key CADILLAC DTS 2010 1.G Workshop Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2010, Model line: DTS, Model: CADILLAC DTS 2010 1.GPages: 480, PDF Size: 17.56 MB

Page 337 of 480

How to Reset the Engine Oil Life

System

The Engine Oil Life System calculates when to changethe engine oil and filter based on vehicle use. Wheneverthe oil is changed, reset the system so it can calculatewhen the next oil change is required. If a situation occurswhere the oil is changed prior to a CHANGE ENGINE OILSOON message in the Driver Information Center (DIC)being turned on, reset the system.

After the oil has been changed, the CHANGE ENGINEOIL SOON message must be reset:

1. Turn the key to the ON/RUN position withoutstarting the engine.

2. Press the INFO button on the Driver InformationCenter (DIC) until OIL LIFE REMAINING isdisplayed. SeeDIC Operation and Displays onpage 4-62.

3. Press and hold the INFO RESET button until 100%is displayed. This resets the oil life indicator.

4. Turn the key to LOCK/OFF.

If the CHANGE ENGINE OIL SOON message comesback on when the vehicle is started, the engine oillife system has not reset. Repeat the procedure.

What to Do with Used Oil

Used engine oil contains certain elements that can beunhealthy for your skin and could even cause cancer.Do not let used oil stay on your skin for very long. Cleanyour skin and nails with soap and water, or a goodhand cleaner. Wash or properly dispose of clothing orrags containing used engine oil. See the manufacturer’swarnings about the use and disposal of oil products.

Used oil can be a threat to the environment. If youchange your own oil, be sure to drain all the oil from thefilter before disposal. Never dispose of oil by putting itin the trash, pouring it on the ground, into sewers, or intostreams or bodies of water. Recycle it by taking it to aplace that collects used oil.

Engine Air Cleaner/Filter

SeeEngine Compartment Overview on page 6-12forthe location of the engine air cleaner/filter.

When to Inspect the Engine Air

Cleaner/Filter

Inspect the air cleaner/filter at the MaintenanceIIintervals and replace it at the first oil change after each50,000 mile (80 000 km) interval. SeeScheduledMaintenance on page 7-3for more information. If youare driving in dusty/dirty conditions, inspect the filterat each engine oil change.

6-17

Page 350 of 480

Power Steering Fluid

The power steering fluidreservoir is located next tothe underhood fuseblock on the passengerside of the vehicle.SeeEngine CompartmentOverview on page 6-12for more informationon location.

When to Check Power Steering Fluid

It is not necessary to regularly check power steering fluidunless you suspect there is a leak in the system oryou hear an unusual noise. A fluid loss in this systemcould indicate a problem. Have the system inspectedand repaired.

How to Check Power Steering Fluid

To check the power steering fluid:

1. Turn the key off and let the engine compartmentcool down.

2. Wipe the cap and the top of the reservoir clean.

3. Unscrew the cap and wipe the dipstick with a cleanrag.

4. Replace the cap and completely tighten it.

5. Remove the cap again and look at the fluid level onthe dipstick.

The level should be at the FULL COLD mark. Ifnecessary, add only enough fluid to bring the level up tothe mark.

What to Use

To determine what kind of fluid to use, seeRecommended Fluids and Lubricants on page 7-8.Always use the proper fluid.

Notice:Use of the incorrect fluid may damage thevehicle and the damages may not be covered bythe vehicle’s warranty. Always use the correct fluidlisted inRecommended Fluids and Lubricantson page 7-8.

6-30

Page 380 of 480

•The TPMS sensor matching process was started

but not completed or not completed successfullyafter rotating the vehicle’s tires. The DIC messageand TPMS malfunction light should go off oncethe TPMS sensor matching process is performedsuccessfully. See “TPMS Sensor Matching Process”later in this section.

•One or more TPMS sensors are missing or

damaged. The DIC message and the TPMSmalfunction light should go off when the TPMSsensors are installed and the sensor matchingprocess is performed successfully. See yourdealer/retailer for service.

•Replacement tires or wheels do not match your

vehicle’s original equipment tires or wheels.Tires and wheels other than those recommendedfor your vehicle could prevent the TPMS fromfunctioning properly. SeeBuying New Tires onpage 6-64.

•Operating electronic devices or being near facilities

using radio wave frequencies similar to the TPMScould cause the TPMS sensors to malfunction.

If the TPMS is not functioning it cannot detect or signala low tire condition. See your dealer/retailer forservice if the TPMS malfunction light and DIC messagecomes on and stays on.

