CADILLAC SEVILLE 1998 4.G Owners Manual

Manufacturer: CADILLAC, Model Year: 1998, Model line: SEVILLE, Model: CADILLAC SEVILLE 1998 4.GPages: 378, PDF Size: 21.99 MB

Page 311 of 378

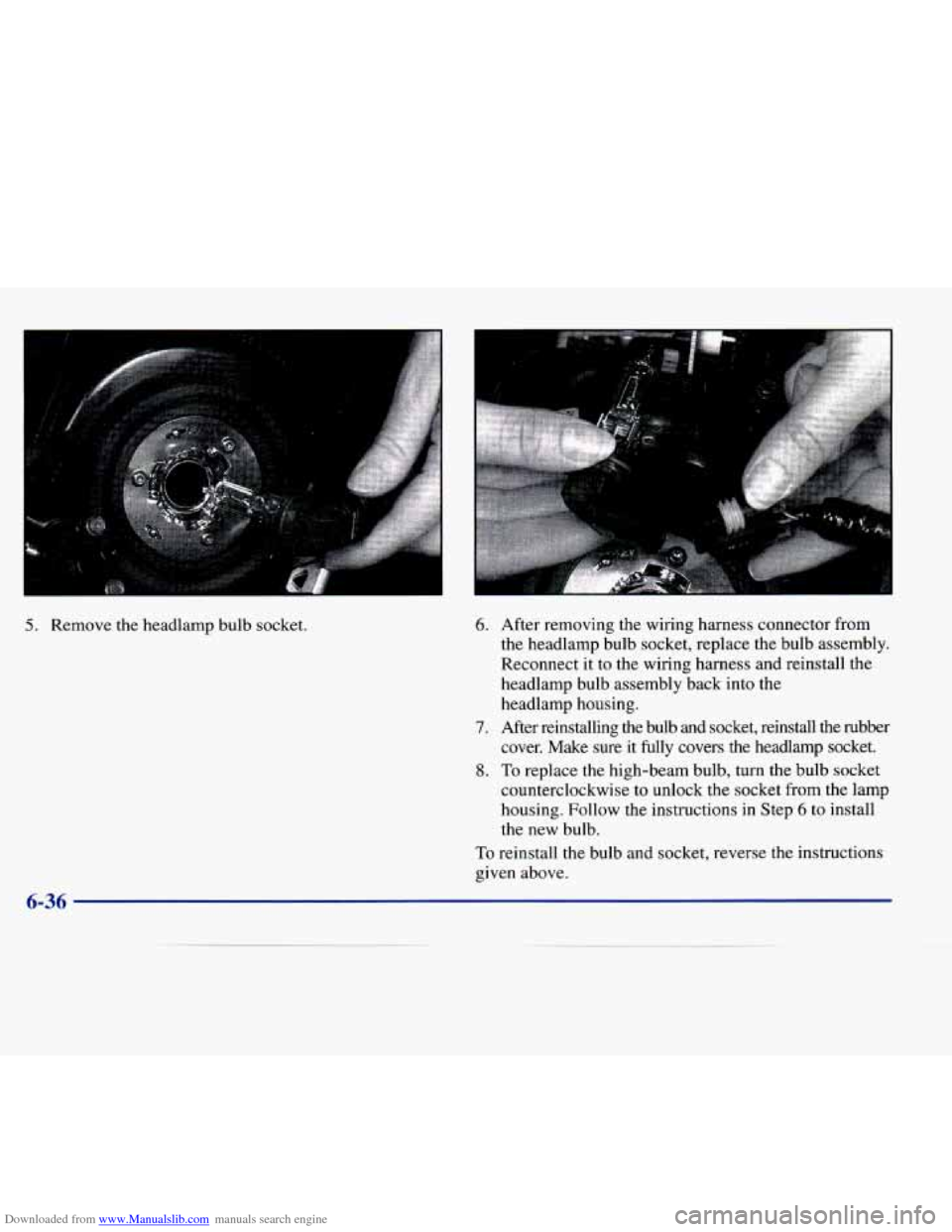

Downloaded from www.Manualslib.com manuals search engine 5. Remove the headlamp bulb socket. 6.

7.

8.

After removing the wiring harness connector from

the headlamp bulb socket, replace the bulb assembly.

