torque CHERY TIGGO 2009 Service User Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 79 of 1903

Downloaded from www.Manualslib.com manuals search engine ENGINE UNIT REPAIR

Engine Block

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Connecting Rod Cap Bolts 1st Step: Tighten the bolt to 25 N·m

2nd Step: Tighten the bolt an additional 90°

Main Bearing Cap Bolts 1st Step: Tighten the bolt to 45 N·m

2nd Step: Tighten the bolt an additional 180°

Lower Cylinder Block Bolts 23

Clearance Specifications

DESCRIPTIONSPECIFICATION (mm)

Surface Distortion Limit 0.15

Inner Diameter Standard 81

Out-Of-Round < 0.008

Taper < 0.01

Disassembly

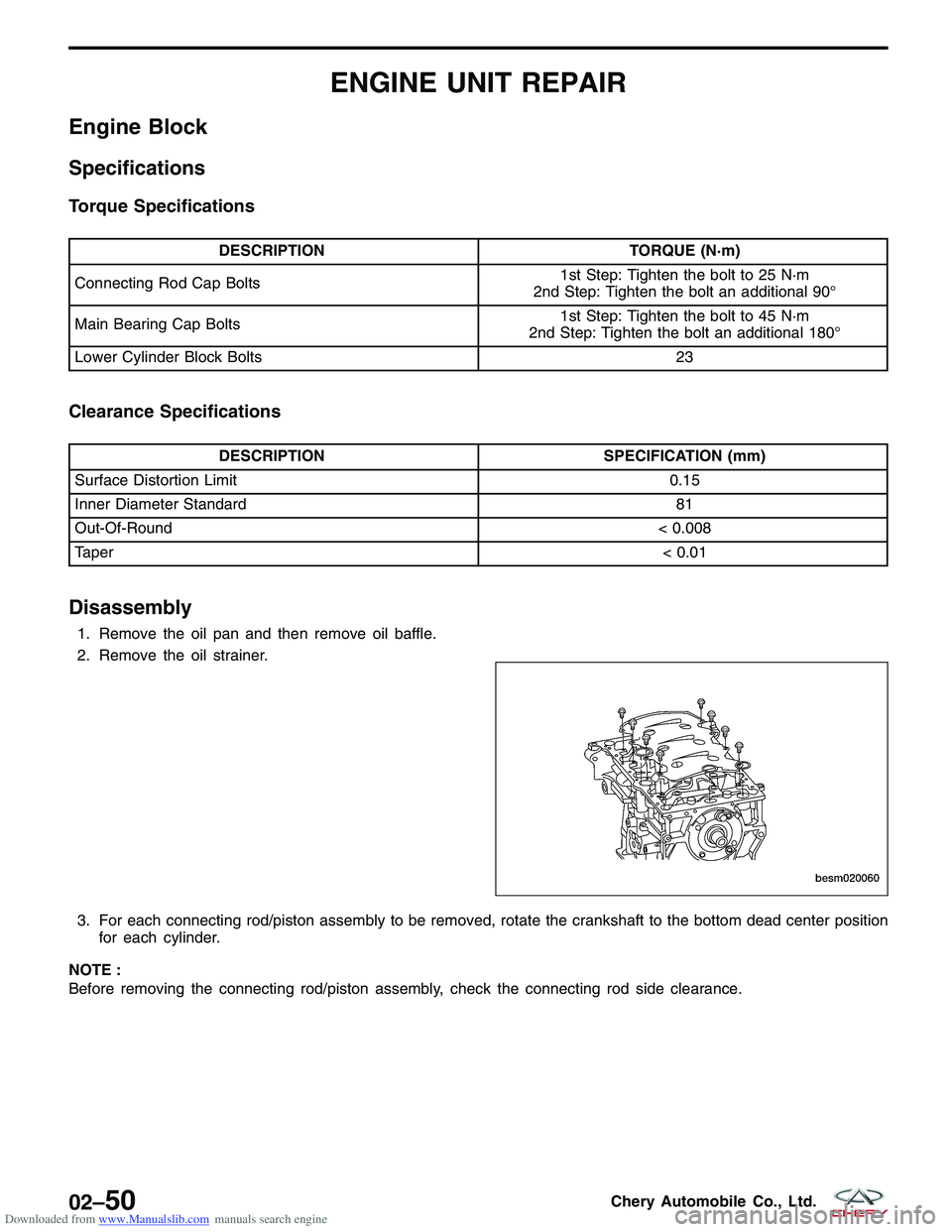

1. Remove the oil pan and then remove oil baffle.

2. Remove the oil strainer.

3. For each connecting rod/piston assembly to be removed, rotate the crankshaft to the bottom dead center position

for each cylinder.

NOTE :

Before removing the connecting rod/piston assembly, check the connecting rod side clearance.

BESM020060

02–50Chery Automobile Co., Ltd.

Page 87 of 1903

Downloaded from www.Manualslib.com manuals search engine Connecting Rods

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Connecting Rod Bolts 1st Step: Tighten bolts to 25 N·m

2nd Step: Tighten the connecting rod bolts an additional 90°

Clearance Specifications

DESCRIPTION SPECIFICATION (mm)

