torque CADILLAC SEVILLE 1993 4.G Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 1993, Model line: SEVILLE, Model: CADILLAC SEVILLE 1993 4.GPages: 407, PDF Size: 22.28 MB

Page 137 of 407

Downloaded from www.Manualslib.com manuals search engine GARAGE DOOR OPENER (OPTION)

This option allows you

to open up to three

garage doors. The

transmitter unit fits the

overhead panel.

Your Cadillac dealer can tell you about the hand held power pack unit

and the installation you’ll need at home to make this work. If your

Cadillac is equipped with an Electriclears heated windshield,

you’ll have

to be closer to the garage door for the transmitter unit to work.

FLOOR MATS

If your Cadillac is equipped with rubber-backed front and rear floor mats,

keep them clean by vacuuming and using a spot cleaner,

if necessary. Do

not machine wash.

TRACTION CONTROL SYSTEM (STS)

Tour traction control system operates only when the system senses that

one or both

of the front wheels is spinning or beginning to lose traction

while driving. This is especially useful

in slippery road conditions. The

traction control system works at all speeds. It limits wheel spin

by using

the antilock and brake systems

to apply the front brakes and by shutting

off furl injectors to reduce engine torque.

You may be able to spin the tires when accelerating from a standstill on

dry

pavement. This is normal. The “Traction Active” message will display on the

drive’s information center when the traction control system is operating.

You may feel the system working through slight movement

of the

accelerator pedal, or you may notice some noise, but this is normal.

Your driver information center is an important source

of information about

your traction control system. See “Driver Information Center” in the Index.

