CADILLAC ESCALADE EXT 2002 2.G Owners Manual

ESCALADE EXT 2002 2.G

CADILLAC

CADILLAC

https://www.carmanualsonline.info/img/23/7924/w960_7924-0.png

CADILLAC ESCALADE EXT 2002 2.G Owners Manual

Trending: child lock, center console, air condition, change key battery, brake fluid, wheel torque, headlamp

Page 351 of 427

6-39

5. Pull the top left and right corners of the grill out so

the clips release. Then pull the grill out and up.6. Remove the horizontal pin from the headlamp

assembly by lifting the end of the pin upward until

it unsnaps and then pulling it toward the center of

the vehicle.

Page 352 of 427

6-40

7. Remove the vertical pin from the headlamp assembly

by turning the end of the pin away from you until it

unsnaps and then pulling it upward.

8. Remove the headlamp assembly by lifting it up

and then pulling it out and away from the front of

the vehicle.

9. Disconnect the electrical connector from the lower

corner of the headlamp assembly. This will give you

better access to the headlamp assembly.

10. Remove the rubber,

circular

-shaped bulb

cap of the affected bulb

from the headlamp

assembly.

11. Turn the bulb connector counterclockwise and

remove it with the old bulb from the headlamp

assembly.

12. Unplug the electrical connector from the old bulb.

13. Plug in the electrical connector to the new bulb,

using care not to touch the bulb with your hands,

fingers or anything damp or oily.

14. Place the connector with the new bulb into the

headlamp assembly and turn it clockwise until it

is tight.

15. Reinstall the rubber, circular

-shaped bulb cap onto

the headlamp assembly.

Page 353 of 427

6-41

16. Reconnect the electrical connector to the lower

corner of the headlamp assembly.

17. Place the headlamp assembly back into the vehicle,

being sure to align the lower locator tab with the

pocket on the vehicle (see arrow). Push the

headlamp assembly straight in and then down

into position.

18. Install the two pins and snap the ends into their

locked position.

19. Reinstall the grille and radiator cover by reversing

the removal procedure described previously.Headlamp Aiming

Your vehicle has a visual optical headlamp aiming

system equipped with horizontal aim indicators.

The aim has been preset at the factory and should

need no further adjustment. This is true even though

your horizontal aim indicators may not fall exactly on

the ª0º (zero) marks on their scales.

Page 354 of 427

6-42

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the low beam

may be necessary if it is difficult to see lane markers

(for horizontal aim), or if oncoming drivers flash their

high beams at you (for vertical aim). If you believe

your headlamps need to be re

-aimed, we recommend

that you take your vehicle to your dealer for service.

However, it is possible for you to re

-aim your

headlamps as described in the following procedure.

NOTICE:

To make sure your headlamps are aimed

properly, read all the instructions before

beginning. Failure to follow these instructions

could cause damage to headlamp parts.

The vehicle should be properly prepared as follows:

�The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall or other flat

surface.

�The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall or

other flat surface.

�The vehicle should be placed so it is perpendicular to

the wall or other flat surface.

�The vehicle should not have any snow, ice or mud

attached to it.

�The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

�The vehicle should be normally loaded with a full

tank of fuel and one person or 160 lbs. (75 kg) on the

driver's seat.

�Tires should be properly inflated.

�Start the vehicle and rock it to level the suspension.

Headlamp aiming is done with the vehicle low beam

lamps. The high beam lamps will be correctly aimed if

the low beam lamps are aimed properly.

