heating CHERY TIGGO 2009 Service Owner's Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 834 of 1903

Downloaded from www.Manualslib.com manuals search engine 4.CHECK FUEL SYSTEM PRESSURE

• Release the fuel system pressure (See Fuel Pressure Relief Procedure in Section 04 Fuel Delivery).

• Check fuel system pressure (See Fuel Pressure Test in Section 04 Fuel Delivery).

Is fuel pressure correct?

Ye s>>Go to the next step.

No

>>If the fuel pressure is greater than 400 kPa (4.0 bar):

� Replace the fuel pressure regulator.

If the fuel pressure is less than 400 kPa (4.0 bar):

� Check the fuel supply system for restrictions or leaks.

� If no problems, repair or replace fuel filter, pressure regulator or fuel pump assembly.

5.CHECK EXHAUST SYSTEM

• Check the exhaust system for restrictions.

Is there a restriction in the exhaust system?

Ye s>>Repair as necessary.

No

>>Go to the next step.

6.CHECK ENGINE OVERHEATING

• Is the engine overheating (hot start concern only)?

For hot start concerns, does engine appear to be overheating?

Ye s>>Repair the engine cooling system.

No

>>Go to the next step.

7.CHECK POSITIVE CRANKCASE VENTILATION (PCV) SYSTEM

• Remove the PCV valve and shake it.

Does PCV valve rattle?

Ye s>>Go to the next step.

No

>>Replace the PCV valve.

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03–550Chery Automobile Co., Ltd.

Page 836 of 1903

Downloaded from www.Manualslib.com manuals search engine Fast Idle

The following conditions apply to this symptom:

•The engine idles at a higher than recommended speed.

1.VERIFY ENGINE OPERATES AT NORMAL OPERATING TEMPERATURE

• Check the engine operating temperature.

Does the engine appear to be either overheating or not reaching normal operating temperature?

Ye s>>Repair the engine cooling system.

No

>>Go to the next step.

2.PRELIMINARY CHECKS

• Carry out the following preliminary checks:

� Vacuum leaks

� Throttle plate and linkage

� Intake air tube (leaks)

� Correct sealing of intake manifold and components attached to intake air tube

Are all checks OK?

Ye s>>Go to the next step.

No

>>Repair as necessary.

Verify the symptom no longer exists.

3.CHECK ECM DTC

• Turn the ignition switch on.

• With the scan tool X-431, select view DTC and data stream in ECM.

Are there any DTCs present?

Ye s>>See the Diagnostic Trouble Code (DTC) List.

Go to the specific diagnostic test to troubleshoot the DTC.

No

>>See Diagnostic Help for additional information.

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03–552Chery Automobile Co., Ltd.

