electrical CHEVROLET CAMARO 1967 1.G Chassis User Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 80 of 659

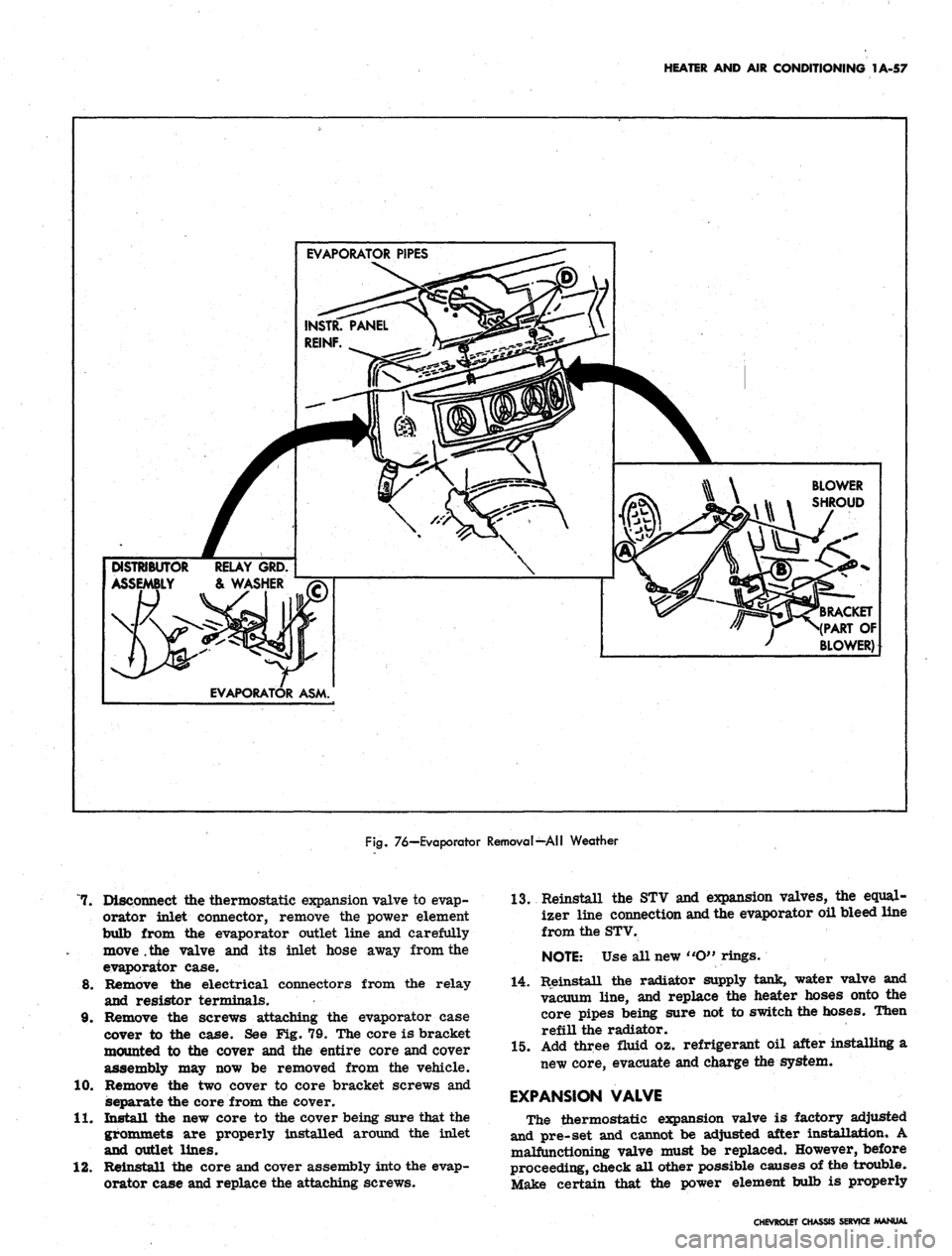

HEATER AND AIR CONDITIONING 1A-57

EVAPORATOR PIPES

DISTRIBUTOR RELAY GRD.

ASSEMBLY & WASHER

EVAPORATOR ASM.

BLOWER

SHROUD

(RACKET

(PART OF

BLOWER)

Fig.

76—Evaporator Removal—All Weather

7. Disconnect the thermostatic expansion valve to evap-

orator inlet connector, remove the power element

bulb from the evaporator outlet line and carefully

move .the valve and its inlet hose away from the

evaporator case.

8. Remove the electrical connectors from the relay

and resistor terminals.

9. Remove the screws attaching the evaporator case

cover to the case. See Fig. 79. The core is bracket

mounted to the cover and the entire core and cover

assembly may now be removed from the vehicle.

10.

Remove the two cover to core bracket screws and

separate the core from the cover.

11.

Install the new core to the cover being sure that the

grommets are properly installed around the inlet

and outlet lines.

12.

Reinstall the core and cover assembly into the evap-

orator case and replace the attaching screws.

13.

Reinstall the STV and expansion valves, the equal-

izer line connection and the evaporator oil bleed line

from the STV.

NOTE:

Use all new «O" rings.

14.

