window CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 121 of 659

CORVETTE BODY

1B-14

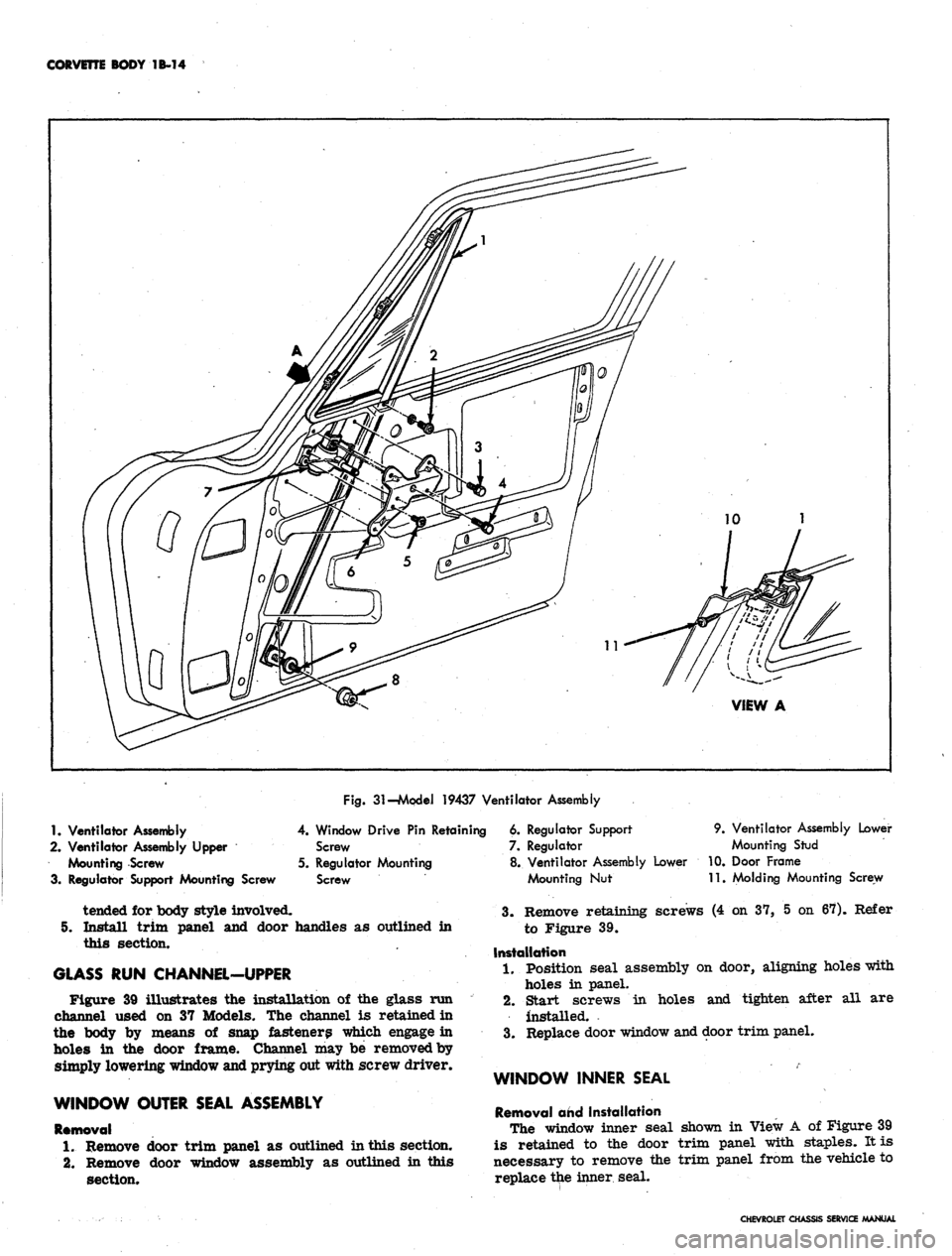

Fig.

31-Mpdei 19437 Ventilator Assembly

1.

Ventilator Assembly

2.

Ventilator Assembly Upper

Mounting Screw

3. Regulator Support Mounting Screw

4.

Window Drive

Pin

Retaining

Screw

5. Regulator Mounting

Screw

tended

for

body style involved.

5. Install trim panel

and

door handles

as

outlined

in

this section.

GLASS

RUN

CHANNEL-UPPER

Figure

39

illustrates

the

installation

of the

glass

run

channel used

on 37

Models.

