check oil CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 90 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection

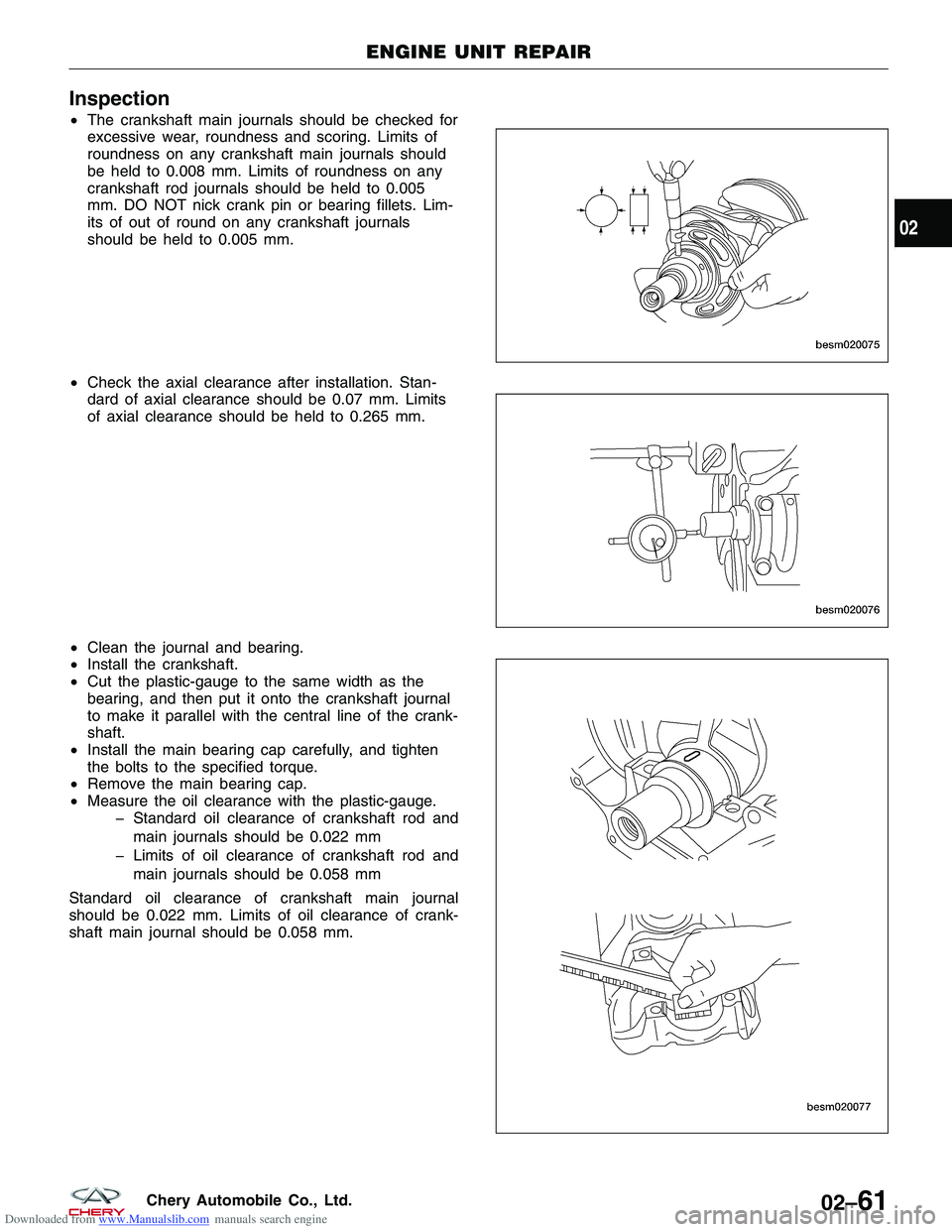

•The crankshaft main journals should be checked for

excessive wear, roundness and scoring. Limits of

roundness on any crankshaft main journals should

be held to 0.008 mm. Limits of roundness on any

crankshaft rod journals should be held to 0.005

mm. DO NOT nick crank pin or bearing fillets. Lim-

its of out of round on any crankshaft journals

should be held to 0.005 mm.

