dimensions CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 3 of 659

SECTION O

INFORMATION AND LUBRICATION

CONTENTS OF THIS SECTION

Page

General Information o-l

Lubrication 0-13

GENERAL INFORMATION

Model Identification and Vehicle Dimensions

Chevrolet

Chevelle

Chevy n

Corvette

Camaro

Page

0-1

0-1

0-2

0-2

0-3

0-3

Page

Unit and Serial Numbers o-3

Engine Number o-3

Vehicle Serial Number 0r3

Keys and Locks 0-4

Pushing,Towing and Lifting 0-7

Series

Biscayne

Bel Air

Tmpala.

Impala

Super Sport

Caprice

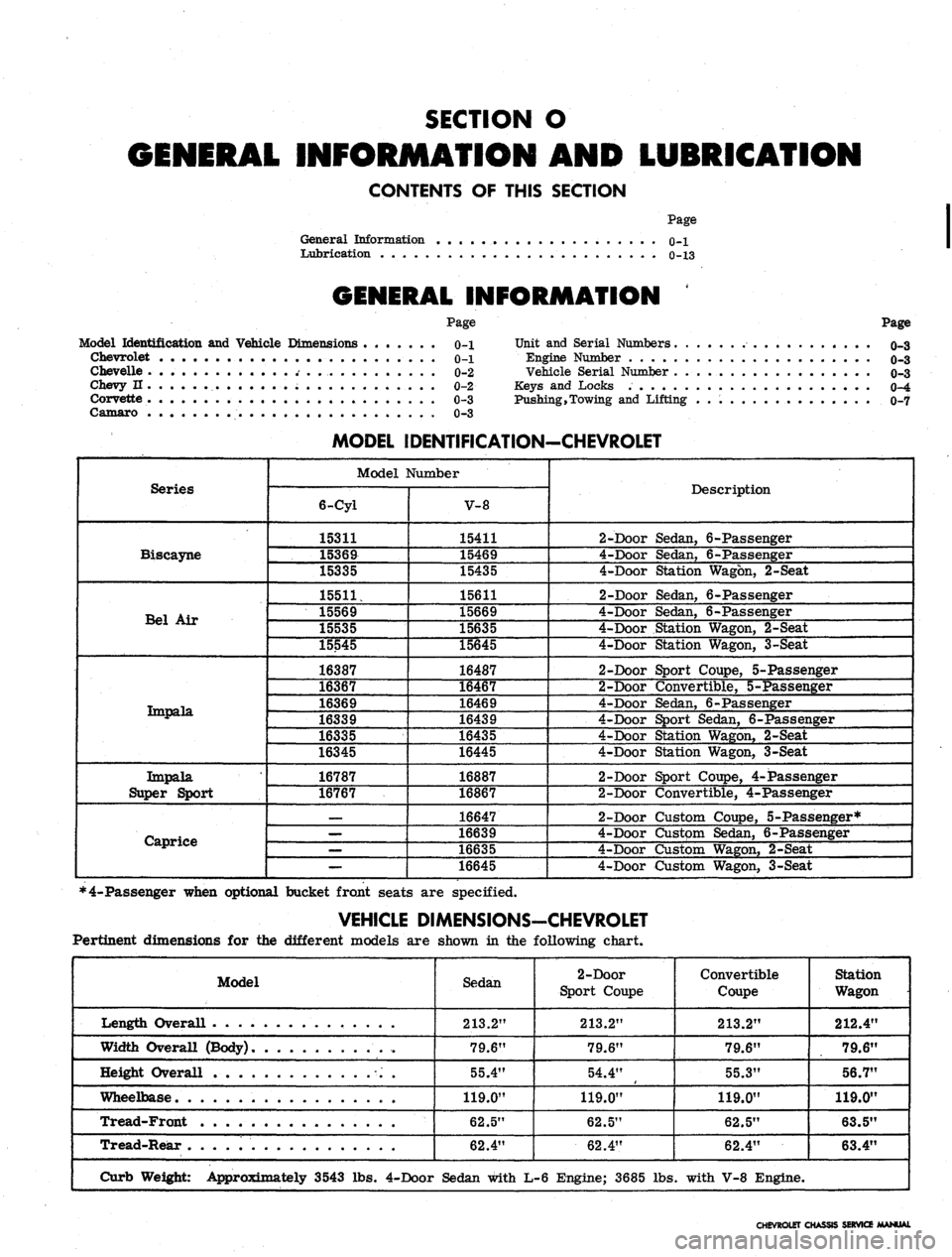

MODEL IDENTIFICATION-CHEVROLET

Model Number

6-Cyl

15311

15369

15335

15511,

15569

15535

15545

16387

16367

16369

16339

16335

16345

16787

16767

—

—

—

—

V-8

15411

15469

15435

15611

15669

15635

15645

16487

16467

16469

16439

16435

16445

16887

16867

16647

16639

16635

16645

Description

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Station Wagon, 3-Seat

2-Door Sport Coupe, 5-Passenger

2-Door Convertible, 5-Passenger

4-Door Sedan, 6-Passenger

4-Door Sport Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Station Wagon, 3-Seat

2-Door Sport Coupe, 4-Passenger

2-Door Convertible, 4-Passenger

2-Door Custom Coupe, 5-Passenger*

4-Door Custpm Sedan, 6-Passenger

4-Door Custom Wagon, 2-Seat

4-Door Custom Wagon, 3-Seat

*4-Passenger when optional bucket front seats are specified.

VEHICLE DIMENSIONS-CHEVROLET

Pertinent dimensions for the different models are shown in the following chart.

Model

Length Overall . .

Width Overall (Body)

Height Overall

Wheelbase

Tread-Front

Tread-Rear

Curb Weight: Approximately 3543 lbs.

Sedan

213.2"

79.6"

55.4"

119.0"

62.5"

62.4"

4-Door Sedan with

2-Door

Sport Coupe

213.2"

79.6"

54.4"

119.0"

62.5"

62.4"

L-6 Engine; 3685 lbs

Convertible

Coupe

213.2"

79.6"

55.3"

119.0"

62.5"

62.4"

. with V-8 Engine.

