wheel CHERY TIGGO 2009 Service Manual PDF

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1328 of 1903

Downloaded from www.Manualslib.com manuals search engine WARNING!

Only frame contact or wheel lift hoisting equipment can be used on this vehicle. It cannot be hoisted using

equipment designed to lift a vehicle by the rear axle. If this type of hoisting equipment is used, damage to rear

suspension components will occur.

CAUTION:

If a rear suspension component becomes bent, damaged or fails, no attempt should be made to

straighten or repair it. Always replace it with a new component.

Operation

The rear suspension utilizes an independent multi-link arm design. This suspension system allows the wheels to

react to road imperfections independent of each other. This independent action offers improved isolation from the

effects of jounce and rebound.

1 - Rear Sub-Frame Assembly

2 - Rear Suspension Upper Rocker Arm Assembly

3 - Rear Spring Pad

4 - Bolt

5 - Nut

6 - Washer

7 - Left Brake Line Bracket

8 - Rear Coil Spring

9 - Left Brake Line Support

10 - Left Rear Trailing Arm Assembly

11 - Left Rear Strut Assembly12 - Rear Stabilizer Lever Assembly

13 - Rear Suspension Left Lower Rocker Arm Assembly

14 - Left Rear Stabilizer Bar Link

15 - Right Rear Stabilizer Bar Link

16 - Rear Suspension Right Lower Rocker Arm Assembly

17 - Rear Stabilizer Bar

18 - Rubber Support

19 - Rubber Bushing Assembly

20 - Right Rear Strut Assembly

21 - Right Rear Trailing Arm Assembly

22 - Rear Coil Spring

GENERAL INFORMATION

LTSM100035

10

10–27Chery Automobile Co., Ltd.

Page 1329 of 1903

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

Rear Stabilizer Bar Link 40 - 50

Lower Suspension Lever 40 - 50

Rear Shock Absorber to Rear Shock Absorber Mounting

Bracket 40-50

Control Arm Knuckle Pin to Control Arm 140 - 160

Rear Axle Front Suspension to Rear Sub-Frame 115 - 125

Rear Axle Front Suspension to Rear Driving Axle 75 - 85

Control Arm And Sub-Frame 170 - 190

Rear Rubber Buffer Assembly to Vehicle Body 22 - 28

Rear Axle Rear Suspension Cushion Assembly to Rear

Axle 75-85

Upper Link to Rear Sub-Frame 100 - 120

Lower Control Arm to Rear Sub-Frame 100 - 120

Lower Control Arm to Trailing Arm 100 - 120

Upper Link to Trailing Arm 100 - 120

Rear Suspension to Bracket 115 - 125

Rear Suspension, Longitudinal Beam Of Engine And

Sub-Frame 75-85

Rear Stabilizer Bar Clamp to Vehicle Body 22 - 28

Rear Trailing Arm to Vehicle Body 140 - 160

Soft Gasket And Bracket Of Rear Suspension 110 - 130

Sub-Frame And Gasket Of Vehicle (Rear) Body 170 - 190

Sub-Frame And Longitudinal Beam Assembly 75 - 85

Upper End Of Rear Shock Absorber to Vehicle Body 22 - 28

Wheel Mounting Nut \

11

0

GENERAL INFORMATION

10–28Chery Automobile Co., Ltd.

Page 1330 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Vehicle Inspection

Inspect the rear axle for the following:

•Check the rear axle for loose bearings.

• Check the rear axle hub for any damage or excessive runout.

Vibration At High Speed

This problem could be a result of the following:

•Foreign material (mud, etc.) packed on the backside of the wheel(s).

• Out of balance tires or wheels.

• Improper tire or wheel runout.

10

10–29Chery Automobile Co., Ltd.

Page 1335 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

Coil springs are designed to store energy and subsequently release it, and to absorb shock and maintain a force

between contacting surfaces. Coil springs are rated for specific vehicle applications.

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Use a jack to support the rear trailing arm.

