light CADILLAC XT5 2020 Owners Manual

[x] Cancel search | Manufacturer: CADILLAC, Model Year: 2020, Model line: XT5, Model: CADILLAC XT5 2020Pages: 384, PDF Size: 6.52 MB

Page 269 of 384

268 VEHICLE CARE

new brake linings are installed. Add or

remove fluid, as necessary, only when

work is done on the brake hydraulic

system.

{Warning

If too much brake fluid is added, it

can spill on the engine and burn,

if the engine is hot enough. You or

others could be burned, and the

vehicle could be damaged. Add

brake fluid only when work is done

on the brake hydraulic system.

When the brake fluid falls to a low

level, the brake warning light comes

on. See Brake System Warning Light

0 117.

Brake fluid absorbs water over time

which degrades the effectiveness of

the brake fluid. Replace brake fluid at

the specified intervals to prevent

increased stopping distance. See

Maintenance Schedule 0332. What to Add

Use only GM approved DOT 3 brake

fluid from a clean, sealed container.

See

Recommended Fluids and

Lubricants 0342.{Warning

The wrong or contaminated brake

fluid could result in damage to the

brake system. This could result in

the loss of braking leading to a

possible injury. Always use the

proper GM approved brake fluid.

Caution

If brake fluid is spilled on the

vehicle's painted surfaces, the paint

finish can be damaged. Immediately

wash off any painted surface.

Battery - North America

The original equipment battery is

maintenance free. Do not remove the

cap and do not add fluid. Refer to the replacement number on

the original battery label when a new

battery is needed. For replacement of

the battery, see your dealer.

The vehicle has an Absorbed Glass

Mat (AGM) 12-volt battery.

Installation of a standard 12-volt

battery will result in reduced 12-volt

battery life.

When using a 12-volt battery charger

on the 12-volt AGM battery, some

chargers have an AGM battery setting

on the charger. If available, use the

AGM setting on the charger, to limit

charge voltage to 14.8 volts.

Stop/Start System

This vehicle has a Stop/Start system

to shut off the engine to help

conserve fuel. See

Stop/Start System

0 177.

{Warning

WARNING: Battery posts,

terminals, and related accessories

contain lead and lead compounds,

(Continued)

Page 274 of 384

VEHICLE CARE 273

Bulb Replacement

For the proper type of replacement

bulbs, or any bulb changing procedure

not listed in this section, contact your

dealer.

Caution

Do not replace incandescent bulbs

with aftermarket LED replacement

bulbs. This can cause damage to

the vehicle electrical system.

Halogen Bulbs

{Warning

Halogen bulbs have pressurized gas

inside and can burst if you drop or

scratch the bulb. You or others

could be injured. Be sure to read

and follow the instructions on the

bulb package.

LED Lighting

This vehicle has several LED lamps.

For replacement of any LED lighting

assembly, contact your dealer.

Electrical System

Electrical System Overload

The vehicle has fuses and circuit

breakers to protect against an

electrical system overload.

When the current electrical load is too

heavy, the circuit breaker opens and

closes, protecting the circuit until the

current load returns to normal or the

problem is fixed. This greatly reduces

the chance of circuit overload and fire

caused by electrical problems.

Fuses and circuit breakers protect

power devices in the vehicle.

Replace a bad fuse with a new one of

the identical size and rating.

If there is a problem on the road and

a fuse needs to be replaced, the

same amperage fuse can be borrowed.

Choose some feature of the vehicle

that is not needed to use and replace

it as soon as possible.