Station

Wagon

212.4"

79.6"

56.7"

119.0"

63.5"

63.4"

CHEVROLET CHASSIS SERVICE MANUAL

Page 4 of 659

GENERAL INFORMATION 0-2

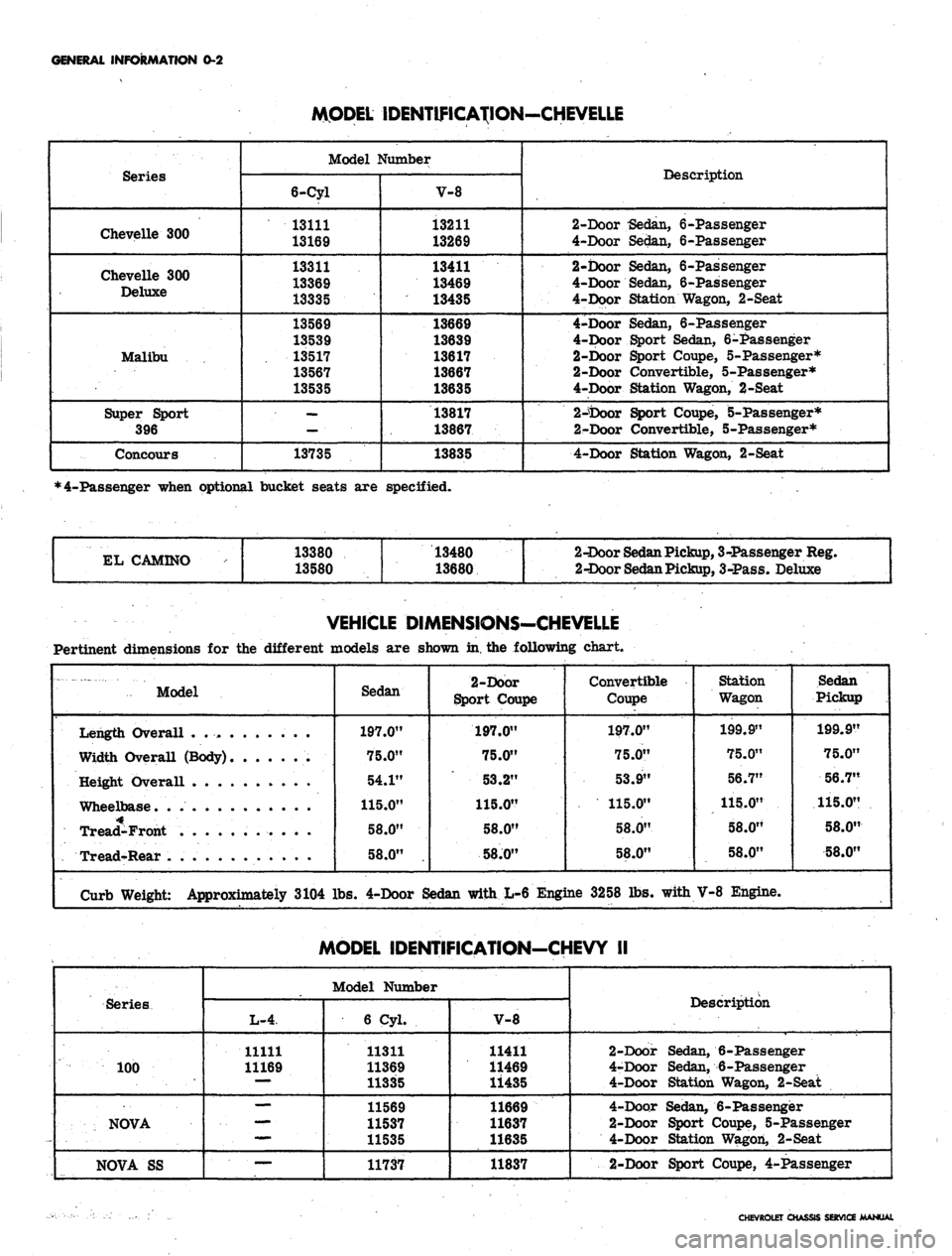

MODEL IDENTIFICATION-CHEVELLE

Series

Chevelle 300

Chevelle 300

Deluxe

Malibu

Super Sport

396

Concours

Model Number

6-Cyl

13111

13169

13311

13369

13335

13569

13539

13517

13567

13535

—

13735

V-8

13211

13269

13411

13469

13435

13669

13639

13617

13667

13635

13817

13867

13835

Description

2-Door -Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Sedan, 6-Passenger

4-Door Sport Sedan, 6-Passenger

2-Door Sport Coupe, 5-Passenger*

2-Door Convertible, 5-Passenger*

4-Door Station Wagon, 2-Seat

2-tooor Sport Coupe, 5-Passenger*

2-Door Convertible, 5-Passenger*

4-Door Station Wagon, 2-Seat

*4-Passenger when optional bucket seats are specified.

EL CAMINO

13380

13580

13480

13680

2-Door

Sedan

Pickup,

3-Passenger Reg.

2-Door

Sedan

Pickup,

3-Pass. Deluxe

VEHICLE DIMENSIONS-CHEVELLE

Pertinent dimensions for the different models are shown in, the following chart.

Model

Sedan

197.0"

75.0"

54.1"

115.0"

58.0"

58.0"

2-Door

Sport Coupe

197.0"

75.0"

53.2"

115.0"

58.0"

58J0"

Convertible

Coupe

197.0"

75.0"

53.9"

115.0"

58.0"

58.0"

Station

Wagon

199.9"

75.0"

56.7"

115.0"

58.0"

58.0"

Sedan

Pickup

199.9"

75.0"

56.7"

115.0"

58.0"

58.0"

Length Overall .

Width Overall (Body)

Height Overall . . .

Wheelbase. .

Tread-Front

Tread-Rear .

Curb Weight: Approximately 3104 lbs. 4-Door Sedan with L-6 Engine 3258 lbs. with V-8 Engine.

MODEL IDENTIFICATION-CHEVY II

Series

100

NOVA

NOVA SS

Model Number

L-4

11111

11169

mmm.

