service CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 1500 of 1903

Downloaded from www.Manualslib.com manuals search engine SYSTEM CONTROLS

GENERAL INFORMATION13-19

Description 13-19

Operation 13-21

Specifications 13-23

Special Tools 13-23ON-VEHICLE SERVICE13-24

Recirculation Door Actuator 13-24

Removal & Installation 13-24

13–18Chery Automobile Co., Ltd.

Page 1505 of 1903

Downloaded from www.Manualslib.com manuals search engine Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

All General Service Screws 5

Recirculation door actuator screws 2

Special Tools

Digital Multimeter

Fluke 15B & 17B

GENERAL INFORMATION

13

13–23Chery Automobile Co., Ltd.

Page 1506 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

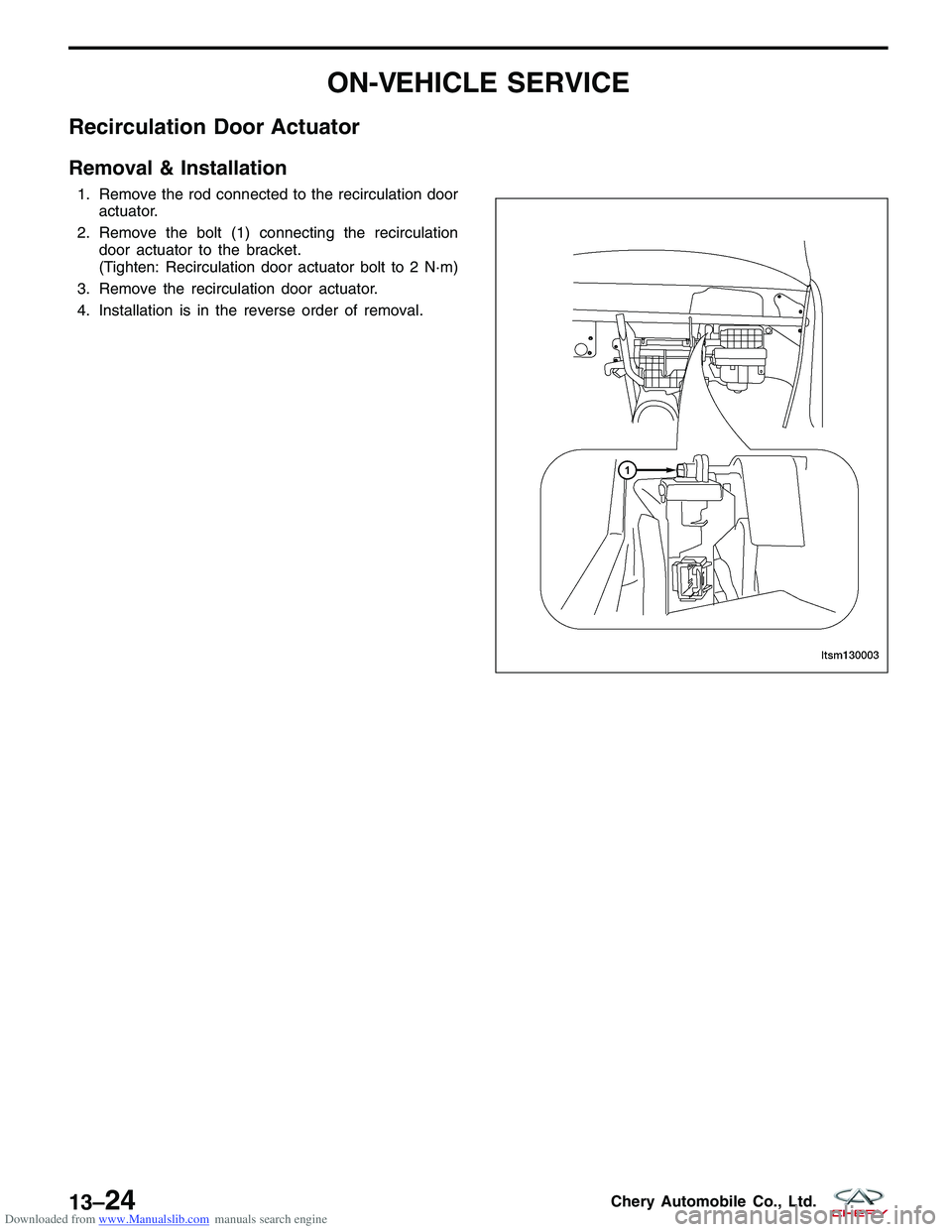

Recirculation Door Actuator

Removal & Installation

1. Remove the rod connected to the recirculation dooractuator.

2. Remove the bolt (1) connecting the recirculation door actuator to the bracket.

(Tighten: Recirculation door actuator bolt to 2 N·m)

