differential CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 944 of 1903

Downloaded from www.Manualslib.com manuals search engine TRANSAXLE & TRANSFER CASE

08

CONTENTSpage

DP0 Automatic Transaxle .............................................................. 08-1

F4A4 Automatic Transaxle ........................................................... 08-143

5-Speed Manual Transaxle ........................................................... 08-246

Front Differential ................................................................... 08-307

Clutch System ..................................................................... 08-316

Transfer Case (4x4) ................................................................. 08-326

DP0 AUTOMATIC TRANSAXLE

GENERAL INFORMATION08-3

Description 08-3

Operation 08-6

Specifications 08-7

Special Tools 08-8

Electrical Schematics 08-10

DP0 Transaxle Control Module (TCM)

Connector Pin-Out Table 08-18

DIAGNOSIS & TESTING08-19

Diagnostic Help 08-19

Intermittent DTC Troubleshooting 08-19

Ground Inspection 08-19

Diagnostic Tools 08-19

Diagnostic Trouble Code (DTC) List 08-20

DP0 Automatic Transaxle DTC List 08-20

Diagnostic Trouble Code (DTC) Tests 08-22

P0641 - Sensor Feed 08-22

P0657 - Solenoid Power Supply Circuit

Shorted To Voltage 08-28

P0657 - Solenoid Power Supply Circuit

Open 08-32

P0705 - Multi-Function Switch:

Prohibited Position 08-37

P0710 - Fluid Temperature Sensor 08-42

P0715 - Turbine Speed Sensor Affected

By Interference 08-46

P0730 - Ratio Of Transaxle Error 08-50

P0753 - Shift Solenoid Valve 1 (SSV1)

Open Circuit Or Short To Power Supply

Or Short To Ground 08-56 P0758 - Shift Solenoid Valve 2 (SSV2)

Open Circuit Or Short To Power Supply

Or Short To Ground 08-62

P0763 - Shift Solenoid Valve 3 (SSV3)

Short To Power Supply, P0763 - Shift

Solenoid Valve 3 (SSV3) Open Or

Short To Ground Circuit 08-68

P0768 - Shift Solenoid Valve 4 (SSV4)

Short To Power Supply, P0768 - Shift

Solenoid Valve 4 (SSV4) Open Or

Short To Ground Circuit 08-74

P0773 - Shift Solenoid Valve 5 (SSV5)

Short To Power Supply, P0773 - Shift

Solenoid Valve 5 (SSV5) Open Or

Short To Ground Circuit 08-81

P0775 - EVM (Modulation Solenoid

Valve) Open Circuit Or Short To

Ground, P0775 - EVM (Modulation

Solenoid Valve) Shorted To Voltage 08-87

P0795 - Torque Converter Lock

Solenoid Valve (EVLU) Open Circuit Or

Short To Ground, P0795 - Torque

Converter Lock Solenoid Valve (EVLU)

Short To Voltage 08-93

P0840 - Pressure Sensor 08-99

P1928 - Shift Lock Solenoid Valve

Circuit Shorted To Voltage 08-104

P1928 - Shift Lock Solenoid Valve

Open Circuit Or Short To Ground 08-109

P2709 - Shift Solenoid Valve 6 (SSV6)

Short To Power Supply 08-114

P2709 - Shift Solenoid Valve 6 (SSV6)

Open Circuit Or Short To Ground 08-119

08

08–1Chery Automobile Co., Ltd.

Page 946 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

Description

The DP0 automatic transaxle is a four-speed transaxle that is a conventional hydraulic/mechanical transaxle assem-

bly with an integral differential, and is controlled with adaptive electronic controls and monitors. The hydraulic system

of the transaxle consists of the transaxle fluid, fluid passages, hydraulic valves, fluid pump, and various line pressure

control components.

The Transaxle Control Module (TCM) is the heart of the electronic control system and relies on information from

various direct and indirect inputs (sensors, switches, etc.) to determine driver demand and vehicle operating condi-

tions. With this information, the ECM/TCM can calculate and perform timely and quality shifts through various output

or control devices.

The TCM also performs certain self-diagnostic functions and provides comprehensive information (sensor data,

DTCs, etc.) which is helpful in proper diagnosis and repair. This information can be viewed with the X-431 scan tool.

08

08–3Chery Automobile Co., Ltd.