—

6 Cyl.

11311

11369

11335

11569

11537

11535

11737

V-8

11411

11469

11435

11669

11637

11635

11837

Description

2-Door Sedan, 6-Passenger

4-Door Sedan, 6-Passenger

4-Door Station Wagon, 2-Seat

4-Door Sedan, 6-Passenger

2-Door Sport Coupe, 5-Passenger

4-Door Station Wagon, 2-Seat

2-Door Sport Coupe, 4-Passenger

CHEVROLET CHASSIS SERVICE MANUAL

Page 5 of 659

GENERAL INFORMATION 0-3

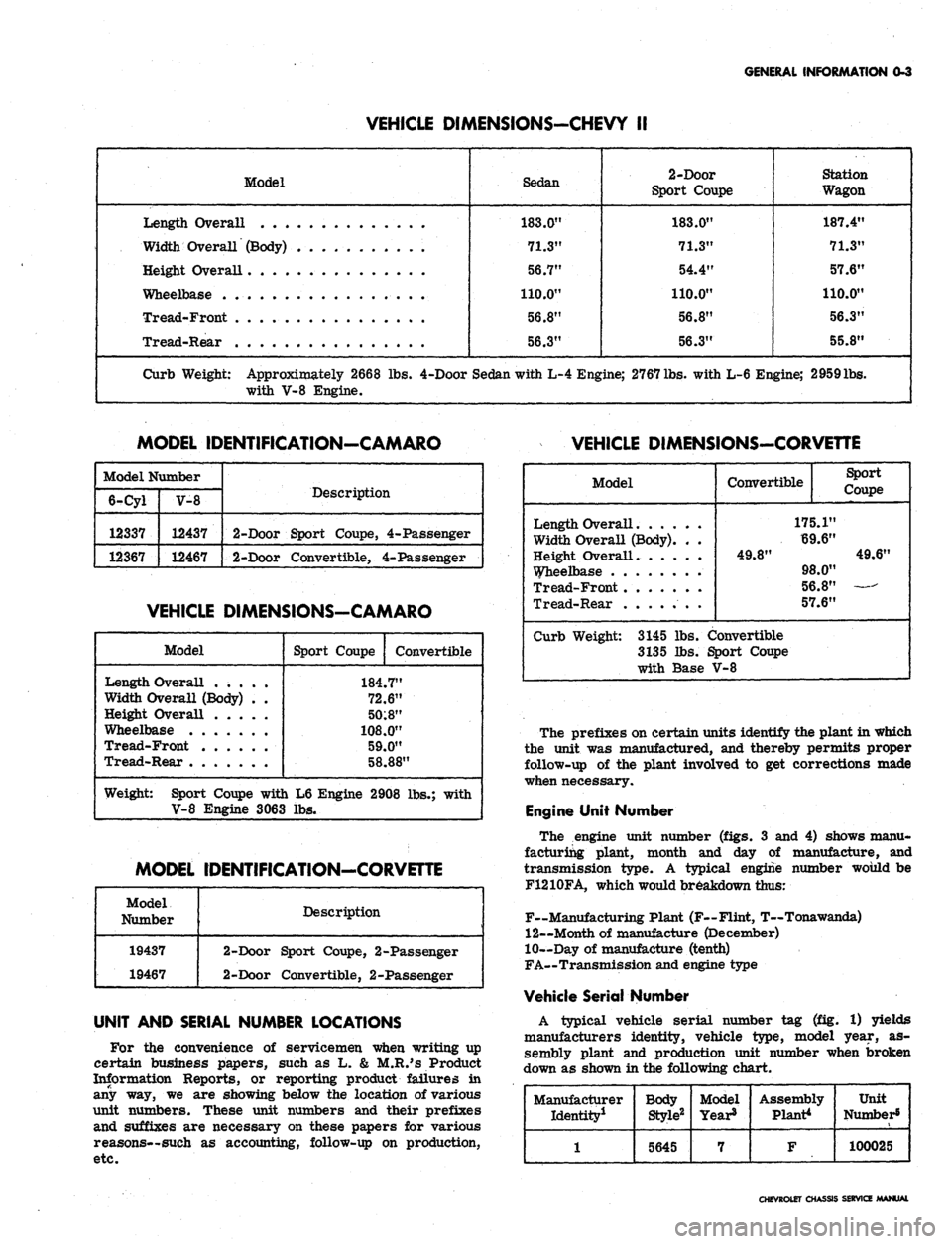

VEHICLE DIMENSIONS-CHEVY II

Model

Length Overall

Width Overall (Body) . . . .

Height Overall

Wheelbase

Tread-Front

Tread-Rear . . .

Sedan

183.0"

71.3"

56.7"

110.0"

56.8"

56.3"

2-Door

Sport Coupe

183.0"

71.3"

54.4"

110.0"

56.8"

56.3"

Station

Wagon

187.4"

71.3"

57.6"

110.0"

56.3"

55.8"

Curb Weight: Approximately 2668 lbs. 4-Door Sedan with L-4 Engine; 2767

lbs.

with L-6 Engine; 2959lbs.

with V-8 Engine.

MODEL IDENTIFICATION-CAMARO

VEHICLE DIMENSIONS-CORVEnE

Model Number

6-Cyl

12337

12367

V-8

12437

12467

Description

2-Door Sport Coupe, 4-Passenger

2-Door Convertible, 4-Passenger

VEHICLE DIMENSIONS-CAMARO

Model

Length Overall .....

Width Overall (Body) . .

Height Overall

Wheelbase

Tread-Front

Tread-Rear

Sport Coupe

Convertible

184.7"

72.6"

50:8"

108.0"

59.0"

58.88"

Weight: Sport Coupe with L6 Engine 2908 lbs.; with

V-8 Engine 3063 lbs.

MODEL IDENTIFICATION-CORVETTE

Model

Number

19437

19467

Description

2-Door Sport Coupe, 2-Passenger

2-Door Convertible, 2-Passenger

UNIT AND SERIAL NUMBER LOCATIONS

For the convenience of servicemen when writing up

certain business papers, such as L. & M.R.'s Product

Information Reports, or reporting product failures in

any way, we are showing below the location of various

unit numbers. These unit numbers and their prefixes

and suffixes are necessary on these papers for various

reasons—such as accounting, follow-up on production,

etc.

Model

Length Overall

Width Overall (Body). . .

Height Overall.

Wheelbase

Tread-Front

Tread-Rear .

Convertible

Sport

Coupe

175.1"

69.6"

49.8"

49.6"

98.0"

56.8"

57.6"

Curb Weight: 3145 lbs. Convertible

3135 lbs. Sport Coupe

with Base V-8

The prefixes on certain units identify the plant in which

the unit was manufactured, and thereby permits proper

follow-up of the plant involved to get corrections made

when necessary.

Engine Unit Number

The engine unit number (figs. 3 and 4) shows manu-

facturing plant, month and day of manufacture, and

transmission type. A typical engine number would be

F1210FA, which would breakdown thus:

F~Manufacturing Plant (F—Flint, T—Tonawanda)

12—Month of manufacture (December)

10—Day of manufacture (tenth)

FA—Transmission and engine type

Vehicle Serial Number

A typical vehicle serial number tag (fig. 1) yields

manufacturers identity, vehicle type, model year, as-

sembly plant and production unit number when broken

down as shown in the following chart.

