window CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 23 of 659

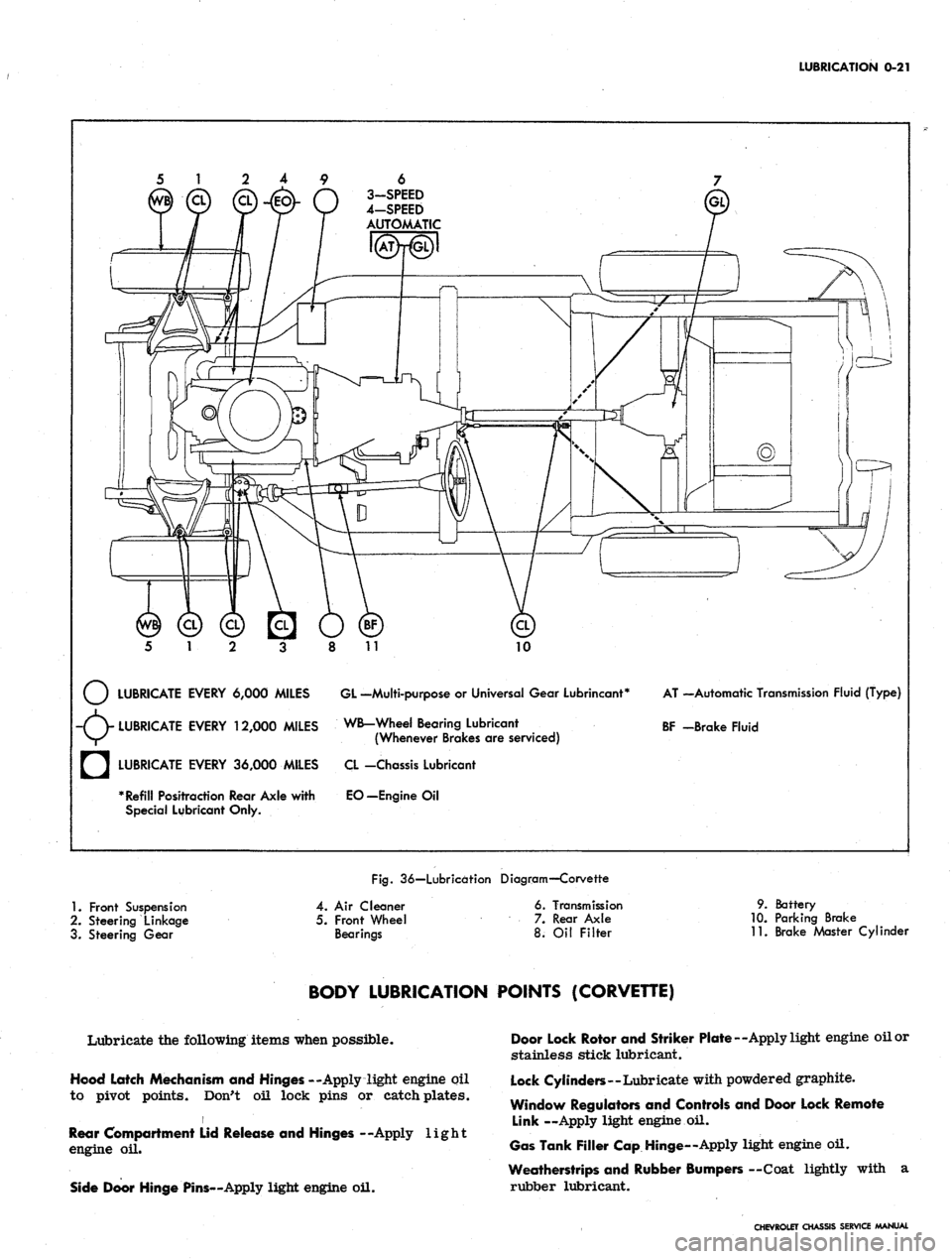

LUBRICATION

0-21

6

3-SPEED

4-SPEED

AUTOMATIC

10

LUBRICATE EVERY 6,000 MILES GL -Multi-purpose

or

Universal Gear Lubrincant*

-(V LUBRICATE EVERY 12,000 MILES WB-Wheel Bearing Lubricant

V/^ (Whenever Brakes

are

serviced)

AT —Automatic Transmission Fluid (Type)

BF -Brake Fluid

a

LUBRICATE EVERY 36,000 MILES

* Refill Positraction Rear Axle with

Special Lubricant Only.

CL -Chassis Lubricant

EO—Engine

Oil

Fig.

36—Lubrication Diagram—Corvette

1.

Front Suspension

2.

Steering Linkage

3. Steering Gear

4.

Air

Cleaner

5. Front Wheel

Bearings

6. Transmission

7. Rear Axle

8.

Oil

Filter

9. Battery

10.

Parking Brake

11.

Brake Master Cylinder

BODY LUBRICATION POINTS (CORVETTE)

Lubricate the following items when possible.

Hood Latch Mechanism and Hinges --Apply light engine oil

to pivot points. Don't oil lock pins or catch plates.

i

Rear Compartment Lid Release and Hinges --Apply light

engine

oil.

Side Door Hinge Pins—Apply light engine oil.

Door Lock Rotor and Striker Plate—Apply light engine oil or

stainless stick lubricant.

Lock Cylinders—Lubricate with powdered graphite.

Window Regulators and Controls and Door Lock Remote

Link —Apply light engine

oil.

Gas Tank Filler Cap Hinge—Apply light engine oil.

Weatherstrips and Rubber Bumpers —Coat lightly with

a

rubber lubricant.

CHEVROLET CHASSIS SERVICE MANUAL

Page 49 of 659

HEATER AND AIR CONDITIONING 1A-26

clockwise for medium and high blower speed, as

desired. Low blower speed is automatic during

cooling operations.

4.

"Def-Pull". This knob should be pushed fully in.

Additional Cooling Hints

1.

The center barrel outlet in the dash may be rotated

to deflect air as desired or used to act as a shut off

door.

2.

The right and left ball outlets may be rotated to

deflect air in the direction desired. Each outlet has

a shut off valve operated by a knob approximately

4 in. inboard. When the knob is horizontal, the valve

is open.

3.

There are two (2) additional outlets in the bottom of

the ducts approximately 6" inboard from the valve

knobs. A rotating cover will open these outlets to

provide cool air for the feet if desired.

4.

When first entering a very warm car, open the

windows for a few minutes until the interior of the

car has cooled off.

Heating

1.

"Air Pull-Fan". Pull this knob fully out. Rotate

the knob clockwise for low, medium or high blower

speed as desired. If just a small amount of heat is

desired, leave the fan on low or medium speed and

regulate the temperature with the "Cool In-Hot Pull"

knob.

2.

"Air Cond-Pull". This knob should normally be

pushed fully in. However, during cool, damp days

it is possible, by pulling this knob fully out, to de-

humidify the air by passing it through the evaporator

core before reheating to the desired outlet

temperature.

3.

"Cool In-Hot Pull". Pull this knob out as far as

necessary to provide the temperature desired.

4.

"Def-Pull". Pull this knob all the way out for

maximum defrosting or de-icing. When the knob is

partly out, a portion of the hot air is used for de-

frosting and the balance is discharged through the

heater outlet.