3. Remove the recirculation door actuator.

4. Installation is in the reverse order of removal.

LTSM130003

13–24Chery Automobile Co., Ltd.

Page 1507 of 1903

Downloaded from www.Manualslib.com manuals search engine AIR DISTRIBUTION

GENERAL INFORMATION13-26

Description 13-26

Operation 13-26

Specifications 13-26

Special Tools 13-27

DIAGNOSIS & TESTING13-28

Blower Motor Electrical Troubleshooting 13-28

Blower Motor Noise 13-28

Blower Motor Vibration 13-28

ON-VEHICLE SERVICE13-29

HVAC Housing 13-29

Removal & Installation 13-29

Blower Motor 13-30

Description 13-30

Operation 13-30

Removal & Installation 13-31

13

13–25Chery Automobile Co., Ltd.

Page 1508 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

All models are equipped with a common HVAC housing assembly that combines A/C and heating capabilities into a

single unit mounted within the passenger compartment. The HVAC housing assembly consists of three separate

housings:

•HVAC housing — The HVAC housing is mounted to the dash panel behind the instrument panel and contains

the A/C evaporator. The HVAC housing has mounting provisions for the air inlet housing, blower motor and the

air distribution housing.

• Air distribution housing — The air distribution housing is mounted to the rear of the HVAC housing and con-

tains the heater core, blend-air and mode-air doors and door linkage.

• Air inlet housing — The air inlet housing is mounted to the passenger side end of the HVAC housing. The air

inlet housing contains the recirculation-air door and actuator.

Operation

The A/C system is designed for the use of a non-CFC, R-134a refrigerant and uses an A/C evaporator to cool and

dehumidify the incoming air prior to blending it with the heated air. Temperature control determines the discharge air

temperature by operating the temperature control cable, which moves the blend-air door. This allows an almost

immediate control of the output air temperature of the system. The mode door cable operates the mode-air doors

which direct the flow of the conditioned air out the various air outlets, depending on the mode selected. When

equipped with A/C, the recirculation door actuator operates the recirculation-air door which closes off the fresh air

intake and recirculates the air already inside the vehicle. The electric recirculation door actuator and the blower motor

are connected to the vehicle electrical system by the instrument panel wire harness. The blower motor controls the

velocity of air flowing through the HVAC housing assembly by spinning the blower wheel within the HVAC housing at

the selected speed by use of the blower motor resistor, which is around the blower motor.

The air distribution housing must be removed from the HVAC housing and disassembled for service of the blend-air

and mode-air doors. The air inlet housing must be removed from the HVAC housing and disassembled for service of

the recirculation-air door. The HVAC housing must be removed from the vehicle and disassembled for service of the

A/C evaporator.

Specifications

Torque Specifications

DESCRIPTION TORQUE (N·m)

All General Service Screws 2

Evaporator Bolts 4

Expansion Valve Bolts 10

Pipeline Stent 4

Refrigerant Lines To A/C Accumulator 6

Condenser Bolts 6

Refrigerant Lines To A/C Compressor Bolt 30

Refrigerant Lines 10

Refrigerant Lines To A/C Evaporator Bolt 25

13–26Chery Automobile Co., Ltd.