Manufacturer

Identity1

1

Body

Style2

5645

Model

Year8

7

Assembly

Plant*

F

Unit

Number5

100025

CHEVROLET CHASSIS SERVICE /MANUAL

Page 161 of 659

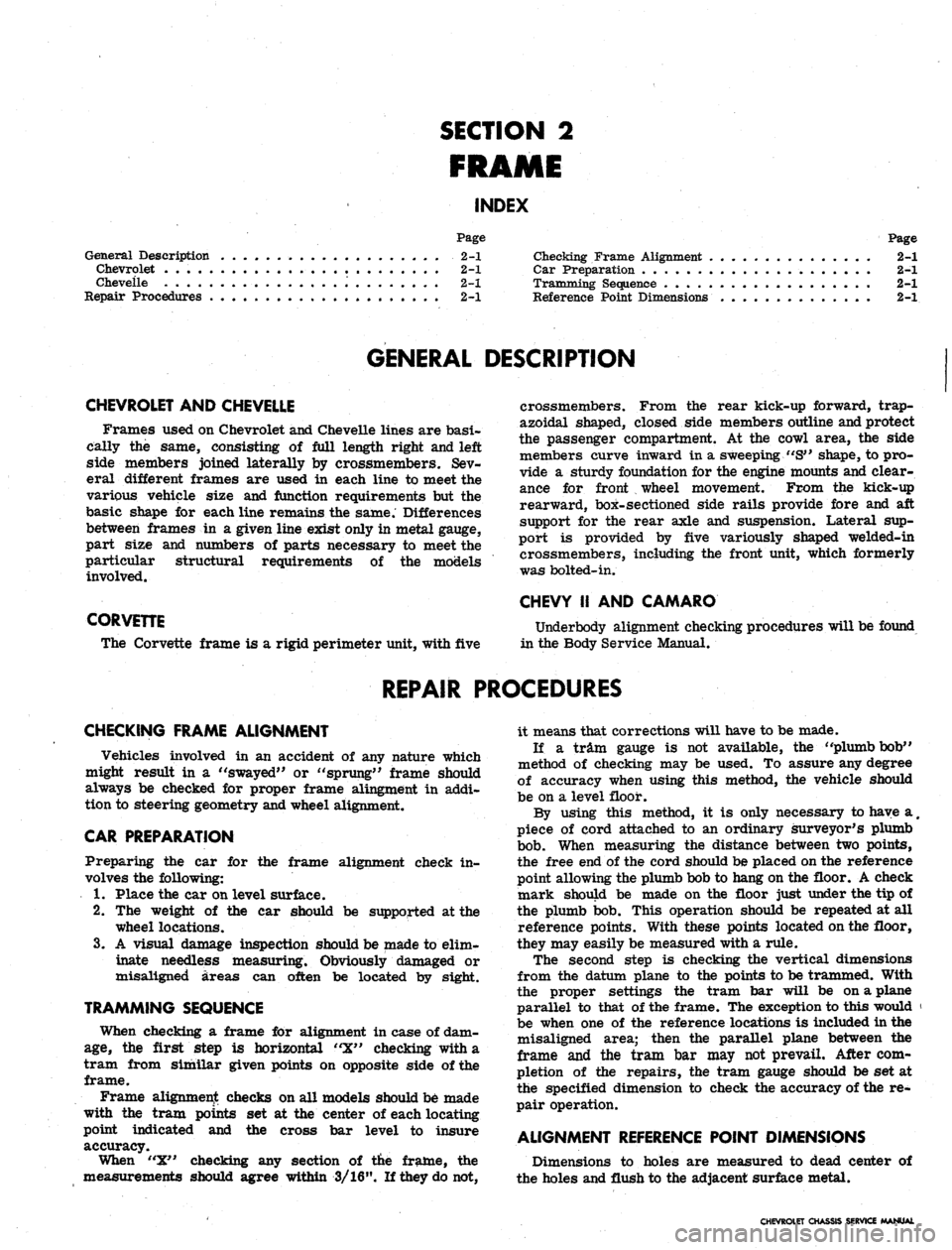

SECTION 2

FRAME

INDEX

Page

General Description 2-1

Chevrolet 2-1

Cheveile '. 2-1

Repair Procedures 2-1

Page

Checking Frame Alignment 2-1

Car Preparation 2-1

Tramming Sequence 2-1

Reference Point Dimensions 2-1

GENERAL DESCRIPTION

CHEVROLET AND CHEVELLE

Frames used on Chevrolet and Cheveile lines are basi-

cally the same, consisting of full length right and left

side members joined laterally by crossmembers. Sev-

eral different frames are used in each line to meet the

various vehicle size and function requirements but the

basic shape for each line remains the same. Differences

between frames in a given line exist only in metal gauge,

part size and numbers of parts necessary to meet the

particular structural requirements of the models

involved.

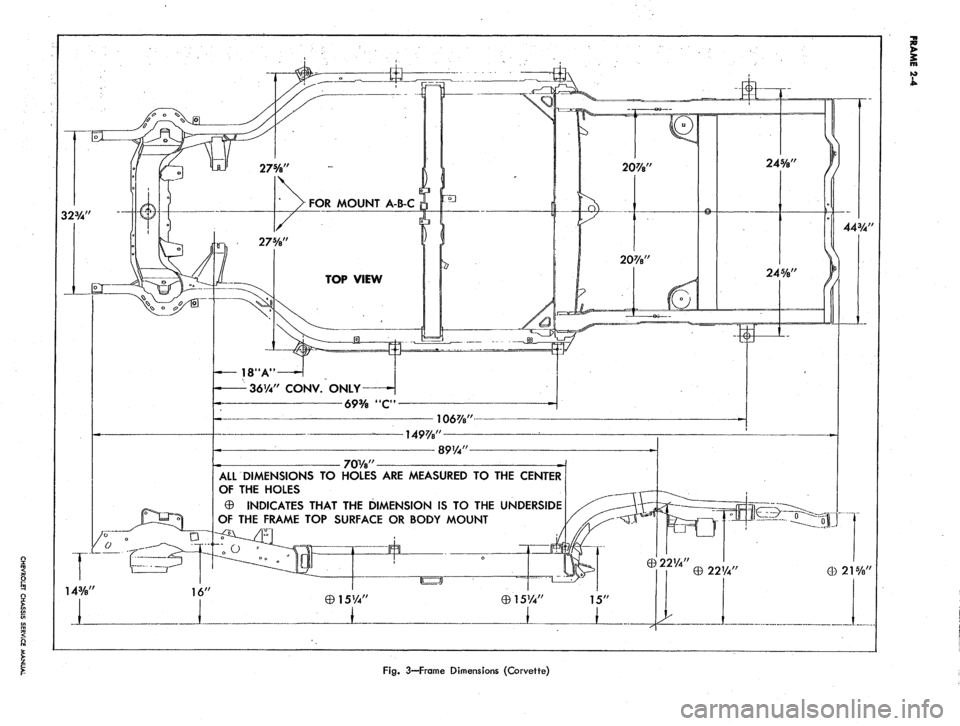

CORVETTE

The Corvette frame is a rigid perimeter unit, with five

crossmembers. From the rear kick-up forward, trap-

azoidal shaped, closed side members outline and protect

the passenger compartment. At the cowl area, the side

members curve inward in a sweeping "S" shape, to pro-

vide a sturdy foundation for the engine mounts and clear-

ance for front wheel movement. From the kick-up

rearward, box-sectioned side rails provide fore and aft

support for the rear axle and suspension. Lateral sup-

port is provided by five variously shaped welded-in

crossmembers, including the front unit, which formerly

was bolted-in.

CHEVY II AND CAMARO

Underbody alignment checking procedures will be found

in the Body Service Manual.

REPAIR PROCEDURES

CHECKING FRAME ALIGNMENT

Vehicles involved in an accident of any nature which

might result in a "swayed" or "sprung" frame should

always be checked for proper frame alingment in addi-

tion to steering geometry and wheel alignment.

CAR PREPARATION

Preparing the car for the frame alignment check in-

volves the following:

1.

Place the car on level surface.

2.

The weight of the car should be supported at the

wheel locations.

3.

A visual damage inspection should be made to elim-

inate needless measuring. Obviously damaged or

misaligned areas can often be located by sight.

TRAMMING SEQUENCE

When checking a frame for alignment in case of dam-

age,

the first step is horizontal "X" checking with a

tram from similar given points on opposite side of the

frame.

Frame alignment checks on all models should be made

with the tram points set at the center of each locating

point indicated and the cross bar level to insure

accuracy.

When "X" checking any section of the frame, the

measurements should agree within 3/16". If they do not,

it means that corrections will have to be made.