GENERAL INFORMATION

In any vocation or trade, there are established proce-

dures and practices that have been developed after many

years of experience. In addition, occupational hazards

may be present that require the observation of certain

precautions or use of special tools and equipment. Ob-

serving the procedures, practices and precautions of

servicing refrigeration equipment will greatly reduce the

possibilities of damage to the customers' equipment as

well as virtually eliminate the element of hazard to the

serviceman.

PRECAUTIONS IN HANDLING REFRIGERANT-12

Refrigerant-12 is transparent and colorless in both the

gaseous and liquid state. It has a boiling point of 21.7^

below zero and, therefore, at all normal temperatures

and pressures it will be a vapor. The vapor is heavier

than air and is noninflammable, nonexplosive, non-

poisonous (except when in contact with an open flame)

and noncorrosive (except when in contact with water).

The following precautions in handling R-12 should be

observed at all times.

• All refrigerant drums are shipped with a heavy metal

screw cap. The purpose of the cap is to protect the

valve and safety plug from damage. It is good .prac-

tice to replace the cap after each use of the drum.

• If it is ever necessary to transport or carry a drum

or can of refrigerant in a car, keep it in the luggage

compartment. Refrigerant should not be exposed to

the radiant heat from the sun for the resulting in-

crease in pressure may cause the safety plug to

release or the drum or can to burst..

• Drums or disposable cans should never be subjected

to high temperature when adding refrigerant to the

system. In most instances, heating the drum or can

is required to raise the pressure in the container

higher than the pressure in the system during the

operation. It would be unwise to place the drum on a

gas stove, radiator or use a blow torch while pre-

paring for the charging operation, for a serious ac-

cident can result. Don't depend on the safety

plug - many drums have burst when the safety plug

failed.' Remember, high pressure means that great

forces are being exerted against the walls of the

container. A bucket of warm water, not over 125°F,

or warm wet rags around the container is all the heat

that is required.

• Do not weld or steam clean on or near the system.

Welding or steam cleaning can result in a dangerous

pressure buildup in the system.

• When filling a small drum from a large one, never

fill the drum completely. Space should always be

allowed above the liquid for expansion. If the drum

were completely full and the temperature was in-

creased, hydraulic pressure with its tremendous

force would result.

• Discharging large quantities of R-12 into a room can

usually be done safely as the vapor would produce

no ill effects, however, in the event of an accidental

rapid discharge of the system it is recommended

that inhalation of large quantities of R-12 be avoided.

This caution is especially important if the area con-

tains a flame producing device such as a gas heater.

While R-12 normally is nonpoisonous, heavy con-

centrations.. of it in contact with a live flame will

produce a toxic gas. The same gas will also attack

all bright metal surfaces.

• Protection of the eyes is of vital importance! When

working around a refrigerating system, an accident

may cause liquid refrigerant to hit the face. If the

eyes are protected with goggles or glasses, no

serious damage can result. Just remember, any

R-12 liquid that you can touch or that touches you is

at least 21.7"F. below zero. The eyeballs can't take

much of this temperature. If R-12 liquid should

strike the eyeballs, here is what to do:

1.

Keep calm.

2.

Do not rub the eyes! Splash the affected area with

quantities of cold water to gradually get the tem-

perature above the freezing point. The use of min-

eral, cod liver or an antiseptic oil is important in

CHEVROLET CHASSIS SERVICE MANUAL

Page 56 of 659

HEATER AND AIR CONDITIONING 1A-33

within the system. The following fixed conditions must be

adhered to in order to make it possible to compare the

performance of the system being tested with the stan-

dards below:

1.

Doors and windows closed. (Car inside or in shade.)

2.

Hood up and engine exhaust suitably ventilated.

3.

Vehicle in NEUTRAL with engine running at 2000

rpm.

4.

Air Conditioning controls set for -

• Maximum cooling.

• High blower speed.

5.

TEMP knob and AIR knob set for full recirculating

air. On Comfortron systems* move the control lever

to REAR and pull the white vacuum hose from the

transducer. Plug the hose. An alternate method is to

install the J-22368 Tester (described later in this

section) and operate it on MANUAL control to main-

tain maximum cooling and blower speed.

6. Gauge set installed.

7.

System settled out (run-in approximately

10

minutes).

8. A thermometer placed in front of vehicle grille and

another in the right hand diffuser outlet.

