torque CHERY TIGGO 2009 Service Owner's Guide

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 180 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

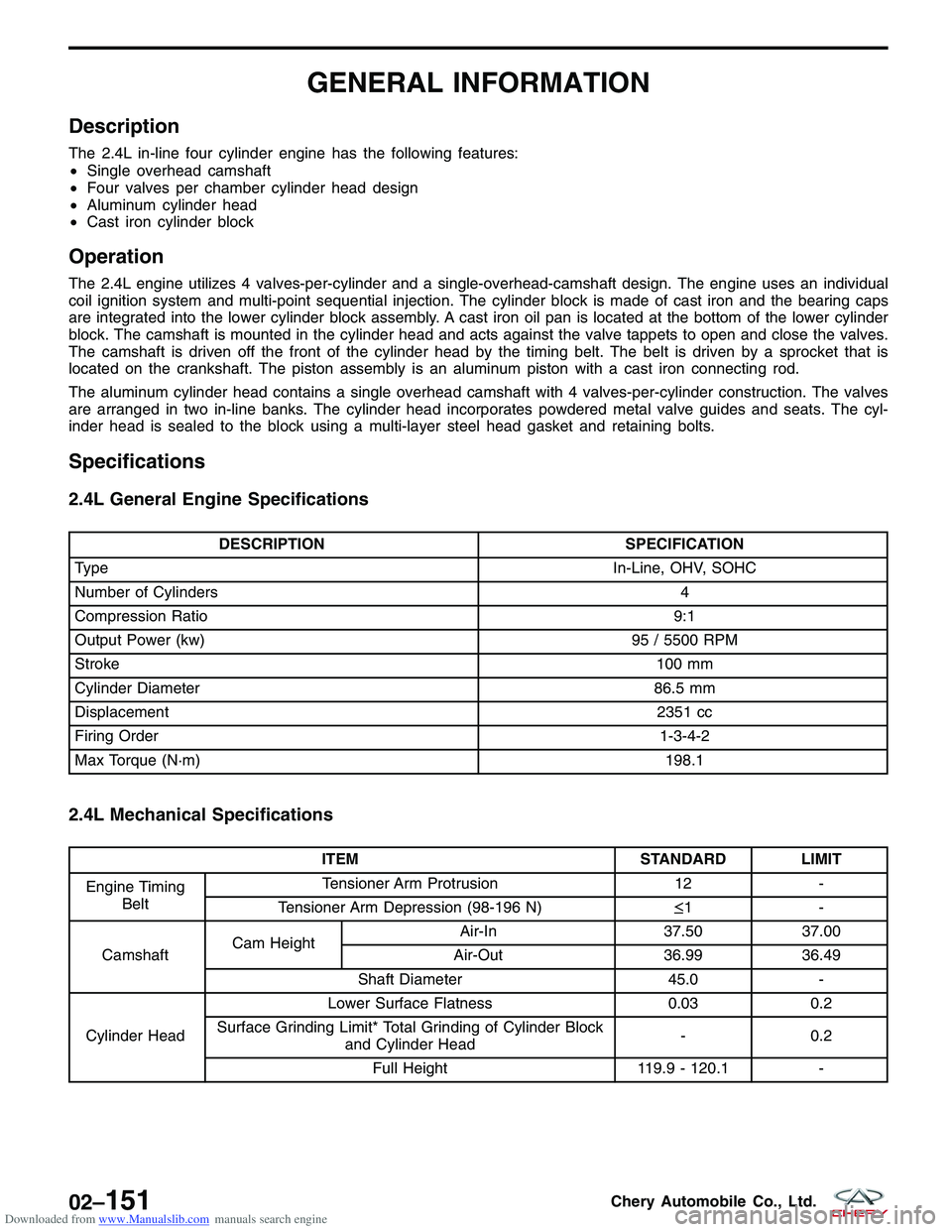

Description

The 2.4L in-line four cylinder engine has the following features:

•Single overhead camshaft

• Four valves per chamber cylinder head design

• Aluminum cylinder head

• Cast iron cylinder block

Operation

The 2.4L engine utilizes 4 valves-per-cylinder and a single-overhead-camshaft design. The engine uses an individual

coil ignition system and multi-point sequential injection. The cylinder block is made of cast iron and the bearing caps

are integrated into the lower cylinder block assembly. A cast iron oil pan is located at the bottom of the lower cylinder

block. The camshaft is mounted in the cylinder head and acts against the valve tappets to open and close the valves.

The camshaft is driven off the front of the cylinder head by the timing belt. The belt is driven by a sprocket that is

located on the crankshaft. The piston assembly is an aluminum piston with a cast iron connecting rod.

The aluminum cylinder head contains a single overhead camshaft with 4 valves-per-cylinder construction. The valves

are arranged in two in-line banks. The cylinder head incorporates powdered metal valve guides and seats. The cyl-

inder head is sealed to the block using a multi-layer steel head gasket and retaining bolts.