Page 1511 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

HVAC Housing

Removal & Installation

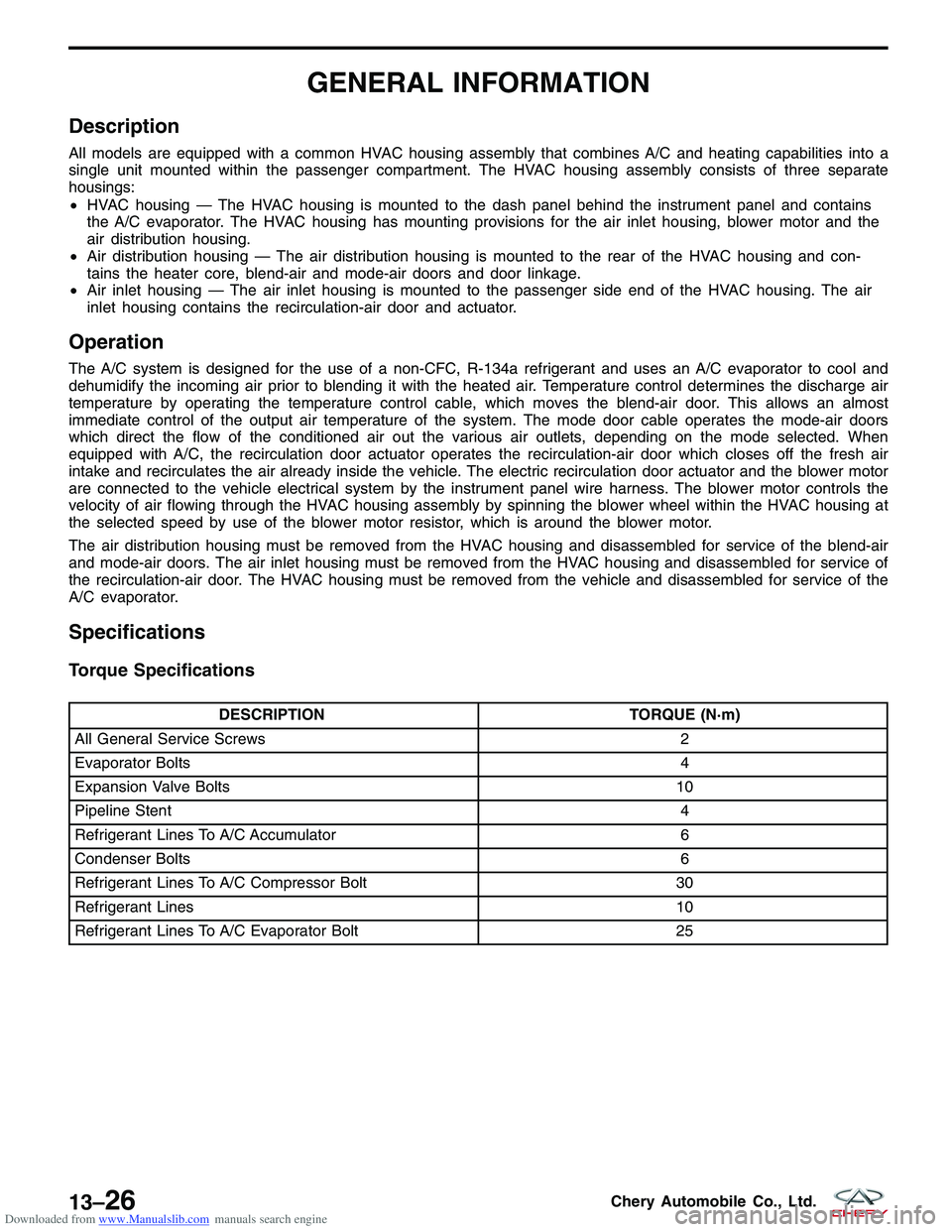

1. Evacuate the A/C system (See A/C System Evacuation and Recharge in Section 13 Heating & Air Conditioning).

2. Drain the cooling system and then disconnectheater hoses (1). (See Cooling System Draining &

Filling in Section 06 Cooling).

