power steering CHERY TIGGO 2009 Service Repair Manual

[x] Cancel search | Manufacturer: CHERY, Model Year: 2009, Model line: TIGGO, Model: CHERY TIGGO 2009Pages: 1903, PDF Size: 33.38 MB

Page 26 of 1903

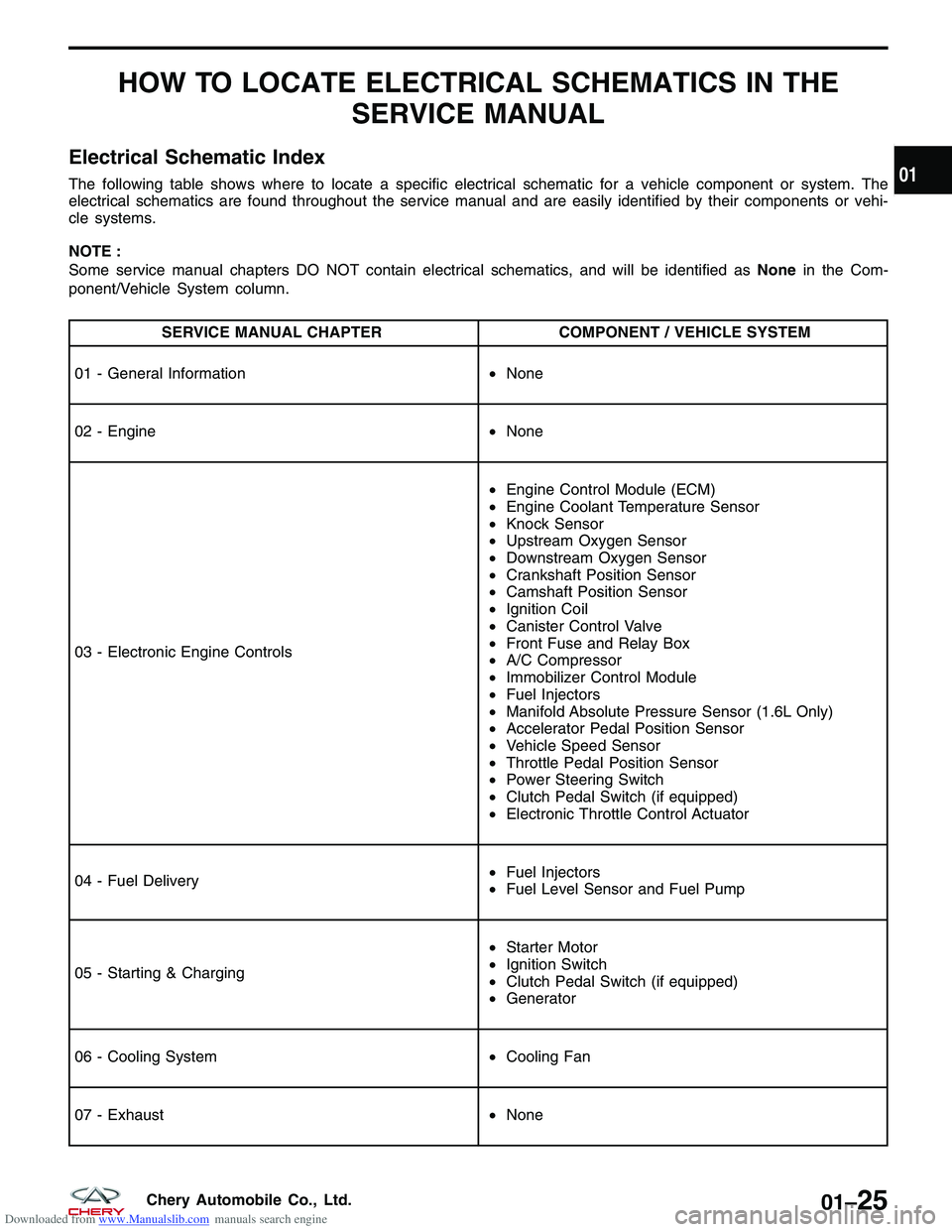

Downloaded from www.Manualslib.com manuals search engine HOW TO LOCATE ELECTRICAL SCHEMATICS IN THESERVICE MANUAL

Electrical Schematic Index

The following table shows where to locate a specific electrical schematic for a vehicle component or system. The

electrical schematics are found throughout the service manual and are easily identified by their components or vehi-

cle systems.

NOTE :

Some service manual chapters DO NOT contain electrical schematics, and will be identified as Nonein the Com-

ponent/Vehicle System column.

SERVICE MANUAL CHAPTER COMPONENT / VEHICLE SYSTEM

01 - General Information •None

02 - Engine •None

03 - Electronic Engine Controls •

Engine Control Module (ECM)

• Engine Coolant Temperature Sensor

• Knock Sensor

• Upstream Oxygen Sensor

• Downstream Oxygen Sensor

• Crankshaft Position Sensor

• Camshaft Position Sensor

• Ignition Coil

• Canister Control Valve

• Front Fuse and Relay Box

• A/C Compressor

• Immobilizer Control Module

• Fuel Injectors

• Manifold Absolute Pressure Sensor (1.6L Only)

• Accelerator Pedal Position Sensor

• Vehicle Speed Sensor

• Throttle Pedal Position Sensor

• Power Steering Switch

• Clutch Pedal Switch (if equipped)

• Electronic Throttle Control Actuator

04 - Fuel Delivery •

Fuel Injectors

• Fuel Level Sensor and Fuel Pump

05 - Starting & Charging •

Starter Motor

• Ignition Switch

• Clutch Pedal Switch (if equipped)

• Generator

06 - Cooling System •Cooling Fan

07 - Exhaust •None

01

01–25Chery Automobile Co., Ltd.