123

Page 221 of 407

Downloaded from www.Manualslib.com manuals search engine F

P

r

I 1

P

c

c

c

c

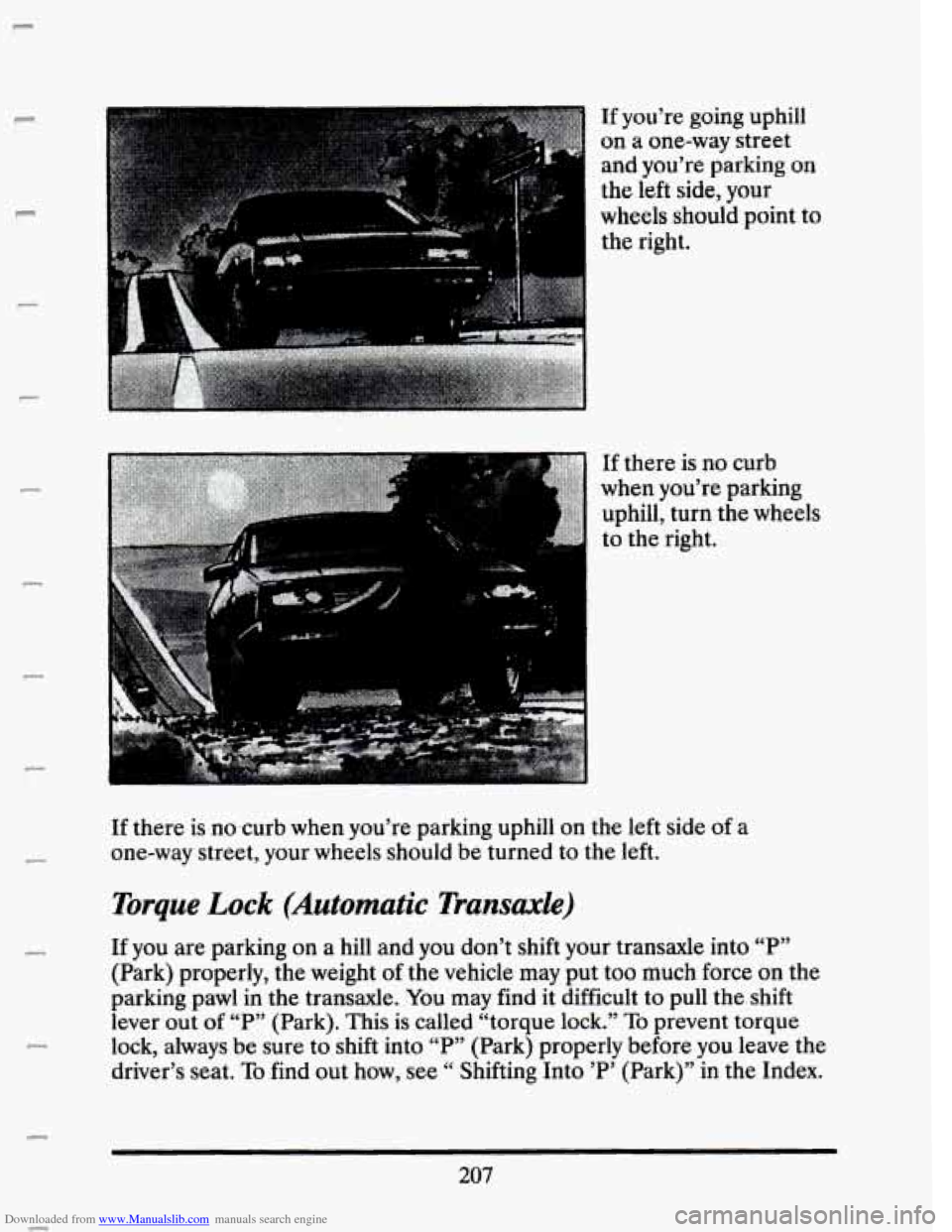

If you’re going uphill

on a one-way street

and you’re parking on

the left side, your

wheels should point to

the right.

.. , . -.

If there is no curb

when you’re parking

uphill, turn the wheels

to the right.

If there is no,curb when you’re parking uphill on the left side

of a

one-way street, your wheels should

be turned to the left.

Torque Lock (Automatic Transaxle)

If you are parking on a hill and you don’t shift your transaxle into “P”

(Park) properly, the weight

of the vehicle may put too much force on the

parking pawl in the transaxle. You may find it difficult to

pull the shift

lever out

of “P” (Park). This is called “torque lock.” To prevent torque

lock, always

be sure to shift into “P” (Park) properly before you leave the

driver’s seat.

To find out how, see “ Shifting Into ’P’ (Park)” in the Index.

c

207

P

Page 222 of 407

Downloaded from www.Manualslib.com manuals search engine If “torque lock” does occur, you may need to have another vehicle pusn

yours a little uphill to take some of the pressure from the transaxle, so

you can pull the shift lever out of “P” (Park).

‘WINTER DmNG

V

Here are some tips for winter driving:

0 Have your Cadillac in good shape for winter. Be sure your engine

coolant

mix is correct.

Snow tires can help in loose snow, but they may give you less traction

on ice than regular tires.

If you do not expect to be driving in deep

snow,

but may have to travel over ice, you may not want to switch to

snow tires at all.

You may want to put winter emergency supplies in your trunk.

