

The rider has switched off the

ASC system.

with OE Automatic Stability

Control (ASC): Activate the ASC function

( 58)

ASC fault General warning light shows

yellow.

ASC symbol appears on

the display.

The ASC control unit has detec-

ted a fault. The ASC function is

not available. You can continue to ride. Bear

in mind that the ASC function is not available. Bear in mind

the more detailed information

on situations that can lead to

an ASC fault ( 85).

Have the fault rectified as

quickly as possible by a

specialist workshop, preferably

an authorised BMW Motorrad

dealer.

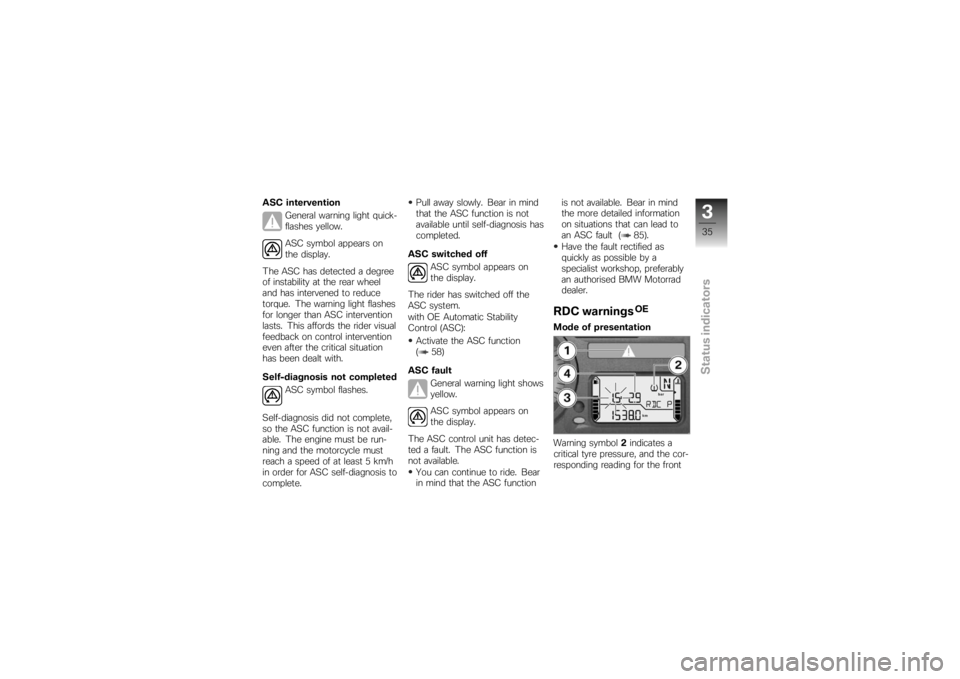

RDC warnings

OE

Mode of presentation

Warning symbol 2indicates a

critical tyre pressure, and the cor-

responding reading for the front

335zStatus indicators

Page 62 of 168

Turn adjusting screw1clock-

wise.

The adjusting screw is in-

dexed and is easier to turn

if you push the handbrake lever

forward.

Span between handlebar grip

and handbrake lever increases.

Turn adjusting screw 1

counter-clockwise.

Span between handlebar grip

and handlebar lever decreases.

MirrorsAdjusting mirrorsTurn the mirror to the correct

position.

Adjusting mirror armPush the protective cap up

over the threaded fastener on

the mirror arm.

Slacken nut 1(left-hand

thread).

Turn the mirror arm to the ap-

propriate position.

Tighten nut 1to the specified

tightening torque, while holding

the mirror arm to ensure that it

does not move out of position.

Mirror to clamping piece

22 Nm

460zOperation

Page 86 of 168

exceptional riding conditions can

lead to a fault message being

issued.

Exceptional riding

conditions:Heating up with the motorcycle

on the centre stand or an auxil-

iary stand, engine idling or with

a gear engaged.

Rear wheel locked by the en-

gine brake for a lengthy period,

for example while descending

off-road.