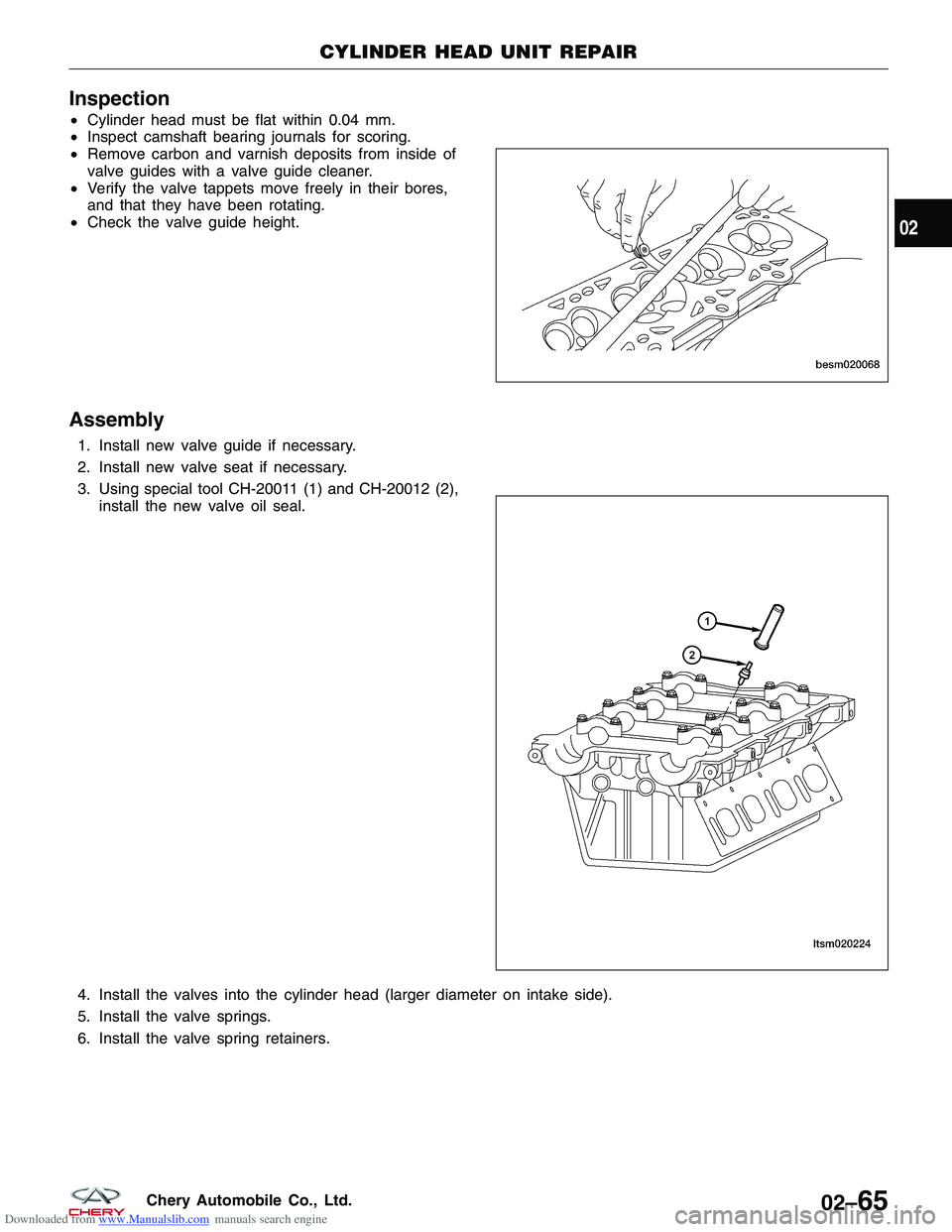

• Check the axial clearance after installation. Stan-

dard of axial clearance should be 0.07 mm. Limits

of axial clearance should be held to 0.265 mm.

• Clean the journal and bearing.

• Install the crankshaft.

• Cut the plastic-gauge to the same width as the

bearing, and then put it onto the crankshaft journal

to make it parallel with the central line of the crank-

shaft.

• Install the main bearing cap carefully, and tighten

the bolts to the specified torque.

• Remove the main bearing cap.

• Measure the oil clearance with the plastic-gauge.

� Standard oil clearance of crankshaft rod and

main journals should be 0.022 mm

� Limits of oil clearance of crankshaft rod and main journals should be 0.058 mm

Standard oil clearance of crankshaft main journal

should be 0.022 mm. Limits of oil clearance of crank-

shaft main journal should be 0.058 mm.

ENGINE UNIT REPAIR

BESM020075

BESM020076

BESM020077

02

02–61Chery Automobile Co., Ltd.