Specifications

2.4L General Engine Specifications

DESCRIPTION SPECIFICATION

Type In-Line, OHV, SOHC

Number of Cylinders 4

Compression Ratio 9:1

Output Power (kw) 95 / 5500 RPM

Stroke 100 mm

Cylinder Diameter 86.5 mm

Displacement 2351 cc

Firing Order 1-3-4-2

Max Torque (N·m) 198.1

2.4L Mechanical Specifications

ITEMSTANDARD LIMIT

Engine Timing Belt Tensioner Arm Protrusion

12-

Tensioner Arm Depression (98-196 N) ≤1-

Camshaft Cam Height Air-In

37.5037.00

Air-Out 36.9936.49

Shaft Diameter 45.0-

Cylinder Head Lower Surface Flatness

0.030.2

Surface Grinding Limit* Total Grinding of Cylinder Block and Cylinder Head -

0.2

Full Height 119.9 - 120.1-

02–151Chery Automobile Co., Ltd.

Page 182 of 1903

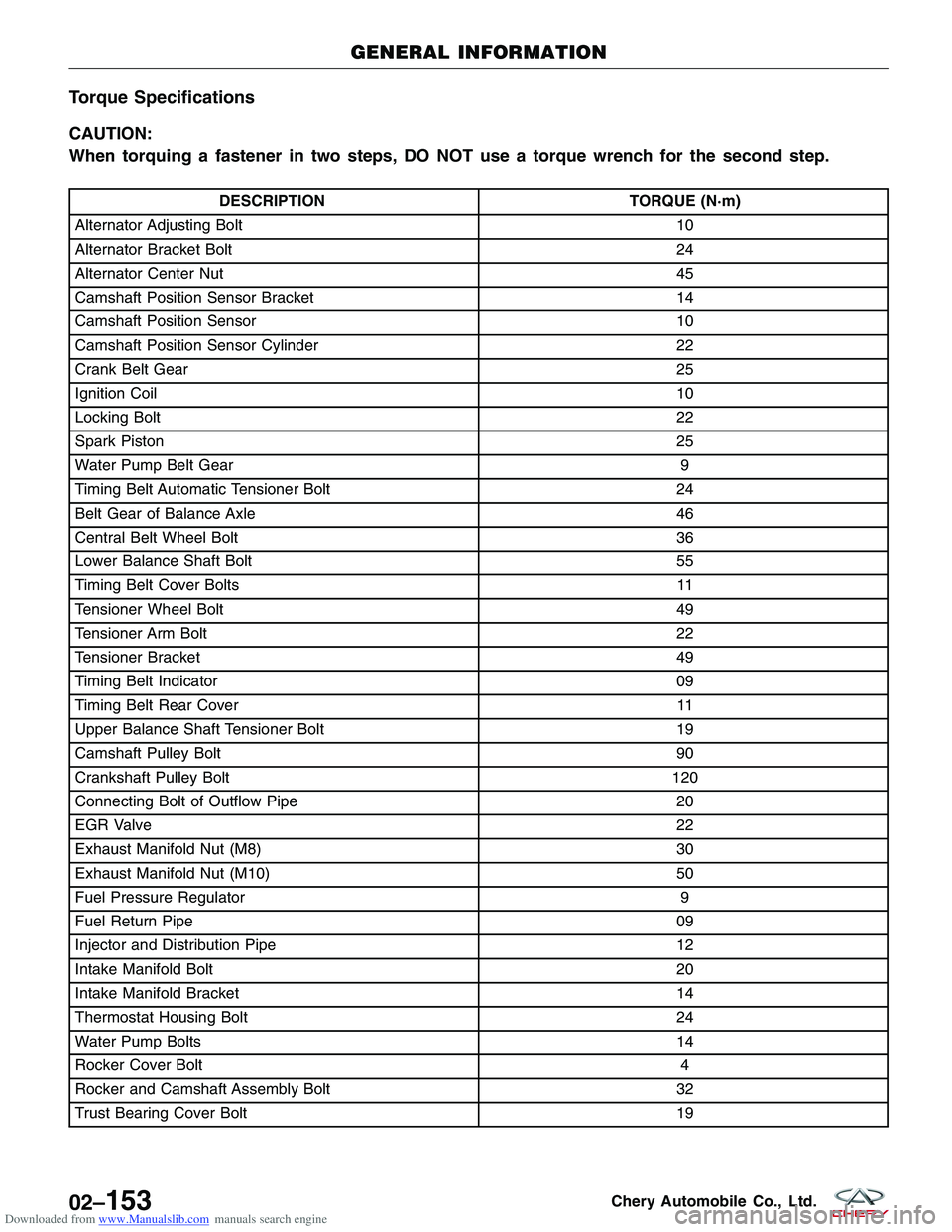

Downloaded from www.Manualslib.com manuals search engine Torque Specifications

CAUTION:

When torquing a fastener in two steps, DO NOT use a torque wrench for the second step.

DESCRIPTIONTORQUE (N·m)

Alternator Adjusting Bolt 10

Alternator Bracket Bolt 24

Alternator Center Nut 45

Camshaft Position Sensor Bracket 14

Camshaft Position Sensor 10

Camshaft Position Sensor Cylinder 22

Crank Belt Gear 25

Ignition Coil 10

Locking Bolt 22

Spark Piston 25

Water Pump Belt Gear 9

Timing Belt Automatic Tensioner Bolt 24

Belt Gear of Balance Axle 46

Central Belt Wheel Bolt 36

Lower Balance Shaft Bolt 55

Timing Belt Cover Bolts 11

Tensioner Wheel Bolt 49

Tensioner Arm Bolt 22

Tensioner Bracket 49

Timing Belt Indicator 09

Timing Belt Rear Cover 11

Upper Balance Shaft Tensioner Bolt 19

Camshaft Pulley Bolt 90

Crankshaft Pulley Bolt 120

Connecting Bolt of Outflow Pipe 20

EGR Valve 22

Exhaust Manifold Nut (M8) 30

Exhaust Manifold Nut (M10) 50

Fuel Pressure Regulator 9

Fuel Return Pipe 09

Injector and Distribution Pipe 12

Intake Manifold Bolt 20

Intake Manifold Bracket 14

Thermostat Housing Bolt 24

Water Pump Bolts 14

Rocker Cover Bolt 4

Rocker and Camshaft Assembly Bolt 32

Trust Bearing Cover Bolt 19

GENERAL INFORMATION

02–153Chery Automobile Co., Ltd.