Reconnect it to the wiring harness and reinstall the

headlamp bulb assembly back into the

headlamp housing.

After reinstalling the bulb and socket, reinstall the rubber

cover. Make sure it fully covers the headlamp socket.

To replace the high-beam bulb, turn the bulb socket

counterclockwise to unlock the socket from the lamp

housing. Follow the instructions

in Step 6 to install

the new bulb.

To reinstall the bulb and socket, reverse the instructions

given above.

6-36

Page 312 of 378

Downloaded from www.Manualslib.com manuals search engine Headlamp Aiming

Your vehicle has the composite headlamp system.

These headlamps have horizontal and vertical aim indicators. The aim has been pre-set at the factory

and should need no further adjustment.

If your vehicle is damaged

in an accident and the

headlamp aim seems to be affected, see your dealer. Headlamps on damaged vehicles may require recalibration of the horizontal aim by your dealer.

To check the aim, the vehicle should be properly

prepared as follows:

Place the vehicle on a level pad or surface.

The vehicle should not have any snow, ice or mud

attached to it.

0

0

0

0

The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

There should not be any cargo or loading

of the

vehicle, except it should have a full tank of fuel and

one person or

160 lbs. (75 kg) on the driver’s seat.

Tires should be properly inflated.

Rock the vehicle to stabilize the suspension.

NOTICE:

To make sure your headlamps are aimed

properly, read all the instructions before

beginning. Failure to follow these instructions

could cause damage to headlamp parts.