Page 27 of 1903

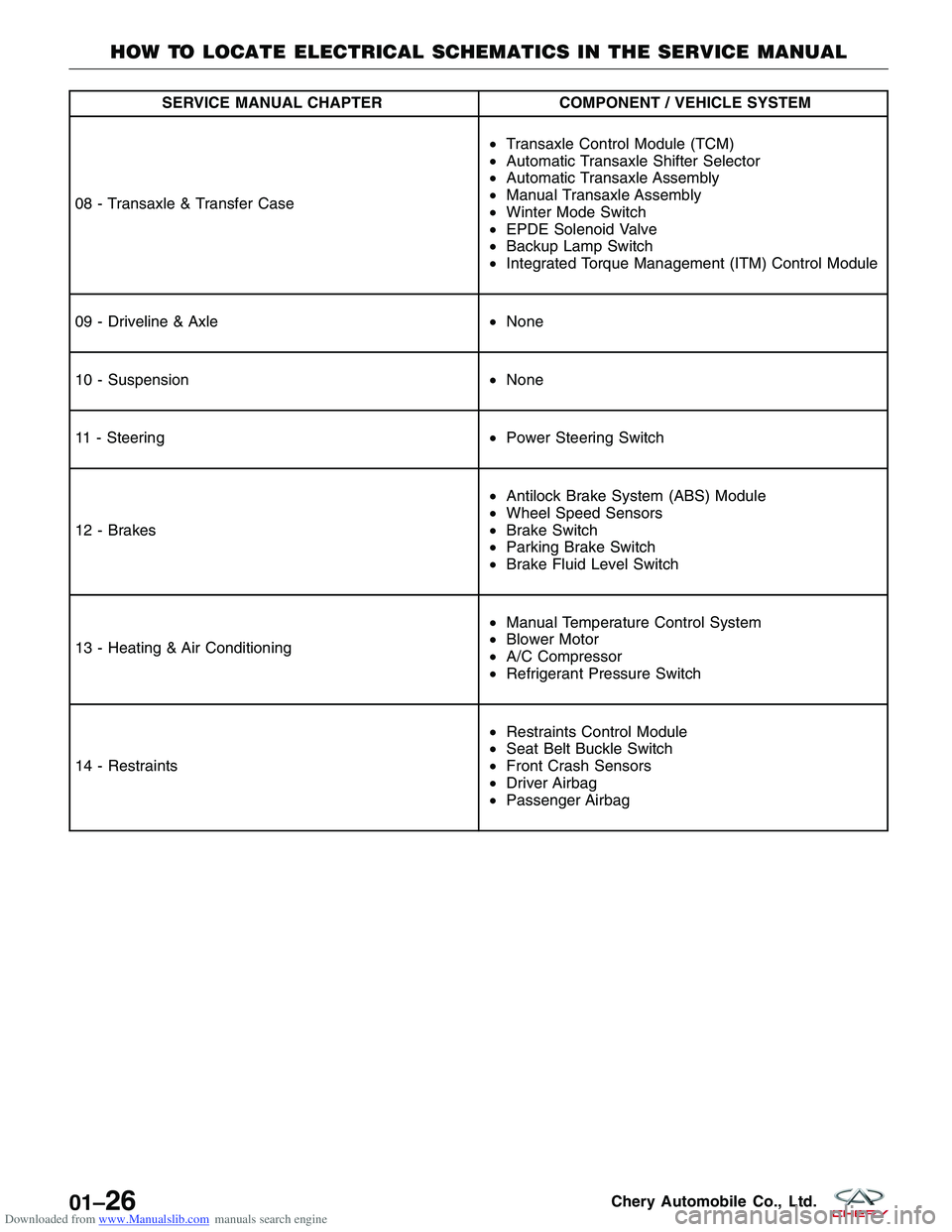

Downloaded from www.Manualslib.com manuals search engine SERVICE MANUAL CHAPTERCOMPONENT / VEHICLE SYSTEM

08 - Transaxle & Transfer Case •

Transaxle Control Module (TCM)

• Automatic Transaxle Shifter Selector

• Automatic Transaxle Assembly

• Manual Transaxle Assembly

• Winter Mode Switch

• EPDE Solenoid Valve

• Backup Lamp Switch

• Integrated Torque Management (ITM) Control Module

09 - Driveline & Axle •None

10 - Suspension •None

11 - Steering •Power Steering Switch

12 - Brakes •

Antilock Brake System (ABS) Module

• Wheel Speed Sensors

• Brake Switch

• Parking Brake Switch

• Brake Fluid Level Switch

13 - Heating & Air Conditioning •

Manual Temperature Control System

• Blower Motor

• A/C Compressor

• Refrigerant Pressure Switch

14 - Restraints •

Restraints Control Module

• Seat Belt Buckle Switch

• Front Crash Sensors

• Driver Airbag

• Passenger Airbag

HOW TO LOCATE ELECTRICAL SCHEMATICS IN THE SERVICE MANUAL

01–26Chery Automobile Co., Ltd.