The

channel

is

retained

in

the body

by

means

of

snap fasteners which engage

in

holes

in the

door frame. Channel

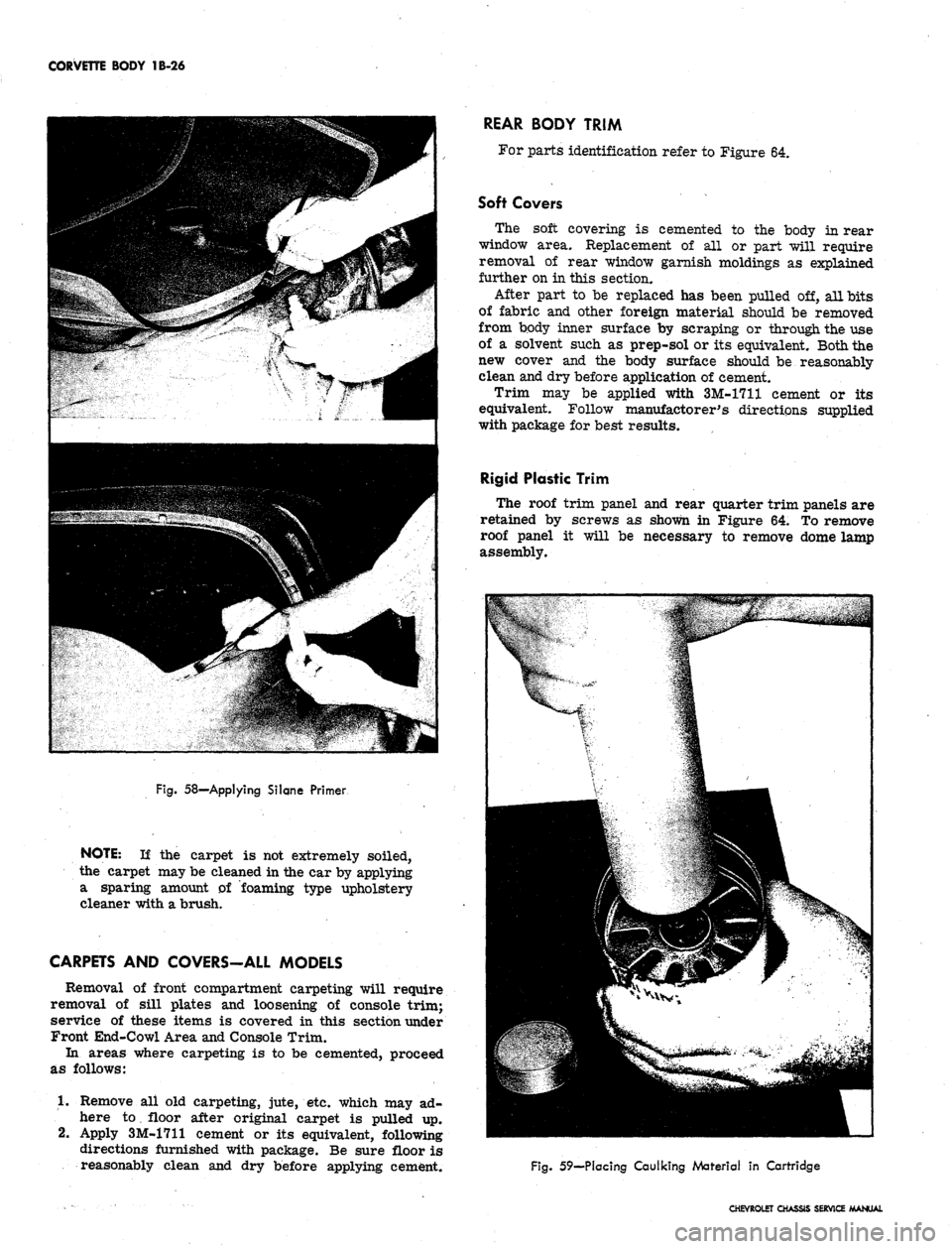

may be

removed by

simply lowering window and prying out with screw driver.

WINDOW OUTER SEAL ASSEMBLY

Removal

1.

Remove door trim panel

as

outlined in this section.

2.

Remove door window assembly

as

outlined

in

this

section.

6. Regulator Support

7. Regulator

8. Ventilator Assembly Lower

Mounting

Nut

9. Ventilator Assembly Lower

Mounting Stud

10.

Door Frame

11.

Molding Mounting Screw

3.

Remove retaining screws (4 on 37, 5 on 67). Refer

to Figure 39.

Installation

1.

Position seal assembly on door, aligning holes with

holes in panel.

2.

Start screws in holes and tighten after all are

installed.

3.

Replace door window and door trim panel.

WINDOW INNER SEAL

Removal and Installation

The window inner seal shown in View A of Figure 39

is retained to the door trim panel with staples. It is

necessary to remove the trim panel from the vehicle to

replace the inner seal.