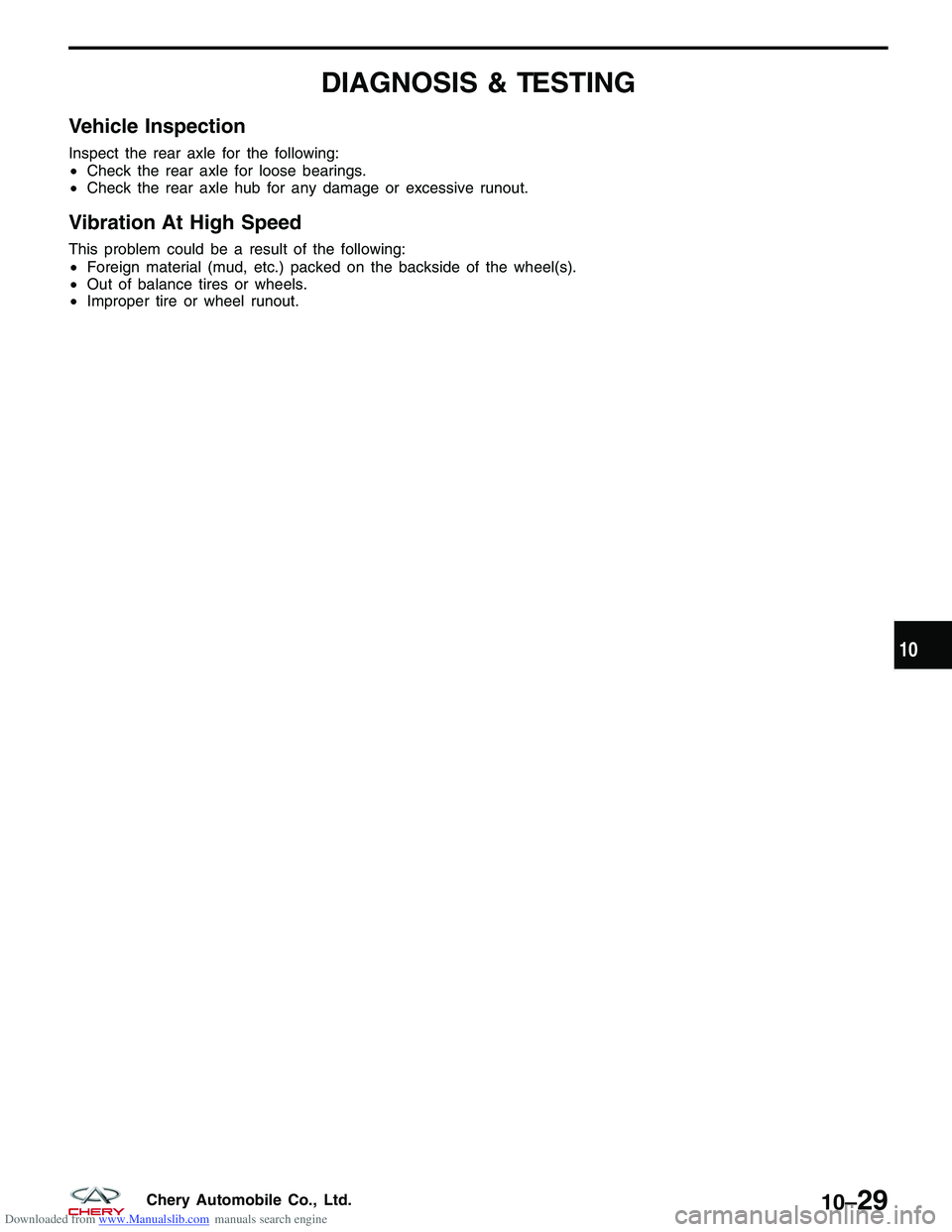

4. Remove the retaining bolt (1) that connects the lower control arm to rear trailing arm.

(Tighten: Lower control arm to rear trailing arm bolt

to 80-100 N·m)