Page 46 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

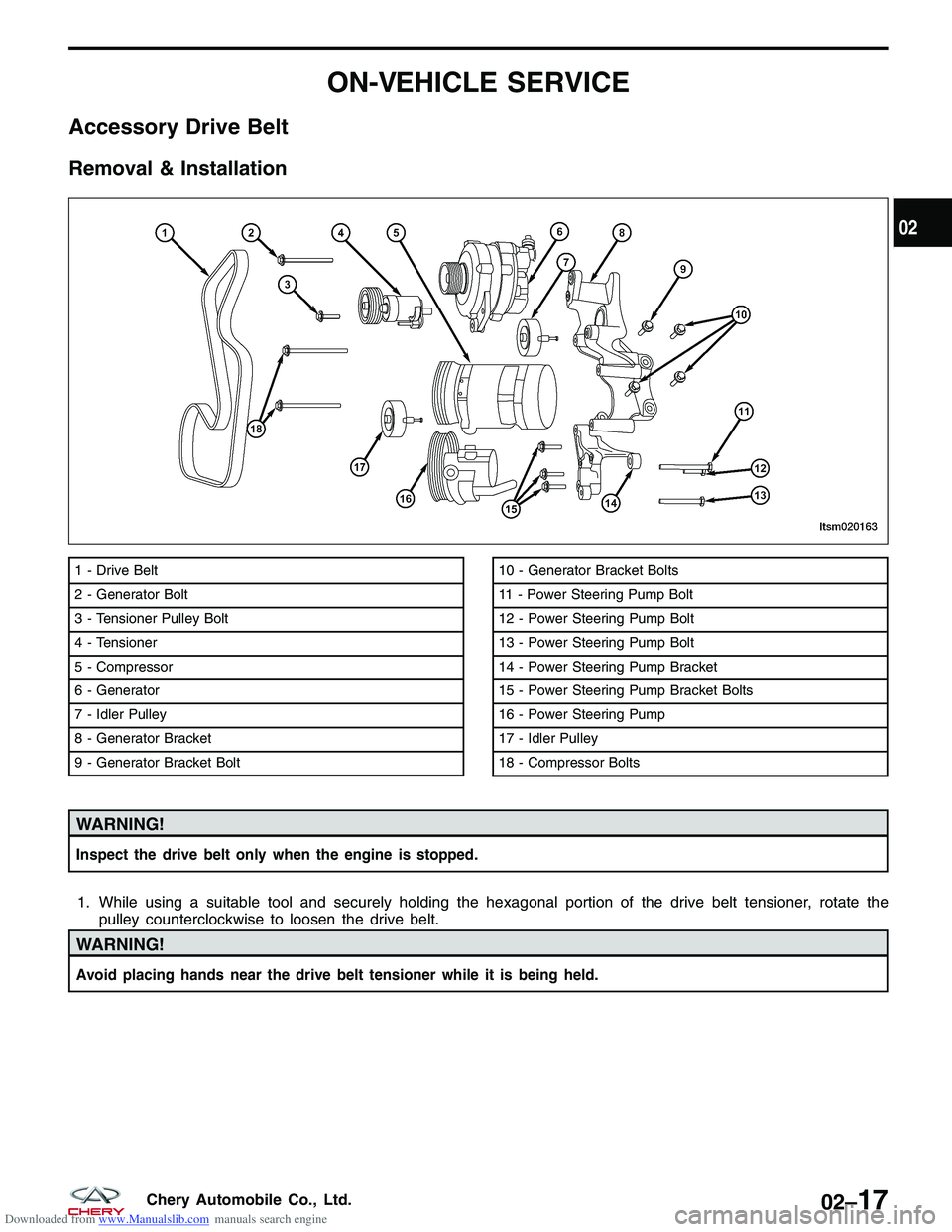

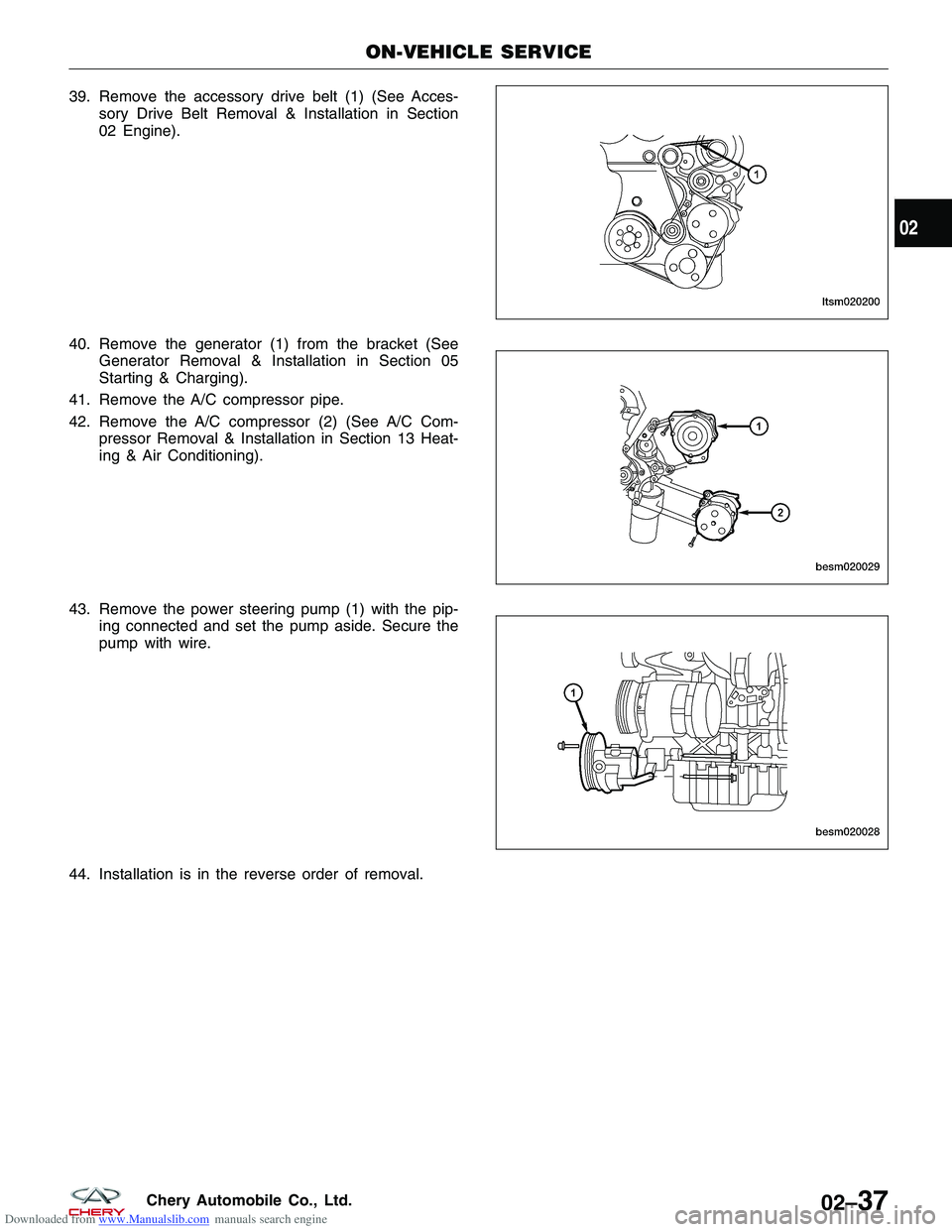

Accessory Drive Belt

Removal & Installation

WARNING!