If a fault message is issued on

account of exceptional riding

conditions as outlined above, you

can reactivate the ABS function

by switching the ignition off and

on again.

What significance

devolves on regular

maintenance?

Invariably, a technical sys-

tem cannot perform beyond

the abilities dictated by its level

of maintenance.

In order to ensure that the BMW

Motorrad ABS is always main-

tained in optimum condition, it

is essential for you to comply

strictly with the specified inspec-

tion intervals.

Reserves for safetyThe potentially shorter braking

distances which BMW Motorrad

Integral ABS permits must not be

used as an excuse for careless

riding. ABS is primarily a means

of ensuring a safety margin in

genuine emergencies.

Take care when cornering. When

you apply the brakes on a corner,

the motorcycle's weight and momentum take over and even

BMW Motorrad Integral ABS is

unable to counteract their effects.

Electronic engine

management with BMW

Motorrad ASC

OE

How does ASC work?The BMW Motorrad ASC com-

pares the speed of rotation of the

front wheel and the rear wheel.

The differential is used to com-

pute slip as a measure of the

reserves of stability available at

the rear wheel. If slip exceeds a

certain limit the electronic engine

management system intervenes,

adapting engine torque accord-

ingly.

684zEngineering details

Page 88 of 168

If the front wheel lifts clear of the

ground under severe accelera-

tion, the ASC reduces engine

torque until the front wheel re-

gains contact with the ground.

Under these circumstances,

BMW Motorrad recommends

rolling the throttle slightly closed

so as to restore stability with the

least possible delay.

When riding on a slippery sur-

face, never snap the throttle

twistgrip fully closed without

pulling the clutch at the same

time. Engine braking torque can

cause the rear wheel to lock, with

a corresponding loss of stability.

The BWM Motorrad ASC is un-

able to control a situation of this

nature.

Tyre pressure

monitoring RDC

OE

FunctionA sensor integrated into each

tyre measures the air temperat-

ure and the air pressure inside

the tyre and transmits this in-

formation to the control unit.

Each sensor has a centrifugal-

force tripswitch that does not

enable transmission of the meas-

ured values until the motorcycle

has accelerated to about 30 km/

h. The display shows

--

for

each tyre until the tyre-pressure

signal is received for the first

time. The sensors continue to

transmit the measured-value sig-

nals for approximately 15 minutes

after the motorcycle comes to a

stop.

The control unit can adminis-

trate four sensors, so two dif-

ferent sets of wheels with RDC

sensors can be alternated on the motorcycle. An error mes-

sage is issued if wheels without

sensors are fitted to a motorcycle

equipped with an RDC control

unit.

Temperature

compensationThe tyre-pressure readings

shown by the multifunction

display are temperature-

compensated; the reference tyre

temperature for these readings

is always 20 °C. The air lines

available to the public in petrol

stations and motorway service

areas almost invariably show

temperature-dependent tyre

pressures, so in most instances

these gauge readings will not

tally with the readings shown by

the multifunction display.

686zEngineering details

Page 100 of 168

General instructionsThe Maintenance chapter de-

scribes straightforward proced-

ures for checking and replacing

certain wear parts.

Special tightening torques are lis-

ted as applicable. The tightening

torques for the threaded fasten-

ers on your motorcycle are listed

in the section entitled "Technical

data".

You will find information on more

extensive maintenance and re-

pair work in the Repair Manual

on DVD/CD-ROM (RepROM) for

your motorcycle, which is avail-

able from your authorised BMW

Motorrad dealer.

Some of the work calls for spe-

cial tools and a thorough know-

ledge of motorcycles. If you

are in doubt consult a specialist

workshop, preferably your author-

ised BMW Motorrad dealer.