Page 280 of 384

VEHICLE CARE 279

FusesUsage

F16 Sunroof

F17 Body control module 1

F18 Instrument cluster

F19 –

F20 Rear seat entertainment

F21 Body control module 4

F22 Infotainment/USB data/Aux jack

F23 Body control module 2

F24 USB charger/ Wireless charging

F25 Park aid/electronic transmission range

system

F26 Communications integration module

F27 Video Fuses

Usage

F28 Heating, ventilation, and air conditioning

display

F29 Radio

F30 Steering wheel adjustment controls

F31 Electronic brake control module

electric brake

booster

F32 DC AC inverter

F33 Driver power seat

F34 Passenger power seat

F35 Battery IEC 1 feed

F36 Electric power steering

F37 Rear seat entertainment/USB

charge/Wireless

charging module

F38 Body control module 8

F39 – Circuit

Breakers Usage

F40 –

F41 –

F42 Auxiliary power outlet/Lighter

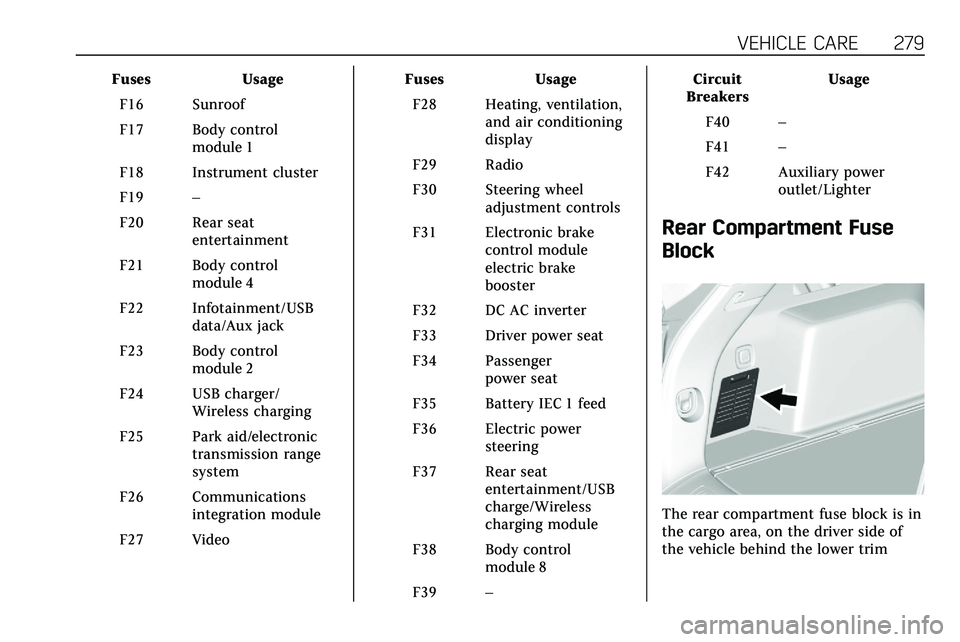

Rear Compartment Fuse

Block

The rear compartment fuse block is in

the cargo area, on the driver side of

the vehicle behind the lower trim

Page 288 of 384

VEHICLE CARE 287

Aspect Ratio:The relationship of

a tire's height to its width.

Belt

:A rubber coated layer of

cords between the plies and the

tread. Cords may be made from

steel or other reinforcing

materials.

Bead

:The tire bead contains steel

wires wrapped by steel cords that

hold the tire onto the rim.

Bias Ply Tire

:A pneumatic tire in

which the plies are laid at

alternate angles less than

90 degrees to the centerline of the

tread.

Cold Tire Pressure

:The amount

of air pressure in a tire, measured

in kPa (kilopascal) or psi (pounds

per square inch) before a tire has

built up heat from driving. See

Tire Pressure 0289.

Curb Weight

:The weight of a

motor vehicle with standard and

optional equipment including the maximum capacity of fuel, oil, and

coolant, but without passengers

and cargo.

DOT Markings

:A code molded

into the sidewall of a tire

signifying that the tire is in

compliance with the U.S.

Department of Transportation

(DOT) Motor Vehicle Safety

Standards. The DOT code includes

the Tire Identification Number

(TIN), an alphanumeric designator

which can also identify the tire

manufacturer, production plant,

brand, and date of production.

GVWR

:Gross Vehicle Weight

Rating. See Vehicle Load Limits

0 170.

GAWR FRT

:Gross Axle Weight

Rating for the front axle. See

Vehicle Load Limits 0170.

GAWR RR

:Gross Axle Weight

Rating for the rear axle. See

Vehicle Load Limits 0170. Intended Outboard Sidewall

:

The side of an asymmetrical tire

that must always face outward

when mounted on a vehicle.

Kilopascal (kPa)

:The metric unit

for air pressure.

Light Truck (LT-Metric) Tire

:A

tire used on light duty trucks and

some multipurpose passenger

vehicles.

Load Index

:An assigned number

ranging from 1 to 279 that

corresponds to the load carrying

capacity of a tire.

