clock BUICK LACROSSE 2009 User Guide

[x] Cancel search | Manufacturer: BUICK, Model Year: 2009, Model line: LACROSSE, Model: BUICK LACROSSE 2009Pages: 428

Page 298 of 428

How to Add Coolant to the Cooling

System (3.8L V6 Engine)

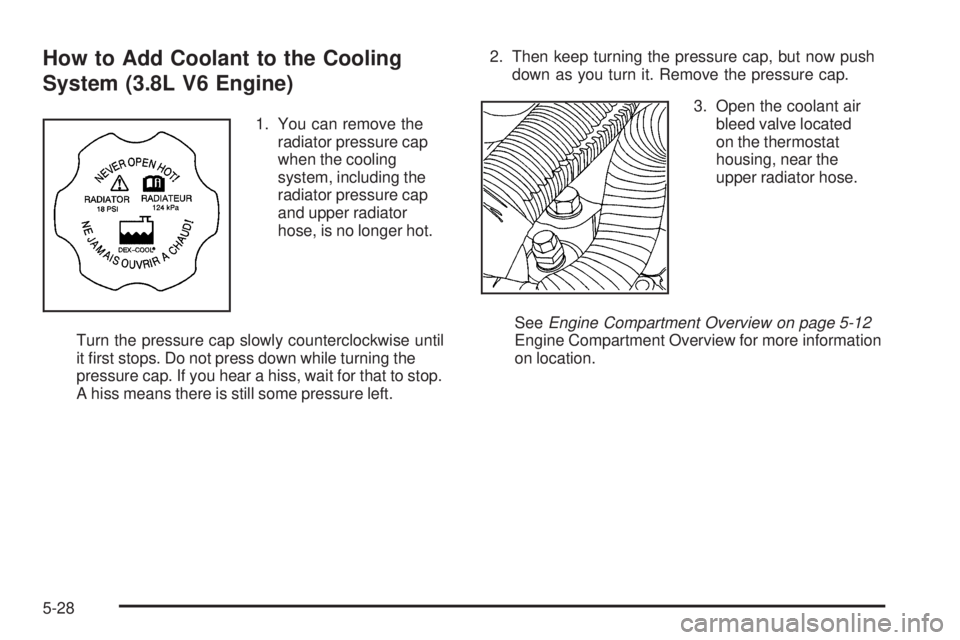

1. You can remove the

radiator pressure cap

when the cooling

system, including the

radiator pressure cap

and upper radiator

hose, is no longer hot.

Turn the pressure cap slowly counterclockwise until

it �rst stops. Do not press down while turning the

pressure cap. If you hear a hiss, wait for that to stop.

A hiss means there is still some pressure left.2. Then keep turning the pressure cap, but now push

down as you turn it. Remove the pressure cap.

3. Open the coolant air

bleed valve located

on the thermostat

housing, near the

upper radiator hose.

SeeEngine Compartment Overview on page 5-12

Engine Compartment Overview for more information

on location.

5-28

Page 300 of 428

How to Add Coolant to the Cooling

System (5.3L V8 Engine)