Page 94 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection

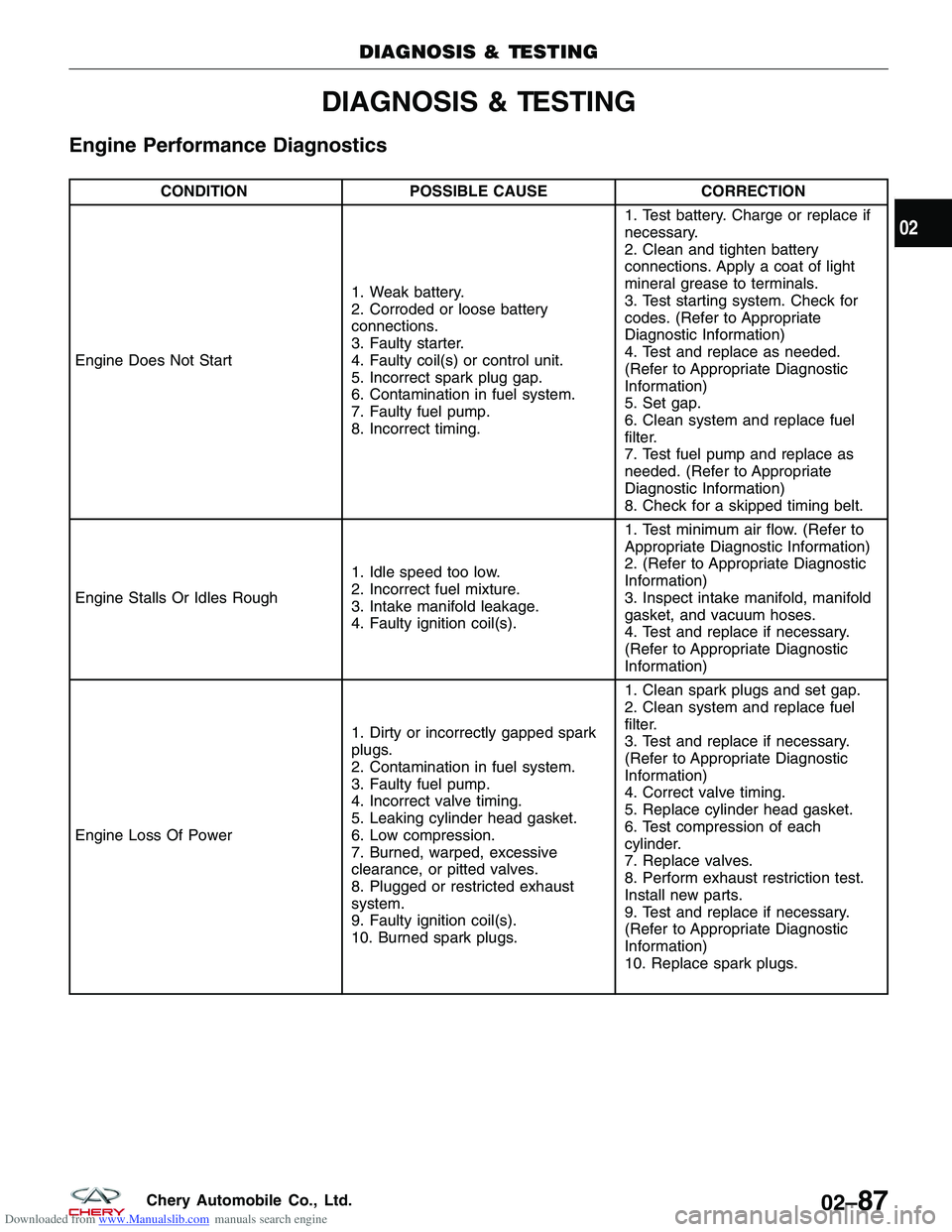

•Cylinder head must be flat within 0.04 mm.

• Inspect camshaft bearing journals for scoring.

• Remove carbon and varnish deposits from inside of

valve guides with a valve guide cleaner.

• Verify the valve tappets move freely in their bores,

and that they have been rotating.

• Check the valve guide height.

Assembly

1. Install new valve guide if necessary.

2. Install new valve seat if necessary.

3. Using special tool CH-20011 (1) and CH-20012 (2),

install the new valve oil seal.

4. Install the valves into the cylinder head (larger diameter on intake side).

5. Install the valve springs.

6. Install the valve spring retainers.

CYLINDER HEAD UNIT REPAIR

BESM020068

LTSM020224

02

02–65Chery Automobile Co., Ltd.

Page 116 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Engine Performance Diagnostics

