CADILLAC XLR 2004 1.G Owners Manual

Manufacturer: CADILLAC, Model Year: 2004, Model line: XLR, Model: CADILLAC XLR 2004 1.GPages: 356, PDF Size: 2.36 MB

Page 261 of 356

Jump Starting

If your battery has run down, you may want to use

another vehicle and some jumper cables to start your

vehicle. Be sure to follow the steps below to do it safely.

{CAUTION:

Batteries can hurt you. They can be dangerous

because:

·They contain acid that can burn you.

·They contain gas that can explode or

ignite.

·They contain enough electricity to

burn you.

If you do not follow these steps exactly, some

or all of these things can hurt you.

Notice:If you try to start your vehicle by pushing

or pulling it, you could damage your vehicle. Do not

push or pull your vehicle to start it; instead, use

the jump starting procedure in this manual to start

your vehicle when the battery has run down.

1. Check the other vehicle. It must have a 12-volt

battery with a negative ground system.

Notice:If the other vehicle's system is not a 12-volt

system with a negative ground, both vehicles can

be damaged. Only use vehicles with 12-volt systems

with negative grounds to jump start your vehicle.

2. Get the vehicles close enough so the jumper cables

can reach, but be sure the vehicles are not touching

each other. If they are, it could cause a ground

connection you do not want. You would not be able

to start your vehicle, and the bad grounding

could damage the electrical systems.

To avoid the possibility of the vehicles rolling, set

the parking brake ®rmly on both vehicles involved in

the jump start procedure. Put an automatic

transmission in PARK (P) or a manual transmission

in NEUTRAL before setting the parking brakes.

5-39

Page 262 of 356

Notice:If you leave your radio or other accessories

on during the jump starting procedure, they could

be damaged. The repairs would not be covered

by your warranty. Always turn off your radio and

other accessories when jump starting your vehicle.

3. Turn off the ignition on both vehicles. Unplug

unnecessary accessories plugged into the cigarette

lighter or in the accessory power outlet. Turn off

the radio and all lamps that are not needed. This will

avoid sparks and help save both batteries. And it

could save your radio!

4. Open the hoods and locate the batteries. Find the

positive (+) and negative (-) terminal locations on

each vehicle. See

Engine Compartment Overview

on page 5-12for more information on location.

{CAUTION:

An electric fan can start up even when the

engine is not running and can injure you. Keep

hands, clothing and tools away from any

underhood electric fan.

{CAUTION:

Using a match near a battery can cause battery

gas to explode. People have been hurt doing

this, and some have been blinded. Use a

¯ashlight if you need more light.

Be sure the battery has enough water. You do

not need to add water to the ACDelco

žbattery

installed in your new vehicle. But if a battery

has ®ller caps, be sure the right amount of

¯uid is there. If it is low, add water to take care

of that ®rst. If you do not, explosive gas could

be present.

Battery ¯uid contains acid that can burn you.

Do not get it on you. If you accidentally get it

in your eyes or on your skin, ¯ush the place

with water and get medical help immediately.

5-40

Page 263 of 356

{CAUTION:

Fans or other moving engine parts can injure

you badly. Keep your hands away from moving

parts once the engine is running.

