compression ratio CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 30 of 1903

Downloaded from www.Manualslib.com manuals search engine ENGINE

02

CONTENTSpage

1.6L & 1.8L Engine Mechanical ......................................................... 02-1

2.0L Engine Mechanical .............................................................. 02-76

2.4L Engine Mechanical ............................................................. 02-149

1.6L & 1.8L ENGINE MECHANICAL

GENERAL INFORMATION02-3

Description 02-3

Operation 02-3

Specifications 02-3

Special Tools 02-7

Lubrication System 02-10

DIAGNOSIS & TESTING02-13

Engine Performance Diagnostics 02-13

Engine Mechanical Diagnostics 02-14

Cylinder Compression Pressure Test 02-16

Cylinder Head Gasket Test 02-16

ON-VEHICLE SERVICE02-17

Accessory Drive Belt 02-17

Removal & Installation 02-17

Air Cleaner Element 02-18

Removal & Installation 02-18

Air Cleaner Housing 02-18

Removal & Installation 02-18

Cylinder Head Cover 02-19

Removal & Installation 02-19

Camshaft 02-20

Removal & Installation 02-20

Cylinder Head 02-23

Removal & Installation 02-23

Front Crankshaft Oil Seal 02-25

Removal & Installation 02-25 Rear Crankshaft Oil Seal

02-27

Removal & Installation 02-27

Engine Mounts 02-29

Removal & Installation - Left Mount 02-29

Removal & Installation - Right Mount 02-30

Removal & Installation - Front Mount 02-30

Removal & Installation - Rear Mount 02-31

Engine Assembly 02-31

Removal & Installation 02-31

Engine Timing Belt 02-38

Removal & Installation 02-38

Exhaust Manifold 02-41

Removal & Installation 02-41

Intake Manifold 02-43

Removal & Installation 02-43

Idler Pulley 02-45

Removal & Installation 02-45

Oil Filter 02-46

Removal & Installation 02-46

Oil Pan 02-47

Removal & Installation 02-47

Oil Pump 02-48

Removal & Installation 02-48

Oil Strainer 02-49

Removal & Installation 02-49

02

02–1Chery Automobile Co., Ltd.