Connecting Rod Radial Clearance 0.016 - 0.051

Connecting Rod Axial Clearance 0.002 - 0.013

Disassembly

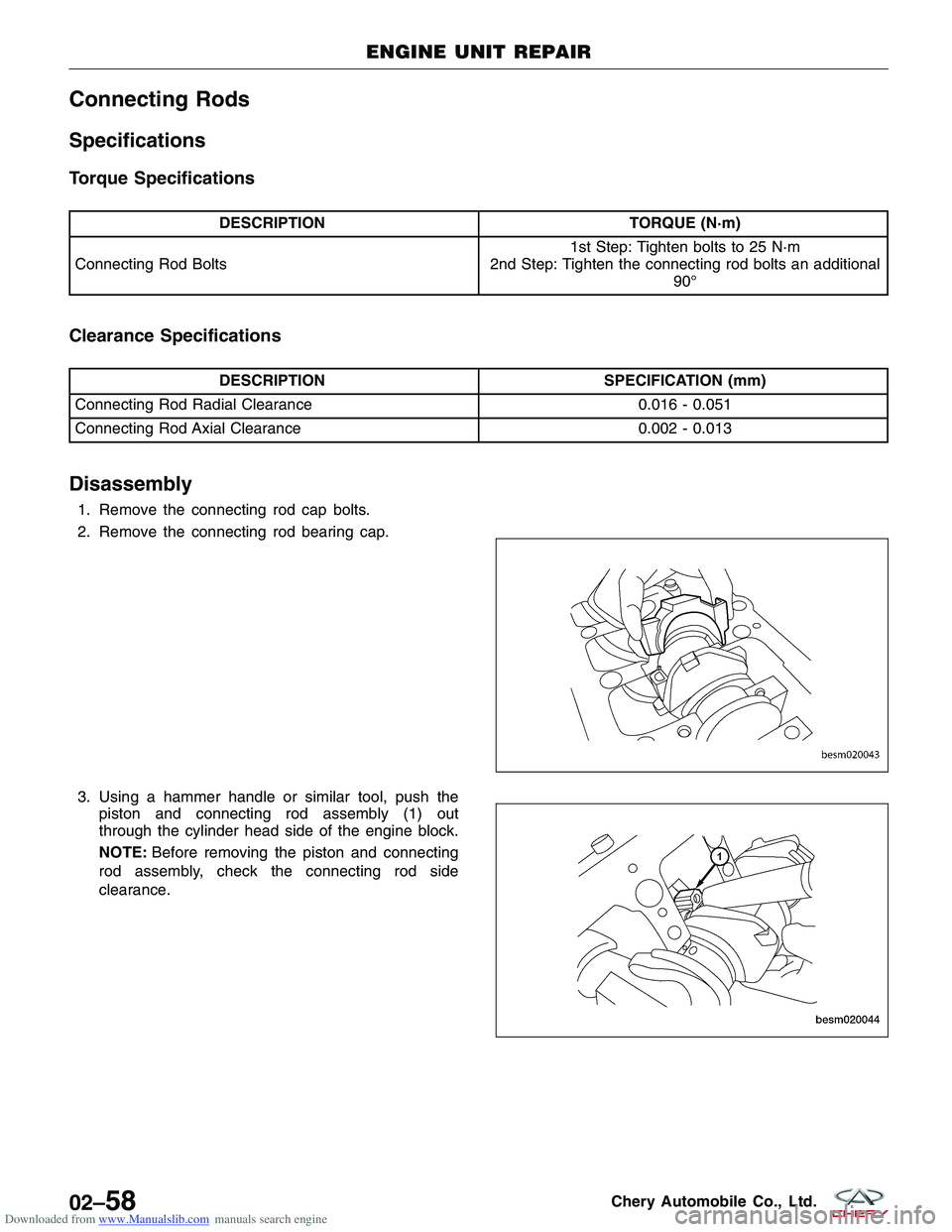

1. Remove the connecting rod cap bolts.

2. Remove the connecting rod bearing cap.

3. Using a hammer handle or similar tool, push the

piston and connecting rod assembly (1) out

through the cylinder head side of the engine block.

NOTE: Before removing the piston and connecting

rod assembly, check the connecting rod side

clearance.

ENGINE UNIT REPAIR

BESM020043

BESM020044

02–58Chery Automobile Co., Ltd.

Page 88 of 1903

Downloaded from www.Manualslib.com manuals search engine 4. Remove the connecting rod bearings.CAUTION: When removing the connecting rod

side bearings, note the installation position.

Keep them in the correct order.

Inspection

•Check the radial clearance of connecting rod bearing.

CONNECTING ROD RADIAL CLEARANCE

Radial Clearance 0.016 - 0.051 mm

Assembly

NOTE :

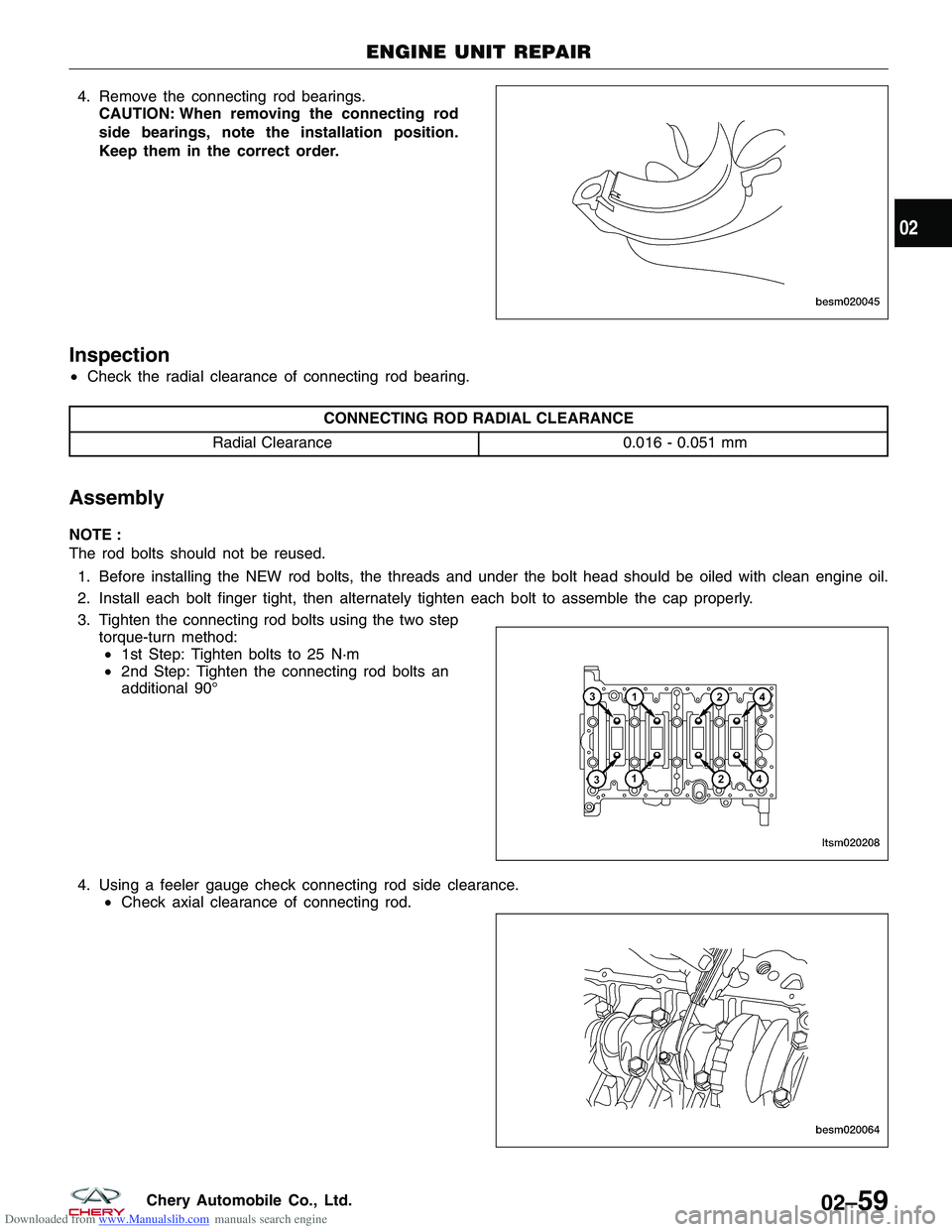

The rod bolts should not be reused.