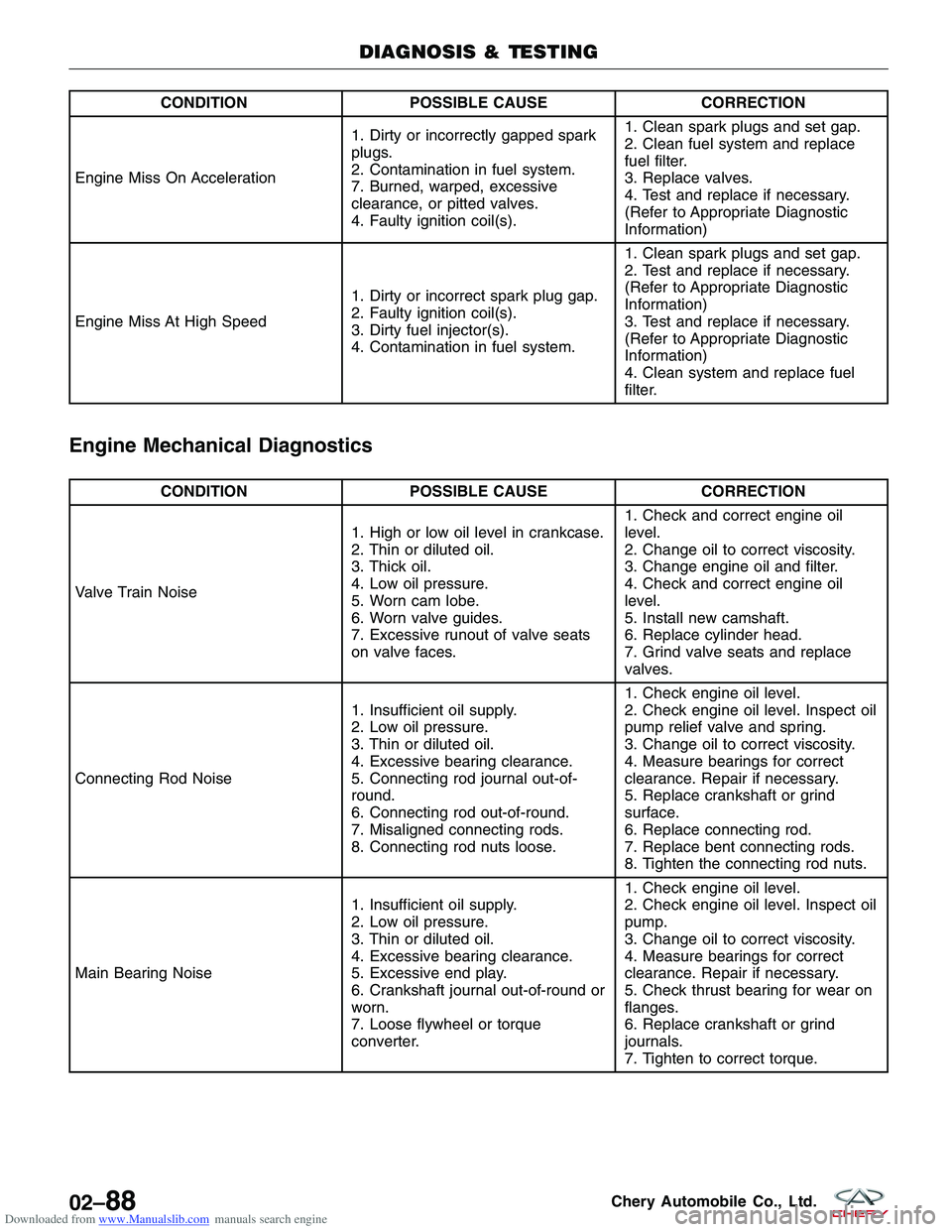

CONDITIONPOSSIBLE CAUSE CORRECTION

Engine Does Not Start 1. Weak battery.

2. Corroded or loose battery

connections.

3. Faulty starter.

4. Faulty coil(s) or control unit.

5. Incorrect spark plug gap.

6. Contamination in fuel system.

7. Faulty fuel pump.

8. Incorrect timing.1. Test battery. Charge or replace if

necessary.

2. Clean and tighten battery

connections. Apply a coat of light

mineral grease to terminals.

3. Test starting system. Check for

codes. (Refer to Appropriate

Diagnostic Information)

4. Test and replace as needed.

(Refer to Appropriate Diagnostic

Information)

5. Set gap.

6. Clean system and replace fuel

filter.

7. Test fuel pump and replace as

needed. (Refer to Appropriate

Diagnostic Information)

8. Check for a skipped timing belt.

Engine Stalls Or Idles Rough 1. Idle speed too low.

2. Incorrect fuel mixture.

3. Intake manifold leakage.

4. Faulty ignition coil(s).1. Test minimum air flow. (Refer to

Appropriate Diagnostic Information)

2. (Refer to Appropriate Diagnostic

Information)

3. Inspect intake manifold, manifold

gasket, and vacuum hoses.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Loss Of Power 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

3. Faulty fuel pump.

4. Incorrect valve timing.

5. Leaking cylinder head gasket.

6. Low compression.

7. Burned, warped, excessive

clearance, or pitted valves.

8. Plugged or restricted exhaust

system.

9. Faulty ignition coil(s).

10. Burned spark plugs.1. Clean spark plugs and set gap.

2. Clean system and replace fuel

filter.

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Correct valve timing.

5. Replace cylinder head gasket.

6. Test compression of each

cylinder.

7. Replace valves.

8. Perform exhaust restriction test.

Install new parts.

9. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

10. Replace spark plugs.

DIAGNOSIS & TESTING

02

02–87Chery Automobile Co., Ltd.

Page 117 of 1903

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSE CORRECTION

Engine Miss On Acceleration 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

7. Burned, warped, excessive

clearance, or pitted valves.

4. Faulty ignition coil(s).1. Clean spark plugs and set gap.

2. Clean fuel system and replace

fuel filter.

3. Replace valves.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Miss At High Speed 1. Dirty or incorrect spark plug gap.

2. Faulty ignition coil(s).

3. Dirty fuel injector(s).

4. Contamination in fuel system.1. Clean spark plugs and set gap.

2. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Clean system and replace fuel

filter.

Engine Mechanical Diagnostics

CONDITION

POSSIBLE CAUSE CORRECTION

Valve Train Noise 1. High or low oil level in crankcase.