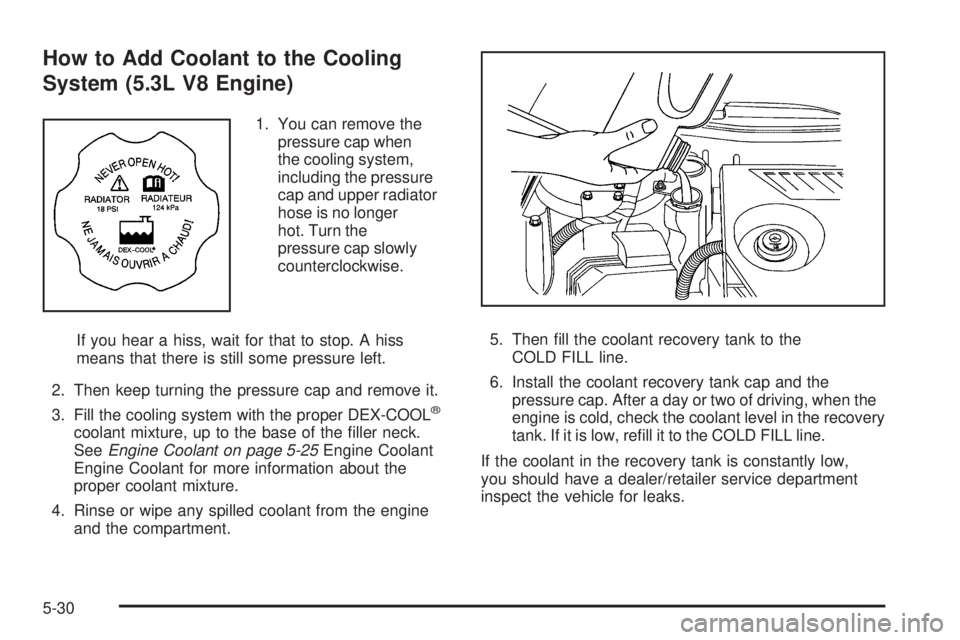

1. You can remove the

pressure cap when

the cooling system,

including the pressure

cap and upper radiator

hose is no longer

hot. Turn the

pressure cap slowly

counterclockwise.

If you hear a hiss, wait for that to stop. A hiss

means that there is still some pressure left.

2. Then keep turning the pressure cap and remove it.

3. Fill the cooling system with the proper DEX-COOL

®

coolant mixture, up to the base of the �ller neck.

SeeEngine Coolant on page 5-25Engine Coolant

Engine Coolant for more information about the

proper coolant mixture.

4. Rinse or wipe any spilled coolant from the engine

and the compartment.5. Then �ll the coolant recovery tank to the

COLD FILL line.

6. Install the coolant recovery tank cap and the

pressure cap. After a day or two of driving, when the

engine is cold, check the coolant level in the recovery

tank. If it is low, re�ll it to the COLD FILL line.

If the coolant in the recovery tank is constantly low,

you should have a dealer/retailer service department

inspect the vehicle for leaks.

5-30

Page 318 of 428

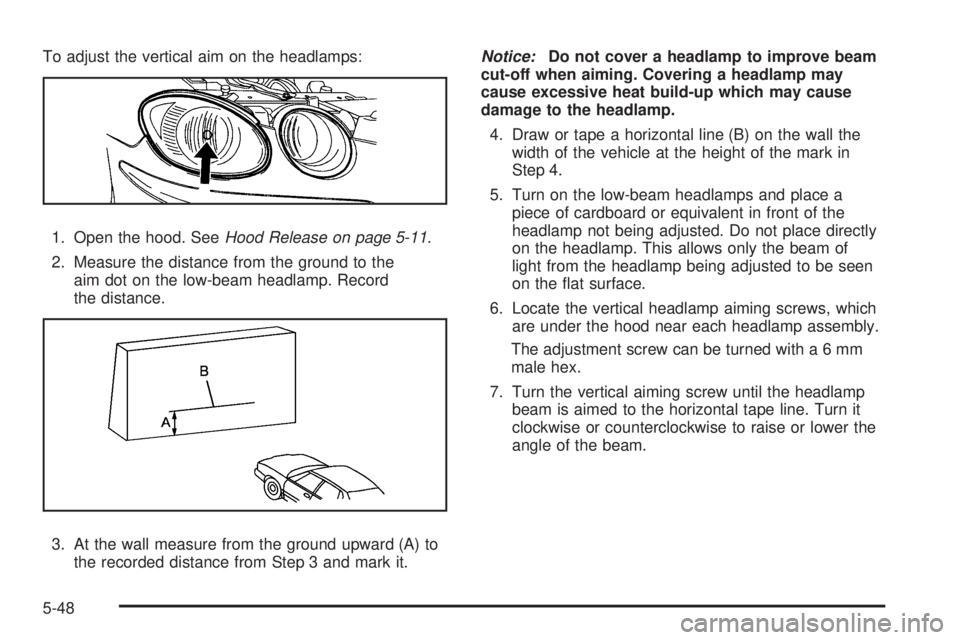

To adjust the vertical aim on the headlamps:

1. Open the hood. SeeHood Release on page 5-11.

2. Measure the distance from the ground to the

aim dot on the low-beam headlamp. Record

the distance.