Maximum Inf lation Pressure

:

The maximum air pressure to

which a cold tire can be inflated.

The maximum air pressure is

molded onto the sidewall.

Maximum Load Rating

:The load

rating for a tire at the maximum

permissible inflation pressure for

that tire.

Page 289 of 384

288 VEHICLE CARE

Maximum Loaded Vehicle

Weight

:The sum of curb weight,

accessory weight, vehicle capacity

weight, and production options

weight.

Normal Occupant Weight

:The

number of occupants a vehicle is

designed to seat multiplied by

68 kg (150 lb). See Vehicle Load

Limits 0170.

Occupant Distribution

:

Designated seating positions.

Outward Facing Sidewall

:The

side of an asymmetrical tire that

has a particular side that faces

outward when mounted on a

vehicle. The side of the tire that

contains a whitewall, bears white

lettering, or bears manufacturer,

brand, and/or model name

molding that is higher or deeper

than the same moldings on the

other sidewall of the tire. Passenger (P-Metric) Tire

:A tire

used on passenger cars and some

light duty trucks and

multipurpose vehicles.

Recommended Inf lation

Pressure

:Vehicle manufacturer's

recommended tire inflation

pressure as shown on the tire

placard. See Tire Pressure 0289

and

Vehicle Load Limits 0170.

Radial Ply Tire

:A pneumatic tire

in which the ply cords that extend

to the beads are laid at 90 degrees

to the centerline of the tread.

Rim

:A metal support for a tire

and upon which the tire beads are

seated.

Sidewall

:The portion of a tire

between the tread and the bead.

Speed Rating

:An alphanumeric

code assigned to a tire indicating

the maximum speed at which a

tire can operate. Traction

:The friction between

the tire and the road surface. The

amount of grip provided.

Tread

:The portion of a tire that

comes into contact with the road.

Treadwear Indicators

:Narrow

bands, sometimes called wear

bars, that show across the tread of

a tire when only 1.6 mm (1/16 in)

of tread remains. See When It Is

Time for New Tires 0297.

UTQGS (Uniform Tire Quality

Grading Standards)

:A tire

information system that provides

consumers with ratings for a tire's

traction, temperature, and

treadwear. Ratings are determined

by tire manufacturers using

government testing procedures.

The ratings are molded into the

sidewall of the tire. See Uniform

Tire Quality Grading 0299.

Page 293 of 384

292 VEHICLE CARE

Tire Pressure Monitor

Operation

This vehicle may have a Tire Pressure

Monitor System (TPMS). The TPMS is

designed to warn the driver when a

low tire pressure condition exists.

TPMS sensors are mounted onto each

tire and wheel assembly, excluding the

spare tire and wheel assembly. The

TPMS sensors monitor the air

pressure in the tires and transmit the

tire pressure readings to a receiver

located in the vehicle.

When a low tire pressure condition is

detected, the TPMS illuminates the

low tire pressure warning light on the

instrument cluster. If the warning

light comes on, stop as soon as

possible and inflate the tires to the

recommended pressure shown on the

Tire and Loading Information label.

SeeVehicle Load Limits 0170. A message to check the pressure in a

specific tire displays in the Driver

Information Center (DIC). The low tire

pressure warning light and the DIC

warning message come on at each

ignition cycle until the tires are

inflated to the correct inflation

pressure. Using the DIC, tire pressure

levels can be viewed. For additional

information and details about the DIC

operation and displays see

Driver

Information Center (DIC) 0124.

The low tire pressure warning light

may come on in cool weather when

the vehicle is first started, and then

turn off as the vehicle is driven. This

could be an early indicator that the air

pressure is getting low and needs to

be inflated to the proper pressure.

A Tire and Loading Information label,

attached to your vehicle, shows the

size of the original equipment tires

and the correct inflation pressure for

the tires when they are cold. See

Vehicle Load Limits 0170, for an

example of the Tire and Loading

Information label and its location.

Also see Tire Pressure 0289. The TPMS can warn about a low tire

pressure condition but it does not

replace normal tire maintenance. See

Tire Inspection

0295, Tire Rotation

0 296 and

Tires 0282.