208

U

Page 271 of 407

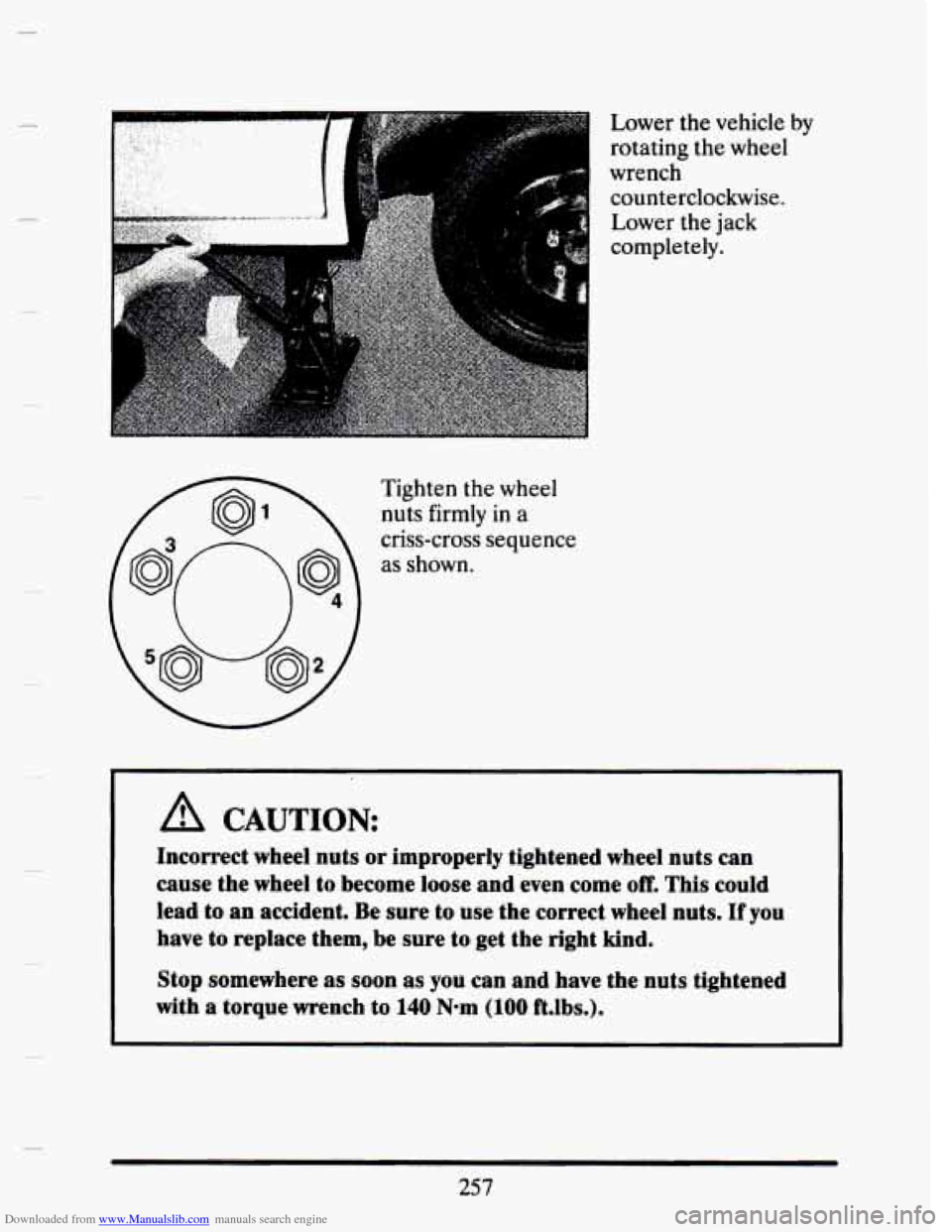

Downloaded from www.Manualslib.com manuals search engine Lower the vehicle by

rotating the wheel

wrench

counterclockwise.

Tighten the wheel nuts

firmly in a

criss-cross sequence as shown. Lower the jack

completely.

1 A CAUTION:

Incorrect wheel nuts or improperly tightened wheel nuts can

cause the wheel to become loose and even come

off. This could

lead to an accident. Be sure to use the correct wheel nuts.

If you

have to replace them, be sure to get the right kind.

Stop somewhere

as soon as you can and have the nuts tightened

with a torque wrench to 140 Nm (100 ft.lbs.).

257

Page 323 of 407

Downloaded from www.Manualslib.com manuals search engine STS recommended tire size is:

GA Performance Blackwall (P225/60ZR 16)

Don’t forget your compact spare tire. It should be at 60 psi (420 kPa).

How to Check Use a good quality pocket-type gage to check tire

pressure. Simply looking at the tires

will not tell you the pressure,

especially if you have radial tires

-- which may look properly inflated even

if they’re underinflated.

If your tires have valve caps, be sure to put them back on. They help

prevent leaks

by keeping out dirt and moisture.