Reinstall the radiator supply tank, water valve and

vacuum line, and replace the heater hoses onto the

core pipes being sure not to switch the hoses. Then

refill the radiator.

15.

Add three fluid oz. refrigerant oil after installing a

new core, evacuate and charge the system.

EXPANSION VALVE

The thermostatic expansion valve is factory adjusted

and pre-set and cannot be adjusted after installation. A

malfunctioning valve must be replaced. However, before

proceeding, check all other possible causes of the trouble.

Make certain that the power element bulb is properly

CHEVROLET CHASSIS SERVICE MANUAL

Page 83 of 659

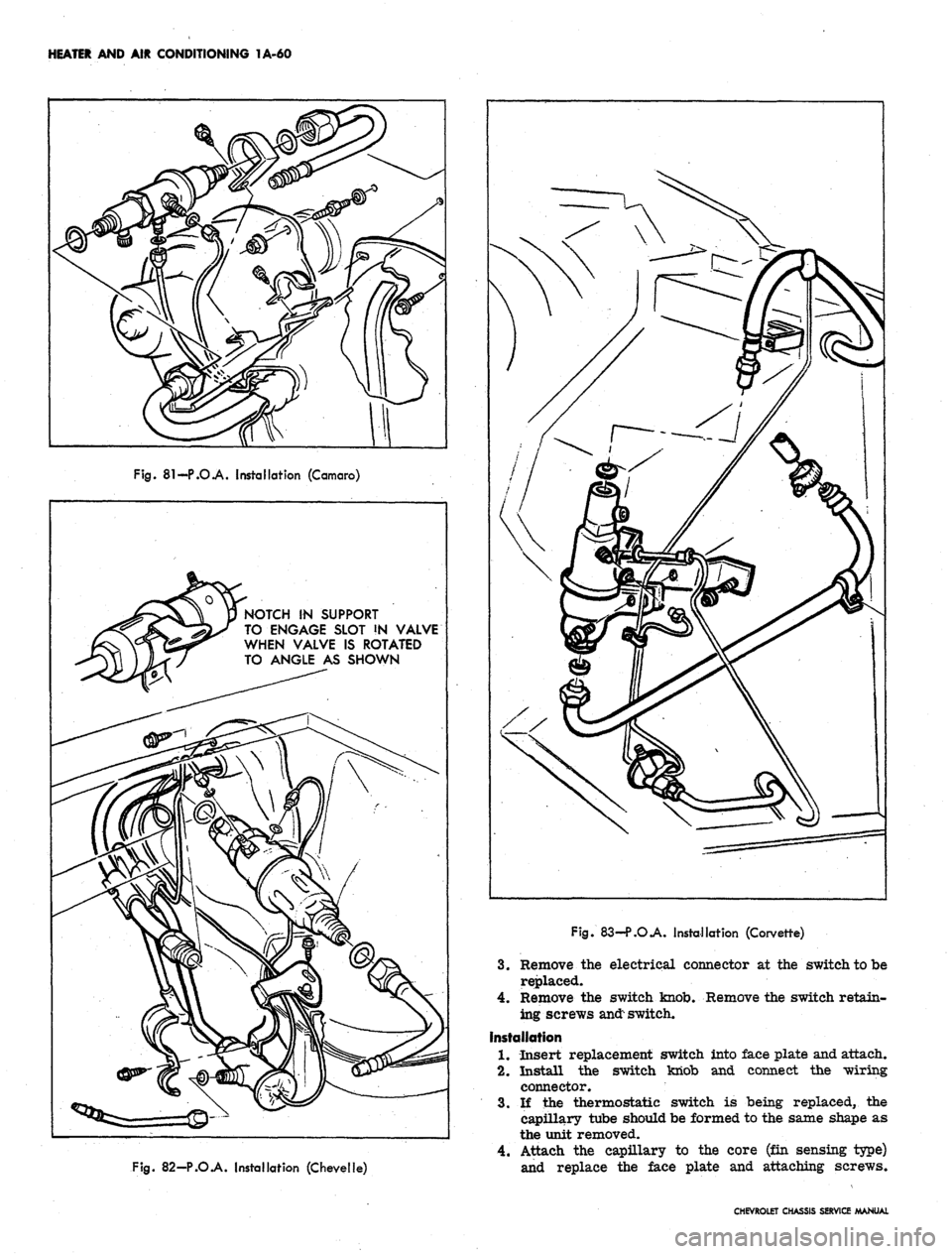

HEATER AND AIR CONDITIONING 1A-60

Fig.

81-P.O.A. Installation (Camaro)

NOTCH IN SUPPORT

TO ENGAGE SLOT !N VALVE

WHEN VALVE IS ROTATED

TO ANGLE AS SHOWN

Fig.

82-P.O.A. Installation (Chevelle)

Fig.

83—P.O.A. Installation (Corvette)

3.

Remove the electrical connector at the switch to be

replaced.

4.

Remove the switch knob. Remove the switch retain-

ing screws

and:

switch.

Installation

1.

Insert replacement switch into face plate and attach.

2.

Install the switch knob and connect the wiring

connector.

3.