1. Before installing the NEW rod bolts, the threads and under the bolt head should be oiled with clean engine oil.

2. Install each bolt finger tight, then alternately tighten each bolt to assemble the cap properly.

3. Tighten the connecting rod bolts using the two step torque-turn method:• 1st Step: Tighten bolts to 25 N·m

• 2nd Step: Tighten the connecting rod bolts an

additional 90°

4. Using a feeler gauge check connecting rod side clearance. •Check axial clearance of connecting rod.

ENGINE UNIT REPAIR

BESM020045

LTSM020208

BESM020064

02

02–59Chery Automobile Co., Ltd.

Page 89 of 1903

Downloaded from www.Manualslib.com manuals search engine Crankshaft

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Main Bearing Cap Bolts 1st Step: Tighten the bolt to 45 N·m

2nd Step: Tighten the bolt an additional 180°

Lower Cylinder Block Bolts 23

Clearance Specifications

DESCRIPTIONSPECIFICATION (mm)

Diameter of Crankshaft Main Journals 53.981 - 54

Diameter of Crankshaft Rod Journals 47.884 - 47.9

Out-of-Round Maximum of Crankshaft Main Journals 0.008

Axial Clearance of Crankshaft 0.07 - 0.265

Radial Clearance of Crankshaft 0.0035 - 0.034

Coaxality Crankshaft Main Journal 0.05

Thrust Washer Thickness 2.4 - 2.405

Disassembly

1. Remove the front crankshaft oil seal (See Front Crankshaft Oil Seal Removal & Installation in Section 02

Engine).

2. Remove the rear crankshaft oil seal (See Rear Crankshaft Oil Seal Removal & Installation in Section 02 Engine).

3. Remove the pistons with connecting rod assemblies.

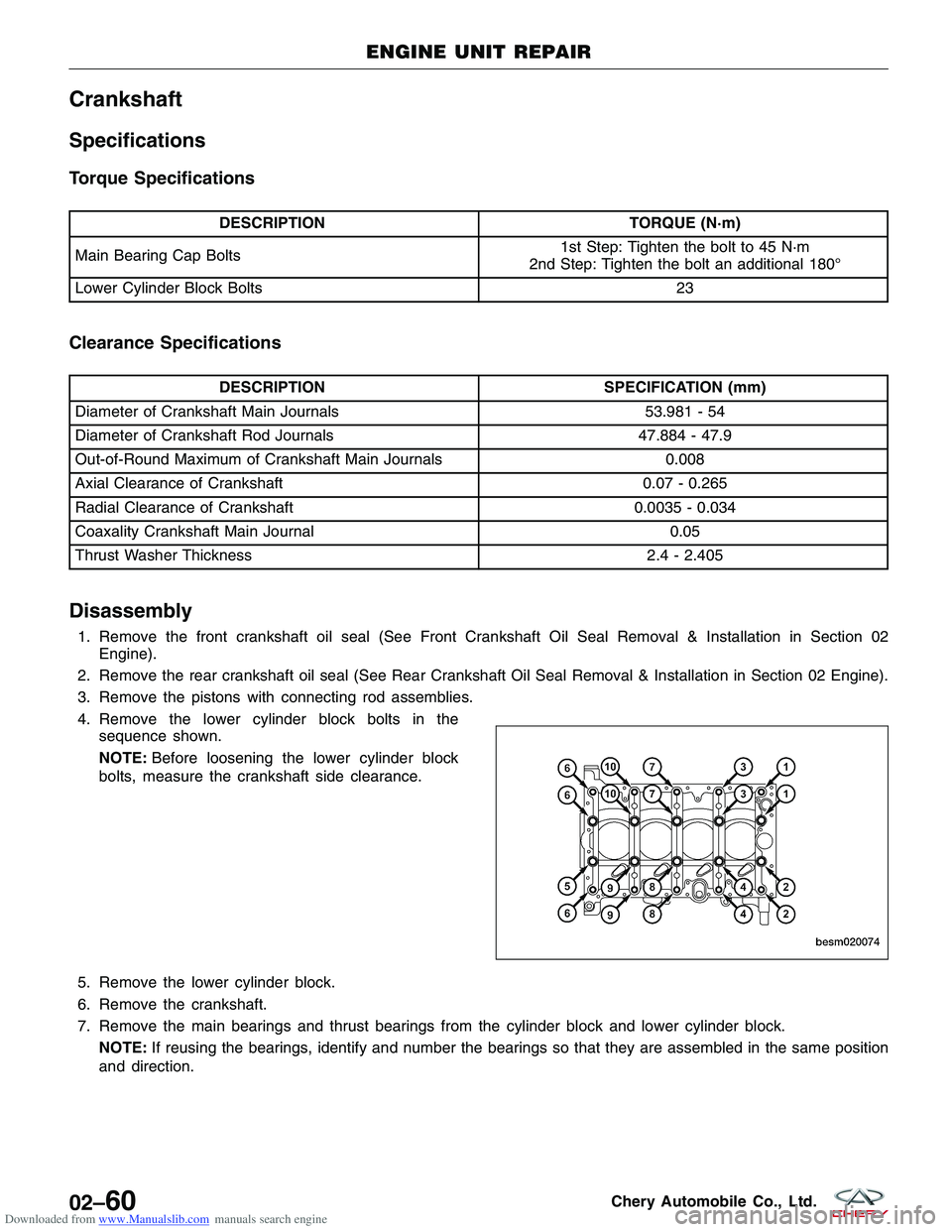

4. Remove the lower cylinder block bolts in the sequence shown.

NOTE: Before loosening the lower cylinder block

bolts, measure the crankshaft side clearance.

