torque CHERY TIGGO 2009 Service Workshop Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 850 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The electronic ignition system consists of the following components:

•Engine Control Module (ECM)

• Ignition Coil

• Spark Plugs

• Spark Plug Wires

• Camshaft Position (CMP) Sensor

• Crankshaft Position (CKP) Sensor

Operation

The ignition system utilizes a split ignition coil which supplies secondary voltage to two cylinders. When the ignition

coil discharges, two spark plugs fire at the same time. The Engine Control Module (ECM) uses inputs from the

Crankshaft Position (CKP) Sensor to determine the Top Dead Center (TDC) position of the piston for cylinder number

one, and the Camshaft Position (CMP) Sensor to determine which ignition coil to energize.

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

Spark Plugs 30

Ignition Coil Bolts 6

Spark Plug Specifications

DESCRIPTIONGAP

FR7DTC 0.7 mm - 1.1 mm

03–566Chery Automobile Co., Ltd.

Page 867 of 1903

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Vapor Canister Bolts 10

Special Tools

Diagnostic Scan Tool

X-431

Engine AnalyzerKES-200

GENERAL INFORMATION

03

03–583Chery Automobile Co., Ltd.

Page 877 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The fuel delivery system is enabled when it reaches the following conditions:

•Turn the ignition switch ON (engine off), the fuel delivery system is enabled for 3-6 seconds.

• The Engine Control Module (ECM) receives a Crankshaft Position (CKP) sensor signal.

The fuel injectors are a solenoid-operated valve that meter fuel flow to each cylinder. The fuel injectors are opened

and closed constantly during engine operation. The amount of fuel is controlled by the length of time the fuel injector

is held open. The fuel injectors are powered by a 12 V source and are controlled through the ground side of the

circuit by the ECM.

The fuel pump operation is defined in the fuel system control strategy and is controlled by the ECM.

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

Fuel Rail Bracket Bolts 11

Fuel Filter Mounting Bolts 10

EVAP Emissions Assembly

1 - Fuel Filter Assembly

2 - Fuel Delivery and Return Pipes

3 - EVAP Pipe I

4 - Fuel Delivery Pipe III

5 - Fuel Delivery Pipe IV

6 - Air Duct

7 - Fuel Delivery Pipe V

8 - Pipe Clamps9 - EVAP Hose V

10 - Fuel Delivery Hose

11 - Air Duct

12 - Canister Assembly

13 - Canister Bracket Assembly

14 - Bolt

15 - EVAP Hose I

GENERAL INFORMATION

LTSM040010

04–4Chery Automobile Co., Ltd.

Page 900 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The battery, starting and charging systems operate in conjunction with one another, and must be tested as a com-

plete system. For correct operation of starting/charging systems, all components used in these 3 systems must per-

form within specifications. When attempting to diagnose any of these systems, it is important that you keep their

interdependency in mind. These components form two separate circuits, a high amperage circuit that feeds the

starter motor up to 150 amps, and a control circuit that operates on less than 20 amps.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Starter Mounting Bolts 30

Battery Positive Cable Nut 15

Special Tools

Digital Multimeter

Fluke 15B & 17B

GENERAL INFORMATION

05

05–3Chery Automobile Co., Ltd.

Page 906 of 1903

Downloaded from www.Manualslib.com manuals search engine Battery Tray

Removal & Installation

1. Disconnect the negative battery cable.

2. Disconnect the positive battery cable.

3. Remove the battery hold down.

4. Remove the battery.

5. Remove the three bolts (1) from the battery tray.

6. Lift the battery tray out of the engine compartmentand remove from the vehicle.

7. Installation is in the reverse order of removal.

Starter Motor Assembly

Description

The starter motor is mounted with two bolts to the transaxle housing and is located on the side of the engine. The

starter motor incorporates several features to create a reliable, efficient, compact, lightweight and powerful unit. The

electric motor of the starter features electromagnetic field coils wound around pole shoes, and brushes contact the

motor commutator. The starter motor is serviced only as a unit and cannot be repaired.

Operation

The starter motor is equipped with a planetary gear reduction system. The planetary gear reduction system consists

of a gear that is integral to the output end of the electric motor armature shaft that is in continual engagement with

a larger gear that is splined to the input end of the starter pinion gear shaft. This feature makes it possible to reduce

the dimensions of the starter. At the same time, it allows higher armature rotational speed and delivers increased

torque through the starter pinion gear to the starter ring gear.