Page 32 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

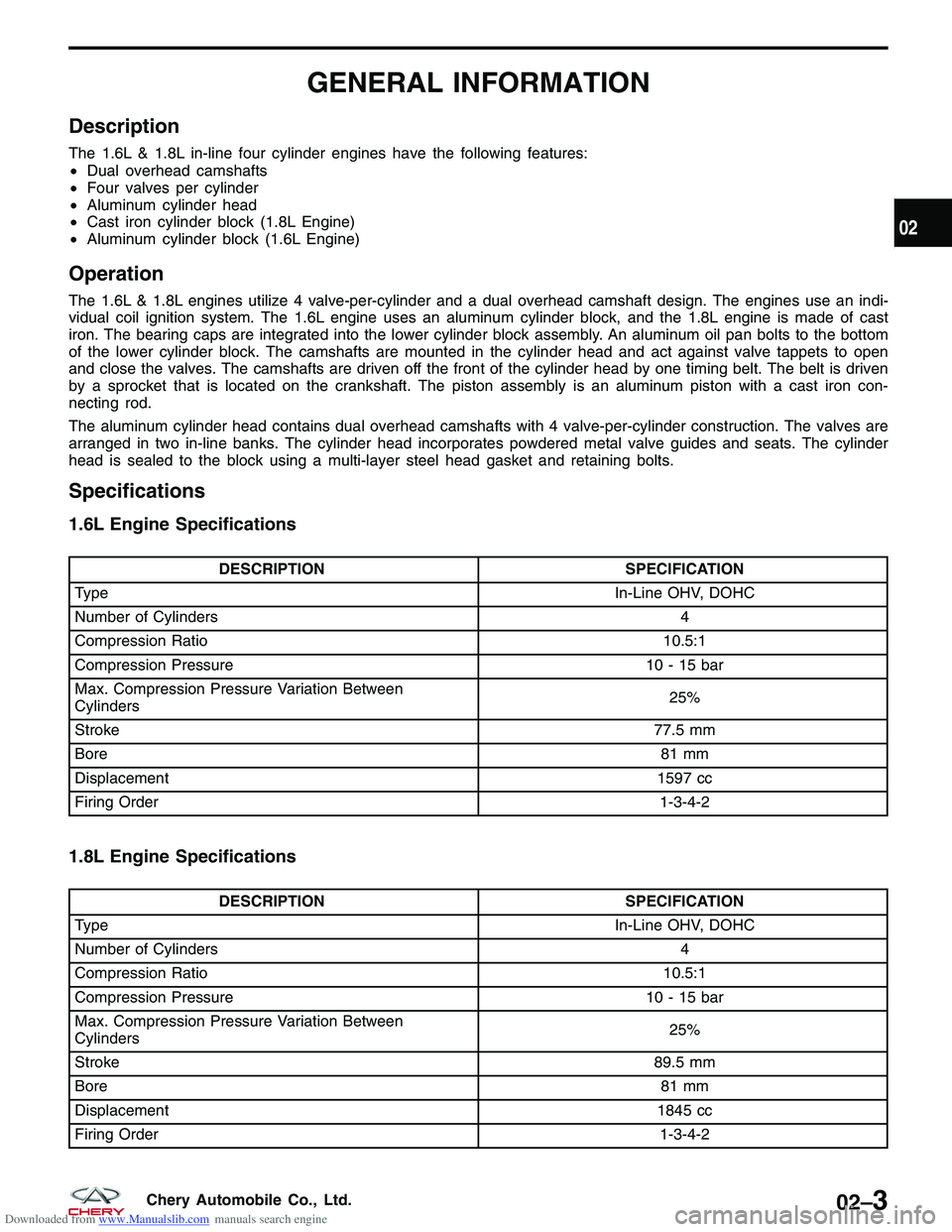

Description

The 1.6L & 1.8L in-line four cylinder engines have the following features:

•Dual overhead camshafts

• Four valves per cylinder

• Aluminum cylinder head

• Cast iron cylinder block (1.8L Engine)

• Aluminum cylinder block (1.6L Engine)

Operation

The 1.6L & 1.8L engines utilize 4 valve-per-cylinder and a dual overhead camshaft design. The engines use an indi-

vidual coil ignition system. The 1.6L engine uses an aluminum cylinder block, and the 1.8L engine is made of cast

iron. The bearing caps are integrated into the lower cylinder block assembly. An aluminum oil pan bolts to the bottom

of the lower cylinder block. The camshafts are mounted in the cylinder head and act against valve tappets to open

and close the valves. The camshafts are driven off the front of the cylinder head by one timing belt. The belt is driven

by a sprocket that is located on the crankshaft. The piston assembly is an aluminum piston with a cast iron con-

necting rod.

The aluminum cylinder head contains dual overhead camshafts with 4 valve-per-cylinder construction. The valves are

arranged in two in-line banks. The cylinder head incorporates powdered metal valve guides and seats. The cylinder

head is sealed to the block using a multi-layer steel head gasket and retaining bolts.

Specifications

1.6L Engine Specifications

DESCRIPTION SPECIFICATION

Type In-Line OHV, DOHC

Number of Cylinders 4

Compression Ratio 10.5:1

Compression Pressure 10 - 15 bar

Max. Compression Pressure Variation Between

Cylinders 25%

Stroke 77.5 mm

Bore 81 mm

Displacement 1597 cc

Firing Order 1-3-4-2

1.8L Engine Specifications

DESCRIPTIONSPECIFICATION

Type In-Line OHV, DOHC

Number of Cylinders 4

Compression Ratio 10.5:1

Compression Pressure 10 - 15 bar

Max. Compression Pressure Variation Between

Cylinders 25%

Stroke 89.5 mm

Bore 81 mm

Displacement 1845 cc

Firing Order 1-3-4-2

02

02–3Chery Automobile Co., Ltd.