Page 183 of 1903

Downloaded from www.Manualslib.com manuals search engine DESCRIPTIONTORQUE (N·m)

Cylinder Head Bolts 1st Step: Tighten the bolt to 78 N·m

2nd Step: Completely loosen the bolt

3rd Step: Retighten the bolt to 20 N·m

4th Step: Tighten the bolt an additional 90°

5th Step: Finish tightening the bolt an additional 90°

Engine Oil Pump Cover Bolt 16

Front Cover Bolts 24

Flange Bolt 37

Oil Pan Drain Plug 45

Oil Pan 18

Oil Pressure Switch 10

Oil Pressure Relief Plug 45

Oil Plug 24

Oil Strainer Screw Bolts 19

Oil Filter Adapter Bolts 19

Connecting Rod Nuts 1st Step: Tighten the nuts to 20 N·m

2nd Step: Tighten the nuts an additional 90°-100°

Flywheel Bolts 135

Oil Seal Cover Screw Bolts 11

Crankshaft Main Bearing Bolts 1st Step: Tighten the bolts to 25 N·m

2nd Step: Tighten the bolts an additional 90°-100°

Special Tools

Camshaft Pulley Spanner Wrench MB-990767

Driver HandleMB-990938

GENERAL INFORMATION

02

02–154Chery Automobile Co., Ltd.

Page 193 of 1903

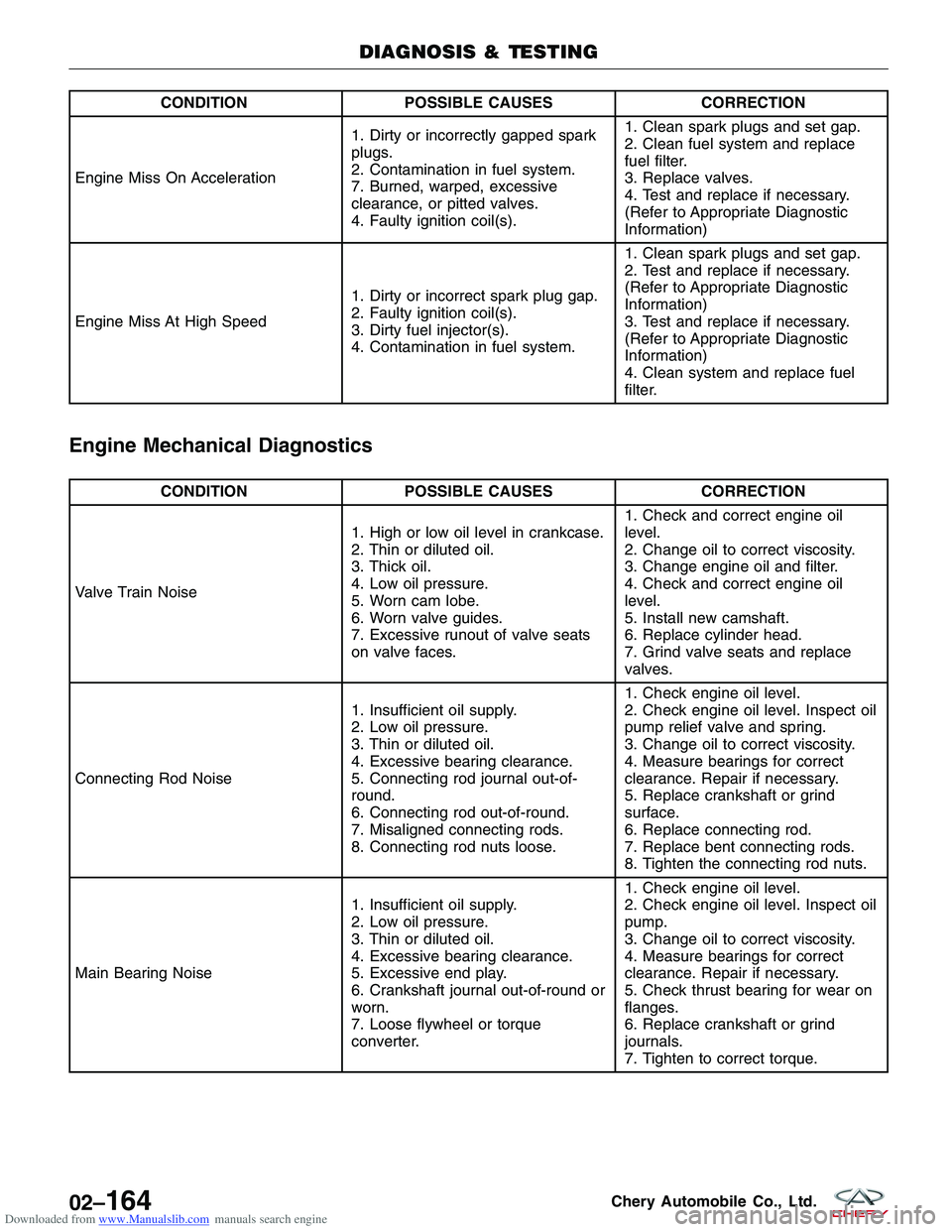

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSES CORRECTION

Engine Miss On Acceleration 1. Dirty or incorrectly gapped spark

plugs.