Page 948 of 1903

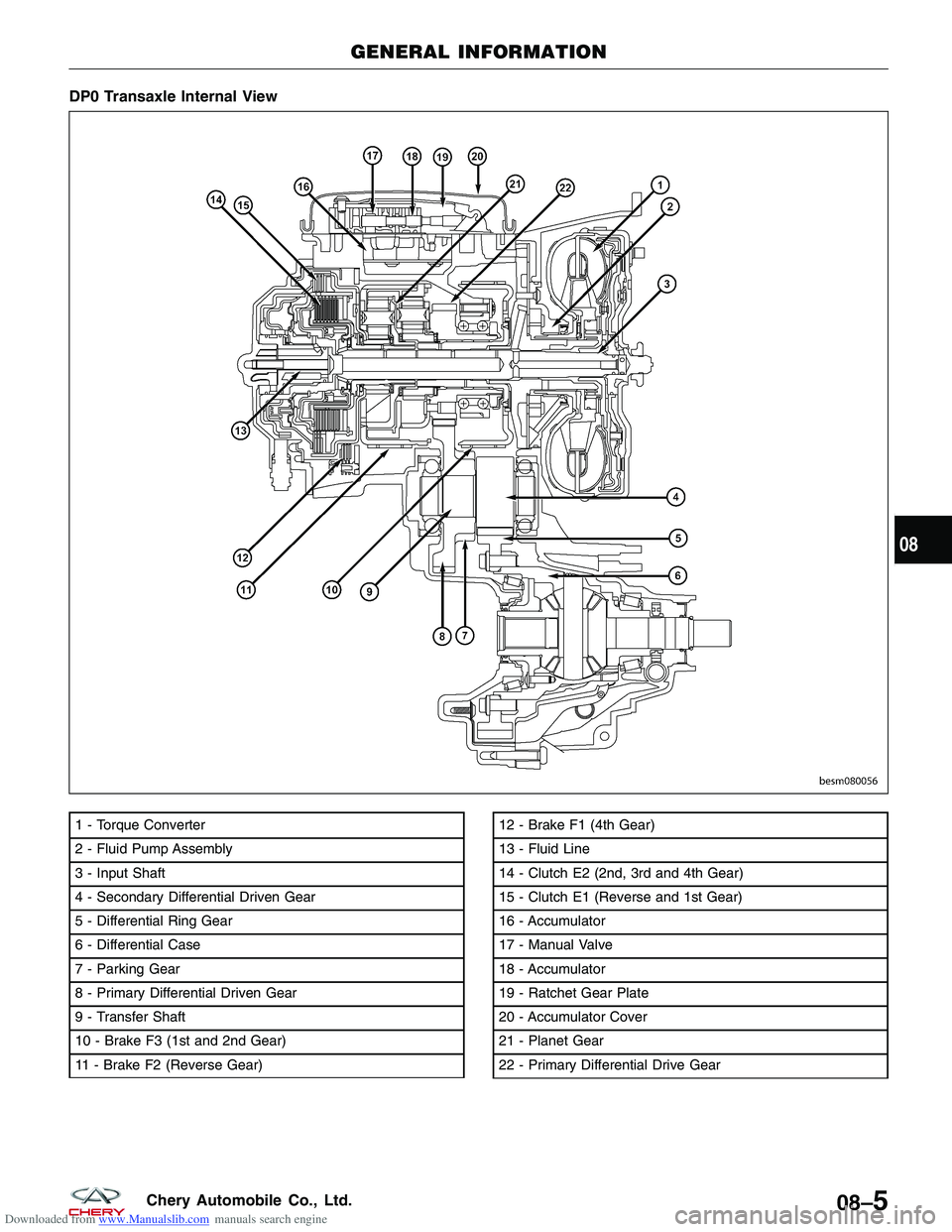

Downloaded from www.Manualslib.com manuals search engine DP0 Transaxle Internal View

1 - Torque Converter

2 - Fluid Pump Assembly

3 - Input Shaft

4 - Secondary Differential Driven Gear

5 - Differential Ring Gear

6 - Differential Case

7 - Parking Gear

8 - Primary Differential Driven Gear

9 - Transfer Shaft

10 - Brake F3 (1st and 2nd Gear)

11 - Brake F2 (Reverse Gear)12 - Brake F1 (4th Gear)

13 - Fluid Line

14 - Clutch E2 (2nd, 3rd and 4th Gear)

15 - Clutch E1 (Reverse and 1st Gear)

16 - Accumulator

17 - Manual Valve

18 - Accumulator

19 - Ratchet Gear Plate

20 - Accumulator Cover

21 - Planet Gear

22 - Primary Differential Drive Gear

GENERAL INFORMATION

BESM080056

08

08–5Chery Automobile Co., Ltd.

