light CHERY TIGGO 2009 Service Manual PDF

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 932 of 1903

Downloaded from www.Manualslib.com manuals search engine Removal & Installation - 2.4L

WARNING!

Always allow the engine to cool before opening the cooling system. Do not remove the coolant pressure relief

cap when the engine is operating or the cooling system is hot. The cooling system is under pressure; steam and

hot liquid can come out forcefully when the cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

1. Drain the cooling system (See Cooling System Draining Procedure in Section 06 Cooling System).

2. Remove the accessory drive belt (See Accessory Drive Belt Removal & Installation in Section 02 Engine).

3. Remove the engine timing belt (See Engine Timing Belt Removal & Installation in Section 02 Engine).

4. Remove the upper balance shaft timing belt (See Upper Balance Shaft Timing Belt Removal & Installation inSection 02 Engine).

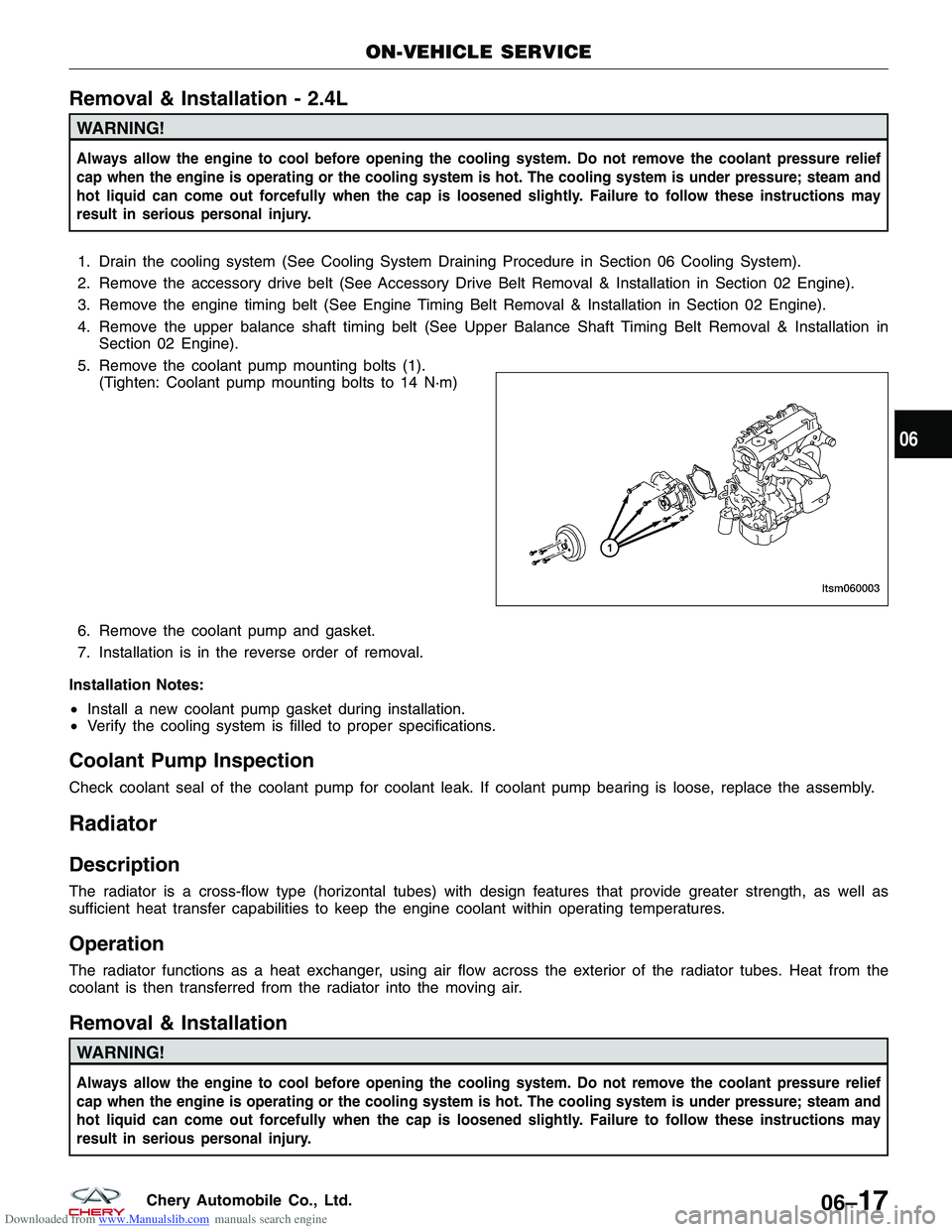

5. Remove the coolant pump mounting bolts (1). (Tighten: Coolant pump mounting bolts to 14 N·m)

6. Remove the coolant pump and gasket.

7. Installation is in the reverse order of removal.

Installation Notes:

• Install a new coolant pump gasket during installation.

• Verify the cooling system is filled to proper specifications.

Coolant Pump Inspection

Check coolant seal of the coolant pump for coolant leak. If coolant pump bearing is loose, replace the assembly.

Radiator

Description

The radiator is a cross-flow type (horizontal tubes) with design features that provide greater strength, as well as

sufficient heat transfer capabilities to keep the engine coolant within operating temperatures.

Operation

The radiator functions as a heat exchanger, using air flow across the exterior of the radiator tubes. Heat from the

coolant is then transferred from the radiator into the moving air.

Removal & Installation

WARNING!