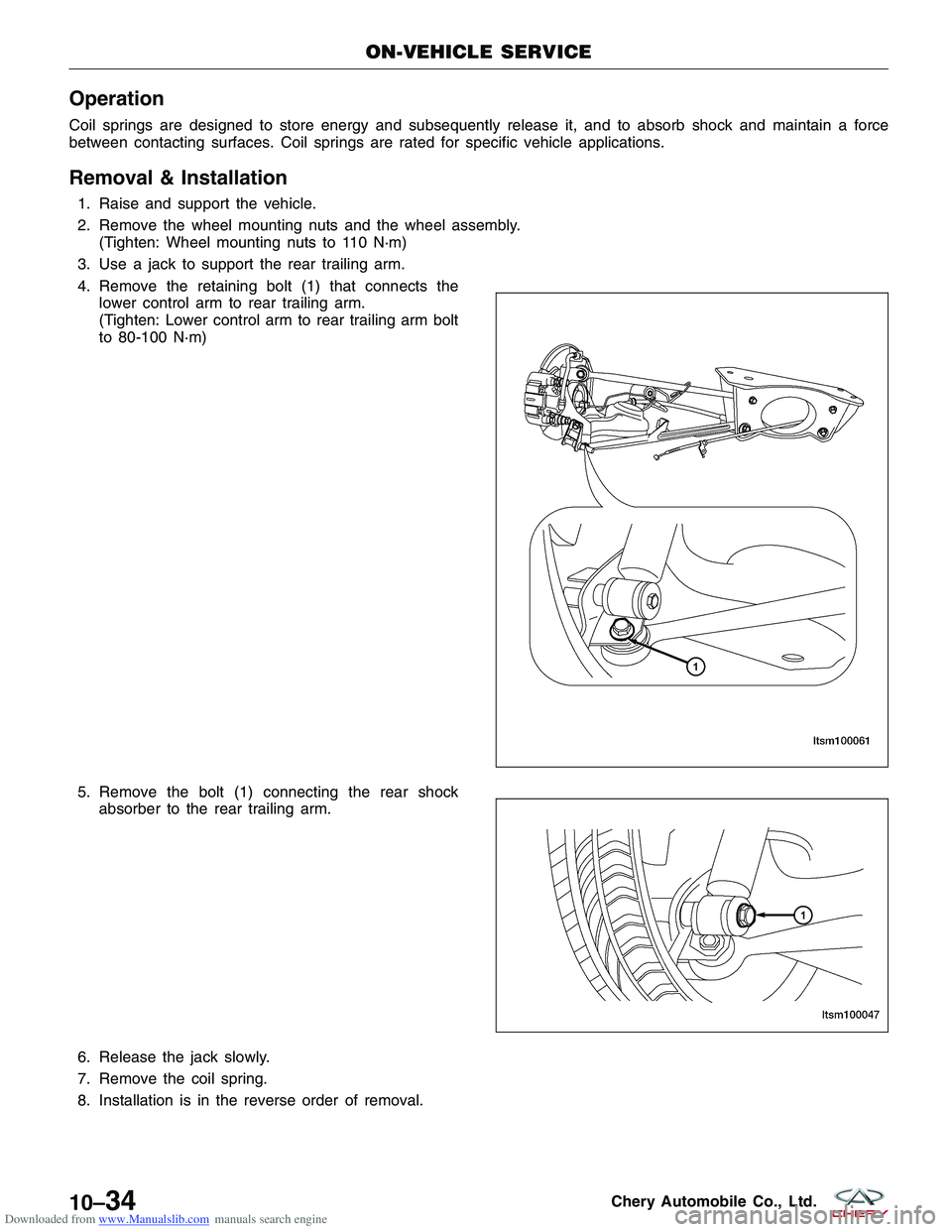

5. Remove the bolt (1) connecting the rear shock absorber to the rear trailing arm.

6. Release the jack slowly.

7. Remove the coil spring.

8. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM100061

LTSM100047

10–34Chery Automobile Co., Ltd.