5. Remove the lower cylinder block.

6. Remove the crankshaft.

7. Remove the main bearings and thrust bearings from the cylinder block and lower cylinder block. NOTE: If reusing the bearings, identify and number the bearings so that they are assembled in the same position

and direction.

ENGINE UNIT REPAIR

BESM020074

02–60Chery Automobile Co., Ltd.

Page 90 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection

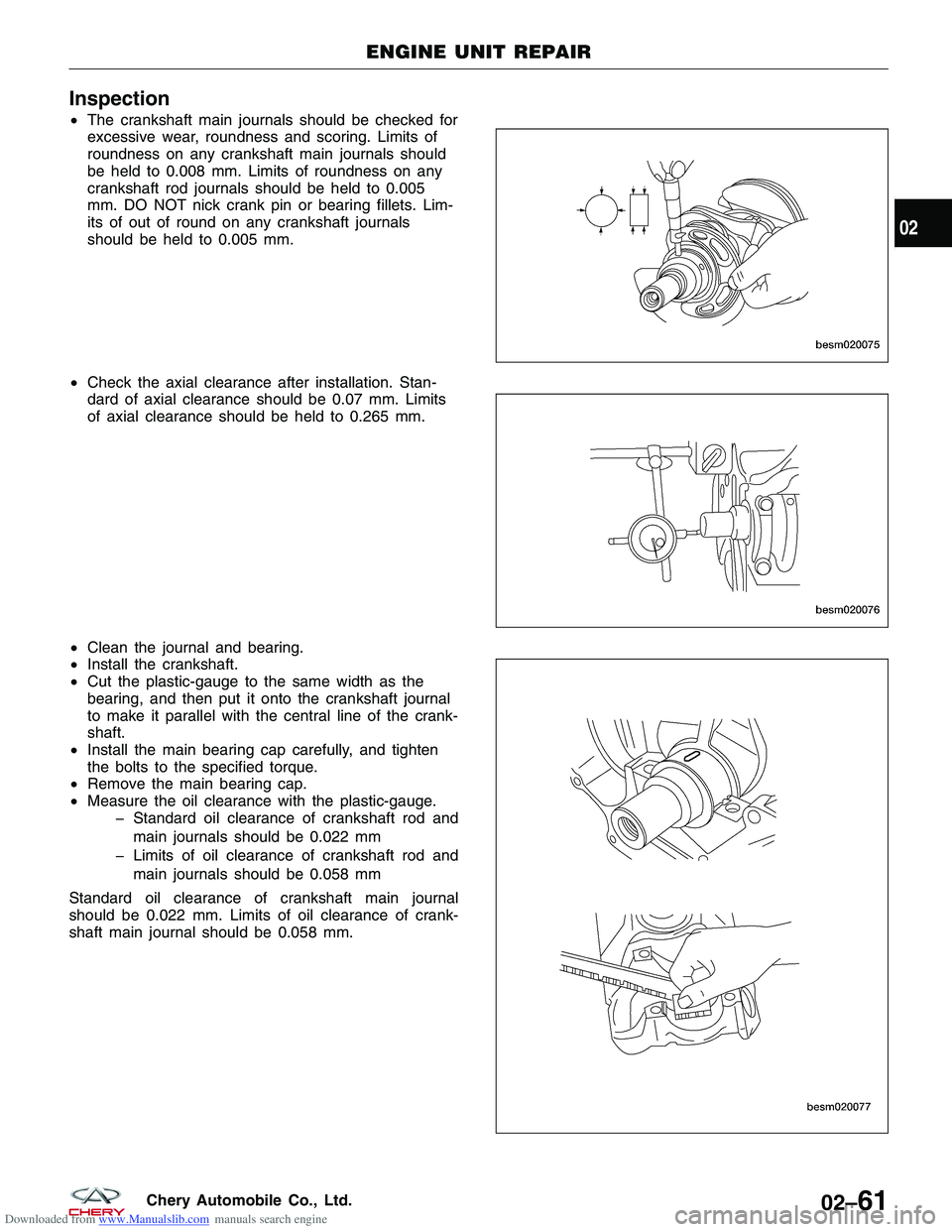

•The crankshaft main journals should be checked for

excessive wear, roundness and scoring. Limits of

roundness on any crankshaft main journals should

be held to 0.008 mm. Limits of roundness on any

crankshaft rod journals should be held to 0.005

mm. DO NOT nick crank pin or bearing fillets. Lim-

its of out of round on any crankshaft journals

should be held to 0.005 mm.