Page 105 of 1903

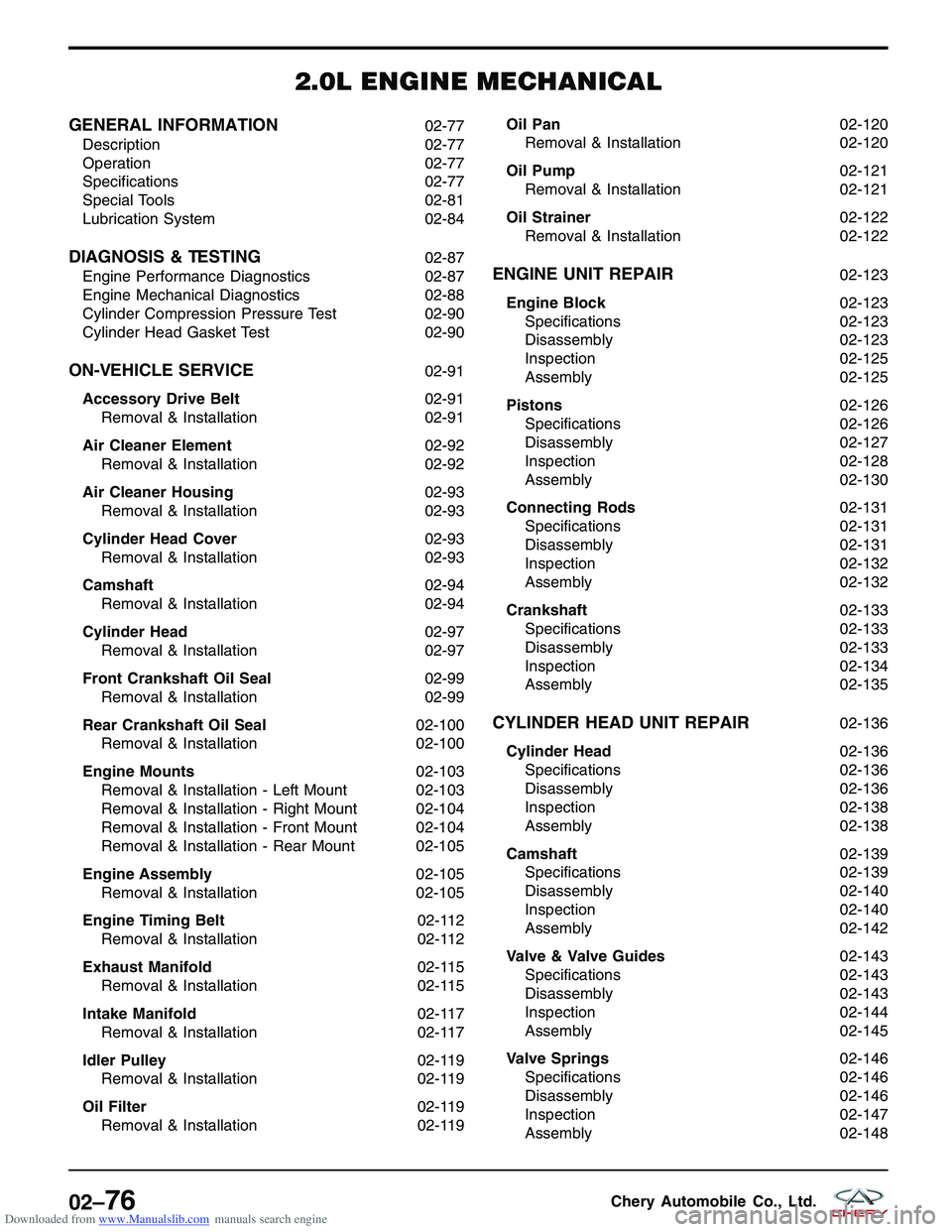

Downloaded from www.Manualslib.com manuals search engine 2.0L ENGINE MECHANICAL

GENERAL INFORMATION02-77

Description 02-77

Operation 02-77

Specifications 02-77

Special Tools 02-81

Lubrication System 02-84

DIAGNOSIS & TESTING02-87

Engine Performance Diagnostics 02-87

Engine Mechanical Diagnostics 02-88

Cylinder Compression Pressure Test 02-90

Cylinder Head Gasket Test 02-90

ON-VEHICLE SERVICE02-91

Accessory Drive Belt 02-91

Removal & Installation 02-91

Air Cleaner Element 02-92

Removal & Installation 02-92

Air Cleaner Housing 02-93

Removal & Installation 02-93

Cylinder Head Cover 02-93

Removal & Installation 02-93

Camshaft 02-94

Removal & Installation 02-94

Cylinder Head 02-97

Removal & Installation 02-97

Front Crankshaft Oil Seal 02-99

Removal & Installation 02-99

Rear Crankshaft Oil Seal 02-100

Removal & Installation 02-100

Engine Mounts 02-103

Removal & Installation - Left Mount 02-103

Removal & Installation - Right Mount 02-104

Removal & Installation - Front Mount 02-104

Removal & Installation - Rear Mount 02-105

Engine Assembly 02-105

Removal & Installation 02-105

Engine Timing Belt 02-112

Removal & Installation 02-112

Exhaust Manifold 02-115

Removal & Installation 02-115

Intake Manifold 02-117

Removal & Installation 02-117

Idler Pulley 02-119

Removal & Installation 02-119

Oil Filter 02-119

Removal & Installation 02-119Oil Pan

02-120

Removal & Installation 02-120

Oil Pump 02-121

Removal & Installation 02-121

Oil Strainer 02-122

Removal & Installation 02-122

ENGINE UNIT REPAIR02-123

Engine Block 02-123

Specifications 02-123

Disassembly 02-123

Inspection 02-125

Assembly 02-125

Pistons 02-126

Specifications 02-126

Disassembly 02-127

Inspection 02-128

Assembly 02-130

Connecting Rods 02-131

Specifications 02-131

Disassembly 02-131

Inspection 02-132

Assembly 02-132

Crankshaft 02-133

Specifications 02-133

Disassembly 02-133

Inspection 02-134

Assembly 02-135

CYLINDER HEAD UNIT REPAIR02-136

Cylinder Head 02-136

Specifications 02-136

Disassembly 02-136

Inspection 02-138

Assembly 02-138

Camshaft 02-139

Specifications 02-139

Disassembly 02-140

Inspection 02-140

Assembly 02-142

Valve & Valve Guides 02-143

Specifications 02-143

Disassembly 02-143

Inspection 02-144

Assembly 02-145

Valve Springs 02-146

Specifications 02-146

Disassembly 02-146

Inspection 02-147

Assembly 02-148

02–76Chery Automobile Co., Ltd.