3. At the wall measure from the ground upward (A) to

the recorded distance from Step 3 and mark it.Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

4. Draw or tape a horizontal line (B) on the wall the

width of the vehicle at the height of the mark in

Step 4.

5. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being adjusted. Do not place directly

on the headlamp. This allows only the beam of

light from the headlamp being adjusted to be seen

on the �at surface.

6. Locate the vertical headlamp aiming screws, which

are under the hood near each headlamp assembly.

The adjustment screw can be turned with a 6 mm

male hex.

7. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. Turn it

clockwise or counterclockwise to raise or lower the

angle of the beam.

5-48

Page 320 of 428

Taillamps, Turn Signal, Sidemarker,

Stoplamps and Back-up Lamps

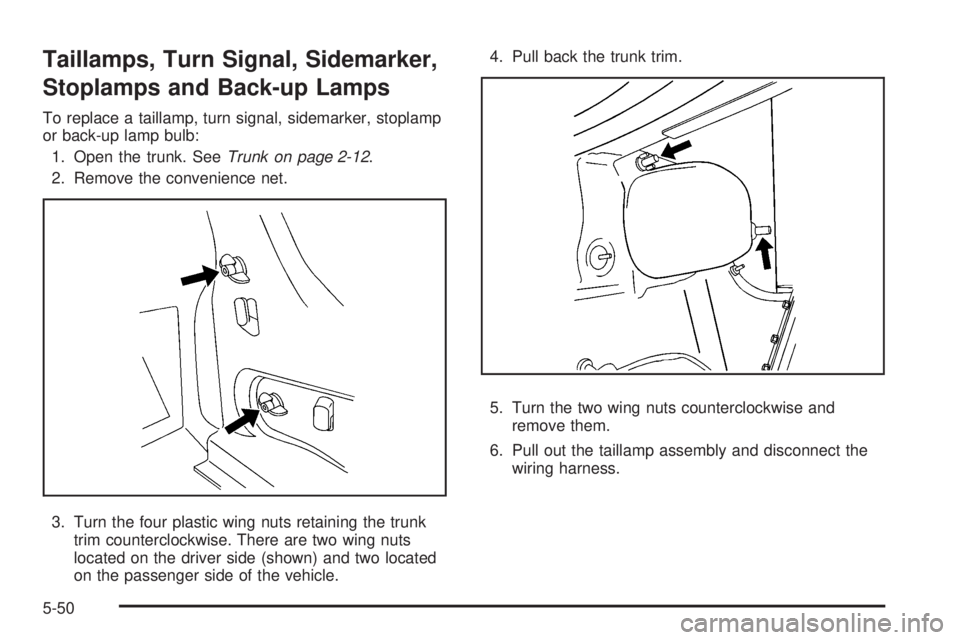

To replace a taillamp, turn signal, sidemarker, stoplamp

or back-up lamp bulb:

1. Open the trunk. SeeTrunk on page 2-12.

2. Remove the convenience net.

3. Turn the four plastic wing nuts retaining the trunk

trim counterclockwise. There are two wing nuts

located on the driver side (shown) and two located

on the passenger side of the vehicle.4. Pull back the trunk trim.

5. Turn the two wing nuts counterclockwise and

remove them.

6. Pull out the taillamp assembly and disconnect the

wiring harness.