Page 313 of 378

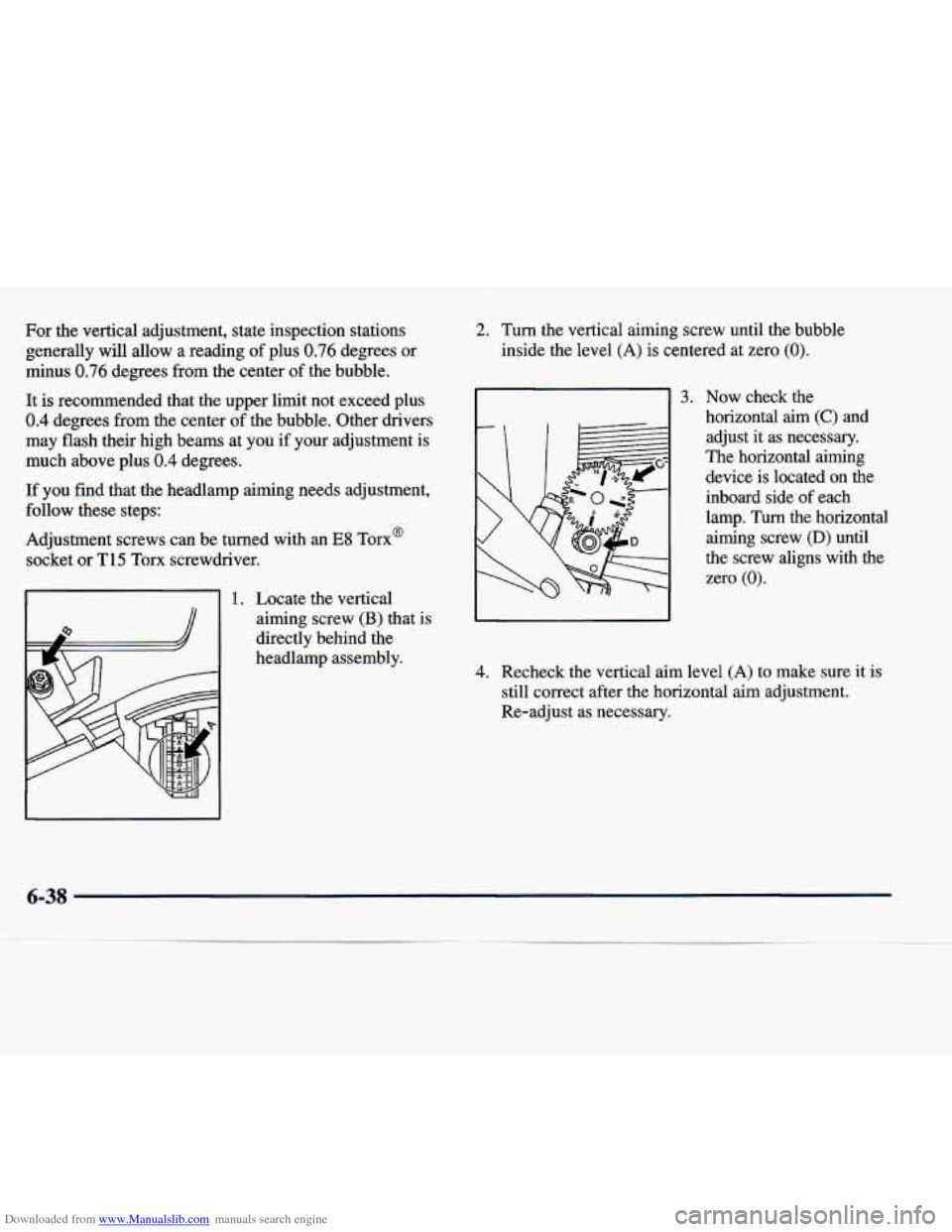

Downloaded from www.Manualslib.com manuals search engine For the vertical adjustment, state inspection stations generally

will allow a reading of plus 0.76 degrees or

minus

0.76 degrees from the center of the bubble.

It is recommended that the upper limit not exceed plus

0.4 degrees from the center of the bubble. Other drivers

may flash their high beams at you

if your adjustment is

much above plus

0.4 degrees.

If you find that the headlamp aiming needs adjustment,

follow these steps:

Adjustment screws can be turned with an

E8 Torx@

socket or

T15 Torx screwdriver.

Ill 1. Locate the vertical

aiming screw

(B) that is

directly behind the

headlamp assembly.

2. Turn the vertical aiming screw until the bubble

inside the level

(A) is centered at zero (0).

3. Now check the horizontal

aim (C) and

adjust it as necessary.

The horizontal aiming

device is located on the

inboard side of each

lamp. Turn the horizontal

aiming screw

(D) until

the screw aligns with the

zero

(0).

4. Recheck the vertical aim level (A) to make sure it is

still correct after the horizontal aim adjustment.

Re-adjust as necessary.