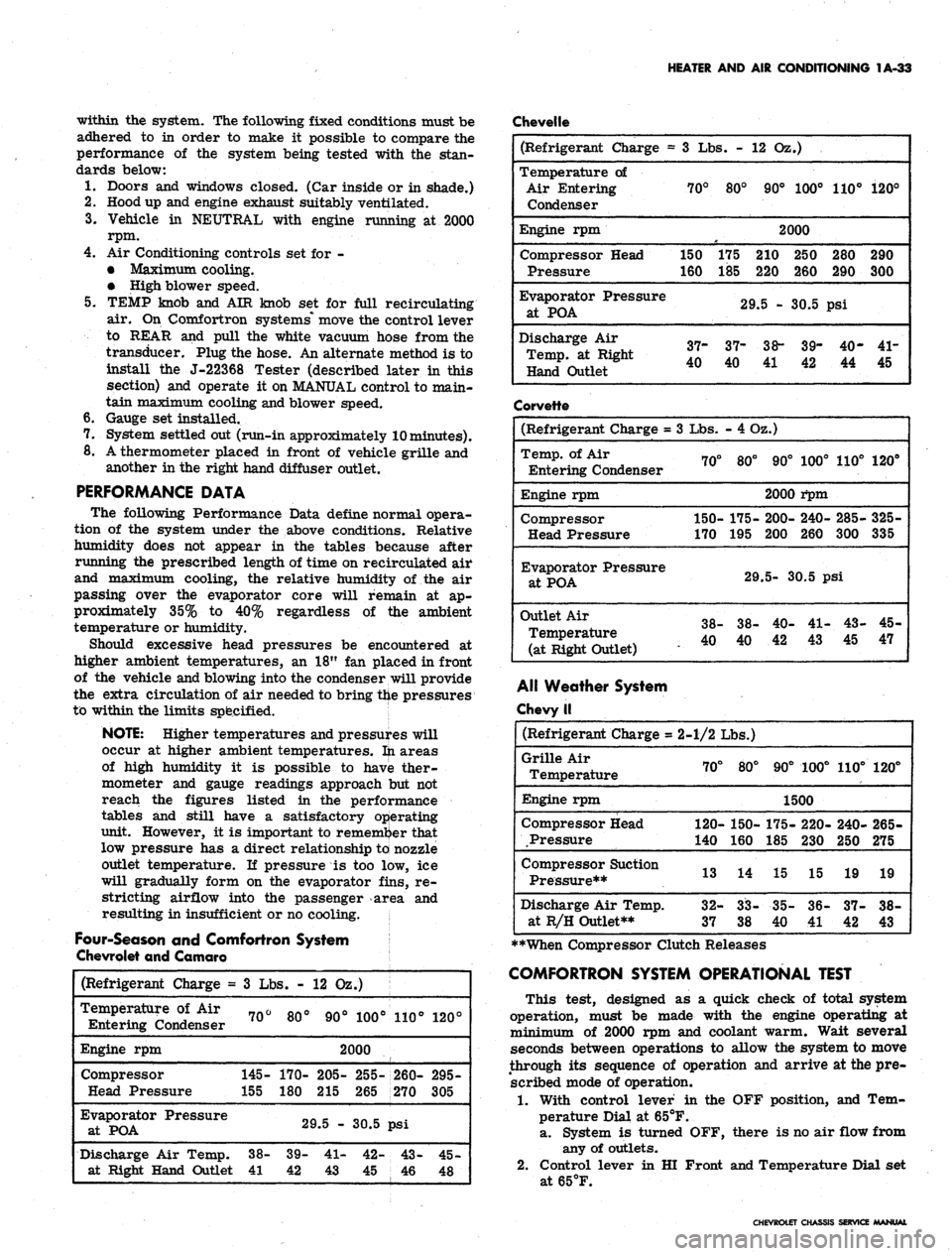

PERFORMANCE DATA

The following Performance Data define normal opera-

tion of the system under the above conditions. Relative

humidity does not appear in the tables because after

running the prescribed length of time on recirculated air

and maximum cooling, the relative humidity of the air

passing over the evaporator core will remain at ap-

proximately 35% to 40% regardless of the ambient

temperature or humidity.

Should excessive head pressures be encountered at

higher ambient temperatures, an 18" fan placed in front

of the vehicle and blowing into the condenser will provide

the extra circulation of air needed to bring the pressures

to within the limits specified.

NOTE: Higher temperatures and pressures will

occur at higher ambient temperatures, fti areas

of high humidity it is possible to have ther-

mometer and gauge readings approach but not

reach the figures listed in the performance

tables and still have a satisfactory operating

unit. However, it is important to remember that

low pressure has a direct relationship to nozzle

outlet temperature. If pressure is too low, ice

will gradually form on the evaporator fins, re-

stricting airflow into the passenger area and

resulting in insufficient or no cooling.

Four-Season and Comfortron System

Chevrolet and Camaro

Chevelle

(Refrigerant

Charge

=

Temperature

of Air

Entering Condenser

Engine rpm

Compressor

Head Pressure

Evaporator Pressure

at POA

Discharge Air Temp,

at Right Hand Outlet

3

Lbs. -

70°

145-

155

38-

41

80°

170-

180

12 02

90°

.)

100°

2000

205-

215

29.5 -

39-

42

41-

43

255-

265

30.5

42-

45

110°

260-

270

psi

43-

46

120°

295-

305

45-

48

(Refrigerant Charge =

Temperature of

Air Entering

Condenser

Engine rpm

Compressor Head

Pressure

Evaporator

Pressure

at

POA

Discharge Air

Temp, at Right

Hand Outlet

3 Lbs. -

70°

150

160

37-

40

80°

175

185

12 Oz.)

90° 100°

2000

210 250

220 260

29.5 - 30.5

37-

40

38-

39-

41 42

110°

280

290

psi

40-

44

120°

290

300

41-

45

Corvette

(Refrigerant Charge =

Temp, of Air

Entering Condenser

Engine rpm

Compressor

Head Pressure

Evaporator

Pressure

at

POA

Outlet

Air

Temperature

(at Right

Outlet)

3

Lbs.

70°

150-

170

38-

40

- 4 Oz.)

80°

175-

195

29

38-

40

90°

2000

200-

200

100°

i*pm

240-

260

110°

285-

300

5-

30.5 psi

40-

42

41-

43

43-

45

120°

325-

335

45-

47

Alt Weather System

Chevy II

(Refrigerant

Charge

=

Grille Air

Temperature

Engine rpm

Compressor Head

Pressure

Compressor Suction

Pressure**

Discharge Air Temp,

at R/H Outlet**

2-1/2 Lbs.)

70°

120-

140

13

32-

37

80°

150-

160

14

CO

OO

CO

CO

90°

100°

1500

175-

185

15

35-

40

220-

230

15

36-

41

110°

240-

250

19

37-

42

120°

265-

275

19

38-

43

**When Compressor Clutch Releases

COMFORTRON SYSTEM OPERATIONAL TEST

This test, designed as a quick check of total system

operation, must be made with the engine operating at

minimum of 2000 rpm and coolant warm. Wait several

seconds between operations to allow the system to move

through its sequence of operation and arrive at the pre-

scribed mode of operation.

1.

With control lever in the OFF position, and Tem-

perature Dial at 65°F.

a. System is turned OFF, there is no air flow from

any of outlets.

2.

Control lever in HI Front and Temperature Dial set

at65°F.

CHEVROLET CHASSIS SERVICE MANUAL

Page 57 of 659

HEATER AND AIR CONDITIONING 1A-34

a. Blower comes on High speed.

b.

Cold air comes from A/C outlets.

3.

Rotate Temperature Dial to 85°F.

a. Blower speed will decrease to Low speed then

increase to Medium or High.

b.

Air temperature changes from Cold to Hot and

comes out heater outlet.

4.

Move control lever to LOW Front, with Temperature

Dial at 85°F. Blower operates at Low and Medium

speeds.

5.

Move control lever to Rear, set Temperature Dial

at 65°F.

a. Blower goes to High speed and maintains high

air flow.

b.

All air comes from A/C outlets.

6. Move control lever to DE-FOG.

a. Blower is on Medium or High Speeds.

b.

Air comes from Defroster and Heater Outlets.

7.

Move control lever to DE-ICE.

a. Blower is on High Speed.

b.

Air temperature goes to warm and most of air

comes from defroster nozzle, with small amount

of air coming from heater outlet.

c. Outside air door is open - (door valve is closed

to car body).

8. Move control lever to REAR (dial at 65°). Outside

air door moves outboard. (Door valve is open to

car body).

CHEVROLET COMFORTRON TESTER

The J-22368 Automatic Temperature Control Tester

when in AUTOMATIC position, may be used to perform

Comfortron system checks without disturbing normal car

operation.

Under MANUAL control tester allows the operator to

set and hold a predetermined blower speed

and.

temper-

ature. The tester can also be used to measure external

system voltages by using the probe.

To Install the Tester

1.

Remove the three-terminal male connector from the

Amplifier on the Comfortron control head.

2.

Plug this connector into the three terminal female

connector (with yellow wire)

on

the Tester.

3.

Plug the remaining three-terminal male connector

on the Tester into the Amplifier on the control head.

4.

Attach the black ground lead to any good ground

point available in the car.

5.

Remove the large vacuum hose from Transducer and

connect it to the Tester vacuum hose nipple.

6. Connect the Tester vacuum hose (short hose) to the

Transducer.