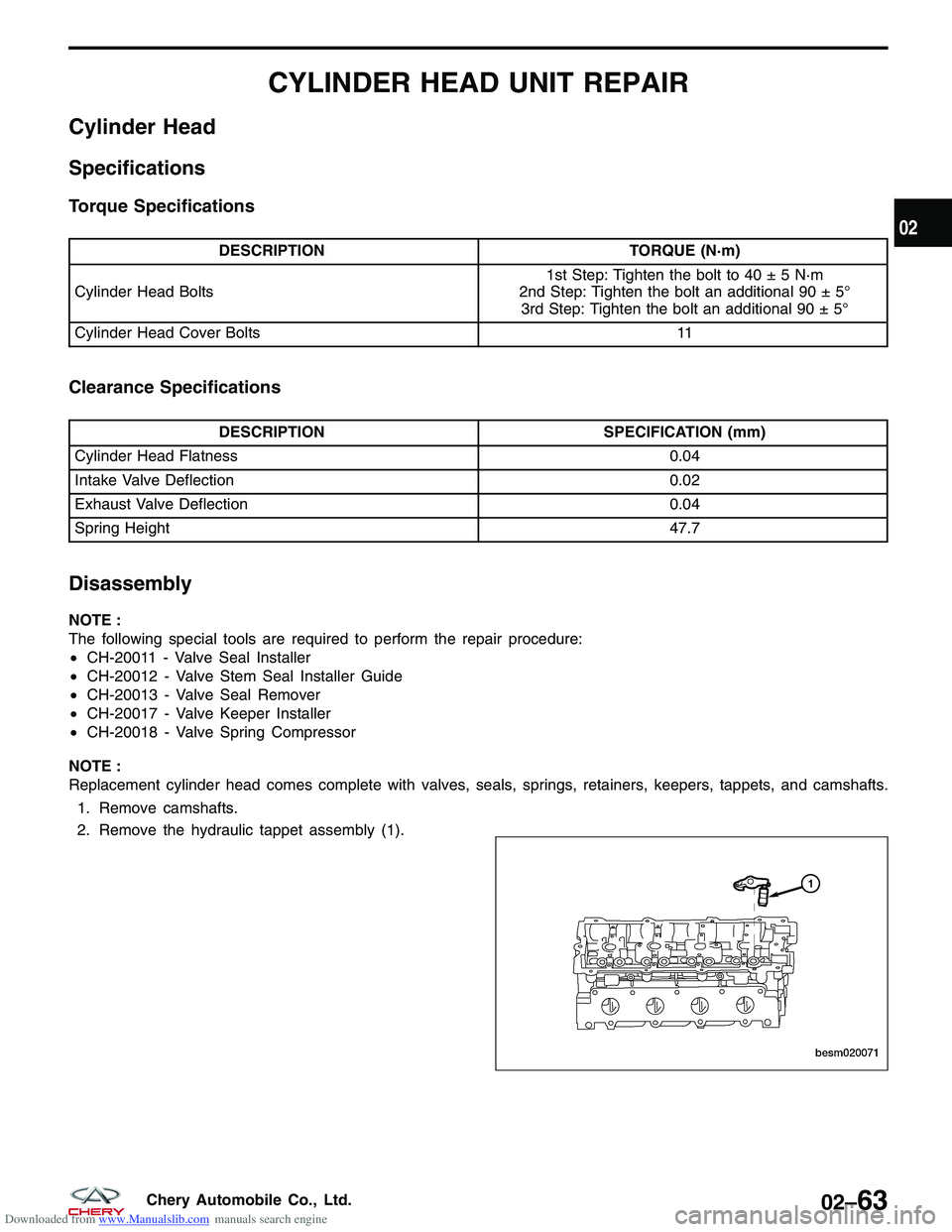

• Check the axial clearance after installation. Stan-

dard of axial clearance should be 0.07 mm. Limits

of axial clearance should be held to 0.265 mm.

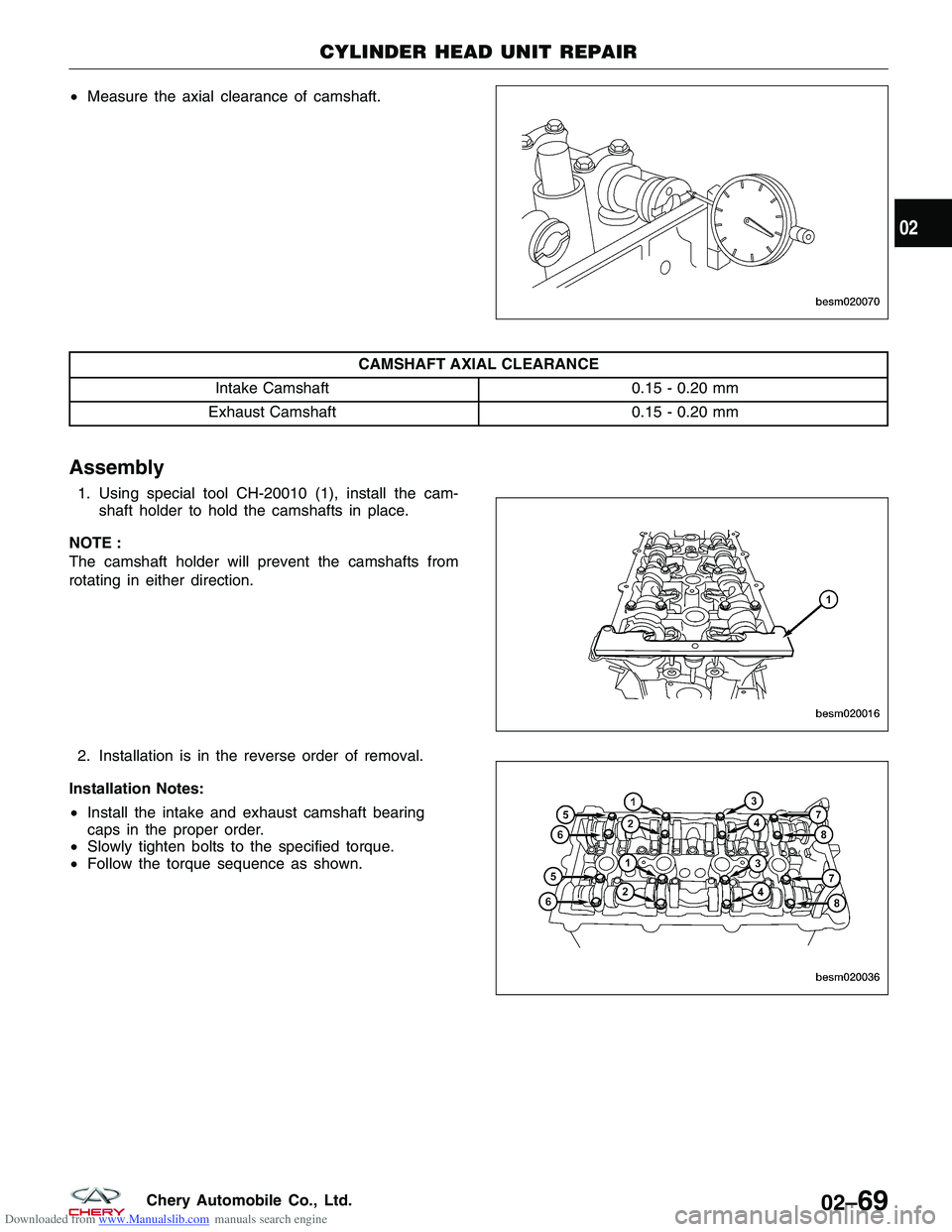

• Clean the journal and bearing.

• Install the crankshaft.

• Cut the plastic-gauge to the same width as the

bearing, and then put it onto the crankshaft journal

to make it parallel with the central line of the crank-

shaft.

• Install the main bearing cap carefully, and tighten

the bolts to the specified torque.

• Remove the main bearing cap.

• Measure the oil clearance with the plastic-gauge.