Page 918 of 1903

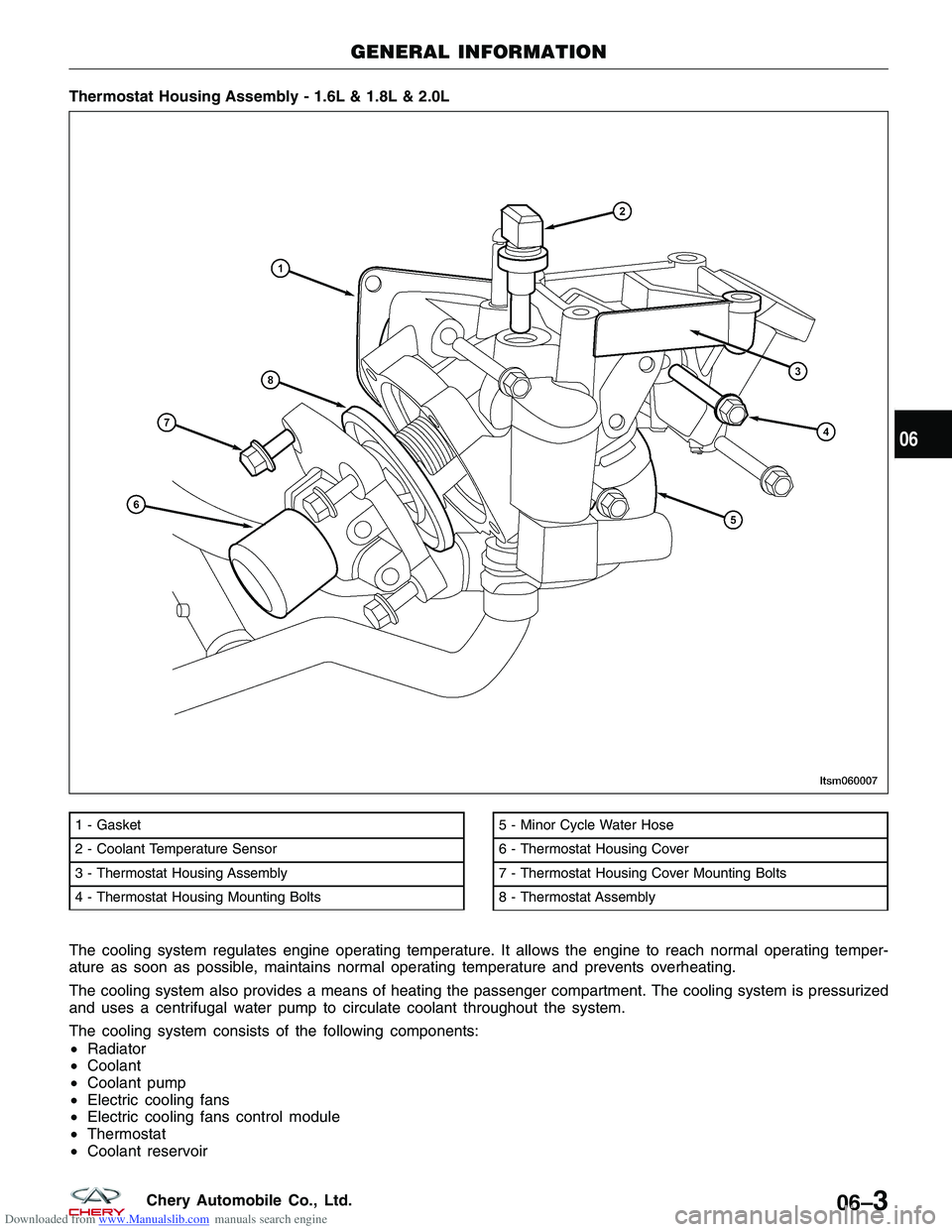

Downloaded from www.Manualslib.com manuals search engine The cooling system regulates engine operating temperature. It allows the engine to reach normal operating temper-

ature as soon as possible, maintains normal operating temperature and prevents overheating.

The cooling system also provides a means of heating the passenger compartment. The cooling system is pressurized

and uses a centrifugal water pump to circulate coolant throughout the system.

The cooling system consists of the following components:

•Radiator

• Coolant

• Coolant pump

• Electric cooling fans

• Electric cooling fans control module

• Thermostat

• Coolant reservoir

Thermostat Housing Assembly - 1.6L & 1.8L & 2.0L

1 - Gasket

2 - Coolant Temperature Sensor

3 - Thermostat Housing Assembly

4 - Thermostat Housing Mounting Bolts5 - Minor Cycle Water Hose

6 - Thermostat Housing Cover

7 - Thermostat Housing Cover Mounting Bolts

8 - Thermostat Assembly

GENERAL INFORMATION

LTSM060007

06

06–3Chery Automobile Co., Ltd.

Page 928 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Cooling System Draining and Filling

Cooling System Draining Procedure

WARNING!

Never remove the pressure relief cap, under any conditions, while the engine is operating or hot. Failure to fol-

low these instructions could result in personal injury or damage to the cooling system or engine. To avoid hav-

ing scalding hot coolant or steam blow out of the cooling system, use extreme care when removing the pressure

relief cap. Wait until the engine has cooled, then wrap a thick cloth around the pressure relief cap and turn it

slowly one turn (counterclockwise). Step back while the pressure is released from the cooling system. When you

are certain all the pressure has been released, using a cloth turn and remove the pressure relief cap. Failure to

follow these instructions may result in serious personal injury.

