ECU CHEVROLET CAMARO 1967 1.G Chassis Workshop Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 605 of 659

BUMPERS 14-4

tighten any bolts until all bolts have been installed.

Installation

1.

Position bumper bracket and brace on the frame

aligning holes in frame with those in bracket and

brace.

2.

Loosely install bolts, lock washers and nuts. Note

that eight sided adjustment washers (fig. 4) are

placed at the inside surface of each rear frame

channel. Dial washers as required to position

bumper at correct height.

Tighten all mounting bolts securely, connect back-up

lamp and license plate lamp wiring, and lower rear

of vehicle.

GENERAL DESCRIPTION-CHEVY II

The front and rear bumpers are of a one piece design

with the parking and turn signal assemblies attached to

each outboard end of the front bumper.

SERVICE OPERATIONS

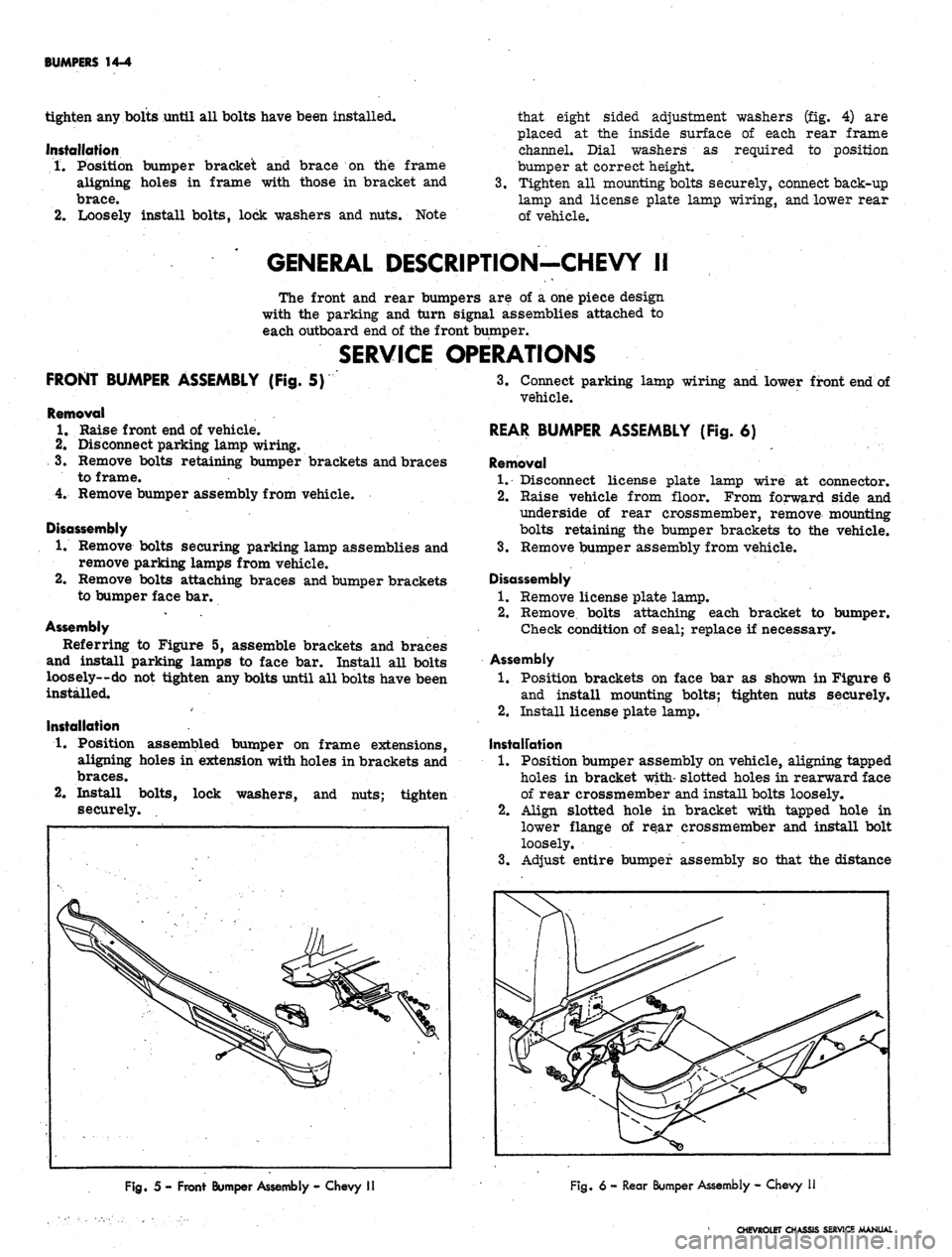

FRONT BUMPER ASSEMBLY (Fig. 5)

Removal

1.

Raise front end of vehicle.

2.

Disconnect parking lamp wiring.

3.

Remove bolts retaining bumper brackets and braces

to frame.

4.

Remove bumper assembly from vehicle.

Disassembly

1.

Remove bolts securing parking lamp assemblies and

remove parking lamps from vehicle.

2.

Remove bolts attaching braces and bumper brackets

to bumper face bar.

Assembly

Referring to Figure 5, assemble brackets and braces

and install parking lamps to face bar. Install all bolts

loosely—do not tighten any bolts until all bolts have been

installed.

Installation

1.

Position assembled bumper on frame extensions,

aligning holes in extension with holes in brackets and

braces.

2.

Install bolts, lock washers, and nuts; tighten

securely.

3.

Connect parking lamp wiring and lower front end of

vehicle.

REAR BUMPER ASSEMBLY (Fig. 6)

Removal

1.

Disconnect license plate lamp wire at connector.

2.

Raise vehicle from floor. From forward side and

underside of rear crossmember, remove mounting

bolts retaining the bumper brackets to the vehicle.

3.

Remove bumper assembly from vehicle.

Disassembly

1.

Remove license plate lamp.

2.

Remove, bolts attaching each bracket to bumper.

Check condition of seal; replace if necessary.

Assembly

1.

Position brackets on face bar as shown in Figure 6

and install mounting bolts; tighten nuts securely.