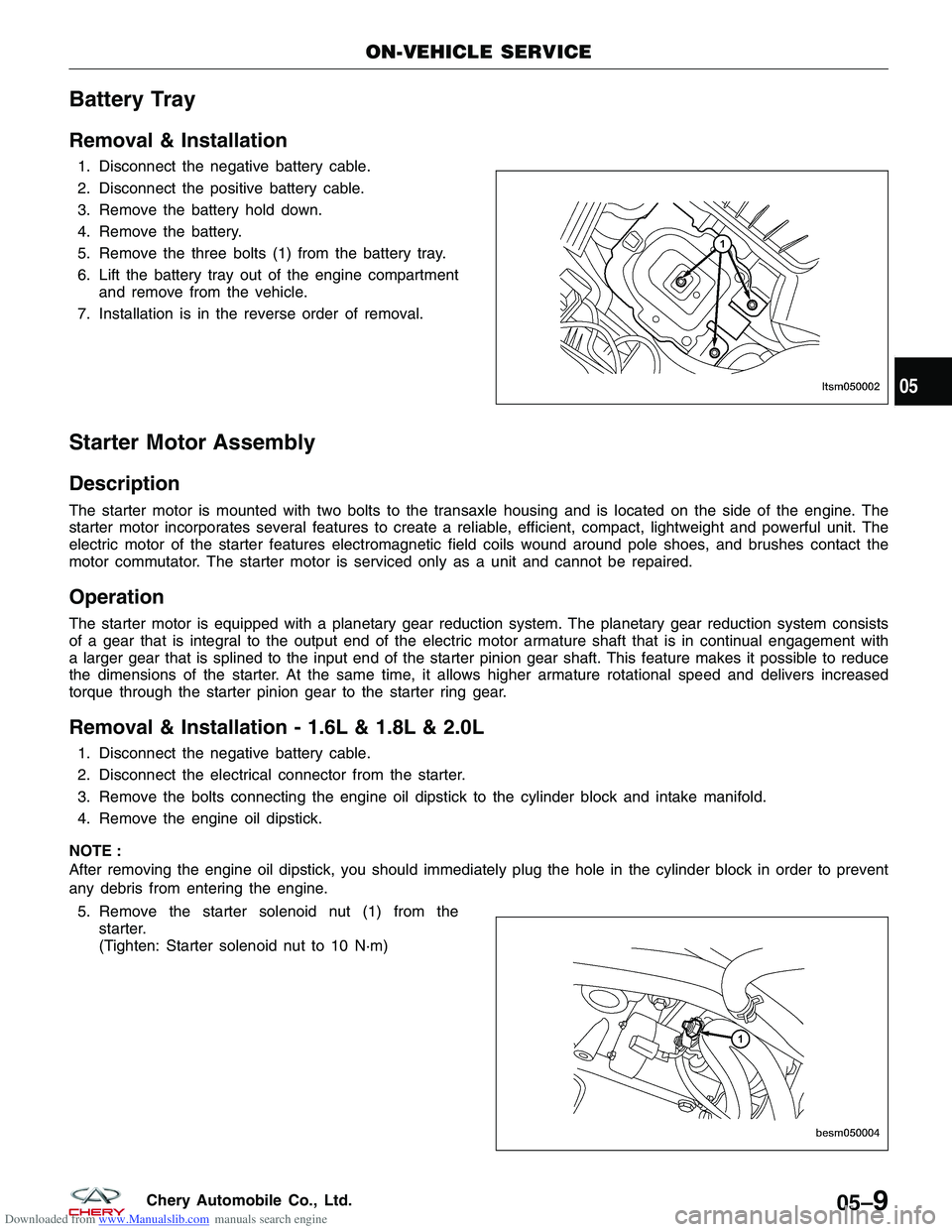

Removal & Installation - 1.6L & 1.8L & 2.0L

1. Disconnect the negative battery cable.

2. Disconnect the electrical connector from the starter.

3. Remove the bolts connecting the engine oil dipstick to the cylinder block and intake manifold.

4. Remove the engine oil dipstick.

NOTE :

After removing the engine oil dipstick, you should immediately plug the hole in the cylinder block in order to prevent

any debris from entering the engine. 5. Remove the starter solenoid nut (1) from the starter.

(Tighten: Starter solenoid nut to 10 N·m)

ON-VEHICLE SERVICE

LTSM050002

BESM050004

05

05–9Chery Automobile Co., Ltd.

Page 910 of 1903

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Generator Cable Nut 13

Generator Mounting Bolts 30

Generator Adjustment Bracket Bolts 25

Special Tools

Digital Multimeter

Fluke 15B & 17B

GENERAL INFORMATION

05

05–13Chery Automobile Co., Ltd.

Page 920 of 1903

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Coolant Pump Mounting Bolts 14

Radiator Support Mounting Bolts 5

Coolant Fan Mounting Bolts 5

Thermostat Mounting Bolts 13

Fluid Specifications

DESCRIPTIONCAPACITY (L)

Cooling System 7.0

Special Tools

Cooling System Pressure Tester

GENERAL INFORMATION

06

06–5Chery Automobile Co., Ltd.