Always allow the engine to cool before opening the cooling system. Do not remove the coolant pressure relief

cap when the engine is operating or the cooling system is hot. The cooling system is under pressure; steam and

hot liquid can come out forcefully when the cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

ON-VEHICLE SERVICE

LTSM060003

06

06–17Chery Automobile Co., Ltd.

Page 934 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The radiator cooling fan operation is controlled by the Engine Control Module (ECM) and the fan relays, with inputs

from the following:

•Engine coolant temperature

• Automatic transaxle fluid temperature (with DP0 transaxle)

• A/C signal

Inspect the cooling fan for proper low speed and high speed operation:

• The low speed fan should be switched on at 98°C and switched off at 94°C.

• The high speed fan should be switched on at 105°C and switched off at 101°C.

• If the water temperature is greater than 101°C after the fan is switched off, the fan will continue to operate for

1 minute.

• If the water temperature is greater than 94°C after the fan is switched off, the fan will continue to operate for

0.5 minute.

• If the water temperature is less than 85°C after the fan is switched off, the fan will stop operating.

Removal & Installation

WARNING!

Always allow the engine to cool before opening the cooling system. Do not remove the coolant pressure relief

cap when the engine is operating or the cooling system is hot. The cooling system is under pressure; steam and

hot liquid can come out forcefully when the cap is loosened slightly. Failure to follow these instructions may

result in serious personal injury.

1. Disconnect the negative battery cable.

2. Drain the cooling system (See Cooling System Draining Procedure in Section 06 Cooling System).

3. Disconnect the upper radiator hose from the radiator.

4. Disconnect the cooling fan electrical connector and the cooling fan ground cable connected to the body.

5. Remove the cooling fan mounting bolts (1) to the

radiator.

(Tighten: Cooling fan mounting bolts to 5 N·m)

6. Remove the radiator fan from the engine compartment.

7. Remove the cooling fan from its support, if necessary.

8. Installation is in the reverse order of removal.

Installation Notes:

• Verify the cooling system is filled to proper specifications.

Cooling Fan Inspection

1. Using the following table, apply battery voltage to the specified connector terminals.

2. Verify that the fan motor operates smoothly when voltage is applied.

3. If the test results are not as specified, replace the fan motor.

ON-VEHICLE SERVICE

LTSM060008

06

06–19Chery Automobile Co., Ltd.

Page 1212 of 1903

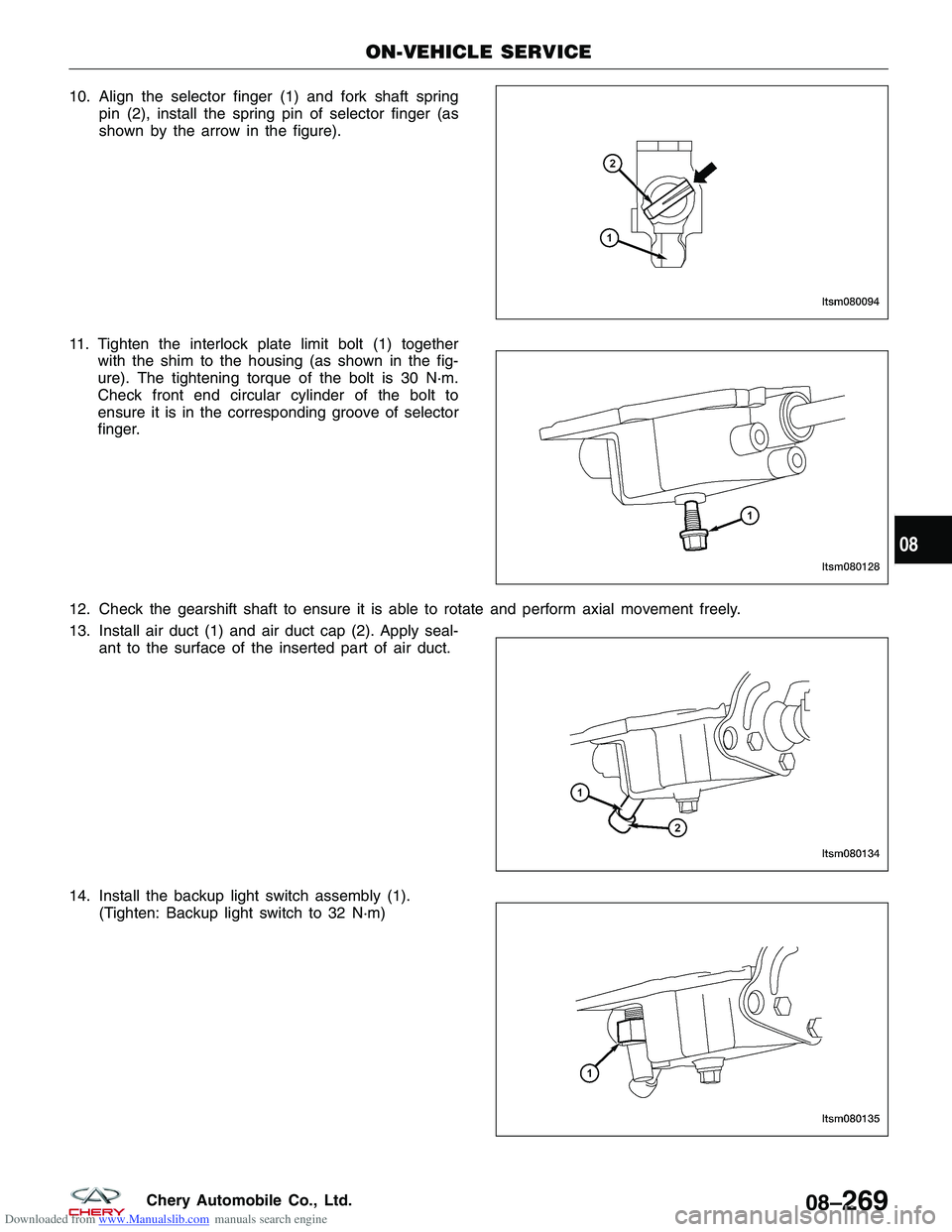

Downloaded from www.Manualslib.com manuals search engine 10. Align the selector finger (1) and fork shaft springpin (2), install the spring pin of selector finger (as