2. Contamination in fuel system.

7. Burned, warped, excessive

clearance, or pitted valves.

4. Faulty ignition coil(s).1. Clean spark plugs and set gap.

2. Clean fuel system and replace

fuel filter.

3. Replace valves.

4. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

Engine Miss At High Speed 1. Dirty or incorrect spark plug gap.

2. Faulty ignition coil(s).

3. Dirty fuel injector(s).

4. Contamination in fuel system.1. Clean spark plugs and set gap.

2. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

3. Test and replace if necessary.

(Refer to Appropriate Diagnostic

Information)

4. Clean system and replace fuel

filter.

Engine Mechanical Diagnostics

CONDITION

POSSIBLE CAUSES CORRECTION

Valve Train Noise 1. High or low oil level in crankcase.

2. Thin or diluted oil.

3. Thick oil.

4. Low oil pressure.

5. Worn cam lobe.

6. Worn valve guides.

7. Excessive runout of valve seats

on valve faces.1. Check and correct engine oil

level.

2. Change oil to correct viscosity.

3. Change engine oil and filter.

4. Check and correct engine oil

level.

5. Install new camshaft.

6. Replace cylinder head.

7. Grind valve seats and replace

valves.

Connecting Rod Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Connecting rod journal out-of-

round.

6. Connecting rod out-of-round.

7. Misaligned connecting rods.

8. Connecting rod nuts loose.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump relief valve and spring.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Replace crankshaft or grind

surface.

6. Replace connecting rod.

7. Replace bent connecting rods.

8. Tighten the connecting rod nuts.

Main Bearing Noise 1. Insufficient oil supply.

2. Low oil pressure.

3. Thin or diluted oil.

4. Excessive bearing clearance.

5. Excessive end play.

6. Crankshaft journal out-of-round or

worn.

7. Loose flywheel or torque

converter.1. Check engine oil level.

2. Check engine oil level. Inspect oil

pump.

3. Change oil to correct viscosity.

4. Measure bearings for correct

clearance. Repair if necessary.

5. Check thrust bearing for wear on

flanges.

6. Replace crankshaft or grind

journals.

7. Tighten to correct torque.

DIAGNOSIS & TESTING

02–164Chery Automobile Co., Ltd.