If the thermostatic switch is being replaced, the

capillary tube should be formed to the same shape as

the unit removed.

4.

Attach the capillary to the core (fin sensing type)

and replace the face plate and attaching screws.

CHEVROLET CHASSIS SERVICE MANUAL

Page 84 of 659

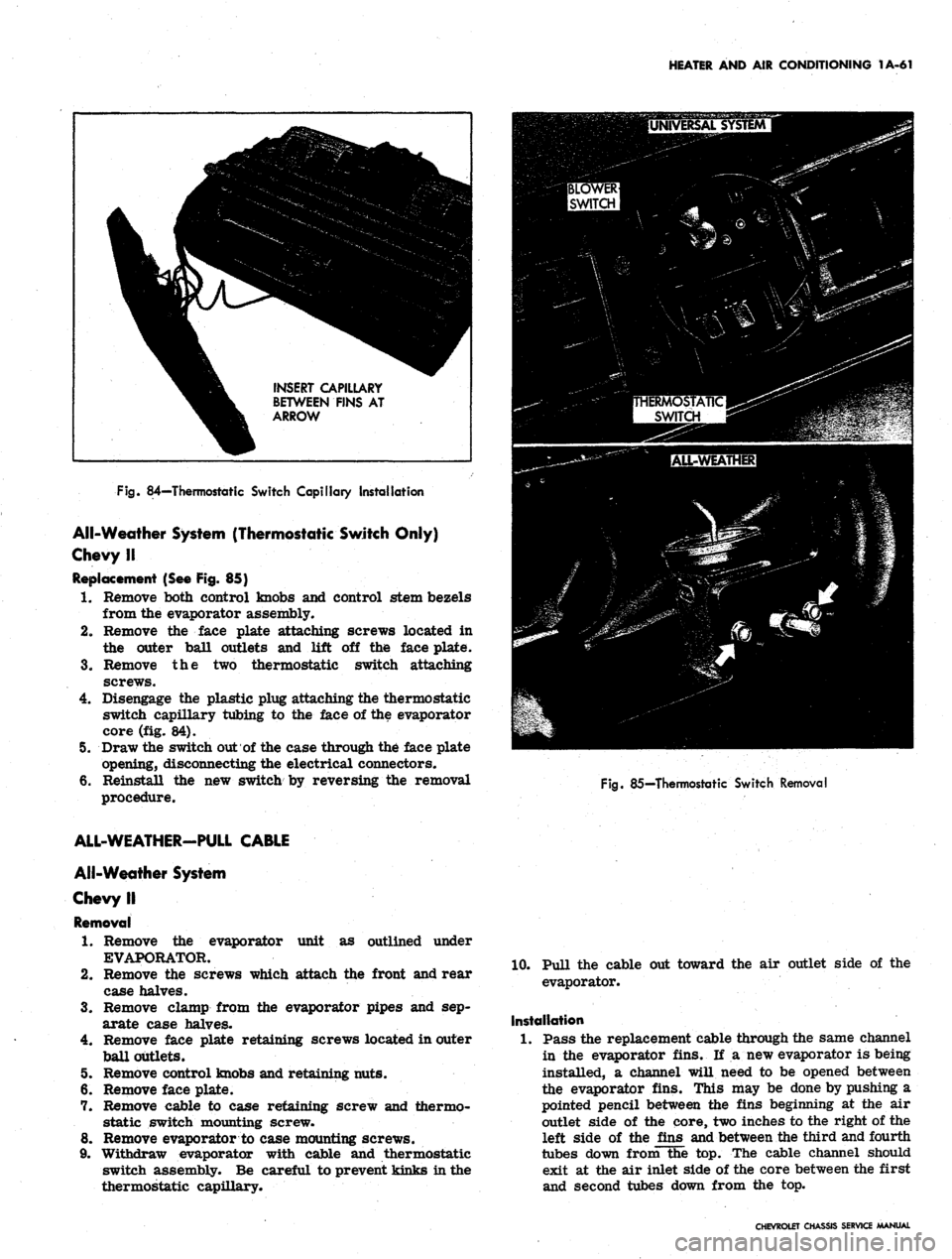

HEATER AND AIR CONDITIONING 1A-61

INSERT CAPILLARY

BETWEEN FINS AT

ARROW

Fig.

84—Thermostatic Switch Capillary Installation

All-Weather System (Thermostatic Switch Only)

Chevy II

Replacement (See Fig. 85)

1.

Remove both control knobs and control stem bezels

from the evaporator assembly.

2.

Remove the face plate attaching screws located in

the outer ball outlets and lift off the face plate.

3.

Remove the two thermostatic switch attaching

screws.

4.

Disengage the plastic plug attaching the thermostatic

switch capillary tubing to the face of the evaporator

core (fig. 84).

5. Draw the switch out of the case through the face plate

opening, disconnecting the electrical connectors.

6. Reinstall the new switch by reversing the removal

procedure.

Fig.

85—Thermostatic Switch Removal

unit as outlined under

ALL-WEATHER-PULL CABLE

All-Weather System

Chevy II

Removal

1.

Remove the evaporator

EVAPORATOR.

2.

Remove the screws which attach the front and rear

case halves.