Inspect the drive belt only when the engine is stopped.

1. While using a suitable tool and securely holding the hexagonal portion of the drive belt tensioner, rotate thepulley counterclockwise to loosen the drive belt.

WARNING!

Avoid placing hands near the drive belt tensioner while it is being held.

1 - Drive Belt

2 - Generator Bolt

3 - Tensioner Pulley Bolt

4 - Tensioner

5 - Compressor

6 - Generator

7 - Idler Pulley

8 - Generator Bracket

9 - Generator Bracket Bolt10 - Generator Bracket Bolts

11 - Power Steering Pump Bolt

12 - Power Steering Pump Bolt

13 - Power Steering Pump Bolt

14 - Power Steering Pump Bracket

15 - Power Steering Pump Bracket Bolts

16 - Power Steering Pump

17 - Idler Pulley

18 - Compressor Bolts

LTSM020163

02

02–17Chery Automobile Co., Ltd.

Page 62 of 1903

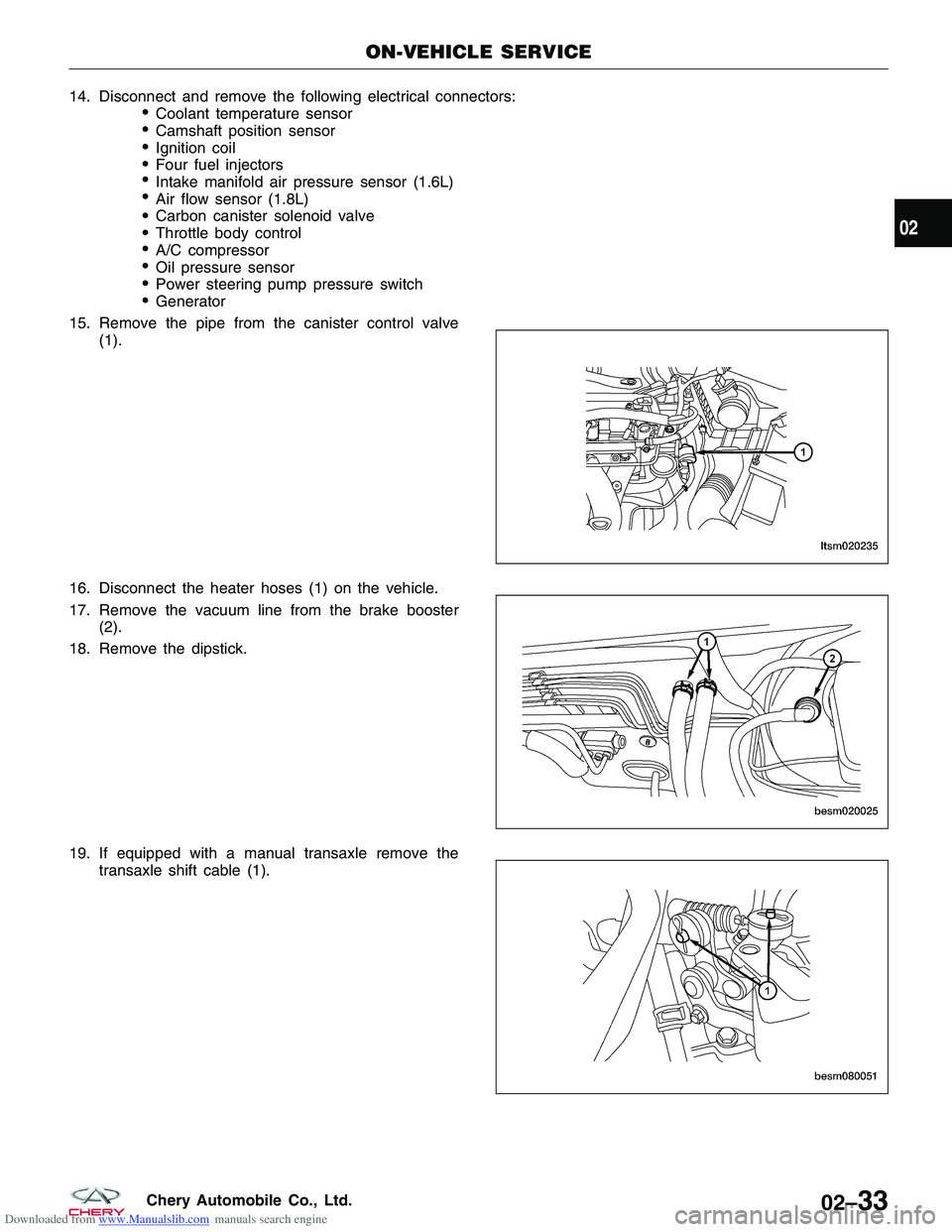

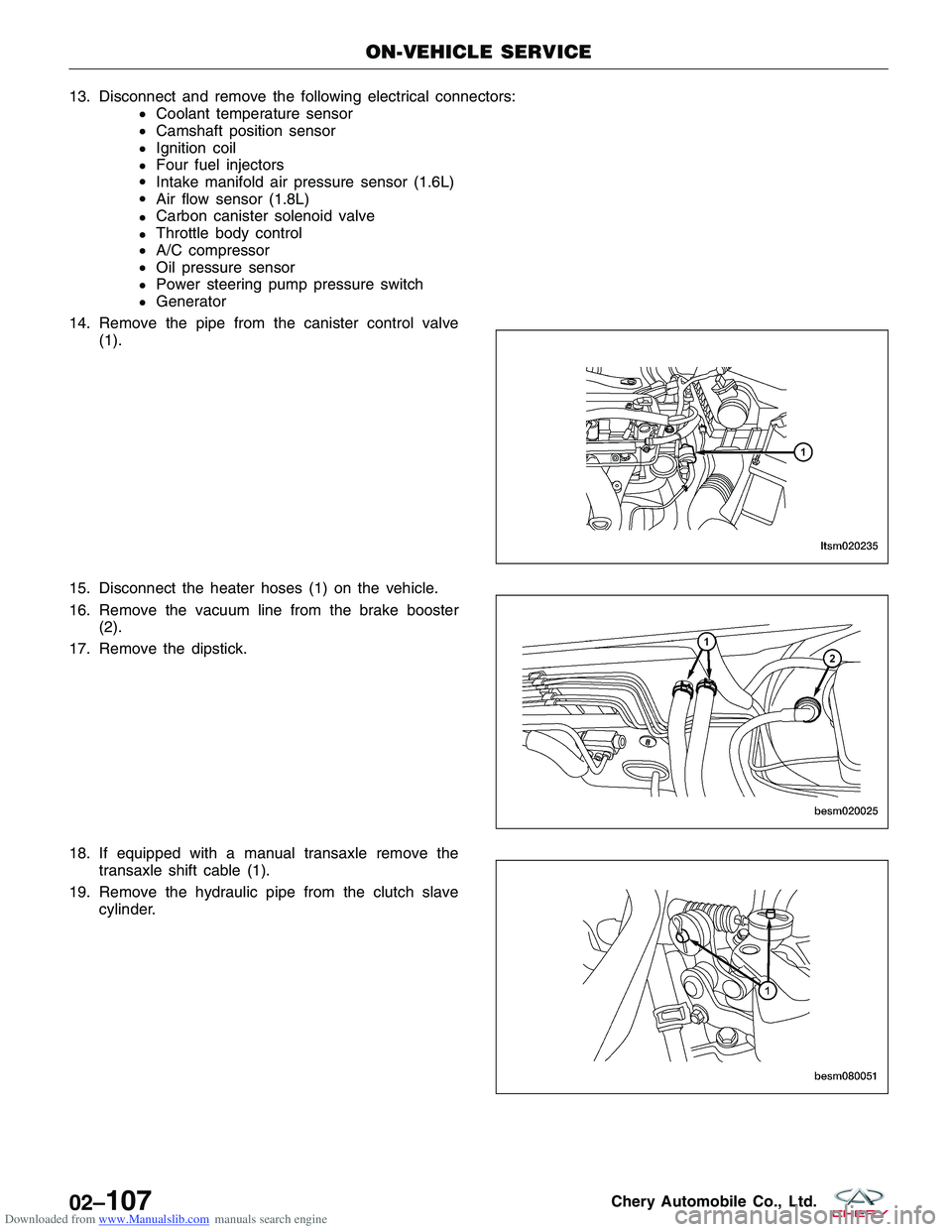

Downloaded from www.Manualslib.com manuals search engine 14.Disconnectandremovethefollowingelectricalconnectors:

€Coolanttemperaturesensor

€Camshaftpositionsensor

€Ignitioncoil

€Fourfuelinjectors

€Intakemanifoldairpressuresensor(1.6L)

€Airflowsensor(1.8L)

€Carboncanistersolenoidvalve

€Throttlebodycontrol

€A/Ccompressor

€Oilpressuresensor

€Powersteeringpumppressureswitch

€Generator

15.Removethepipefromthecanistercontrolvalve

(1).

16.Disconnecttheheaterhoses(1)onthevehicle.

17.Removethevacuumlinefromthebrakebooster

(2).

18.Removethedipstick.

19.Ifequippedwithamanualtransaxleremovethe

transaxleshiftcable(1).

ON-VEHICLESERVICE

LTSM020235

BESM020025

BESM080051

02

02–33CheryAutomobileCo.,Ltd.