Page 951 of 1903

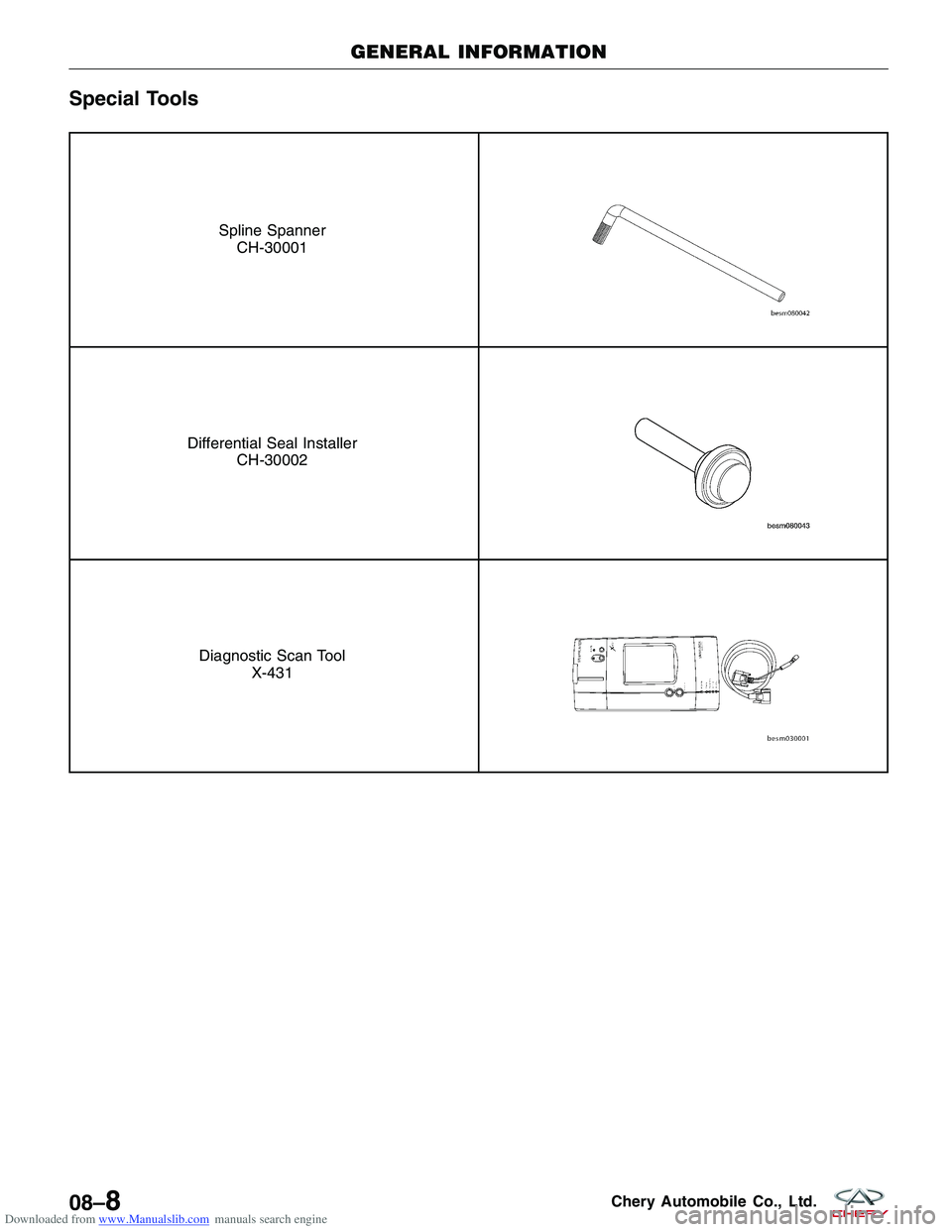

Downloaded from www.Manualslib.com manuals search engine Special Tools

Spline SpannerCH-30001

Differential Seal Installer CH-30002

Diagnostic Scan Tool X-431

GENERAL INFORMATION

08–8Chery Automobile Co., Ltd.