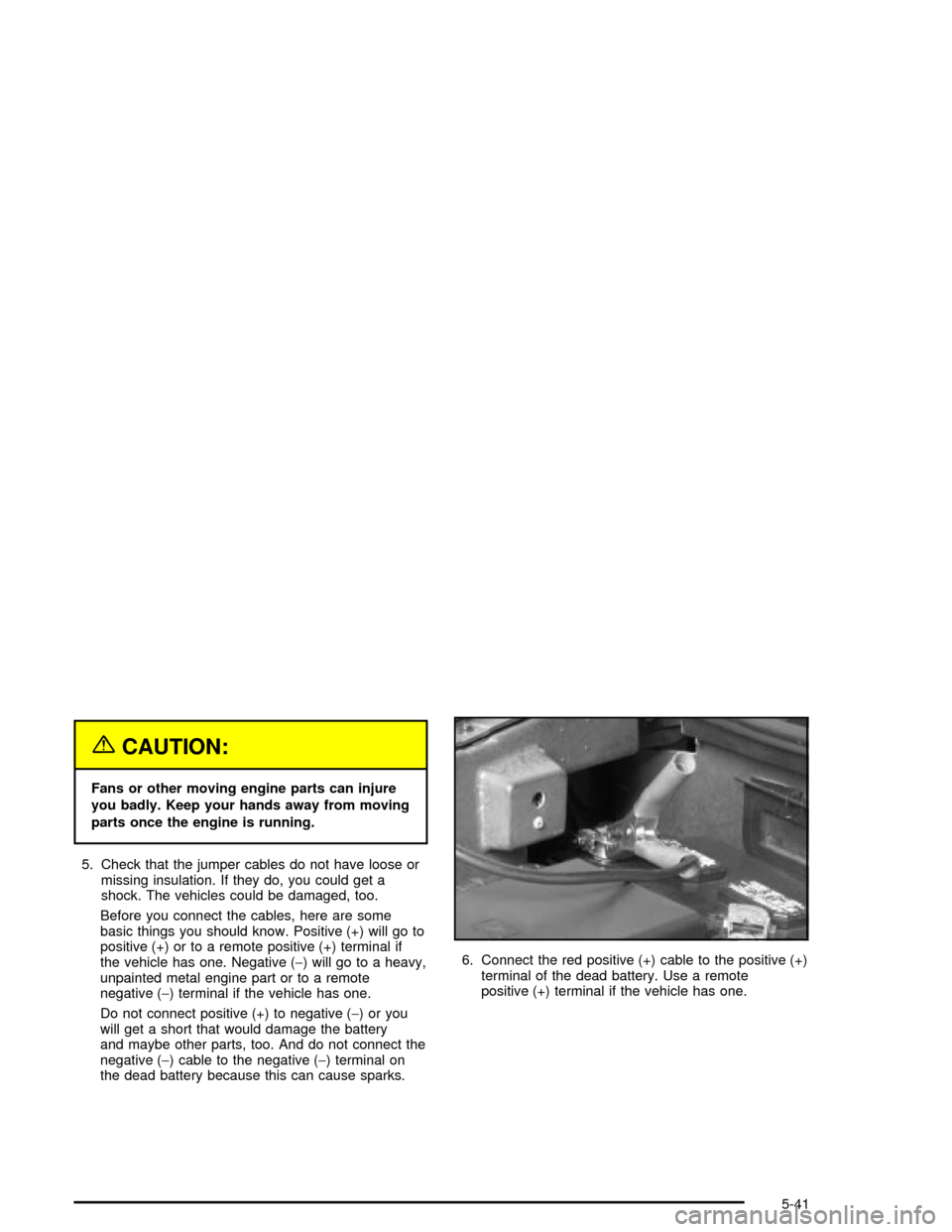

5. Check that the jumper cables do not have loose or

missing insulation. If they do, you could get a

shock. The vehicles could be damaged, too.

Before you connect the cables, here are some

basic things you should know. Positive (+) will go to

positive (+) or to a remote positive (+) terminal if

the vehicle has one. Negative (-) will go to a heavy,

unpainted metal engine part or to a remote

negative (-) terminal if the vehicle has one.

Do not connect positive (+) to negative (-)oryou

will get a short that would damage the battery

and maybe other parts, too. And do not connect the

negative (-) cable to the negative (-) terminal on

the dead battery because this can cause sparks.6. Connect the red positive (+) cable to the positive (+)

terminal of the dead battery. Use a remote

positive (+) terminal if the vehicle has one.

5-41

Page 264 of 356

7. Do not let the other end

touch metal. Connect it

to the positive (+)

terminal of the good

battery. Use a remote

positive (+) terminal if

the vehicle has one.8. Now connect the black

negative (-) cable to

the negative (-)

terminal of the good

battery. Use a remote

negative (-) terminal

if the vehicle has one.

Do not let the other end touch anything until the

next step. The other end of the negative (-) cable

does notgo to the dead battery. It goes to a

heavy, unpainted metal engine part or to a remote

negative (-) terminal on the vehicle with the

dead battery.