� Standard oil clearance of crankshaft rod and

main journals should be 0.022 mm

� Limits of oil clearance of crankshaft rod and main journals should be 0.058 mm

Standard oil clearance of crankshaft main journal

should be 0.022 mm. Limits of oil clearance of crank-

shaft main journal should be 0.058 mm.

ENGINE UNIT REPAIR

BESM020075

BESM020076

BESM020077

02

02–61Chery Automobile Co., Ltd.

Page 92 of 1903

Downloaded from www.Manualslib.com manuals search engine CYLINDER HEAD UNIT REPAIR

Cylinder Head

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Cylinder Head Bolts 1st Step: Tighten the bolt to 40 ± 5 N·m

2nd Step: Tighten the bolt an additional 90 ± 5° 3rd Step: Tighten the bolt an additional 90 ± 5°

Cylinder Head Cover Bolts 11

Clearance Specifications

DESCRIPTIONSPECIFICATION (mm)

Cylinder Head Flatness 0.04

Intake Valve Deflection 0.02

Exhaust Valve Deflection 0.04

Spring Height 47.7

Disassembly

NOTE :

The following special tools are required to perform the repair procedure:

•CH-20011 - Valve Seal Installer

• CH-20012 - Valve Stem Seal Installer Guide

• CH-20013 - Valve Seal Remover

• CH-20017 - Valve Keeper Installer

• CH-20018 - Valve Spring Compressor

NOTE :

Replacement cylinder head comes complete with valves, seals, springs, retainers, keepers, tappets, and camshafts. 1. Remove camshafts.

2. Remove the hydraulic tappet assembly (1).

BESM020071

02

02–63Chery Automobile Co., Ltd.

Page 98 of 1903

Downloaded from www.Manualslib.com manuals search engine •Measure the axial clearance of camshaft.

CAMSHAFT AXIAL CLEARANCE

Intake Camshaft 0.15 - 0.20 mm

Exhaust Camshaft 0.15 - 0.20 mm

Assembly

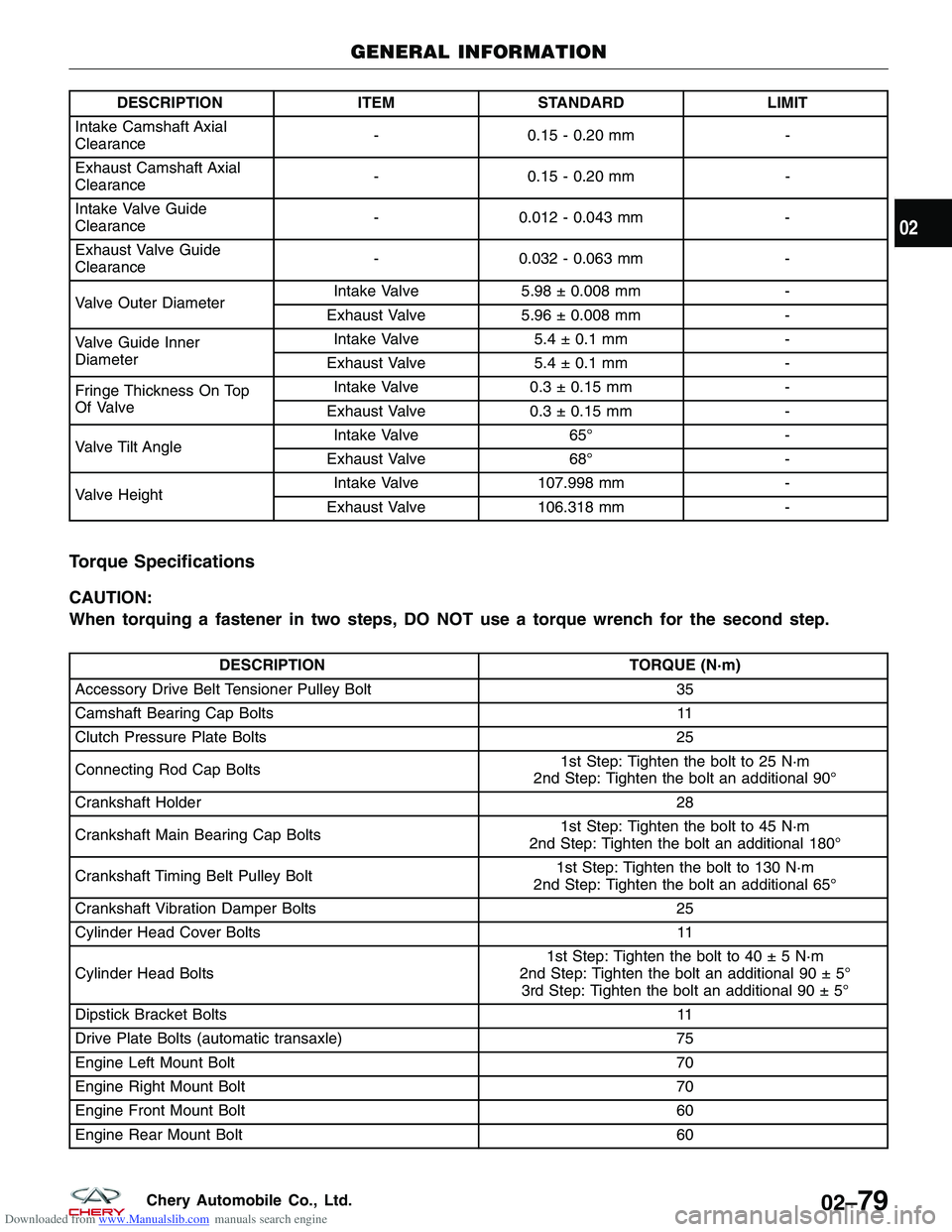

1. Using special tool CH-20010 (1), install the cam-

shaft holder to hold the camshafts in place.

NOTE :

The camshaft holder will prevent the camshafts from

rotating in either direction.

2. Installation is in the reverse order of removal.

Installation Notes:

• Install the intake and exhaust camshaft bearing

caps in the proper order.

• Slowly tighten bolts to the specified torque.

• Follow the torque sequence as shown.

CYLINDER HEAD UNIT REPAIR

BESM020070

BESM020016

BESM020036

02

02–69Chery Automobile Co., Ltd.