Page 1190 of 1903

Downloaded from www.Manualslib.com manuals search engine GENERAL INFORMATION

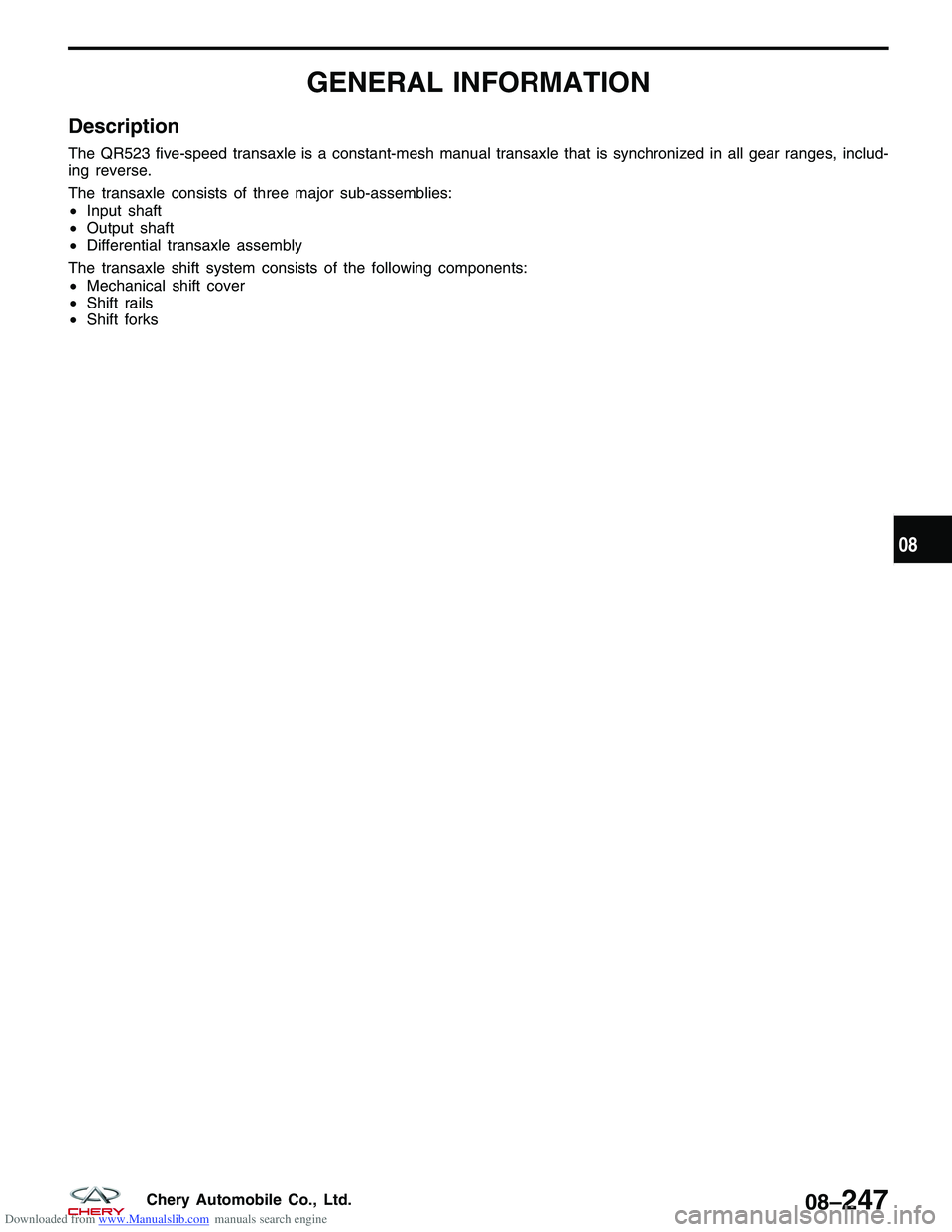

Description

The QR523 five-speed transaxle is a constant-mesh manual transaxle that is synchronized in all gear ranges, includ-

ing reverse.

The transaxle consists of three major sub-assemblies:

•Input shaft

• Output shaft

• Differential transaxle assembly

The transaxle shift system consists of the following components:

• Mechanical shift cover

• Shift rails

• Shift forks

08

08–247Chery Automobile Co., Ltd.