2.

Install license plate lamp.

Instalfation

1.

Position bumper assembly on vehicle, aligning tapped

holes in bracket with- slotted holes in rearward face

of rear crossmember and install bolts loosely.

2.

Align slotted hole in bracket with tapped hole in

lower flange of rear crossmember and install bolt

loosely.

3.

Adjust entire bumper assembly so that the distance

Fig.

5 - Front Bumper Assembly - Chevy

Fig.

6 - Rear Bumper Assembly - Chevy

CHEVROLET CHASSIS SERVICE MANUAL

Page 608 of 659

BUMPERS 14-7

only and the distance between inner upper brace and

frame filled in with shims. Bolts may then be installed

to secure brace to frame.

REAR LICENSE PLATE HOUSING

The rear license plate housing may be removed from

the vehicle by removing the license plate and removing

the retaining screws as shown in Figure 9.

Fig.

9- Rear License Plate Housing

GENERAL DESCRIPTION-CAMARO

The Camaro front and rear bumpers are of a single

piece wrap around design. The front license plate bracket

functions as a bumper support between the valance panel

and bumper. Holes in the underside of bumpers, slightly

inboard of lower bumper bracket bolt, provide for new

jack load rest stud for jacking purposes.

SERVICE OPERATIONS

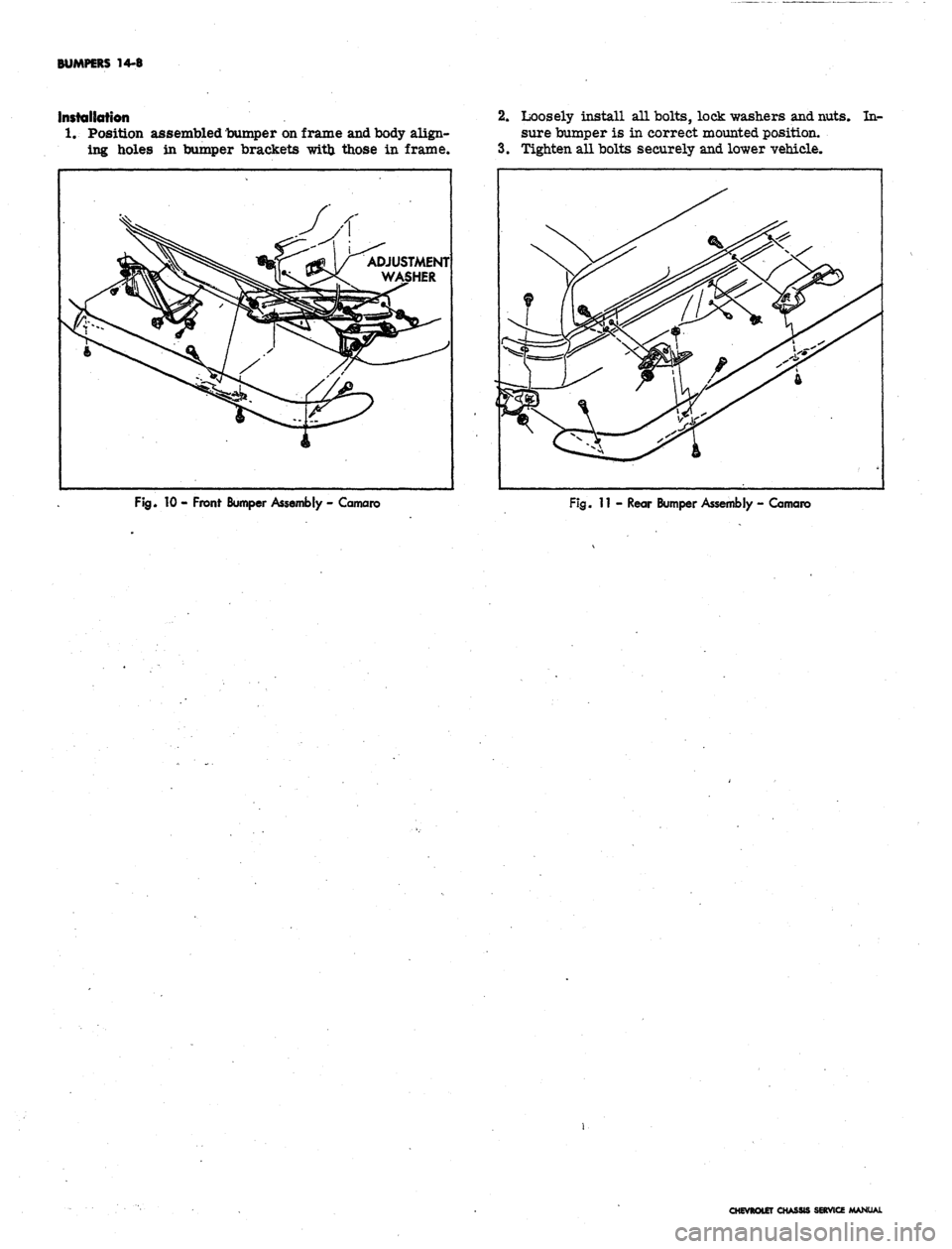

FRONT BUMPER ASSEMBLY (Fig. 10)

Removal

1.

Raise and support front end of vehicle.

2.

Remove bolts securing bumper support brackets to

frame.

3.

Remove bolts, one on each side at fender extension

panels, securing bumper to outer bumper bracket.

4.

Remove screws and nuts securing license plate

bracket to valance panel and remove bumper from

vehicle.

Disassembly

1.

Remove bolts attaching two support brackets to

bumper.

2.

Remove screw and nut securing license plate bracket

to bumper.

Assembly

Assemble the front bumper following the disassembly

procedure in reverse order. Install all bolts loosely; do

not tighten any bolts until all bolts are installed.

Installation

1.

Position assembled bumper on frame horns aligning

holes in bumper brackets with those in frame.

2.

Loosely install bolts, lock washers, and nuts. .Note

3.

the eight sided adjustment washers (fig. 10) are

placed in the tab of each bumper bracket. Dial the

adjustment washers in the tabs as required to posi-

tion the bumper at the correct mounted height.