shown by the arrow in the figure).

11. Tighten the interlock plate limit bolt (1) together with the shim to the housing (as shown in the fig-

ure). The tightening torque of the bolt is 30 N·m.

Check front end circular cylinder of the bolt to

ensure it is in the corresponding groove of selector

finger.

12. Check the gearshift shaft to ensure it is able to rotate and perform axial movement freely.

13. Install air duct (1) and air duct cap (2). Apply seal- ant to the surface of the inserted part of air duct.

14. Install the backup light switch assembly (1). (Tighten: Backup light switch to 32 N·m)

ON-VEHICLE SERVICE

LTSM080094

LTSM080128

LTSM080134

LTSM080135

08

08–269Chery Automobile Co., Ltd.

Page 1240 of 1903

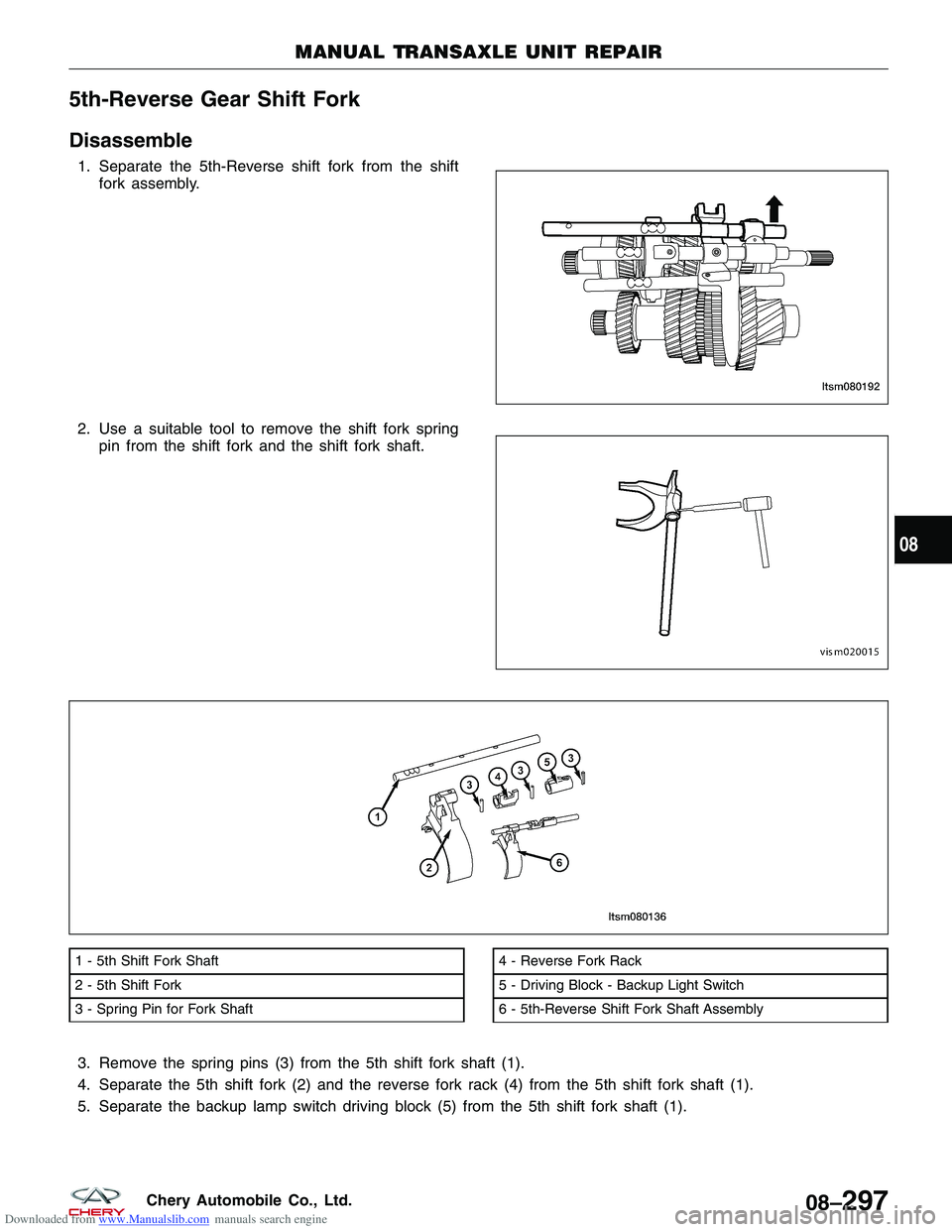

Downloaded from www.Manualslib.com manuals search engine 5th-Reverse Gear Shift Fork