6-38

Page 314 of 378

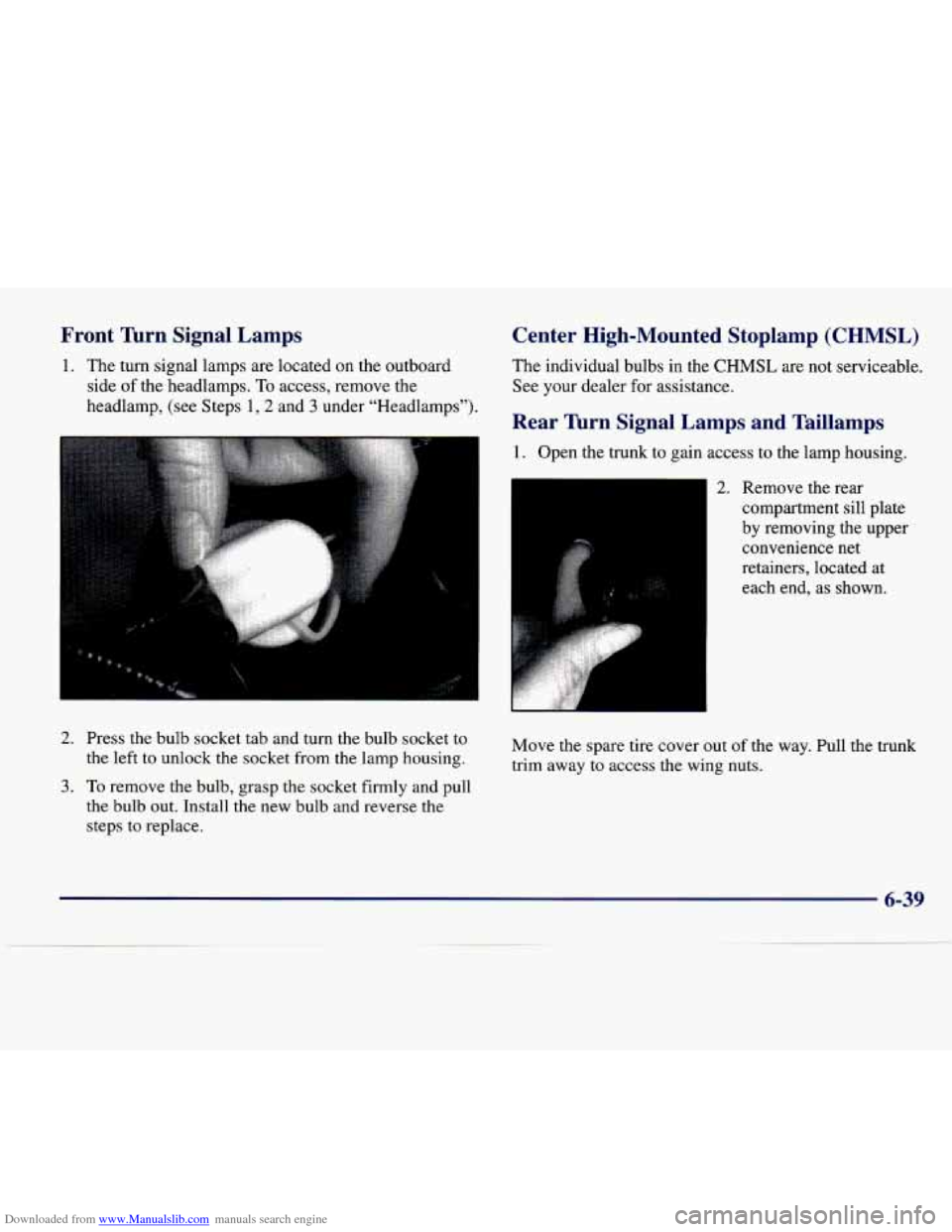

Downloaded from www.Manualslib.com manuals search engine Front Tlurn Signal Lamps

1. The turn signal lamps are located on the outboard

side of the headlamps. To access, remove the

headlamp,

(see Steps 1,2 and 3 under “Headlamps”).

2. Press the bulb socket tab and turn the bulb socket to

the left to unlock the socket from the lamp housing.

3. To remove the bulb, grasp the socket firmly and pull

the bulb out. Install the new bulb and reverse the

steps

to replace.

Center High-Mounted Stoplamp (CHMSL)

The individual bulbs in the CHMSL are not serviceable.

See your dealer for assistance.

Rear Turn Signal Lamps and Taillamps

1. Open the trunk to gain access to the lamp housing.

2. Remove the rear

compartment sill plate

by removing the upper

convenience net

retainers, located at

each end, as shown.

Move the spare tire cover out

of the way. Pull the trunk

trim away to access the wing nuts.