TPMS Sensor Matching Process

Each TPMS sensor has a unique identification code.Any time you rotate your vehicle’s tires or replace one ormore of the TPMS sensors, the identification codeswill need to be matched to the new tire/wheel position.The sensors are matched to the tire/wheel positionsin the following order: driver side front tire, passengerside front tire, passenger side rear tire, and driverside rear tire using a TPMS diagnostic tool. See yourdealer/retailer for service.

The TPMS sensors can also be matched to eachtire/wheel position by increasing or decreasing the tire’sair pressure. If increasing the tire’s air pressure, donot exceed the maximum inflation pressure indicated onthe tire’s sidewall.

To decrease air-pressure out of a tire you can use thepointed end of the valve cap, a pencil-style air pressuregage, or a key.

You have two minutes to match the first tire/wheelposition, and five minutes overall to match all fourtire/wheel positions. If it takes longer than two minutes,to match the first tire and wheel, or more than fiveminutes to match all four tire and wheel positions thematching process stops and you need to start over.

6-60

Page 381 of 480

The TPMS sensor matching process is outlined below:

1. Set the parking brake.

2. Turn the ignition switch to ON/RUN with theengine off.

3. Press the Remote Keyless Entry (RKE) transmitter’slock and unlock buttons at the same time forapproximately five seconds. The horn sounds twiceto signal the receiver is in relearn mode andTIRE LEARNING ACTIVE message displays on theDIC screen.

4. Start with the driver side front tire.

5. Remove the valve cap from the valve cap stem.Activate the TPMS sensor by increasing ordecreasing the tire’s air pressure for five seconds,or until a horn chirp sounds. The horn chirp,which may take up to 30 seconds to sound,confirms that the sensor identification code hasbeen matched to this tire and wheel position.

6. Proceed to the passenger side front tire, and repeatthe procedure in Step 5.

7. Proceed to the passenger side rear tire, and repeatthe procedure in Step 5.

8. Proceed to the driver side rear tire, and repeat theprocedure in Step 5. The horn sounds two times toindicate the sensor identification code has beenmatched to the driver side rear tire, and theTPMS sensor matching process is no longer active.The TIRE LEARNING ACTIVE message on theDIC display screen goes off.