CHEVROLET CHASSIS SERVICE MANUAL

Page 122 of 659

CORVETTE BODY 1B-15

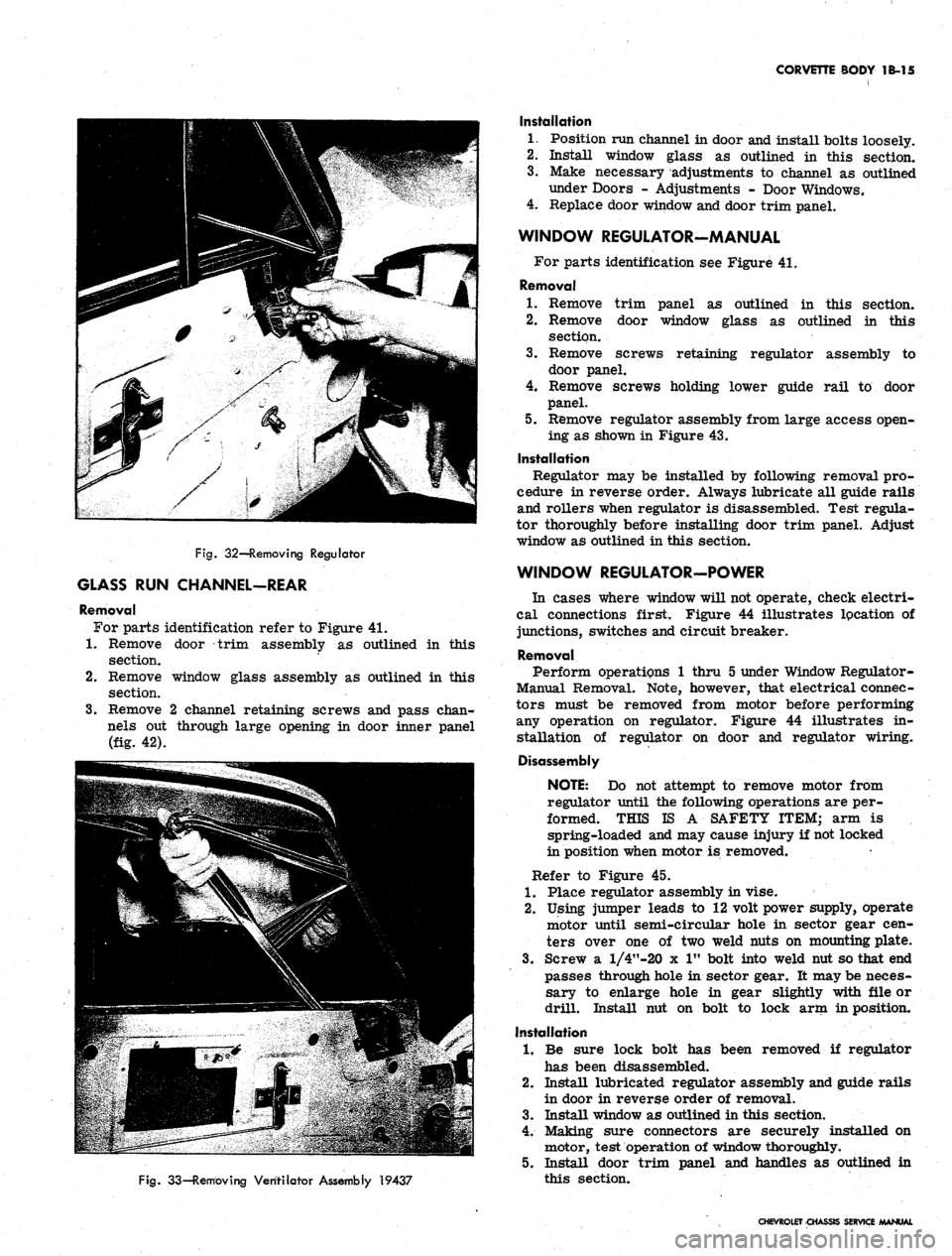

Fig.

32—Removing Regulator

GLASS RUN CHANNEL-REAR

Removal

For parts identification refer to Figure 41.

1.

Remove door trim assembly as outlined in this

section.

2.

Remove window glass assembly as outlined in this

section.

3.

Remove 2 channel retaining screws and pass chan-

nels out through large opening in door inner panel

(fig. 42).

Fig.

33—Removing Ventilator Assembly 19437

Installation

1.

Position run channel in door and install bolts loosely.

2.

Install window glass as outlined in this section.

3.

Make necessary adjustments to channel as outlined

under Doors - Adjustments - Door Windows.

4.

Replace door window and door trim panel.

WINDOW REGULATOR-MANUAL

For parts identification see Figure 41.

Removal

1.

Remove trim panel as outlined in this section.

2.

Remove door window glass as outlined in this

section.

3.

Remove screws retaining regulator assembly to

door panel.

4.

Remove screws holding lower guide rail to door

panel.

5. Remove regulator assembly from large access open-

ing as shown in Figure 43.

Installation

Regulator may be installed by following removal pro-

cedure in reverse order. Always lubricate all guide rails

and rollers when regulator is disassembled. Test regula-

tor thoroughly before installing door trim panel. Adjust

window as outlined in this section.

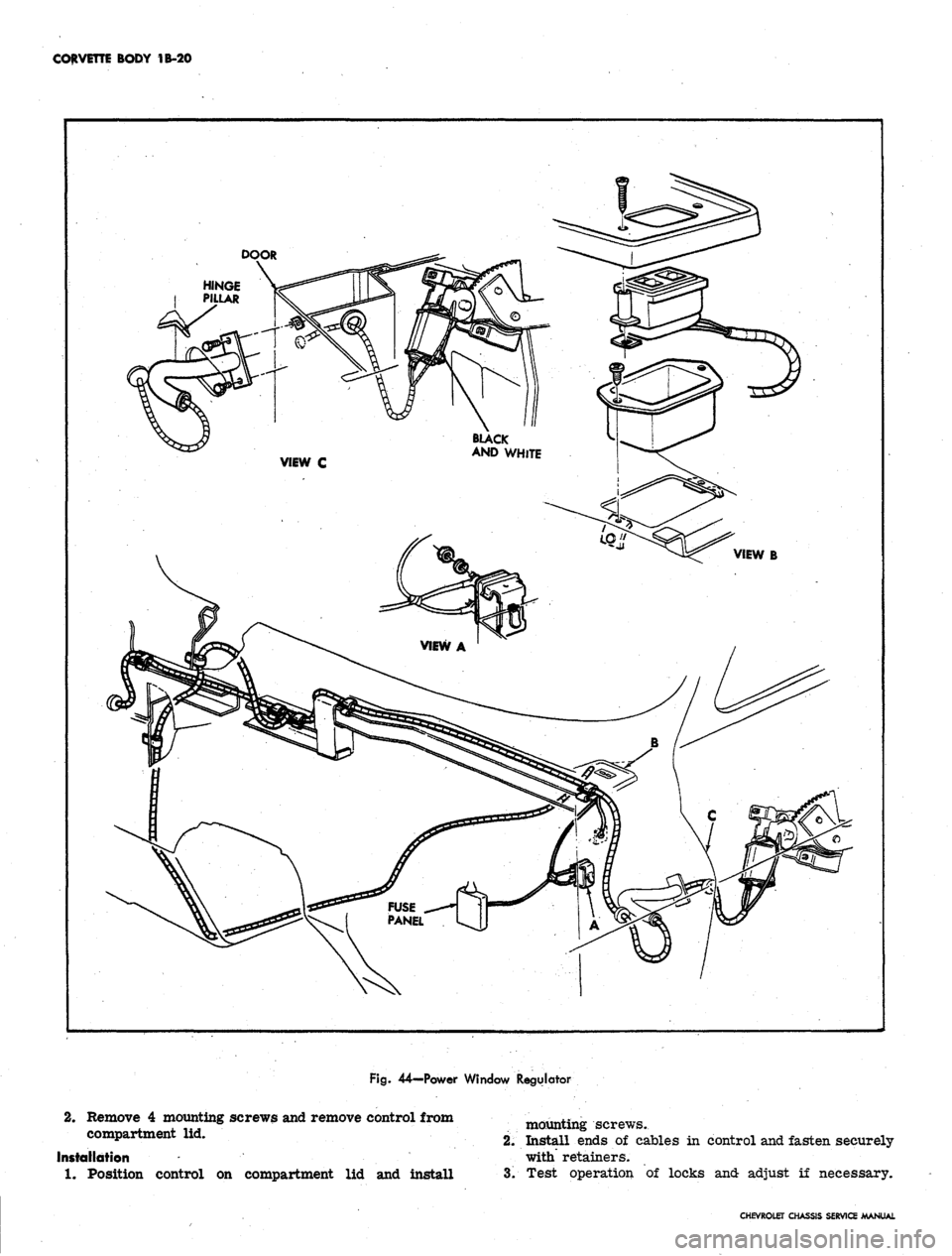

WINDOW REGULATOR-POWER

In cases where window will not operate, check electri-

cal connections first. Figure 44 illustrates lpcation of

junctions, switches and circuit breaker.