If a tram gauge is not available, the "plumb bob"

method of checking may be used. To assure any degree

of accuracy when using this method, the vehicle should

be on a level floor.

By using this method, it is only necessary to have a

#

piece of cord attached to an ordinary surveyor's plumb

bob.

When measuring the distance between two points,

the free end of the cord should be placed on the reference

point allowing the plumb bob to hang on the floor. A check

mark should be made on the floor just under the tip of

the plumb bob. This operation should be repeated at all

reference points. With these points located on the floor,

they may easily be measured with a rule.

The second step is checking the vertical dimensions

from the datum plane to the points to be trammed. With

the proper settings the tram bar will be on a plane

parallel to that of the frame. The exception to this would '

be when one of the reference locations is included in the

misaligned area; then the parallel plane between the

frame and the tram bar may not prevail. After com-

pletion of the repairs, the tram gauge should be set at

the specified dimension to check the accuracy of the re-

pair operation.

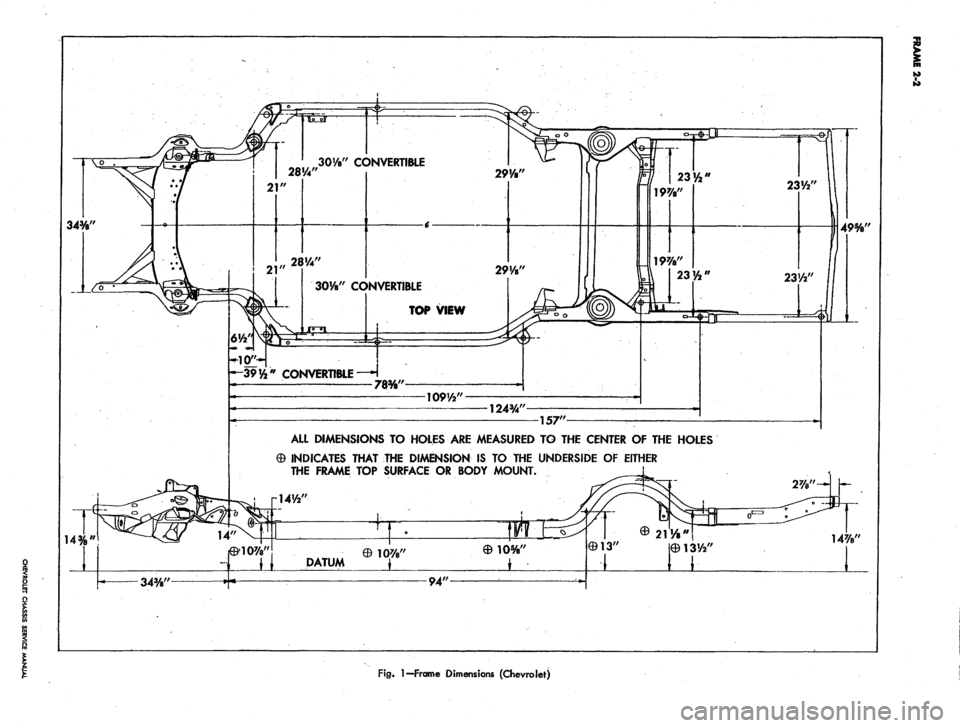

ALIGNMENT REFERENCE POINT DIMENSIONS

Dimensions to holes are measured to dead center of

the holes and flush to the adjacent surface metal.

CHEVROLET CHASSIS SERVICE MANUAL

Page 162 of 659

To"

34%"

14%"

21

28%"

" CONVERTIBLE

21

2914"

28%"

30y8" CONVERTIBLE

TOP VIEW

29V8"

—39 y2" CONVERTIBLE —H

78%"

109Vr2"

124%"

157"

ALL DIMENSIONS TO HOLES ARE MEASURED TO THE CENTER OF THE HOLES

0 INDICATES THAT THE DIMENSION IS TO THE UNDERSIDE OF EITHER

THE FRAME TOP SURFACE OR BODY MOUNT.

141/2"

DATUM

©10%"

231/*'

23W

L

49%'

14%'

34%"

94'

Fig.

1—Frame Dimensions (Chevrolet)

Page 163 of 659

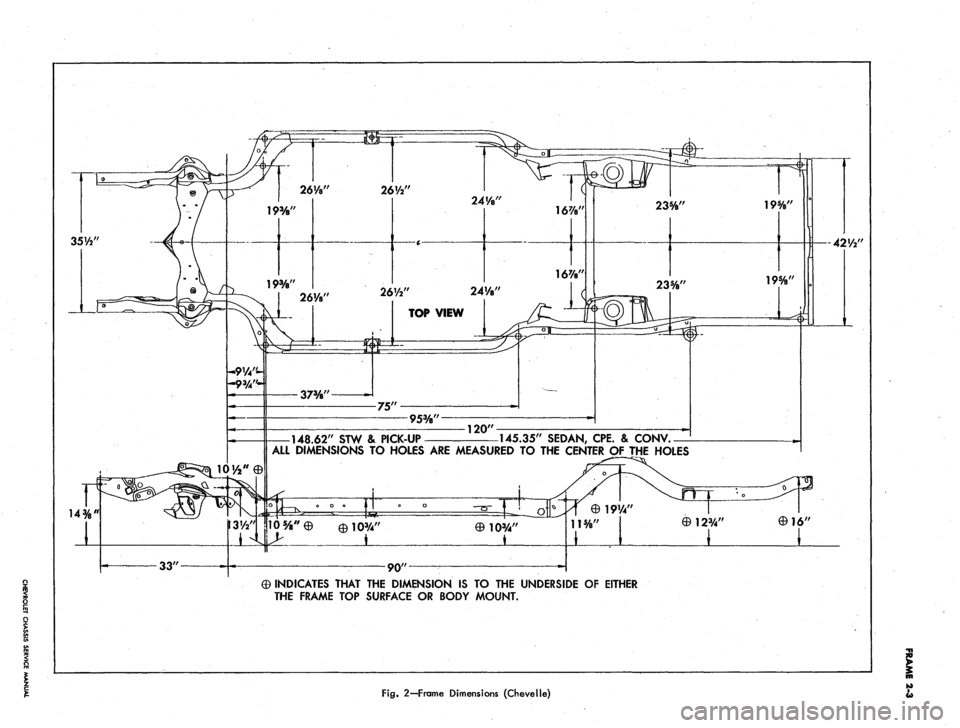

35%*

14%

26VV

26V2"

24VB"

16%'

16%'

26l/s'/

-9V4"-

10'/a"

0

26V2" 24V8"

TOP

VIEW

37W

75"

95%"

148.62"

STW & PICK-UP

120"

235/8"

145.35"

SEDAN,

CPE.

&

CONV.

ALL

DIMENSIONS

TO

HOLES

ARE

MEASURED

TO THE

CENTER

OF

THE

HOLES

eio%"

L_

©123/4"

19%"

195/8"

-42'/2"

33"

90"

0 INDICATES THAT

THE

DIMENSION

IS TO THE

UNDERSIDE

OF

EITHER

THE FRAME

TOP

SURFACE

OR

BODY MOUNT.