3. Remove the instrument panel (See Instrument Panel Removal & Installation in Section 15 Body & Accessories).

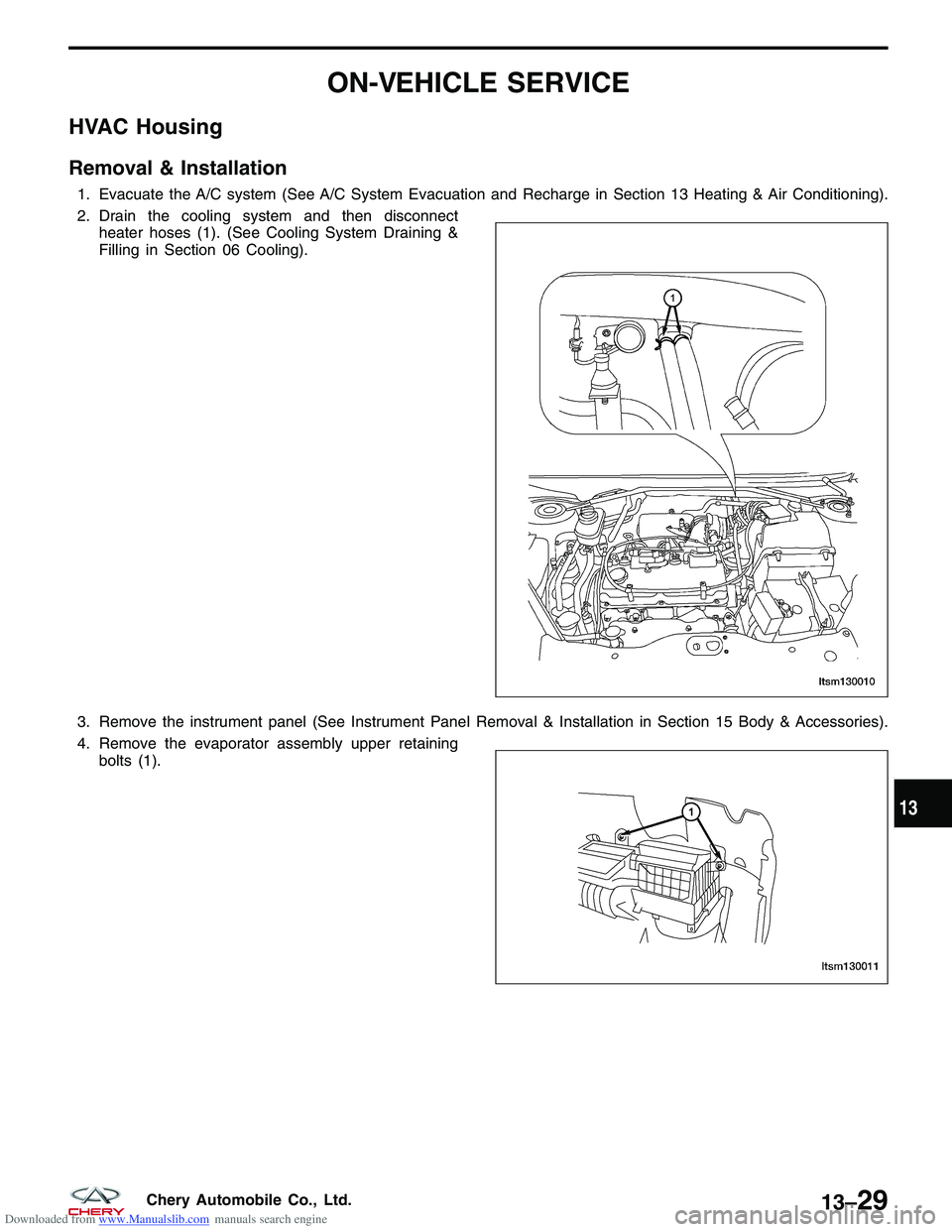

4. Remove the evaporator assembly upper retaining bolts (1).

LTSM130010

LTSM130011

13

13–29Chery Automobile Co., Ltd.

Page 1512 of 1903

Downloaded from www.Manualslib.com manuals search engine 5. Remove the evaporator assembly lower retainingbolts (1).

6. Disconnect the electrical connectors. Remove the evaporator assembly.

7. Installation is in the reverse order of removal.

Installation Notes:

• Lubricate new rubber O-ring seals with clean refrigerant oil and install them and new gaskets onto the refriger-

ant line fittings.

• Use only the specified O-rings as they are made of a special material for the R-134a system.

• Use only refrigerant oil recommended for the A/C compressor in the vehicle.

• Recharge the A/C system (See A/C System Evacuation and Recharge in Section 13 Heating & Air Condition-

ing).