Removal

Perform operations 1 thru 5 under Window Regulator-

Manual Removal. Note, however, that electrical connec-

tors must be removed from motor before performing

any operation on regulator. Figure 44 illustrates in-

stallation of regulator on door and regulator wiring.

Disassembly

NOTE:

Do not attempt to remove motor from

regulator until the following operations are per-

formed. THIS IS A SAFETY ITEM; arm is

spring-loaded and may cause injury if not locked

in position when motor is removed.

Refer to Figure 45.

1.

Place regulator assembly in vise.

2.

Using jumper leads to 12 volt power supply, operate

motor until semi-circular hole in sector gear cen-

ters over one of two weld nuts on mounting plate.

3.

Screw a l/4"-20 x 1" bolt into weld nut so that end

passes through hole in sector gear. It may be neces-

sary to enlarge hole in gear slightly with file or

drill. Install nut on bolt to lock arm in position.

Installation

1.

Be sure lock bolt has been removed if regulator

has been disassembled.

2.

Install lubricated regulator assembly and guide rails

in door in reverse order of removal.

3.

Install window as outlined in this section.

4.

Making sure connectors are securely installed on

motor, test operation of window thoroughly.

5. Install door trim panel and handles as outlined in

this section.

CHEVROLET CHASSIS SERVICE MANUAL

Page 123 of 659

CORVETTE

BODY

1B-16

1.

Ventilator Assembly

2.

Ventilator Assembly Mounting

Screw

3.

Window Drive

Pin

Retaining Screw

4.

Regulator Mounting Screw

Fig.

34-Model 19467 Ventilator Assembly

5. Regulator

6. Ventilator Assembly Mounting

Nut - Upper

7. Ventilator Assembly Mounting

Stud - Upper

8. Ventilator Assembly Mounting

Stud - Lower

9. Ventilator Assembly Mounting

Nut -

•

Lower

DOOR LOCK AND REMOTE CONTROLS

For parts identification refer to Figure 46.

Removal

1.

Roll door window fully up.

2.

Remove door trim panel as outlined in this section.

3.

Remove two screws holding door lock remote con-

trol assembly and disengage control from lock re-

mote control rod.

4.

Remove cover from larger access hole in door inner

panel.

5. Remove two screws retaining remote locking control

assembly and disengage control from remote control

locking rod.

6. Remove 4 screws retaining lock assembly, disengage

control rods and remove lock from door pocket.

Installation

To install lock and controls follow removal assembly

in reverse order. All components should be lubricated

before installation.

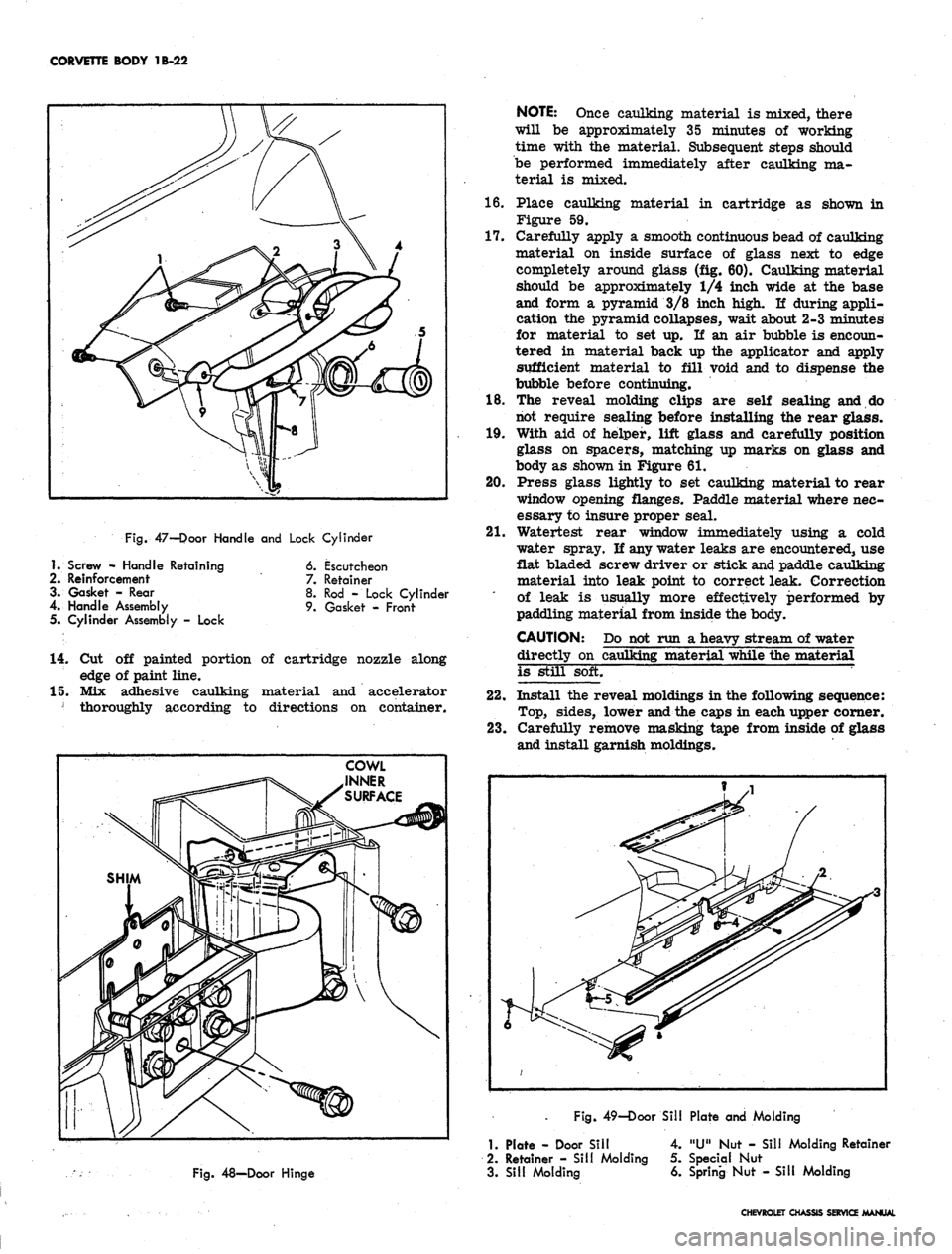

OUTER HANDLE

For parts identification refer to Figure 47.