Page 205 of 1903

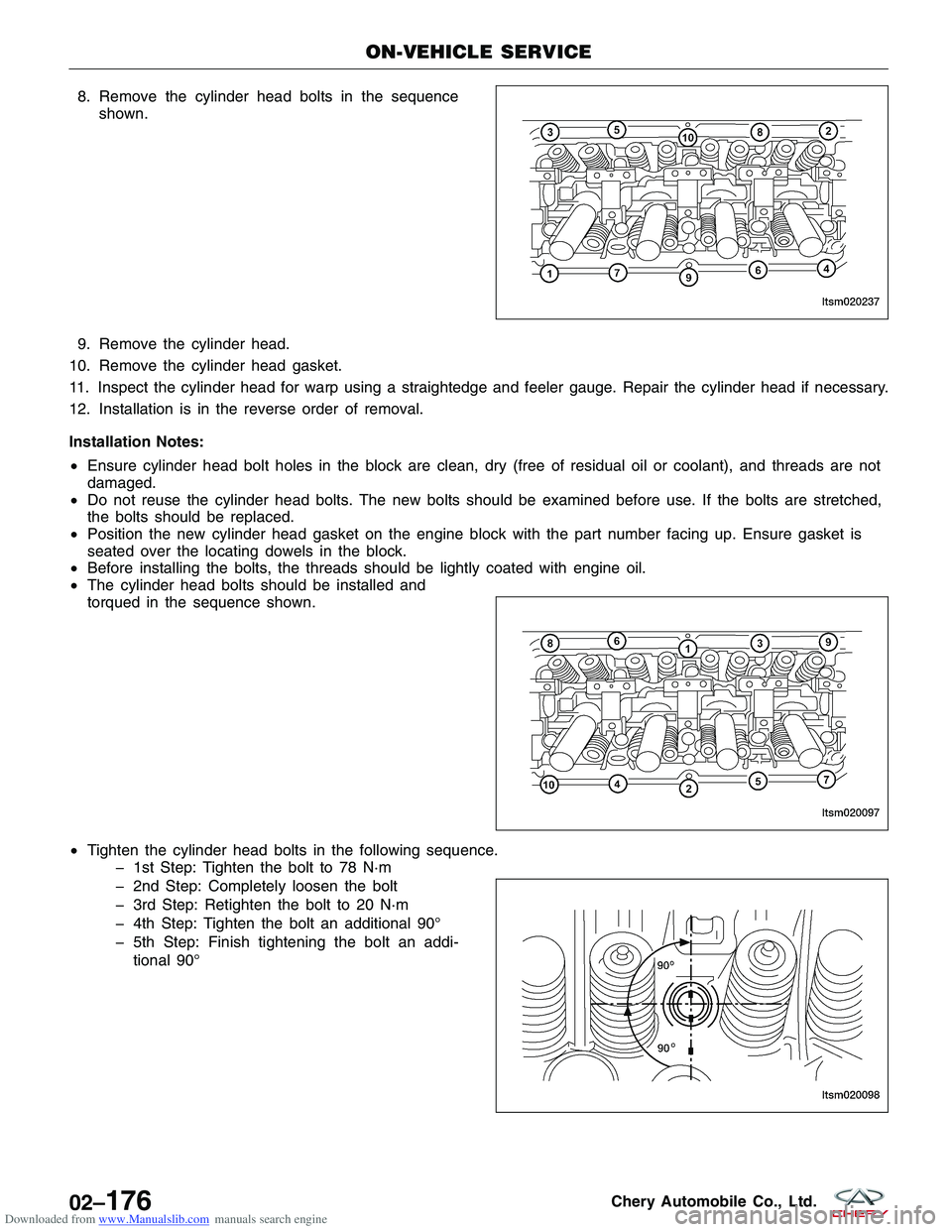

Downloaded from www.Manualslib.com manuals search engine 8. Remove the cylinder head bolts in the sequenceshown.

9. Remove the cylinder head.

10. Remove the cylinder head gasket.

11. Inspect the cylinder head for warp using a straightedge and feeler gauge. Repair the cylinder head if necessary.

12. Installation is in the reverse order of removal.

Installation Notes:

• Ensure cylinder head bolt holes in the block are clean, dry (free of residual oil or coolant), and threads are not

damaged.

• Do not reuse the cylinder head bolts. The new bolts should be examined before use. If the bolts are stretched,

the bolts should be replaced.

• Position the new cylinder head gasket on the engine block with the part number facing up. Ensure gasket is

seated over the locating dowels in the block.

• Before installing the bolts, the threads should be lightly coated with engine oil.

• The cylinder head bolts should be installed and

torqued in the sequence shown.

• Tighten the cylinder head bolts in the following sequence.

� 1st Step: Tighten the bolt to 78 N·m

� 2nd Step: Completely loosen the bolt

� 3rd Step: Retighten the bolt to 20 N·m

� 4th Step: Tighten the bolt an additional 90°

� 5th Step: Finish tightening the bolt an addi-

tional 90°

ON-VEHICLE SERVICE

LTSM020237

LTSM020097

LTSM020098

02–176Chery Automobile Co., Ltd.