Page 106 of 1903

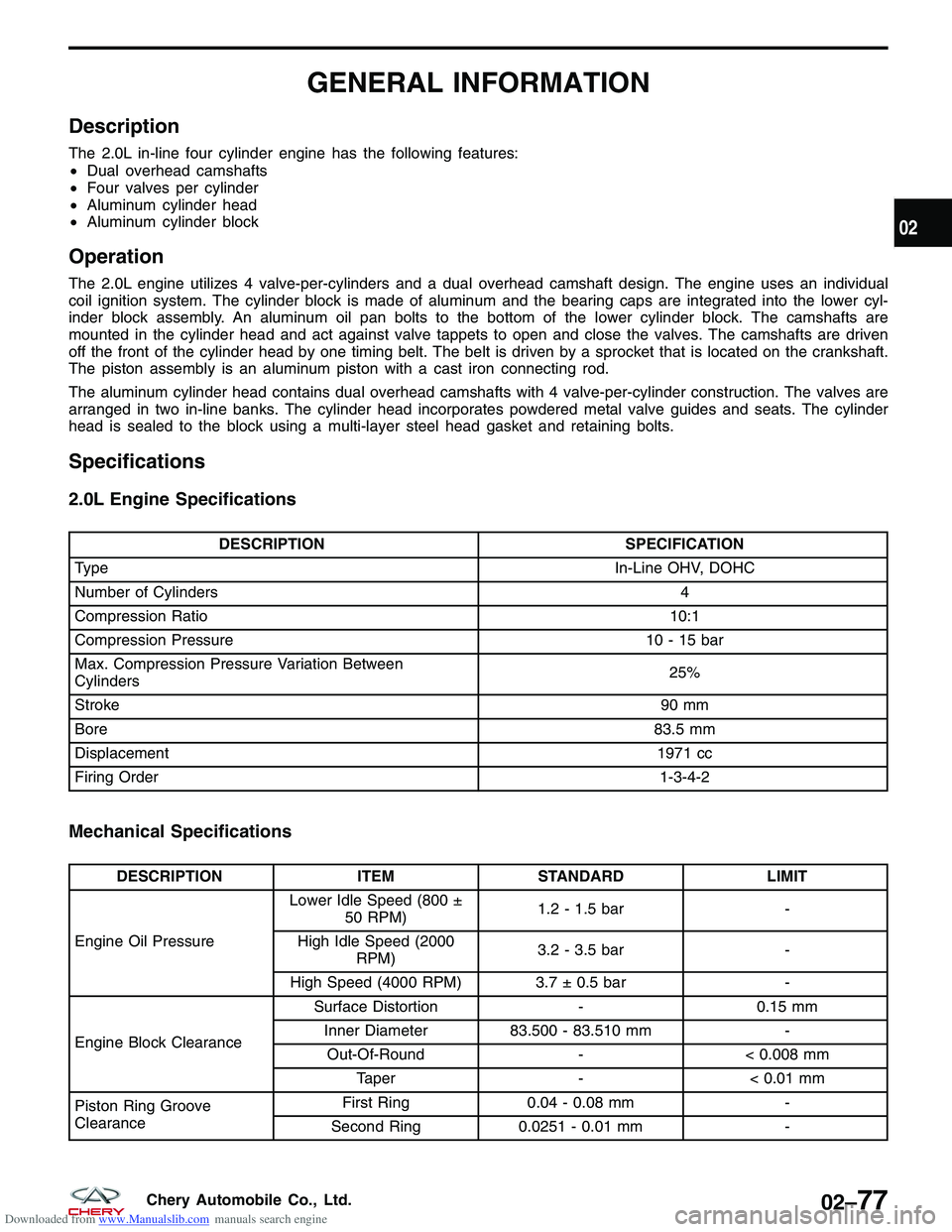

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The 2.0L in-line four cylinder engine has the following features:

•Dual overhead camshafts

• Four valves per cylinder

• Aluminum cylinder head

• Aluminum cylinder block

Operation

The 2.0L engine utilizes 4 valve-per-cylinders and a dual overhead camshaft design. The engine uses an individual

coil ignition system. The cylinder block is made of aluminum and the bearing caps are integrated into the lower cyl-

inder block assembly. An aluminum oil pan bolts to the bottom of the lower cylinder block. The camshafts are

mounted in the cylinder head and act against valve tappets to open and close the valves. The camshafts are driven

off the front of the cylinder head by one timing belt. The belt is driven by a sprocket that is located on the crankshaft.