9. Turn the ignition switch to LOCK/OFF.

10. Set all four tires to the recommended air pressurelevel as indicated on the Tire and LoadingInformation label.

11. Put the valve caps back on the valve stems.

6-61

Page 427 of 480

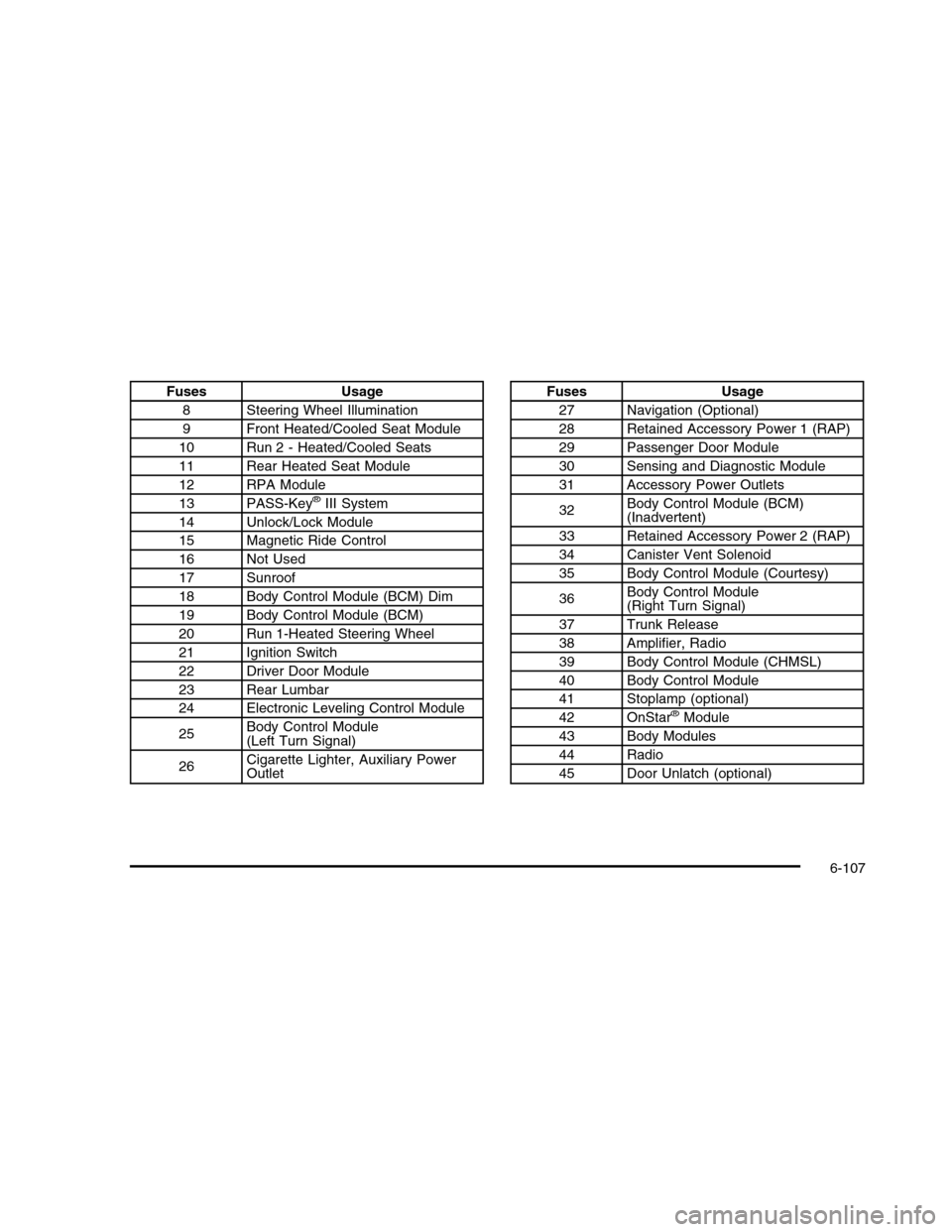

FusesUsage

8Steering Wheel Illumination

9Front Heated/Cooled Seat Module

10Run 2 - Heated/Cooled Seats

11Rear Heated Seat Module

12RPA Module

13PASS-Key®III System

14Unlock/Lock Module

15Magnetic Ride Control

16Not Used

17Sunroof

18Body Control Module (BCM) Dim

19Body Control Module (BCM)

20Run 1-Heated Steering Wheel

21Ignition Switch

22Driver Door Module

23Rear Lumbar

24Electronic Leveling Control Module

25Body Control Module(Left Turn Signal)

26Cigarette Lighter, Auxiliary PowerOutlet

FusesUsage

27Navigation (Optional)

28Retained Accessory Power 1 (RAP)

29Passenger Door Module

30Sensing and Diagnostic Module

31Accessory Power Outlets

32Body Control Module (BCM)(Inadvertent)

33Retained Accessory Power 2 (RAP)

34Canister Vent Solenoid

35Body Control Module (Courtesy)

36Body Control Module(Right Turn Signal)

37Trunk Release

38Amplifier, Radio

39Body Control Module (CHMSL)

40Body Control Module

41Stoplamp (optional)

42OnStar®Module

43Body Modules

44Radio

45Door Unlatch (optional)

6-107

Page 434 of 480

•Fluids visual leak check (or every 12 months,

whichever occurs first). A leak in any system mustbe repaired and the fluid level checked.

•Engine air cleaner filter inspection. SeeEngine Air

Cleaner/Filter on page 6-17.

•Brake system inspection (or every 12 months,

whichever occurs first).

•Steering and suspension inspection. Visual

inspection for damaged, loose, or missing parts orsigns of wear.

•Engine cooling system inspection. Visual inspection

of hoses, pipes, fittings, and clamps andreplacement, if needed.

•Windshield wiper blade inspection for wear,

cracking, or contamination and windshield and wiperblade cleaning, if contaminated. SeeWindshieldand Wiper Blades on page 6-97. Worn or damagedwiper blade replacement. SeeWindshield WiperBlade Replacement on page 6-44.

•Body hinges and latches, key lock cylinders,

console hinges, and glove box door hingeslubrication. SeeRecommended Fluids andLubricants on page 7-8. More frequent lubricationmay be required when vehicle is exposed to acorrosive environment.

Applying silicone grease on weatherstrips with aclean cloth makes them last longer, seal better, andnot stick or squeak.

•Restraint system component check. SeeChecking

the Restraint Systems on page 2-74.

•Automatic transmission fluid level check and adding

fluid, if needed. SeeAutomatic Transmission Fluidon page 6-19.

Additional Required Services

At Each Fuel Stop

•Engine oil level check. SeeEngine Oil on

page 6-13.

•Engine coolant level check. SeeEngine Coolant on

page 6-23.

•Windshield washer fluid level check. SeeWindshield

Washer Fluid on page 6-31.

Once a Month

•Tire inflation check. SeeInflation - Tire Pressure on

page 6-54.