6-39

Page 315 of 378

Downloaded from www.Manualslib.com manuals search engine _I

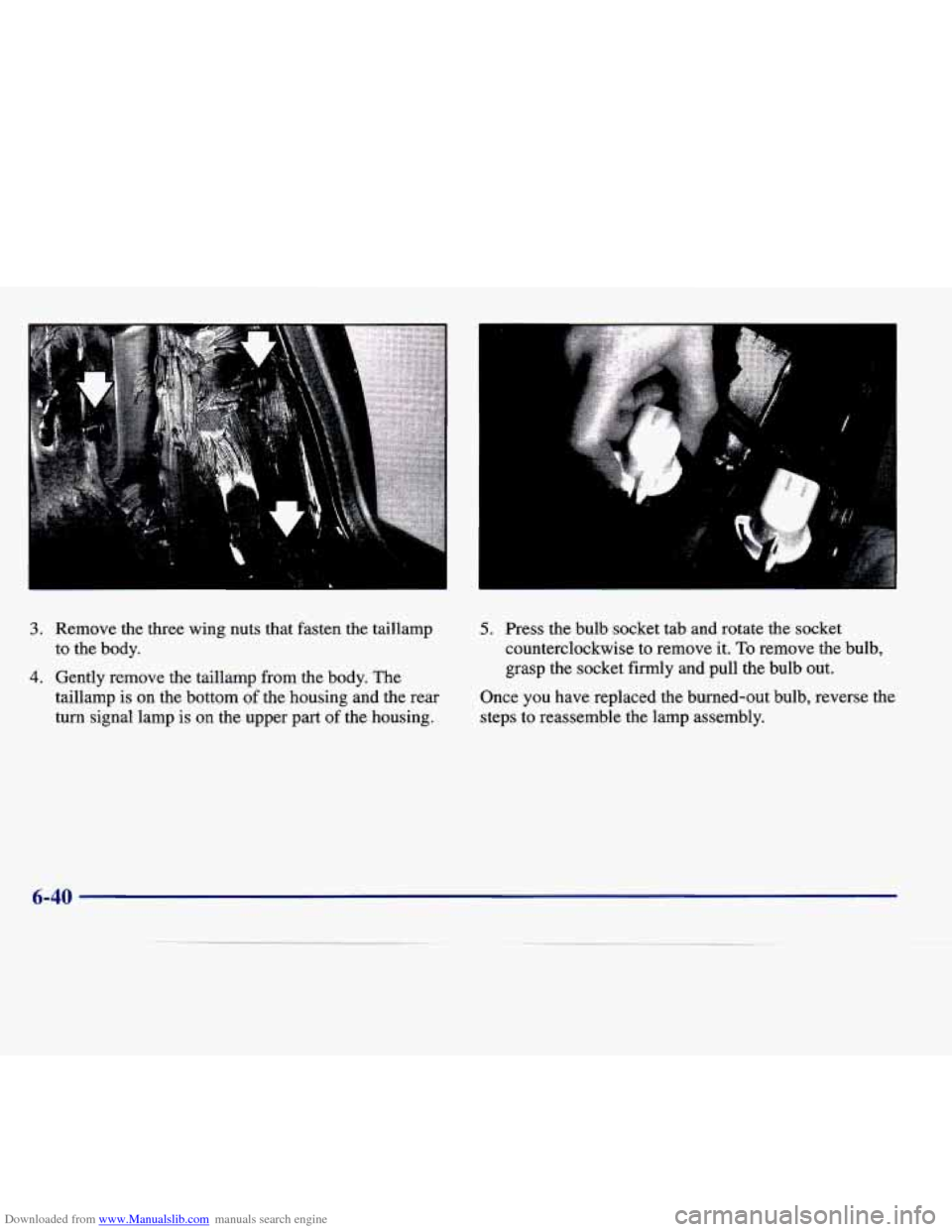

3. Remove the three wing nuts that fasten the taillamp

to the body.

4. Gently remove the taillamp from the body. The

taillamp

is on the bottom of the housing and the rear

turn signal lamp is on the upper part of the housing.

5. Press the bulb socket tab and rotate the socket

counterclockwise to remove it. To remove the bulb,

grasp the socket

firmly and pull the bulb out.

Once you have replaced the burned-out bulb, reverse the

steps to reassemble the lamp assembly.

6-40

Page 316 of 378

Downloaded from www.Manualslib.com manuals search engine Windshield Wiper Blade -

Replacement

It’s a good idea to clean or replace the wiper blade assembly on a regular basis or when worn. For proper

windshield wiper blade length and type, see “Normal

Maintenance Replacement

Parts” later in this section.

To replace the wiper blade assembly:

1. Lift the wiper up from the windshield and set into

the vertically-locked position.

2. Press the tab that holds the wiper blade to the arm.

3. Slide the blade down and off the arm.

4. Slide in the new blade and snap into place.

Tires

Your new vehicle comes with high-quality tires made by

a leading tire manufacturer.

If you ever have questions

about your tire warranty and where to obtain service, see

your Cadillac Warranty booklet for details.

6-41

Page 317 of 378

Downloaded from www.Manualslib.com manuals search engine A CAUTION:

Poorly maintained and improperly used tires

are dangerous.

e

e

e

Overloading your tires can cause

overheating as

a result of too much friction.

You could have an air-out and a serious

accident. See “Loading Your Vehicle” in

the Index.

Underinflated tires pose the same danger as

overloaded tires. The resulting accident

could cause serious injury. Check all tires

frequently to maintain the recommended

pressure. Tire pressure should be checked

when your tires are cold.

Overinflated

tires are more likely to be

cut, punctured or broken by

a sudden

impact

-- such as when you hit a pothole.