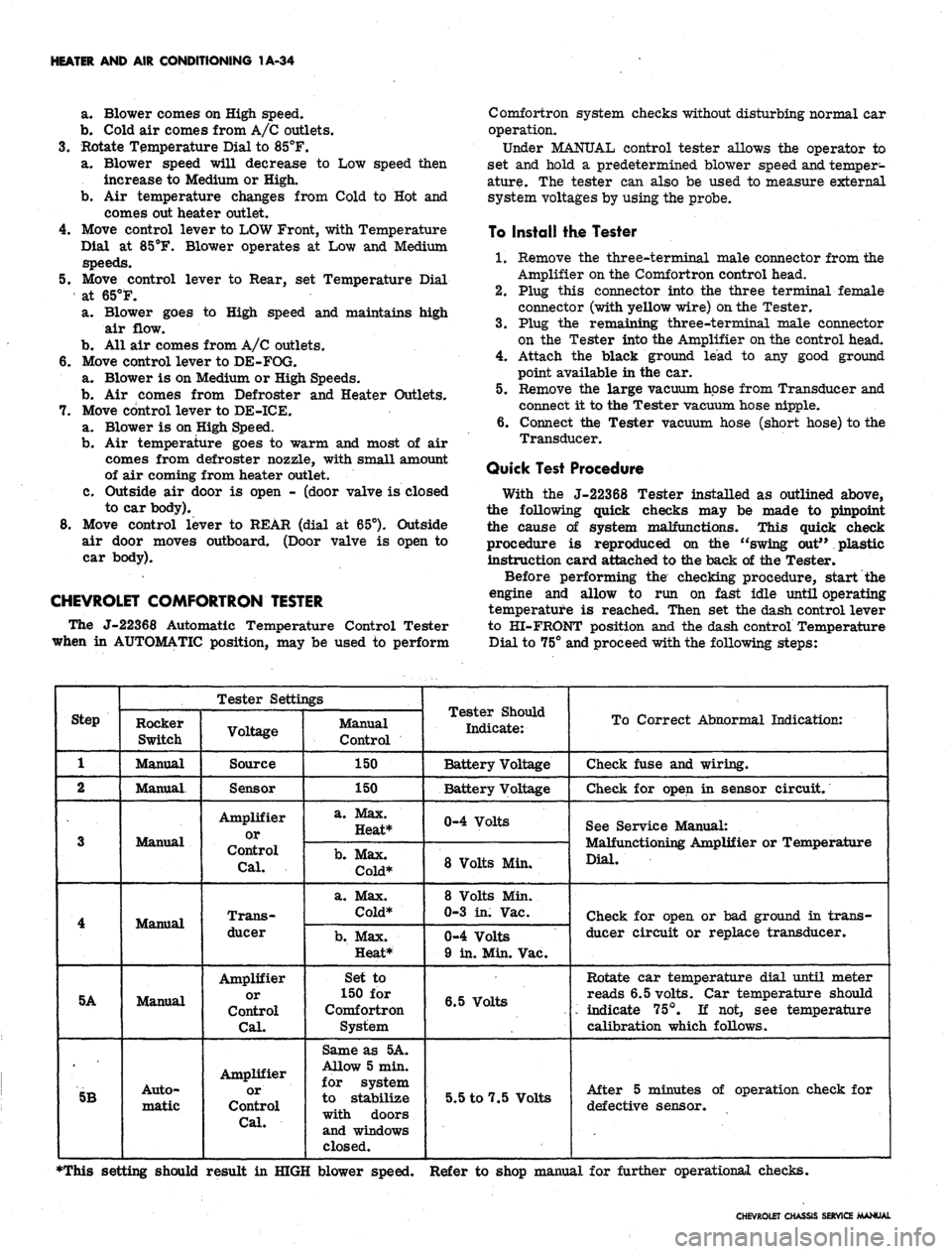

Quick Test Procedure

With the J-22368 Tester installed as outlined above,

the following quick checks may be made to pinpoint

the cause of system malfunctions. This quick check

procedure is reproduced on the "swing out" plastic

instruction card attached to the back of the Tester.

Before performing the checking procedure, start the

engine and allow to run on fast idle until operating

temperature is reached. Then set the dash control lever

to HI-FRONT position and the dash control Temperature

Dial to 75° and proceed with the following steps:

Step

1

2

3

4

5A

5B

Tester Settings

Rocker

Switch

Manual

Manual.

Manual

Manual

Manual

Auto-

matic

Voltage

Source

Sensor

Amplifier

or

Control

Cal.

Trans-

ducer

Amplifier

or

Control

Cal.

Amplifier

or

Control

Cal.

Manual

Control

150

150

a. Max.

Heat*

b.

Max.

Cold*

a. Max.

Cold*

b.

Max.

Heat*

Set to

150 for

Comfortron

System

Same as 5A.

Allow 5 min.

for system

to stabilize

with doors

and windows

closed.

Tester Should

Indicate:

Battery Voltage

Battery Voltage

0-4 Volts

8 Volts Min.

8 Volts Min.

0-3 in. Vac.

0-4 Volts

9 in. Min. Vac.

6.5 Volts

5.5 to 7.5 Volts

To Correct Abnormal Indication:

Check fuse and wiring.

Check for open in sensor circuit.

See Service Manual:

Malfunctioning Amplifier or Temperature

Dial.

Check for open or bad ground in trans-

ducer circuit or replace transducer.

Rotate car temperature dial until meter

reads 6.5 volts. Car temperature should

'•- indicate 75°. If not, see temperature

calibration which follows.

After 5 minutes of operation check for

defective sensor.

•This setting should result in HIGH blower speed. Refer to shop manual for further operational checks.