Page 108 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONITEMSTANDARD LIMIT

Intake Camshaft Axial

Clearance -

0.15 - 0.20 mm -

Exhaust Camshaft Axial

Clearance -

0.15 - 0.20 mm -

Intake Valve Guide

Clearance -

0.012 - 0.043 mm -

Exhaust Valve Guide

Clearance -

0.032 - 0.063 mm -

Valve Outer Diameter Intake Valve

5.98 ± 0.008 mm -

Exhaust Valve 5.96 ± 0.008 mm -

Valve Guide Inner

Diameter Intake Valve

5.4 ± 0.1 mm -

Exhaust Valve 5.4 ± 0.1 mm -

Fringe Thickness On Top

Of Valve Intake Valve

0.3 ± 0.15 mm -

Exhaust Valve 0.3 ± 0.15 mm -

Valve Tilt Angle Intake Valve

65°-

Exhaust Valve 68°-

Valve Height Intake Valve

107.998 mm -

Exhaust Valve 106.318 mm -

Torque Specifications

CAUTION:

When torquing a fastener in two steps, DO NOT use a torque wrench for the second step.

DESCRIPTION TORQUE (N·m)

Accessory Drive Belt Tensioner Pulley Bolt 35

Camshaft Bearing Cap Bolts 11

Clutch Pressure Plate Bolts 25

Connecting Rod Cap Bolts 1st Step: Tighten the bolt to 25 N·m

2nd Step: Tighten the bolt an additional 90°

Crankshaft Holder 28

Crankshaft Main Bearing Cap Bolts 1st Step: Tighten the bolt to 45 N·m

2nd Step: Tighten the bolt an additional 180°

Crankshaft Timing Belt Pulley Bolt 1st Step: Tighten the bolt to 130 N·m

2nd Step: Tighten the bolt an additional 65°

Crankshaft Vibration Damper Bolts 25

Cylinder Head Cover Bolts 11

Cylinder Head Bolts 1st Step: Tighten the bolt to 40 ± 5 N·m

2nd Step: Tighten the bolt an additional 90 ± 5° 3rd Step: Tighten the bolt an additional 90 ± 5°

Dipstick Bracket Bolts 11

Drive Plate Bolts (automatic transaxle) 75

Engine Left Mount Bolt 70

Engine Right Mount Bolt 70

Engine Front Mount Bolt 60

Engine Rear Mount Bolt 60

GENERAL INFORMATION

02

02–79Chery Automobile Co., Ltd.

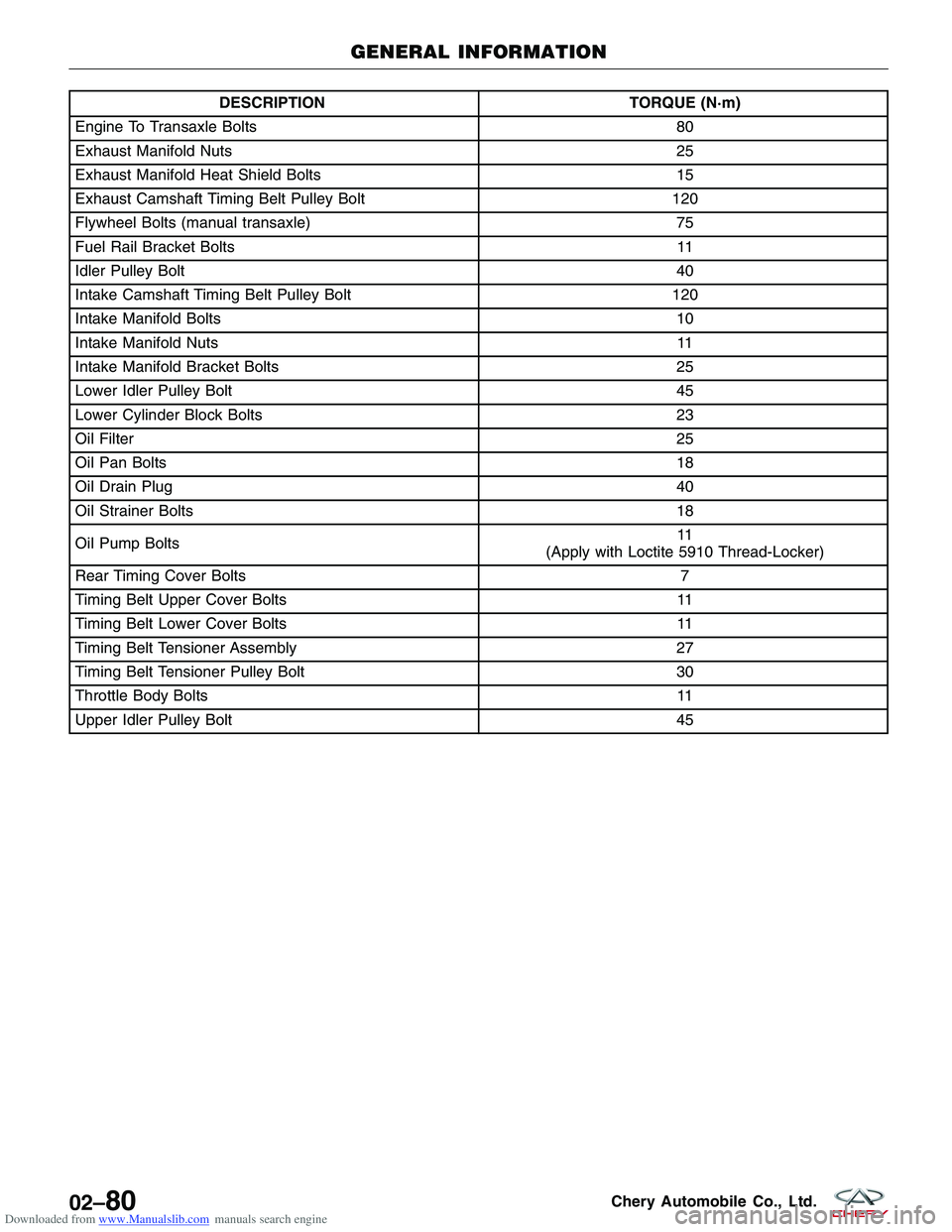

Page 109 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONTORQUE (N·m)

Engine To Transaxle Bolts 80

Exhaust Manifold Nuts 25

Exhaust Manifold Heat Shield Bolts 15

Exhaust Camshaft Timing Belt Pulley Bolt 120

Flywheel Bolts (manual transaxle) 75

Fuel Rail Bracket Bolts 11

Idler Pulley Bolt 40

Intake Camshaft Timing Belt Pulley Bolt 120

Intake Manifold Bolts 10

Intake Manifold Nuts 11

Intake Manifold Bracket Bolts 25

Lower Idler Pulley Bolt 45

Lower Cylinder Block Bolts 23

Oil Filter 25

Oil Pan Bolts 18

Oil Drain Plug 40

Oil Strainer Bolts 18

Oil Pump Bolts 11

(Apply with Loctite 5910 Thread-Locker)

Rear Timing Cover Bolts 7

Timing Belt Upper Cover Bolts 11

Timing Belt Lower Cover Bolts 11

Timing Belt Tensioner Assembly 27

Timing Belt Tensioner Pulley Bolt 30

Throttle Body Bolts 11

Upper Idler Pulley Bolt 45

GENERAL INFORMATION

02–80Chery Automobile Co., Ltd.