2. Thin or diluted oil.

3. Thick oil.

4. Low oil pressure.

5. Worn cam lobe.

6. Worn valve guides.

7. Excessive runout of valve seats

on valve faces.1. Check and correct engine oil

level.

2. Change oil to correct viscosity.

3. Change engine oil and filter.

4. Check and correct engine oil

level.

5. Install new camshaft.

6. Replace cylinder head.

7. Grind valve seats and replace

valves.

Connecting Rod Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Connecting rod journal out-of-

round.

6. Connecting rod out-of-round.

7. Misaligned connecting rods.

8. Connecting rod nuts loose.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Replace crankshaft or grind

surface.

6. Replace connecting rod.

7. Replace bent connecting rods.

8. Tighten the connecting rod nuts.

Main Bearing Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Excessive end play.

6. Crankshaft journal out-of-round or

worn.

7. Loose flywheel or torque

converter.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Check thrust bearing for wear on

flanges.

6. Replace crankshaft or grind

journals.

7. Tighten to correct torque.

DIAGNOSIS & TESTING

02–88Chery Automobile Co., Ltd.

Page 118 of 1903

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSE CORRECTION

Oil Pressure Drop 1. Low oil level.

2. Faulty oil pressure sending unit.

3. Low oil pressure.

4. Clogged oil filter.

5. Thin or diluted oil.

6. Excessive bearing clearance.1. Check engine oil level.

2. Install new sending unit.

3. Check sending unit and main

bearing oil clearance.

4. Install new oil filter.

5. Change oil to correct viscosity.

6. Measure bearings for correct

clearance.

Oil Leaks 1. Misaligned or deteriorated

gaskets.

2. Loose fastener, broken or porous

metal part.

3. Misaligned or deteriorated cup or

threaded plug.1. Replace gasket.

2. Tighten, repair or replace the part.

3. Replace if necessary.

Oil Consumption Or Spark Plugs

Fouled 1. PCV system malfunction.

2. Worn, scuffed or broken rings.

3. Carbon in oil ring slots.

4. Rings fitted too tightly in grooves.

5. Worn valve guide(s).

6. Valve stem seal(s) worn or

damaged.1. Check system and repair if

necessary.

2. Hone cylinder bores. Install new

rings.

3. Install new rings.

4. Remove rings and check grooves.

If groove is not proper width, replace

piston.

5. Replace cylinder head.

6. Replace seal(s).

DIAGNOSIS & TESTING

02

02–89Chery Automobile Co., Ltd.

Page 119 of 1903

Downloaded from www.Manualslib.com manuals search engine Cylinder Compression Pressure Test

•The result of a cylinder compression pressure test can be utilized to diagnose several engine malfunctions.

• Ensure the battery is completely charged and the engine starter motor is in good operating condition. Otherwise

the indicated compression pressures may not be valid for diagnostic purposes.

� Check engine oil level and add oil if necessary.

� Disconnect the spark plug wires.

� Remove all spark plugs from engine (as spark plugs are being removed, check electrodes for abnormal

firing indicators fouled, hot, oily, etc.).

� Record cylinder number of each spark plug for future reference.

� Disconnect fuel injector electrical connectors.

� Be sure throttle blade is fully open during the compression check.

� Insert compression pressure adaptor or the equivalent into each spark plug hole in cylinder head.

� Crank engine until maximum pressure is reached on gauge. Record each cylinder pressure.

� Compression should not be less than 1000 kPa and not vary more than 25 percent from cylinder to cylinder.

� If one or more cylinders have abnormally low compression pressures, repeat the compression test.

� If the same cylinder or cylinders repeat an abnormally low reading on the second compression test, it could indicate the existence of a problem with the cylinder in question.

NOTE :

The recommended compression pressures are to be used only as a guide to diagnosing engine problems. An engine

should not be disassembled to determine the cause of low compression unless some malfunction is present.

Cylinder Head Gasket Test

• A cylinder head gasket leak can be located between adjacent cylinders, between a cylinder and the adjacent

water jacket or from an oil passage to the exterior of the engine.

• Possible indications of the cylinder head gasket leaking between adjacent cylinders are:

� Loss of engine power

� Engine misfiring

� Poor fuel economy

• Possible indications of the cylinder head gasket leaking between a cylinder and an adjacent water jacket are:

� Engine overheating

� Loss of coolant

� Excessive steam (white smoke) emitting from exhaust

� Coolant foaming

DIAGNOSIS & TESTING

02–90Chery Automobile Co., Ltd.

Page 152 of 1903

Downloaded from www.Manualslib.com manuals search engine ENGINE UNIT REPAIR

Engine Block

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Connecting Rod Cap Bolts 1st Step: Tighten the bolt to 25 N·m

2nd Step: Tighten the bolt an additional 90°

Main Bearing Cap Bolts 1st Step: Tighten the bolt to 45 N·m

2nd Step: Tighten the bolt an additional 180°

Lower Cylinder Block Bolts 23

Clearance Specifications

DESCRIPTIONSPECIFICATION (mm)

Surface Distortion Limit 0.15

Inner Diameter Standard 84

Out-Of-Round < 0.008

Taper < 0.01

Disassembly

1. Remove the oil pan and then remove oil baffle.

2. Remove the oil strainer.

3. For each connecting rod/piston assembly to be removed, rotate the crankshaft to the bottom dead center position

for each cylinder.