Removal

1.

Remove door trim panel as outlined in this section.

Remove larger access hole cover.

2.

Roll door window fully up.

3.

Working through access hole, remove 2 door handle

retaining screws.

4.

Remove handle from door outer surface. Retrieve

reinforcement from inside door pocket. Discard old

Installation

1.

Install new gaskets and position door handle on door

outer panel.

2.

Position reinforcement on door inner panel and in-

stall handle retaining screws.

3.

Carefully check operation of door lock.

4.

Install door trim panel as outlined in this section.

CHEVROLET CHASSIS SERVICE MANUAL

Page 124 of 659

CORVETTE BODY 1B-17

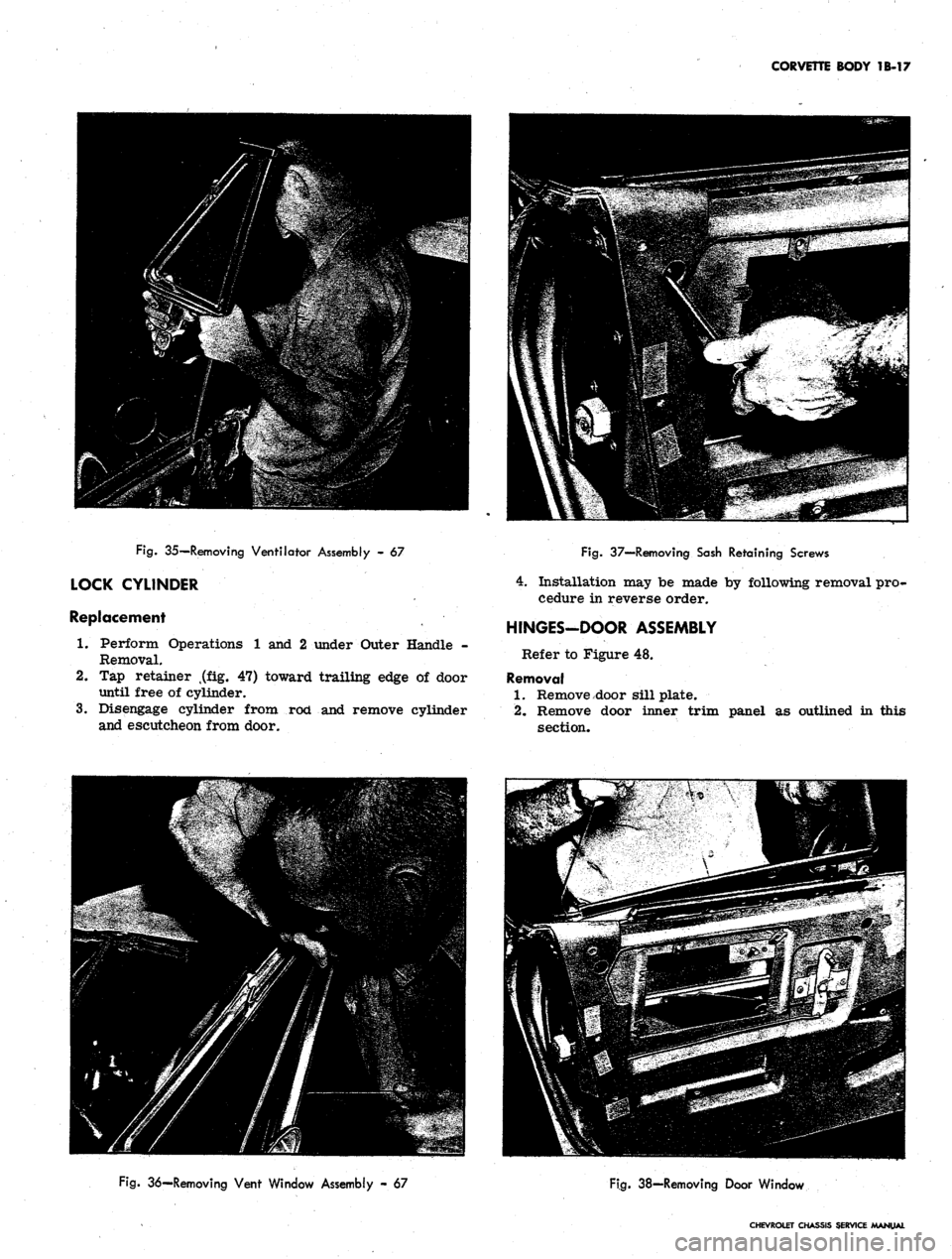

Fig.

35—Removing Ventilator Assembly - 67

LOCK CYLINDER

Replacement

1.

Perform Operations 1 and 2 under Outer Handle -

Removal.

2.

Tap retainer t(flLg. 47) toward trailing edge of door

until free of cylinder.

3.

Disengage cylinder from rod and remove cylinder

and escutcheon from door.

Fig.

37—Removing Sash Retaining Screws

4.

Installation may be made by following removal pro-

cedure in reverse order.

HINGES-DOOR ASSEMBLY

Refer to Figure 48.

Removal

1.

Remove door sill plate.

2.

Remove door inner trim panel as outlined in this

section.

Fig.

36—Removing Vent Window Assembly - 67

Fig.