Page 1336 of 1903

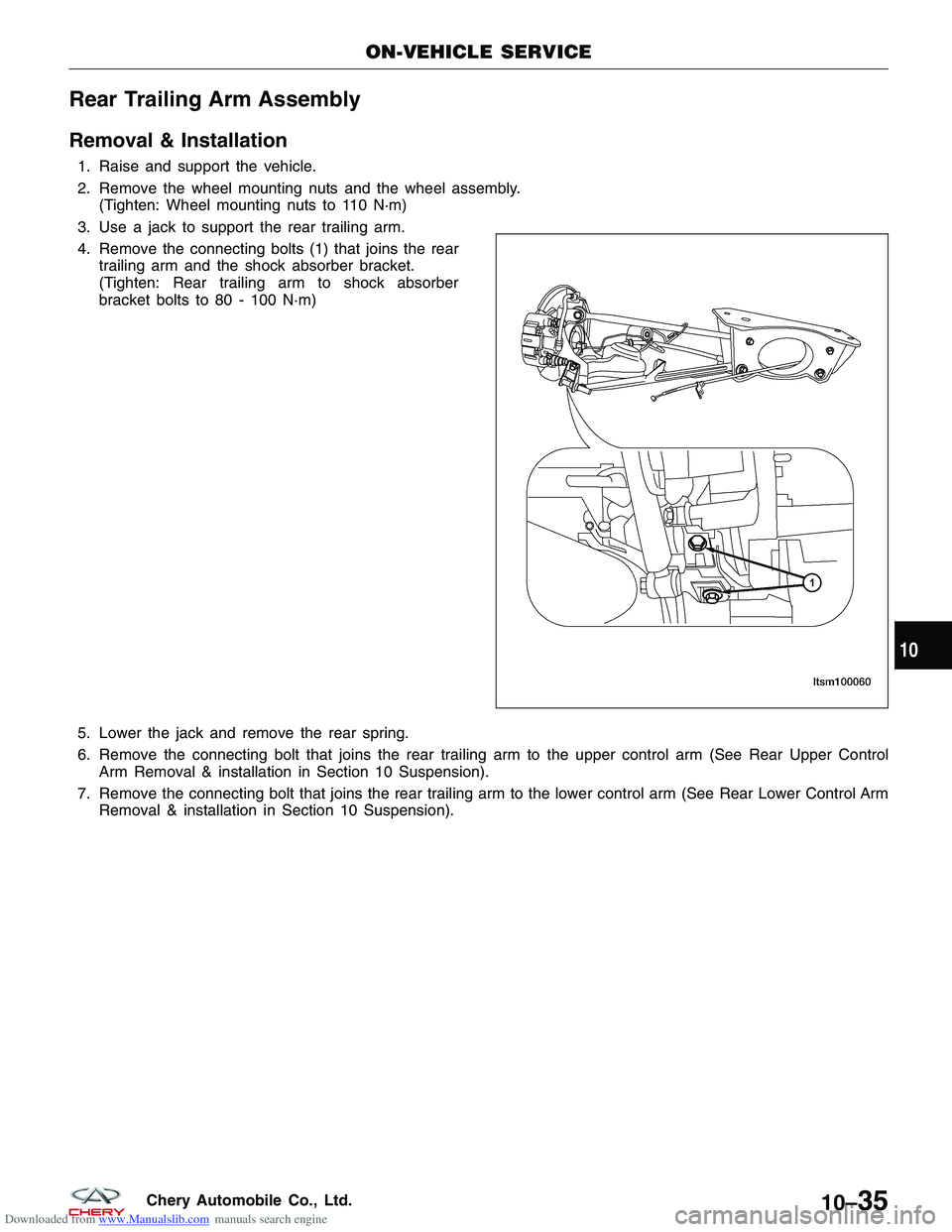

Downloaded from www.Manualslib.com manuals search engine Rear Trailing Arm Assembly

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Use a jack to support the rear trailing arm.

4. Remove the connecting bolts (1) that joins the rear trailing arm and the shock absorber bracket.

(Tighten: Rear trailing arm to shock absorber

bracket bolts to 80 - 100 N·m)

5. Lower the jack and remove the rear spring.

6. Remove the connecting bolt that joins the rear trailing arm to the upper control arm (See Rear Upper Control Arm Removal & installation in Section 10 Suspension).

7. Remove the connecting bolt that joins the rear trailing arm to the lower control arm (See Rear Lower Control Arm Removal & installation in Section 10 Suspension).

ON-VEHICLE SERVICE

LTSM100060

10

10–35Chery Automobile Co., Ltd.

Page 1339 of 1903

Downloaded from www.Manualslib.com manuals search engine ALIGNMENT

GENERAL INFORMATION10-39

Description 10-39

Operation 10-39

Pre-Wheel Alignment Inspection 10-39

Wheel Alignment Setup 10-40

Specifications 10-40

DIAGNOSIS & TESTING10-42

Vehicle Inspection 10-42

Tire Wear 10-42

Tire Wear Chart 10-42

Alignment Troubleshooting Chart 10-43

ON-VEHICLE SERVICE10-44

Front Wheel Alignment 10-44

Front Wheel Alignment Specifications 10-44

Front Axle Toe-In Adjustment 10-44

Front Camber Adjustment 10-44

Rear Wheel Alignment 10-45

Rear Wheel Alignment Specifications 10-45

Rear Axle Toe-In Adjustment 10-45

Rear Camber Adjustment 10-46

10–38Chery Automobile Co., Ltd.

Page 1340 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

Vehicle wheel alignment is the positioning of all interrelated front and rear suspension angles. These angles affect the

handling and steering of the vehicle when it is in motion. Proper wheel alignment is essential for efficient steering,

good directional stability, and proper tire wear.

The method of checking a vehicle’s front and rear wheel alignment varies depending on the manufacturer and type

of equipment used. The manufacturer’s instructions should always be followed to ensure accuracy of the alignment.