NOTE :

Before removing the connecting rod/piston assembly, check the connecting rod side clearance.

BESM020060

02–123Chery Automobile Co., Ltd.

Page 154 of 1903

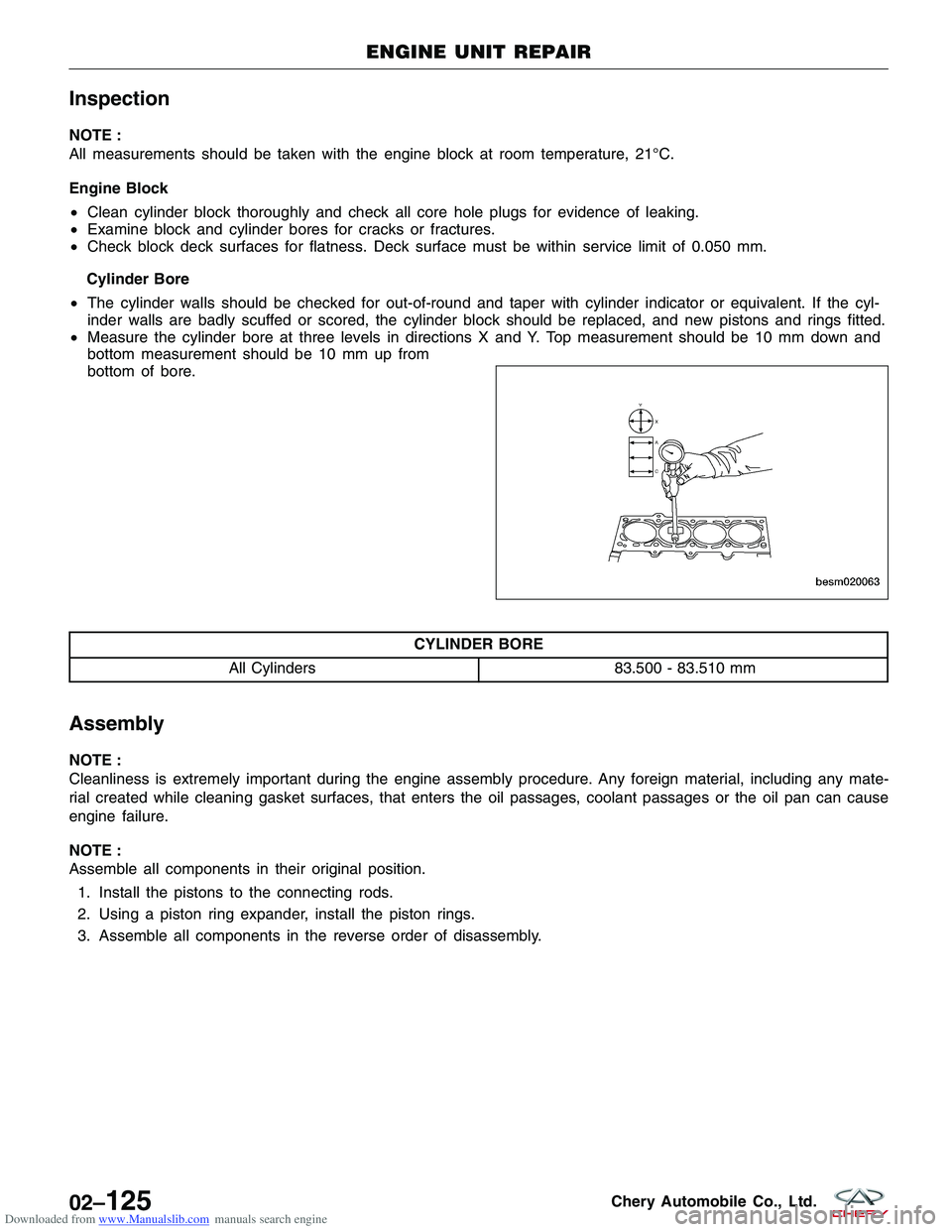

Downloaded from www.Manualslib.com manuals search engine Inspection

NOTE :

All measurements should be taken with the engine block at room temperature, 21°C.

Engine Block

•Clean cylinder block thoroughly and check all core hole plugs for evidence of leaking.

• Examine block and cylinder bores for cracks or fractures.

• Check block deck surfaces for flatness. Deck surface must be within service limit of 0.050 mm.

Cylinder Bore

• The cylinder walls should be checked for out-of-round and taper with cylinder indicator or equivalent. If the cyl-

inder walls are badly scuffed or scored, the cylinder block should be replaced, and new pistons and rings fitted.