3.

Remove clamp from the evaporator pipes and sep-

arate case halves.

4.

Remove face plate retaining screws located in outer

ball outlets.

5. Remove control knobs and retaining nuts.

6. Remove face plate.

7. Remove cable to case retaining screw and thermo-

static switch mounting screw.

8. Remove evaporator to case mounting screws.

9. Withdraw evaporator with cable and thermostatic

switch assembly. Be careful to prevent kinks in the

thermostatic capillary.

10.

Pull the cable out toward the air outlet side of the

evaporator.

Installation

1.

Pass the replacement cable through the same channel

in the evaporator fins. If a new evaporator is being

installed, a channel will need to be opened between

the evaporator fins. This may be done by pushing a

pointed pencil between the fins beginning at the air

outlet side of the core, two inches to the right of the

left side of the fins and between the third and fourth

tubes down from the top. The cable channel should

exit at the air inlet side of the core between the first

and second tubes down from the top.

CHEVROLET CHASSIS SERVICE MANUAL

Page 85 of 659

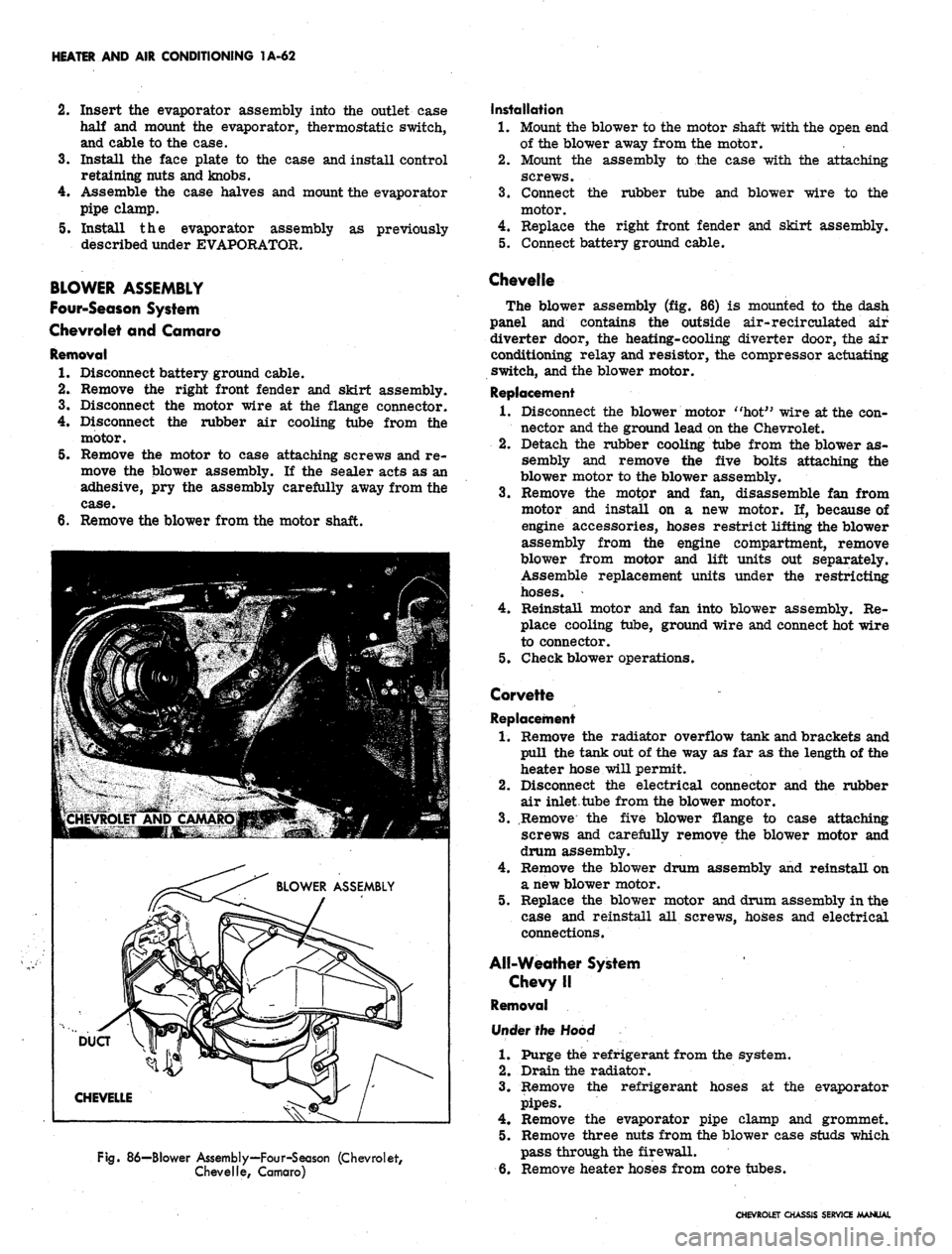

HEATER AND AIR CONDITIONING 1A-62

2.

Insert the evaporator assembly into the outlet case

half and mount the evaporator, thermostatic switch,

and cable to the case.

3.

Install the face plate to the case and install control

retaining nuts and knobs.

4.