Fig.

2—Frame Dimensions (Chevelle)

I

Page 164 of 659

FOR MOUNT A-B-C

18'A"

36V4"

CONV. ONLY

69%

JIC"

ALL DIMENSIONS TO HOLES ARE MEASURED TO THE CENTER

OF THE HOLES

0 INDICATES THAT THE DIMENSION IS TO THE UNDERSIDE

OF THE FRAME TOP SURFACE OR BODY MOUNT

Fig.

3—Frame Dimensions (Corvette)

Page 180 of 659

FRONT SUSPENSION 3-16

available the following procedure may also be

used (fig. 22-Alternate Method).

1.

Support car on suitable hoist or jack (so control

arms may swing free) and remove the wheel and

tire assembly, shock absorber, and stabilizer link

at control arm.

2.

Place suitable jack stand under the lower control

arm cross shaft.

3.

Follow Steps 2-5 as outlined on previous page.

4.

Turn head of tool screw to partially compress

spring.

5. Remove the three control arm cross shaft attaching

bolts,

washers and nuts.

6. Carefully lower jack stand and if necessary increase

compression on spring and when coil spring is out of

its upper seat, relax tension on spring (fig. 22).

7. By using a pry bar to assist, if necessary, remove

the coil spring from the lower control arm.

8. Installation is the reverse of the above procedure.

Carefully follow instructions for installing spring

tool.

LOWER CONTROL ARM SPHERICAL JOINT

Chevrolet, Chevelle, Comoro and Corvette

Inspection

The lower control arm spherical joint should be re-

placed whenever wear is indicated in the upper joint

inspection.

NOTE: The lower control arm spherical joint

is a loose fit in the assembly when not connected

to the steering knuckle.

Only if inspection of each upper joint indicates them

both to be within limits, inspect each lower joint for ex-

cessive wear as follows:

1.

After reconnecting upper joints to steering knuckles,

support vehicle weight on wheels or wheel hubs.

2.

With outside micrometer or caliper, measure dis-

tance from top of lubrication fitting to bottom of ball

stud, and record the dimensions for each side.

3.

Then support vehicle weight at outer end of each

lower control arm, so that wheels or wheel hubs are

free,

then repeat Step 2.

4.

If the difference in dimensions on either side is

greater than 1/16" (.0625"), the joint is excessively

worn and both lower joints should be replaced.

If inspection of lower spherical joints does not indicate

excessive wear, inspect further as follows:

5.

On Chevrolet Only--Examine lubrication hole in each

joint assembly after cleaning out hole. Look for evi-

dence of the liner partially or fully blocking lubrica-

tion opening. Such evidence indicates that liner is

disintegrating and that both lower spherical joints

should be replaced.

Another indication of lower spherical joint excessive

wear is indicated when difficulty is experienced when

lubricating the joint. If the liner has worn to the point

where the lubrication grooves in the liner have worn

away, then abnormal pressure is required to force lubri-

cant through the joint. This is another reason to recom-

mend replacement of both lower joints.

If the above inspections do not indicate any reason for

spherical joint replacements, test the torque tightness of

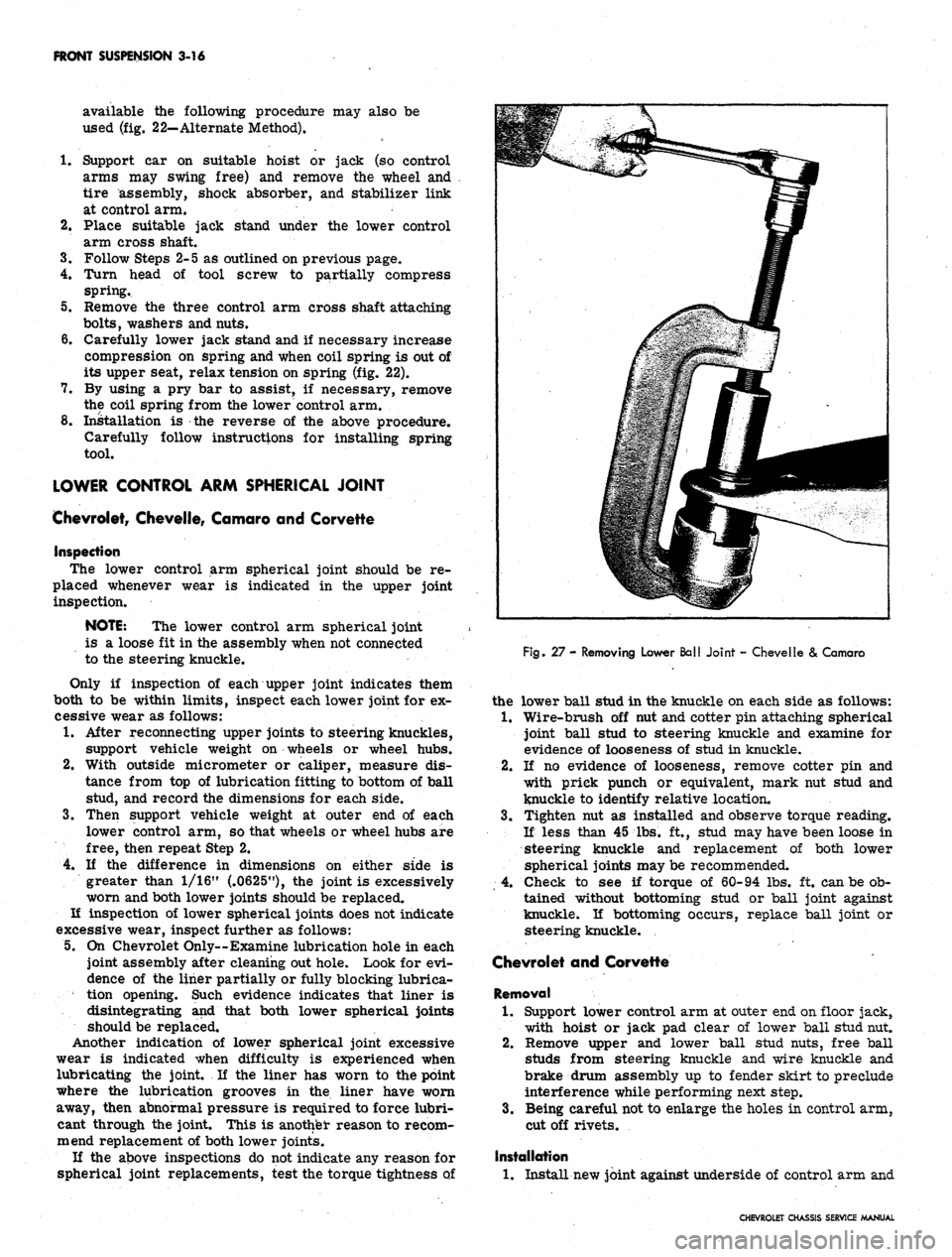

Fig. 27 - Removing Lower Ball Joint - Chevelle

&

Camaro

the lower ball stud in the knuckle on each side as follows:

1.