Page 63 of 1903

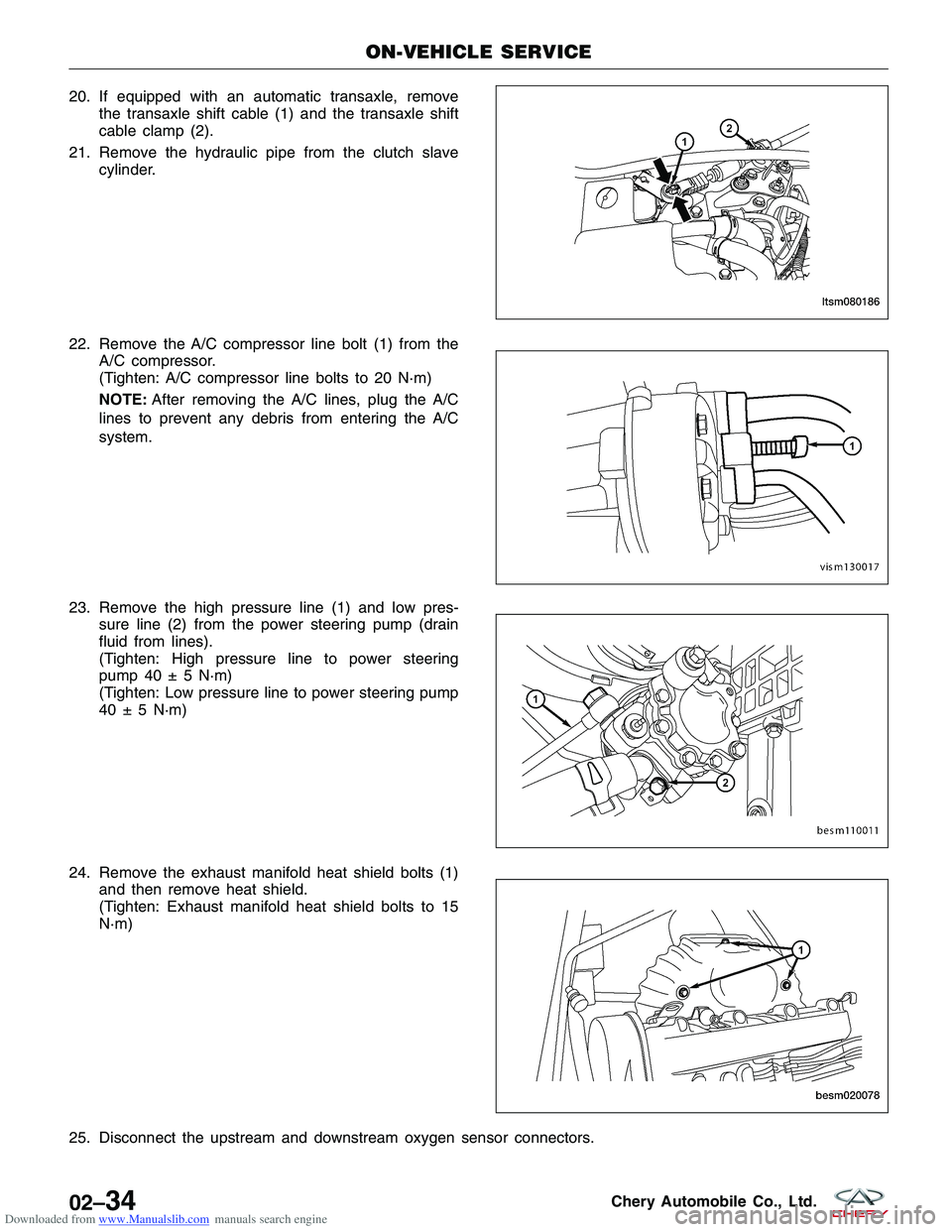

Downloaded from www.Manualslib.com manuals search engine 20. If equipped with an automatic transaxle, removethe transaxle shift cable (1) and the transaxle shift

cable clamp (2).

21. Remove the hydraulic pipe from the clutch slave cylinder.

22. Remove the A/C compressor line bolt (1) from the A/C compressor.

(Tighten: A/C compressor line bolts to 20 N·m)

NOTE: After removing the A/C lines, plug the A/C

lines to prevent any debris from entering the A/C

system.

23. Remove the high pressure line (1) and low pres- sure line (2) from the power steering pump (drain

fluid from lines).

(Tighten: High pressure line to power steering

pump 40 ± 5 N·m)

(Tighten: Low pressure line to power steering pump

40 ± 5 N·m)

24. Remove the exhaust manifold heat shield bolts (1) and then remove heat shield.

(Tighten: Exhaust manifold heat shield bolts to 15

N·m)

25. Disconnect the upstream and downstream oxygen sensor connectors.

ON-VEHICLE SERVICE

LTSM080186

VISM130017

BESM110011

BESM020078

02–34Chery Automobile Co., Ltd.

Page 66 of 1903

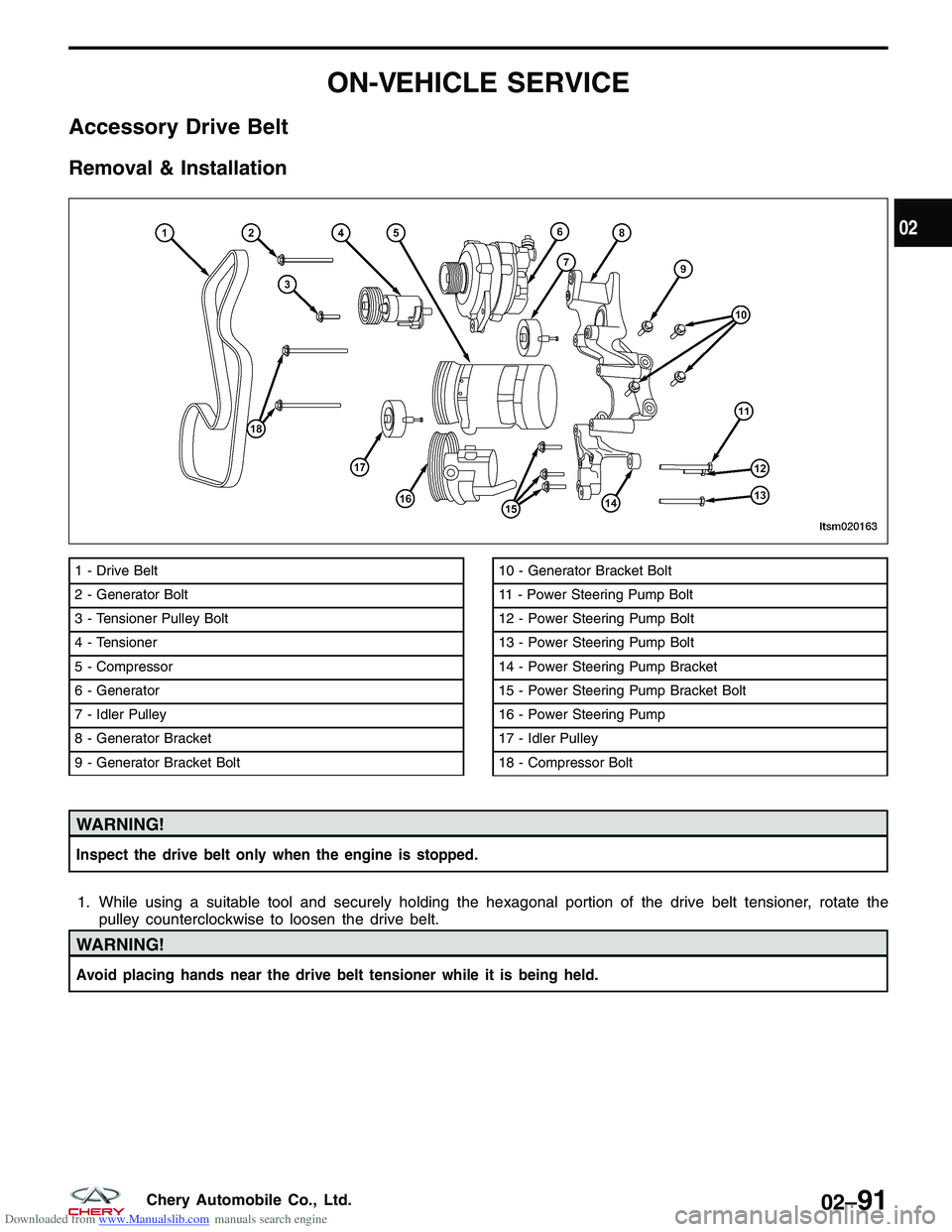

Downloaded from www.Manualslib.com manuals search engine 39. Remove the accessory drive belt (1) (See Acces-sory Drive Belt Removal & Installation in Section

02 Engine).

40. Remove the generator (1) from the bracket (See Generator Removal & Installation in Section 05

Starting & Charging).