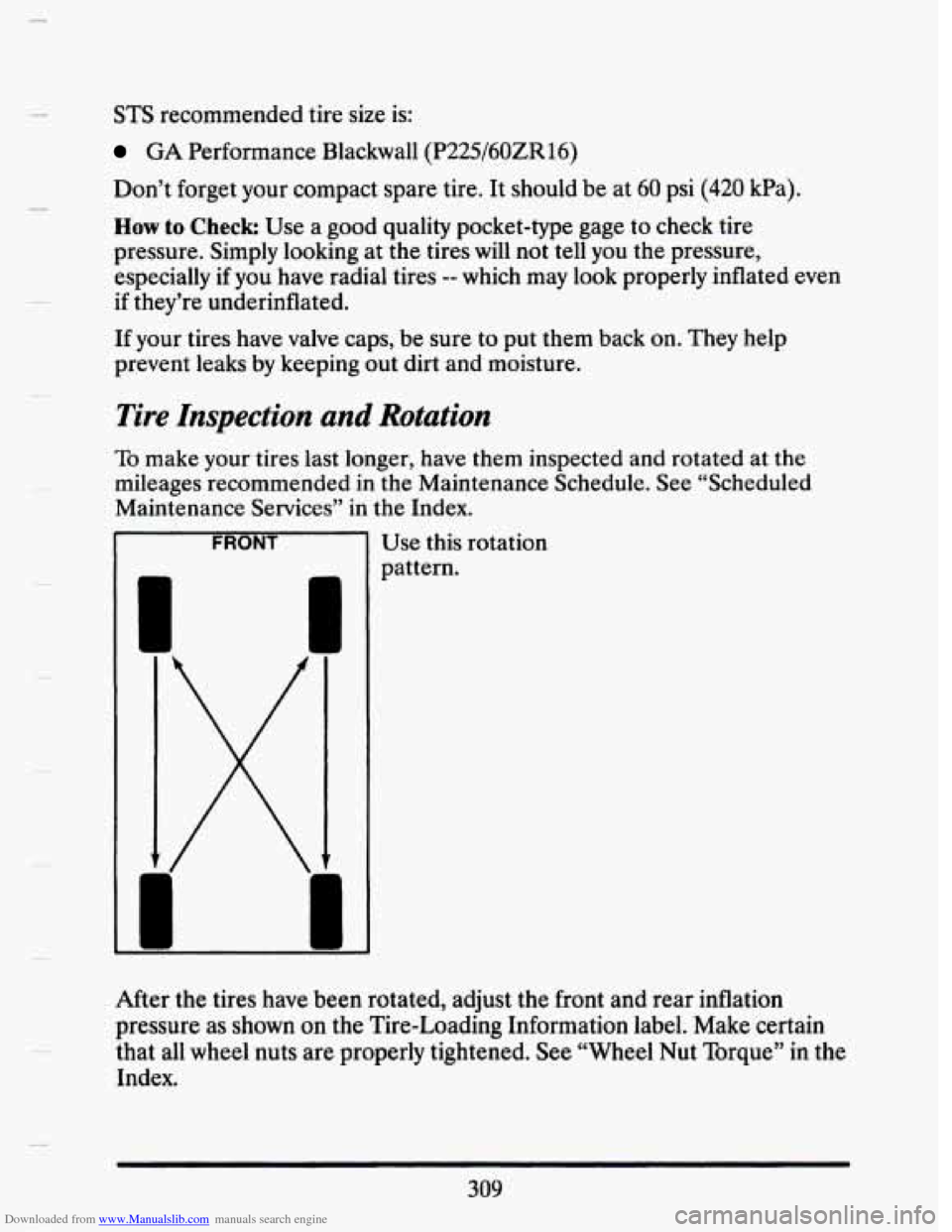

Tire Inspection and Rotation

To make your tires last longer, have them inspected and rotated at the

mileages recommended

in the Maintenance Schedule. See “Scheduled

Maintenance Services”

in the Index.

FRONT Use this rotation

pattern.

After the tires have been rotated, adjust the front and rear inflation

pressure as

shown on the Tire-Loading Information label. Make certain

that

all wheel nuts are properly tightened. See “Wheel Nut Torque’’ in the

Index.