CHEVROLET CHASSIS SERVICE MANUAL

Page 58 of 659

HEATER AND AIR CONDITIONING 1A-35

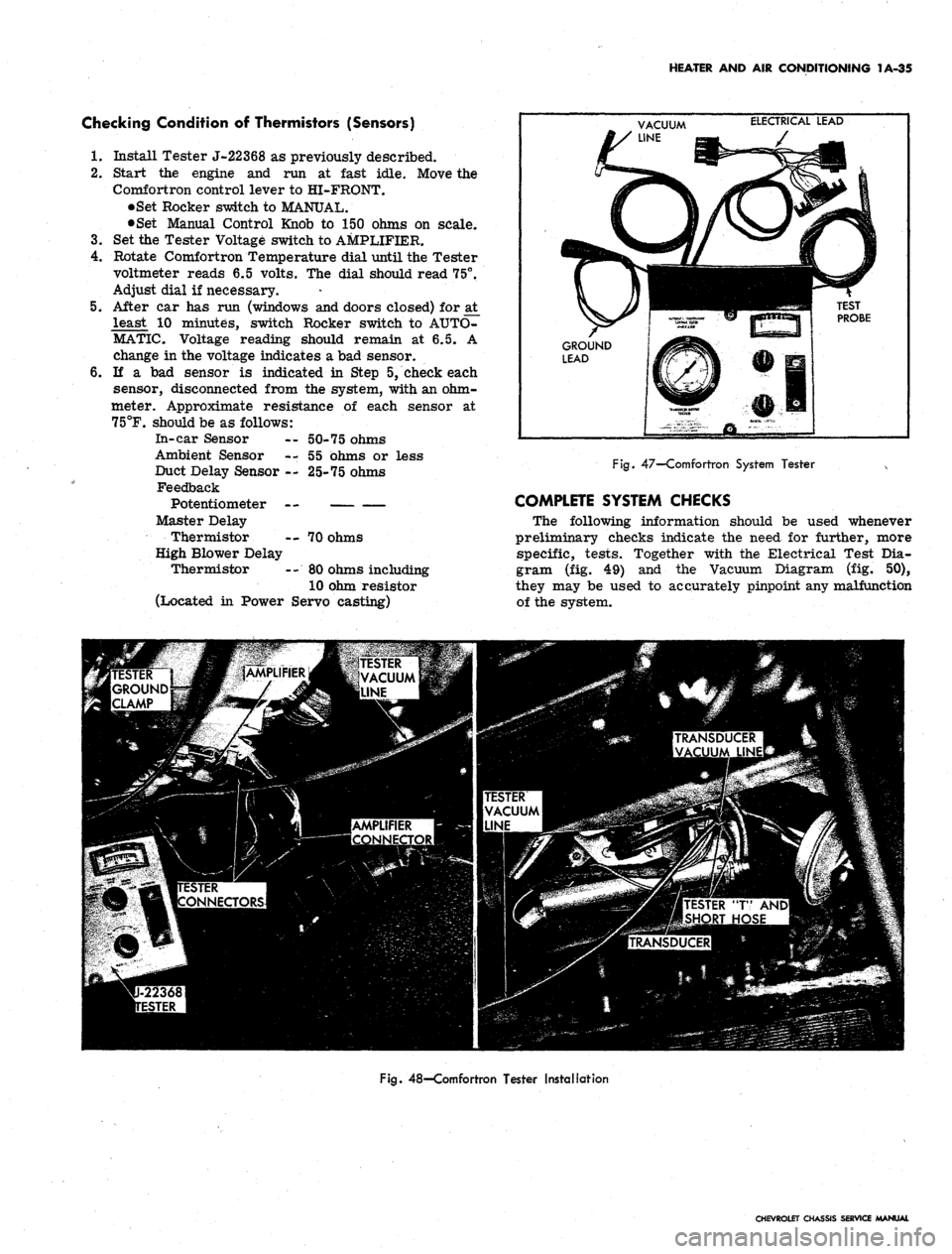

Checking Condition of Thermistors (Sensors)

1.

Install Tester J-22368 as previously described.

2.

Start the engine and run at fast idle. Move the

Comfortron control lever to HI-FRONT.

•Set Rocker switch to MANUAL.

•Set Manual Control Knob to 150 ohms on scale.

3.

Set the Tester Voltage switch to AMPLIFIER.

4.

Rotate Comfortron Temperature dial until the Tester

voltmeter reads 6.5 volts. The dial should read 75°,

Adjust dial if necessary.

5.

After car has run (windows and doors closed) for at

least 10 minutes, switch Rocker switch to AUTO-

MATIC. Voltage reading should remain at 6.5. A

change in the voltage indicates a bad sensor.

6. If a bad sensor is indicated in Step 5, check each

sensor, disconnected from the system, with an ohm-

meter. Approximate resistance of each sensor at

75°F.

should be as follows:

In-car Sensor — 50-75 ohms

Ambient Sensor --,55 ohms or less

Duct Delay Sensor -.- 25-75 ohms

Feedback

Potentiometer —

Master Delay

Thermistor -- 70 ohms

High Blower Delay

Thermistor -- 80 ohms including

10 ohm resistor

(Located in Power Servo casting)

VACUUM

ELECTRICAL LEAD

GROUND

LEAD

Fig.

47—Comfortron System Tester x

COMPLETE SYSTEM CHECKS

The following information should be used whenever

preliminary checks indicate the need for further, more

specific, tests. Together with the Electrical Test Dia-

gram (fig. 49) and the Vacuum Diagram (fig. 50),

they may be used to accurately pinpoint any malfunction

of the system.

Fig.

48—Comfortron Tester Installation

CHEVROLET OU

SERVICE MANUAL

Page 108 of 659

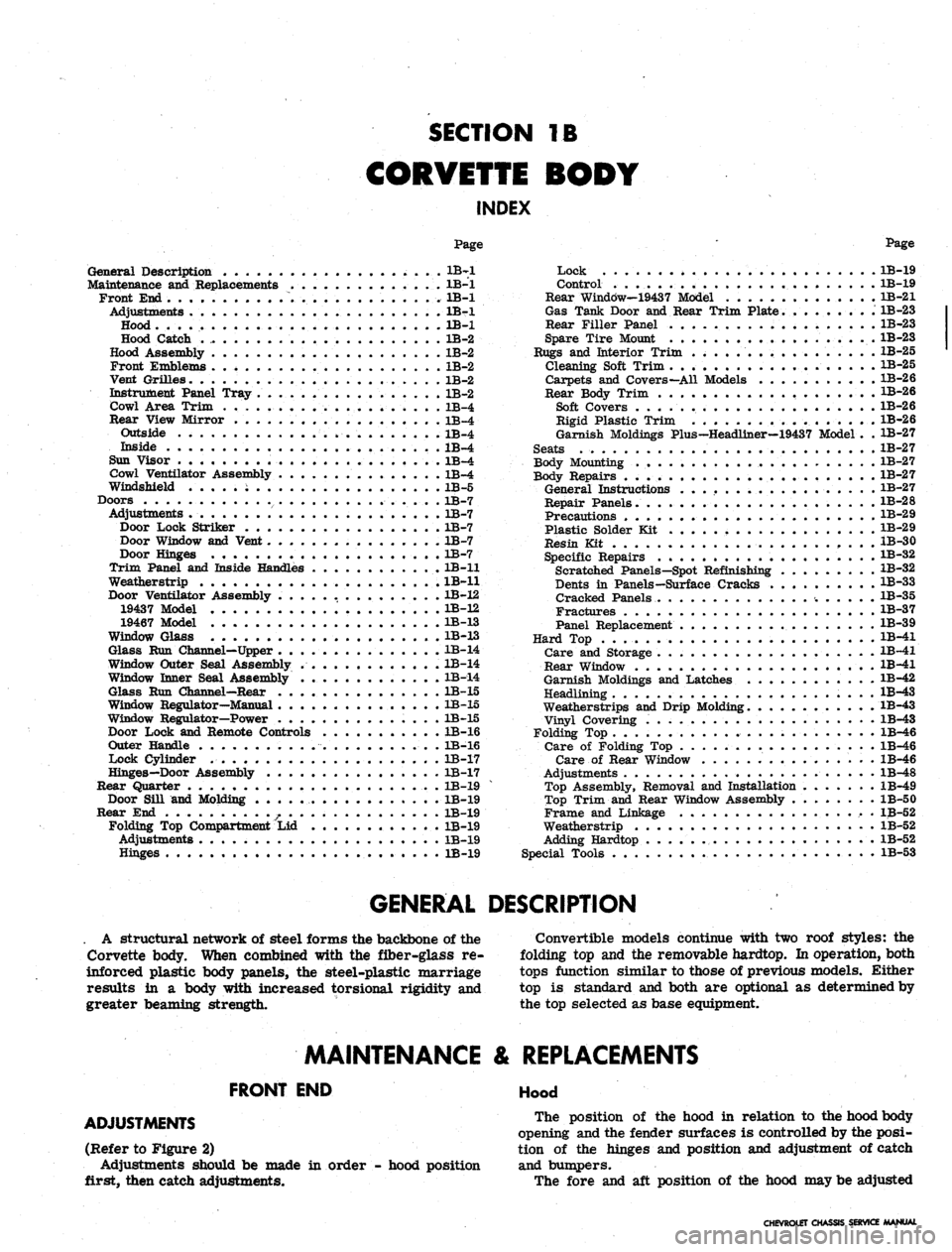

SECTION

IB

CORVETTE BODY

INDEX

Page

General Description . . * • •.