41. Remove the A/C compressor pipe.

42. Remove the A/C compressor (2) (See A/C Com- pressor Removal & Installation in Section 13 Heat-

ing & Air Conditioning).

43. Remove the power steering pump (1) with the pip- ing connected and set the pump aside. Secure the

pump with wire.

44. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020200

BESM020029

BESM020028

02

02–37Chery Automobile Co., Ltd.

Page 120 of 1903

Downloaded from www.Manualslib.com manuals search engine ON-VEHICLE SERVICE

Accessory Drive Belt

Removal & Installation

WARNING!

Inspect the drive belt only when the engine is stopped.

1. While using a suitable tool and securely holding the hexagonal portion of the drive belt tensioner, rotate thepulley counterclockwise to loosen the drive belt.

WARNING!

Avoid placing hands near the drive belt tensioner while it is being held.

1 - Drive Belt

2 - Generator Bolt

3 - Tensioner Pulley Bolt

4 - Tensioner

5 - Compressor

6 - Generator

7 - Idler Pulley

8 - Generator Bracket

9 - Generator Bracket Bolt10 - Generator Bracket Bolt

11 - Power Steering Pump Bolt

12 - Power Steering Pump Bolt

13 - Power Steering Pump Bolt

14 - Power Steering Pump Bracket

15 - Power Steering Pump Bracket Bolt

16 - Power Steering Pump

17 - Idler Pulley

18 - Compressor Bolt

LTSM020163

02

02–91Chery Automobile Co., Ltd.

Page 136 of 1903

Downloaded from www.Manualslib.com manuals search engine 13.Disconnectandremovethefollowingelectricalconnectors:

€Coolanttemperaturesensor

€Camshaftpositionsensor

€Ignitioncoil

€Fourfuelinjectors

€Intakemanifoldairpressuresensor(1.6L)

€Airflowsensor(1.8L)

€Carboncanistersolenoidvalve

€Throttlebodycontrol

€A/Ccompressor

€Oilpressuresensor

€Powersteeringpumppressureswitch

€Generator

14.Removethepipefromthecanistercontrolvalve

(1).

15.Disconnecttheheaterhoses(1)onthevehicle.

16.Removethevacuumlinefromthebrakebooster

(2).

17.Removethedipstick.

18.Ifequippedwithamanualtransaxleremovethe

transaxleshiftcable(1).

19.Removethehydraulicpipefromtheclutchslave

cylinder.

ON-VEHICLESERVICE

LTSM020235

BESM020025

BESM080051

02–107CheryAutomobileCo.,Ltd.

Page 137 of 1903

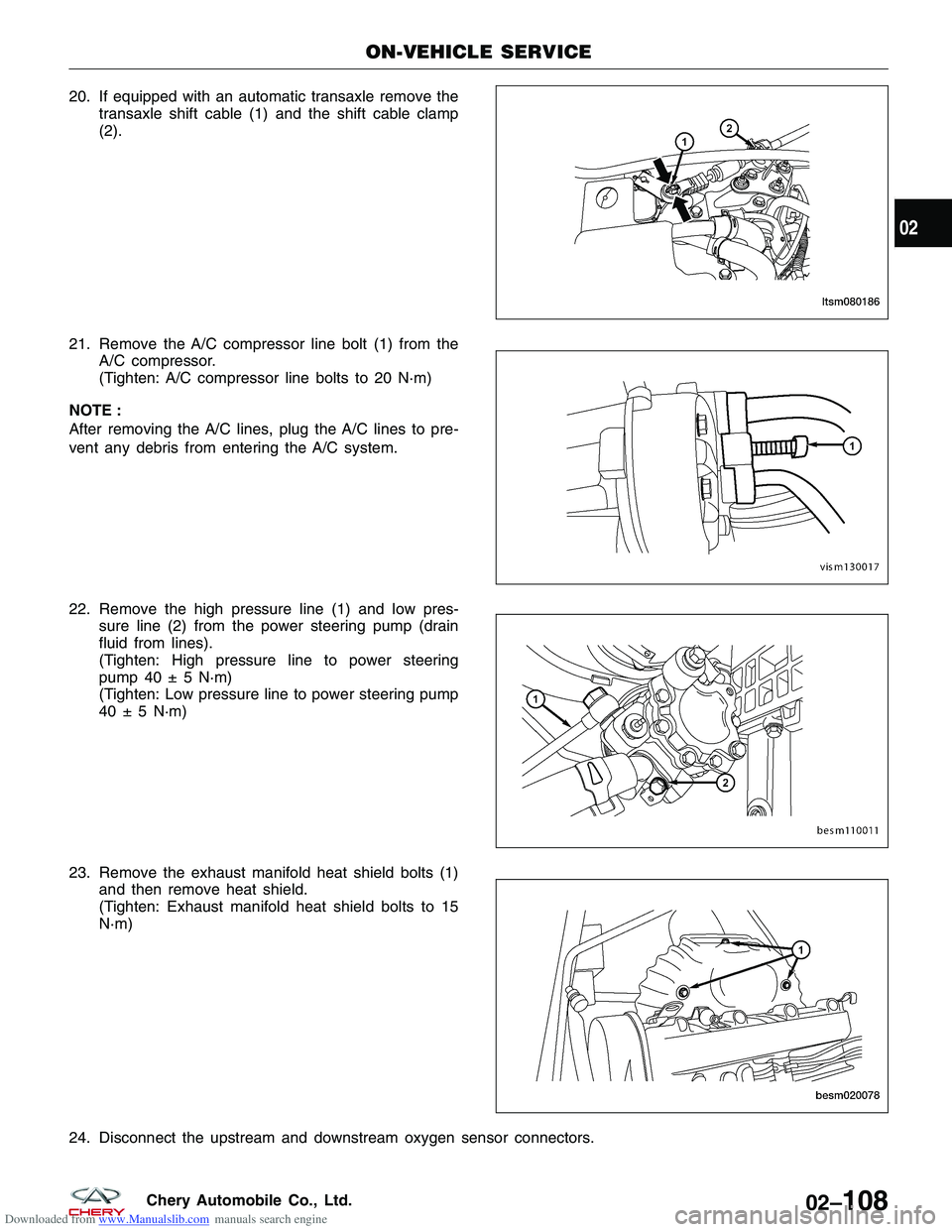

Downloaded from www.Manualslib.com manuals search engine 20. If equipped with an automatic transaxle remove thetransaxle shift cable (1) and the shift cable clamp

(2).