Tighten all bolts securely and lower vehicle.

REAR BUMPER ASSEMBLY (Fig. 11)

Removal

1.

Raise and support rear end of vehicle.

2.

Remove bolts securing bumper brackets to frame

and rear fenders.

3.

Remove screws securing license plate bracket to

body and remove bumper from vehicle.

Disassembly

1.

Remove bolts securing four support brackets to

bumper.

2.

Remove rivets securing license plate bracket to

bumper.

Assembly

Assemble the rear bumper following the disassembly

procedure in reverse order. Install all bolts loosely; do

not tighten any bolts until all bolts are installed.

CHEVROLET CHASSIS SERVICE MANUAL

Page 609 of 659

BUMPERS 14-8

Ifistaliotion

1.

Position assembled bumper on frame and body align-

ing holes in bumper brackets with those in frame.

2.

Loosely install all bolts, lock washers and nuts. In-

sure bumper is in correct mounted position.

3.

Tighten all bolts securely and lower vehicle.

Fig.

10 - Front Bumper Assembly - Camaro

Fig.

11 - Rear Bumper Assembly - Camaro

CHEVROLET CHASSIS SERVICE MANUAL

Page 622 of 659

ACCESSORIES 15-13

SYSTEM TEST

CHECKS AND ADJUSTMENTS

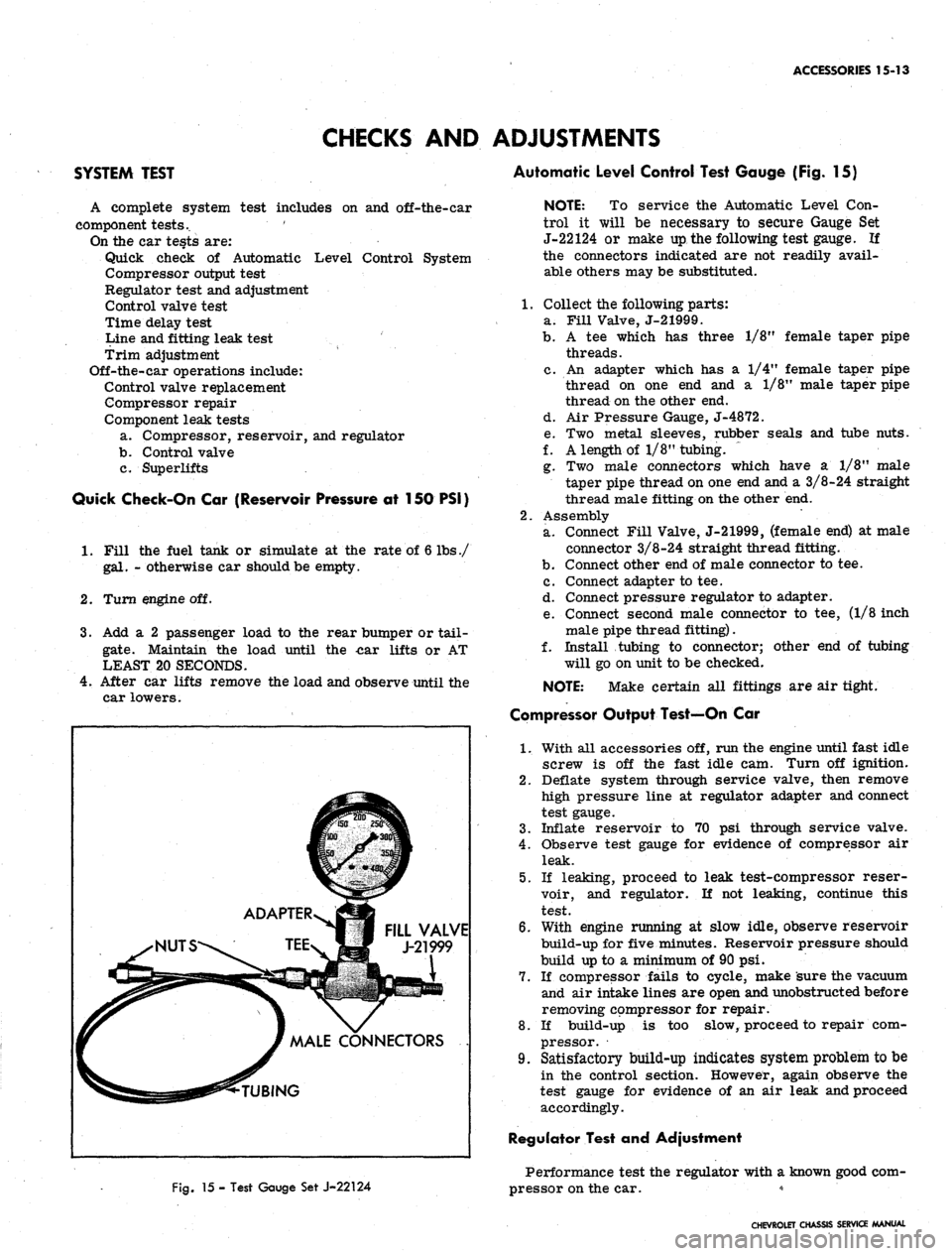

Automatic Level Control Test Gauge (Fig. 15)

A complete system test includes on and off-the-car

component tests.. '

On the car tests are:

Quick check of Automatic Level Control System

Compressor output test

Regulator test and adjustment

Control valve test

Time delay test

Line and fitting leak test

Trim adjustment

Off-the-car operations include:

Control valve replacement

Compressor repair

Component leak tests

a. Compressor, reservoir, and regulator

b.

Control valve

c. Superlifts

Quick Check-On Car (Reservoir Pressure at 150 PSI)

1.

Fill the fuel tank or simulate at the rate of 6 lbs./

gal.

- otherwise car should be empty.

2.

Turn engine off.

3.

Add a 2 passenger load to the rear bumper or tail-

gate.

Maintain the load until the -car lifts or AT

LEAST 20 SECONDS.