Page 355 of 427

6-43

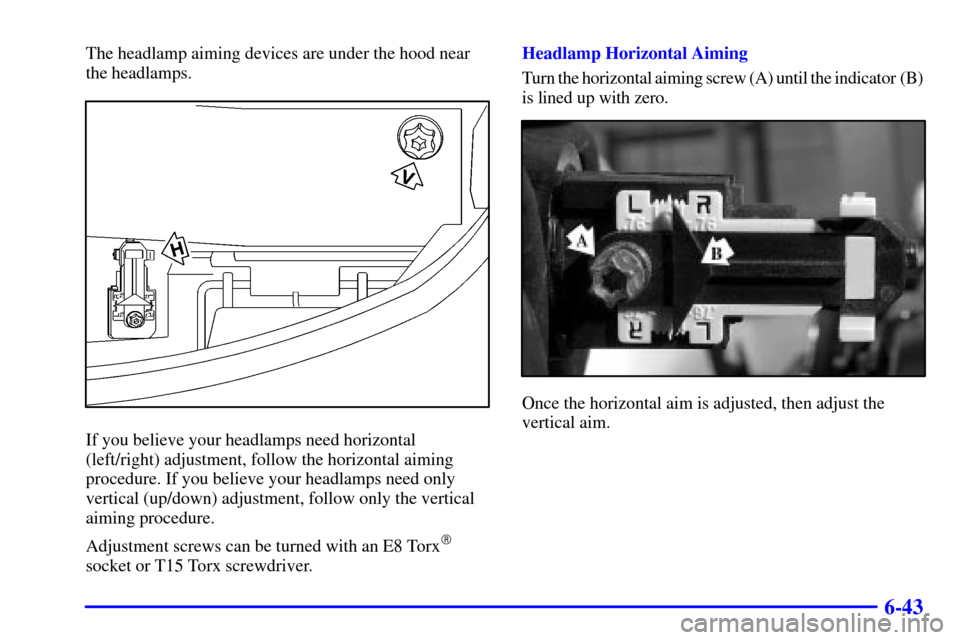

The headlamp aiming devices are under the hood near

the headlamps.

If you believe your headlamps need horizontal

(left/right) adjustment, follow the horizontal aiming

procedure. If you believe your headlamps need only

vertical (up/down) adjustment, follow only the vertical

aiming procedure.

Adjustment screws can be turned with an E8 Torx

�

socket or T15 Torx screwdriver.Headlamp Horizontal Aiming

Turn the horizontal aiming screw (A) until the indicator (B)

is lined up with zero.

Once the horizontal aim is adjusted, then adjust the

vertical aim.

Page 356 of 427

6-44

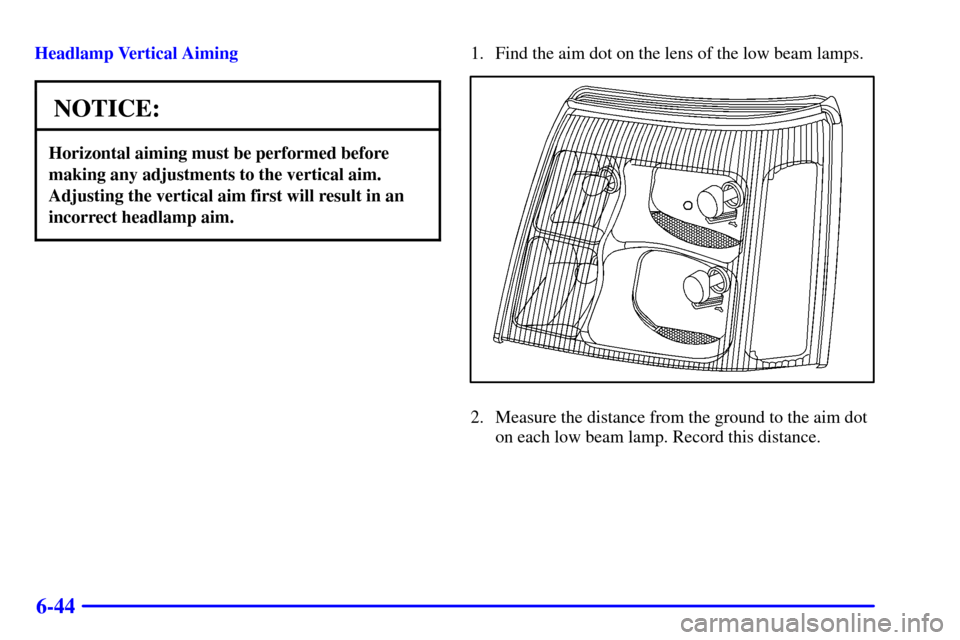

Headlamp Vertical Aiming

NOTICE:

Horizontal aiming must be performed before

making any adjustments to the vertical aim.

Adjusting the vertical aim first will result in an

incorrect headlamp aim.

1. Find the aim dot on the lens of the low beam lamps.

2. Measure the distance from the ground to the aim dot

on each low beam lamp. Record this distance.