• Measure the cylinder bore at three levels in directions X and Y. Top measurement should be 10 mm down and

bottom measurement should be 10 mm up from

bottom of bore.

CYLINDER BORE

All Cylinders 83.500 - 83.510 mm

Assembly

NOTE :

Cleanliness is extremely important during the engine assembly procedure. Any foreign material, including any mate-

rial created while cleaning gasket surfaces, that enters the oil passages, coolant passages or the oil pan can cause

engine failure.

NOTE :

Assemble all components in their original position.

1. Install the pistons to the connecting rods.

2. Using a piston ring expander, install the piston rings.

3. Assemble all components in the reverse order of disassembly.

ENGINE UNIT REPAIR

BESM020063

02–125Chery Automobile Co., Ltd.

Page 156 of 1903

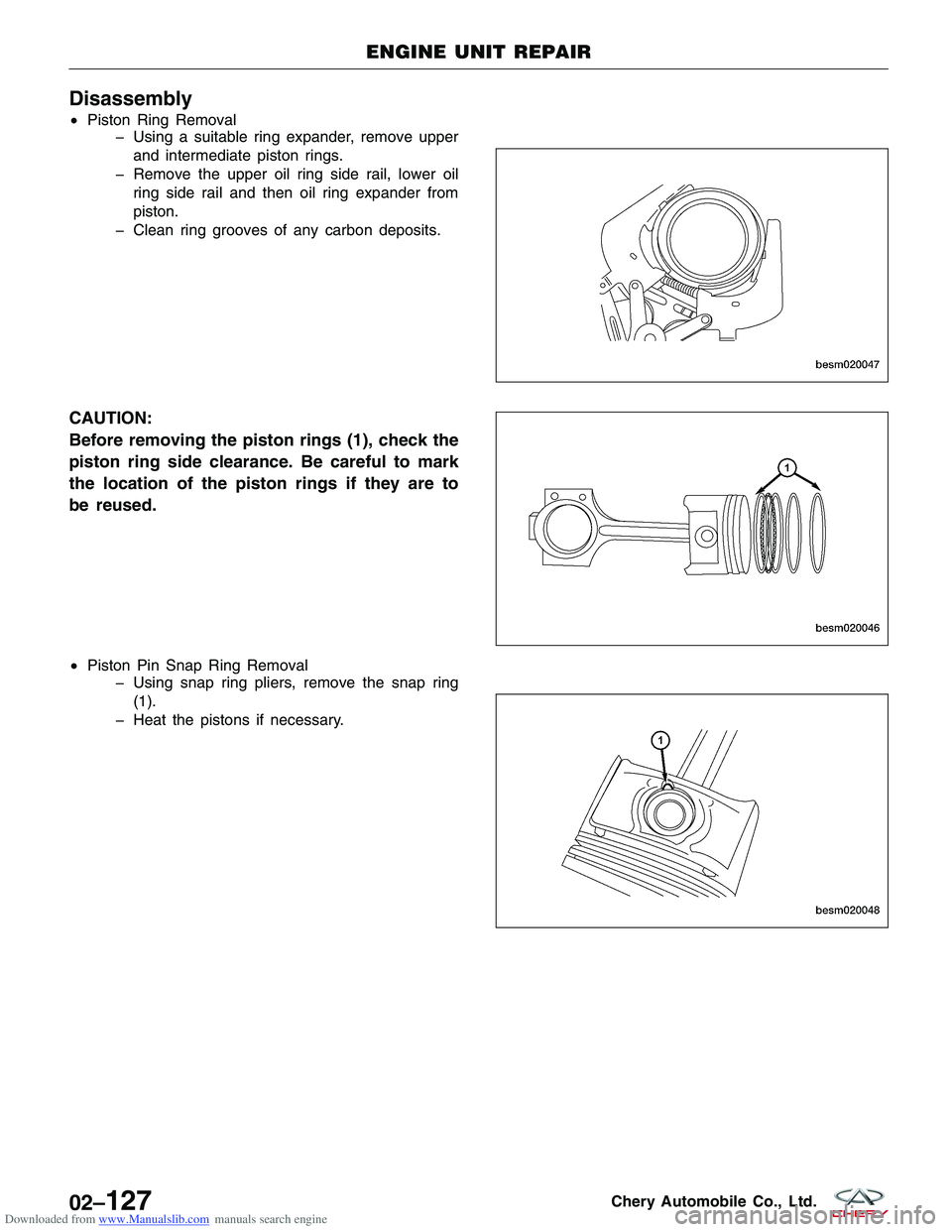

Downloaded from www.Manualslib.com manuals search engine Disassembly

•Piston Ring Removal

� Using a suitable ring expander, remove upper

and intermediate piston rings.

� Remove the upper oil ring side rail, lower oil ring side rail and then oil ring expander from

piston.

� Clean ring grooves of any carbon deposits.

CAUTION:

Before removing the piston rings (1), check the

piston ring side clearance. Be careful to mark

the location of the piston rings if they are to

be reused.