Disassemble

1. Separate the 5th-Reverse shift fork from the shiftfork assembly.

2. Use a suitable tool to remove the shift fork spring pin from the shift fork and the shift fork shaft.

3. Remove the spring pins (3) from the 5th shift fork shaft (1).

4. Separate the 5th shift fork (2) and the reverse fork rack (4) from the 5th shift fork shaft (1).

5. Separate the backup lamp switch driving block (5) from the 5th shift fork shaft (1).

1 - 5th Shift Fork Shaft

2 - 5th Shift Fork

3 - Spring Pin for Fork Shaft4 - Reverse Fork Rack

5 - Driving Block - Backup Light Switch

6 - 5th-Reverse Shift Fork Shaft Assembly

MANUAL TRANSAXLE UNIT REPAIR

LTSM080192 VISM020015

LTSM080136

08

08–297Chery Automobile Co., Ltd.

Page 1241 of 1903

Downloaded from www.Manualslib.com manuals search engine Assemble

Assemble in the reverse order of disassembly.

NOTE :

•Check and ensure the shift fork is properly installed to the fork shaft, there should be NO axial or radial motion in

the fork shaft.

• Check and ensure the fork rack is properly installed to the fork shaft, there should be NO axial or radial motion in

the fork shaft.

• Check and ensure backup light driving block is properly installed to the fork shaft, there should be NO axial or

radial motion in the fork shaft.

• Check the fork shaft surface for any damage.

• Check the position of the three spring pins, ensure the pins are in proper alignment. The extension of both ends

of the three spring pins should not exceed 3 mm.

3rd-4th Gear Shift Fork

Disassemble

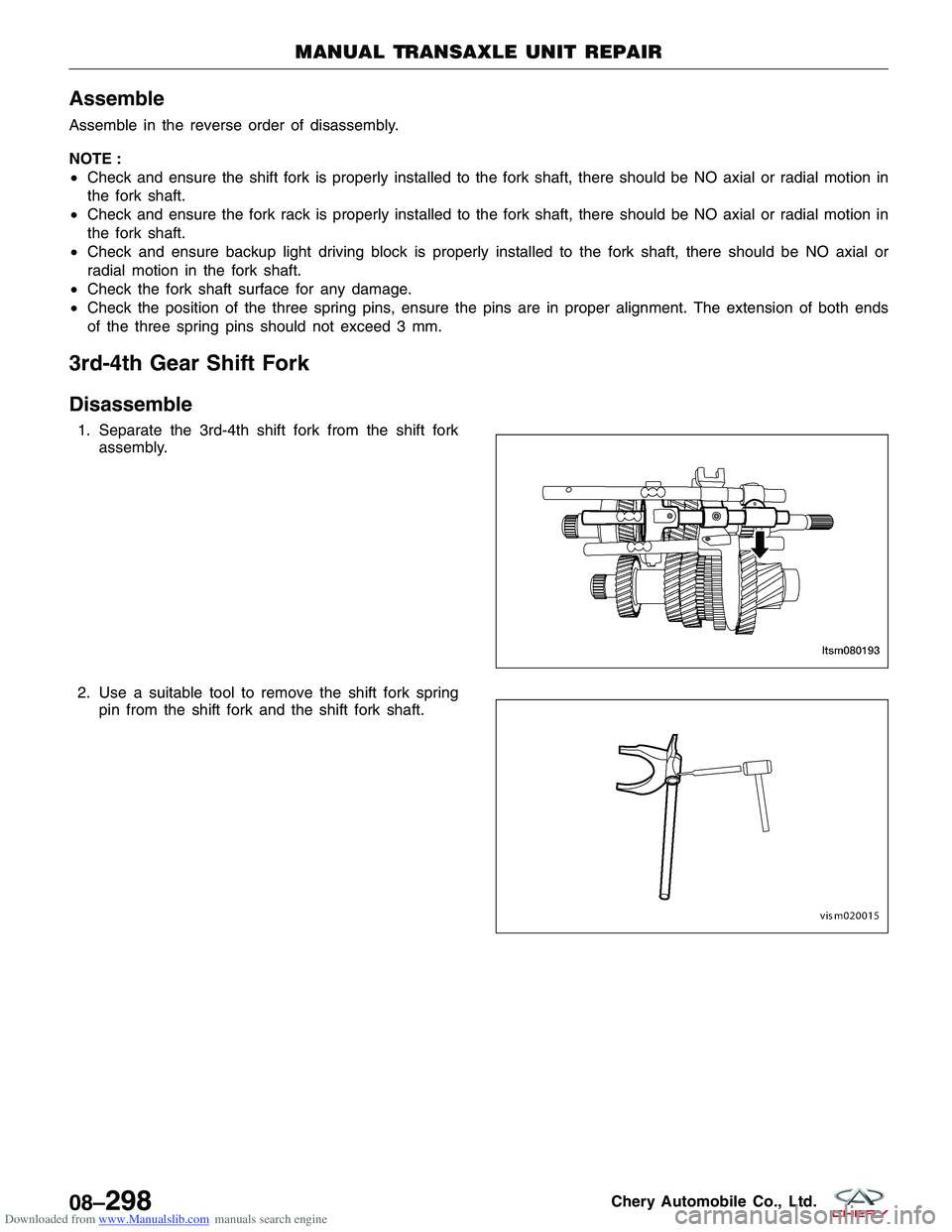

1. Separate the 3rd-4th shift fork from the shift fork

assembly.