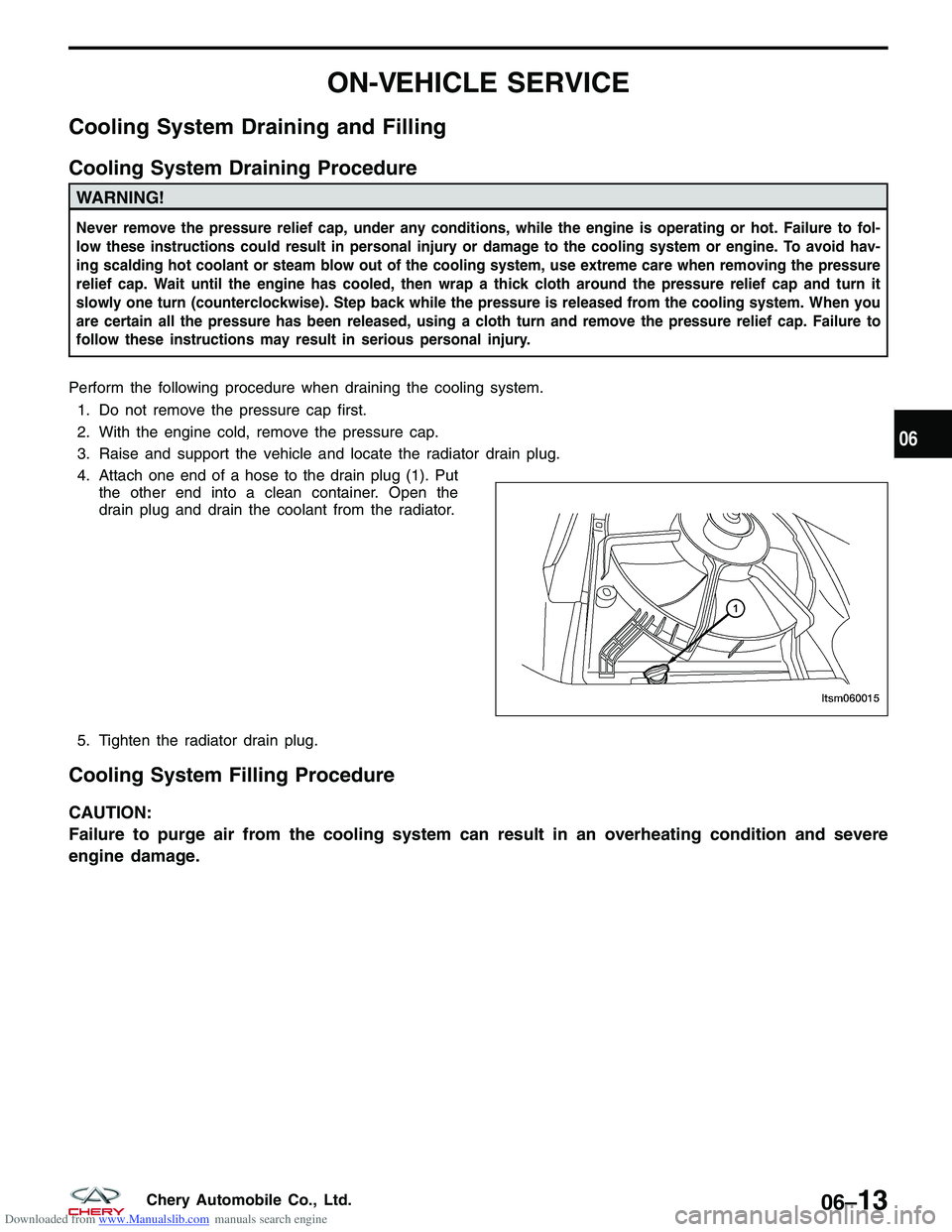

Perform the following procedure when draining the cooling system.1. Do not remove the pressure cap first.