Keep tires

at the recommended pressure.

CAUTION: (Continued)

I CAUTION: (Continued) I

0 Worn, old tires can cause accidents. If your

tread is badly worn, or if your tires have

been damaged, replace them.

See “Inflation

-- Tire Pressure” in this section

for inflation pressure adjustment for higher

speed driving.

Inflation -- Tire Pressure

The Tire-Loading Information label, which is located an

the rear edge of the driver’s door, shows the correct

inflation pressures

for your tires when they’re cold.

“Cold” means your vehicle has been sitting for at least

three hours or driven no more than

1 mile (1.6 km).

If you’ll be driving at high speeds (e.g., speeds of 100 mph

(160 km/h) or higher), where it is legal, set the cold

inflation pressure to the maximum inflation pressure

shown on the tire sidewall, or to

38 psi (265 Wa),

whichever is lower. See the example below. When you end

this high-speed driving, return to the cold inflation

pressure shown on the Tire-Loading Information label.

6-42

Page 318 of 378

Downloaded from www.Manualslib.com manuals search engine Example:

You’ll find maximum load and inflation pressure

molded on the tire’s sidewall, in small letters, near the

rim flange. It will read something

like this: Maximum

load

690 kg (1521 lbs.) @ 300 kPa (44 psi) Max. Press.

For this example, you would set the inflation pressure

for high-speed driving at

38 psi (265 kPa).

NOTICE:

Don’t let anyone tell you that underinflation or

overinflation is

all right. It’s not. If your tires

don’t have enough

air (underinflation), you can

get the following:

4) Too much flexing

4) Too much heat

4) Tire overloading

Bad wear

Bad handling

a Bad fuel economy.

NOTICE: (Continued)

I NOTICE: (Continued)

If your tires have too much air (overinflation),

you can get the following:

Unusual wear

Bad handling

Rough ride

0 Needless damage from road hazards.

When

to Check

Check your tires once a month or more.

Don’t forget your compact spare tire. It should be at

60 psi (420 Pa).

How to Check

Use a good quality pocket-type gage to check tire

pressure. You can’t

tell if your tires are properly inflated

simply by looking at them. Radial tires may

look

properly inflated even when they’re underinflated.

Be sure to put the valve caps back on the valve stems.

They help prevent leaks by keeping out

dirt and moisture.