2. Use a suitable tool to remove the shift fork spring pin from the shift fork and the shift fork shaft.

MANUAL TRANSAXLE UNIT REPAIR

LTSM080193

VISM020015

08–298Chery Automobile Co., Ltd.

Page 1359 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Power Steering Troubleshooting Chart

Review this troubleshooting chart any time a power steering system problem is present. This chart will help deter-

mine if the power steering pump or power steering gear is functioning properly.

CONDITIONPOSSIBLE CAUSES CORRECTION

Steering Wheel Is Loose · Steering wheel retaining bolt loose.

· Loose steering column to

instrument panel fasteners.· Check steering wheel retaining bolt

torque and tighten to specifications if

necessary.

· Check steering column to

instrument panel fastener torque and

tighten to specifications if necessary.

Steering Catches, Surges Or Sticks

In Certain Positions Or Is Difficult To

Turn · Low power steering fluid level.

· Tire(s) not properly inflated.

· Loose or slipping power steering/

accessory drive belt.

· Lack of lubrication in steering gear

outer tie rod end(s).· Check fluid level and fill to proper

level if necessary. Check for leaks.

Make sure all air is bled from

system.

· Check and inflate tires to the

specified pressure.

· Verify belt tension. Replace belt

auto-tensioner and belt if necessary.

· Check the outer tie rod ends.

Steering Wheel Does Not Return To

Center Position · Tire(s) not properly inflated.

· Improper front wheel alignment.· Check and inflate tires to the

specified pressure.

· Check and adjust wheel alignment

if necessary.

Excessive Steering Wheel Kickback

From Road Inputs · Air in power steering fluid.

· Power steering gear loose on

cradle/sub-frame.

· Steering column, coupling or

intermediate shaft worn or loose.

· Power steering pump flow is too

low.· Inspect for excessive air bubbles in

fluid (fluid will appear foamy and

lighter in color). Inspect hoses for

leaks and replace if necessary.

Bleed air from fluid.

· Inspect gear mounting bolts.

Replace if necessary and tighten to

specifications.

· Rotate steering wheel back-and-

forth while inspecting intermediate

shaft going into steering gear. Look

for excessive free-play. Retighten if

loose bolt is found. Replace steering

column, coupling or intermediate

shaft if necessary.

· Perform power steering flow and

pressure test. Look for low or erratic

flow or pressure. Replace power

steering pump if necessary.

11 –4Chery Automobile Co., Ltd.

Page 1368 of 1903

Downloaded from www.Manualslib.com manuals search engine Inspection - Steering System