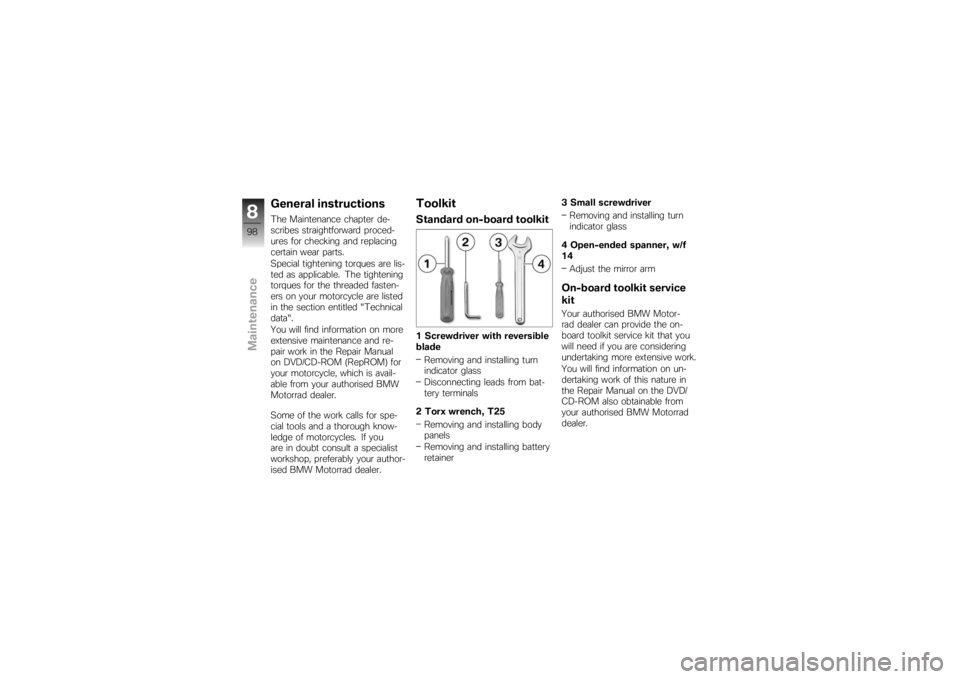

ToolkitStandard on-board toolkit1 Screwdriver with reversible

bladeRemoving and installing turn

indicator glass

Disconnecting leads from bat-

tery terminals

2 Torx wrench, T25 Removing and installing body

panels

Removing and installing battery

retainer 3 Small screwdriver

Removing and installing turn

indicator glass

4 Open-ended spanner, w/f

14 Adjust the mirror arm

On-board toolkit service

kitYour authorised BMW Motor-

rad dealer can provide the on-

board toolkit service kit that you

will need if you are considering

undertaking more extensive work.

You will find information on un-

dertaking work of this nature in

the Repair Manual on the DVD/

CD-ROM also obtainable from

your authorised BMW Motorrad

dealer.