4.

After car lifts remove the load and observe until the

car lowers.

FILL VALVE

J-21999

CONNECTORS

Fig.

15 - Test Gauge Set J-22124

NOTE: To service the Automatic Level Con-

trol it will be necessary to secure Gauge Set

J-22124 or make up the following test gauge. If

the connectors indicated are not readily avail-

able others may be substituted.

1.

Collect the following parts:

a. Fill Valve, J-21999.

b.

A tee which has three 1/8M female taper pipe

threads.

c. An adapter which has a 1/4" female taper pipe

thread on one end and a 1/8" male taper pipe

thread on the other end.

d. Air Pressure Gauge, J-4872.

e. Two metal sleeves, rubber seals and tube nuts.

f. A length of 1/8" tubing. ~

g. Two male connectors which have a 1/8" male

taper pipe thread on one end and a 3/8-24 straight

thread male fitting on the other end.

2.

Assembly

a. Connect Fill Valve, J-21999, (female end) at male

connector 3/8-24 straight thread fitting.

b.

Connect other end of male connector to tee.

c. Connect adapter to tee.

d. Connect pressure regulator to adapter.

e. Connect second male connector to tee, (1/8 inch

male pipe thread fitting).

f. Install tubing to connector; other end of tubing

will go on unit to be checked.

NOTE:

Make certain all fittings are air tight.

Compressor Output Test—On Car

1.

With all accessories off, run the engine until fast idle

screw is off the fast idle cam. Turn off ignition.

2.

Deflate system through service valve, then remove

high pressure line at regulator adapter and connect

test gauge.

3.

Inflate reservoir to 70 psi through service valve.

4.

Observe test gauge for evidence of compressor air

leak.

5.

If leaking, proceed to leak test-compressor reser-

voir, and regulator. If not leaking, continue this

test.

6. With engine running at slow idle, observe reservoir

build-up for five minutes. Reservoir pressure should

build up to a minimum of 90 psi.

7.

If compressor fails to cycle, make sure the vacuum

and air intake lines are open and unobstructed before

removing compressor for repair.

8. If build-up is too slow, proceed to repair com-

pressor.

9. Satisfactory build-up indicates system problem to be

in the control section. However, again observe the

test gauge for evidence of an air leak and proceed

accordingly.

Regulator Test and Adjustment

Performance test the regulator with a known good com-

pressor on the car. *

CHEVROLET CHASSIS SERVICE MANUAL

Page 624 of 659

ACCESSORIES 15-15

Control Valve

1.

Remove control valve unit from car.

2.

Clean exterior of control valve thoroughly.

3.

Connect test gauge and air pressure source to intake

adapter and open air pressure (80-110 psi).

4.

Submerge unit in water. No air should escape if

overtravel lever is in "neutral" position. If bubbles

escape from Superlift port, replace control valve.

5. Shut, off air pressure and detach test gauge from air

intake port. Plug intake port with Fill Valve,

J-21999 (female end).

6. Connect test gauge to Superlift port and open air

pressure.

7. With overtravel lever in "neutral" position no air

should escape. If bubbles escape from exhaust port,

replace control valve.

8. If air escapes around edge of cover plate, tighten

screws on replace gasket.

9. R(emove control valve from water. Actuate over-

travel lever to expel any water from unit.

10.

Sjiut off air pressure and remove line from Superlift

[

Lines and Fittings

1.

Eisconnect overtravel lever from link.

2.

Bold lever up in intake position for maximum Super-

lift inflation and release.

3.

iieak check all connections with a soap and water

splution.

[.

Superlifts

1.

disconnect lines and remove unit from car.

2.

ijiflate individually to 50-60 psi utilizing Fill Valves

jt-21999. Submerge in water and observe unit for

leaks.

3.

Install Superlifts.