5-50

Page 321 of 428

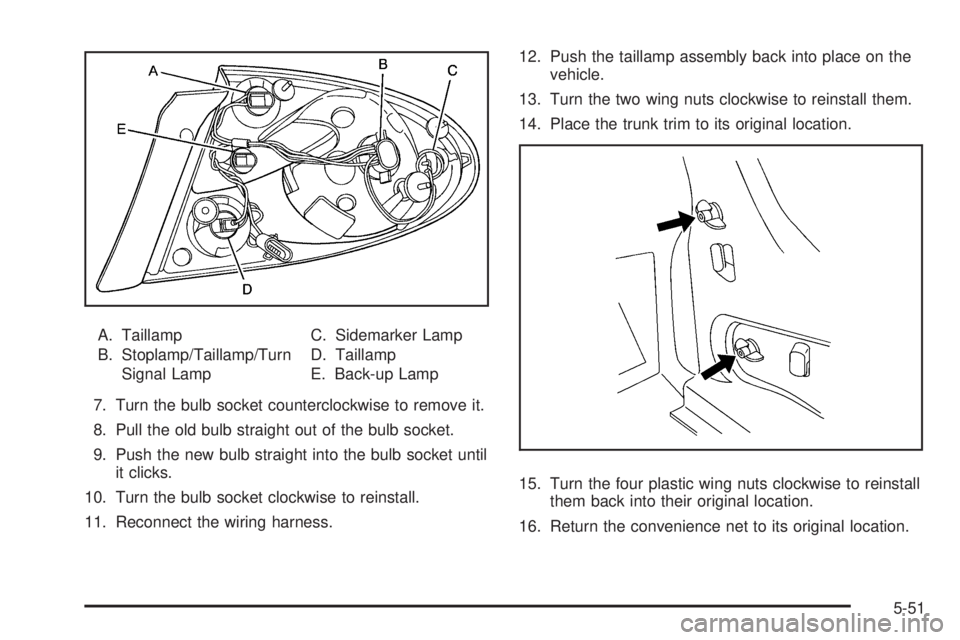

A. Taillamp

B. Stoplamp/Taillamp/Turn

Signal LampC. Sidemarker Lamp

D. Taillamp

E. Back-up Lamp

7. Turn the bulb socket counterclockwise to remove it.

8. Pull the old bulb straight out of the bulb socket.

9. Push the new bulb straight into the bulb socket until

it clicks.

10. Turn the bulb socket clockwise to reinstall.

11. Reconnect the wiring harness.12. Push the taillamp assembly back into place on the

vehicle.

13. Turn the two wing nuts clockwise to reinstall them.

14. Place the trunk trim to its original location.

15. Turn the four plastic wing nuts clockwise to reinstall

them back into their original location.

16. Return the convenience net to its original location.

5-51

Page 322 of 428

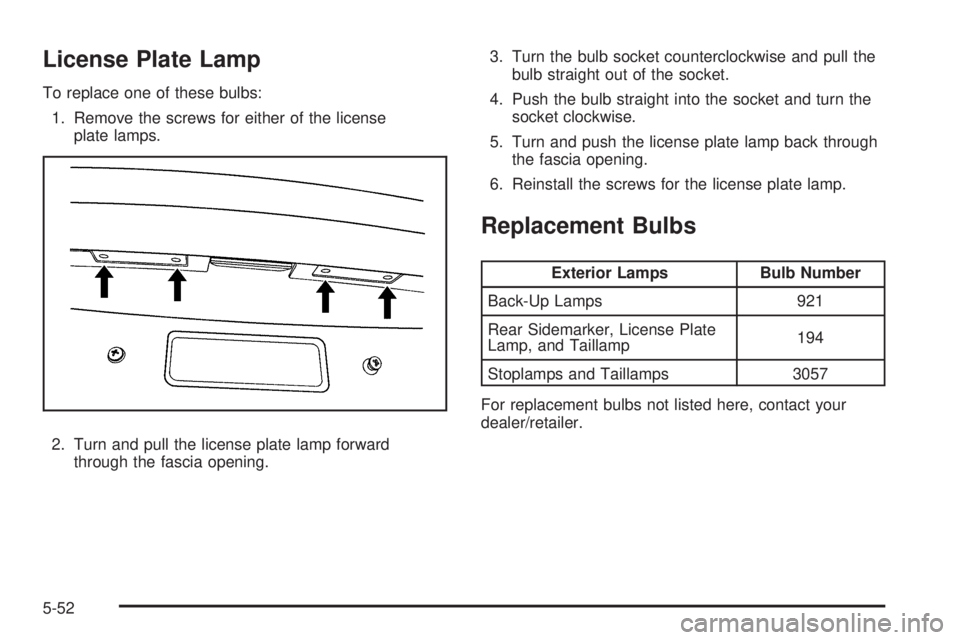

License Plate Lamp

To replace one of these bulbs:

1. Remove the screws for either of the license

plate lamps.