On this vehicle, the suspension angles that can be adjusted are as follows:

Front Axle

•Camber

• Caster

• Toe-in

Rear Axle

• Camber

• Toe-in

Check the wheel alignment and make all wheel alignment adjustments with the vehicle standing at its proper curb

height specification. Curb height is the normal riding height of the vehicle. It is measured from a certain point on the

vehicle to the ground or a designated area while the vehicle is sitting on a flat, level surface.

Operation

Curb Height Measurement

The wheel alignment is to be checked and all alignment adjustments made with the vehicle at its required curb height

specification.

• Vehicle height is to be checked with the vehicle on a flat, level surface, preferably a vehicle alignment rack.

• The tires are to be inflated to the recommended pressure.

• All tires are to be the same size as standard equipment.

• Vehicle height is checked with the fuel tank full of fuel, and no passenger or luggage compartment load.

• Vehicle height is not adjustable.

• If the measurement is not within specifications, inspect the vehicle for bent or weak suspension components.

• Compare the parts tag on the suspect coil spring(s) to the parts book and the vehicle sales code, checking for

a match.

• Once removed from the vehicle, compare the coil spring height to a new or known good coil spring. The

heights should vary if the suspect spring is weak.

NOTE :

Prior to reading the curb height measurement, the front and rear of the vehicle must be jounced to settle the sus-

pension. Induce jounce by pushing down on the center of the bumper (fascia), using care not to damage the vehicle,

moving the vehicle up and down, gradually increasing the suspension travel with each stroke. Release the bumper at

the bottom of each stroke, repeating this action several times. Perform this to both front and rear suspensions an

equal number of times.

Pre-Wheel Alignment Inspection

Before any attempt is made to change or correct the wheel alignment, the following inspection and necessary cor-

rections must be made to the vehicle to ensure proper alignment. 1. Verify the fuel tank is full of fuel. If the fuel tank is not full, the reduction in weight will affect the curb height of the vehicle and the alignment specifications.

2. The passenger and luggage compartments of the vehicle should be free of any load that is not factory equip- ment.

10

10–39Chery Automobile Co., Ltd.