The piston assembly is an aluminum piston with a cast iron connecting rod.

The aluminum cylinder head contains dual overhead camshafts with 4 valve-per-cylinder construction. The valves are

arranged in two in-line banks. The cylinder head incorporates powdered metal valve guides and seats. The cylinder

head is sealed to the block using a multi-layer steel head gasket and retaining bolts.

Specifications

2.0L Engine Specifications

DESCRIPTION SPECIFICATION

Type In-Line OHV, DOHC

Number of Cylinders 4

Compression Ratio 10:1

Compression Pressure 10 - 15 bar

Max. Compression Pressure Variation Between

Cylinders 25%

Stroke 90 mm

Bore 83.5 mm

Displacement 1971 cc

Firing Order 1-3-4-2

Mechanical Specifications

DESCRIPTIONITEMSTANDARD LIMIT

Engine Oil Pressure Lower Idle Speed (800 ±

50 RPM) 1.2 - 1.5 bar

-

High Idle Speed (2000 RPM) 3.2 - 3.5 bar

-

High Speed (4000 RPM) 3.7 ± 0.5 bar -

Engine Block Clearance Surface Distortion

-0.15 mm

Inner Diameter 83.500 - 83.510 mm -

Out-Of-Round -< 0.008 mm

Taper -< 0.01 mm

Piston Ring Groove

Clearance First Ring

0.04 - 0.08 mm -

Second Ring 0.0251 - 0.01 mm -

02

02–77Chery Automobile Co., Ltd.