Page 1192 of 1903

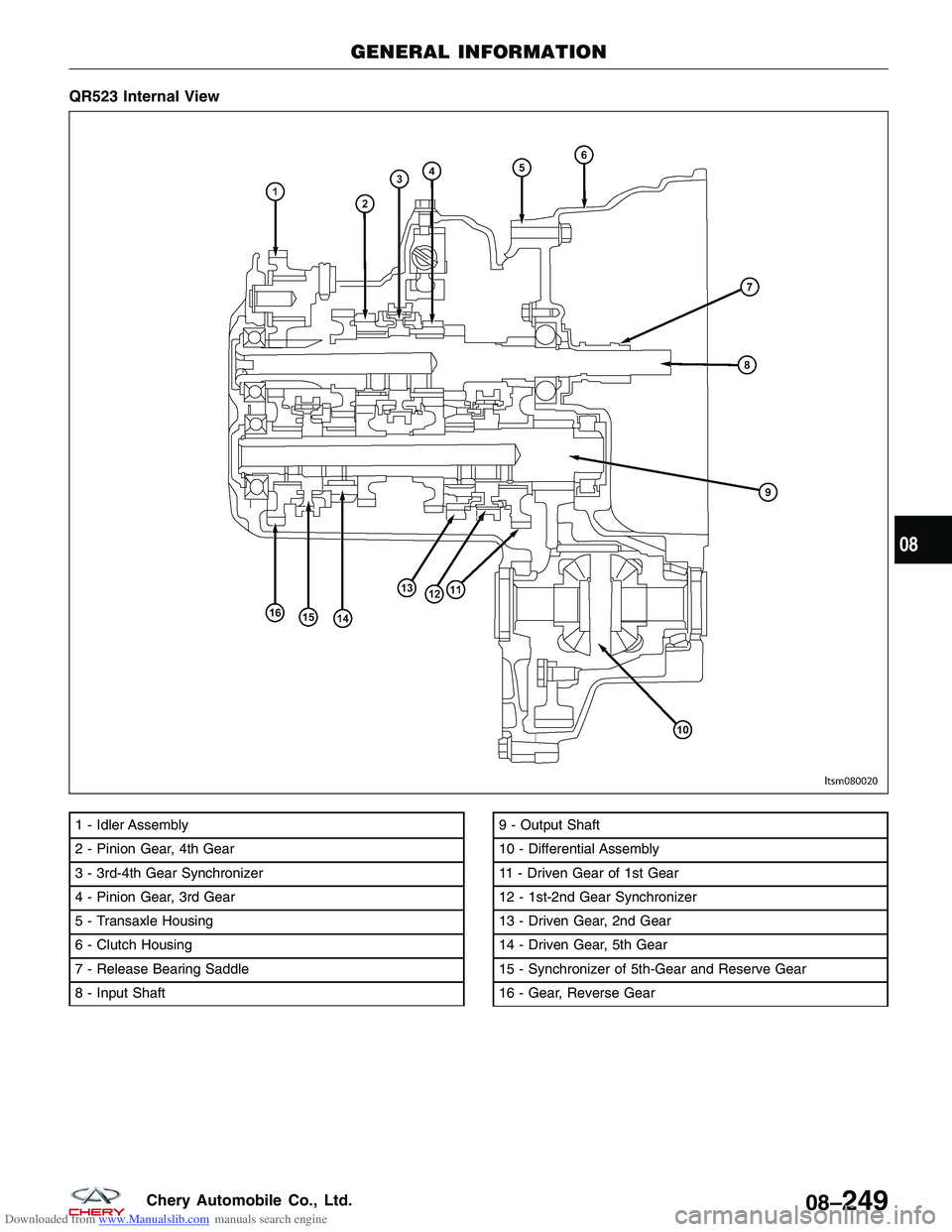

Downloaded from www.Manualslib.com manuals search engine QR523 Internal View

1 - Idler Assembly

2 - Pinion Gear, 4th Gear

3 - 3rd-4th Gear Synchronizer

4 - Pinion Gear, 3rd Gear

5 - Transaxle Housing

6 - Clutch Housing

7 - Release Bearing Saddle

8 - Input Shaft9 - Output Shaft

10 - Differential Assembly

11 - Driven Gear of 1st Gear

12 - 1st-2nd Gear Synchronizer

13 - Driven Gear, 2nd Gear

14 - Driven Gear, 5th Gear

15 - Synchronizer of 5th-Gear and Reserve Gear

16 - Gear, Reverse Gear

GENERAL INFORMATION

LTSM080020

08

08–249Chery Automobile Co., Ltd.

Page 1193 of 1903

Downloaded from www.Manualslib.com manuals search engine Operation

The following are the details of the manual transaxle:

Neutral

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. Since no synchro-

nizers are engaged on either the input or output shafts, power is not transmitted to the output shafts, power is not

transmitted to the output shaft and the differential does not turn.