309

Page 354 of 407

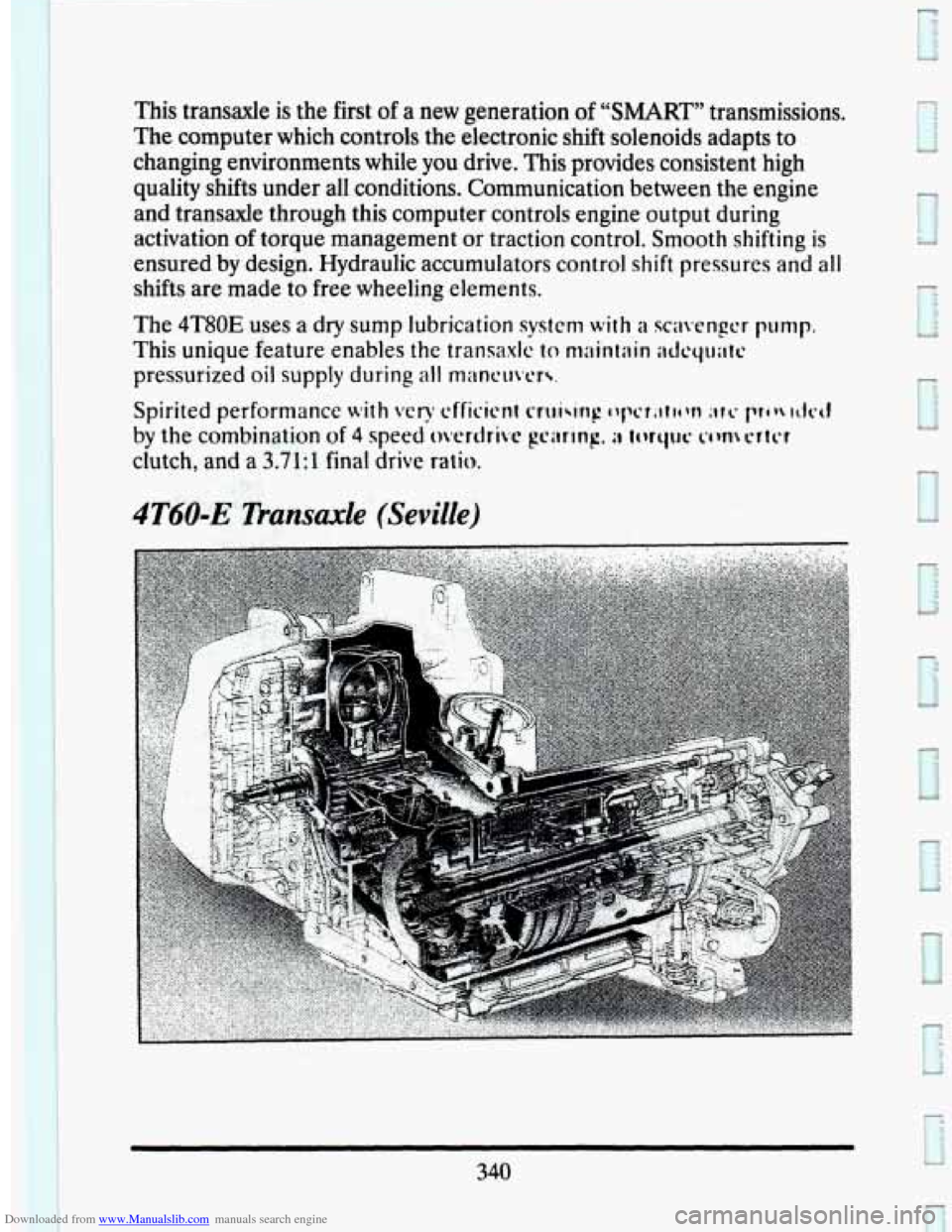

Downloaded from www.Manualslib.com manuals search engine This transaxle is the first of a new generation of “SMART” transmissions.

The computer which controls the electronic shift solenoids adapts to

changing environments while you drive. This provides consistent high

quality shifts under all conditions. Communication between the engine

and transaxle through this computer controls engine output during

activation

of torque management or traction control. Smooth shifting is

ensured by design. Hydraulic accumulators control shift pressures and all

shifts are made to free wheeling elements.

The 4T80E uses a

dry sump lubrication system with a scavenger pump.

This unique feature enables the transaxlc to maintain itdcqlriltt!

pressurized oil supply during all mancl~vcr\.

340

Page 355 of 407

Downloaded from www.Manualslib.com manuals search engine The Hydra-matic 4T60-E 4-speed overdrive, electronic transaxle consists

primarily of a five element torque converter;

two planetary gear sets,

various clutches, final drive assembly, differential assembly, an\

d a control

valve body.

The torque converter houses a pump, turbine, pressure plate which is

splined to the turbine, and a stator assembly, serving as a fluid coupling, it

smoothly transmits power

from the engine to the transaxle. It also

hydraulically provides additional torque

when required. When applied,

the pressure plate provides a mechanical direct drive coupling of the

engine to the transaxle.

The

two planetary gear sets provide the four forward gear ratios and

reverse. Changing of the gear ratios is

fully automatic and is

accomplished through the use

of various electronic and mechanical

requirements. Four multiple disc clutches,

two roller clutches, a sprag

clutch, and three bands provide the friction elements required to obtain

the various ratios with the planetary gear sets.