Page 223 of 1903

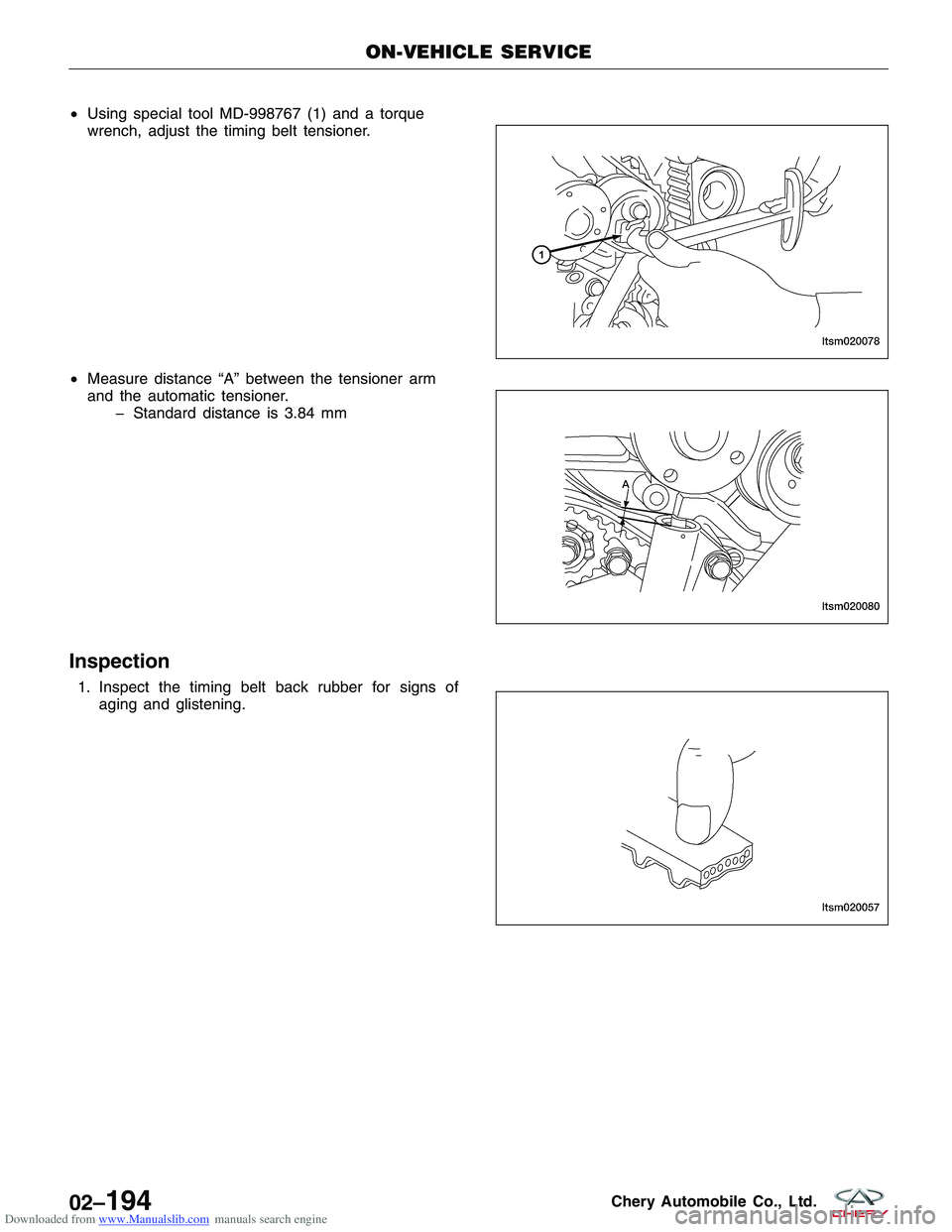

Downloaded from www.Manualslib.com manuals search engine •Using special tool MD-998767 (1) and a torque

wrench, adjust the timing belt tensioner.

• Measure distance “A” between the tensioner arm

and the automatic tensioner.

� Standard distance is 3.84 mm

Inspection

1. Inspect the timing belt back rubber for signs ofaging and glistening.

ON-VEHICLE SERVICE

LTSM020078

LTSM020080

LTSM020057

02–194Chery Automobile Co., Ltd.

Page 243 of 1903

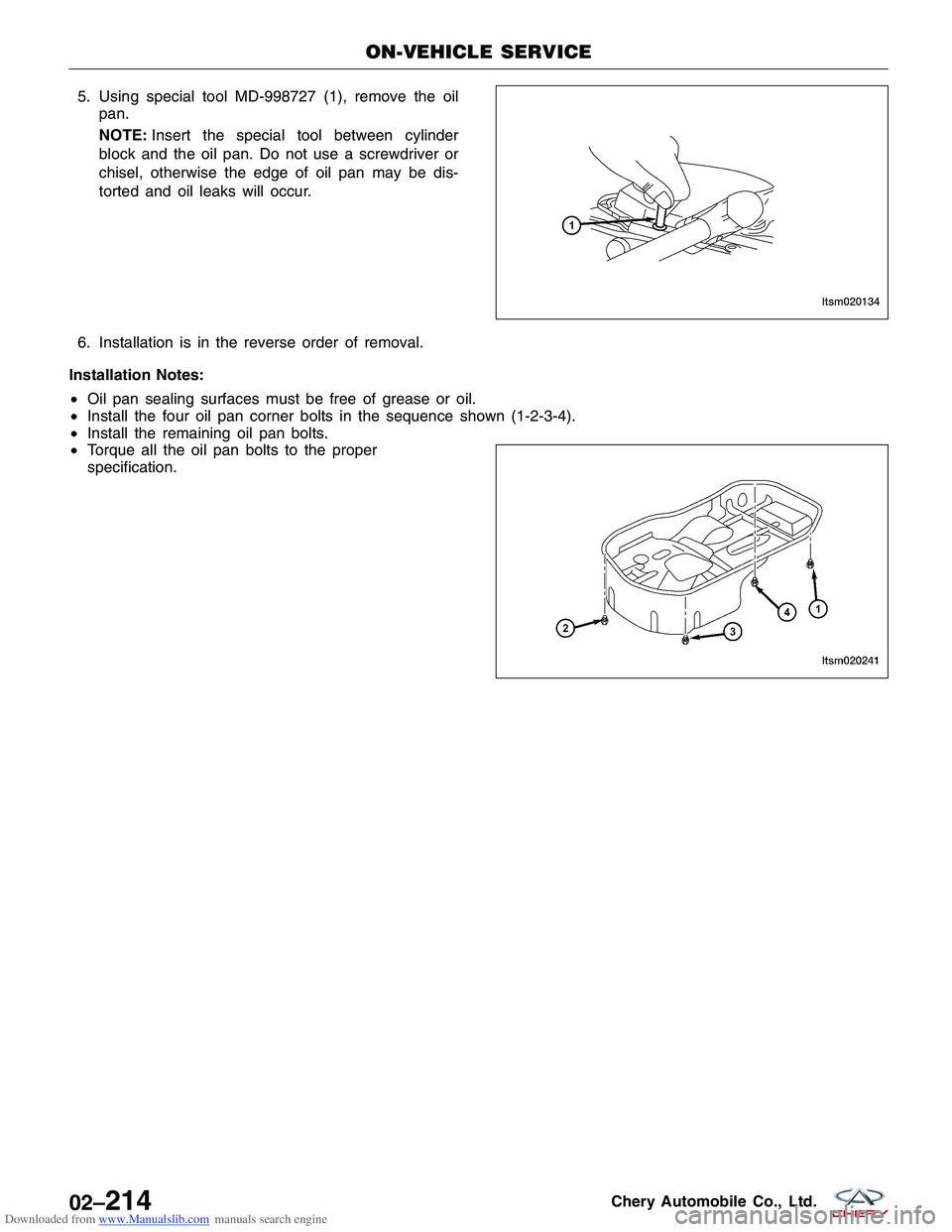

Downloaded from www.Manualslib.com manuals search engine 5. Using special tool MD-998727 (1), remove the oilpan.