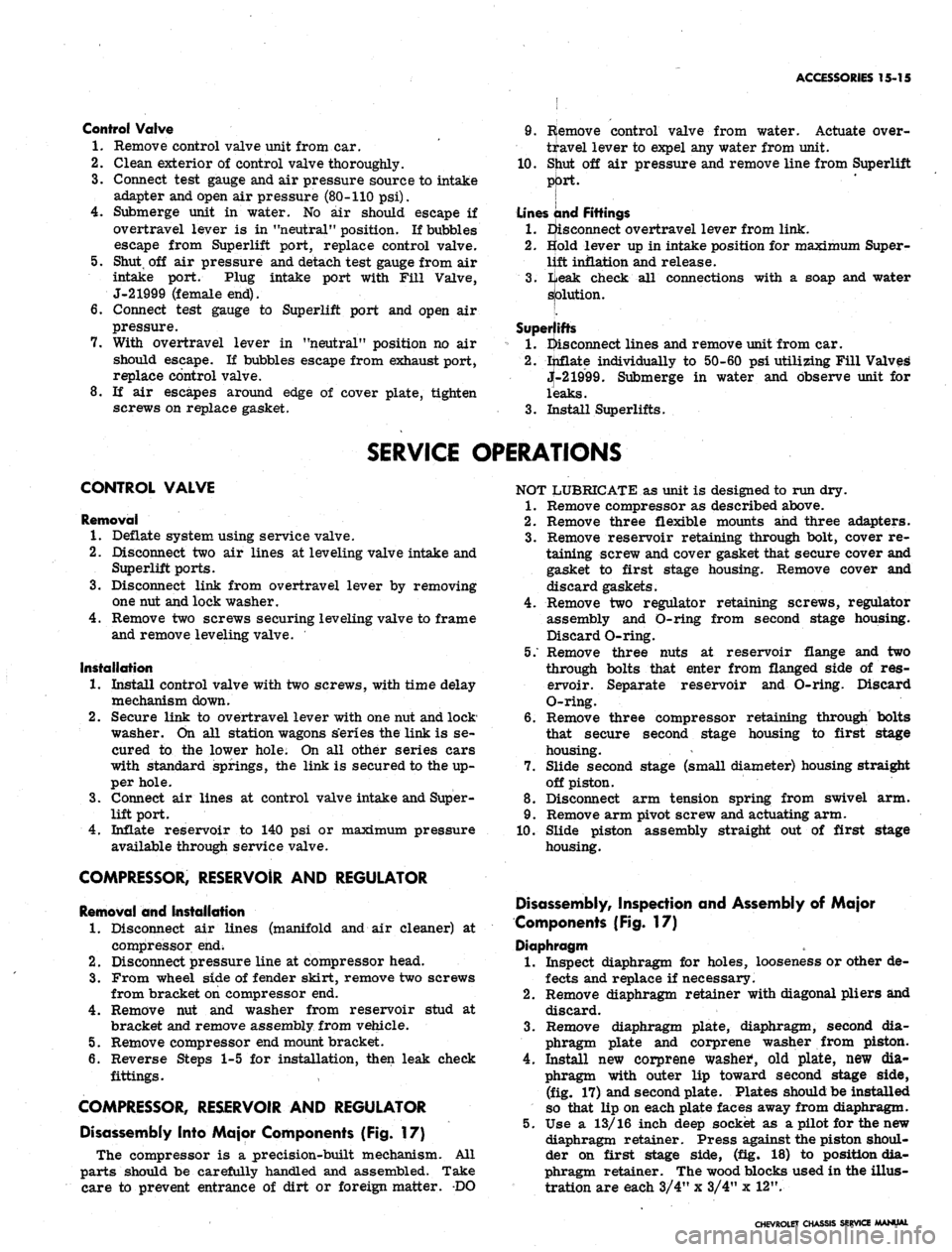

SERVICE OPERATIONS

CONTROL VALVE

Removal

1.

Deflate system using service valve.

2.

Disconnect two air lines at leveling valve intake and

Superlift ports.

3.

Disconnect link from overtravel lever by removing

one nut and lock washer.

4.

Remove two screws securing leveling valve to frame

and remove leveling valve.

Installation

1.

Install control valve with two screws, with time delay

mechanism down.

2.

Secure link to overtravel lever with one nut and lock

washer. On all station wagons s'eries the link is se-

cured to the lower hole. On all other series cars

with standard springs, the link is secured to the up-

per hole.

3.

Connect air lines at control valve intake and Super-

lift port.

4.

Inflate reservoir to 140 psi or maximum pressure

available through service valve.

COMPRESSOR, RESERVOIR AND REGULATOR

Removal and Installation

1.

Disconnect air lines (manifold and air cleaner) at

compressor end;

2.

Disconnect pressure line at compressor head.

3.

From wheel side of fender skirt, remove two screws

from bracket on compressor end.

4.

Remove nut and washer from reservoir stud at

bracket and remove assembly from vehicle.

5. Remove compressor end mount bracket.

6. Reverse Steps 1-5 for installation, then leak check

fittings.

COMPRESSOR, RESERVOIR AND REGULATOR

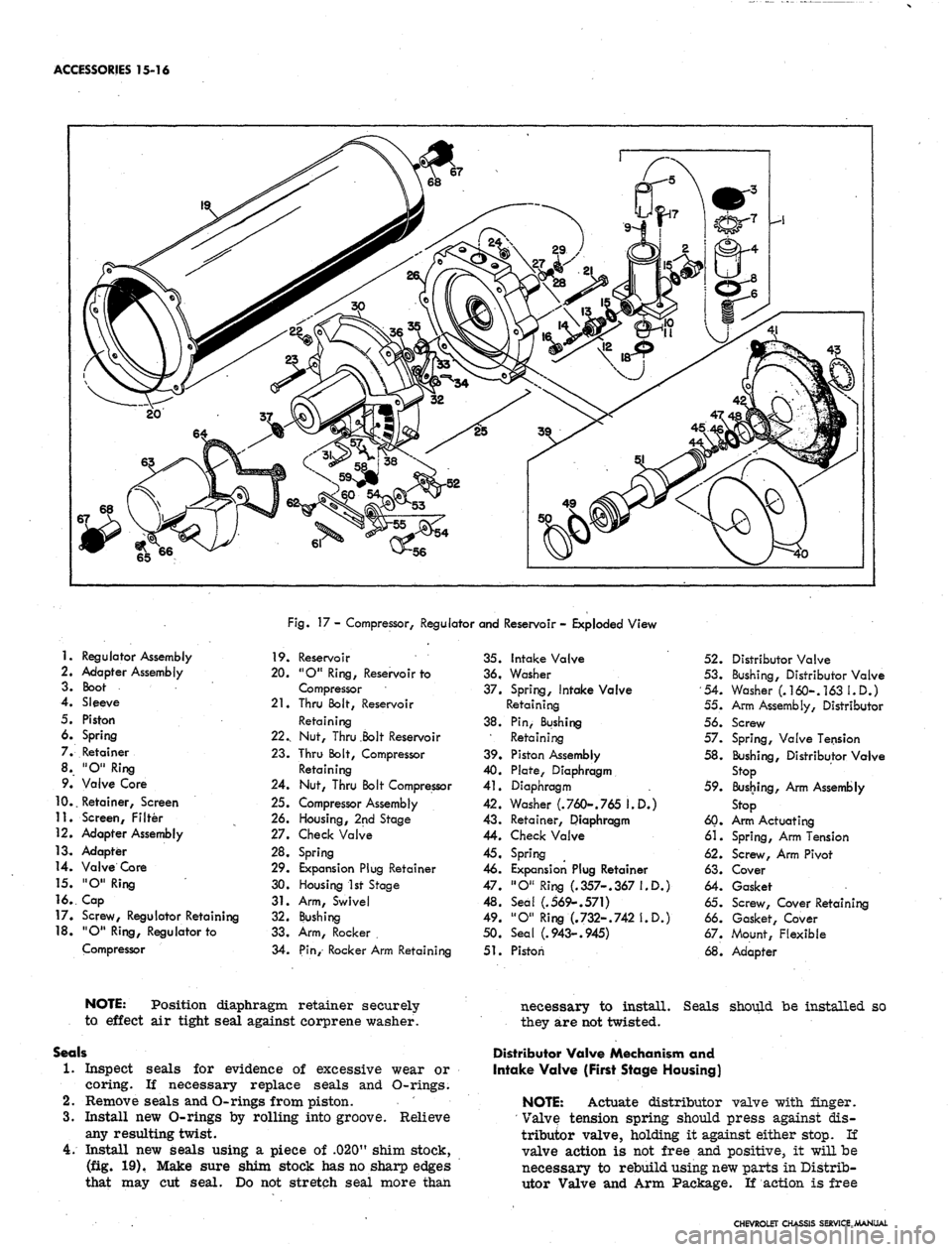

Disassembly Into Major Components (Fig. 17)

The compressor is a precision-built mechanism. All

parts should be carefully handled and assembled. Take

care to prevent entrance of dirt or foreign matter. DO

NOT LUBRICATE as unit is designed to run dry.