1st Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft first

gear is integral to the input shaft, and is in constant mesh with the intermediate shaft first speed gear. Because of

this constant mesh, the output shaft first speed gear freewheels until first gear is selected. As the gearshift lever is

moved to the first gear position, the 1-2 fork moves the 1-2 synchronizer sleeve towards first gear on the output

shaft. The synchronizer sleeve engages the first gear clutch teeth, engaging the gear to the output shaft, and allow-

ing power to transmit through the output shaft to the differential.

2nd Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft

second gear is integral to the input shaft, and is in constant mesh with the output shaft second speed gear. Because

of this constant mesh, the output shaft second speed gear freewheels until second gear is selected. As the gearshift

lever is moved to the second gear position, the 1-2 fork moves the 1-2 synchronizer sleeve towards second gear on

the output shaft. The synchronizer sleeve engages the second gear clutch teeth, engaging the gear to the output

shaft, and allowing power to transmit through the output shaft to the differential.

3rd Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft third

speed gear is in constant mesh with the output shaft 3-4 cluster gear which is fixed to the output shaft. Because of

this constant mesh, the input shaft third speed gear freewheels until third gear is selected. As the gearshift lever is

moved to the third gear position, the 3-4 fork moves the 3-4 synchronizer sleeve towards third gear on the input

shaft. The synchronizer sleeve engages the third gear clutch teeth, engaging the gear to the input shaft, and allowing

power to transmit through the output shaft to the differential.

4th Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft fourth

speed gear is in constant mesh with the output shaft 3-4 cluster gear which is fixed to the output shaft. Because of

this constant mesh, the input shaft fourth speed gear freewheels until fourth gear is selected. As the gearshift lever

is moved to the fourth gear position, the 3-4 fork moves the 3-4 synchronizer sleeve towards fourth gear on the input

shaft. The synchronizer sleeve engages the fourth gear clutch teeth, engaging the gear to the input shaft, and allow-

ing power to transmit through the output shaft to the differential.

5th Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft fifth

speed gear is pressed on to the input shaft, and is in constant mesh with the output shaft fifth speed gear. Because

of this constant mesh, the output shaft fifth speed gear freewheels until fifth gear is selected. As the gearshift lever

is moved to the fifth gear position, the 5-R fork moves the 5-R synchronizer sleeve towards the output shaft fifth

speed gear. The synchronizer sleeve engages the fifth gear clutch teeth, engaging the gear to the input shaft, and

allowing power to transmit through the output shaft to the differential.

Reverse Gear

Engine power is transmitted to the input shaft via the clutch assembly and the input shaft turns. The input shaft

reverse gear is integral to the input shaft, and is in constant mesh with the reverse idler gear. The reverse idler gear,

which reverses the rotation of the output shaft, is in constant mesh with the output shaft reverse gear. Because of

this constant mesh, the output shaft reverse gear freewheels until reverse gear is selected. As the gearshift lever is

moved to the reverse gear position, the 5-R fork moves the 5-R synchronizer sleeve towards the output shaft reverse

gear. The synchronizer sleeve engages the reverse gear clutch teeth, engaging the gear to the output shaft, and

allowing power to transmit through the output shaft to the differential.

GENERAL INFORMATION

08–250Chery Automobile Co., Ltd.