Assemble the case halves and mount the evaporator

pipe clamp.

5. Install the evaporator assembly as previously

described under EVAPORATOR.

BLOWER ASSEMBLY

Four-Season System

Chevrolet and Camaro

Removal

1.

Disconnect battery ground cable.

2.

Remove the right front fender and skirt assembly.

3.

Disconnect the motor wire at the flange connector.

4.

Disconnect the rubber air cooling tube from the

motor.

5. Remove the motor to case attaching screws and re-

move the blower assembly. If the sealer acts as an

adhesive, pry the assembly carefully away from the

6. Remove the blower from the motor shaft.

Fig.

86—Blower Assembly—Four-Season (Chevrolet,

Chevelle, Camaro)

Installation

1.

Mount the blower to the motor shaft with the open end

of the blower away from the motor.

2.

Mount the assembly to the case with the attaching

screws.

3.

Connect the rubber tube and blower wire to the

motor.

4.

Replace the right front fender and skirt assembly.

5. Connect battery ground cable.

Chevelle

The blower assembly (fig. 86) is mounted to the dash

panel and contains the outside air-recirculated air

diverter door, the heating-cooling diverter door, the air

conditioning relay and resistor, the compressor actuating

switch, and the blower motor.

Replacement

1.

Disconnect the blower motor "hot" wire at the con-

nector and the ground lead on the Chevrolet.

2.

Detach the rubber cooling tube from the blower as-

sembly and remove the five bolts attaching the

blower motor to the blower assembly.

3.

Remove the motor and fan, disassemble fan from

motor and install on a new motor. If, because of

engine accessories, hoses restrict lifting the blower

assembly from the engine compartment, remove

blower from motor and lift units out separately.

Assemble replacement units under the restricting

hoses.

4.

Reinstall motor and fan into blower assembly. Re-

place cooling tube, ground wire and connect hot wire

to connector.

5. Check blower operations.

Corvette

Replacement

1.

Remove the radiator overflow tank and brackets and

pull the tank out of the way as far as the length of the

heater hose will permit.

2.

Disconnect the electrical connector and the rubber

air inlet tube from the blower motor.

3.

Remove the five blower flange to case attaching

screws and carefully remove the blower motor and

drum assembly.

4.

Remove the blower drum assembly and reinstall on

a new blower motor.

5. Replace the blower motor and drum assembly in the

case and reinstall all screws, hoses and electrical

connections.

All-Weather System

Chevy II

Removal

Under the Hood

1.

Purge the refrigerant from the system.

2.

Drain the radiator.

3.

Remove the refrigerant hoses at the evaporator

pipes.

4.

Remove the evaporator pipe clamp and grommet.

5. Remove three nuts from the blower case studs which

pass through the firewall.