Page 1341 of 1903

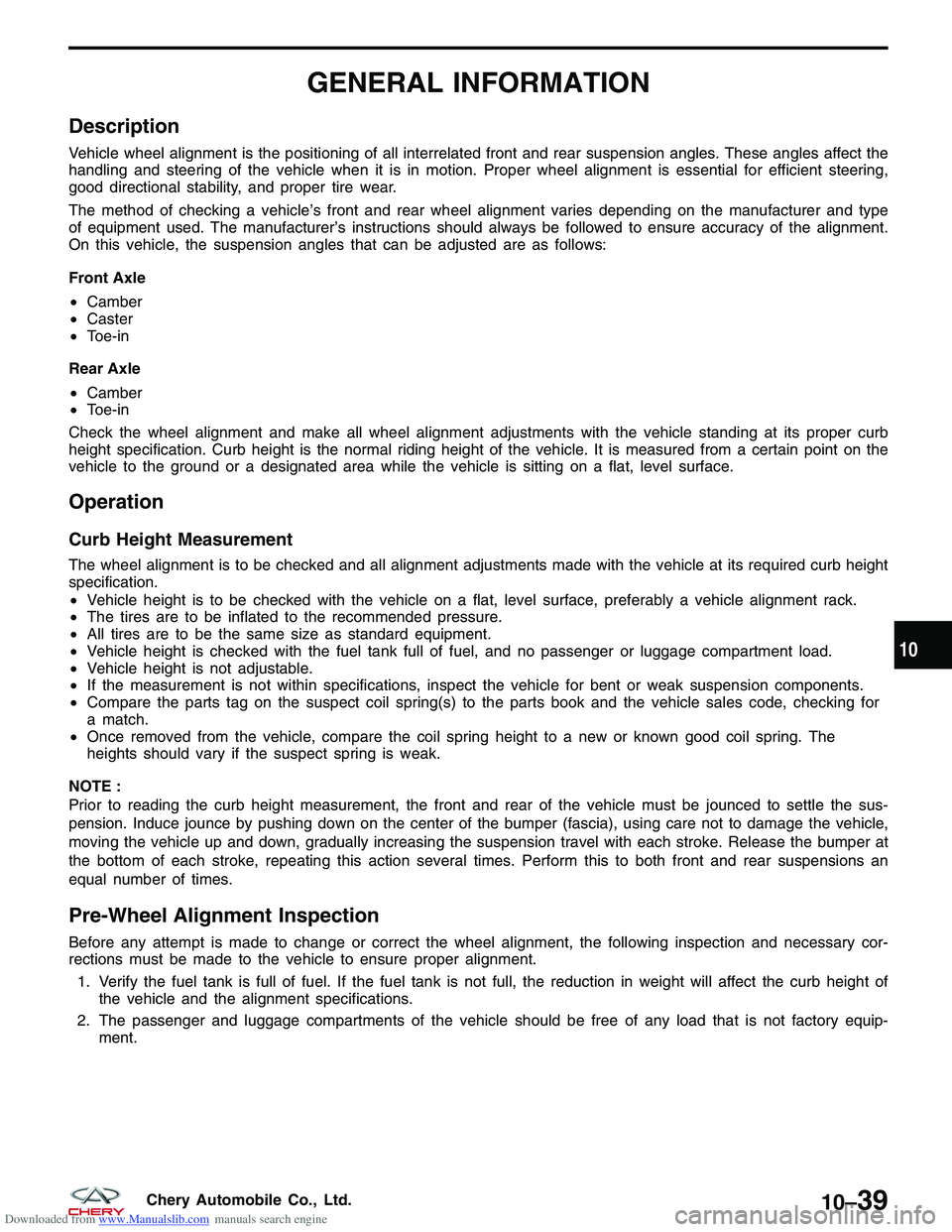

Downloaded from www.Manualslib.com manuals search engine 3. Check the tires on the vehicle. The tires are to beinflated to the recommended air pressure. All tires

must be the same size and in good condition with

approximately the same tread wear.

4. Check the front tire and wheel assemblies for excessive radial runout.

5. Inspect all suspension component fasteners for looseness and proper torque.

6. Inspect all ball joints and all steering linkage for looseness and any sign of wear or damage.

7. Inspect the rubber bushings on all the suspension components for signs of wear or deterioration. If any bushings show signs of wear or deterioration, they should be replaced prior to aligning the vehicle.

8. Check vehicle curb height.

Wheel Alignment Setup

1. Position the vehicle on an alignment rack.

2. Install all required alignment equipment on the vehicle, per the alignment equipment manufacturer’s instructions. On this vehicle, a four-wheel alignment is recommended.

3. Read the vehicle’s current front and rear alignment settings. Compare the vehicle’s current alignment settings to the vehicle specifications for camber, caster and toe-in.

NOTE :

Prior to reading the vehicle’s alignment readouts, the front and rear of vehicle should be jounced. Induce jounce (rear

first, then front) by grasping the center of the bumper and jouncing each end of the vehicle an equal number of

times. The bumper should always be released when vehicle is at the bottom of the jounce cycle.

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

Camber Adjustment Bolts 100

Inner Tie Rod Adjuster Jam Nut 30

Rear Lower Control Arm Eccentric Cam Bolt 80 - 100

Rear Upper Control Arm Eccentric Cam Bolt 80 - 100

Wheel Mounting Nuts 110

GENERAL INFORMATION

LTSM100027

LTSM110026

10–40Chery Automobile Co., Ltd.