5-42

Page 265 of 356

9. Connect the other end of the negative (-) cable at

least 18 inches (45 cm) away from the dead battery,

but not near engine parts that move. The electrical

connection is just as good there, and the chance

of sparks getting back to the battery is much less.

10. Now start the vehicle with the good battery and run

the engine for a while.

11. Try to start the vehicle that had the dead battery. If

it will not start after a few tries, it probably needs

service.

Notice:If the jumper cables are removed in the

wrong order, electrical shorting may occur and

damage the vehicle. The repairs would not be

covered by your warranty. Remove the jumper

cables in the correct order, making sure that the

cables do not touch each other or other metal.

5-43

Page 266 of 356

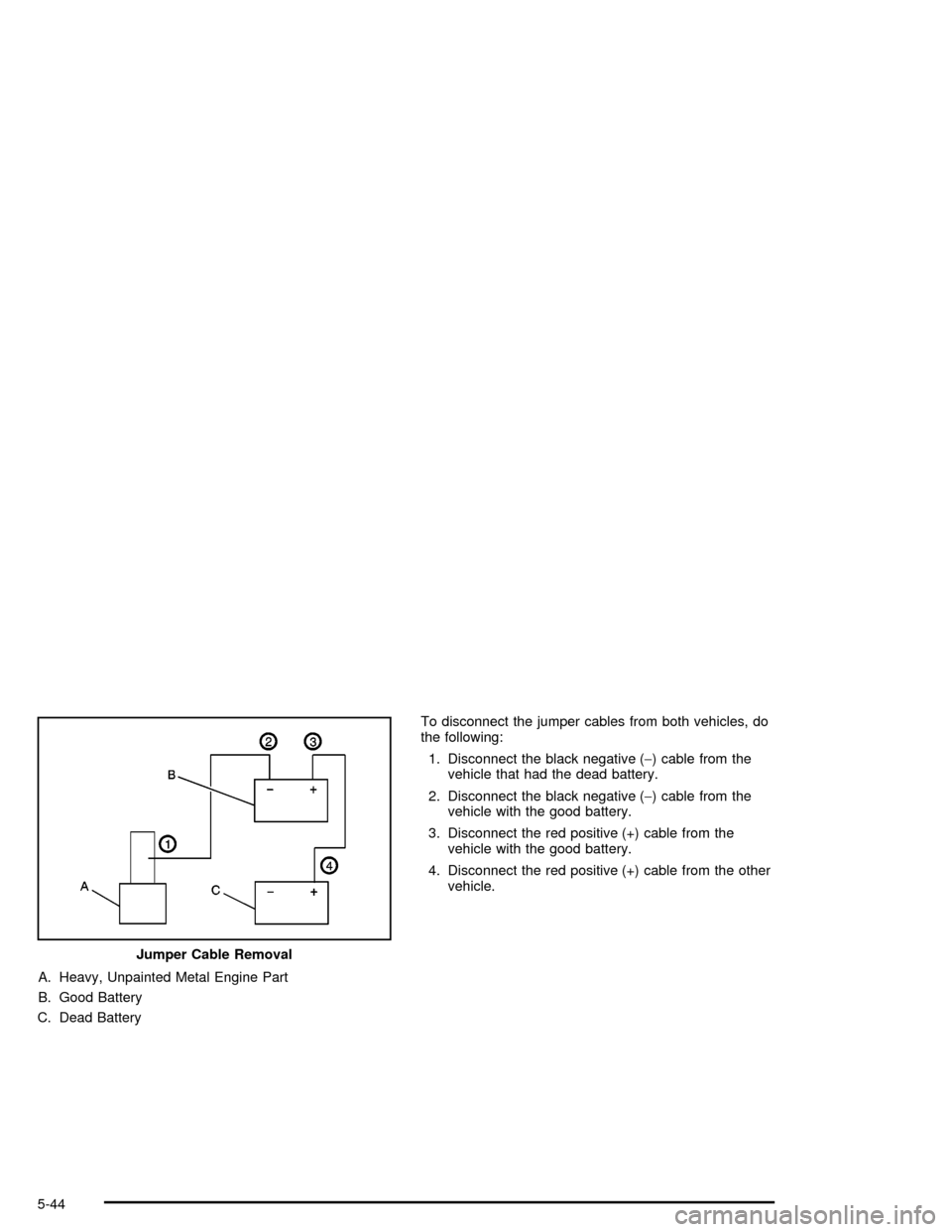

A. Heavy, Unpainted Metal Engine Part

B. Good Battery

C. Dead BatteryTo disconnect the jumper cables from both vehicles, do

the following:

1. Disconnect the black negative (-) cable from the

vehicle that had the dead battery.

2. Disconnect the black negative (-) cable from the

vehicle with the good battery.

3. Disconnect the red positive (+) cable from the

vehicle with the good battery.

4. Disconnect the red positive (+) cable from the other

vehicle.