6. Remove heater hoses from core tubes.

CHEVROLET CHASSIS SERVICE MANUAL

Page 86 of 659

HEATER AND AIR CONDITIONING 1A-63

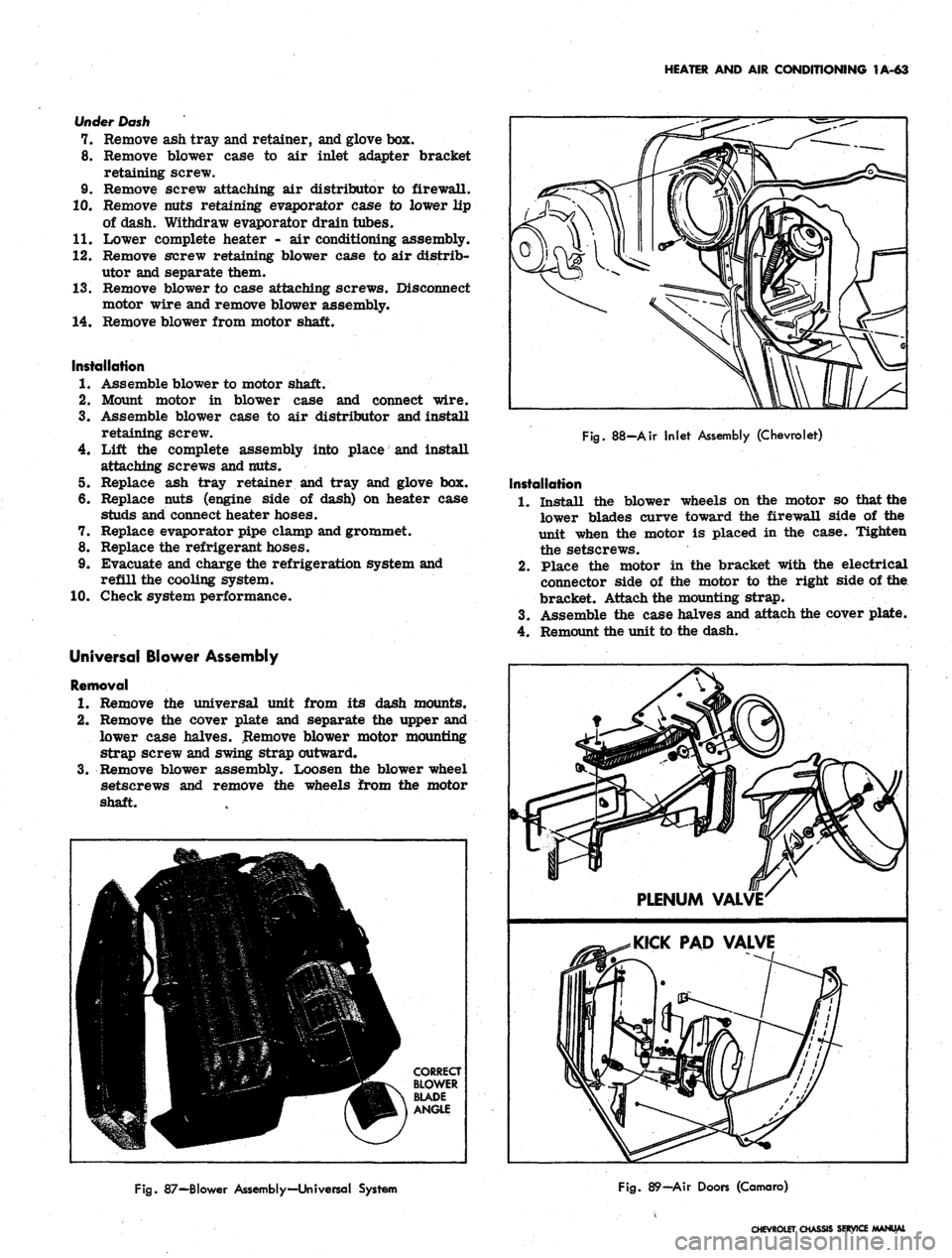

Under Dash

7. Remove ash tray and retainer, and glove box.

8. Remove blower case to air inlet adapter bracket

retaining screw.

9. Remove screw attaching air distributor to firewall.

10.

Remove nuts retaining evaporator case to lower lip

of dash. Withdraw evaporator drain tubes.

11.

Lower complete heater - air conditioning assembly.

12.

Remove screw retaining blower case to air distrib-

utor and separate them.

13.

Remove blower to case attaching screws. Disconnect

motor wire and remove blower assembly.

14.

Remove blower from motor shaft.

Installation

1.

Assemble blower to motor shaft.

2.

Mount motor in blower case and connect wire.

3.

Assemble blower case to air distributor and install

retaining screw.

4.

Lift the complete assembly into place and install

attaching screws and nuts.

5. Replace ash tray retainer and tray and glove box.

6. Replace nuts (engine side of dash) on heater case

studs and connect heater hoses.

7. Replace evaporator pipe clamp and grommet.

8. Replace the refrigerant hoses.

9. Evacuate and charge the refrigeration system and

refill the cooling system.

10.

Check system performance.

Universal Blower Assembly

Removal

1.

Remove the universal unit from its dash mounts.

2.

Remove the cover plate and separate the upper and

lower case halves. Remove blower motor mounting

strap screw and swing strap outward.

3.

Remove blower assembly. Loosen the blower wheel

setscrews and remove the wheels from the motor

shaft. . ' .

Fig.

88-Air Inlet Assembly (Chevrolet)

Installation

1.

Install the blower wheels on the motor so that the

lower blades curve toward the firewall side of the

unit when the motor is placed in the case. Tighten

the setscrews.

2.

Place the motor in the bracket with the electrical

connector side of the motor to the right side of the

bracket. Attach the mounting strap.

3.

Assemble the case halves and attach the cover plate.

4.

Remount the unit to the dash.

Fig.

87—Blower Assembly—Universal System

Fig.

89—Air Doors (Camaro)