2. With the engine cold, remove the pressure cap.

3. Raise and support the vehicle and locate the radiator drain plug.

4. Attach one end of a hose to the drain plug (1). Put the other end into a clean container. Open the

drain plug and drain the coolant from the radiator.

5. Tighten the radiator drain plug.

Cooling System Filling Procedure

CAUTION:

Failure to purge air from the cooling system can result in an overheating condition and severe

engine damage.

LTSM060015

06

06–13Chery Automobile Co., Ltd.

Page 963 of 1903

Downloaded from www.Manualslib.com manuals search engine NOTE :

Using the TCM electrical harness test tool will help prevent electrical connector terminal damage.

Diagnostic Trouble Code (DTC) List

DP0 Automatic Transaxle DTC List

DTCDTC DEFINITION

P0218 Automatic Transaxle Overheating

P0603 Internal Control Module Memory

P0604 RAM

P0605 Checksum Error

P0641 Sensor Feed

P0657 Solenoid Power Supply Circuit Shorted To Voltage

P0657 SSV Feed Circuit Open

P0705 Multi-function Switch: Prohibited Position

P0706 Multi-function Switch: Intermediate Position

P0709 Multi-function Switch: Affected by Interference

P0710 Fluid Temperature Sensor

P0715 No Turbine Speed Sensor Signal

P0715 Turbine Speed Sensor Affected by Interference

P0720 No Vehicle Speed Sensor Signal

P0720 Vehicle Speed Sensor Affected by Interference

P0720 Vehicle Speed Sensor Signal Consistency

P0730 Cylinder Slip

P0740 Lock-up

P0753 EVS1 Circuit Open

P0753 EVS1 Circuit Shorted To Ground

P0753 EVS1 Circuit Shorted To Voltage

P0758 EVS2 Circuit Open

P0758 EVS2 Circuit Shorted To Voltage

P0763 EVS3 Circuit Open

P0763 EVS3 Circuit Shorted To Voltage

P0768 EVS4 Circuit Open

P0768 EVS4 Circuit Shorted To Ground

P0768 EVS4 Circuit Shorted To Voltage

P0773 EVS5 Circuit Open

P0773 EVS5 Circuit Shorted To Voltage

P0775 EVM (Electronic Valve Modulation) Circuit Open

P0775 EVM (Electronic Valve Modulation) Circuit Shorted To Voltage

P0795 EVLU Circuit Open

P0795 EVLU Shorted To Voltage

P0819 Flick Shift Contact Duration

P0819 Flick Shift Contacts

P0840 Pressure Sensor

P0850 P/N Contact

DIAGNOSIS & TESTING

08–20Chery Automobile Co., Ltd.