38-Removing Door Window

CHEVROLET CHASSIS SERVICE /MANUAL

Page 125 of 659

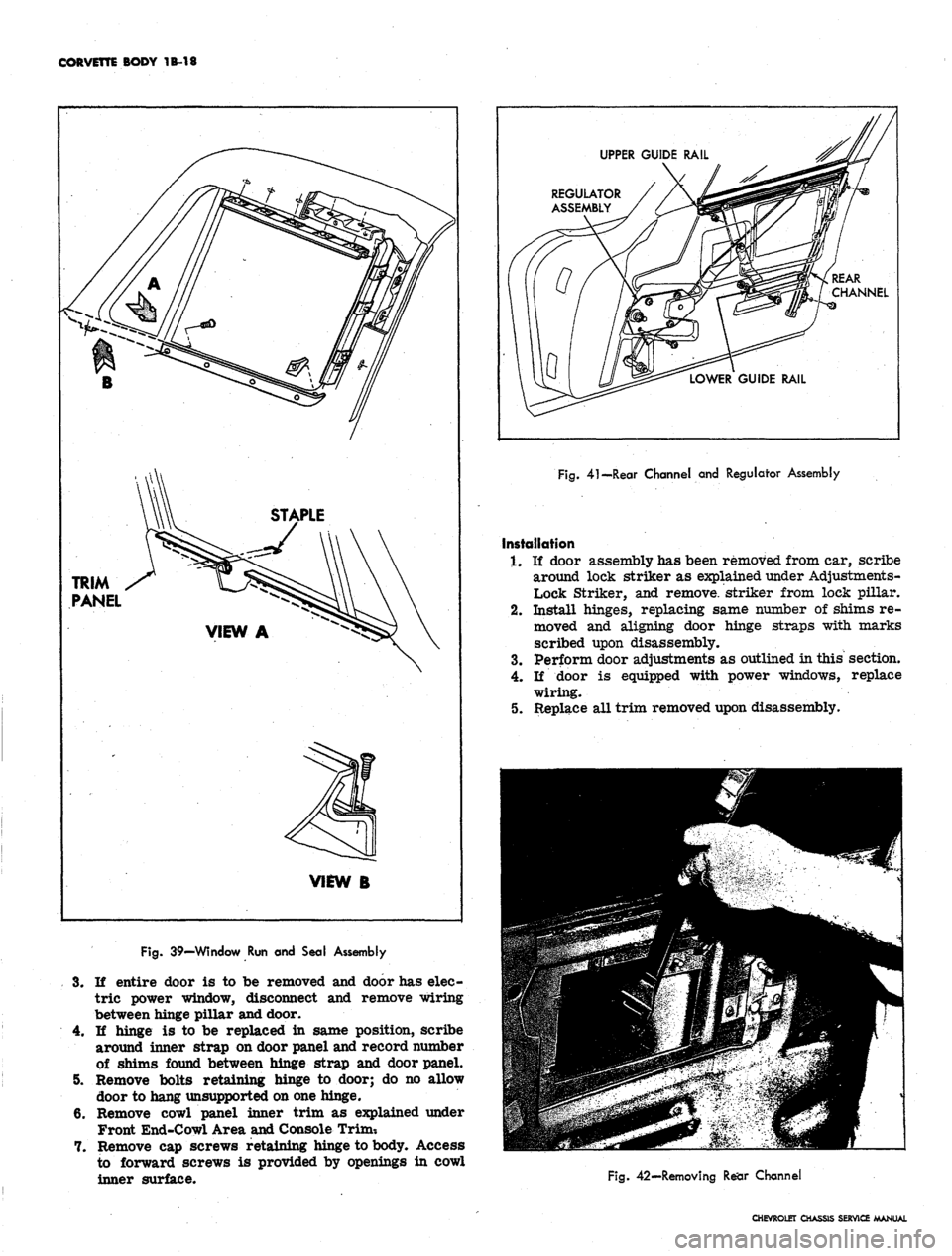

CORVETTE BODY 18-18

TRIM

PANEL

VIEW A

view B

UPPER GUIDE

\

REGULATOR / /

ASSEMBLY / A-

RAIL ,

MS

o Y \ C^^^

Jlf

3) \ JJ

LOWER GUIDE RAIL

y

< REAR

/ CHANNEL

Fig.

41—Rear Channel and Regulator Assembly

Installation

1.

If door assembly has been removed from car, scribe

around lock striker as explained under Adjustments-

Lock Striker, and remove, striker from lock pillar.

2.

Install hinges, replacing same number of shims re-

moved and aligning door hinge straps with marks

scribed upon disassembly.

3.

Perform door adjustments as outlined in this section.

4.

If door is equipped with power windows, replace

wiring.

5.

Replace all trim removed upon disassembly.

Fig.

39—Window Run and Seal Assembly

3.

If entire door is to be removed and door has elec-

tric power window, disconnect and remove wiring

between hinge pillar and door.

4.

If hinge is to be replaced in same position, scribe

around inner strap on door panel and record number

of shims found between hinge strap and door panel.

5. Remove bolts retaining hinge to door; do no allow

door to hang unsupported on one hinge.

6. Remove cowl panel inner trim as explained under

Front End-Cowl Area and Console Trim-.

7. Remove cap screws retaining hinge to body. Access

to forward screws is provided by openings in cowl

inner surface.

Fig.

42—Removing Rear Channel

CHEVROLET CHASSIS SERVICE MANUAL

Page 127 of 659

CORVETTE BODY

1B-20

DOOR

Fig.

44—Power Window Regulator

2.

Remove

4

mounting screws and remove control from

compartment

lid.

Installation

*

1.

Position control

on

compartment

lid and

install

mounting screws.

2.

Install ends of cables in control and fasten securely

with retainers.

3.

Test operation of locks and adjust if necessary.

CHEVROLET CHASSIS SERVICE MANUAL

Page 128 of 659

CORVETTE BODY 1B-21

Fig.

45—

Locking Regulator Arm in Place

REAR WINDOW-ADHESIVE CAULKED-

19437 MODEL

For parts identification refer to Figure 55.

1.

Remove the 2 rear window garnish moldings by re-

moving the 14 attaching screws.

2.

Pry molding caps from reveal moldings.

3.

Carefully remove lower, side, and top reveal mold-

ings after marking their position on body with tape.

4.

Secure one end of steel music wire to piece of wood

for handle. Insert other end through caulking mater-

ial at lower corner of rear window; then secure end

of wire to another piece of wood (fig. 56).

5. With the aid of helper, carefully cut through caulking

material (using a sawing motion) with the steel wire;

up side of window, across top, down opposite side,

and across bottom of window.