Page 939 of 1903

Downloaded from www.Manualslib.com manuals search engine WARNING!

Exhaust gases contain carbon monoxide which can be harmful to your health and are potentially lethal. Exhaust

system leaks should be repaired immediately. Never operate the engine in enclosed areas. Failure to follow

these instructions may result in personal injury or death.

Operation

In order to reduce vehicle emissions released by the engine, the catalytic converter is required to perform in all oper-

ating conditions. This reduction is especially beneficial during the cold start and warm up phases of operation, which

is when a majority of the tailpipe emissions occur on today’s vehicles because the catalytic converter has not yet

reached its operating temperature. The exhaust system channels exhaust gases from the engine and away from the

vehicle.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Catalytic Converter Mounting Nuts 50

Exhaust Manifold Flange Bolts 49 ± 5

Muffler Mounting Nuts 50

GENERAL INFORMATION

07

07–3Chery Automobile Co., Ltd.

Page 940 of 1903

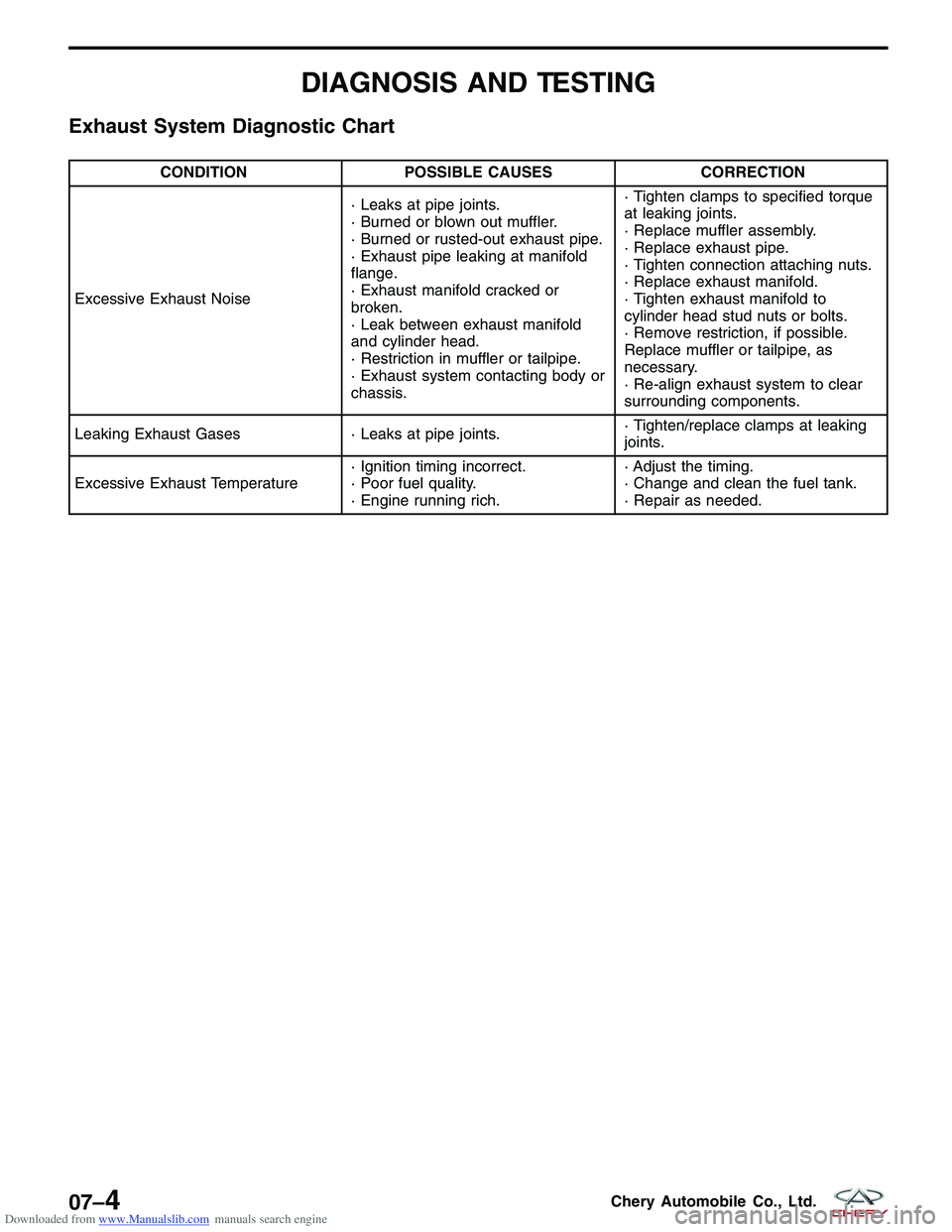

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS AND TESTING

Exhaust System Diagnostic Chart

CONDITIONPOSSIBLE CAUSES CORRECTION

Excessive Exhaust Noise · Leaks at pipe joints.