Page 117 of 1903

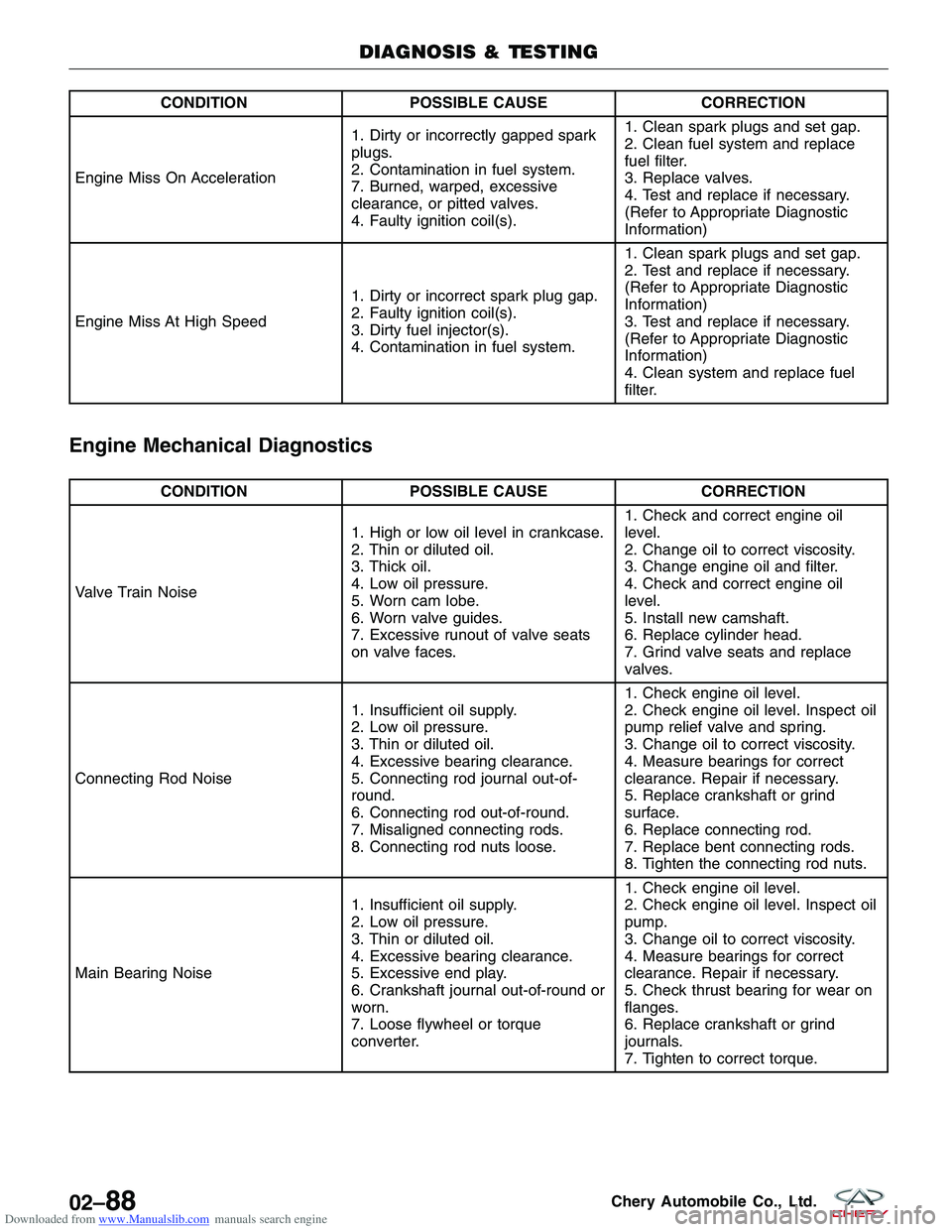

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSE CORRECTION

Engine Miss On Acceleration 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

7. Burned, warped, excessive

clearance, or pitted valves.

4. Faulty ignition coil(s).1. Clean spark plugs and set gap.

2. Clean fuel system and replace

fuel filter.

3. Replace valves.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Miss At High Speed 1. Dirty or incorrect spark plug gap.

2. Faulty ignition coil(s).

3. Dirty fuel injector(s).

4. Contamination in fuel system.1. Clean spark plugs and set gap.

2. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Clean system and replace fuel

filter.

Engine Mechanical Diagnostics

CONDITION

POSSIBLE CAUSE CORRECTION

Valve Train Noise 1. High or low oil level in crankcase.

2. Thin or diluted oil.

3. Thick oil.

4. Low oil pressure.

5. Worn cam lobe.

6. Worn valve guides.

7. Excessive runout of valve seats

on valve faces.1. Check and correct engine oil

level.

2. Change oil to correct viscosity.

3. Change engine oil and filter.

4. Check and correct engine oil

level.

5. Install new camshaft.

6. Replace cylinder head.

7. Grind valve seats and replace

valves.

Connecting Rod Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Connecting rod journal out-of-

round.

6. Connecting rod out-of-round.

7. Misaligned connecting rods.

8. Connecting rod nuts loose.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Replace crankshaft or grind

surface.

6. Replace connecting rod.

7. Replace bent connecting rods.

8. Tighten the connecting rod nuts.

Main Bearing Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Excessive end play.

6. Crankshaft journal out-of-round or

worn.

7. Loose flywheel or torque

converter.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Check thrust bearing for wear on

flanges.

6. Replace crankshaft or grind

journals.

7. Tighten to correct torque.

DIAGNOSIS & TESTING

02–88Chery Automobile Co., Ltd.