2. Turn and pull the license plate lamp forward

through the fascia opening.3. Turn the bulb socket counterclockwise and pull the

bulb straight out of the socket.

4. Push the bulb straight into the socket and turn the

socket clockwise.

5. Turn and push the license plate lamp back through

the fascia opening.

6. Reinstall the screws for the license plate lamp.

Replacement Bulbs

Exterior Lamps Bulb Number

Back-Up Lamps 921

Rear Sidemarker, License Plate

Lamp, and Taillamp194

Stoplamps and Taillamps 3057

For replacement bulbs not listed here, contact your

dealer/retailer.

5-52

Page 348 of 428

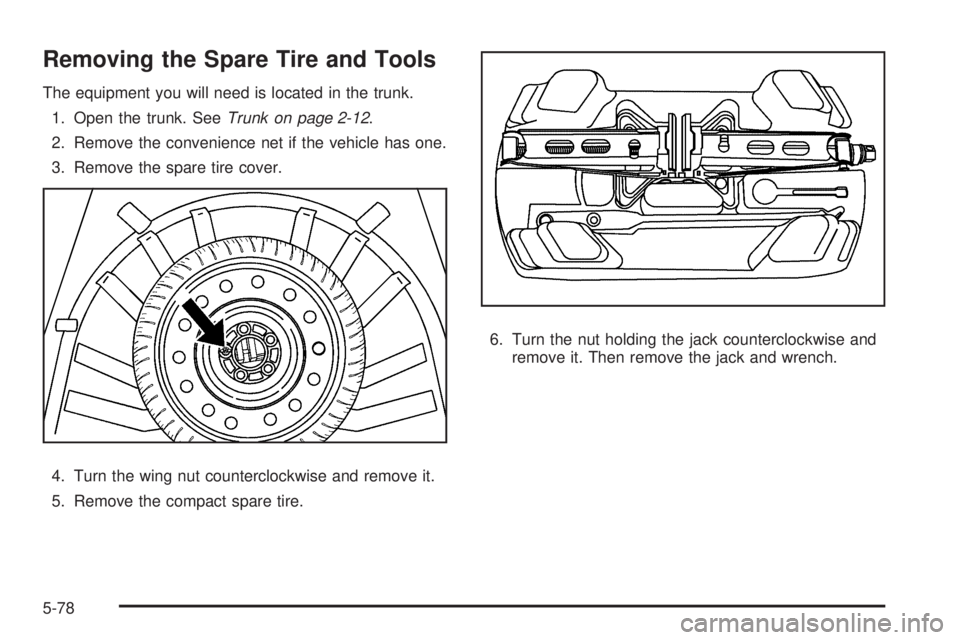

Removing the Spare Tire and Tools

The equipment you will need is located in the trunk.

1. Open the trunk. SeeTrunk on page 2-12.

2. Remove the convenience net if the vehicle has one.

3. Remove the spare tire cover.

4. Turn the wing nut counterclockwise and remove it.

5. Remove the compact spare tire.6. Turn the nut holding the jack counterclockwise and

remove it. Then remove the jack and wrench.

