wheel torque BUICK CENTURY 2003 Owner's Manual

[x] Cancel search | Manufacturer: BUICK, Model Year: 2003, Model line: CENTURY, Model: BUICK CENTURY 2003Pages: 344, PDF Size: 2.57 MB

Page 241 of 344

Brake Wear

Your vehicle has front disc brakes and rear drum

brakes.

Disc brake pads have built-in wear indicators that make

a high-pitched warning sound when the brake pads

are worn and new pads are needed. The sound

may come and go or be heard all the time your vehicle

is moving (except when you are pushing on the

brake pedal ®rmly).

{CAUTION:

The brake wear warning sound means that

soon your brakes won't work well. That could

lead to an accident. When you hear the brake

wear warning sound, have your vehicle

serviced.

Notice:Continuing to drive with worn-out brake

pads could result in costly brake repair.Some driving conditions or climates may cause a brake

squeal when the brakes are ®rst applied or lightly

applied. This does not mean something is wrong with

your brakes.

Properly torqued wheel nuts are necessary to help

prevent brake pulsation. When tires are rotated, inspect

brake pads for wear and evenly tighten wheel nuts in

the proper sequence to GM torque speci®cations.

Your rear drum brakes don't have wear indicators, but if

you ever hear a rear brake rubbing noise, have the

rear brake linings inspected immediately. Also, the rear

brake drums should be removed and inspected each

time the tires are removed for rotation or changing.

When you have the front brake pads replaced have the

rear brakes inspected, too.

Brake linings should always be replaced as complete

axle sets.

See

Brake System Inspection on page 6-15.

Brake Pedal Travel

See your dealer if the brake pedal does not return to

normal height, or if there is a rapid increase in

pedal travel. This could be a sign of brake trouble.

Brake Adjustment

Every time you apply the brakes, with or without the

vehicle moving, your brakes adjust for wear.

5-41

Page 260 of 344

Tire Inspection and Rotation

Tires should be rotated every 7,500 miles (12 500 km).

Any time you notice unusual wear, rotate your tires

as soon as possible and check wheel alignment. Also

check for damaged tires or wheels. See

When It Is Time

for New Tires on page 5-61andWheel Replacement

on page 5-64for more information.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The ®rst rotation