1.

Remove compressor as described above.

2.

Remove three flexible mounts and three adapters.

3.

Remove reservoir retaining through bolt, cover re-

taining screw and cover gasket that secure cover and

gasket to first stage housing. Remove cover and

discard gaskets.

4.

Remove two regulator retaining screws, regulator

assembly and O-ring from second stage housing.

Discard O-ring.

5/ Remove three nuts at reservoir flange and two

through bolts that enter from flanged side of res-

ervoir. Separate reservoir and O-ring. Discard

O-ring.

6. Remove three compressor retaining through bolts

that secure second stage housing to first stage

housing.

7. Slide second stage (small diameter) housing straight

off piston.

8. Disconnect arm tension spring from swivel arm.

9. Remove arm pivot screw and actuating arm.

10.

Slide piston assembly straight out of first stage

housing.

Disassembly, Inspection and Assembly of Major

Components (Fig. 17)

Diaphragm

1.

Inspect diaphragm for holes, looseness or other de-

fects and replace if necessary.

2.

Remove diaphragm retainer with diagonal pliers and

discard.

3.

Remove diaphragm plate, diaphragm, second dia-

phragm plate and corprene washer from piston.

4.

Install new corprene washed, old plate, new dia-

phragm with outer lip toward second stage side,

(fig. 17) and second plate. Plates should be installed

so that lip on each plate faces away from diaphragm.

5. Use a 13/16 inch deep socket as a pilot for the new

diaphragm retainer. Press against the piston shoul-

der on first stage side, (fig. 18) to position dia-

phragm retainer. The wood blocks used in the illus-

tration are each 3/4" x 3/4" x 12".

CHEVROLET CHASSIS SERVICE MANUAL

Page 625 of 659

ACCESSORIES 15-16

Fig.

17 - Compressor, Regulator and Reservoir - Exploded View

1.

Regulator Assembly

2.

Adapter Assembly

3. Boot

4.

Sleeve

5. Piston

6. Spring

7. Retainer

8. "O" Ring

9. Valve Core

10..

Retainer, Screen

11.

Screen, Filter

12.

Adapter Assembly

13.

Adapter

14.

Valve Core

15.

"O" Ring

16..

Cap

17.

Screw, Regulator Retaining

18.

"O" Ring, Regulator to

Compressor

19.

Reservoir

20.

"O" Ring, Reservoir to

Compressor

21.

Thru Bolt, Reservoir

Retaining

22.,

Nut, Thru .Bolt Reservoir

23.

Thru Bolt, Compressor

Retaining

24.

Nut, Thru Bolt Compressor

25.

Compressor Assembly

26.

Housing, 2nd Stage

27.

Check Valve

28.

Spring

29.

Expansion Plug Retainer

30.

Housing 1st Stage

31.

Arm, Swivel

32.

Bushing

33.

Arm, Rocker .

34.

Pin, Rocker Arm Retaining

35.

Intake Valve

36,

Washer

37.

Spring, Intake Valve

Retaining

38.

Pin, Bushing

Retaining

39.

Piston Assembly

40.

Plate, Diaphragm

41.

Diaphragm

42.

Washer (.760-.765 I.D.)

43.

Retainer, Diaphragm

44.

Check Valve

45.

Spring

46.

Expansion Plug Retainer

47.

"O" Ring (.357-.367 I.D.)

48.

Seal (.569-.571)

49.

"O" Ring (.732-.742 I.D.)

50.

Seal (.943-.945)

51.

Piston

52.

Distributor Valve

53.

Bushing, Distributor Valve

54.

Washer (.160-. 163 I.D.)

55. Arm Assembly, Distributor

56. Screw

57. Spring, Valve Tension

58.

Bushing, Distributor Valve

Stop

59. Bussing, Arm Assembly

Stop

60.

Arm Actuating

61.

Spring, Arm Tension

62.

Screw, Arm Pivot

63.

Cover

64.

Gasket

65. Screw, Cover Retaining

66. Gasket, Cover

67. Mount, Flexible

68.

Adapter

NOTE: Position diaphragm retainer securely

to effect air tight seal against corprene washer.

Seals

1.

Inspect seals for evidence of excessive wear or

coring. If necessary replace seals and O-rings.

2.

Remove seals and O-rings from piston.

3.

Install new O-rings by rolling into groove. Relieve

any resulting twist.