898zMaintenance

Page 112 of 168

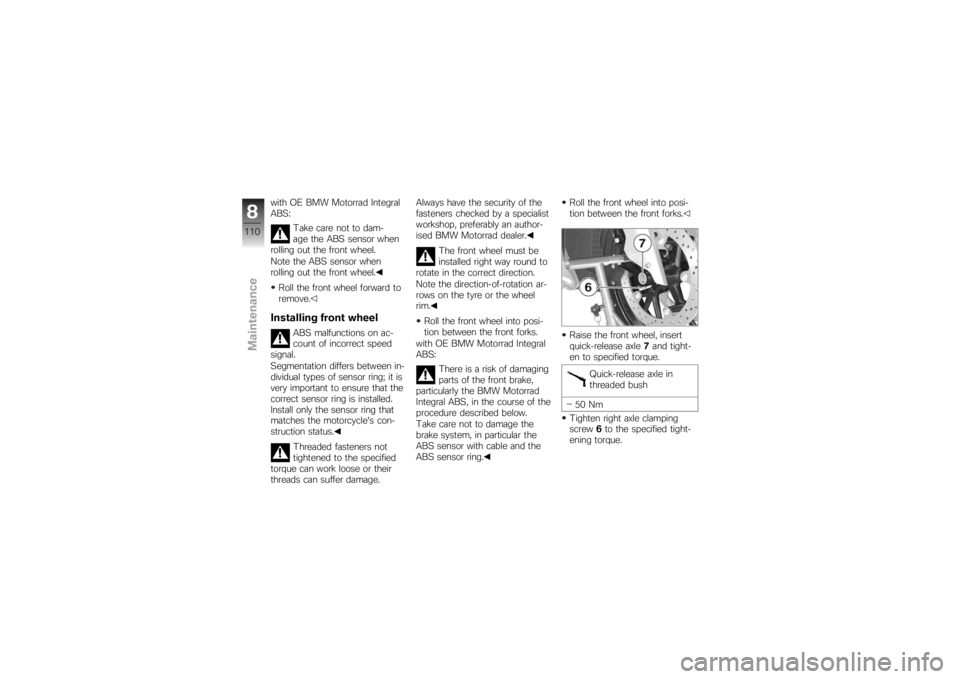

with OE BMW Motorrad Integral

ABS:Take care not to dam-

age the ABS sensor when

rolling out the front wheel.

Note the ABS sensor when

rolling out the front wheel.

Roll the front wheel forward to

remove.Installing front wheel

ABS malfunctions on ac-

count of incorrect speed

signal.

Segmentation differs between in-

dividual types of sensor ring; it is

very important to ensure that the

correct sensor ring is installed.

Install only the sensor ring that

matches the motorcycle's con-

struction status.

Threaded fasteners not

tightened to the specified

torque can work loose or their

threads can suffer damage. Always have the security of the

fasteners checked by a specialist

workshop, preferably an author-

ised BMW Motorrad dealer.

The front wheel must be

installed right way round to

rotate in the correct direction.

Note the direction-of-rotation ar-

rows on the tyre or the wheel

rim.

Roll the front wheel into posi-

tion between the front forks.

with OE BMW Motorrad Integral

ABS:

There is a risk of damaging

parts of the front brake,

particularly the BMW Motorrad

Integral ABS, in the course of the

procedure described below.

Take care not to damage the

brake system, in particular the

ABS sensor with cable and the

ABS sensor ring. Roll the front wheel into posi-

tion between the front forks.

Raise the front wheel, insert

quick-release axle

7and tight-

en to specified torque.

Quick-release axle in

threaded bush

50 Nm

Tighten right axle clamping

screw 6to the specified tight-

ening torque.