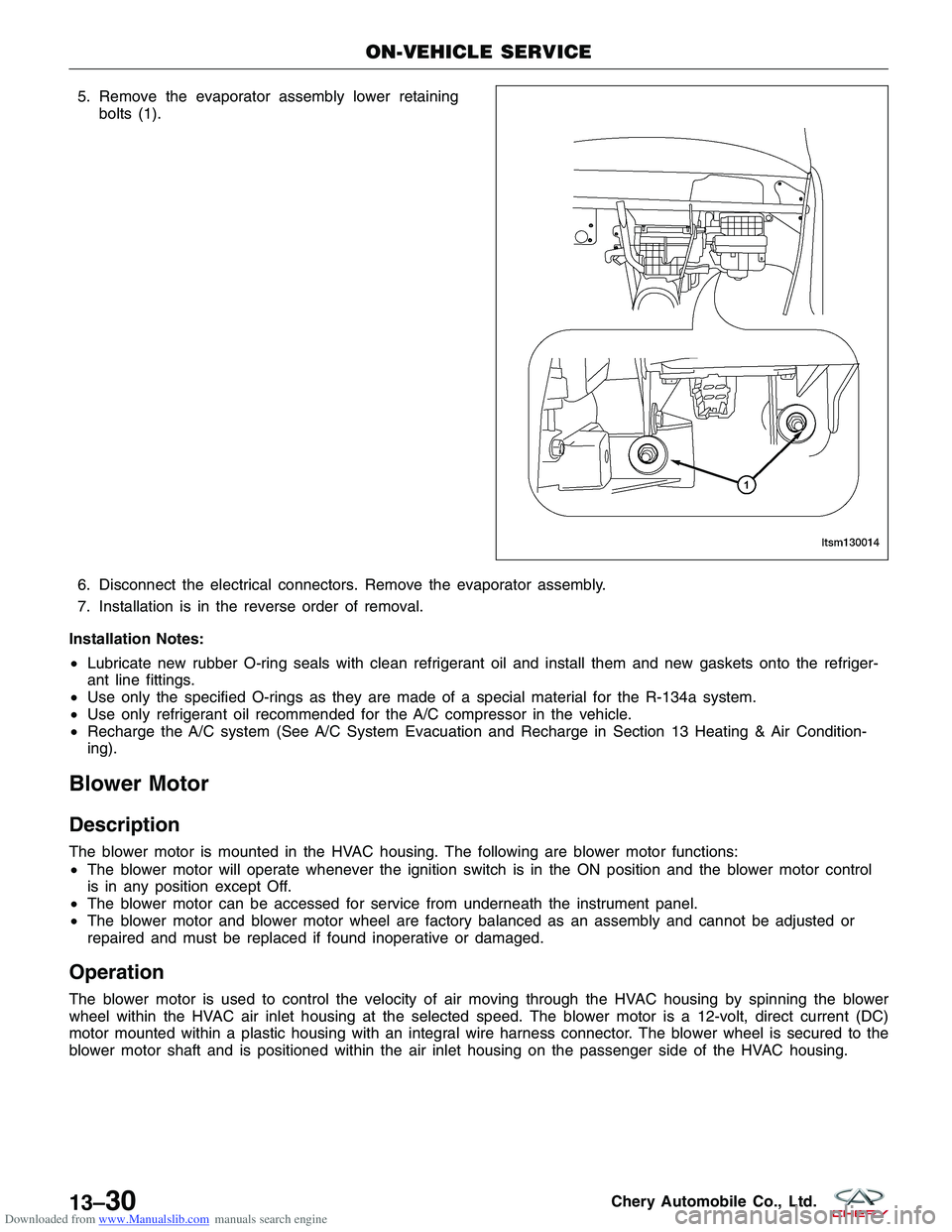

Blower Motor

Description

The blower motor is mounted in the HVAC housing. The following are blower motor functions:

•The blower motor will operate whenever the ignition switch is in the ON position and the blower motor control

is in any position except Off.

• The blower motor can be accessed for service from underneath the instrument panel.

• The blower motor and blower motor wheel are factory balanced as an assembly and cannot be adjusted or

repaired and must be replaced if found inoperative or damaged.