5-78

Page 349 of 428

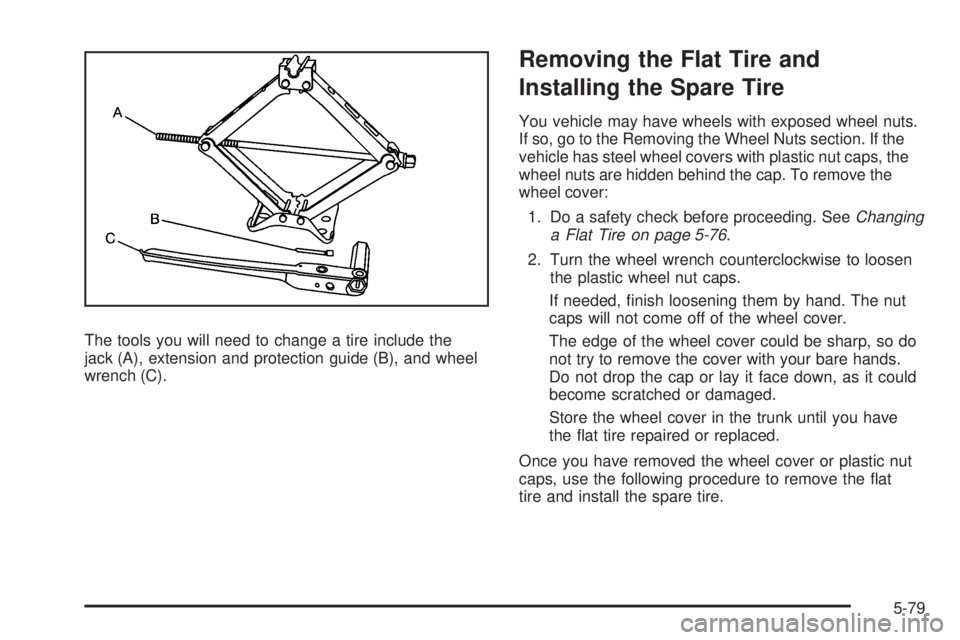

The tools you will need to change a tire include the

jack (A), extension and protection guide (B), and wheel

wrench (C).

Removing the Flat Tire and

Installing the Spare Tire

You vehicle may have wheels with exposed wheel nuts.

If so, go to the Removing the Wheel Nuts section. If the

vehicle has steel wheel covers with plastic nut caps, the

wheel nuts are hidden behind the cap. To remove the

wheel cover:

1. Do a safety check before proceeding. SeeChanging

a Flat Tire on page 5-76.

2. Turn the wheel wrench counterclockwise to loosen

the plastic wheel nut caps.

If needed, �nish loosening them by hand. The nut

caps will not come off of the wheel cover.

The edge of the wheel cover could be sharp, so do

not try to remove the cover with your bare hands.

Do not drop the cap or lay it face down, as it could

become scratched or damaged.

Store the wheel cover in the trunk until you have

the �at tire repaired or replaced.

Once you have removed the wheel cover or plastic nut

caps, use the following procedure to remove the �at

tire and install the spare tire.