Jumper Cable Removal

5-44

Page 267 of 356

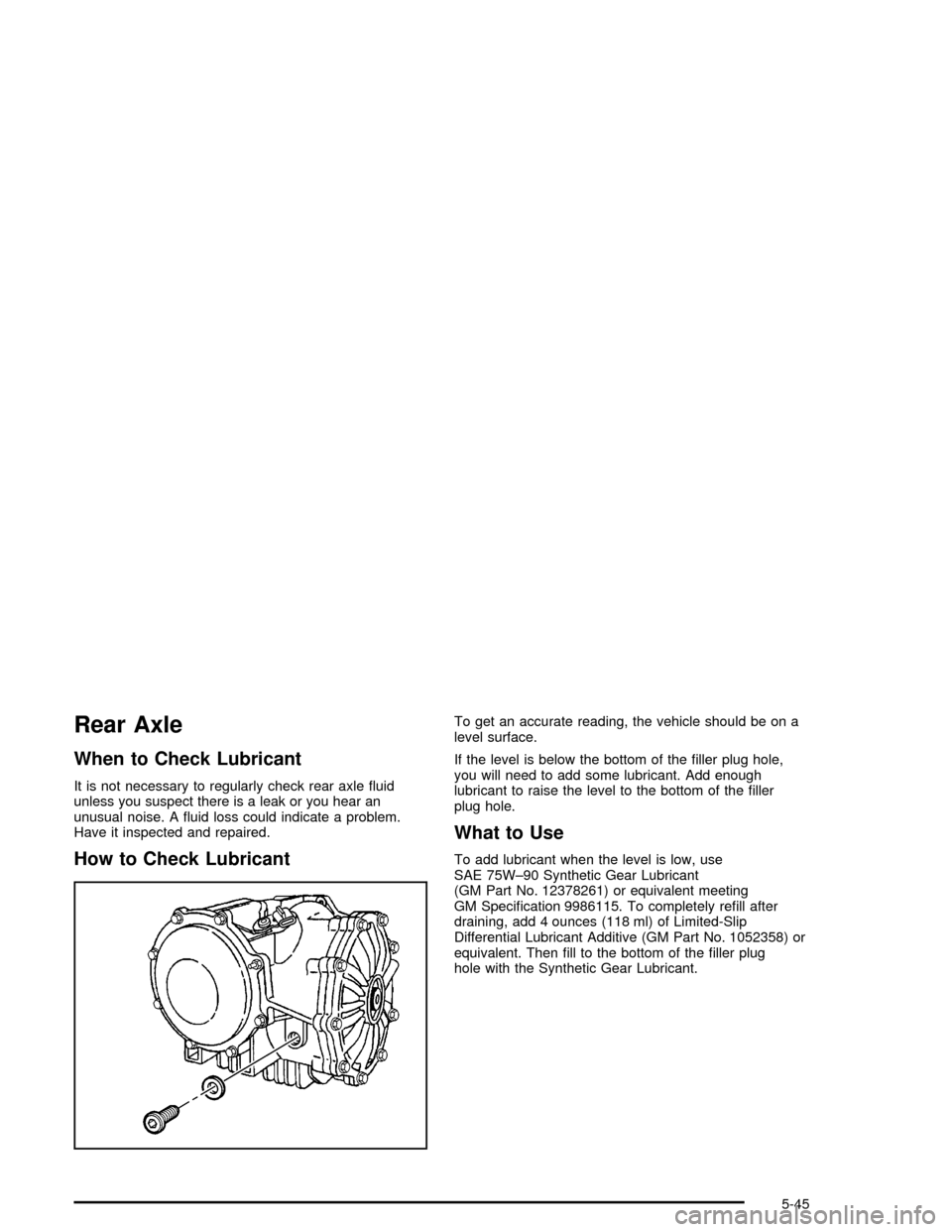

Rear Axle

When to Check Lubricant

It is not necessary to regularly check rear axle ¯uid

unless you suspect there is a leak or you hear an

unusual noise. A ¯uid loss could indicate a problem.

Have it inspected and repaired.

How to Check Lubricant

To get an accurate reading, the vehicle should be on a

level surface.

If the level is below the bottom of the ®ller plug hole,

you will need to add some lubricant. Add enough

lubricant to raise the level to the bottom of the ®ller

plug hole.

What to Use

To add lubricant when the level is low, use

SAE 75W±90 Synthetic Gear Lubricant

(GM Part No. 12378261) or equivalent meeting

GM Speci®cation 9986115. To completely re®ll after

draining, add 4 ounces (118 ml) of Limited-Slip

Differential Lubricant Additive (GM Part No. 1052358) or

equivalent. Then ®ll to the bottom of the ®ller plug

hole with the Synthetic Gear Lubricant.

5-45

Page 268 of 356

Headlamp Aiming

Your vehicle has a visual optical headlamp aiming

system equipped with horizontal aim indicators. The aim

has been preset at the factory and should need no

further adjustment. This is true even though your

horizontal aim indicators may not fall exactly on

the ª0º (zero) marks on their scales.

If your vehicle is damaged in an accident, the headlamp

aim may be affected. Aim adjustment to the low beam

may be necessary if it is difficult to see lane markers (for

horizontal aim), or if oncoming drivers ¯ash their high

beams at you (for vertical aim). If you believe your

headlamps need to be re-aimed, we recommend that

you take your vehicle to your dealer for service.

However, it is possible for you to re-aim your headlamps

as described in the following procedure.

Notice:To make sure your headlamps are aimed

properly, read all the instructions before beginning.

Failure to follow these instructions could cause

damage to headlamp parts.

The vehicle should be properly prepared as follows:

·The vehicle should be placed so the headlamps are

25 ft. (7.6 m) from a light colored wall or other ¯at

surface.

·The vehicle must have all four tires on a perfectly

level surface which is level all the way to the wall

or other ¯at surface.

·The vehicle should be placed so it is perpendicular

to the wall or other ¯at surface.

·The vehicle should not have any snow, ice or mud

attached to it.

·The vehicle should be fully assembled and all other

work stopped while headlamp aiming is being done.

·The vehicle should be normally loaded with a

full tank of fuel and one person or 160 lbs (75 kg) on

the driver's seat.

·Tires should be properly in¯ated.

·Start the vehicle and rock it to level the suspension.