• Piston Pin Snap Ring Removal

� Using snap ring pliers, remove the snap ring

(1).

� Heat the pistons if necessary.

ENGINE UNIT REPAIR

BESM020047

BESM020046

BESM020048

02–127Chery Automobile Co., Ltd.

Page 158 of 1903

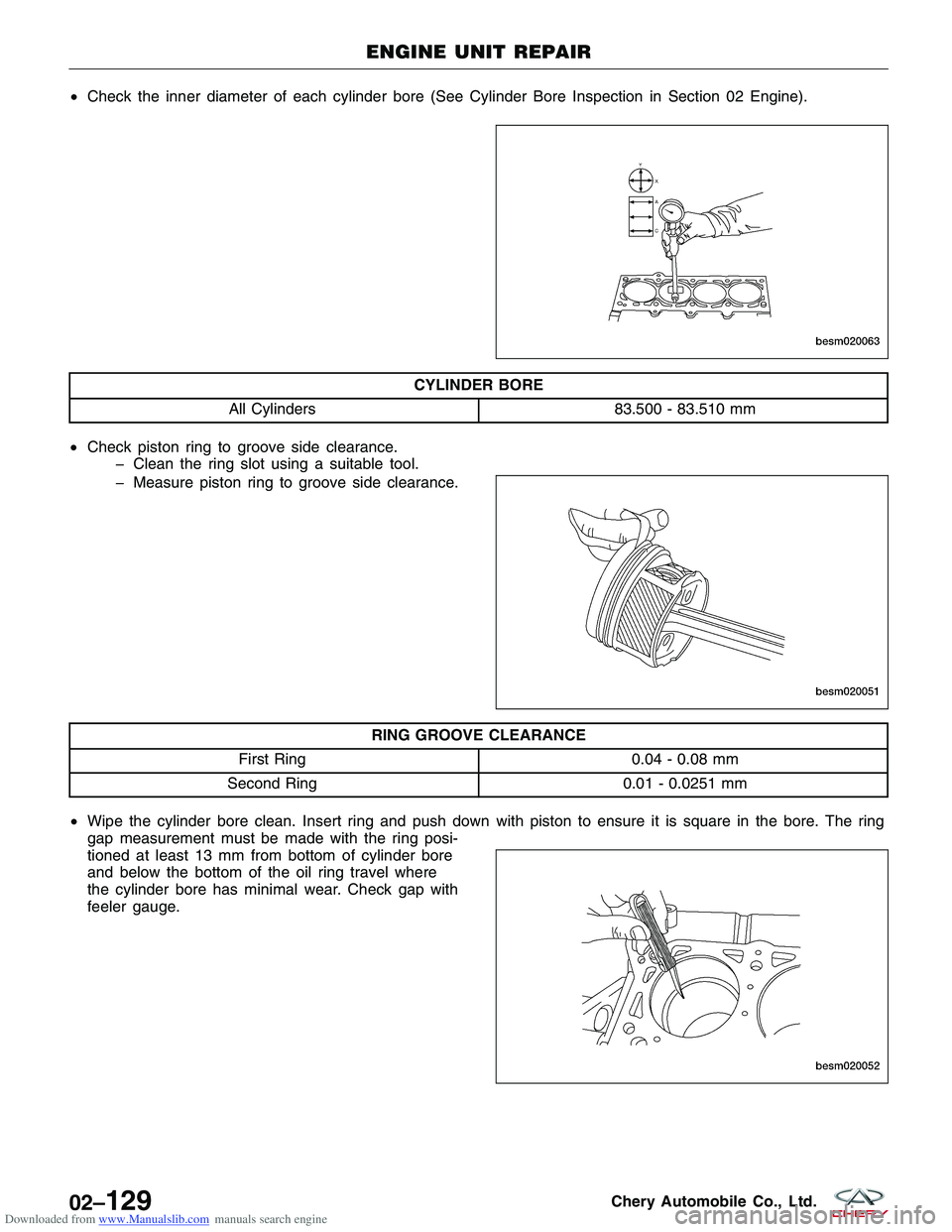

Downloaded from www.Manualslib.com manuals search engine •Check the inner diameter of each cylinder bore (See Cylinder Bore Inspection in Section 02 Engine).

CYLINDER BORE

All Cylinders 83.500 - 83.510 mm

• Check piston ring to groove side clearance.

� Clean the ring slot using a suitable tool.

� Measure piston ring to groove side clearance.

RING GROOVE CLEARANCE

First Ring 0.04 - 0.08 mm

Second Ring 0.01 - 0.0251 mm

• Wipe the cylinder bore clean. Insert ring and push down with piston to ensure it is square in the bore. The ring

gap measurement must be made with the ring posi-

tioned at least 13 mm from bottom of cylinder bore

and below the bottom of the oil ring travel where

the cylinder bore has minimal wear. Check gap with

feeler gauge.

ENGINE UNIT REPAIR

BESM020063

BESM020051

BESM020052

02–129Chery Automobile Co., Ltd.