Caution

Tire sealant materials are not all

the same. A non-approved tire

sealant could damage the TPMS

sensors. TPMS sensor damage

caused by using an incorrect tire

sealant is not covered by the

vehicle warranty. Always use only

the GM approved tire sealant

available through your dealer or

included in the vehicle.

Factory-installed Tire Inflator Kits use

a GM approved liquid tire sealant.

Using non-approved tire sealants

could damage the TPMS sensors. See

Tire Sealant and Compressor Kit 0304

for information regarding the inflator

kit materials and instructions.

Page 294 of 384

VEHICLE CARE 293

TPMS Malfunction Light and

Message

The TPMS will not function properly if

one or more of the TPMS sensors are

missing or inoperable. When the

system detects a malfunction, the low

tire pressure warning light flashes for

about one minute and then stays on

for the remainder of the ignition cycle.

A DIC warning message also displays.

The malfunction light and DIC

warning message come on at each

ignition cycle until the problem is

corrected. Some of the conditions that

can cause these to come on are:

.One of the road tires has been

replaced with the spare tire. The

spare tire does not have a TPMS

sensor. The malfunction light and

DIC message should go off after

the road tire is replaced and the

sensor matching process is

performed successfully. See “TPMS

Sensor Matching Process ”later in

this section.

. The TPMS sensor matching

process was not done or not

completed successfully after

rotating the tires. The malfunction light and the DIC message should

go off after successfully

completing the sensor matching

process. See "TPMS Sensor

Matching Process" later in this

section.

. One or more TPMS sensors are

missing or damaged. The

malfunction light and the DIC

message should go off when the

TPMS sensors are installed and

the sensor matching process is

performed successfully. See your

dealer for service.

. Replacement tires or wheels do

not match the original equipment

tires or wheels. Tires and wheels

other than those recommended

could prevent the TPMS from

functioning properly. See Buying

New Tires 0297.

. Operating electronic devices or

being near facilities using radio

wave frequencies similar to the

TPMS could cause the TPMS

sensors to malfunction.

If the TPMS is not functioning

properly it cannot detect or signal a

low tire pressure condition. See your dealer for service if the TPMS

malfunction light and DIC message

come on and stay on.Tire Fill Alert (If Equipped)

This feature provides visual and

audible alerts outside the vehicle to

help when inflating an underinflated

tire to the recommended cold tire

pressure.

When the low tire pressure warning

light comes on:

1. Park the vehicle in a safe, level place.

2. Set the parking brake firmly.

3. Place the vehicle in P (Park).

4. Add air to the tire that is underinflated. The turn signal

lamp will flash.

When the recommended

pressure is reached, the horn

sounds once and the turn signal

lamp will stop flashing and

briefly turn solid.

Page 295 of 384

294 VEHICLE CARE

Repeat these steps for all

underinflated tires that have

illuminated the low tire pressure

warning light.

{Warning

Overinflating a tire could cause the

tire to rupture and you or others

could be injured. Do not exceed the

maximum pressure listed on the

tire sidewall. SeeTire Sidewall

Labeling 0284 and

Vehicle Load Limits 0170.

If the tire is overinflated by more than

35 kPa (5 psi), the horn will sound

multiple times and the turn signal

lamp will continue to flash for several

seconds after filling stops. To release

and correct the pressure, while the

turn signal lamp is still flashing,

briefly press the center of the valve

stem. When the recommended

pressure is reached, the horn

sounds once. If the turn signal lamp does not flash

within 15 seconds after starting to

inflate the tire, the tire fill alert has

not been activated or is not working.

If the hazard warning flashers are on,

the tire fill alert visual feedback will

not work properly.

The TPMS will not activate the tire fill

alert properly under the following

conditions:

.

There is interference from an

external device or transmitter.

. The air pressure from the inflation

device is not sufficient to inflate

the tire.

. There is a malfunction in

the TPMS.

. There is a malfunction in the horn

or turn signal lamps.

. The identification code of the

TPMS sensor is not registered to

the system.