6. Remove old glass from window opening.

7. Using a sharp scraper or wood chisel, remove ad-

hesive caulking material from body pinchweld flange.

NOTE:

It is not necessary to clean off all the

old caulking material completely from body

opening; however, there should not be any loose

pieces of caulking material left in the opening.

8. Check all reveal molding retaining clips for damage

(24 required). Replace those that are bent or dis-

torted with clips provided in kit.

9. Using weatherstrip adhesive, cement rubber spacers

at bottom, sides, and top of window opening. The

step-type spacers are used at bottom and sides, the

flat type are used at the top, sides, and bottom of

window opening as shown on Figure 55.

10.

Using suction cup holders, position replacement

glass in body opening. Carefully check relationship

of glass to body pinchweld completely around open-

ing. The overlap of glass to body pinchweld and re-

taining flanges should be equal with a minimum over-

lap of 3/16M. Where necessary, position shims under

the lower spacers to obtain required overlap of glass

to body upper and lower flanges.

11.

After proper glass to pinchweld relationship has

been attained, mark position with grease pencil on

glass and body as shown in Figure 57.

12.

Remove glass from body opening and place on pro-

tected surface.

13.

Clean inside edge surface of glass so that glass is

free of any foreign material (oil, grease, etc.).

Using 3/4" masking tape, place tape approximately

1/2 inch from edge of inside surface of glass com-

pletely around glass. Then apply a film of silane

primer to inside edge surface completely around

glass,

also apply silane primer to sealing surface

of pinchweld as shown in Figure 58.

Fig.

46—Door Lock and Remote Controls

1.

Door Lock Remote Control

Assembly

2.

Door Lock Remote Control Knob

3. Door Lock Remote Control Rod

4.

Remote Control Locking Rod

5. Remote Locking Control

Assembly

6. Lock Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 129 of 659

CORVETTE BODY 1B-22

16.

17.

Fig.

47-Door Handle and Lock Cylinder

18.

19.

20.

21.

1.

Screw - Handle Retaining

2.

Reinforcement

3. Gasket - Rear

4.

Handle Assembly

5. Cylinder Assembly - Lock

6. Escutcheon

7.

Retainer

8. Rod - Lock Cylinder

9. Gasket - Front

14.

Cut off painted portion of cartridge nozzle along

edge of paint line.

15.

Mix adhesive caulking material and accelerator

] thoroughly according to directions on container.

NOTE:

Once caulking material is mixed, there

will be approximately 35 minutes of working

time with the material. Subsequent steps should

be performed immediately after caulking ma-

terial is mixed.

Place caulking material in cartridge as shown in

Figure 59.

Carefully apply a smooth continuous bead of caulking

material on inside surface of glass next to edge

completely around glass (fig. 60). Caulking material

should be approximately 1/4 inch wide at the base

and form a pyramid 3/8 inch high. If during appli-

cation the pyramid collapses, wait about 2-3 minutes

for material to set up. If an air bubble is encoun-

tered in material back up the applicator and apply

sufficient material to fill void and to dispense the

bubble before continuing.

The reveal molding clips are self sealing and do

not require sealing before installing the rear glass.

With aid of helper, lift glass and carefully position

glass on spacers, matching up marks on glass and

body as shown in Figure 61.

Press glass lightly to set caulking material to rear

window opening flanges. Paddle material where nec-

essary to insure proper seal.

Watertest rear window immediately using a cold

water spray. If any water leaks are encountered, use

flat bladed screw driver or stick and paddle caulking

material into leak point to correct leak. Correction

of leak is usually more effectively performed by

paddling material from inside the body.

CAUTION: Do not run a heavy stream of water

directly on caulking material while the material

is still soft.

22.

Install the reveal moldings in the following sequence:

Top,

sides, lower and the caps in each upper corner.

23.

Carefully remove masking tape from inside of glass

and install garnish moldings.

Fig.

49—Door Sill Plate and Molding

Fig.

48—Door Hinge

1.

Plate - Door Sill

2.

Retainer - Sill Molding

3. Sill Molding

4.