6-43

Page 319 of 378

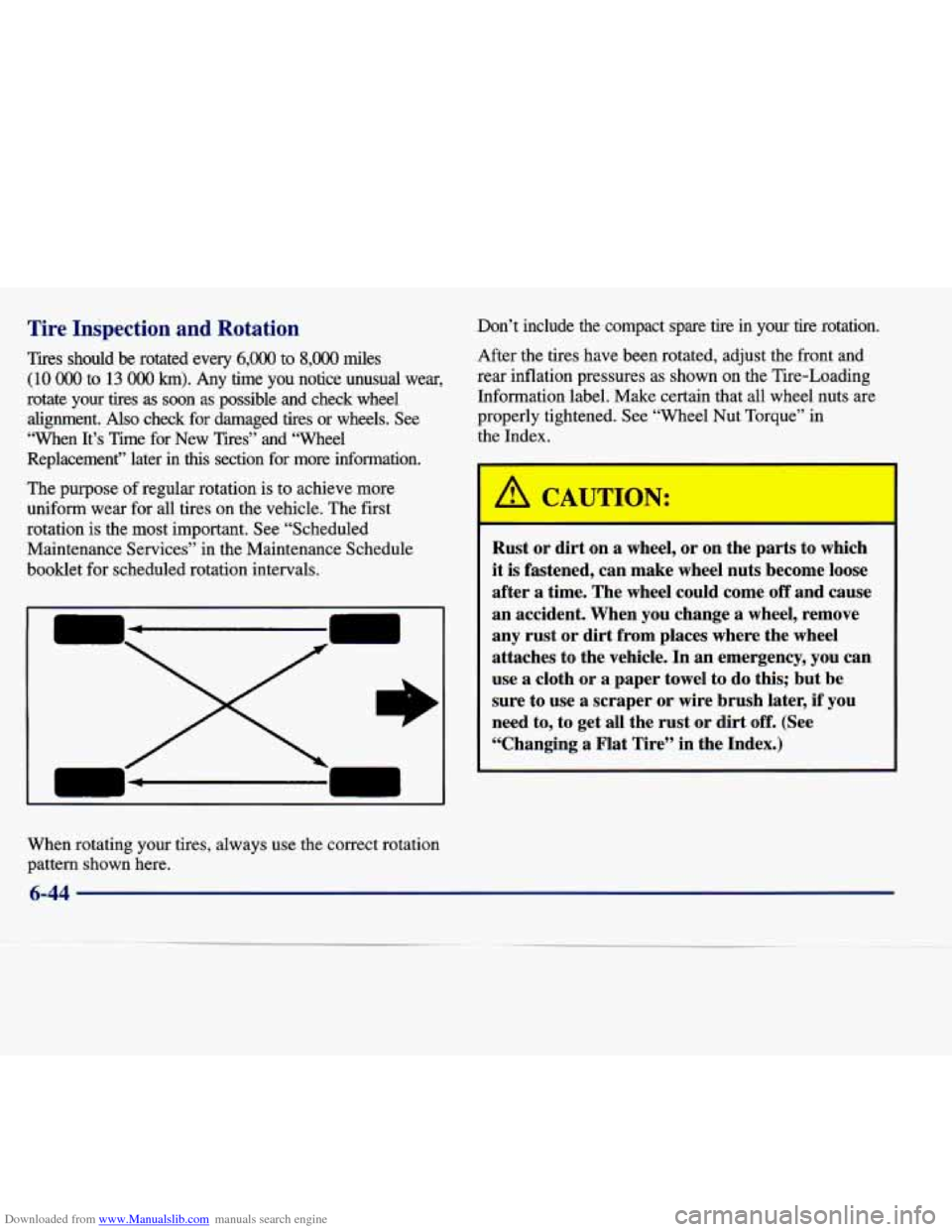

Downloaded from www.Manualslib.com manuals search engine Tire Inspection and Rotation

Tires should be rotated every 6,000 to S,O00 miles

(10 000 to 13 OOO km). Any time you notice unusual wear,

rotate

your tires as soon as possible and check wheel

alignment.

Also check for damaged tires or wheels. See

“When It’s Time for New Tires” and “Wheel

Replacement” later in

this section for more information.

The purpose of regular rotation is to achieve more

uniform wear for all tires on the vehicle. The first

rotation is the most important. See “Scheduled

Maintenance Services” in the Maintenance Schedule

booklet

for scheduled rotation intervals.

When rotating

your tires, always use the correct rotation

pattern shown here. Don’t include the compact spare tire in

your tire rotation.

After the tires have been rotated, adjust the front and

rear inflation pressures as shown on the Tire-Loading Information label. Make certain that all wheel nuts are

properly tightened. See “Wheel Nut Torque” in

the Index.

I

Rust or dirt on a wheel, or on the parts to which

it is fastened, can make wheel nuts become loose

after a time. The wheel could come

off and cause

an accident. When you change

a wheel, remove

any rust or dirt from places where the wheel

attaches to the vehicle. In an emergency, you can

use a cloth or

a paper towel to do this; but be

sure to use

a scraper or wire brush later, if you

need to, to get all the rust or dirt

off. (See

“Changing

a Flat Tire” in the Index.)