CHEVROLET CHASSIS SERVICE

Page 96 of 659

HEATER AND AIR CONDITIONING 1A-73

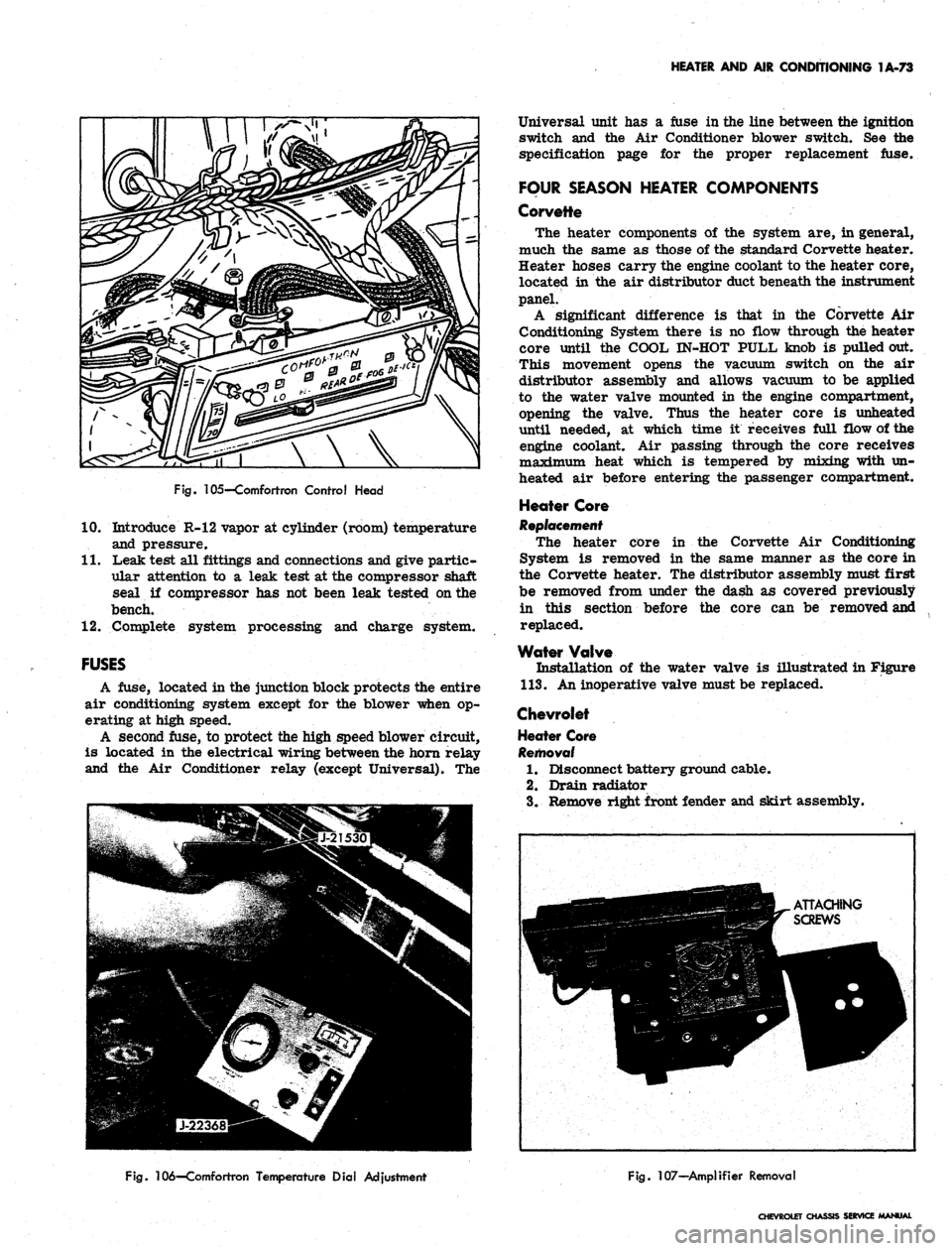

Fig.

105—Comfortron Control Head

10.

Introduce R-12 vapor at cylinder (room) temperature

and pressure.

11.

Leak test all fittings and connections and give partic-

ular attention to a leak test at the compressor shaft

seal if compressor has not been leak tested on the

bench.

12.

Complete system processing and charge system.

FUSES

A fuse, located in the junction block protects the entire

air conditioning system except for the blower when op-

erating at high speed.

A second fuse, to protect the high speed blower circuit,

is located in the electrical wiring between the horn relay

and the Air Conditioner relay (except Universal). The

Universal unit has a fuse in the line between the ignition

switch and the Air Conditioner blower switch. See the

specification page for the proper replacement fuse.

FOUR SEASON HEATER COMPONENTS

Corvette

The heater components of the system are, in general,

much the same as those of the standard Corvette heater.

Heater hoses carry the engine coolant to the heater core,

located in the air distributor duct beneath the instrument

panel.

A significant difference is that in the Corvette Air

Conditioning System there is no flow through the heater

core until the COOL IN-HOT PULL knob is pulled out.

This movement opens the vacuum switch on the air

distributor assembly and allows vacuum to be applied

to the water valve mounted in the engine compartment,

opening the valve. Thus the heater core is unheated

until needed, at which time it receives full flow of the

engine coolant. Air passing through the core receives

maximum heat which is tempered by mixing with un-

heated air before entering the passenger compartment.

Heater Core

Replacement

The heater core in the Corvette Air Conditioning

System is removed in the same manner as the core in

the Corvette heater. The distributor assembly must first

be removed from under the dash as covered previously

in this section before the core can be removed and

replaced.

Water Valve

Installation of the water valve is illustrated in Figure

113.

An inoperative valve must be replaced.

Chevrolet

Heater Core

Removal

1.

Disconnect battery ground cable.

2.

Drain radiator

3.

Remove right front fender and skirt assembly.

Fig.

106—Comfortron Temperature Dial Adjustment

Fig.