Page 1353 of 1903

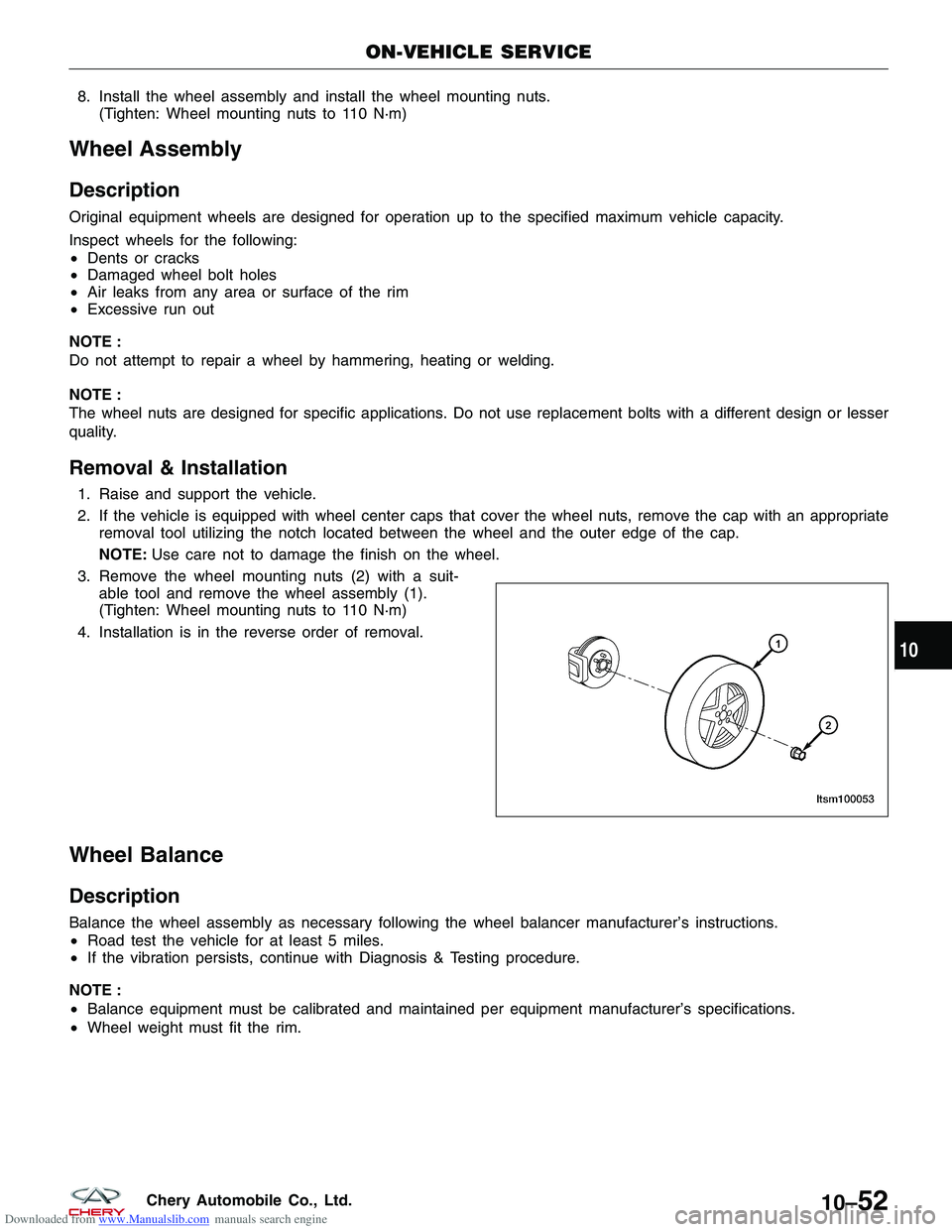

Downloaded from www.Manualslib.com manuals search engine 8. Install the wheel assembly and install the wheel mounting nuts.(Tighten: Wheel mounting nuts to 110 N·m)

Wheel Assembly

Description

Original equipment wheels are designed for operation up to the specified maximum vehicle capacity.

Inspect wheels for the following:

•Dents or cracks

• Damaged wheel bolt holes

• Air leaks from any area or surface of the rim

• Excessive run out

NOTE :

Do not attempt to repair a wheel by hammering, heating or welding.

NOTE :

The wheel nuts are designed for specific applications. Do not use replacement bolts with a different design or lesser

quality.

Removal & Installation

1. Raise and support the vehicle.

2. If the vehicle is equipped with wheel center caps that cover the wheel nuts, remove the cap with an appropriate removal tool utilizing the notch located between the wheel and the outer edge of the cap.

NOTE: Use care not to damage the finish on the wheel.

3. Remove the wheel mounting nuts (2) with a suit- able tool and remove the wheel assembly (1).

(Tighten: Wheel mounting nuts to 110 N·m)

4. Installation is in the reverse order of removal.

Wheel Balance

Description

Balance the wheel assembly as necessary following the wheel balancer manufacturer’s instructions.

• Road test the vehicle for at least 5 miles.

• If the vibration persists, continue with Diagnosis & Testing procedure.

NOTE :

• Balance equipment must be calibrated and maintained per equipment manufacturer’s specifications.

• Wheel weight must fit the rim.

ON-VEHICLE SERVICE

LTSM100053

10

10–52Chery Automobile Co., Ltd.