A hydraulic system (the control valve body), pressurized by a vane type

pump provides the working pressure needed to operate the friction

elements and automatic controls.

341

Page 359 of 407

Downloaded from www.Manualslib.com manuals search engine The power rack and pinion steering system has a rotary spool valve which

directs hydraulic fluid coming from the power steering pump to one side

or the other side

of the rack piston. The integral rack piston is attached to

the rack. The rack piston converts hydraulic pressure to a linear force

which moves the rack left or right. The force is then transmitted through

the inner and outer tie rods to the steering knuckles, which turn the

wheels

If hydraulic assist

is not available, manual control is maintained. However

under these conditions more steering effort is required.

4.6 LITER NORTHSTAR ENGINE

Displacement ............................... .4.6L (279 cu.in.)

No. of Cylinders ................ 32-valve DOHC 8 - 90 Degree V

Power (Acc.

to SAE 51349) ............... 295 (bhp @ 6000 rpm

..................................... 220 (kW @ 6000rpm

Torque (ACC. to

SAE 51349) ............ 290 (lbs. ft. @ 4400 rpm

Bore ........................................ 93mm (3.66 in.)

Stroke

...................................... .84mm (3.31in.)

Compression Ratio

................................... 10.3:l

Cylinder Heads ............................... Cast Aluminum

Intake Manifold

........................ Die Cast Magnesium /

........................... Thermoplastic Air Induction nbes

Valve System

................... Direct Acting Hydraulic Tappets

Intake Valve

................................. 33mm (1.29 in.)

Exhaust Valve

................................ 29mm (1.14 in.)