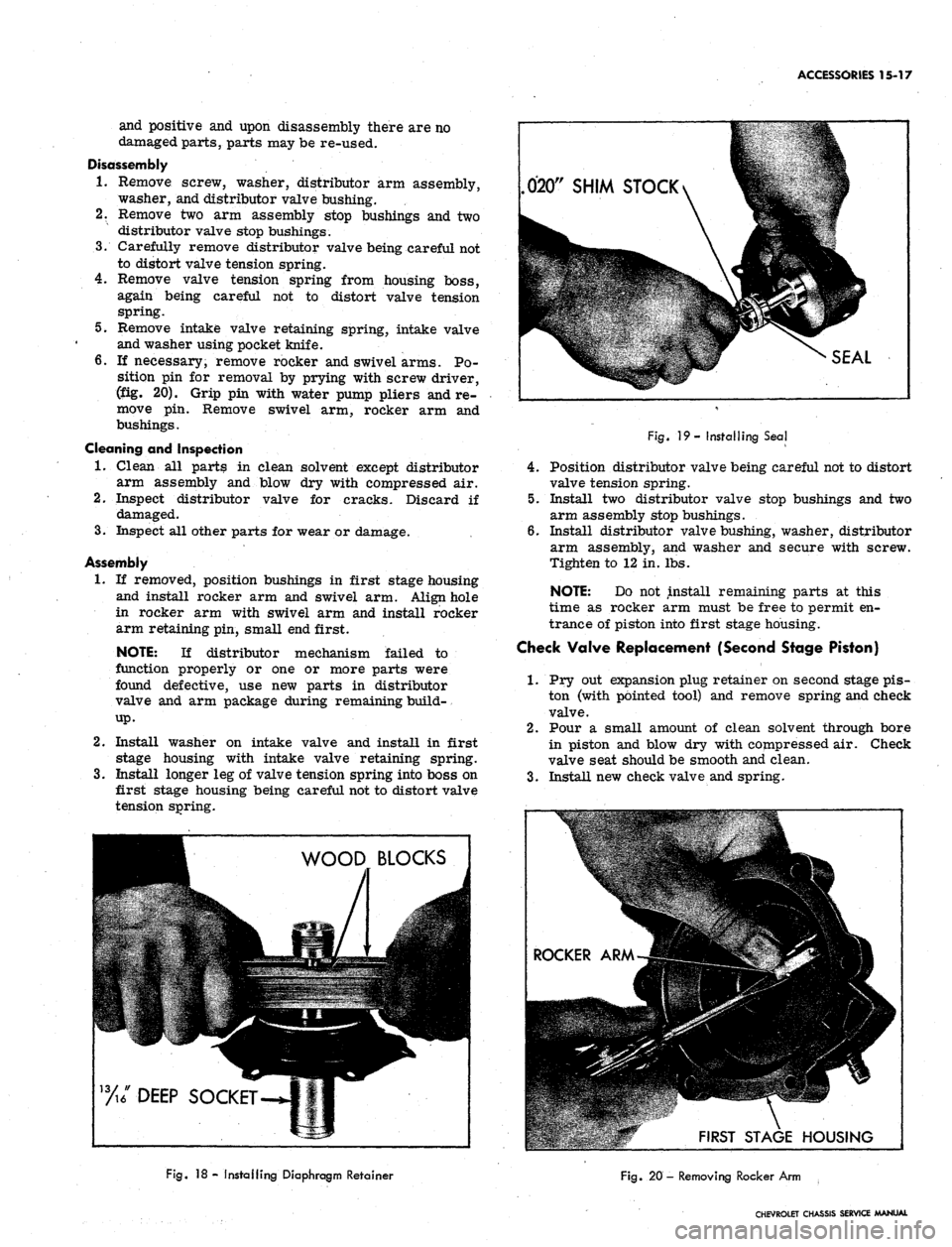

4.

Install new seals using a piece of .020" shim stock,

(fig. 19). Make sure shim stock has no sharp edges

that may cut seal. Do not stretch seal more than

necessary to install. Seals should be installed so

they are not twisted.

Distributor Valve Mechanism and

Intake Valve (First Stage Housing)

NOTE: Actuate distributor valve with finger.

' Valve tension spring should press against dis-

tributor valve, holding it against either stop. If

valve action is not free and positive, it will be

necessary to rebuild using new parts in Distrib-

utor Valve and Arm Package. If action is free

CHEVROLET CHASSIS SERVICE MANUAL

Page 626 of 659

ACCESSORIES 15-17

and positive and upon disassembly there are no

damaged parts, parts may be re-used.

Disassembly

1.

Remove screw, washer, distributor arm assembly,

washer, and distributor valve bushing.

2.

Remove two arm assembly stop bushings and two

distributor valve stop bushings.

3.

Carefully remove distributor valve being careful not

to distort valve tension spring.

4.

Remove valve tension spring from housing boss,

again being careful not to distort valve tension

spring.

5.

Remove intake valve retaining spring, intake valve

and washer using pocket knife.