Page 1483 of 1903

Downloaded from www.Manualslib.com manuals search engine HEATING & AIR CONDITIONING

13

CONTENTSpage

Manual Temperature Control ........................................................... 13-1

System Controls .................................................................... 13-18

Air Distribution ..................................................................... 13-25

System Plumbing ................................................................... 13-32

MANUAL TEMPERATURE CONTROL

GENERAL INFORMATION13-2

Description 13-2

Operation 13-4

Specifications 13-4

Special Tools 13-5

Electrical Schematics 13-6

DIAGNOSIS & TESTING13-12

A/C System Performance 13-12 Heater Performance 13-14

ON-VEHICLE SERVICE13-15

Manual Temperature Control Module 13-15

Removal & Installation 13-15

Blower Motor Resistor 13-16

Removal & Installation 13-16

13

13–1Chery Automobile Co., Ltd.

Page 1484 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

This vehicle is equipped with a common HVAC housing assembly. The system combines air conditioning, heating,

and ventilating capabilities in a single unit housing mounted under the instrument panel. The driver can choose the

following functions from HVAC control panel:

•The inside temperature

• The speed of the blower

• Five different modes of operation

• A/C compressor clutch operation

• Recirculation door position

NOTE :

To maintain the performance level of the heating, ventilation and air conditioning (HVAC) system, the engine cooling

system must be properly maintained. Any obstructions in front of the radiator or A/C condenser will reduce the per-

formance of the A/C and engine cooling systems.

13–2Chery Automobile Co., Ltd.