Page 178 of 1903

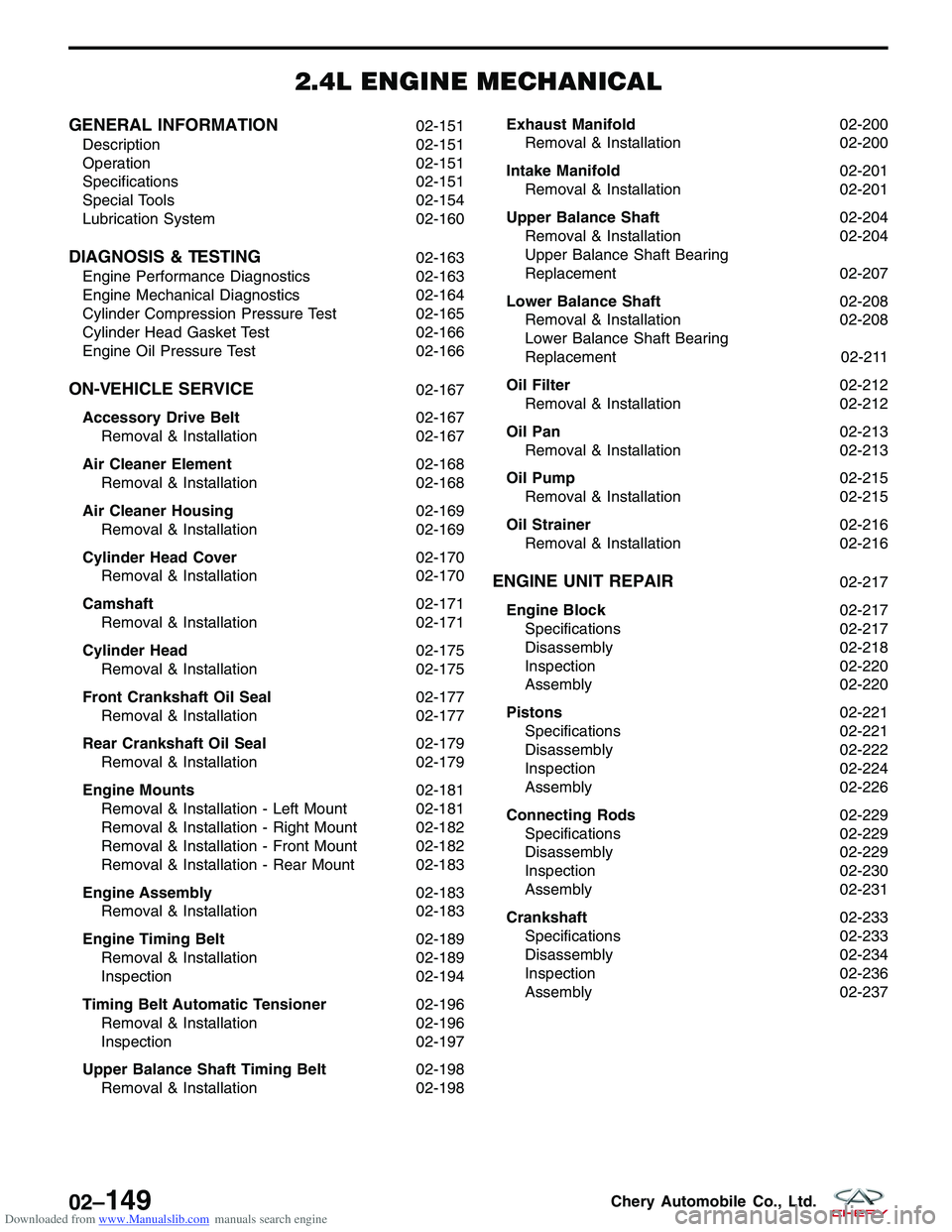

Downloaded from www.Manualslib.com manuals search engine 2.4L ENGINE MECHANICAL

GENERAL INFORMATION02-151

Description 02-151

Operation 02-151

Specifications 02-151

Special Tools 02-154

Lubrication System 02-160

DIAGNOSIS & TESTING02-163

Engine Performance Diagnostics 02-163

Engine Mechanical Diagnostics 02-164

Cylinder Compression Pressure Test 02-165

Cylinder Head Gasket Test 02-166

Engine Oil Pressure Test 02-166

ON-VEHICLE SERVICE02-167

Accessory Drive Belt 02-167

Removal & Installation 02-167

Air Cleaner Element 02-168

Removal & Installation 02-168

Air Cleaner Housing 02-169

Removal & Installation 02-169

Cylinder Head Cover 02-170

Removal & Installation 02-170

Camshaft 02-171

Removal & Installation 02-171

Cylinder Head 02-175

Removal & Installation 02-175

Front Crankshaft Oil Seal 02-177

Removal & Installation 02-177

Rear Crankshaft Oil Seal 02-179

Removal & Installation 02-179

Engine Mounts 02-181

Removal & Installation - Left Mount 02-181

Removal & Installation - Right Mount 02-182

Removal & Installation - Front Mount 02-182

Removal & Installation - Rear Mount 02-183

Engine Assembly 02-183

Removal & Installation 02-183

Engine Timing Belt 02-189

Removal & Installation 02-189

Inspection 02-194

Timing Belt Automatic Tensioner 02-196

Removal & Installation 02-196

Inspection 02-197

Upper Balance Shaft Timing Belt 02-198

Removal & Installation 02-198Exhaust Manifold

02-200

Removal & Installation 02-200

Intake Manifold 02-201

Removal & Installation 02-201

Upper Balance Shaft 02-204

Removal & Installation 02-204

Upper Balance Shaft Bearing

Replacement 02-207

Lower Balance Shaft 02-208

Removal & Installation 02-208

Lower Balance Shaft Bearing

Replacement 02-211

Oil Filter 02-212

Removal & Installation 02-212

Oil Pan 02-213

Removal & Installation 02-213

Oil Pump 02-215

Removal & Installation 02-215

Oil Strainer 02-216

Removal & Installation 02-216

ENGINE UNIT REPAIR02-217

Engine Block 02-217

Specifications 02-217

Disassembly 02-218

Inspection 02-220

Assembly 02-220

Pistons 02-221

Specifications 02-221

Disassembly 02-222

Inspection 02-224

Assembly 02-226

Connecting Rods 02-229

Specifications 02-229

Disassembly 02-229

Inspection 02-230

Assembly 02-231

Crankshaft 02-233

Specifications 02-233

Disassembly 02-234

Inspection 02-236

Assembly 02-237

02–149Chery Automobile Co., Ltd.