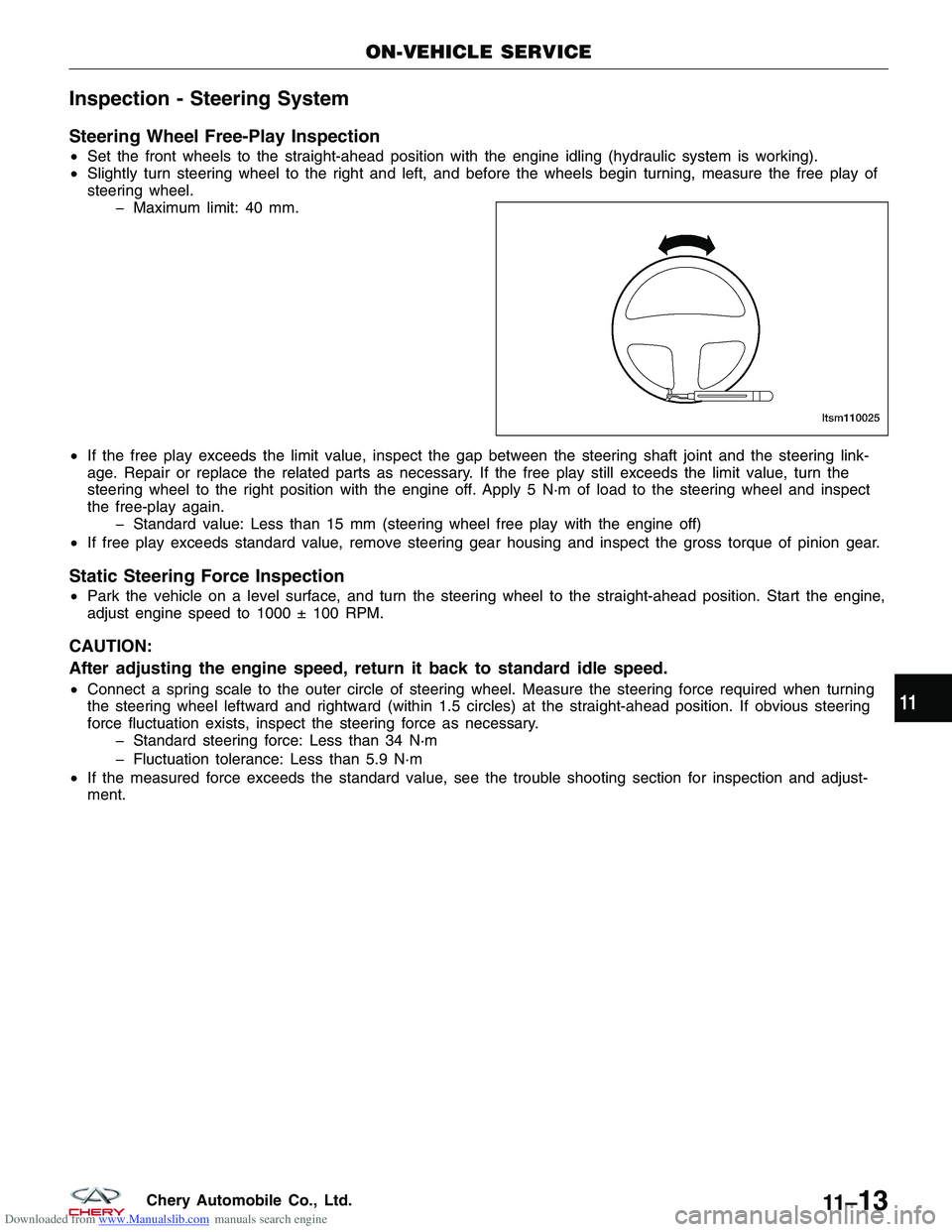

Steering Wheel Free-Play Inspection

•Set the front wheels to the straight-ahead position with the engine idling (hydraulic system is working).

• Slightly turn steering wheel to the right and left, and before the wheels begin turning, measure the free play of

steering wheel.

� Maximum limit: 40 mm.

• If the free play exceeds the limit value, inspect the gap between the steering shaft joint and the steering link-

age. Repair or replace the related parts as necessary. If the free play still exceeds the limit value, turn the

steering wheel to the right position with the engine off. Apply 5 N·m of load to the steering wheel and inspect

the free-play again.

� Standard value: Less than 15 mm (steering wheel free play with the engine off)

• If free play exceeds standard value, remove steering gear housing and inspect the gross torque of pinion gear.

Static Steering Force Inspection

•Park the vehicle on a level surface, and turn the steering wheel to the straight-ahead position. Start the engine,

adjust engine speed to 1000 ± 100 RPM.

CAUTION:

After adjusting the engine speed, return it back to standard idle speed.

•Connect a spring scale to the outer circle of steering wheel. Measure the steering force required when turning

the steering wheel leftward and rightward (within 1.5 circles) at the straight-ahead position. If obvious steering

force fluctuation exists, inspect the steering force as necessary.

� Standard steering force: Less than 34 N·m

� Fluctuation tolerance: Less than 5.9 N·m

• If the measured force exceeds the standard value, see the trouble shooting section for inspection and adjust-

ment.

ON-VEHICLE SERVICE

LTSM110025

11

11 –13Chery Automobile Co., Ltd.

Page 1402 of 1903

Downloaded from www.Manualslib.com manuals search engine DIAGNOSIS & TESTING

Diagnostic Help

Brake diagnosis involves determining if the concern is related to a mechanical, hydraulic, electrical or vacuum oper-

ated component.

NOTE :

The brake reservoir fluid level will decrease in proportion to normal lining wear.

NOTE :

Brake fluid tends to darken over time. This is normal and should not be mistaken for contamination.

Preliminary Brake Check:

•Check the condition of the tires and wheels. Damaged wheels and worn, damaged or under inflated tires can

cause a pull, shudder, vibration and a condition similar to brake grab.

• If a complaint was based on noise while braking, check the suspension components. Jounce the front and the

rear of vehicle and listen for anything that might be caused by a loose, worn or damaged suspension or steer-

ing component.

• Inspect the brake fluid level and condition.

1. If the fluid level is abnormally low, look for any evidence of leaks at the calipers, brake lines, master cyl-

inder and at the Antilock Brake System (ABS) Hydraulic Control Unit (HCU).

2. If the fluid appears to be contaminated, drain a sample to examine.

• The system will have to be flushed if the fluid is separated into layers, or contains a substance other than

brake fluid. The system seals, cups, hoses, master cylinder and HCU will also have to be replaced after flush-

ing. Use clean brake fluid to flush the system.

• Check the parking brake operation. Verify free movement and full release of the cables and the lever. Also note

if the vehicle was being operated with the parking brake partially applied.

• Check the brake pedal operation. Verify that the pedal does not bind and has adequate free play. If the pedal

lacks free play, check the pedal and the power booster for looseness or for a binding condition. DO NOT road

test the vehicle until the condition is located and corrected.

• Check the vacuum booster check valve and vacuum supply hose.

• If the preliminary checks appear to be OK, road test the vehicle.

Brake Noise

CONDITION POSSIBLE CAUSES CORRECTION

Disc Brake Chirp · Excessive brake rotor runout.

· Small particles· Diagnose and correct as

necessary.

Disc Brake Rattle Or Clunk · Broken or missing spring clips.

· Caliper guide pin bolts loose.

· Missing abutment shims.

· Small metal particles· Replace brake pads.

· Tighten guide pin bolts.

· Replace missing abutment shims.

Disc Brake Squeak At Low Speed

(While Applying Light Brake Pedal

Effort) · Brake shoe linings.

· Replace brake pads.

Scraping Or Whirring · ABS wheel speed sensor hitting

tone wheel.· Inspect, correct or replace faulty

component(s).

12

12–7Chery Automobile Co., Ltd.