•

^"i1

Maintenance and Replacements 1B-1

Front End 1B-1

Adjustments IBri

Hood 1B-1

Hood Catch 1B-2

Hood Assembly . 1B-2

Front Emblems 1B-2

Vent Grilles 1B-2

Instrument Panel Tray . 1B-2

Cowl Area Trim

....................

1B-4

Rear View Mirror 1B-4

Outside 1B-4

Inside . 1B-4

Sun Visor . 1B-4

Cowl Ventilator Assembly 1B-4

Windshield ; 1B-5

Doors 1B-7

Adjustments 1B-7

Door Lock Striker 1B-7

Door Window and Vent 1B-7

Door Hinges 1B-7

Trim Panel and Inside Handles IB-11

Weatherstrip 1B-11

Door Ventilator Assembly 1B-12

19437 Model 1B-12

19467 Model 1B-13

Window Glass 1B-13

Glass Run Channel—Upper 1B-14

Window Outer Seal Assembly 1B-14

Window Inner Seal Assembly 1B-14

Glass Run Channel—Rear 1B-15

Window Regulator—Manual 1B-15

Window Regulator—Power 1B-15

Door Lock and Remote Controls 1B-16

Outer Handle . 1B-16

Lock Cylinder 1B-17

Hinges—Door Assembly . 1B-17

Rear Quarter .. . 1B-19

Door Sill and Molding . . 1B-19

Rear End . . r 1B-19

Folding Top Compartment Lid 1B-19

Adjustments . . 1B-19

1B-19

Page

Lock 1B-19

Control 1B-19

Rear Window—19437 Model 1B-21

Gas Tank Door and Rear Trim Plate.,. . . . . . . . 1B-23

Rear Filler Panel 1B-23

Spare Tire Mount 1B-23

Rugs and Interior Trim 1B-25

Cleaning Soft Trim 1B-25

Carpets and Covers—All Models 1B-26

Rear Body Trim , . 1B-26

Soft Covers 1B-26

Rigid Plastic Trim 1B-26

Garnish Moldings Plus-Headliner-19437 Model . . 1B-27

Seats 1B-27

Body Mounting 1B-27

Body Repairs . 1B-27

General Instructions . . . 1B-27

Repair Panels. 1B-28

Precautions 1B-29

Plastic Solder Kit 1B-29

Resin Kit 1B-30

Specific Repairs 1B-32

Scratched Panels-Spot Refinishing 1B-32

Dents in Panels-Surface Cracks !B-33

Cracked Panels . . 1B-35

Fractures 1B-37

Panel Replacement 1B-39

Hard Top . . 1B-41

Care and Storage 1B-41

Rear Window 1B-41

Garnish Moldings and Latches 1B-42

Headlining 1B-43

Weatherstrips and Drip Molding 1B-43

Vinyl Covering . 1B-43

Folding Top 1B-46

Care of Folding Top 1B-46

Care of Rear Window 1B-46

Adjustments 1B-48

Top Assembly, Removal and Installation 1B-49

Top Trim and Rear Window Assembly 1B-50

Frame and Linkage 1B-52

Weatherstrip 1B-52

Adding Hardtop 1B-52

Special Tools 1B-53

GENERAL DESCRIPTION

.

A

structural network

of

steel forms the backbone

of

the

Corvette body. When combined with

the

fiber-glass

re-

inforced plastic body panels,

the

steel-plastic marriage

results

in a

body with increased torsional rigidity

and

greater beaming strength.

Convertible models continue with two roof styles:

the

folding

top

and the removable hardtop. In operation, both

tops function similar to those

of

previous models. Either

top

is

standard and both

are

optional

as

determined by

the top selected

as

base equipment.

MAINTENANCE

&

REPLACEMENTS

FRONT

END

ADJUSTMENTS

(Refer to Figure

2)

Adjustments should

be

made

in

order

-

hood position

first, then catch adjustments.

Hood

The position

of the

hood

in

relation

to

the hood body

opening and the fender surfaces

is

controlled by the posi-

tion

of the

hinges and position

and

adjustment

of

catch

and bumpers.

The fore

and aft

position

of the

hood may be adjusted

CHEVROLET CHASSIS SERVICE MANUAL

Page 114 of 659

CORVETTE BODY

1B-7

HEAT

CONTROL

€P-

CABLE

VIEW A

HOOD RELEASE

Fig.

11—Cowl Ventilator

and

Controls

and reveal moldings; upper garnish molding; lower

garnish molding; side garnish molding; header latch

plates on 19467 Models and rear view mirror.

11.

Clean

up

excess sealer

and

cement with rag damp-

ened with oleum spirits, prep-sol

or

kerosene;

in-

stall wiper arm assemblies.

DOORS

ADJUSTMENTS

Door Lock Striker

Door lock strikers incorporate

an

inter-lock feature

consisting

of a

notch

in the

striker into which the lock

bolt housing extension engages. With

the

inter-lock

feature

it is

very important that

the

lock extension en-

gages properly

in the

striker notch

and

that, where

necessary,

the

correct striker emergency spacers

are

used to obtain proper engagement.

1.

To

adjust striker

up,

down,

in, or

out loosen striker

plate screws and shift striker and adjusting plates

as

required, then tighten screws.

2.

To determine

if

door lock striker emergency spacers

are required, apply modeling clay

or

body caulking

compound

in the

door lock striker notch where

the

lock extension engages,

and

then close

the

door

to

form

a

measurable impression in the clay

or

caulk-

ing compound,

as

shown

in

Figure

24.

Remove

all

clay

or

compound when adjustment

is

completed.

When dimension

"A"

from inside face

of

striker teeth

to center

of

lock extension

is

less than 3/16", install

emergency spacers

and

proper length striker attaching

screws.

NOTE:

Dimension

"B"

from center

of

lock

extension

to

inside face

of

striker notch should

.

never be less than 1/8".

If check indicates need

for

emergency spacers,

pro-

ceed

as

follows:

1.

With pencil, scribe position

of

striker on body pillar.

2.

Remove three door lock striker attaching screws and

remove striker

and

adjusting plates from pillar.

3.

To

install, place striker, shims and adjusting plates

within scribe marks

on

pillar

and

tighten screws.

IMPORTANT: Whenever

a

door

has

been

re-

moved

and

installed,

or

realigned,

the

door

SHOULD NOT be closed completely until

a

visual

check

is

made to determine

if

the lock extension/

will engage

in the

striker notch. Where

re-

quired, door lock striker emergency spacers

should

be

installed

so

that door

can be

closed

and

an

accurate check made to determine emer-

gency spacer requirements.

Door Window and Vent Adjustment

To move

the top of the

window

in or

out, the bottom

ends

of

both

run

channels

are

adjustable.