Wire-brush off nut and cotter pin attaching spherical

joint ball stud to steering knuckle and examine for

evidence of looseness of stud in knuckle.

2.

If no evidence of looseness, remove cotter pin and

with prick punch or equivalent, mark nut stud and

knuckle to identify relative location.

3.

Tighten nut as installed and observe torque reading.

If less than 45 lbs. ft., stud may have been loose in

steering knuckle and replacement of both lower

spherical joints may be recommended.

4.

Check to see if torque of 60-94 lbs. ft. can be ob-

tained without bottoming stud or ball joint against

knuckle. If bottoming occurs, replace ball joint or

steering knuckle.

Chevrolet and Corvette

Removal

1.

Support lower control arm at outer end on floor jack,

with hoist or jack pad clear of lower ball stud nut.

2.

Remove upper and lower ball stud nuts, free ball

studs from steering knuckle and wire knuckle and

brake drum assembly up to fender skirt to preclude

interference while performing next step.

3.

Being careful not to enlarge the holes in control arm,

cut off rivets.

Installation

1.

Install new joint against underside of control arm and

CHEVROLET CHASSIS SERVICE MANUAL

Page 214 of 659

REAR SUSPENSION AND DRIVE LINE 4-24

4

i*

5

Fig.

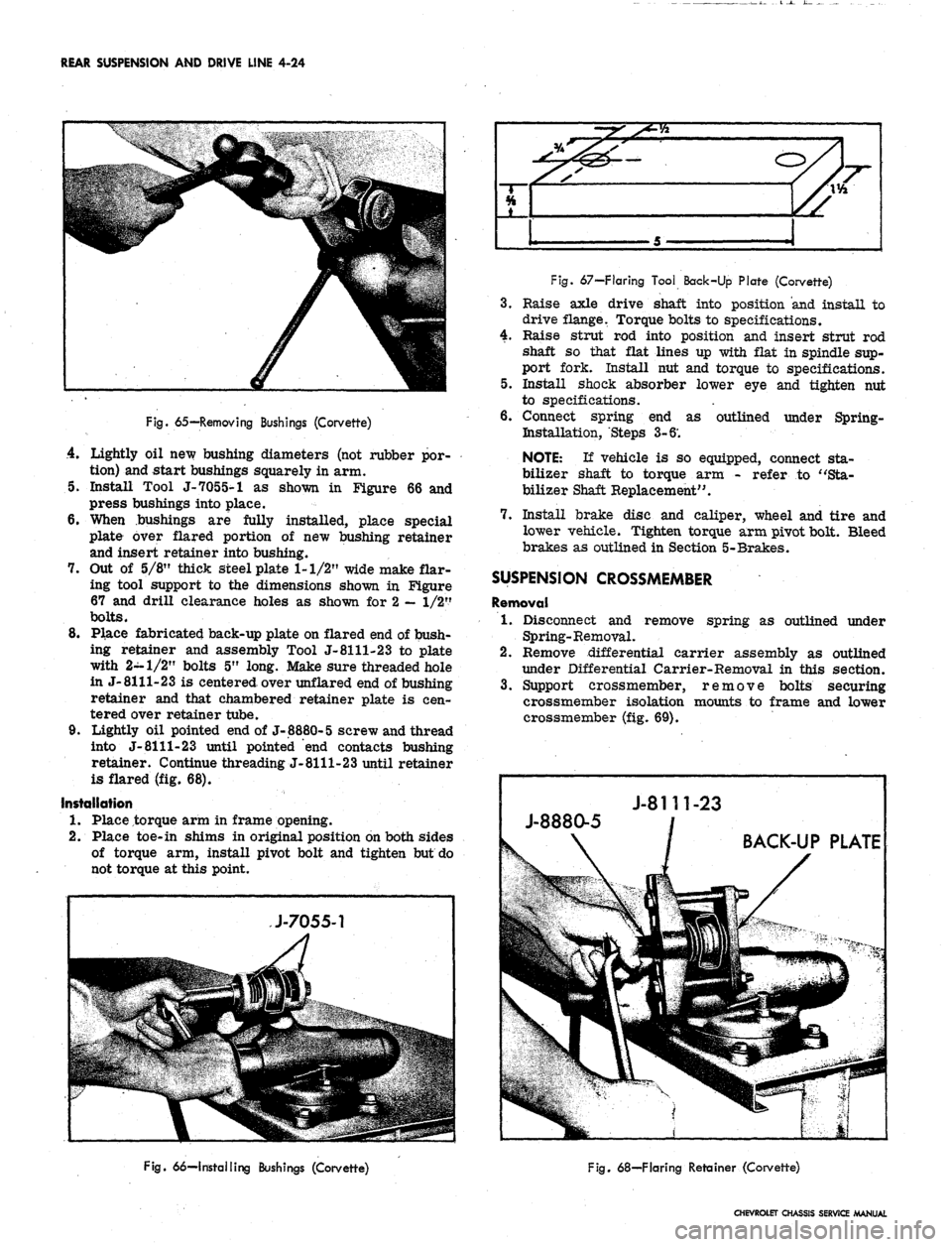

65—Removing Bushings (Corvette)

4.

Lightly oil new bushing diameters (not rubber por-

tion) and start bushings squarely in arm.

5. Install Tool J-7055-1 as shown in Figure 66 and

press bushings into place.

6. When bushings are fully installed, place special

plate over flared portion of new bushing retainer

and insert retainer into bushing.

7. Out of 5/8" thick steel plate 1-1/2" wide make flar-

ing tool support to the dimensions shown in Figure

67 and drill clearance holes as shown for 2

—

1/2"

bolts.

8. Place fabricated back-up plate on flared end of bush-

ing retainer and assembly Tool J-8111-23 to plate

with 2-1/2" bolts 5" long. Make sure threaded hole

in J-8111-23 is centered over unflared end of bushing

retainer and that chambered retainer plate is cen-

tered over retainer tube.

9. Lightly oil pointed end of J-8880-5 screw and thread

into J-

8111-23

until pointed "end contacts bushing

retainer. Continue threading J-8111-23 until retainer

is flared (fig. 68).

Installation

1.

Place torque arm in frame opening.

2.

Place toe-in shims in original position on both sides

of torque arm, install pivot bolt and tighten but do

not torque at this point.

Fig.

67—Flaring Tool Back-Up Plate (Corvette)

3.

Raise axle drive shaft into position and install to

drive flange. Torque bolts to specifications.

4.

Raise strut rod into position and insert strut rod

shaft so that flat lines up with flat in spindle sup-

port fork. Install nut and torque to specifications.

5. Install shock absorber lower eye and tighten nut

to specifications.

6. Connect spring end as outlined under Spring-

Bistallation, Steps 3-6'.

NOTE:

If vehicle is so equipped, connect sta-

bilizer shaft to torque arm - refer to "Sta-

bilizer Shaft Replacement".

7. Install brake disc and caliper, wheel and tire and

lower vehicle. Tighten torque arm pivot bolt. Bleed

brakes as outlined in Section 5-Brakes.

SUSPENSION CROSSMEMBER

Removal

1.