. The battery of the TPMS sensor

is low. If the tire fill alert does not operate

due to TPMS interference, move the

vehicle about 1 m (3 ft) back or

forward and try again. If the tire fill

alert feature is not working, use a tire

pressure gauge.TPMS Sensor Matching Process

Each TPMS sensor has a unique

identification code. The identification

code needs to be matched to a new

tire/wheel position after rotating the

vehicle’s tires or replacing one or more

of the TPMS sensors. The TPMS

sensor matching process should also

be performed after replacing a spare

tire with a road tire containing the

TPMS sensor. The malfunction light

and the DIC message should go off at

the next ignition cycle. The sensors

are matched to the tire/wheel

positions, using a TPMS relearn tool,

in the following order: driver side

front tire, passenger side front tire,

passenger side rear tire, and driver

side rear. See your dealer for service or

to purchase a relearn tool. A TPMS

relearn tool can also be purchased.

See Tire Pressure Monitor Sensor

Activation Tool at

Page 297 of 384

296 VEHICLE CARE

.The tire has a bump, bulge,

or split.

.The tire has a puncture, cut,

or other damage that cannot

be repaired well because of the

size or location of the damage.

Tire Rotation

Tires should be rotated every

12 000 km (7,500 mi). See

Maintenance Schedule0332.

Tires are rotated to achieve a

more uniform wear for all tires.

The first rotation is the most

important.

Anytime unusual wear is noticed,

rotate the tires as soon as

possible, check for proper tire

inflation pressure, and check for

damaged tires or wheels. If the

unusual wear continues after the

rotation, check the wheel

alignment. See When It Is Time for

New Tires 0297 and

Wheel Replacement 0301.

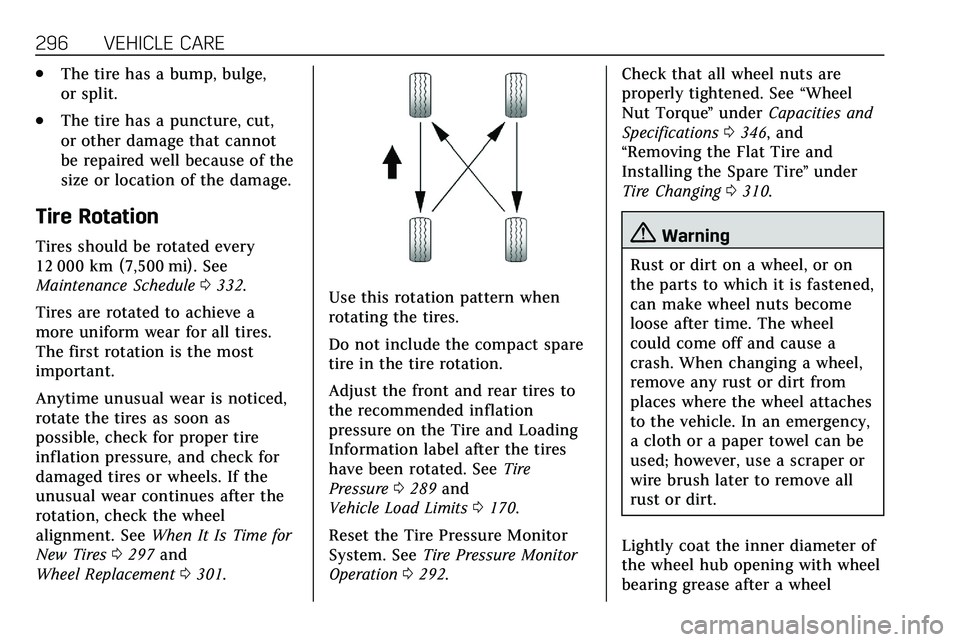

Use this rotation pattern when

rotating the tires.

Do not include the compact spare

tire in the tire rotation.

Adjust the front and rear tires to

the recommended inflation

pressure on the Tire and Loading

Information label after the tires

have been rotated. See Tire

Pressure 0289 and

Vehicle Load Limits 0170.

Reset the Tire Pressure Monitor

System. See Tire Pressure Monitor

Operation 0292. Check that all wheel nuts are

properly tightened. See

“Wheel

Nut Torque ”under Capacities and

Specifications 0346, and

“Removing the Flat Tire and

Installing the Spare Tire ”under

Tire Changing 0310.

{Warning

Rust or dirt on a wheel, or on

the parts to which it is fastened,

can make wheel nuts become

loose after time. The wheel

could come off and cause a

crash. When changing a wheel,

remove any rust or dirt from

places where the wheel attaches

to the vehicle. In an emergency,

a cloth or a paper towel can be

used; however, use a scraper or

wire brush later to remove all

rust or dirt.