The

rear

channel

is

adjusted

by

loosening

the

lower

of

the two

screws

on the

rear face

of

door, "C" Figure 25, and

moving channel

as

necessary.

The

front channel

is ad-

justed

by

removing

the

trim pad and moving the Channel

in

or out by a

stud

and nut

adjustment, "B" Figure 25.

The

top end of the

rear channel

is

not adjustable in

or

out.

On 19467 models

an

adjustment

may be

made

to the

closed-door relationship

of the

vent assembly

to the

windshield frame. This adjustment

is

controlled

by the

stud-nut assembly "B" Figure

25.

The closed position

of the

window

is

controlled

by

bumper assemblies located

at

each end

of

window frame

as shown

in

Figure

26.

^

Access

to

bumper retaining

screw

may be

gained through holes

"D" and

"E"

in

Figure

25.

Door Hinges

The position

of the

door assembly in the body opening

is adjusted

by the

striker plate position covered

pre-

viously

and the

position

of the

door

on

the hinge rear

CHEVROLET

a

SERVICE

Page 118 of 659

CORVETTE BODY 1B-11

CLAYOfc

CAULKING

COMPOUND

Fig. 26-Window Rear Stop - Typical

Fig. 24—Checking Adjustment of Striker

3.

Adjust door as required. Location of hinge retaining

bolts may be seen in Figure 25 at "A". Do not allow

doors to hang on one hinge without support.

4.

Install trim pad and lubricate door "hold opens" and

hinges with Lubriplate or its equivalent.

NOTE:

After performing any door adjustment,

the window and door post should be checked for

alignment and adjusted as necessary. In addi-

tion,

never slam the door after adjustment with-

out first checking the door lock and striker plate

engagement. An adjustment may be necessary.

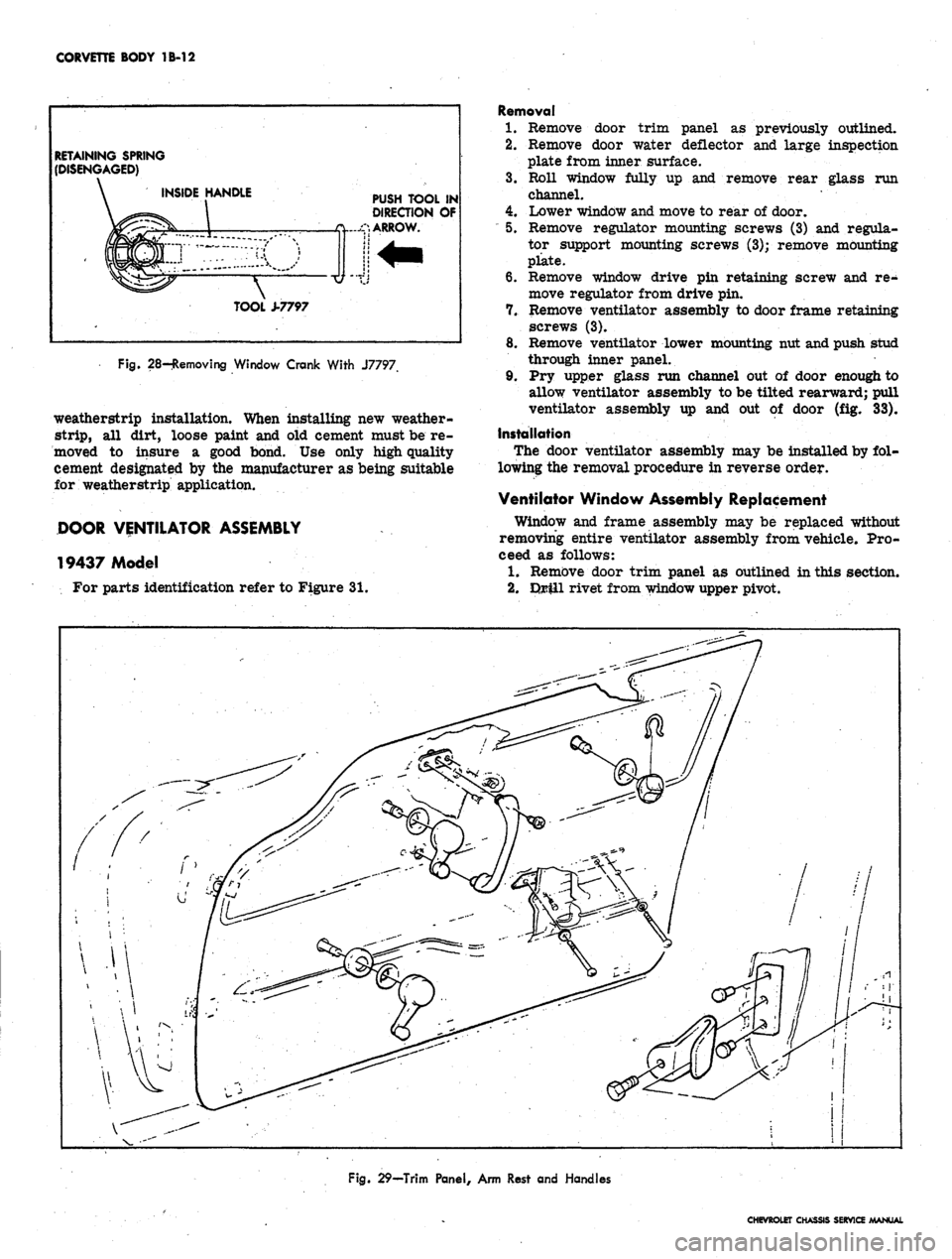

TRIM PANEL, AND INSIDE HANDLES

Figure 29 is an exploded view of integral arm rest,

inside handles, and trim panel fastenings.

Removal of trim panel may be accomplished as

follows:

1.

Remove two screws under arm rest.

2.

Using Tool J-7797, remove clips retaining window

crank and lock remote control as shown in Figure 28.

3.

Remove knob from door lock control by turning

counter-clockwise.

4.

Remove 2 screws retaining inside pull handle.

5. Remove sheet metal screws and special washers

retaining trim panel to door assembly.

6. Pull trim panel out. at bottom, tap bottom edge of

trim panel with hand to disengage from top of door.

Remove trim panel from vehicle.