Operation

The blower motor is used to control the velocity of air moving through the HVAC housing by spinning the blower

wheel within the HVAC air inlet housing at the selected speed. The blower motor is a 12-volt, direct current (DC)

motor mounted within a plastic housing with an integral wire harness connector. The blower wheel is secured to the

blower motor shaft and is positioned within the air inlet housing on the passenger side of the HVAC housing.

ON-VEHICLE SERVICE

LTSM130014

13–30Chery Automobile Co., Ltd.

Page 1513 of 1903

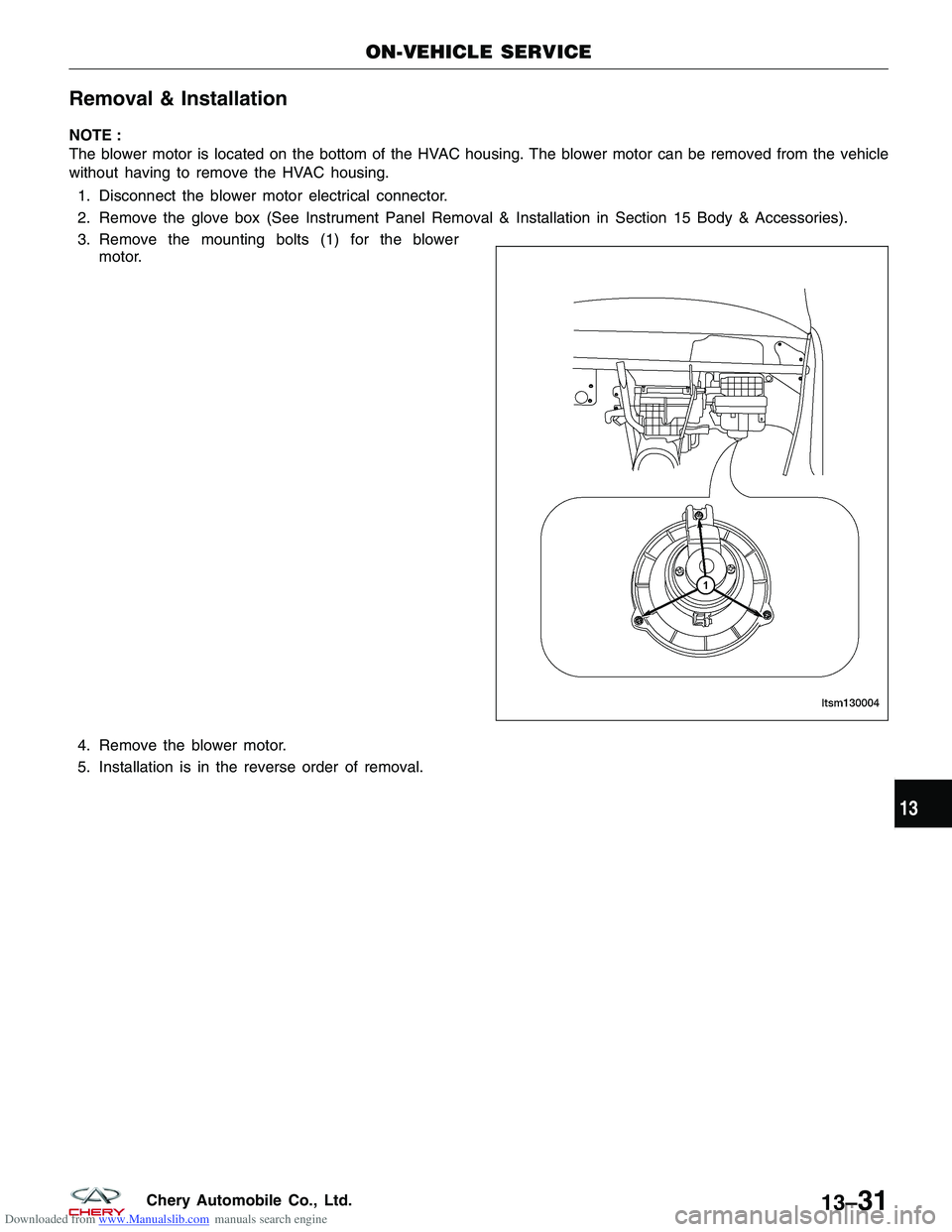

Downloaded from www.Manualslib.com manuals search engine Removal & Installation

NOTE :

The blower motor is located on the bottom of the HVAC housing. The blower motor can be removed from the vehicle

without having to remove the HVAC housing.1. Disconnect the blower motor electrical connector.