Pistons

...................................... Cast Aluminum

Firing Order

.................................. 1-2-7-3-4-5-6-8

Left Bank

.......................................... 2-4-6-8

Right Bank

......................................... 1-3-5-7

Camshaft

................... Induction Hardened Cast Grey Iron

Drive Type

........ Single Row / Staged Drive 8 mm Roller Chain

Main Bearings

......................................... Five

1

1 .................................... 393 (Ndm @ 4400 rpm

Cylinder Block

...... Die Cast Aluminum with Iron Cylinder Bores

345

Page 360 of 407

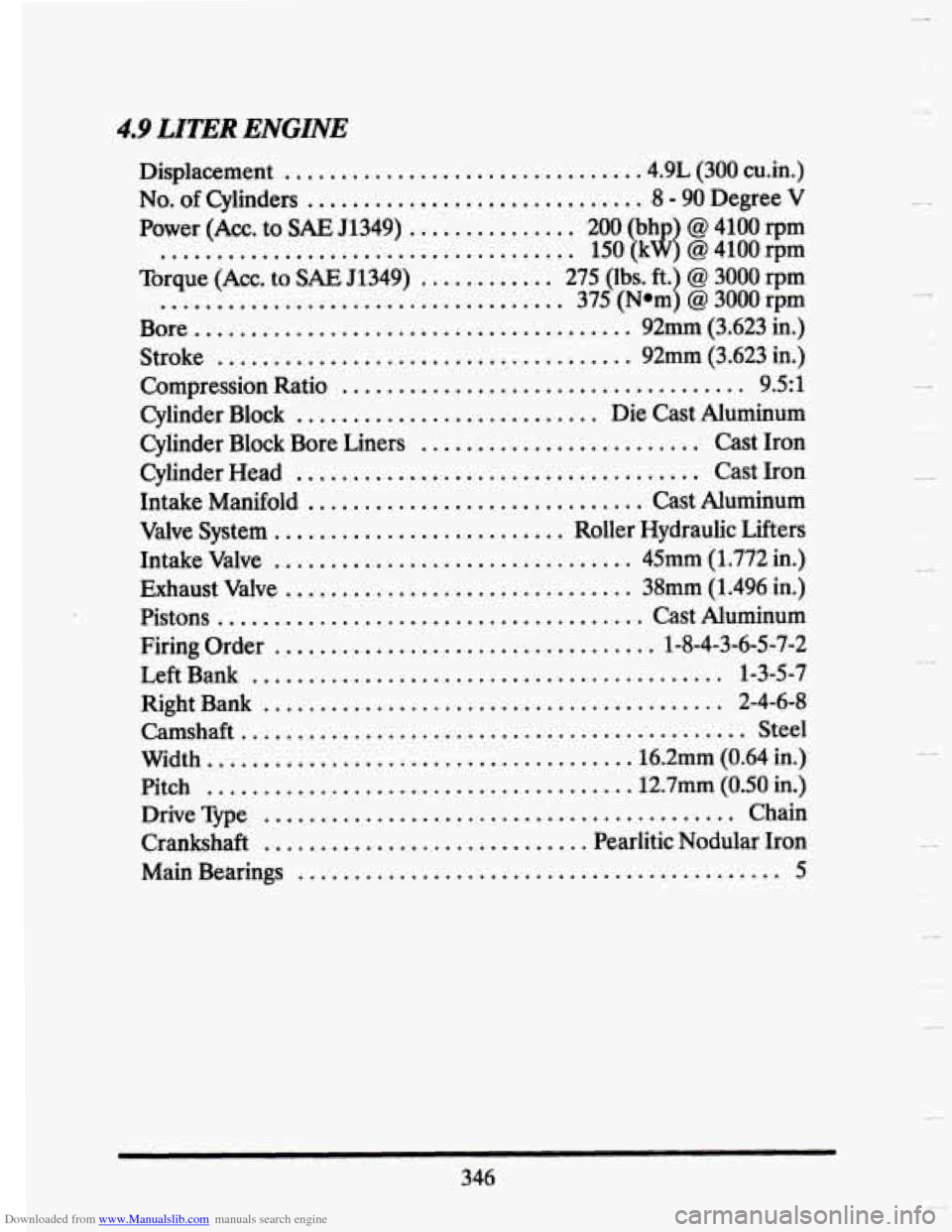

Downloaded from www.Manualslib.com manuals search engine 4.9 LITER ENGINE

Displacement ............................... .4.9L (300 cuin.)

No.

of Cylinders .............................. 8 - 90 Degree V

Power (Acc. to SAE 51349) ............... 200 (bhp @ 4100 rpm

Torque (ACC.

to SAE 51349) ............ 275 (lbs. ft. @ 3000 rpm

Bore

....................................... 92mm (3.623 in.)

Stroke

..................................... 92mm (3.623 in.)

Compression Ratio

.................................... 9.5: 1

Cyiinder Block ........................... Die Cast Aluminum

Cylinder Block Bore Liners

......................... Cast Iron

Cylinder Head

.................................... Cast Iron

Intake Manifold

.............................. Cast Aluminum

Valve System

.......................... Roller Hydraulic Lifters

Intake Valve

................................ 45mm (1.772 in.)

Exhaust Valve

............................... 38mm (1.496 in.)

Pistons

...................................... Cast Aluminum

Firing Order

.................................. 1-8-4-3-6-5-7-2

Left Bank

.......................................... 1-3-5-7

Right Bank

......................................... 2-4-6-8

Camsha

............................................... Steel

Width.

..................................... 16.2mm (0.64 in.)

Pitch

..................................... .12.7mm (0.50 in.)