5-46

Page 269 of 356

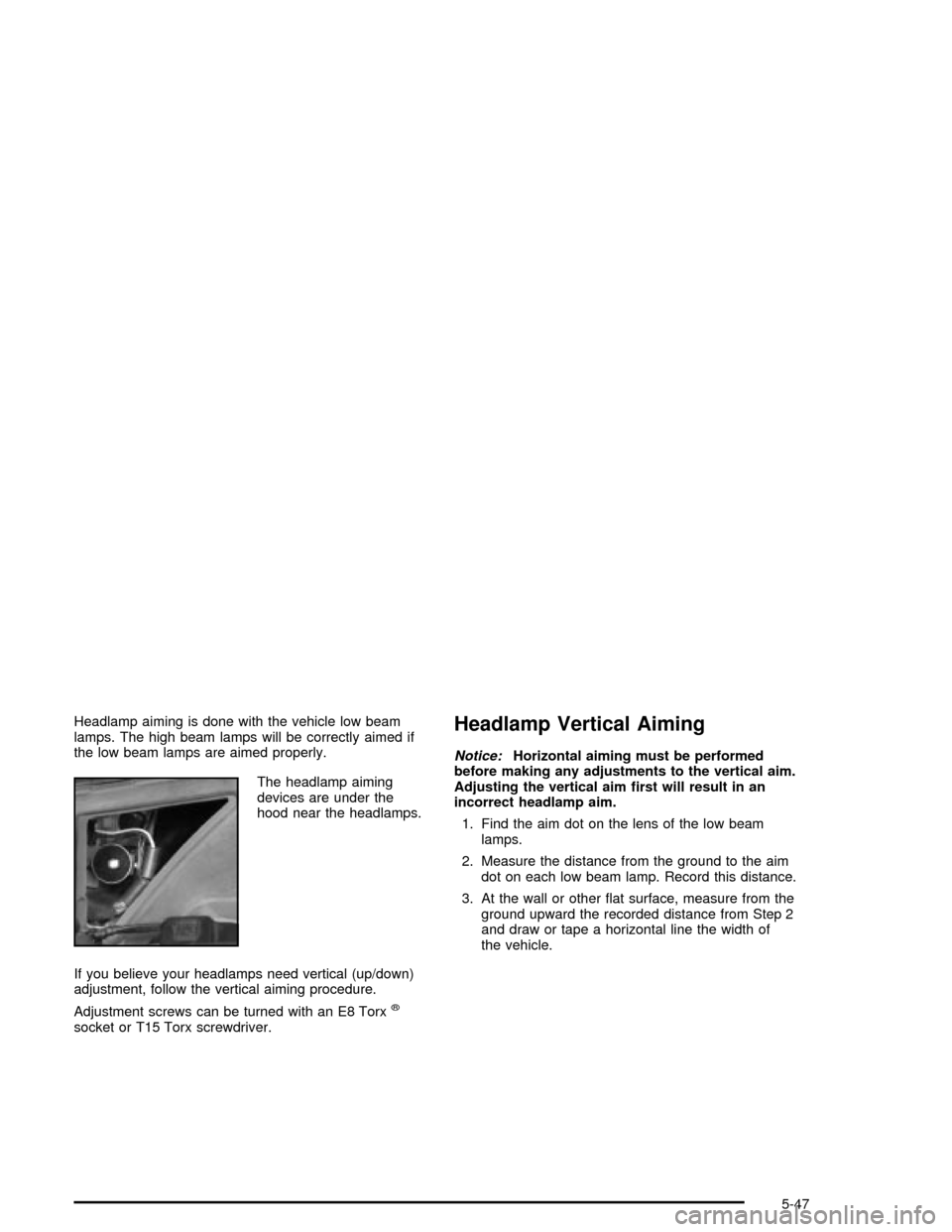

Headlamp aiming is done with the vehicle low beam

lamps. The high beam lamps will be correctly aimed if

the low beam lamps are aimed properly.

The headlamp aiming

devices are under the

hood near the headlamps.

If you believe your headlamps need vertical (up/down)

adjustment, follow the vertical aiming procedure.

Adjustment screws can be turned with an E8 Torx

ž

socket or T15 Torx screwdriver.

Headlamp Vertical Aiming

Notice:Horizontal aiming must be performed

before making any adjustments to the vertical aim.

Adjusting the vertical aim ®rst will result in an

incorrect headlamp aim.

1. Find the aim dot on the lens of the low beam

lamps.

2. Measure the distance from the ground to the aim

dot on each low beam lamp. Record this distance.

3. At the wall or other ¯at surface, measure from the

ground upward the recorded distance from Step 2

and draw or tape a horizontal line the width of

the vehicle.