Page 357 of 427

6-45

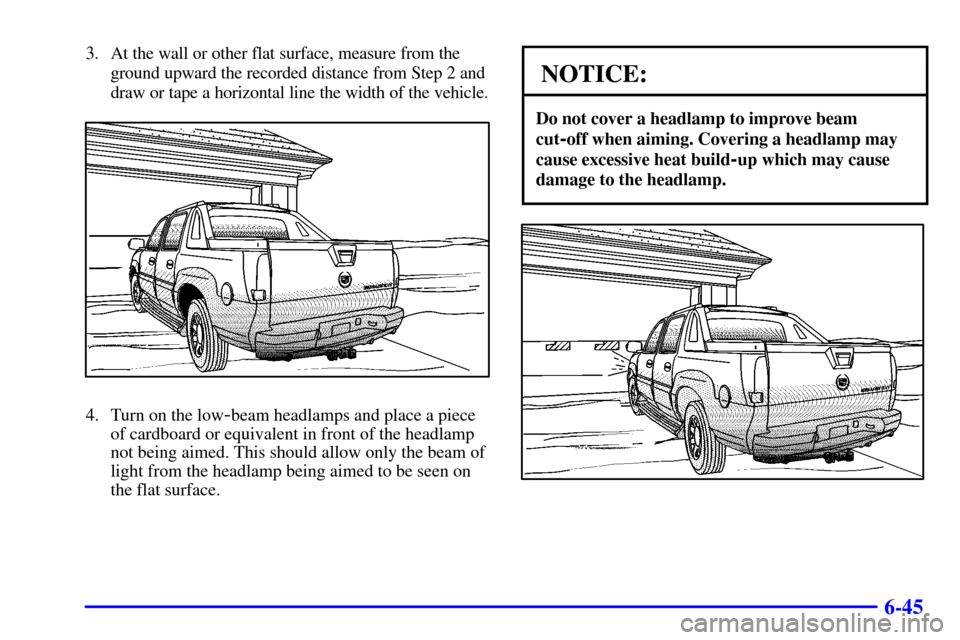

3. At the wall or other flat surface, measure from the

ground upward the recorded distance from Step 2 and

draw or tape a horizontal line the width of the vehicle.

4. Turn on the low-beam headlamps and place a piece

of cardboard or equivalent in front of the headlamp

not being aimed. This should allow only the beam of

light from the headlamp being aimed to be seen on

the flat surface.

NOTICE:

Do not cover a headlamp to improve beam

cut

-off when aiming. Covering a headlamp may

cause excessive heat build

-up which may cause

damage to the headlamp.

Page 358 of 427

6-46

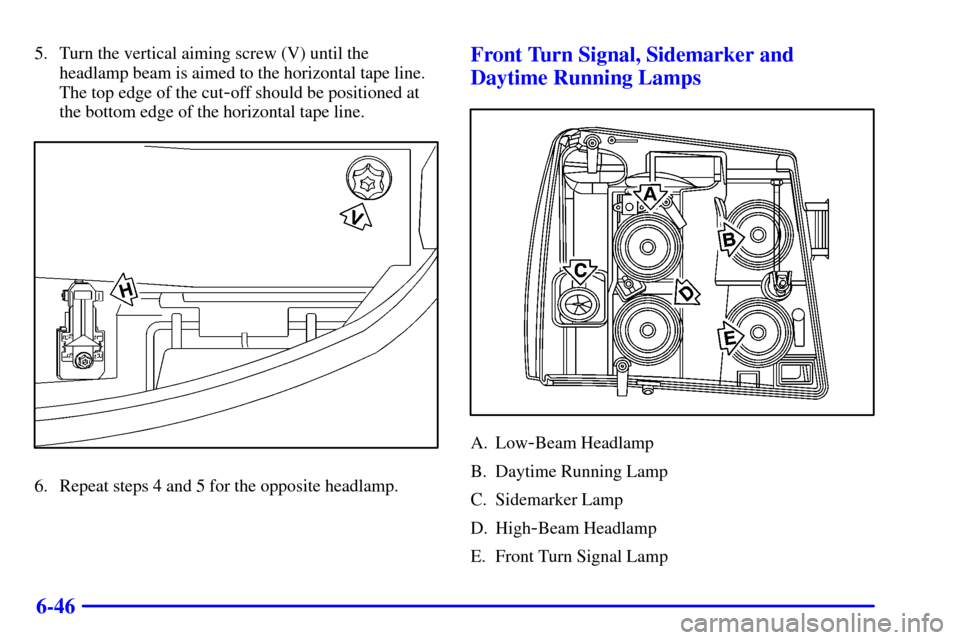

5. Turn the vertical aiming screw (V) until the

headlamp beam is aimed to the horizontal tape line.

The top edge of the cut

-off should be positioned at

the bottom edge of the horizontal tape line.