Lightly coat the inner diameter of

the wheel hub opening with wheel

bearing grease after a wheel

Page 298 of 384

VEHICLE CARE 297

change or tire rotation to prevent

corrosion or rust buildup. Do not

get grease on the wheel mounting

surface or on the wheel nuts or

bolts.

When It Is Time for New

Tires

Factors such as maintenance,

temperatures, driving speeds, vehicle

loading, and road conditions affect the

wear rate of the tires.

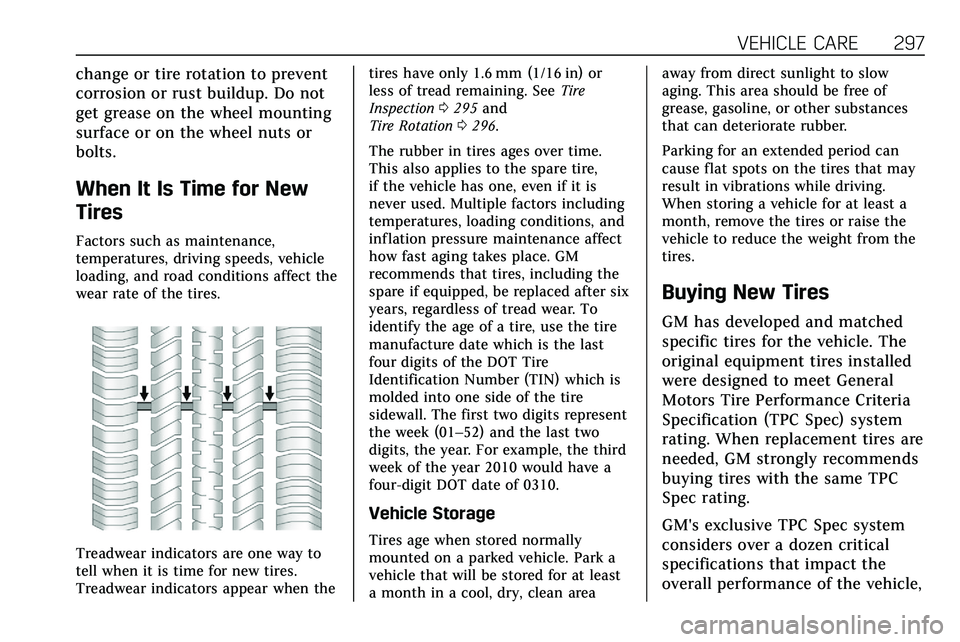

Treadwear indicators are one way to

tell when it is time for new tires.

Treadwear indicators appear when thetires have only 1.6 mm (1/16 in) or

less of tread remaining. See

Tire

Inspection 0295 and

Tire Rotation 0296.

The rubber in tires ages over time.

This also applies to the spare tire,

if the vehicle has one, even if it is

never used. Multiple factors including

temperatures, loading conditions, and

inflation pressure maintenance affect

how fast aging takes place. GM

recommends that tires, including the

spare if equipped, be replaced after six

years, regardless of tread wear. To

identify the age of a tire, use the tire

manufacture date which is the last

four digits of the DOT Tire

Identification Number (TIN) which is

molded into one side of the tire

sidewall. The first two digits represent

the week (01–52) and the last two

digits, the year. For example, the third

week of the year 2010 would have a

four-digit DOT date of 0310.

Vehicle Storage

Tires age when stored normally

mounted on a parked vehicle. Park a

vehicle that will be stored for at least

a month in a cool, dry, clean area away from direct sunlight to slow

aging. This area should be free of

grease, gasoline, or other substances

that can deteriorate rubber.

Parking for an extended period can

cause flat spots on the tires that may

result in vibrations while driving.

When storing a vehicle for at least a

month, remove the tires or raise the

vehicle to reduce the weight from the

tires.

Buying New Tires

GM has developed and matched

specific tires for the vehicle. The

original equipment tires installed

were designed to meet General

Motors Tire Performance Criteria

Specification (TPC Spec) system

rating. When replacement tires are

needed, GM strongly recommends

buying tires with the same TPC

Spec rating.

GM's exclusive TPC Spec system

considers over a dozen critical

specifications that impact the

overall performance of the vehicle,