· Burned or blown out muffler.

· Burned or rusted-out exhaust pipe.

· Exhaust pipe leaking at manifold

flange.

· Exhaust manifold cracked or

broken.

· Leak between exhaust manifold

and cylinder head.

· Restriction in muffler or tailpipe.

· Exhaust system contacting body or

chassis.· Tighten clamps to specified torque

at leaking joints.

· Replace muffler assembly.

· Replace exhaust pipe.

· Tighten connection attaching nuts.

· Replace exhaust manifold.

· Tighten exhaust manifold to

cylinder head stud nuts or bolts.

· Remove restriction, if possible.

Replace muffler or tailpipe, as

necessary.

· Re-align exhaust system to clear

surrounding components.

Leaking Exhaust Gases · Leaks at pipe joints.· Tighten/replace clamps at leaking

joints.

Excessive Exhaust Temperature · Ignition timing incorrect.

· Poor fuel quality.

· Engine running rich.· Adjust the timing.

· Change and clean the fuel tank.

· Repair as needed.

07–4Chery Automobile Co., Ltd.

Page 944 of 1903

Downloaded from www.Manualslib.com manuals search engine TRANSAXLE & TRANSFER CASE

08

CONTENTSpage

DP0 Automatic Transaxle .............................................................. 08-1

F4A4 Automatic Transaxle ........................................................... 08-143

5-Speed Manual Transaxle ........................................................... 08-246

Front Differential ................................................................... 08-307

Clutch System ..................................................................... 08-316

Transfer Case (4x4) ................................................................. 08-326

DP0 AUTOMATIC TRANSAXLE

GENERAL INFORMATION08-3

Description 08-3

Operation 08-6

Specifications 08-7

Special Tools 08-8

Electrical Schematics 08-10

DP0 Transaxle Control Module (TCM)

Connector Pin-Out Table 08-18

DIAGNOSIS & TESTING08-19

Diagnostic Help 08-19

Intermittent DTC Troubleshooting 08-19

Ground Inspection 08-19

Diagnostic Tools 08-19

Diagnostic Trouble Code (DTC) List 08-20

DP0 Automatic Transaxle DTC List 08-20

Diagnostic Trouble Code (DTC) Tests 08-22

P0641 - Sensor Feed 08-22

P0657 - Solenoid Power Supply Circuit

Shorted To Voltage 08-28

P0657 - Solenoid Power Supply Circuit

Open 08-32

P0705 - Multi-Function Switch:

Prohibited Position 08-37

P0710 - Fluid Temperature Sensor 08-42

P0715 - Turbine Speed Sensor Affected

By Interference 08-46

P0730 - Ratio Of Transaxle Error 08-50

P0753 - Shift Solenoid Valve 1 (SSV1)

Open Circuit Or Short To Power Supply

Or Short To Ground 08-56 P0758 - Shift Solenoid Valve 2 (SSV2)

Open Circuit Or Short To Power Supply

Or Short To Ground 08-62

P0763 - Shift Solenoid Valve 3 (SSV3)

Short To Power Supply, P0763 - Shift

Solenoid Valve 3 (SSV3) Open Or

Short To Ground Circuit 08-68

P0768 - Shift Solenoid Valve 4 (SSV4)

Short To Power Supply, P0768 - Shift

Solenoid Valve 4 (SSV4) Open Or

Short To Ground Circuit 08-74

P0773 - Shift Solenoid Valve 5 (SSV5)

Short To Power Supply, P0773 - Shift

Solenoid Valve 5 (SSV5) Open Or

Short To Ground Circuit 08-81

P0775 - EVM (Modulation Solenoid

Valve) Open Circuit Or Short To

Ground, P0775 - EVM (Modulation

Solenoid Valve) Shorted To Voltage 08-87

P0795 - Torque Converter Lock

Solenoid Valve (EVLU) Open Circuit Or

Short To Ground, P0795 - Torque

Converter Lock Solenoid Valve (EVLU)

Short To Voltage 08-93

P0840 - Pressure Sensor 08-99

P1928 - Shift Lock Solenoid Valve

Circuit Shorted To Voltage 08-104

P1928 - Shift Lock Solenoid Valve

Open Circuit Or Short To Ground 08-109

P2709 - Shift Solenoid Valve 6 (SSV6)

Short To Power Supply 08-114

P2709 - Shift Solenoid Valve 6 (SSV6)

Open Circuit Or Short To Ground 08-119

08

08–1Chery Automobile Co., Ltd.