2. Remove the glove box (See Instrument Panel Removal & Installation in Section 15 Body & Accessories).

3. Remove the mounting bolts (1) for the blower motor.

4. Remove the blower motor.

5. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM130004

13

13–31Chery Automobile Co., Ltd.

Page 1514 of 1903

Downloaded from www.Manualslib.com manuals search engine SYSTEM PLUMBING

GENERAL INFORMATION13-33

Description 13-33

Operation 13-33

Specifications 13-33

Special Tools 13-34

DIAGNOSIS & TESTING13-35

Mechanical Problems 13-35

Temperature Control 13-35

A/C Compressor Noise Testing 13-35

Refrigerant System Leaks 13-36

Refrigerant System Empty 13-36

Refrigerant System Low 13-36

ON-VEHICLE SERVICE13-37

A/C System Evacuation and Recharge 13-37

Connecting Refrigerant Recovery/

Recycling Station 13-37

A/C System Evacuation 13-38

A/C System Recharge 13-38

Compressor 13-39

Description 13-39

Operation 13-39

Removal & Installation - 1.6L & 1.8L &

2.0L 13-39

Removal & Installation - 2.4L 13-41 Evaporator

13-42

Description 13-42

Operation 13-42

Removal & Installation 13-42

Condenser 13-42

Description 13-42

Operation 13-42

Removal & Installation 13-43

Accumulator 13-43

Description 13-43

Operation 13-43

Removal & Installation 13-43

Liquid Line 13-44

Description 13-44

Operation 13-44

Removal & Installation 13-44

Suction Line 13-45

Description 13-45

Operation 13-45

Removal & Installation 13-45

Heater Core 13-47

Description 13-47

Operation 13-47

Removal & Installation 13-47

13–32Chery Automobile Co., Ltd.

Page 1515 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The A/C refrigerant lines and pipes are used to carry the refrigerant between the various A/C system components.

Any kinks or sharp bends in the refrigerant lines and hoses will reduce the capacity of the entire A/C system and can

reduce the flow of refrigerant within the system.

Operation

High pressure is produced in a refrigerant system when the A/C compressor is operating. Extreme care must be

exercised to make sure that each of the refrigerant system connections is pressure-tight and leak free. It is a good

practice to inspect all flexible hose refrigerant lines at least once a year to make sure they are in good condition and

properly routed. Depending on vehicle, model and market application, refrigerant lines are connected to each other or

other A/C system components with block-type or quick-connect type fittings. To ensure the integrity of the refrigerant

system, O-rings and/or gaskets may be used to seal the refrigerant system connections. The refrigerant lines and

hoses cannot be repaired and must be replaced if leaking or damaged.

WARNING!

The A/C system contains refrigerant under high pressure. Repairs should only be performed by qualified service

personnel. Serious or fatal injury may result from improper service procedures.

If accidental A/C system discharge occurs, ventilate the work area before resuming service. Large amounts of

refrigerant released in a closed work area will displace the oxygen and cause suffocation and serious or fatal

injury.

CAUTION:

Never add R-12 to a refrigerant system designed to use R-134a. Do not use R-12 equipment or

parts on an R-134a A/C system. These refrigerants are not compatible and damage to the A/C sys-

tem will result.

CAUTION:

Never use R-12 refrigerant oil in an A/C system designed to use R-134a refrigerant oil. These refrig-

erant oils are not compatible and damage to the A/C system will result.

CAUTION:

Do not run the engine with a vacuum pump in operation or with a vacuum present within the A/C

system. Failure to follow this caution will result in serious A/C compressor damage.

CAUTION:

Do not overcharge the refrigerant system. Overcharging will cause excessive compressor head

pressure and can cause compressor noise and A/C system failure.

Specifications

Torque Specifications

DESCRIPTIONTORQUE (N·m)

A/C Compressor Bracket Bolts 40

A/C Compressor Line Bolts 20

13

13–33Chery Automobile Co., Ltd.