is the most important. See ªPart A: Scheduled

Maintenance Services,º in Section 6, for scheduled

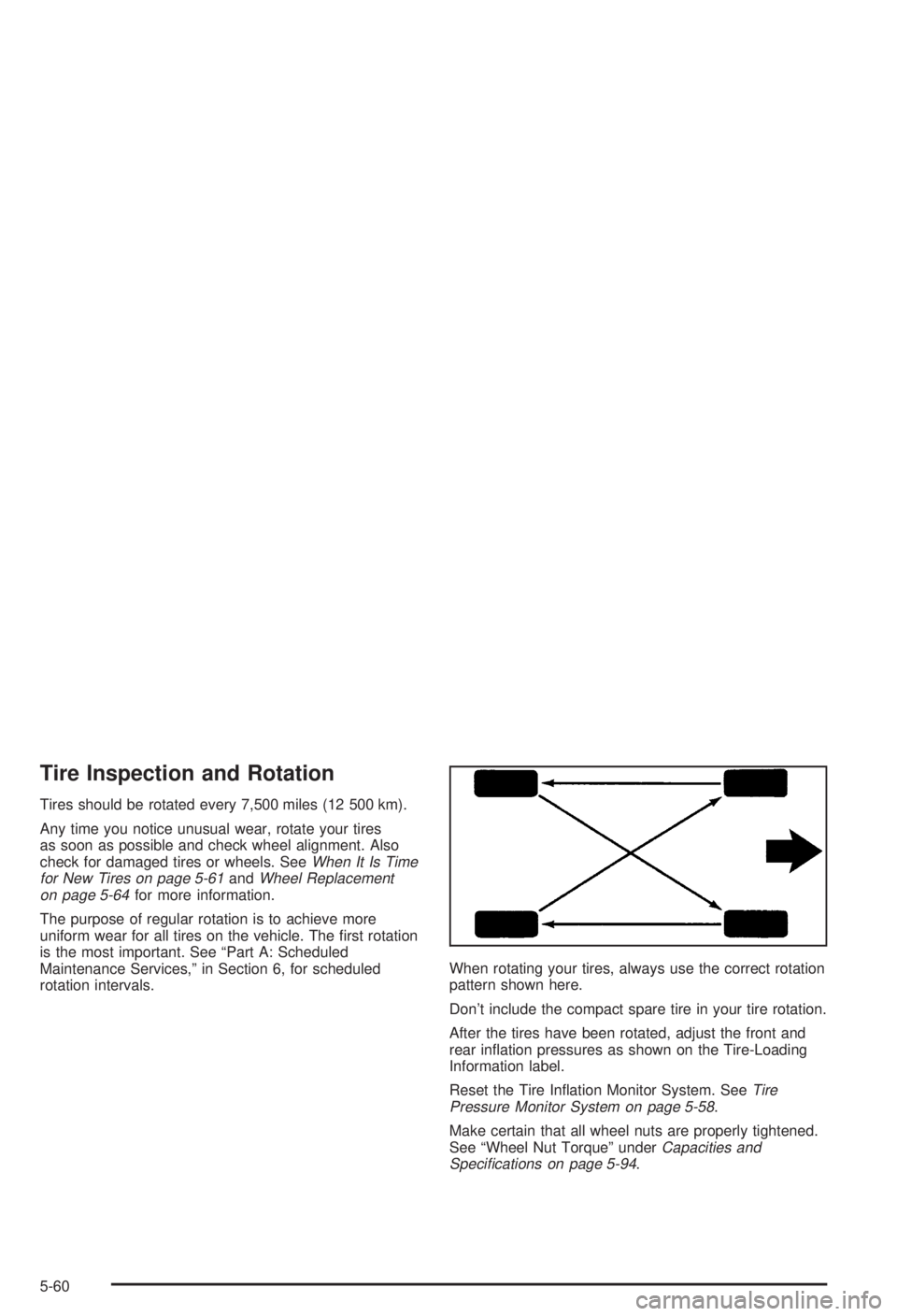

rotation intervals.When rotating your tires, always use the correct rotation

pattern shown here.

Don't include the compact spare tire in your tire rotation.

After the tires have been rotated, adjust the front and

rear in¯ation pressures as shown on the Tire-Loading

Information label.

Reset the Tire In¯ation Monitor System. See

Tire

Pressure Monitor System on page 5-58.

Make certain that all wheel nuts are properly tightened.

See ªWheel Nut Torqueº under

Capacities and

Speci®cations on page 5-94.