5-79

Page 350 of 428

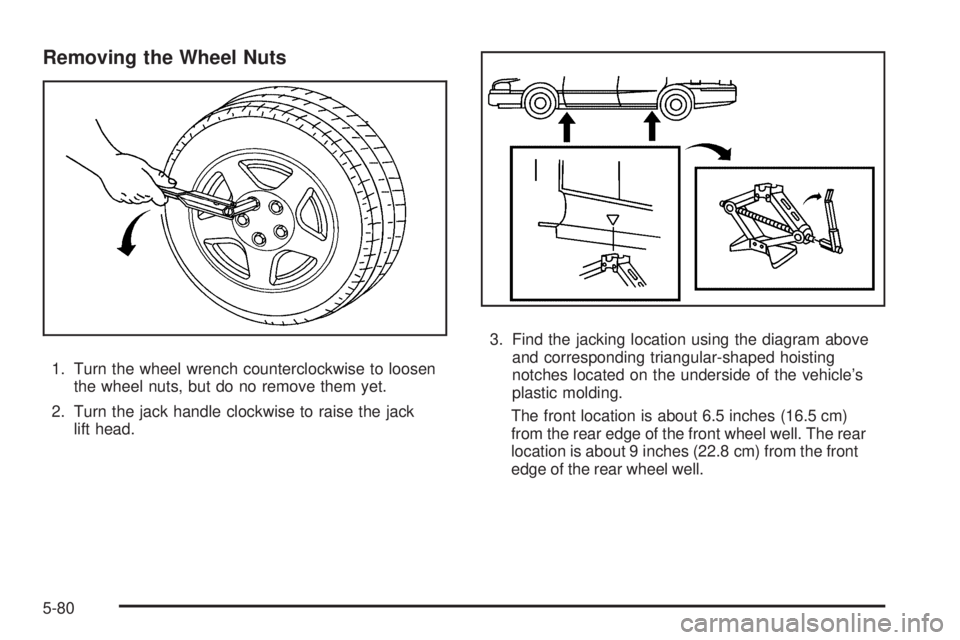

Removing the Wheel Nuts

1. Turn the wheel wrench counterclockwise to loosen

the wheel nuts, but do no remove them yet.

2. Turn the jack handle clockwise to raise the jack

lift head.3. Find the jacking location using the diagram above

and corresponding triangular-shaped hoisting

notches located on the underside of the vehicle’s

plastic molding.

The front location is about 6.5 inches (16.5 cm)

from the rear edge of the front wheel well. The rear

location is about 9 inches (22.8 cm) from the front

edge of the rear wheel well.

5-80

Page 351 of 428

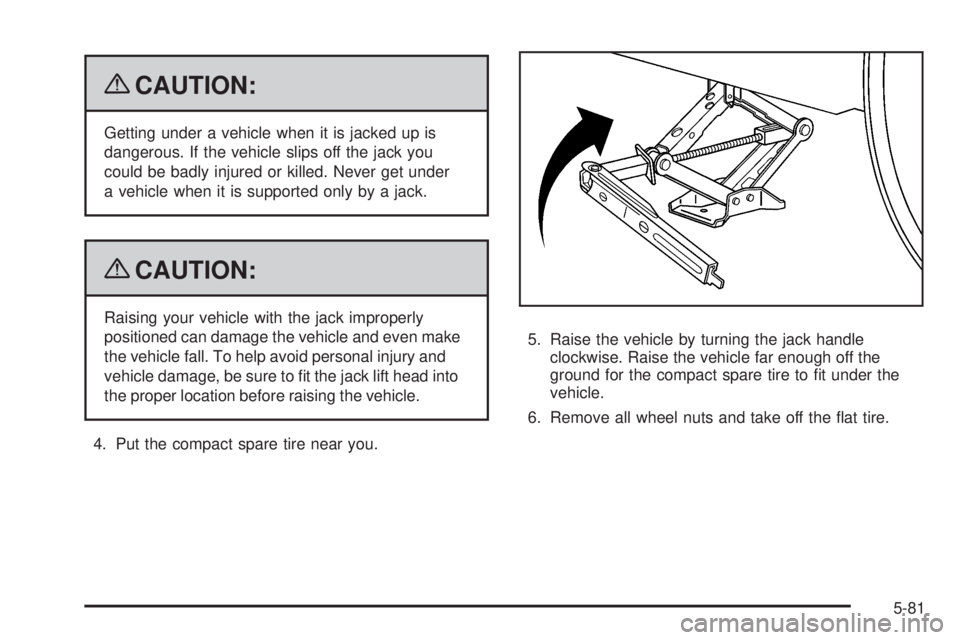

{CAUTION:

Getting under a vehicle when it is jacked up is

dangerous. If the vehicle slips off the jack you

could be badly injured or killed. Never get under

a vehicle when it is supported only by a jack.

{CAUTION:

Raising your vehicle with the jack improperly

positioned can damage the vehicle and even make

the vehicle fall. To help avoid personal injury and

vehicle damage, be sure to �t the jack lift head into

the proper location before raising the vehicle.

4. Put the compact spare tire near you.5. Raise the vehicle by turning the jack handle

clockwise. Raise the vehicle far enough off the

ground for the compact spare tire to �t under the

vehicle.

6. Remove all wheel nuts and take off the �at tire.

5-81