NOTE: Insert the special tool between cylinder

block and the oil pan. Do not use a screwdriver or

chisel, otherwise the edge of oil pan may be dis-

torted and oil leaks will occur.

6. Installation is in the reverse order of removal.

Installation Notes:

• Oil pan sealing surfaces must be free of grease or oil.

• Install the four oil pan corner bolts in the sequence shown (1-2-3-4).

• Install the remaining oil pan bolts.

• Torque all the oil pan bolts to the proper

specification.

ON-VEHICLE SERVICE

LTSM020134

LTSM020241

02–214Chery Automobile Co., Ltd.

Page 246 of 1903

Downloaded from www.Manualslib.com manuals search engine ENGINE UNIT REPAIR

Engine Block

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Connecting Rod Cap Nuts 1st Step: Tighten the nuts to 20 N·m

2nd Step: Tighten the nuts an additional 90°-100°

Main Bearing Cap Bolts 1st Step: Tighten the bolts to 25 N·m

2nd Step: Tighten the bolts an additional 90°-100°

Clearance Specifications

DESCRIPTION SPECIFICATION (mm)

Surface Distortion Limit 0.15

Cylinder Diameter Standard 86.50 - 86.53

Out-Of-Round < 0.008

Taper < 0.01

02

02–217Chery Automobile Co., Ltd.

Page 258 of 1903

Downloaded from www.Manualslib.com manuals search engine Connecting Rods

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Connecting Rod Nuts 1st Step: Tighten the nuts to 20 N·m

2nd Step: Tighten the nuts an additional 90°-100°

Clearance Specifications

DESCRIPTION SPECIFICATION (mm)

Connecting Rod Radial Clearance 0.016 - 0.051

Connecting Rod Axial Clearance 0.002 - 0.013

Disassembly

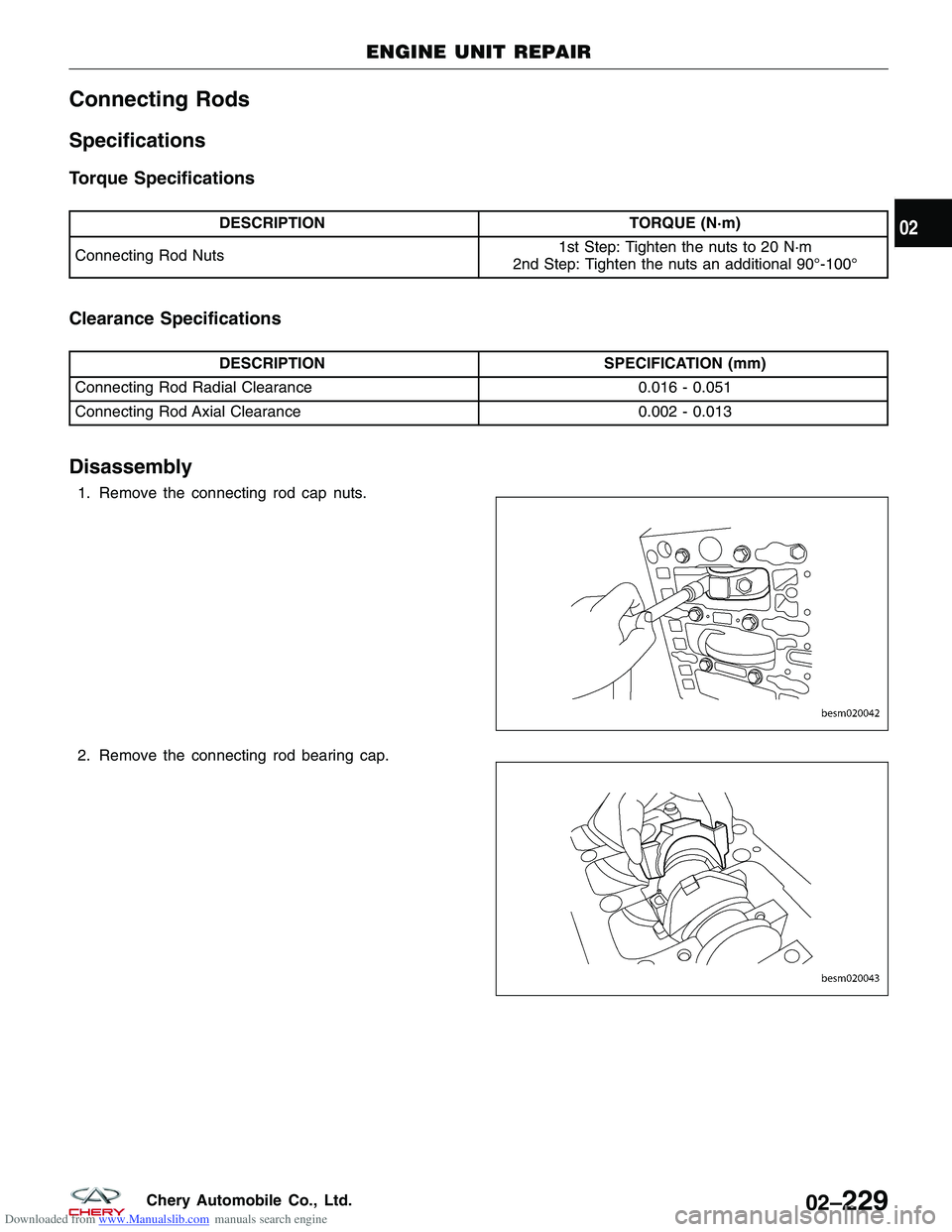

1. Remove the connecting rod cap nuts.

2. Remove the connecting rod bearing cap.

ENGINE UNIT REPAIR

BESM020042

BESM020043

02

02–229Chery Automobile Co., Ltd.