5-60

Page 275 of 344

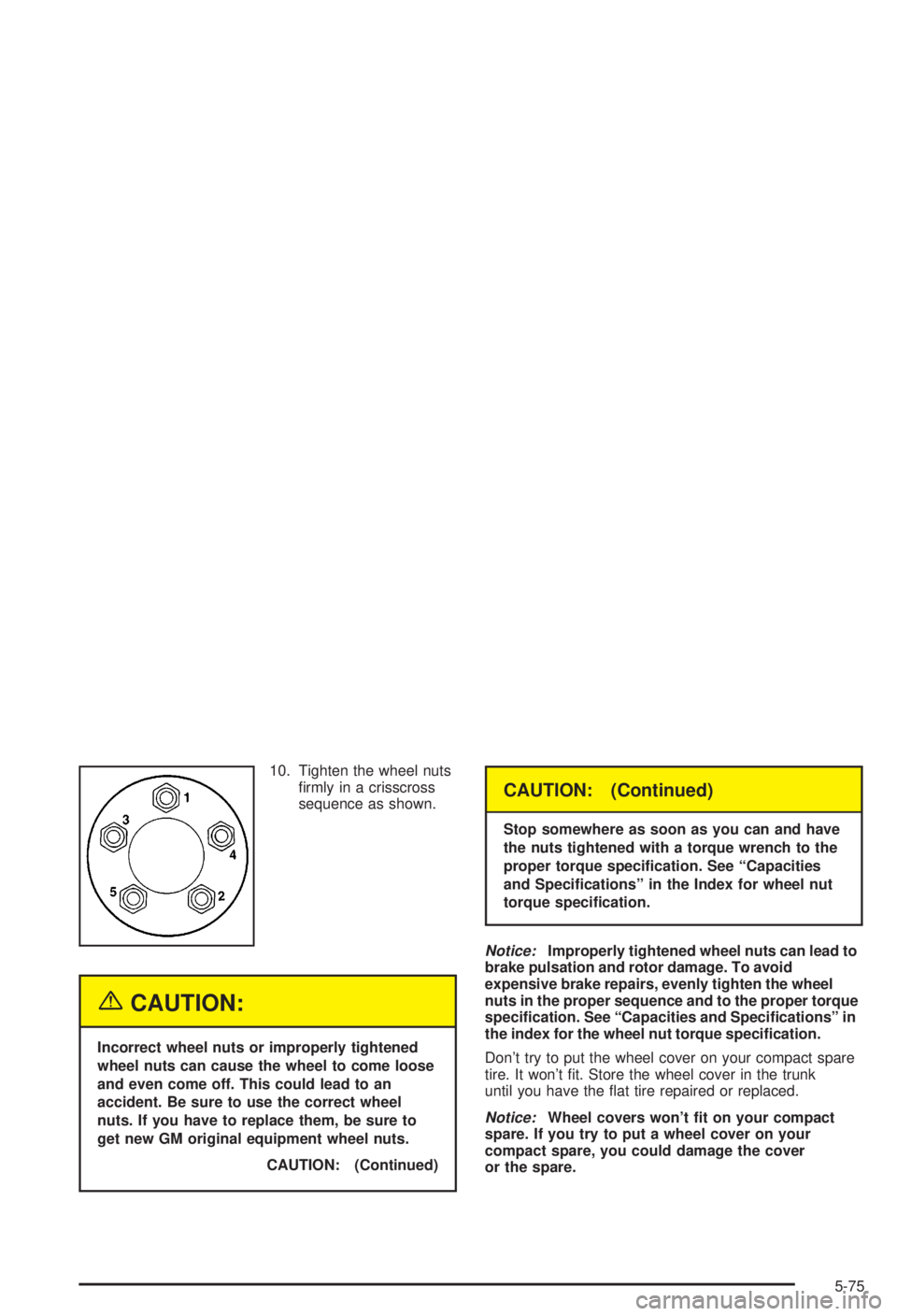

10. Tighten the wheel nuts

®rmly in a crisscross

sequence as shown.

{CAUTION:

Incorrect wheel nuts or improperly tightened

wheel nuts can cause the wheel to come loose

and even come off. This could lead to an

accident. Be sure to use the correct wheel

nuts. If you have to replace them, be sure to

get new GM original equipment wheel nuts.

CAUTION: (Continued)

CAUTION: (Continued)

Stop somewhere as soon as you can and have

the nuts tightened with a torque wrench to the

proper torque speci®cation. See ªCapacities

and Speci®cationsº in the Index for wheel nut

torque speci®cation.

Notice:Improperly tightened wheel nuts can lead to

brake pulsation and rotor damage. To avoid

expensive brake repairs, evenly tighten the wheel

nuts in the proper sequence and to the proper torque

speci®cation. See ªCapacities and Speci®cationsº in

the index for the wheel nut torque speci®cation.

Don't try to put the wheel cover on your compact spare

tire. It won't ®t. Store the wheel cover in the trunk

until you have the ¯at tire repaired or replaced.

Notice:Wheel covers won't ®t on your compact

spare. If you try to put a wheel cover on your

compact spare, you could damage the cover

or the spare.