"U" Nut - Sill Molding Retainer

5. Special Nut

6. Spring Nut - Sill Molding

CHEVROLET CHASSIS SERVICE MANUAL

Page 132 of 659

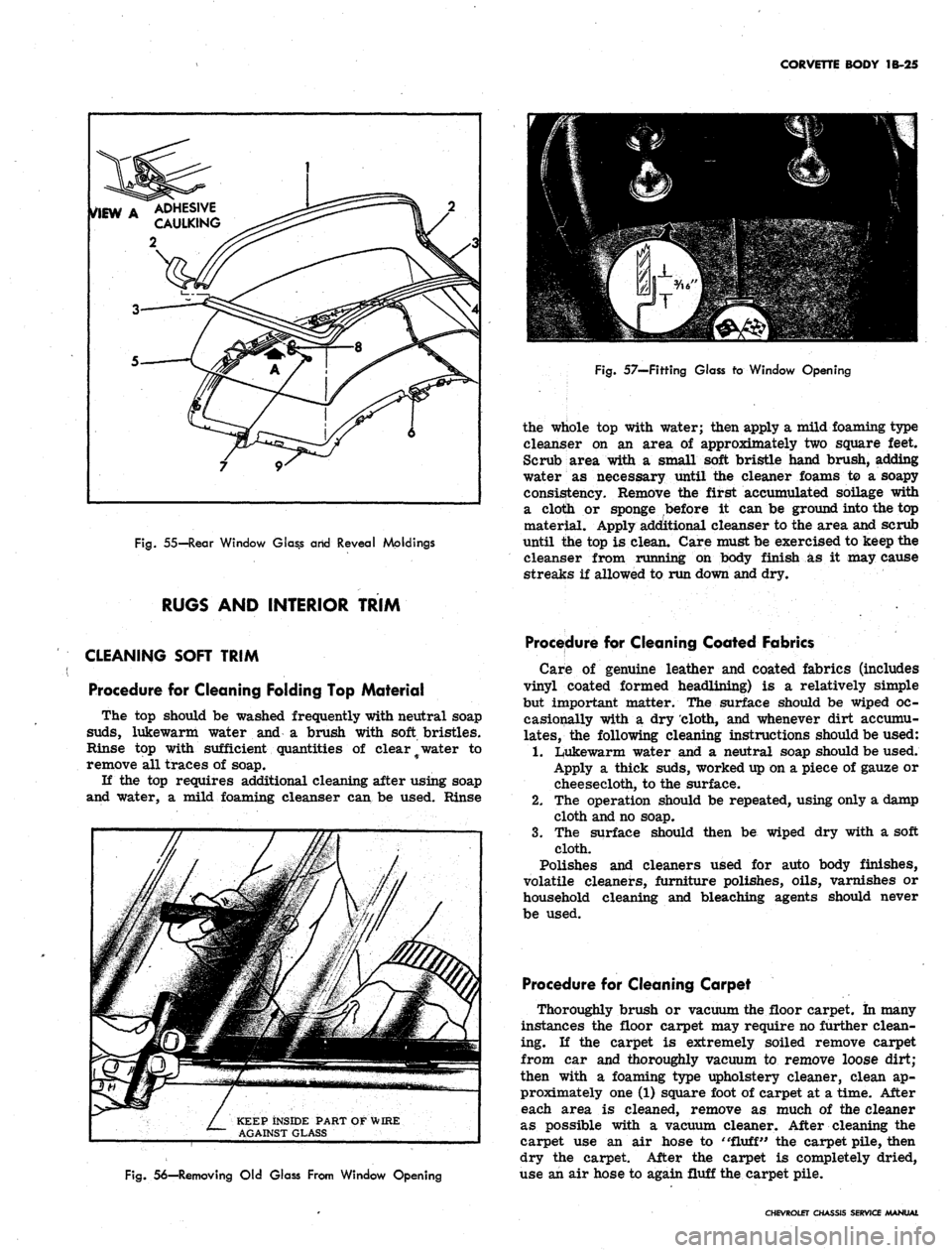

CORVETTE BODY 1B-25

Fig.

55—Rear Window G!as.s arid Reveal Moldings

RUGS AND INTERIOR TRIM

Fig.

57—Fitting Glass to Window Opening

the whole top with water; then apply a mild foaming type

cleanser on an area of approximately two square feet.

Scrub area with a small soft bristle hand brush, adding

water as necessary until the cleaner foams to a soapy

consistency. Remove the first accumulated soilage with

a cloth or sponge before it can be ground into the top

material. Apply additional cleanser to the area and scrub

until the top is clean. Care must be exercised to keep the

cleanser from running on body finish as it may cause

streaks if allowed to run down and dry.

CLEANING SOFT TRIM

Procedure for Cleaning Folding Top Material

The top should be washed frequently with neutral soap

suds,

lukewarm water and a brush with soft bristles.

Rinse top with sufficient quantities of clear # water to

remove all traces of soap.

If the top requires additional cleaning after using soap

and water, a mild foaming cleanser can be used. Rinse

KEEP INSIDE PART OF WIRE

AGAINST GLASS

Fig.

56—Removing Old Glass From Window Opening

Procedure for Cleaning Coated Fabrics

Care of genuine leather and coated fabrics (includes

vinyl coated formed headlining) is a relatively simple

but important matter. The surface should be wiped oc-

casionally with a dry cloth, and whenever dirt accumu-

lates,

the following cleaning instructions should be used:

1.

Lukewarm water and a neutral soap should be used.

Apply a thick suds, worked up on a piece of gauze or

cheesecloth, to the surface.

2.

The operation should be repeated, using only a damp

cloth and no soap.

3.

The surface should then be wiped dry with a soft

cloth.

Polishes and cleaners used for auto body finishes,

volatile cleaners, furniture polishes, oils, varnishes or

household cleaning and bleaching agents should never

be used.

Procedure for Cleaning Carpet

Thoroughly brush or vacuum the floor carpet, in many

instances the floor carpet may require no further clean-

ing. If the carpet is extremely soiled remove carpet

from car and thoroughly vacuum to remove loose dirt;

then with a foaming type upholstery cleaner, clean ap-

proximately one (1) square foot of carpet at a time. After

each area is cleaned, remove as much of the cleaner

as possible with a vacuum cleaner. After cleaning the

carpet use an air hose to

"fluff"

the carpet pile, then

dry the carpet. After the carpet is completely dried,

use an air hose to again fluff the carpet pile.

CHEVROLET CHASSIS SERVICE MANUAL

Page 133 of 659

CORVETTE BODY 1B-26

Fig.

58—-Applying Silqne Primer

NOTE: If the carpet is not extremely soiled,

the carpet may be cleaned in the car by applying

a sparing amount of foaming type upholstery

cleaner with a brush.

CARPETS AND COVERS-ALL MODELS

Removal of front compartment carpeting will require

removal of sill plates and loosening of console trim;

service of these items is covered in this section under

Front End-Cowl Area and Console Trim.

In areas where carpeting is to be cemented, proceed

as follows:

1.

Remove all old carpeting, jute, etc. which may ad-

here to floor after original carpet is pulled up.

2.

Apply 3M-1711 cement or its equivalent, following

directions furnished with package. Be sure floor is

reasonably clean and dry before applying cement.

REAR BODY TRIM

For parts identification refer to Figure 64.

Soft Covers

The soft covering is cemented to the body in rear

window area. Replacement of all or part will require

removal of rear window garnish moldings as explained

further on in this section.

After part to be replaced has been pulled off, all bits

of fabric and other foreign material should be removed

from body inner surface by scraping or through the use

of a solvent such as prep-sol or its equivalent. Both the

new cover and the body surface should be reasonably-

clean and dry before application of cement.

Trim may be applied with 3M-1711 cement or its

equivalent. Follow manufactorer's directions supplied

with package for best results.

Rigid Plastic Trim

The roof trim panel and rear quarter trim panels are

retained by screws as shown in Figure 64. To remove

roof panel it will be necessary to remove dome lamp

assembly.

Fig.

59—Placing Caulking Material In Cartridge

CHEVROLET CHASSIS SERVICE MANUAL