1

6-44

Page 320 of 378

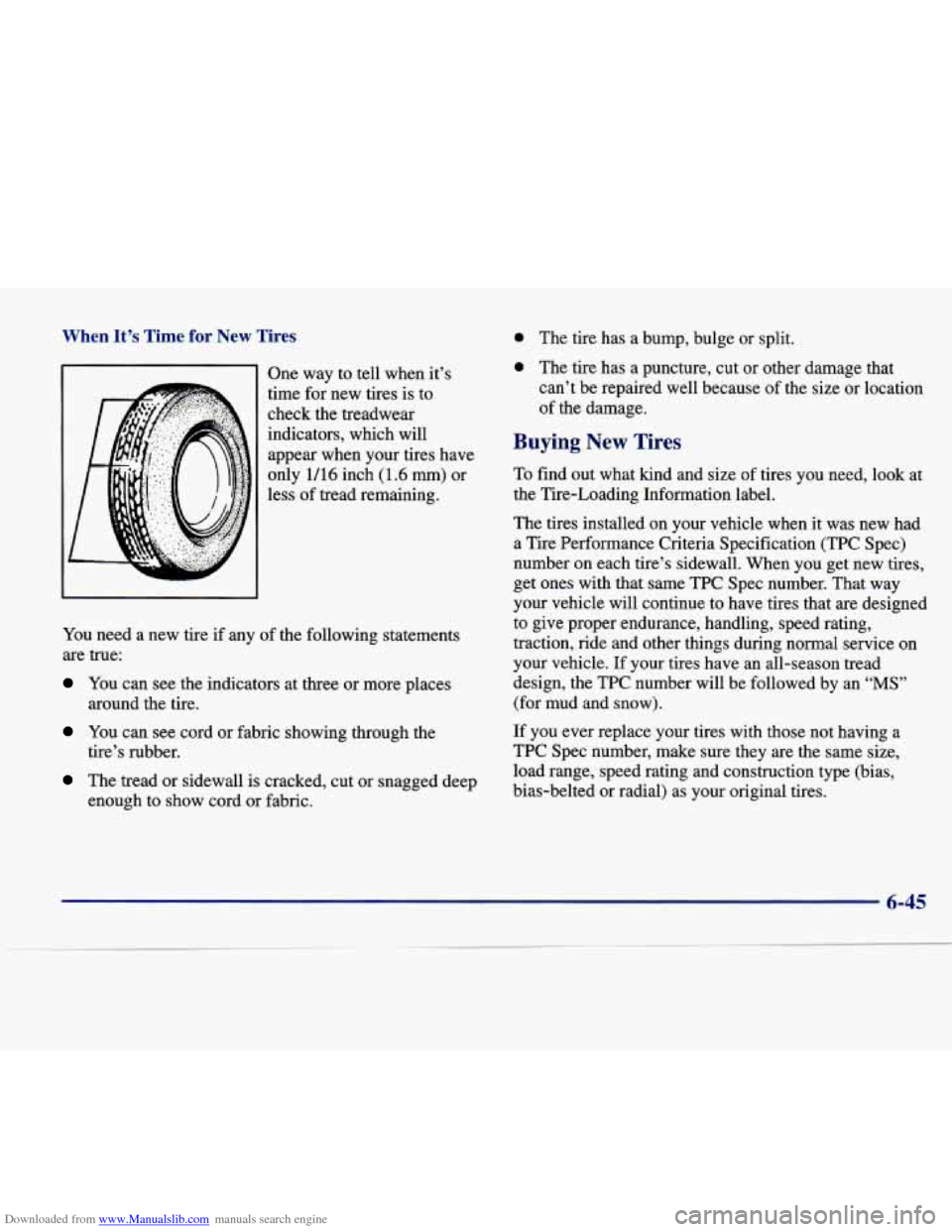

Downloaded from www.Manualslib.com manuals search engine When It’s Time for New Tires

One way to tell when it’s

time for new tires is to

check the treadwear

indicators, which will

appear when your tires have

only

1/16 inch (1.6 mm) or

less of tread remaining.

You need a new tire if any of the following statements

are true:

You can see the indicators at three or more places

around the tire.

You can see cord or fabric showing through the

tire’s rubber.

The tread or sidewall is cracked, cut or snagged deep

enough to show cord or fabric.

0 The tire has a bump, bulge or split.

0 The tire has a puncture, cut or other damage that

can’t be repaired well because of the size or location

of the damage.

Buying New Tires

To find out what kind and size of tires you need, look at

the Tire-Loading Information label.

The tires installed on your vehicle when it was new had

a Tire Performance Criteria Specification (TPC Spec)

number on each tire’s sidewall. When you get new tires,

get ones with that same TPC Spec number. That way

your vehicle will continue to have tires that are designed

to give proper endurance, handling, speed rating,

traction, ride and other things during normal service on

your vehicle. If your tires have an all-season tread

design, the TPC number will be followed by an

“MS”

(for mud and snow).

If you ever replace your tires with those not having a

TPC Spec number, make sure they are the same size,

load range, speed rating and construction type (bias,

bias-belted or radial) as your original tires.

6-45