Page 1342 of 1903

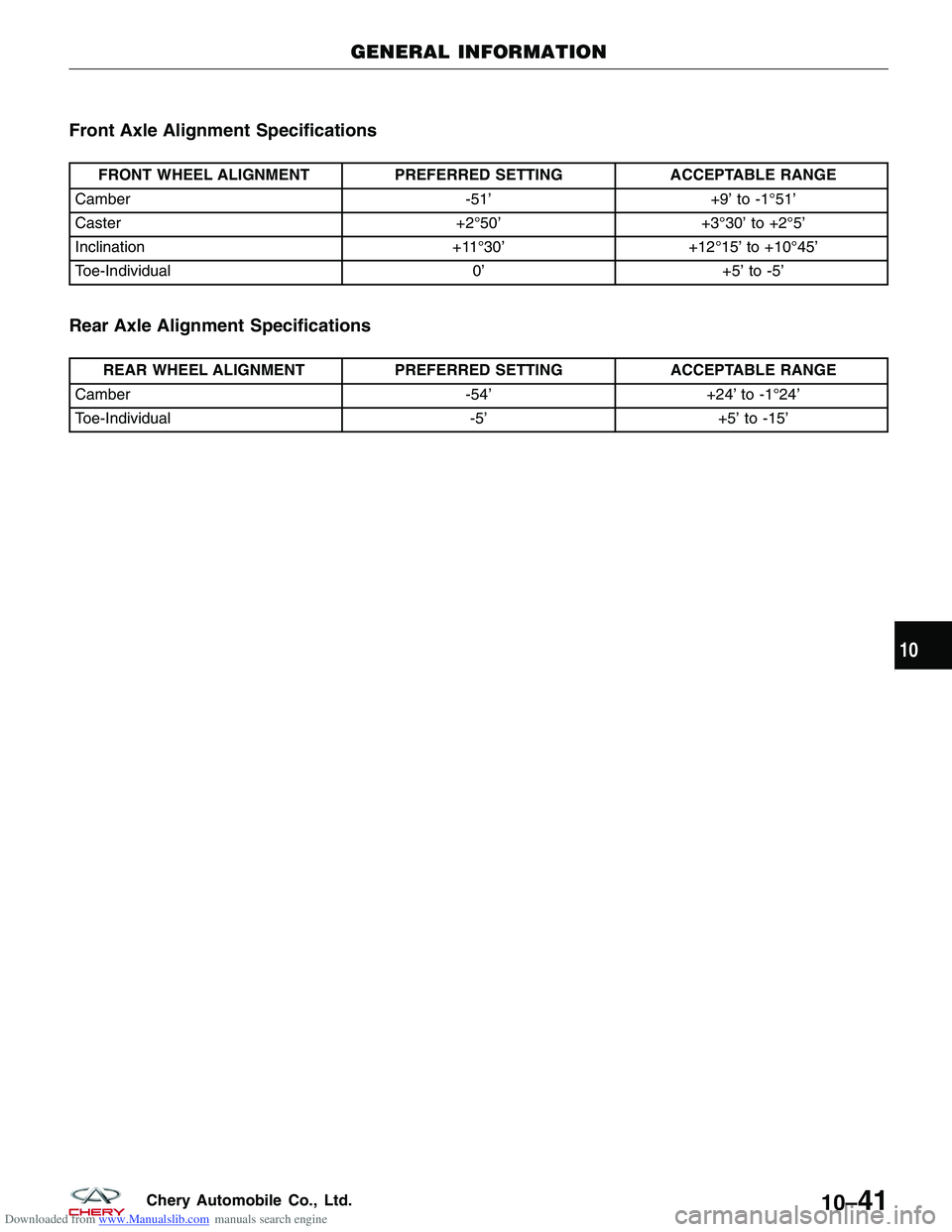

Downloaded from www.Manualslib.com manuals search engine Front Axle Alignment Specifications

FRONT WHEEL ALIGNMENTPREFERRED SETTINGACCEPTABLE RANGE

Camber -51’+9’ to -1°51’

Caster +2°50’+3°30’ to +2°5’

Inclination +11°30’+12°15’ to +10°45’

Toe-Individual 0’+5’ to -5’

Rear Axle Alignment Specifications

REAR WHEEL ALIGNMENT PREFERRED SETTINGACCEPTABLE RANGE

Camber -54’+24’ to -1°24’

Toe-Individual -5’+5’ to -15’

GENERAL INFORMATION

10

10–41Chery Automobile Co., Ltd.