8110zMaintenance

Page 115 of 168

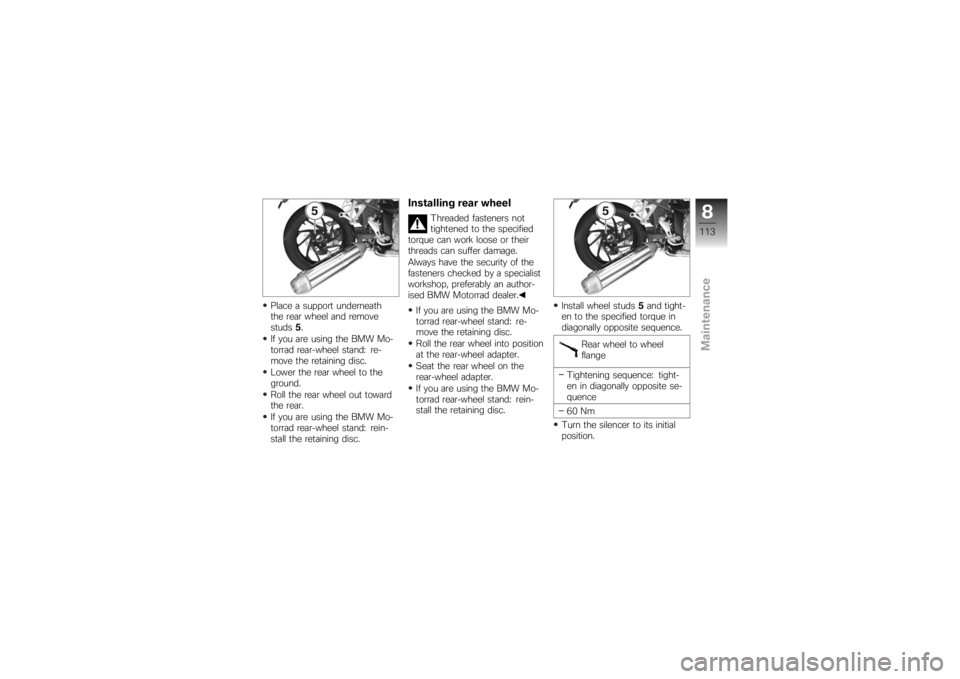

Place a support underneath

the rear wheel and remove

studs5.

If you are using the BMW Mo-

torrad rear-wheel stand: re-

move the retaining disc.

Lower the rear wheel to the

ground.

Roll the rear wheel out toward

the rear.

If you are using the BMW Mo-

torrad rear-wheel stand: rein-

stall the retaining disc.

Installing rear wheel

Threaded fasteners not

tightened to the specified

torque can work loose or their

threads can suffer damage.

Always have the security of the

fasteners checked by a specialist

workshop, preferably an author-

ised BMW Motorrad dealer.

If you are using the BMW Mo-

torrad rear-wheel stand: re-

move the retaining disc.

Roll the rear wheel into position

at the rear-wheel adapter.

Seat the rear wheel on the

rear-wheel adapter.

If you are using the BMW Mo-

torrad rear-wheel stand: rein-

stall the retaining disc. Install wheel studs

5and tight-

en to the specified torque in

diagonally opposite sequence.

Rear wheel to wheel

flange

Tightening sequence: tight-

en in diagonally opposite se-

quence

60 Nm

Turn the silencer to its initial

position.

8113zMaintenance

Page 116 of 168

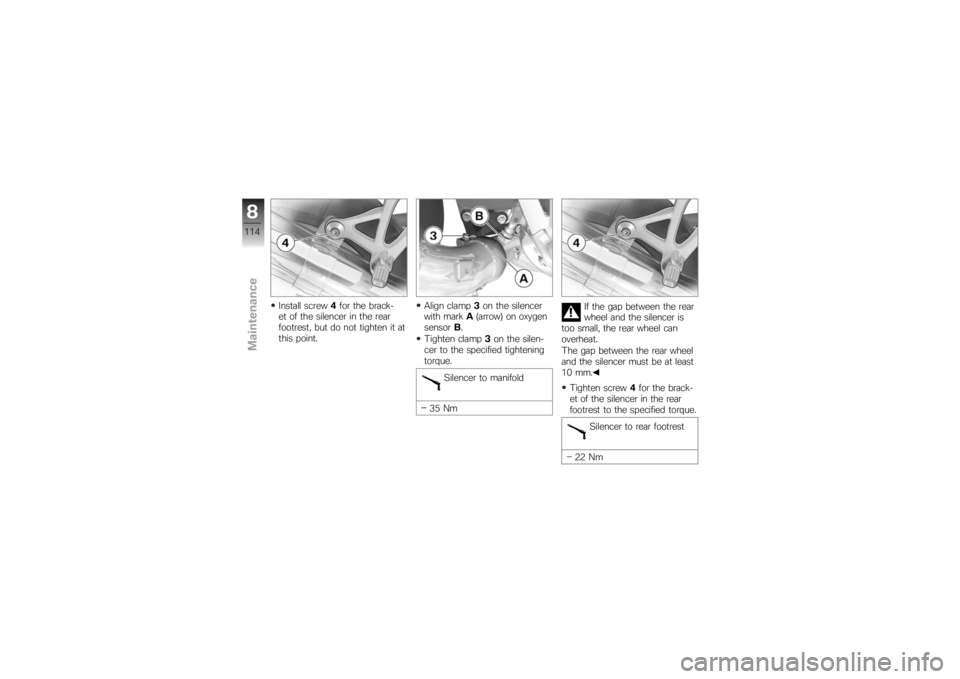

Install screw4for the brack-

et of the silencer in the rear

footrest, but do not tighten it at

this point. Align clamp

3on the silencer

with mark A(arrow) on oxygen

sensor B.