Page 180 of 1903

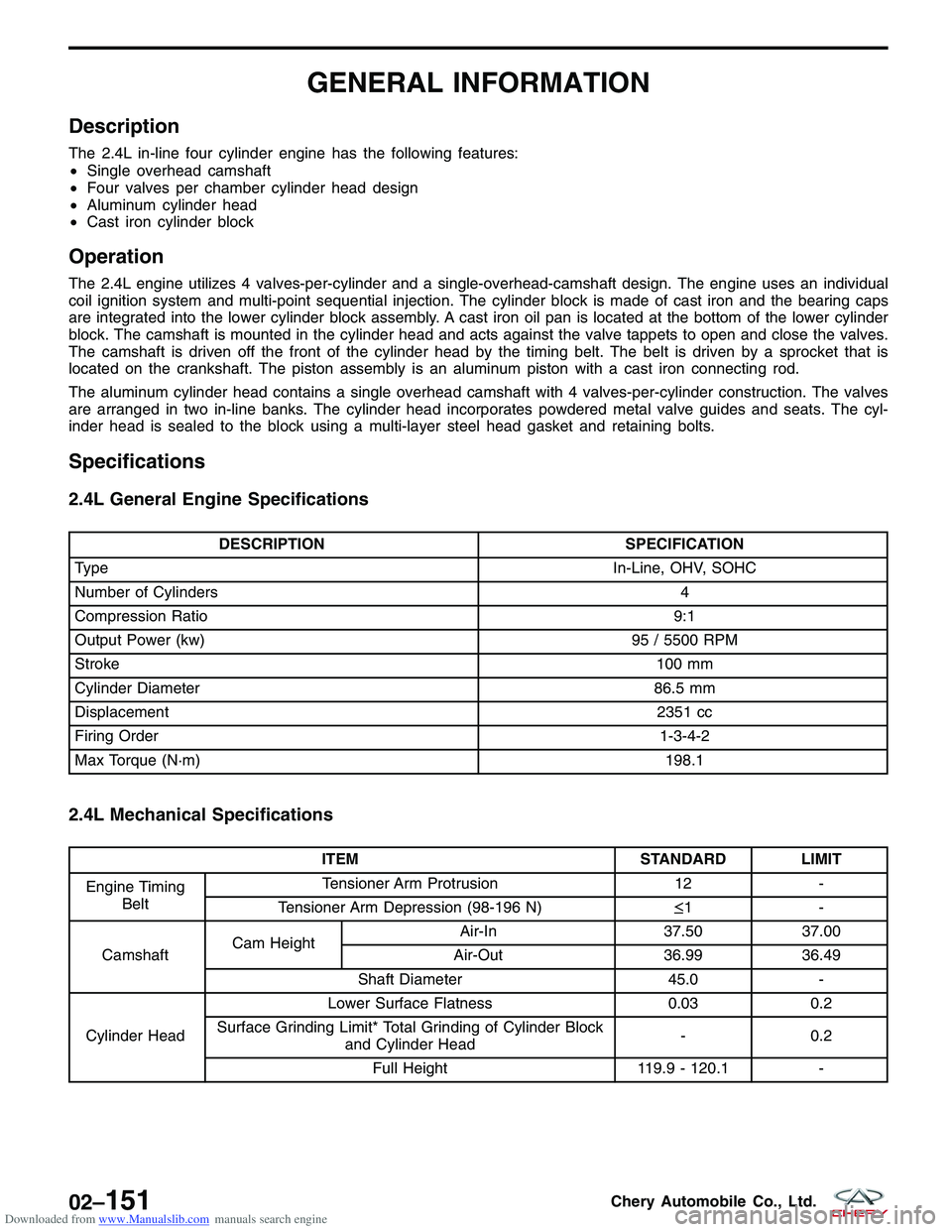

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The 2.4L in-line four cylinder engine has the following features:

•Single overhead camshaft

• Four valves per chamber cylinder head design

• Aluminum cylinder head

• Cast iron cylinder block

Operation

The 2.4L engine utilizes 4 valves-per-cylinder and a single-overhead-camshaft design. The engine uses an individual

coil ignition system and multi-point sequential injection. The cylinder block is made of cast iron and the bearing caps

are integrated into the lower cylinder block assembly. A cast iron oil pan is located at the bottom of the lower cylinder

block. The camshaft is mounted in the cylinder head and acts against the valve tappets to open and close the valves.

The camshaft is driven off the front of the cylinder head by the timing belt. The belt is driven by a sprocket that is

located on the crankshaft. The piston assembly is an aluminum piston with a cast iron connecting rod.

The aluminum cylinder head contains a single overhead camshaft with 4 valves-per-cylinder construction. The valves

are arranged in two in-line banks. The cylinder head incorporates powdered metal valve guides and seats. The cyl-

inder head is sealed to the block using a multi-layer steel head gasket and retaining bolts.

Specifications

2.4L General Engine Specifications

DESCRIPTION SPECIFICATION

Type In-Line, OHV, SOHC

Number of Cylinders 4

Compression Ratio 9:1

Output Power (kw) 95 / 5500 RPM

Stroke 100 mm

Cylinder Diameter 86.5 mm

Displacement 2351 cc

Firing Order 1-3-4-2

Max Torque (N·m) 198.1

2.4L Mechanical Specifications

ITEMSTANDARD LIMIT

Engine Timing Belt Tensioner Arm Protrusion

12-

Tensioner Arm Depression (98-196 N) ≤1-

Camshaft Cam Height Air-In

37.5037.00

Air-Out 36.9936.49

Shaft Diameter 45.0-

Cylinder Head Lower Surface Flatness

0.030.2

Surface Grinding Limit* Total Grinding of Cylinder Block and Cylinder Head -

0.2

Full Height 119.9 - 120.1-

02–151Chery Automobile Co., Ltd.

Page 828 of 1903

Downloaded from www.Manualslib.com manuals search engine Symptom Diagnostic Tests

General Troubleshooting Checks

•Confirm the engine trouble light is working properly.

• Confirm that there are no DTCs recorded with the X-431 Scan Tool.