Page 1495 of 1903

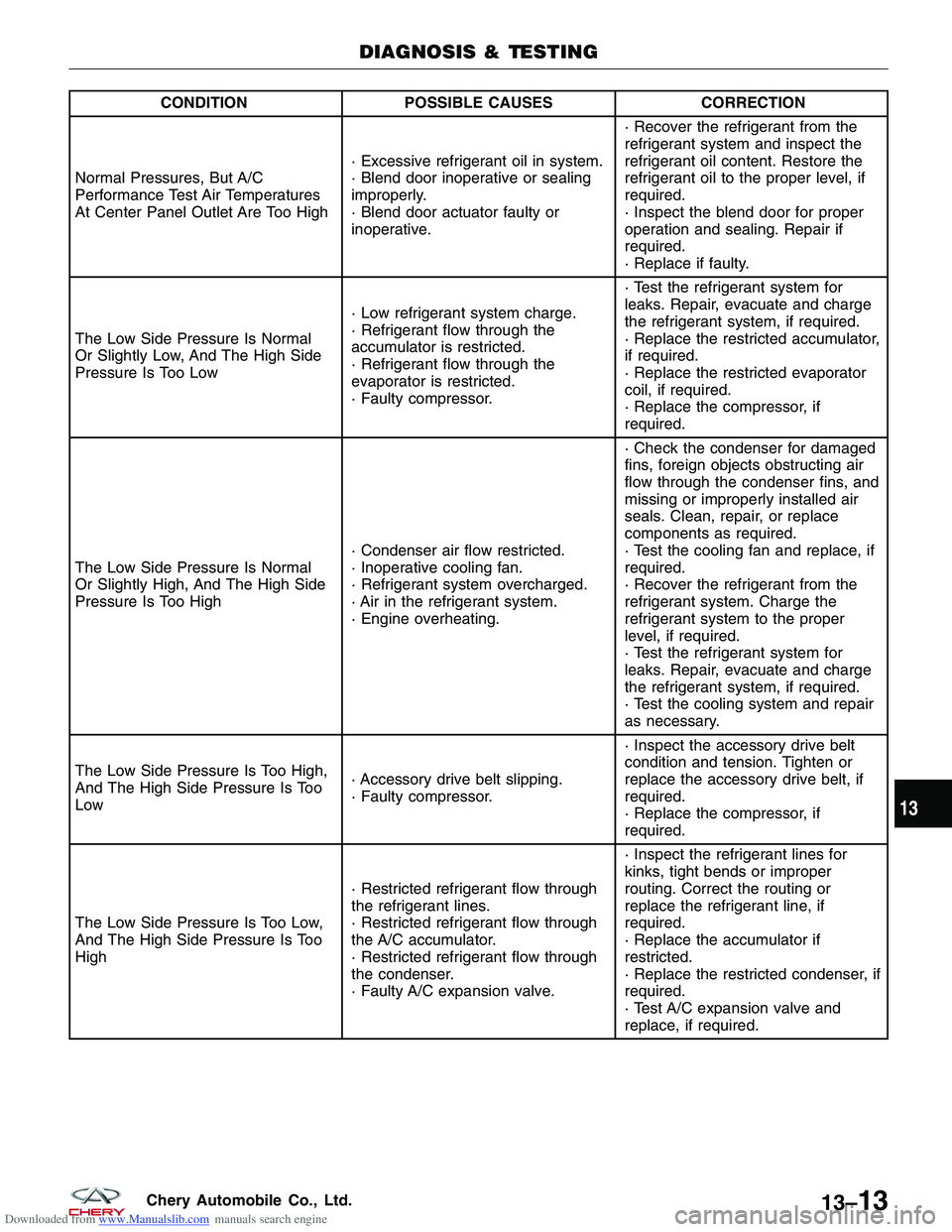

Downloaded from www.Manualslib.com manuals search engine CONDITIONPOSSIBLE CAUSES CORRECTION

Normal Pressures, But A/C

Performance Test Air Temperatures

At Center Panel Outlet Are Too High · Excessive refrigerant oil in system.

· Blend door inoperative or sealing

improperly.

· Blend door actuator faulty or

inoperative.· Recover the refrigerant from the

refrigerant system and inspect the

refrigerant oil content. Restore the

refrigerant oil to the proper level, if

required.

· Inspect the blend door for proper

operation and sealing. Repair if

required.

· Replace if faulty.

The Low Side Pressure Is Normal

Or Slightly Low, And The High Side

Pressure Is Too Low · Low refrigerant system charge.

· Refrigerant flow through the

accumulator is restricted.

· Refrigerant flow through the

evaporator is restricted.

· Faulty compressor.· Test the refrigerant system for

leaks. Repair, evacuate and charge

the refrigerant system, if required.

· Replace the restricted accumulator,

if required.

· Replace the restricted evaporator

coil, if required.

· Replace the compressor, if

required.

The Low Side Pressure Is Normal

Or Slightly High, And The High Side

Pressure Is Too High · Condenser air flow restricted.

· Inoperative cooling fan.

· Refrigerant system overcharged.

· Air in the refrigerant system.

· Engine overheating.· Check the condenser for damaged

fins, foreign objects obstructing air

flow through the condenser fins, and

missing or improperly installed air

seals. Clean, repair, or replace

components as required.

· Test the cooling fan and replace, if

required.

· Recover the refrigerant from the

refrigerant system. Charge the

refrigerant system to the proper

level, if required.

· Test the refrigerant system for

leaks. Repair, evacuate and charge

the refrigerant system, if required.

· Test the cooling system and repair

as necessary.

The Low Side Pressure Is Too High,

And The High Side Pressure Is Too

Low · Accessory drive belt slipping.

· Faulty compressor.· Inspect the accessory drive belt

condition and tension. Tighten or

replace the accessory drive belt, if

required.

· Replace the compressor, if

required.

The Low Side Pressure Is Too Low,

And The High Side Pressure Is Too

High · Restricted refrigerant flow through

the refrigerant lines.

· Restricted refrigerant flow through

the A/C accumulator.

· Restricted refrigerant flow through

the condenser.

· Faulty A/C expansion valve.· Inspect the refrigerant lines for

kinks, tight bends or improper

routing. Correct the routing or

replace the refrigerant line, if

required.

· Replace the accumulator if

restricted.

· Replace the restricted condenser, if

required.

· Test A/C expansion valve and

replace, if required.

DIAGNOSIS & TESTING

13

13–13Chery Automobile Co., Ltd.