Tighten clamp 3on the silen-

cer to the specified tightening

torque.

Silencer to manifold

35 Nm If the gap between the rear

wheel and the silencer is

too small, the rear wheel can

overheat.

The gap between the rear wheel

and the silencer must be at least

10 mm.

Tighten screw 4for the brack-

et of the silencer in the rear

footrest to the specified torque.

Silencer to rear footrest

22 Nm

8114zMaintenance

Page 141 of 168

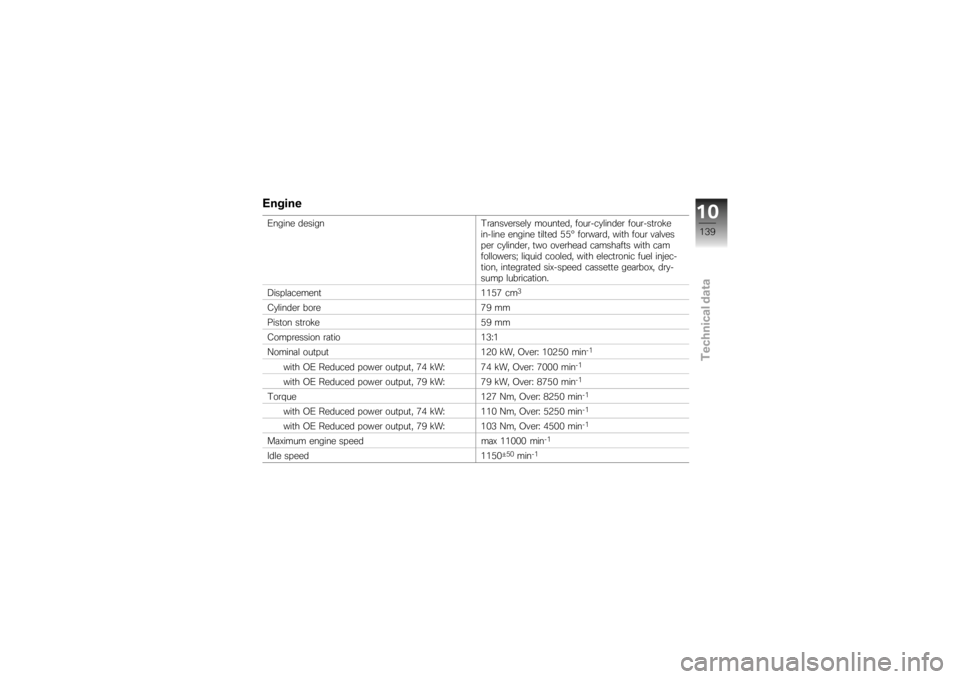

EngineEngine designTransversely mounted, four-cylinder four-stroke

in-line engine tilted 55° forward, with four valves

per cylinder, two overhead camshafts with cam

followers; liquid cooled, with electronic fuel injec-

tion, integrated six-speed cassette gearbox, dry-

sump lubrication.

Displacement 1157 cm

3

Cylinder bore79 mm

Piston stroke 59 mm

Compression ratio 13:1

Nominal output 120 kW, Over: 10250 min

-1

with OE Reduced power output, 74 kW: 74 kW, Over: 7000 min

-1

with OE Reduced power output, 79 kW: 79 kW, Over: 8750 min

-1

Torque127 Nm, Over: 8250 min

-1

with OE Reduced power output, 74 kW: 110 Nm, Over: 5250 min

-1

with OE Reduced power output, 79 kW: 103 Nm, Over: 4500 min

-1

Maximum engine speed max 11000 min

-1

Idle speed1150

±50

min

-1

10139zTechnical data