Page 1194 of 1903

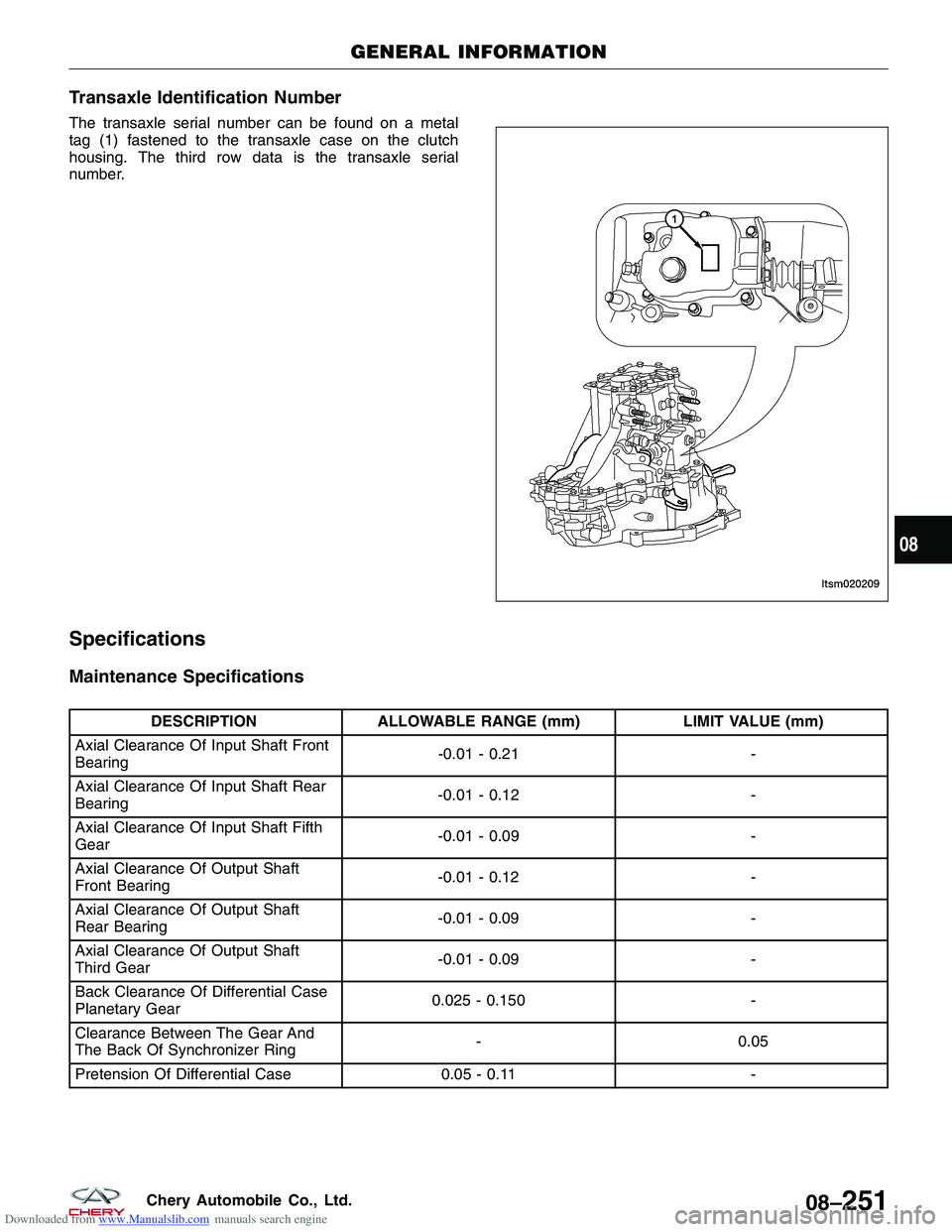

Downloaded from www.Manualslib.com manuals search engine Transaxle Identification Number

The transaxle serial number can be found on a metal

tag (1) fastened to the transaxle case on the clutch

housing. The third row data is the transaxle serial

number.

Specifications

Maintenance Specifications

DESCRIPTIONALLOWABLE RANGE (mm) LIMIT VALUE (mm)

Axial Clearance Of Input Shaft Front

Bearing -0.01 - 0.21

-

Axial Clearance Of Input Shaft Rear

Bearing -0.01 - 0.12

-

Axial Clearance Of Input Shaft Fifth

Gear -0.01 - 0.09

-

Axial Clearance Of Output Shaft

Front Bearing -0.01 - 0.12

-

Axial Clearance Of Output Shaft

Rear Bearing -0.01 - 0.09

-

Axial Clearance Of Output Shaft

Third Gear -0.01 - 0.09

-

Back Clearance Of Differential Case

Planetary Gear 0.025 - 0.150

-

Clearance Between The Gear And

The Back Of Synchronizer Ring -

0.05

Pretension Of Differential Case 0.05 - 0.11-

GENERAL INFORMATION

LTSM020209

08

08–251Chery Automobile Co., Ltd.

Page 1196 of 1903

Downloaded from www.Manualslib.com manuals search engine Special Tools

Installer ConnectorMB-990926

Installer ConnectorMB-990934

Installer ConnectorMB-990935

Fluid Seal/Differential Installer MB-998325

GENERAL INFORMATION

08

08–253Chery Automobile Co., Ltd.