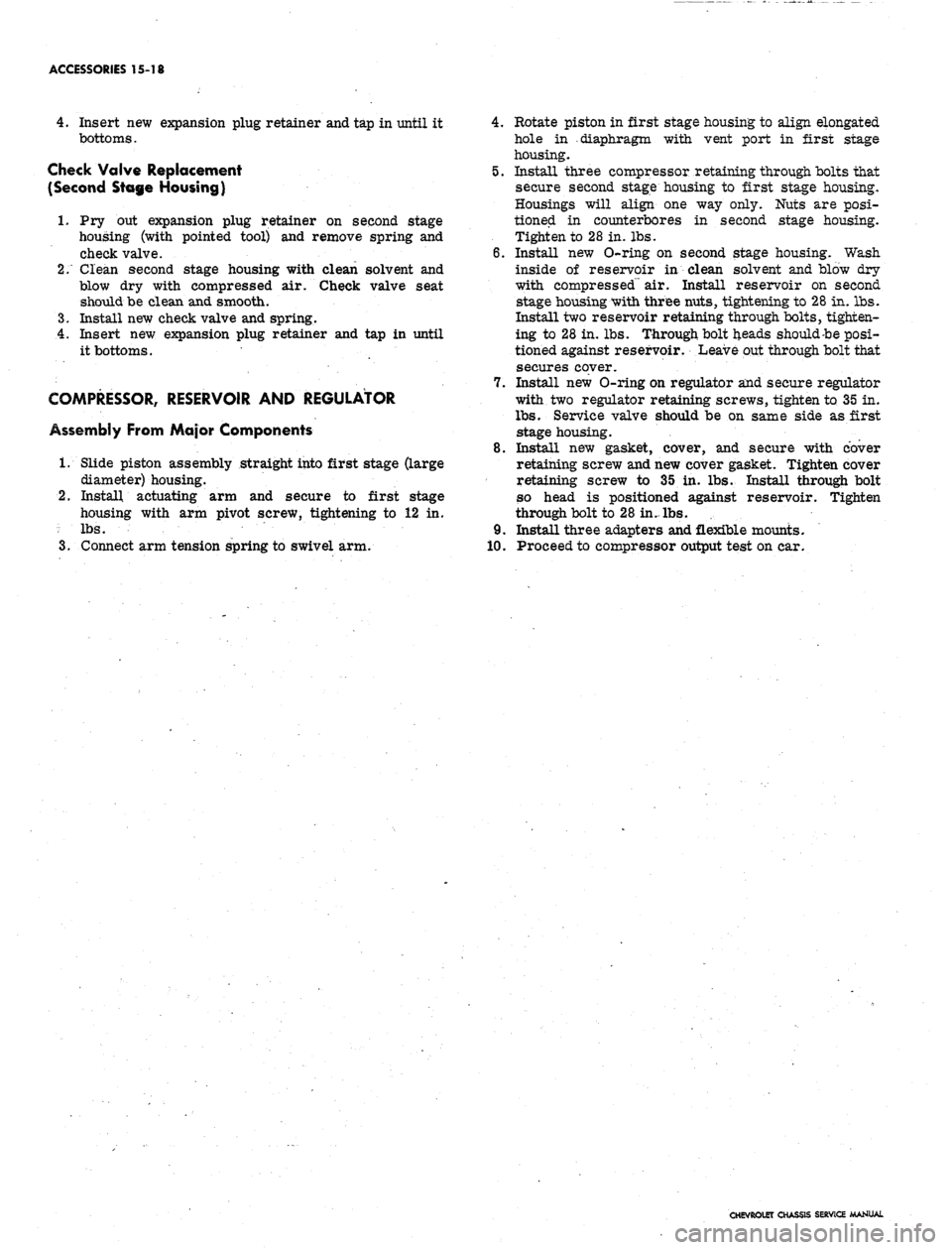

6. If necessary, remove rocker and swivel arms. Po-

sition pin for removal by prying with screw driver,

(fig. 20). Grip pin with water pump pliers and re-

move pin. Remove swivel arm, rocker arm and

bushings.

Cleaning and Inspection

1.

Clean all parts in clean solvent except distributor

arm assembly and blow dry with compressed air.

2.

Inspect distributor valve for cracks. Discard if

damaged.

3.

Inspect all other parts for wear or damage.

Assembly

1.

If removed, position bushings in first stage housing

and install rocker arm and swivel arm. Align hole

in rocker arm with swivel arm and install rocker

arm retaining pin, small end first.

NOTE: If distributor mechanism failed to

function properly or one or more parts were

found defective, use new parts in distributor

valve and arm package during remaining build-

up.

2.

Install washer on intake valve and install in first

stage housing with intake valve retaining spring.

3.

Install longer leg of valve tension spring into boss on

first stage housing being careful not to distort valve

tension spring.

020"

SHIM STOCK

SEAL

Fig.

19- Installing Seal

4.

Position distributor valve being careful not to distort

valve tension spring.

5.

Install two distributor valve stop bushings and two

arm assembly stop bushings.

6. Install distributor valve bushing, washer, distributor

arm assembly, and washer and secure with screw.

Tighten to 12 in. lbs.

NOTE: Do not install remaining parts at this

time as rocker arm must be free to permit en-

trance of piston into first stage housing.

Check Valve Replacement (Second Stage Piston)

1.

Pry out expansion plug retainer on second stage pis-

ton (with pointed tool) and remove spring and check

valve.

2.

Pour a small amount of clean solvent through bore

in piston and blow dry with compressed air. Check

valve seat should be smooth and clean.

3.

Install new check valve and spring.

%/DEEP SOCKET

ROCKER /

WHgggb

I

^RM-j|

111511

FIRST

m

H

STAGE

1 Mill IMW •

W

HOUSING

Fig.

18- Installing Diaphragm Retainer

Fig.

20 - Removing Rocker Arm ,

CHEVROLET CHASSIS SERVICE MANUAL

Page 627 of 659

ACCESSORIES 15-18

4.

Insert new expansion plug retainer and tap in until it

bottoms.

Check Valve Replacement

(Second Stage Housing)

1.

Pry out expansion plug retainer on second stage

housing (with pointed tool) and remove spring and

check valve.

2.

Glean second stage housing with clean solvent and

blow dry with compressed air. Check valve seat

should be clean and smooth.

3.

Install new check valve and spring.

4.

Insert new expansion plug retainer and tap in until

it bottoms.

COMPRESSOR, RESERVOIR AND REGULATOR

Assembly From Major Components

1.

Slide piston assembly straight into first stage (large

diameter) housing.

2.

Install actuating arm and secure to first stage

housing with arm pivot screw, tightening to 12 in.

: lbs. ;

3.

Connect arm tension spring to swivel arm.

9.

10.

Rotate piston in first stage housing to align elongated

hole in diaphragm with vent port in first stage

housing.

Install three compressor retaining through bolts that

secure second stage housing to first stage housing.

Housings will align one way only. Nuts are posi-

tioned in counterbores in second stage housing.

Tighten to 28 in. lbs.

Install new O-ring on second stage housing. Wash

inside of reservoir in clean solvent and blow dry

with compressed" air. Install reservoir on second

stage housing with three nuts, tightening to 28 in. lbs.

Install two reservoir retaining through bolts, tighten-

ing to 28 in. lbs. Through, bolt heads should-be posi-

tioned against reservoir. Leave out through bolt that

secures cover.

Install new O-ring on regulator and secure regulator

with two regulator retaining screws, tighten to 35 in.

lbs.

Service valve should be on same side as first

stage housing.

Install new gasket, cover, and secure with cover

retaining screw and new cover gasket. Tighten cover

retaining screw to 35 in. lbs. Install through bolt

so head is positioned against reservoir. Tighten

through bolt to 28 in. lbs.

Install three adapters and flexible mounts.

Proceed to compressor output test on car.

CHEVROLET CHASSIS SERVICE MANUAL