21. Remove the A/C compressor line bolt (1) from the A/C compressor.

(Tighten: A/C compressor line bolts to 20 N·m)

NOTE :

After removing the A/C lines, plug the A/C lines to pre-

vent any debris from entering the A/C system.

22. Remove the high pressure line (1) and low pres- sure line (2) from the power steering pump (drain

fluid from lines).

(Tighten: High pressure line to power steering

pump 40 ± 5 N·m)

(Tighten: Low pressure line to power steering pump

40 ± 5 N·m)

23. Remove the exhaust manifold heat shield bolts (1) and then remove heat shield.

(Tighten: Exhaust manifold heat shield bolts to 15

N·m)

24. Disconnect the upstream and downstream oxygen sensor connectors.

ON-VEHICLE SERVICE

LTSM080186

VISM130017

BESM110011

BESM020078

02

02–108Chery Automobile Co., Ltd.

Page 140 of 1903

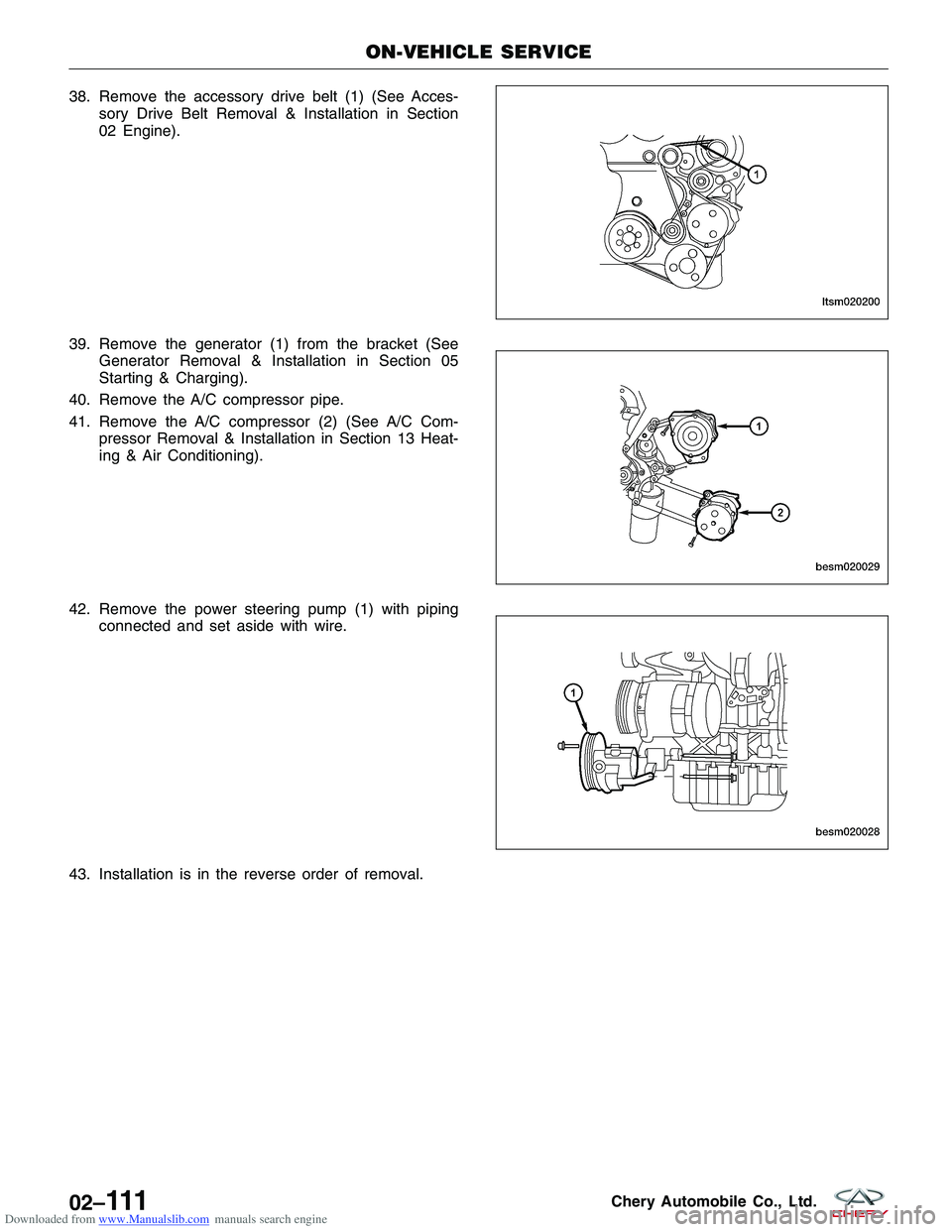

Downloaded from www.Manualslib.com manuals search engine 38. Remove the accessory drive belt (1) (See Acces-sory Drive Belt Removal & Installation in Section

02 Engine).

39. Remove the generator (1) from the bracket (See Generator Removal & Installation in Section 05

Starting & Charging).

40. Remove the A/C compressor pipe.

41. Remove the A/C compressor (2) (See A/C Com- pressor Removal & Installation in Section 13 Heat-

ing & Air Conditioning).

42. Remove the power steering pump (1) with piping connected and set aside with wire.

43. Installation is in the reverse order of removal.

ON-VEHICLE SERVICE

LTSM020200

BESM020029

BESM020028

02–111Chery Automobile Co., Ltd.