Page 259 of 1903

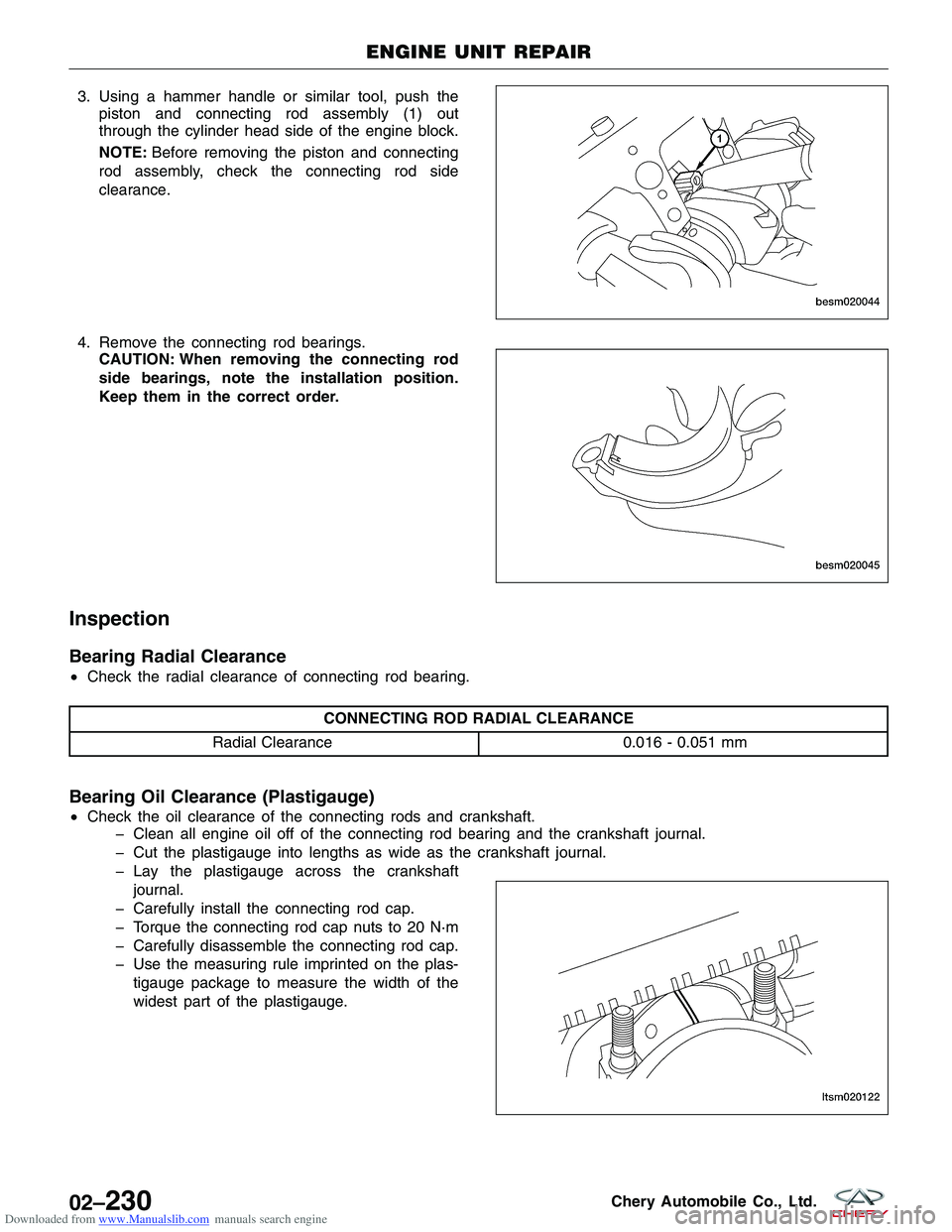

Downloaded from www.Manualslib.com manuals search engine 3. Using a hammer handle or similar tool, push thepiston and connecting rod assembly (1) out

through the cylinder head side of the engine block.

NOTE: Before removing the piston and connecting

rod assembly, check the connecting rod side

clearance.

4. Remove the connecting rod bearings. CAUTION: When removing the connecting rod

side bearings, note the installation position.

Keep them in the correct order.

Inspection

Bearing Radial Clearance

•Check the radial clearance of connecting rod bearing.

CONNECTING ROD RADIAL CLEARANCE

Radial Clearance 0.016 - 0.051 mm

Bearing Oil Clearance (Plastigauge)

•Check the oil clearance of the connecting rods and crankshaft.

� Clean all engine oil off of the connecting rod bearing and the crankshaft journal.

� Cut the plastigauge into lengths as wide as the crankshaft journal.

� Lay the plastigauge across the crankshaft

journal.

� Carefully install the connecting rod cap.

� Torque the connecting rod cap nuts to 20 N·m

� Carefully disassemble the connecting rod cap.

� Use the measuring rule imprinted on the plas- tigauge package to measure the width of the

widest part of the plastigauge.

ENGINE UNIT REPAIR

BESM020044

BESM020045

LTSM020122

02–230Chery Automobile Co., Ltd.