Page 1501 of 1903

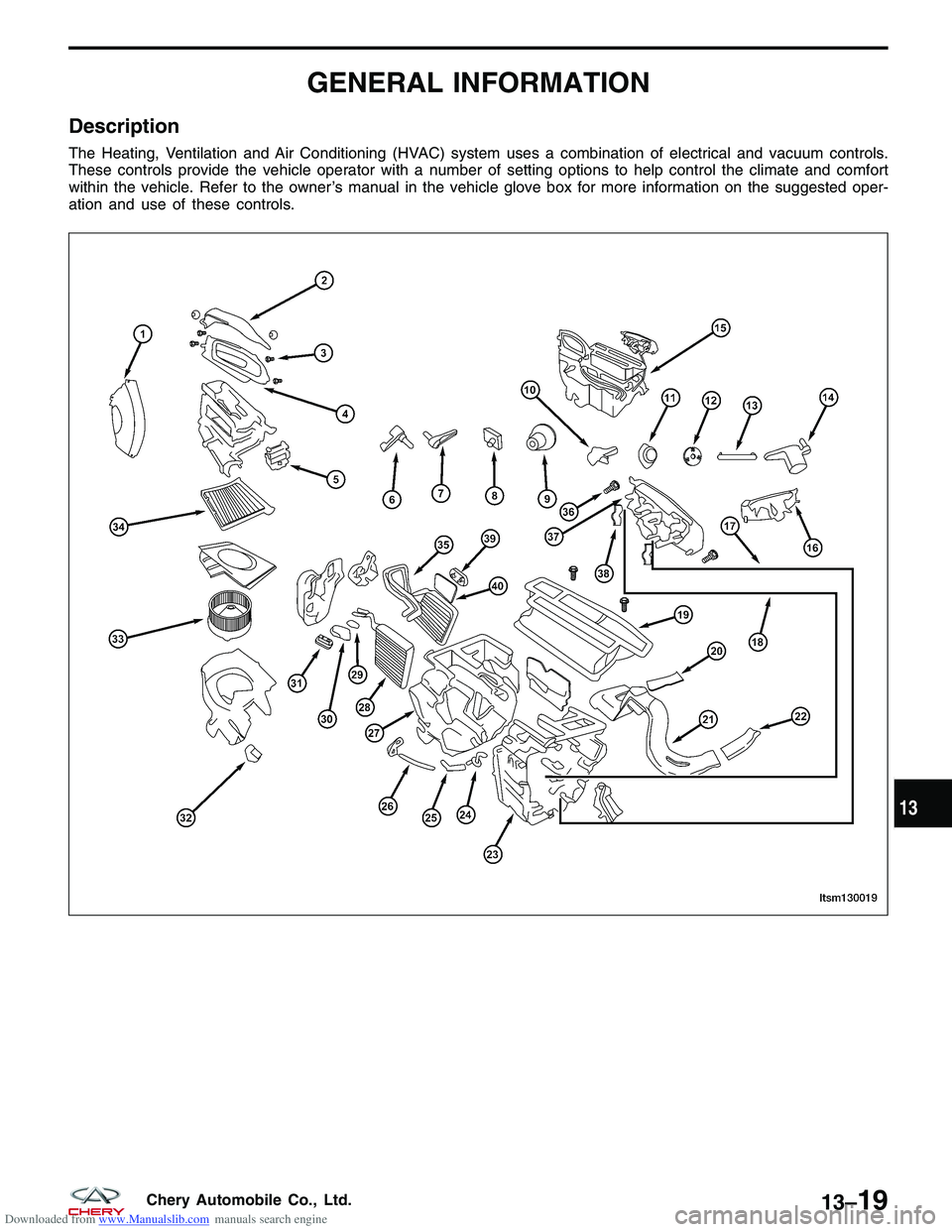

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The Heating, Ventilation and Air Conditioning (HVAC) system uses a combination of electrical and vacuum controls.

These controls provide the vehicle operator with a number of setting options to help control the climate and comfort

within the vehicle. Refer to the owner’s manual in the vehicle glove box for more information on the suggested oper-

ation and use of these controls.

LTSM130019

13

13–19Chery Automobile Co., Ltd.