Page 1416 of 1903

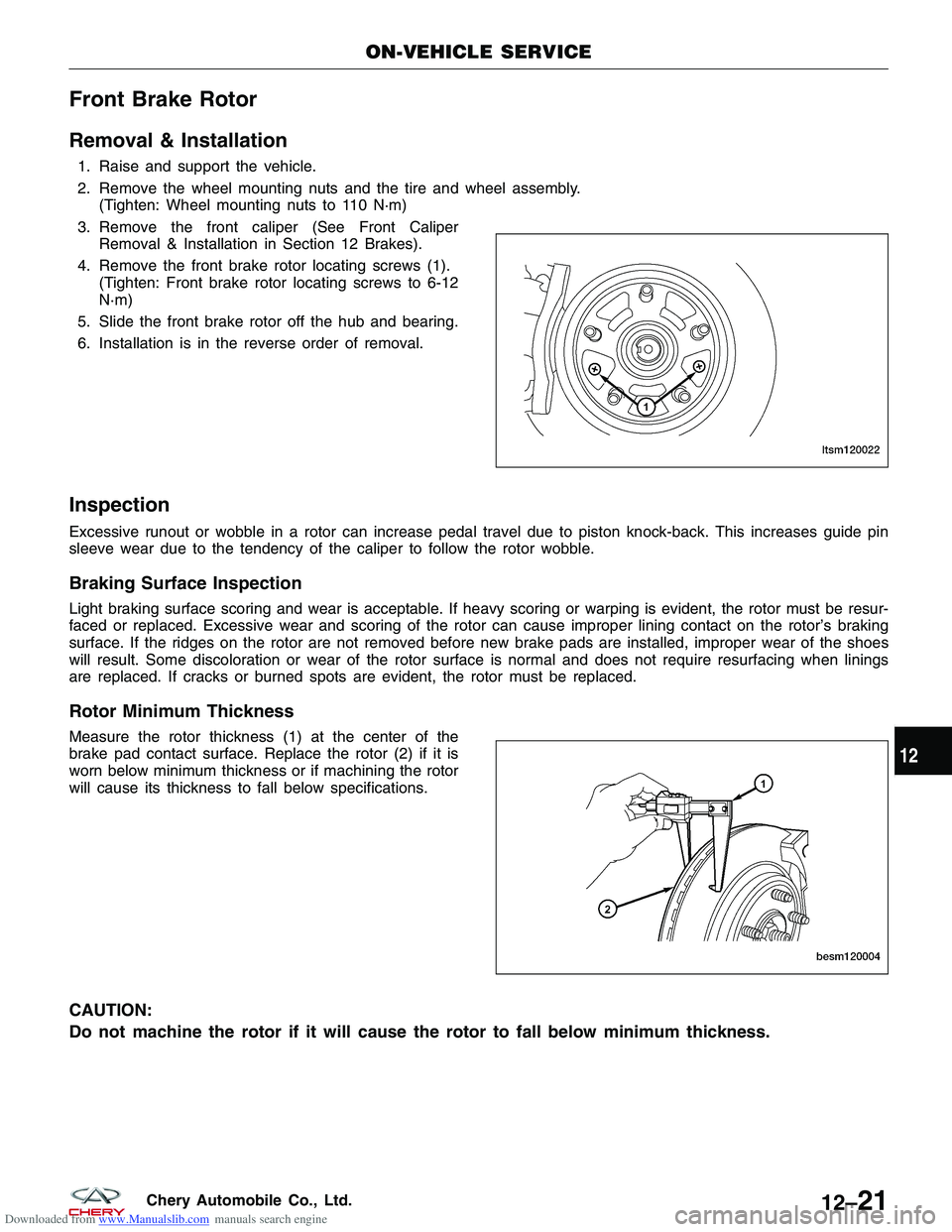

Downloaded from www.Manualslib.com manuals search engine Front Brake Rotor

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.(Tighten: Wheel mounting nuts to 110 N·m)

3. Remove the front caliper (See Front Caliper Removal & Installation in Section 12 Brakes).

4. Remove the front brake rotor locating screws (1). (Tighten: Front brake rotor locating screws to 6-12

N·m)

5. Slide the front brake rotor off the hub and bearing.

6. Installation is in the reverse order of removal.

Inspection

Excessive runout or wobble in a rotor can increase pedal travel due to piston knock-back. This increases guide pin

sleeve wear due to the tendency of the caliper to follow the rotor wobble.

Braking Surface Inspection

Light braking surface scoring and wear is acceptable. If heavy scoring or warping is evident, the rotor must be resur-

faced or replaced. Excessive wear and scoring of the rotor can cause improper lining contact on the rotor’s braking

surface. If the ridges on the rotor are not removed before new brake pads are installed, improper wear of the shoes

will result. Some discoloration or wear of the rotor surface is normal and does not require resurfacing when linings

are replaced. If cracks or burned spots are evident, the rotor must be replaced.

Rotor Minimum Thickness

Measure the rotor thickness (1) at the center of the

brake pad contact surface. Replace the rotor (2) if it is

worn below minimum thickness or if machining the rotor

will cause its thickness to fall below specifications.

CAUTION:

Do not machine the rotor if it will cause the rotor to fall below minimum thickness.

ON-VEHICLE SERVICE

LTSM120022

BESM120004

12

12–21Chery Automobile Co., Ltd.