Page 1216 of 1903

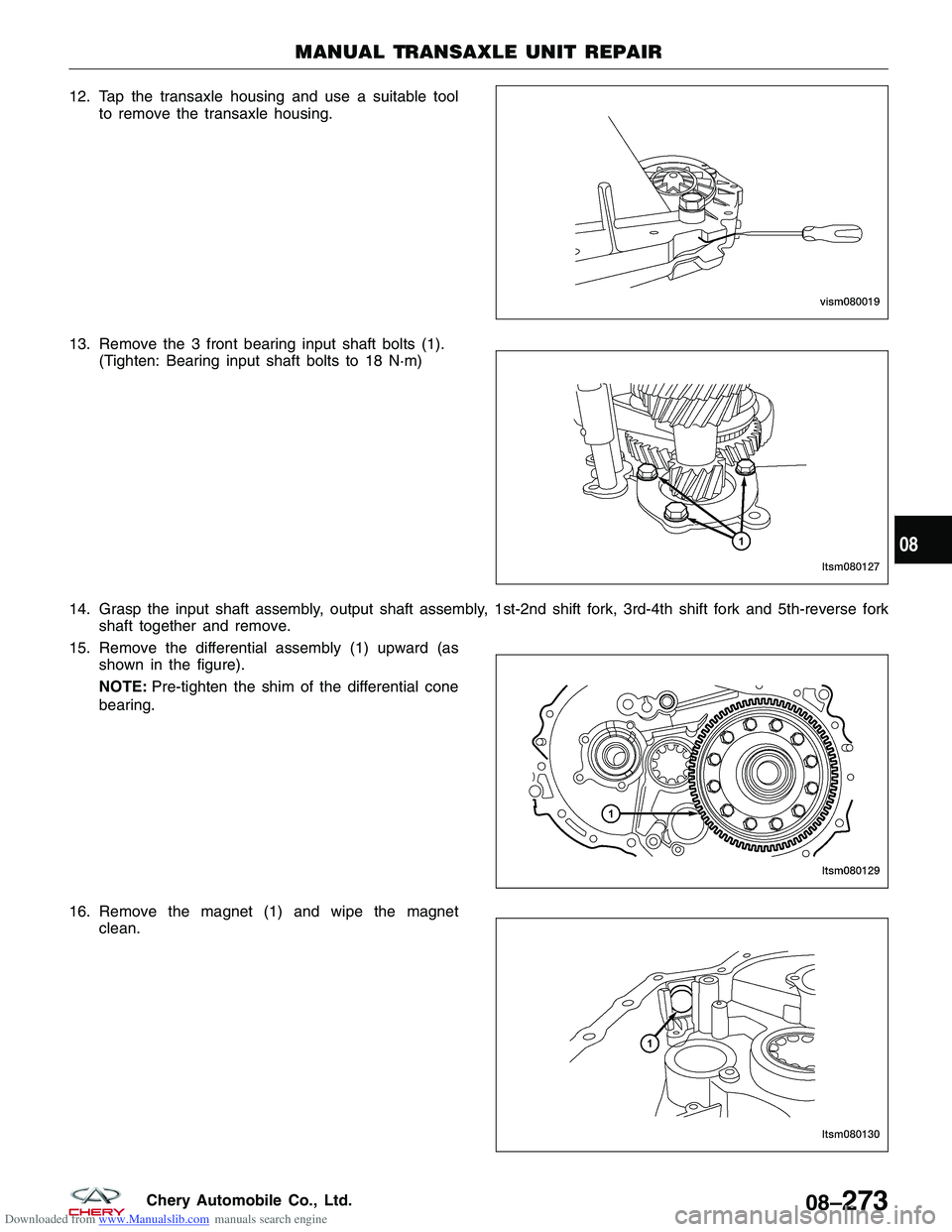

Downloaded from www.Manualslib.com manuals search engine 12. Tap the transaxle housing and use a suitable toolto remove the transaxle housing.

13. Remove the 3 front bearing input shaft bolts (1). (Tighten: Bearing input shaft bolts to 18 N·m)

14. Grasp the input shaft assembly, output shaft assembly, 1st-2nd shift fork, 3rd-4th shift fork and 5th-reverse fork shaft together and remove.

15. Remove the differential assembly (1) upward (as shown in the figure).

NOTE: Pre-tighten the shim of the differential cone

bearing.

16. Remove the magnet (1) and wipe the magnet clean.

MANUAL TRANSAXLE UNIT REPAIR

VISM080019

LTSM080127

LTSM080129

LTSM080130

08

08–273Chery Automobile Co., Ltd.