6. Repeat steps 4 and 5 for the opposite headlamp.

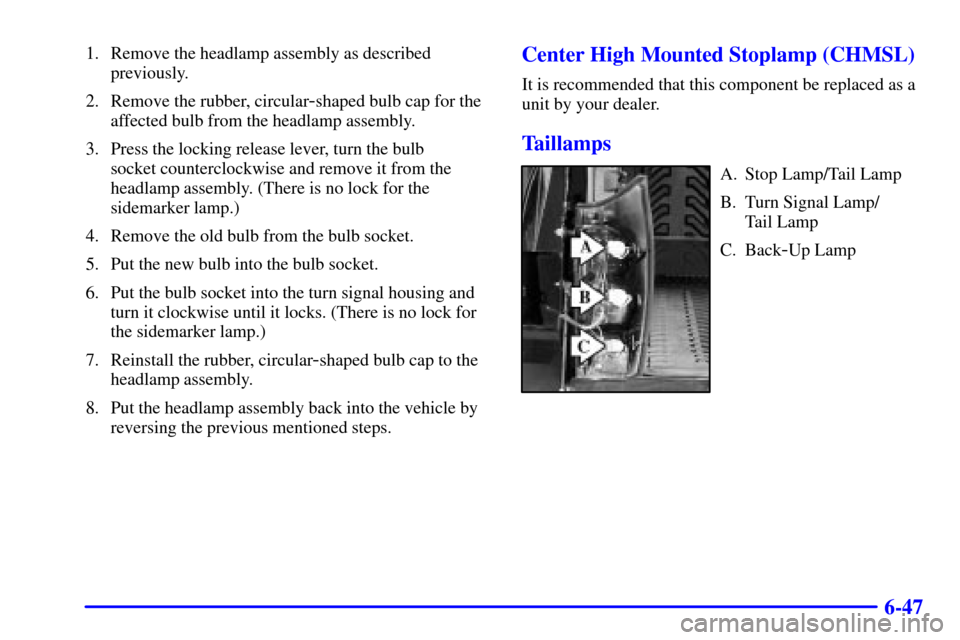

Front Turn Signal, Sidemarker and

Daytime Running Lamps

A. Low-Beam Headlamp

B. Daytime Running Lamp

C. Sidemarker Lamp

D. High

-Beam Headlamp

E. Front Turn Signal Lamp

Page 359 of 427

6-47

1. Remove the headlamp assembly as described

previously.

2. Remove the rubber, circular

-shaped bulb cap for the

affected bulb from the headlamp assembly.

3. Press the locking release lever, turn the bulb

socket counterclockwise and remove it from the

headlamp assembly. (There is no lock for the

sidemarker lamp.)

4. Remove the old bulb from the bulb socket.

5. Put the new bulb into the bulb socket.

6. Put the bulb socket into the turn signal housing and

turn it clockwise until it locks. (There is no lock for

the sidemarker lamp.)

7. Reinstall the rubber, circular

-shaped bulb cap to the

headlamp assembly.

8. Put the headlamp assembly back into the vehicle by

reversing the previous mentioned steps.

Center High Mounted Stoplamp (CHMSL)

It is recommended that this component be replaced as a

unit by your dealer.

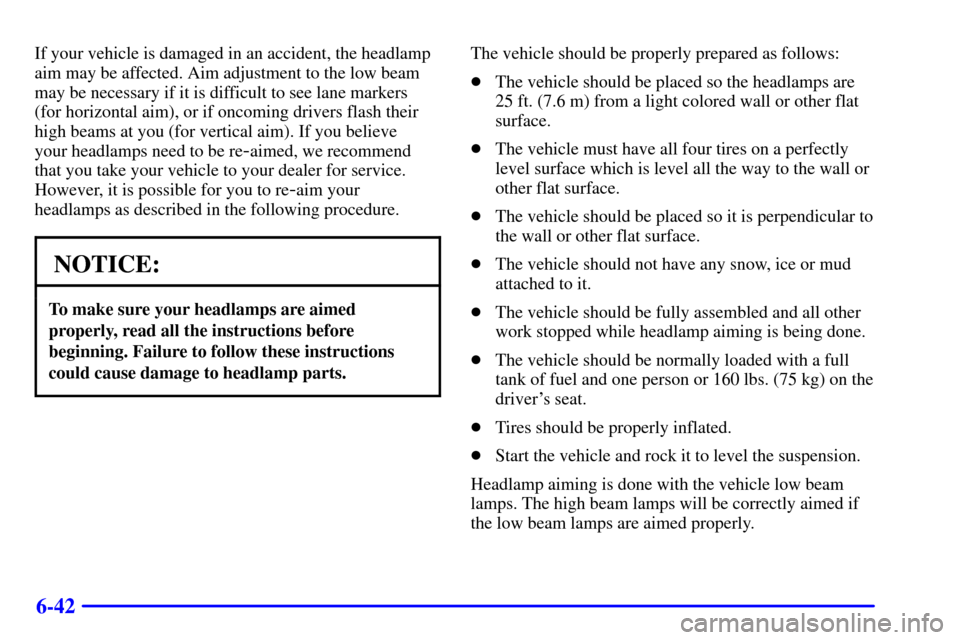

Taillamps

A. Stop Lamp/Tail Lamp

B. Turn Signal Lamp/

Tail Lamp

C. Back

-Up Lamp

Page 360 of 427

6-48

1. Remove the two screws

from the lamp assembly.

2. Remove the lamp assembly.3. Press the release tab and

turn the bulb socket

counterclockwise to

remove it from the

taillamp housing.

4. Pull the bulb straight out from the socket.

5. Press a new bulb into the socket, insert it into the

taillamp housing and turn the socket clockwise into

the taillamp housing until it clicks.

6. Reinstall the rear lamp assembly and tighten

the screws.

Trending: air filter, air condition, air suspension, oil additives, rear view mirror, service, CD player