• Confirm that the customer’s complaint is current, and the conditions that are causing the failure are present.

Visual Inspection

•Check the fuel system for any fuel leakage.

• Check the vacuum system for any broken, kinked or incorrectly linked vacuum pipes or hoses.

• Check the intake air pipe for being jammed, leaking, or damaged.

• Check the ignition system for any broken or aging spark plug wires and verify the engine firing order is correct.

• Check the engine ground cable and verify a clean and tight connection.

• Check the sensors and actuators electrical connectors and verify good contact and tight connection.

NOTE :

Repair any of the above conditions first before continuing with symptom diagnostics.

Diagnostic Help

• Confirm there are no current engine DTCs.

• Confirm that the failure exists and the customer complaint can be verified.

• Inspect the engine following the above steps and verify all engine features are operating properly.

• While servicing the vehicle, verify the service record, vehicle maintenance, engine compression pressures,

mechanical ignition timing and fuel conditions.

• If replacing the Engine Control Module (ECM), carry out the validation test. If the failure no longer exists, the

failure is in the ECM; if the failure still exists, reinstall the original ECM and repeat the diagnostic test.

Symptom Diagnostic Test List

SYMPTOM DEFINITION

Engine Cranks Normal But Will Not Start

Engine Will Not Crank

Hard Start / Long Crank Time

Fast Idle

Lack / Loss Of Power

Back Fires

Engine Poor Driveability

Low Idle / Stalls During Deceleration

Idle Speed Slow Return To Normal Idle

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03–544Chery Automobile Co., Ltd.

Page 838 of 1903

Downloaded from www.Manualslib.com manuals search engine 4.CHECK SECONDARY IGNITION SYSTEM

• Perform the following to test the secondary ignition system:

� Disconnect the injector fuse.

� Remove any of the 4 spark plugs.

� Connect the spark plug to spark plug wire.

� Ground the spark plug on the cylinder block.

� Crank the engine to test the secondary ignition system with the spark plugs removed.

Is a strong blue spark visible at each spark plug while cranking the engine?

Ye s>>Go to the next step.

No

>>Check Camshaft Position (CMP) sensor signal at ECM.

If CMP sensor is OK, check the following:

� Crankshaft Position (CKP) sensor malfunction

� Spark plug wires

� Spark plugs

5.CHECK INTAKE AIR SYSTEM

• Check for MAP/MAF sensor.

Is there any contamination?

Ye s>>Clean or replace the sensor.

No

>>Go to the next step.

6.CHECK EXHAUST SYSTEM

• Check the exhaust system for restrictions.

Is there a restriction in the exhaust system?

Ye s>>Repair as necessary.

No

>>Go to the next step.

7.CHECK BASE ENGINE CONCERNS

• Check for base engine concerns (such as improper compression, worn camshaft/valve train, gasket leaks).

Is a fault indicated?

Ye s>>Repair as necessary.

No

>>Go to the next step.

8.CHECK AUTOMATIC/MANUAL TRANSAXLE OPERATION

• Check the operation of the transaxle.

Is the transaxle operation normal?

Ye s>>Go to the next step.

No

>>Repair as necessary.

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03–554Chery Automobile Co., Ltd.

Page 847 of 1903

Downloaded from www.Manualslib.com manuals search engine 5.CHECK CLUTCH OPERATION CONDITION

• Check clutch operation condition.

Is the transaxle clutch operation normal?

Ye s>>Go to the next step.

No

>>Repair as necessary.

6.CHECK A/C SYSTEM OPERATION

• Start engine.

• Cycle A/C switch from on to off (verify A/C clutch engages condition).

• Check the A/C system operation.

Does the A/C system operate normally?

Ye s>>Go to the next step.

No

>>Repair as necessary.

7.CHECK FUEL SYSTEM PRESSURE

• Release the fuel system pressure (See Fuel Pressure Relief Procedure in Section 04 Fuel Delivery).

• Check fuel system pressure (See Fuel Pressure Test in Section 04 Fuel Delivery).

Is fuel pressure correct?

Ye s>>Go to the next step.

No

>>If the fuel pressure is greater than 400 kPa (4.0 bar):

� Replace the fuel pressure regulator.

If the fuel pressure is less than 400 kPa (4.0 bar):

� Check the fuel supply system for restrictions or leaks.

� If no problems, repair or replace fuel filter, pressure regulator or fuel pump assembly.

8.CHECK FOR BASE ENGINE CONCERNS

• Check for base engine concerns (such as improper compression, worn camshaft/valve train, gasket leaks).

Is a fault indicated?

Ye s>>Repair as necessary.

No

>>See Diagnostic Help for additional information.

ELECTRONIC ENGINE CONTROLS - 2.4L ENGINE SYMPTOM DIAGNOSIS

03

03–563Chery Automobile Co., Ltd.