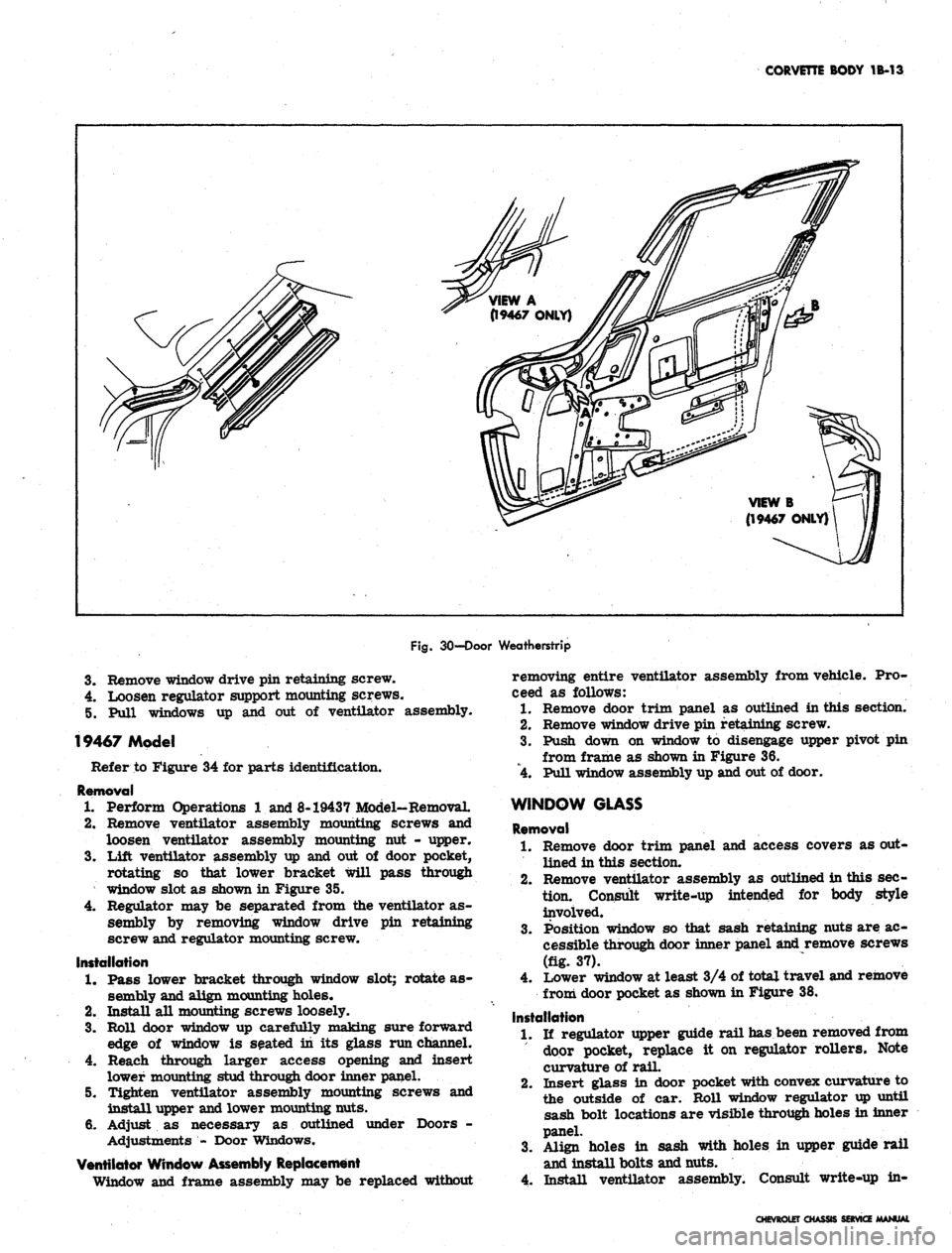

WEATHERSTRIP

Figure

30

illustrates both 19437 and 19467 model door

COWL

Fig.

25-Door Adjustment Points

Fig.

27-Door Hinge

CHEVROLET CHASSIS SERVICE MANUAL

Page 119 of 659

CORVETTE BODY 1B-12

RETAINING SPRING

(DISENGAGED)

INSIDE HANDLE

PUSH TOOL IN

DIRECTION OF

ARROW.

TOOL ±7797

Fig. 28-Removing Window Crank With J7797

weatherstrip installation. When installing new weather-

strip,

all dirt, loose paint and old cement must be re-

moved to insure a good bond. Use only high quality

cement designated by the manufacturer as being suitable

for weatherstrip application.

DOOR VENTILATOR ASSEMBLY

19437 Model

For parts identification refer to Figure 31.

Removal

1.

Remove door trim panel as previously outlined.

2.

Remove door water deflector and large inspection

plate from inner surface.

3.

Roll window fully up and remove rear glass run

channel. •

4.

Lower window and move to rear of door.

"

5. Remove regulator mounting screws (3) and regula-

tor support mounting screws (3); remove mounting

plate.

6. Remove window drive pin retaining screw and re-

move regulator from drive pin.

7. Remove ventilator assembly to door frame retaining

screws (3).

8. Remove ventilator lower mounting nut and push stud

through inner panel.

9. Pry upper glass run channel out of door enough to

allow ventilator assembly to be tilted rearward; pull

ventilator assembly up and out of door (fig. 33).

Installation

The door ventilator assembly may be installed by fol-

lowing the removal procedure in reverse order.

Ventilator Window Assembly Replacement

Window and frame assembly may be replaced without

removing entire ventilator assembly from vehicle. Pro-

ceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Drill rivet from window upper pivot.

Fig. 29—Trim Panel, Arm Rest and Handles

CHEVROLET CHASSIS SERVICE MANUAL

Page 120 of 659

CORVETTE BODY 1B-13

Fig.

30-Door Weatherstrip

3.

Remove window drive pin retaining screw.

4.

Loosen regulator support mounting screws.

5. Pull windows up and out of ventilator assembly.

19467 Model

Refer to Figure 34 for parts identification.

Removal

1.

Perform Operations 1 and 8-19437 Model-Removal.

2.

Remove ventilator assembly mounting screws and

loosen ventilator assembly mounting nut - upper.

3.

Lift ventilator assembly up and out of door pocket,

rotating so that lower bracket will pass through

window slot as shown in Figure 35.

4.

Regulator may be separated from the ventilator as-

sembly by removing window drive pin retaining

screw and regulator mounting screw.

Installation

1.

Pass lower bracket through window slot; rotate as-

sembly and align mounting holes*

2.

Install all mounting screws loosely.

3.

Roll door window up carefully making sure forward

edge of window is seated in its glass run channel.

4.

Reach through larger access opening and insert

lower mounting stud through door inner panel.

5. Tighten ventilator assembly mounting screws and

install upper and lower mounting nuts.

6. Adjust as necessary as outlined under Doors -

Adjustments - Door Windows.

Ventilator Window Assembly Replacement

Window and frame assembly may be replaced without

removing entire ventilator assembly from vehicle. Pro-

ceed as follows:

1.

Remove door trim panel as outlined in this section.

2.

Remove window drive pin retaining screw.

3.

Push down on window to disengage upper pivot pin

from frame as shown in Figure 36.

4.

Pull window assembly up and out of door.

WINDOW GLASS

Removal

1.

Remove door trim panel and access covers as out-

lined in this section.

2.

Remove ventilator assembly as outlined in this sec+

tion.

Consult write-up intended for body style

involved.

Position window so that sash retaining nuts are ac-

cessible through door inner panel and remove screws

(fig. 37).

Lower window at least 3/4 of total travel and remove

3.

4.

from door pocket as shown in Figure 38.

Installation

1.

If regulator upper guide rail has been removed from

door pocket, replace it on regulator rollers. Note

curvature of rail.

2.

Insert glass in door pocket with convex curvature to

the outside of car. Roll window regulator up until

sash bolt locations are visible through holes in inner

panel.

3.

Align holes in sash with holes in upper guide rail

and install bolts and nuts.

4.

Install ventilator assembly. Consult write-up in-

CHEVROLETCH>

SERVICE