Disconnect and remove spring as outlined under

Spring-Removal.

2.

Remove differential carrier assembly as outlined

under Differential Carrier-Removal in this section.

3.

Support crossmember, remove bolts securing

crossmember isolation mounts to frame and lower

crossmember (fig. 69).

Fig.

66—Installing Bushings (Corvette)

Fig.

68—Flaring Retainer (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 500 of 659

CHASSIS SHEET METAL 11-13

HOOD ADJUSTMENT

The alignment of the hood in relation

to*

other sheet

metal parts is controlled by the position of the hood

hinges and the height of the two bumpers, located one at

each end of the radiator support. The adjustments at

the hood latch must be made after the hinges and bumpers

are positioned to yield the dimensions shown in Figure

17.

Latch adjustments are made so that effort required

to open and close the hood is reasonable, and hood align-

ment obtained by hinge and bumper adjustment is main-

tained when the hood is closed. Note that the hood latch

is not designed or intended to correct basic hood align-

ment faults.

To align the hood and lock, proceed as follows:

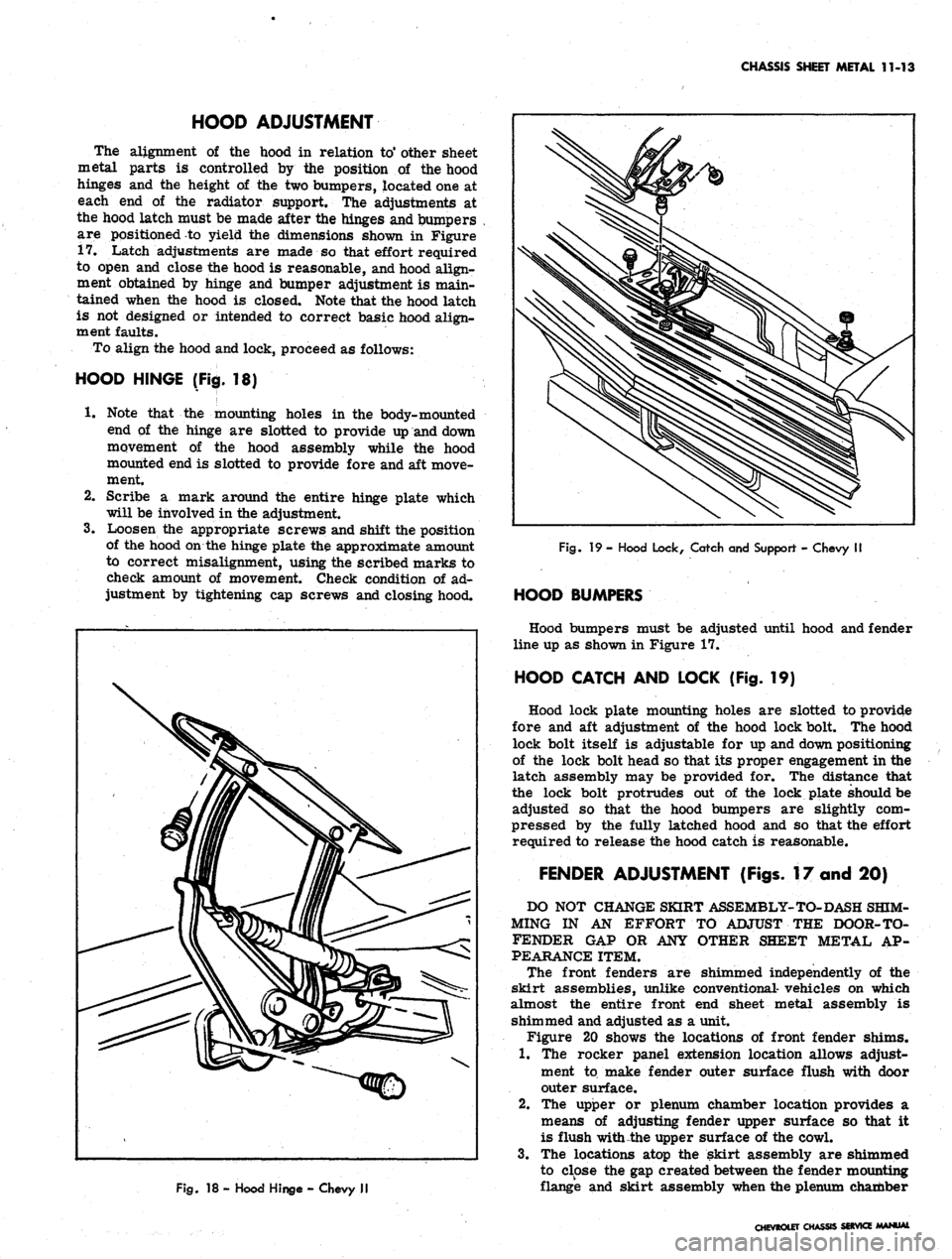

HOOD HINGE (Fig. 18)

1.

Note that the mounting holes in the body-mounted

end of the hinge are slotted to provide up and down

movement of the hood assembly while the hood

mounted end is slotted to provide fore and aft move-

ment.

2.

Scribe a mark around the entire hinge plate which

will be involved in the adjustment.

3.

Loosen the appropriate screws and shift the position

of the hood on the hinge plate the approximate amount

to correct misalignment, using the scribed marks to

check amount of movement. Check condition of ad-

justment by tightening cap screws and closing hood.

Fig.

18 - Hood Hinge - Chevy II

Fig.

19 - Hood Lock, Catch and Support - Chevy II

HOOD BUMPERS

Hood bumpers must be adjusted until hood and fender

line up as shown in Figure 17.

HOOD CATCH AND LOCK (Fig. 19)

Hood lock plate mounting holes are slotted to provide

fore and aft adjustment of the hood lock bolt. The hood

lock bolt itself is adjustable for up and down positioning

of the lock bolt head so that its proper engagement in the

latch assembly may be provided for. The distance that

the lock bolt protrudes out of the lock plate should be

adjusted so that the hood bumpers are slightly com-

pressed by the fully latched hood and so that the effort

required to release the hood catch is reasonable.

FENDER ADJUSTMENT (Figs. 17 and 20)

DO NOT CHANGE SKIRT ASSEMBLY-TO-DASH SHIM-

MING IN AN EFFORT TO ADJUST THE DOOR-TO-

FENDER GAP OR ANY OTHER SHEET METAL AP-

PEARANCE ITEM.

The front fenders are shimmed independently of the

skirt assemblies, unlike conventional- vehicles on which

almost the entire front end sheet metal assembly is

shimmed and adjusted as a unit.

Figure 20 shows the locations of front fender shims.

1.

The rocker panel extension location allows adjust-

ment to make fender outer surface flush with door

outer surface.

2.

The upper or plenum chamber location provides a

means of adjusting fender upper surface so that it

is flush with the upper surface of the cowl.

3.

The locations atop the skirt assembly are shimmed

to close the gap created between the fender mounting

flange and skirt assembly when the plenum chamber

CHEVROLET CHASSIS SWVICE MANUAL