Drive Vpe

.......................................... Chain

Crankshaft

............................. Pearlitic Nodular Iron

..................................... 150 (kW @ 4100 rpm

.................................... 375 (Nom @ 3000 rpm

1

1

I

Main Bearings ........................................... 5

346

Page 361 of 407

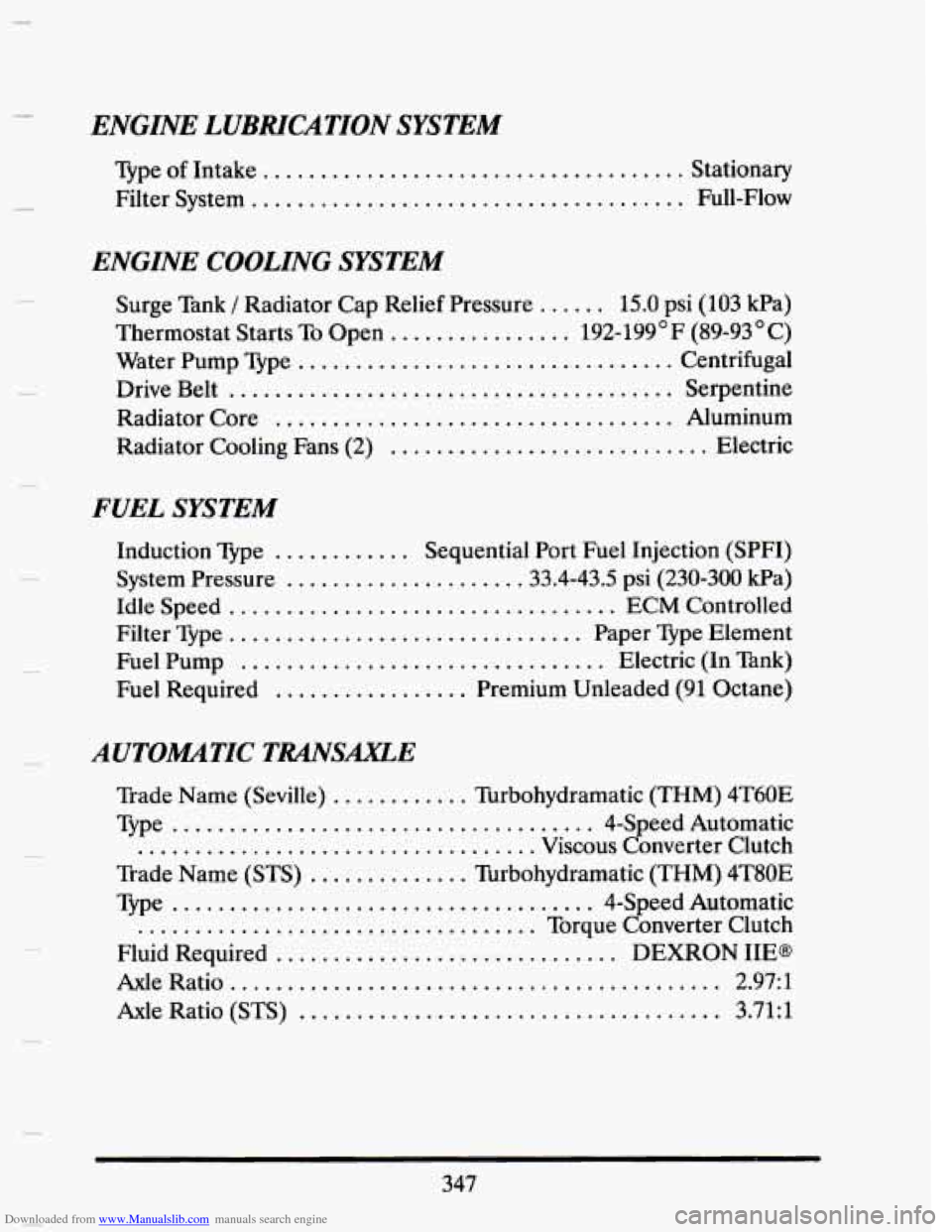

Downloaded from www.Manualslib.com manuals search engine ENGINE LUBRICATION SYSTEM

Type of Intake ..................................... Stationary

Filter System

...................................... Full-Flow

ENGINE COOLING SYSTEM

Surge Tank / Radiator Cap Relief Pressure ...... 15.0 psi (103 kPa)

Thermostat Starts To Open

................ 192-199°F (89-93OC)

Water Pump Type

................................. Centrifugal

Drive Belt

....................................... Serpentine

Radiator Core

................................... Aluminum

Radiator Cooling Fans

(2) ............................ Electric

FUEL SYSTEM

Induction Type ............ Sequential Port Fuel Injection (SPFI)

System Pressure

.................... -33.4-43.5 psi (230-300 kPa)

Idle Speed

.................................. ECM Controlled

Filter Type

............................... Paper Type Element

Fuel Pump

................................ Electric (In Tank)

Fuel Required

................. Premium Unleaded (91 Octane)

AUTOlMATIC TRANSAXLE

Trade Name (Seville) ............ Turbohydramatic (THM) 4T60E

Type

..................................... 4-Speed Automatic

................................... Viscous Converter Clutch

Trade Name

(STS) .............. Turbohydramatic (THM) 4T80E

Type

..................................... 4-Speed Automatic

................................... Torque Converter Clutch

Fluid Required .............................. DEXRON IIEB

Axle Ratio ........................................... 2.97:l

Axle Ratio (STS) ..................................... 3.71:l

347