5-47

Page 270 of 356

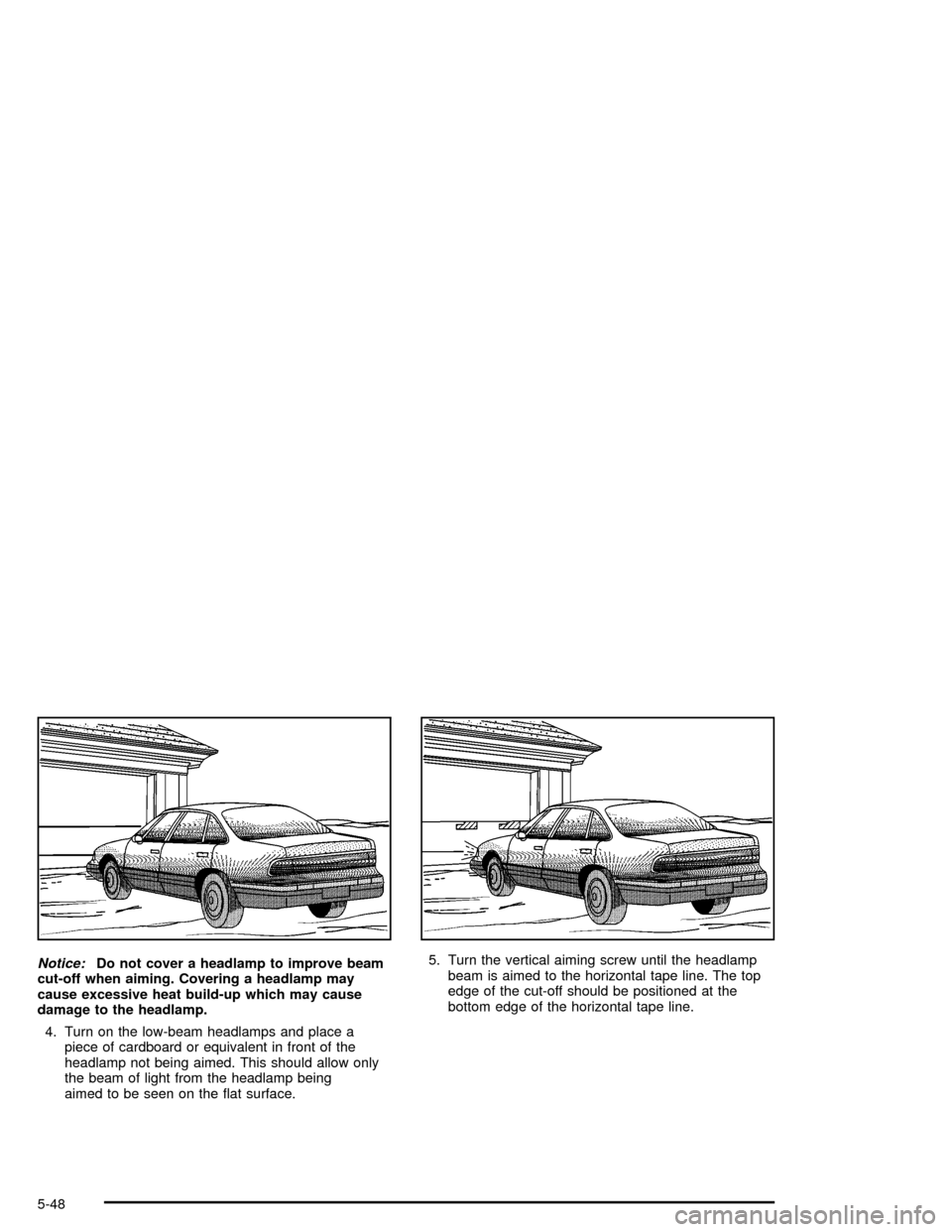

Notice:Do not cover a headlamp to improve beam

cut-off when aiming. Covering a headlamp may

cause excessive heat build-up which may cause

damage to the headlamp.

4. Turn on the low-beam headlamps and place a

piece of cardboard or equivalent in front of the

headlamp not being aimed. This should allow only

the beam of light from the headlamp being

aimed to be seen on the ¯at surface.5. Turn the vertical aiming screw until the headlamp

beam is aimed to the horizontal tape line. The top

edge of the cut-off should be positioned at the

bottom edge of the horizontal tape line.

5-48