•Tire wear inspection. SeeTire Inspection and

Rotation on page 6-62.

7-4

Page 437 of 480

Automatic Transmission Shift Lock

Control System Check

{WARNING:

When you are doing this inspection, the vehicle

could move suddenly. If the vehicle moves, you or

others could be injured.

1. Before starting this check, be sure there is enoughroom around the vehicle. It should be parked on alevel surface.

2. Firmly apply the parking brake. SeeParking Brakeon page 3-30.

Be ready to apply the regular brake immediately ifthe vehicle begins to move.

3. With the engine off, turn the ignition to ON/RUN,but do not start the engine. Without applying theregular brake, try to move the shift lever outof P (Park) with normal effort. If the shift levermoves out of P (Park), contact your dealer/retailerfor service.

Ignition Transmission Lock Check

While parked, and with the parking brake set, try to turnthe ignition to LOCK/OFF in each shift lever position.

•The ignition should turn to LOCK/OFF only

when the shift lever is in P (Park).

•The ignition key should come out only

in LOCK/OFF.

Contact your dealer/retailer if service is required.

7-7

Page 439 of 480

UsageFluid/Lubricant

WindshieldWasherOptikleen®Washer Solvent.

Parking BrakeCable Guides

Chassis Lubricant (GM PartNo. U.S. 12377985, inCanada 88901242) or lubricantmeeting requirements of NLGI #2,Category LB or GC-LB.

Power SteeringSystem

GM Power Steering Fluid(GM Part No. U.S. 89021184, inCanada 89021186).

AutomaticTransmissionDEXRON®-VI AutomaticTransmission Fluid.

Key LockCylinders

Multi-Purpose Lubricant, Superlube(GM Part No. U.S. 12346241, inCanada 10953474).

UsageFluid/Lubricant

Hood LatchAssembly,SecondaryLatch, Pivots,Spring Anchor,and ReleasePawl

Lubriplate Lubricant Aerosol(GM Part No. U.S. 12346293, inCanada 992723) or lubricantmeeting requirements of NLGI #2,Category LB or GC-LB.

Hood and DoorHinges

Multi-Purpose Lubricant, Superlube(GM Part No. U.S. 12346241, inCanada 10953474).

WeatherstripConditioning

Weatherstrip Lubricant (GM PartNo. U.S. 3634770, inCanada 10953518) or DielectricSilicone Grease(GM Part No. U.S. 12345579, inCanada 992887).

7-9

Page 464 of 480

OnStar®

If the vehicle has OnStar and you subscribe to the OnStarservices, please refer to the OnStar Terms andConditions for information on data collection and use.

Navigation System

If your vehicle has a navigation system, use of thesystem may result in the storage of destinations,addresses, telephone numbers, and other tripinformation. Refer to the navigation system operatingmanual for information on stored data and for deletioninstructions.

Radio Frequency

Identification (RFID)

RFID technology is used in some vehicles for functionssuch as tire pressure monitoring and ignition systemsecurity, as well as in connection with conveniencessuch as key fobs for remote door locking/unlocking and

starting, and in-vehicle transmitters for garage dooropeners. RFID technology in GM vehicles does not useor record personal information or link with any otherGM system containing personal information.

Radio Frequency Statement

This vehicle has systems that operate on a radiofrequency that comply with Part 15 of the FederalCommunications Commission (FCC) Rules and withRSS-210/211 of Industry and Science Canada.

Operation is subject to the following two conditions:

1. The device may not cause interference.

2. The device must accept any interference received,including interference that may cause undesiredoperation of the device.

Changes or modifications to any of these systems byother than an authorized service facility could voidauthorization to use this equipment.