Page 1417 of 1903

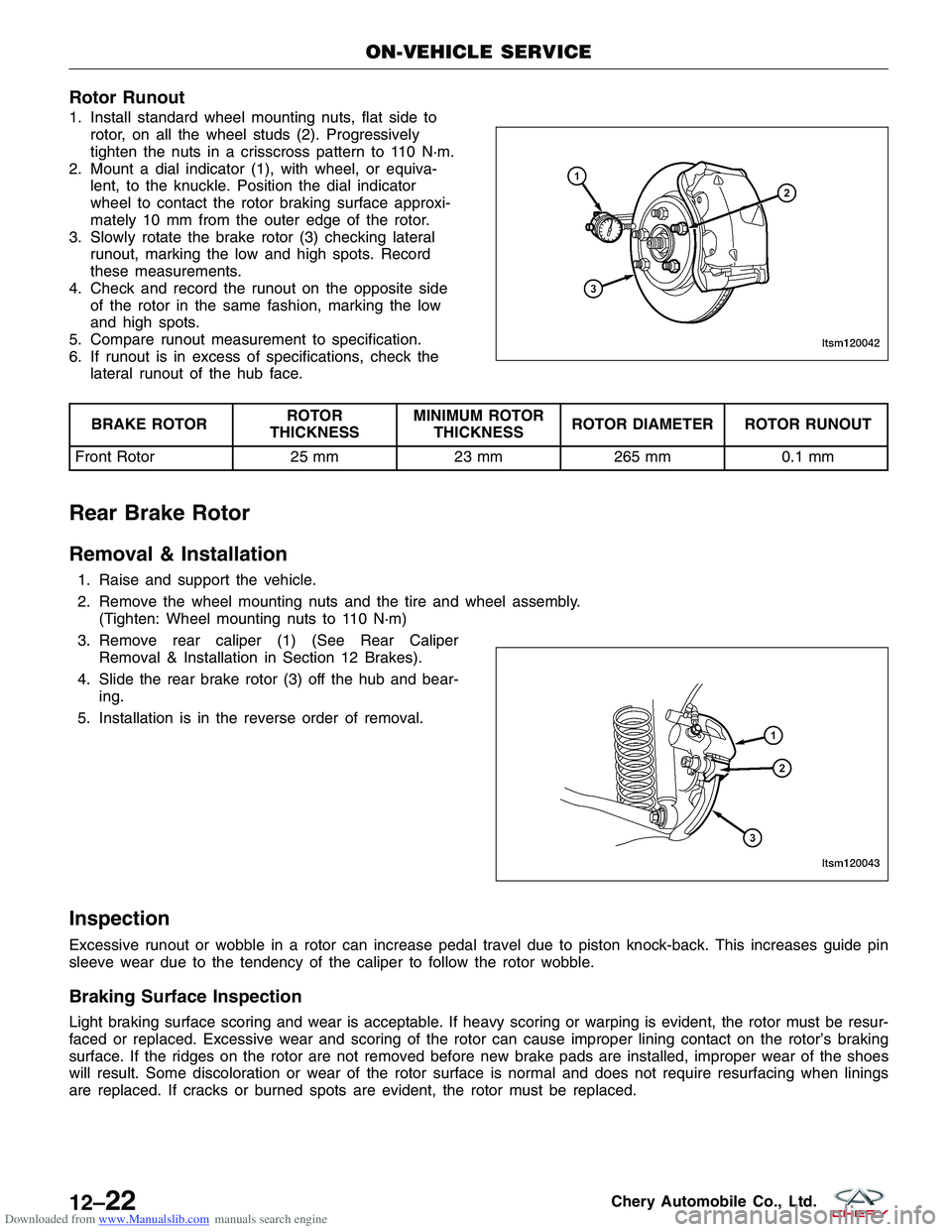

Downloaded from www.Manualslib.com manuals search engine Rotor Runout

1. Install standard wheel mounting nuts, flat side torotor, on all the wheel studs (2). Progressively

tighten the nuts in a crisscross pattern to 110 N·m.

2. Mount a dial indicator (1), with wheel, or equiva- lent, to the knuckle. Position the dial indicator

wheel to contact the rotor braking surface approxi-

mately 10 mm from the outer edge of the rotor.

3. Slowly rotate the brake rotor (3) checking lateral runout, marking the low and high spots. Record

these measurements.

4. Check and record the runout on the opposite side of the rotor in the same fashion, marking the low

and high spots.

5. Compare runout measurement to specification.

6. If runout is in excess of specifications, check the lateral runout of the hub face.

BRAKE ROTOR ROTOR

THICKNESS MINIMUM ROTOR

THICKNESS ROTOR DIAMETER ROTOR RUNOUT

Front Rotor 25 mm23 mm265 mm 0.1 mm

Rear Brake Rotor

Removal & Installation

1. Raise and support the vehicle.

2. Remove the wheel mounting nuts and the tire and wheel assembly.

(Tighten: Wheel mounting nuts to 110 N·m)

3. Remove rear caliper (1) (See Rear Caliper Removal & Installation in Section 12 Brakes).

4. Slide the rear brake rotor (3) off the hub and bear- ing.

5. Installation is in the reverse order of removal.

Inspection

Excessive runout or wobble in a rotor can increase pedal travel due to piston knock-back. This increases guide pin

sleeve wear due to the tendency of the caliper to follow the rotor wobble.

Braking Surface Inspection

Light braking surface scoring and wear is acceptable. If heavy scoring or warping is evident, the rotor must be resur-

faced or replaced. Excessive wear and scoring of the rotor can cause improper lining contact on the rotor’s braking

surface. If the ridges on the rotor are not removed before new brake pads are installed, improper wear of the shoes

will result. Some discoloration or wear of the rotor surface is normal and does not require resurfacing when linings

are replaced. If cracks or burned spots are evident, the rotor must be replaced.

ON-VEHICLE SERVICE

LTSM120042

LTSM120043

12–22Chery Automobile Co., Ltd.