Page 1343 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

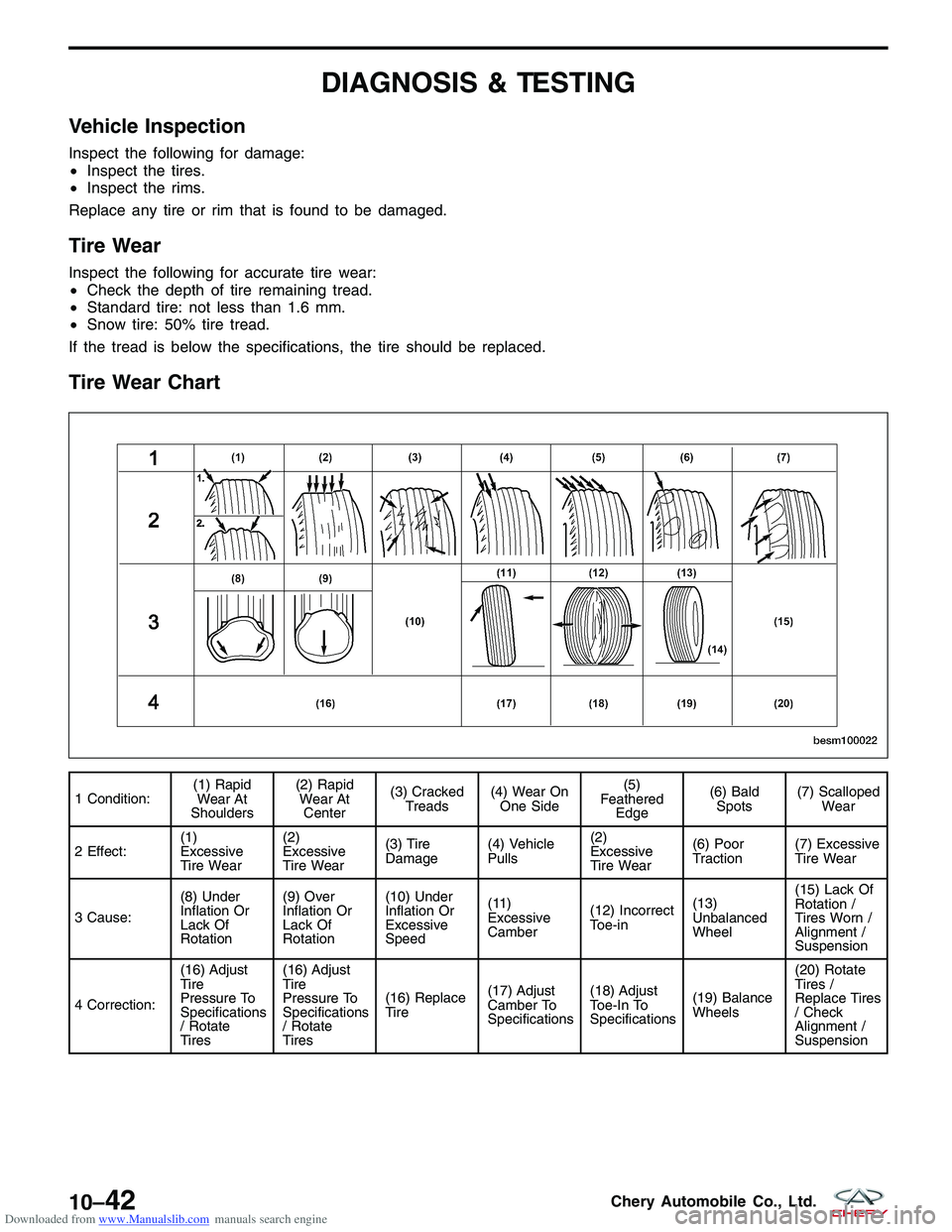

Vehicle Inspection

Inspect the following for damage:

•Inspect the tires.

• Inspect the rims.

Replace any tire or rim that is found to be damaged.

Tire Wear

Inspect the following for accurate tire wear:

• Check the depth of tire remaining tread.

• Standard tire: not less than 1.6 mm.

• Snow tire: 50% tire tread.

If the tread is below the specifications, the tire should be replaced.

Tire Wear Chart

1 Condition: (1) Rapid

Wear At

Shoulders (2) Rapid

Wear At Center (3) Cracked

Treads (4) Wear On

One Side (5)

Feathered Edge (6) Bald

Spots (7) Scalloped

Wear

2 Effect: (1)

Excessive

Tire Wear(2)

Excessive

Tire Wear

(3) Tire

Damage

(4) Vehicle

Pulls(2)

Excessive

Tire Wear(6) Poor

Traction

(7) Excessive

Tire Wear

3 Cause: (8) Under

Inflation Or

Lack Of

Rotation(9) Over

Inflation Or

Lack Of

Rotation(10) Under

Inflation Or

Excessive

Speed

(11)

Excessive

Camber

(12) Incorrect

Toe-in(13)

Unbalanced

Wheel(15) Lack Of

Rotation /

Tires Worn /

Alignment /

Suspension

4 Correction: (16) Adjust

Tire

Pressure To

Specifications

/ Rotate

Tires(16) Adjust

Tire

Pressure To

Specifications

/ Rotate

Tires

(16) Replace

Tire

(17) Adjust

Camber To

Specifications(18) Adjust

Toe-In To

Specifications

(19) Balance

Wheels(20) Rotate

Tires /

Replace Tires

/ Check

Alignment /

Suspension

BESM100022

10–42Chery Automobile Co., Ltd.