8-20

Page 469 of 480

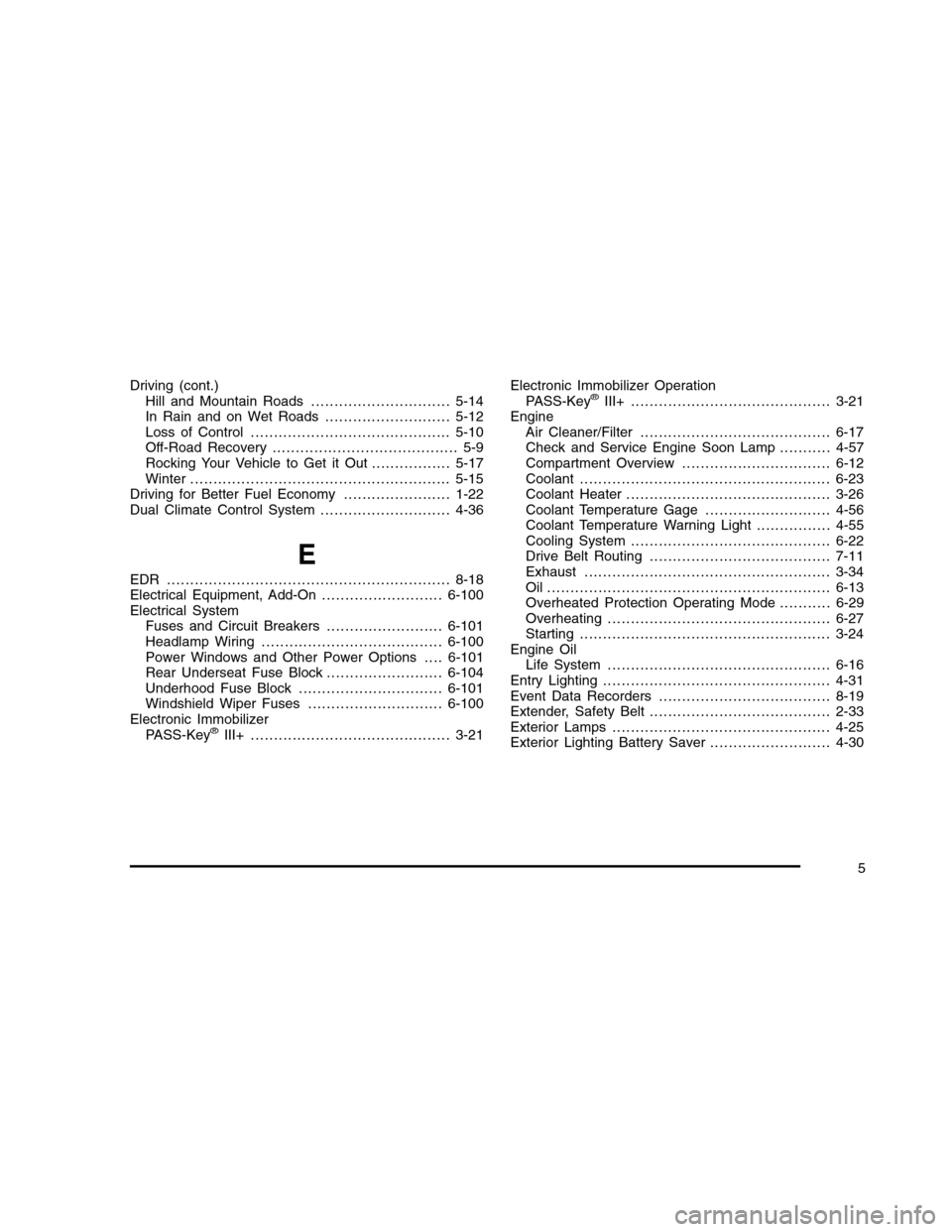

Driving (cont.)Hill and Mountain Roads . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-14In Rain and on Wet Roads . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-12Loss of Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-10Off-Road Recovery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-9Rocking Your Vehicle to Get it Out . . . . . . . . . . . . . . . . . 5-17Winter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5-15Driving for Better Fuel Economy . . . . . . . . . . . . . . . . . . . . . . . 1-22Dual Climate Control System . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-36

E

EDR . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-18Electrical Equipment, Add-On . . . . . . . . . . . . . . . . . . . . . . . . . . 6-100Electrical SystemFuses and Circuit Breakers . . . . . . . . . . . . . . . . . . . . . . . . . 6-101Headlamp Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-100Power Windows and Other Power Options . . . . 6-101Rear Underseat Fuse Block . . . . . . . . . . . . . . . . . . . . . . . . . 6-104Underhood Fuse Block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-101Windshield Wiper Fuses . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-100Electronic ImmobilizerPASS-Key®III+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21

Electronic Immobilizer OperationPASS-Key®III+ . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-21EngineAir Cleaner/Filter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-17Check and Service Engine Soon Lamp . . . . . . . . . . . 4-57Compartment Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-12Coolant . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-23Coolant Heater . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-26Coolant Temperature Gage . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-56Coolant Temperature Warning Light . . . . . . . . . . . . . . . . 4-55Cooling System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-22Drive Belt Routing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7-11Exhaust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-34Oil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-13Overheated Protection Operating Mode . . . . . . . . . . . 6-29Overheating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-27Starting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-24Engine OilLife System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6-16Entry Lighting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-31Event Data Recorders . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8-19Extender, Safety Belt . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-33Exterior Lamps . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-25Exterior Lighting Battery Saver . . . . . . . . . . . . . . . . . . . . . . . . . . 4-30

5