5-75

Page 294 of 344

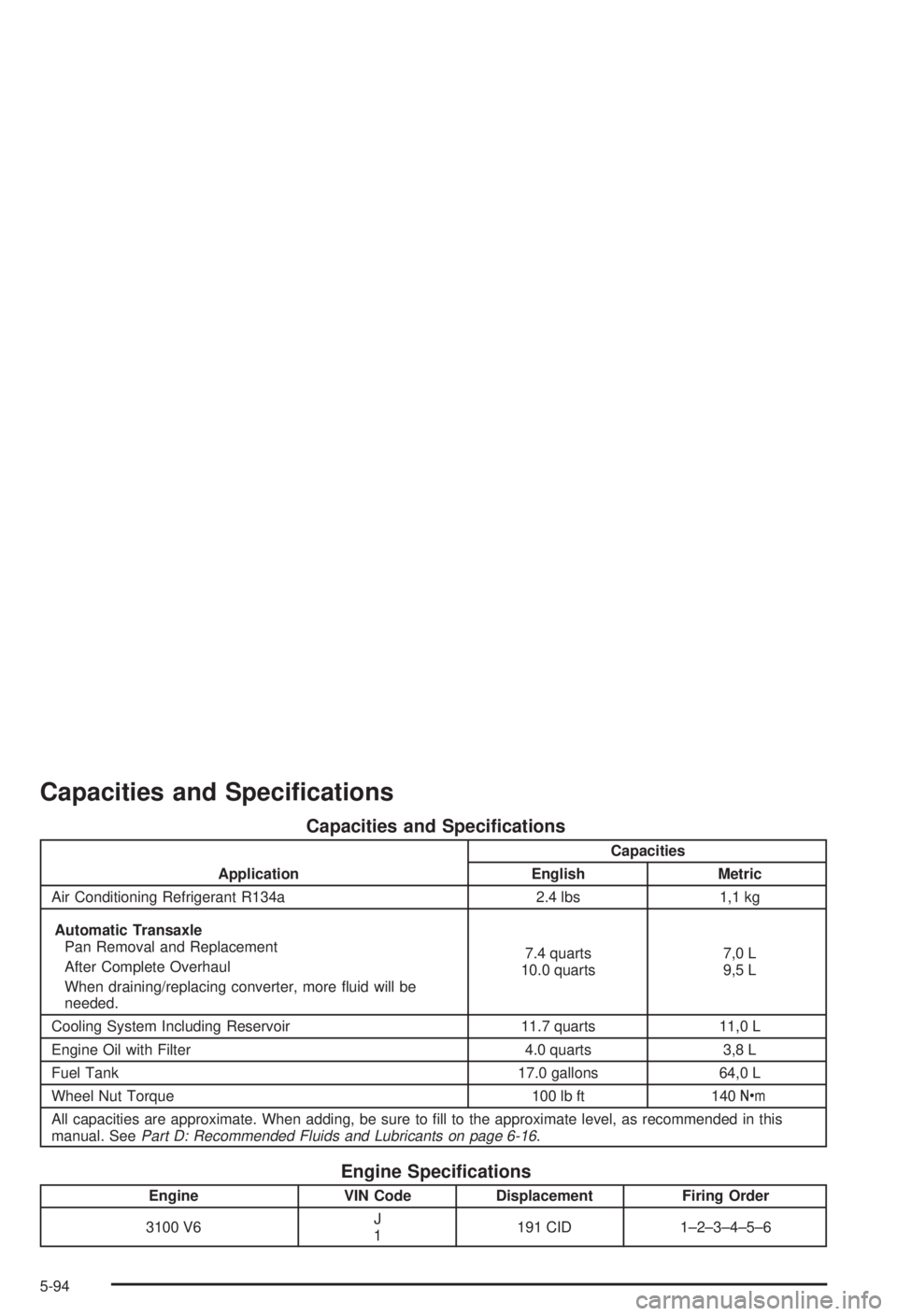

Capacities and Speci®cations

Capacities and Speci®cations

ApplicationCapacities

English Metric

Air Conditioning Refrigerant R134a 2.4 lbs 1,1 kg

Automatic Transaxle

Pan Removal and Replacement

After Complete Overhaul

When draining/replacing converter, more ¯uid will be

needed.7.4 quarts

10.0 quarts7,0 L

9,5 L

Cooling System Including Reservoir 11.7 quarts 11,0 L

Engine Oil with Filter 4.0 quarts 3,8 L

Fuel Tank 17.0 gallons 64,0 L

Wheel Nut Torque 100 lb ft 140Y

All capacities are approximate. When adding, be sure to ®ll to the approximate level, as recommended in this

manual. See

Part D: Recommended Fluids and Lubricants on page 6-16.

Engine Speci®cations

Engine VIN Code Displacement Firing Order

3100 V6J

1191 CID 1±2±3±4±5±6

5-94

Page 342 of 344

Tires (cont.)

Wheel Replacement.....................................5-64

When It Is Time for New Tires......................5-61

To Use the Engine Coolant Heater....................2-22

Top Strap Anchor Location...............................1-42

Top Strap......................................................1-40

Torque Lock...................................................2-28

Total Weight on Your Vehicle's Tires..................4-38

Towing..........................................................4-32

Recreational Vehicle.....................................4-32

Towing a Trailer..........................................4-35

Your Vehicle...............................................4-32

Traction.........................................................3-28

Enhanced Traction System (ETS) Warning

Light......................................................3-28

Enhanced Traction System (ETS)...................4-10

Low Light...................................................3-29

Trailer Brakes.................................................4-38

Transaxle Operation, Automatic.........................2-23

Transaxle.......................................................5-19

Fluid, Automatic...........................................5-19

Transmission, Transaxle, Transfer Case Unit

Repair Manual............................................7-11Transportation Options...................................... 7-8

Trip Odometer................................................3-24

Trunk Assist Handle........................................2-14

Trunk Lock....................................................2-13

Trunk............................................................2-13

Turn and Lane-Change Signals.......................... 3-6

Turn Signal/Multifunction Lever........................... 3-5

Turn Signals When Towing a Trailer..................4-40

U

Underbody Flushing Service.............................6-13

Underhood Fuse Block....................................5-91

Understanding Radio Reception........................3-50

Uniform Tire Quality Grading............................5-63

United States ± Customer Assistance.................. 7-5

Unlocking the Theft-Deterrent Feature After a

Power Loss................................................3-49

Used Replacement Wheels..............................5-65

Using Cleaner on Fabric..................................5-80

14