107—Amplifier Removal

CHEVROLET CHASSIS SERVICE MANUAL

Page 99 of 659

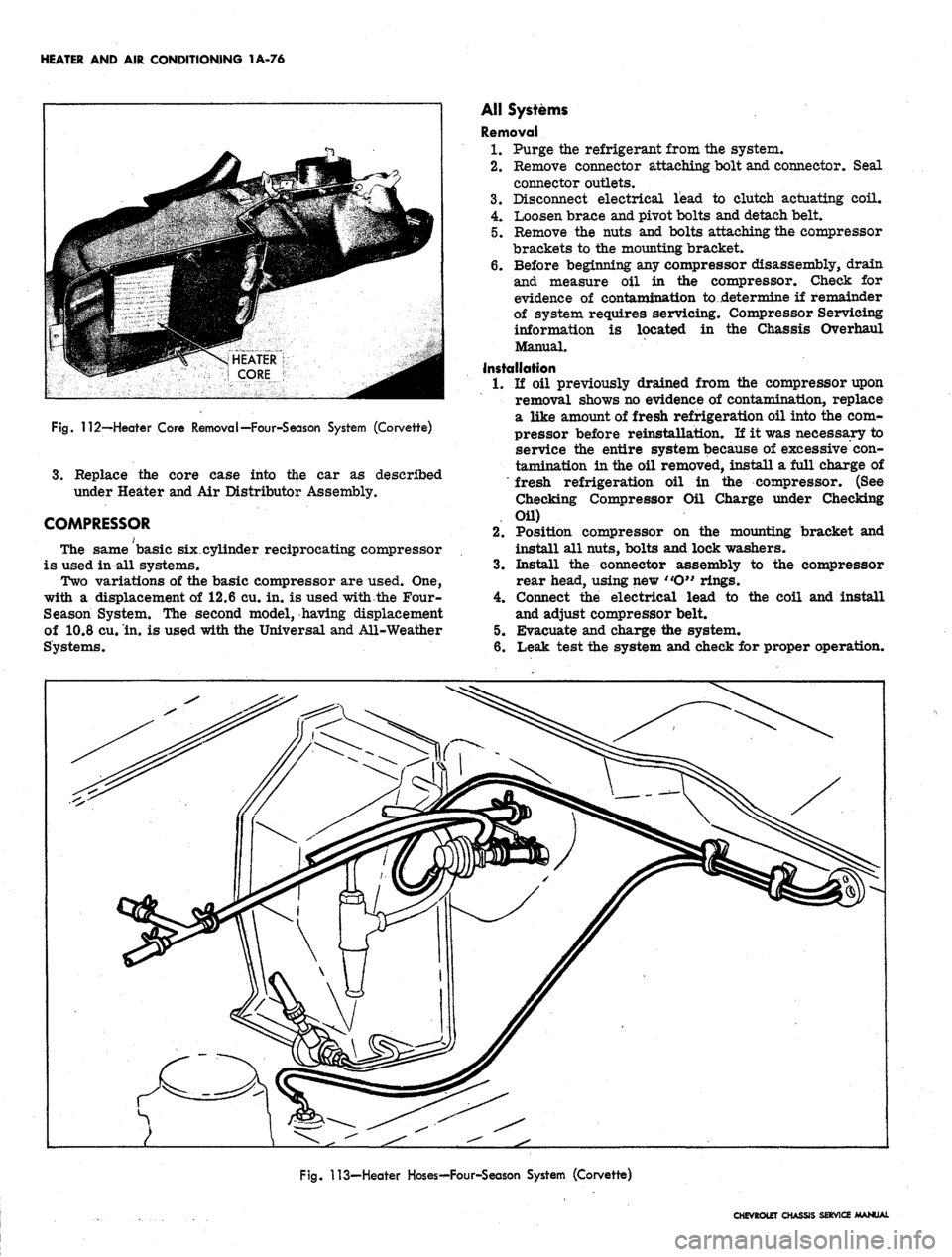

HEATER AND AIR CONDITIONING 1A-76

Fig.

112—-Heater Core Removal—Four-Season System (Corvette)

3.

Replace the core case into the car as described

under Heater and Air Distributor Assembly.

COMPRESSOR

The same basic six.cylinder reciprocating compressor

is used in all systems.

Two variations of the basic compressor are used. One,

with a displacement of 12.6 cu. in. is used with the Four-

Season System. The second model, having displacement

of 10.8 cu. in. is used with the Universal and All-Weather

Systems.

AH Systems

Removal

1.

Purge the refrigerant from the system.

2.

Remove connector attaching bolt and connector. Seal

connector outlets.

3.

Disconnect electrical lead to clutch actuating coil.

4.

Loosen brace and pivot bolts and detach belt.

5. Remove the nuts and bolts attaching the compressor

brackets to the mounting bracket.

6. Before beginning any compressor disassembly, drain

and measure oil in the compressor. Check for

evidence of contamination to ..determine if remainder

of system requires servicing. Compressor Servicing

information is located in the Chassis Overhaul

Manual.

Installation

1.

li oil previously drained from the compressor upon

removal shows no evidence of contamination, replace

a like amount of fresh refrigeration oil into the com-

pressor before reinstallatLon. If it was necessary to

service the entire system because of excessive con-

tamination in the oil removed, install a full charge of

"fresh refrigeration oil in the compressor. (See

Checking Compressor Oil Charge under Checking

Oil)

2.

Position compressor on the mounting bracket and

install all nuts, bolts and lock washers.

3.

Install the connector assembly to the compressor

rear head, using new "O" rings.

4.

Connect the electrical lead to the coil and install

and adjust compressor belt.

5. Evacuate and charge the system.

6. Leak test the system and check for proper operation.

Fig.

113—Heater Hoses^-Four-Season System (Corvette)

CHEVROLET CHASSIS SERVICE MANUAL

Page 112 of 659

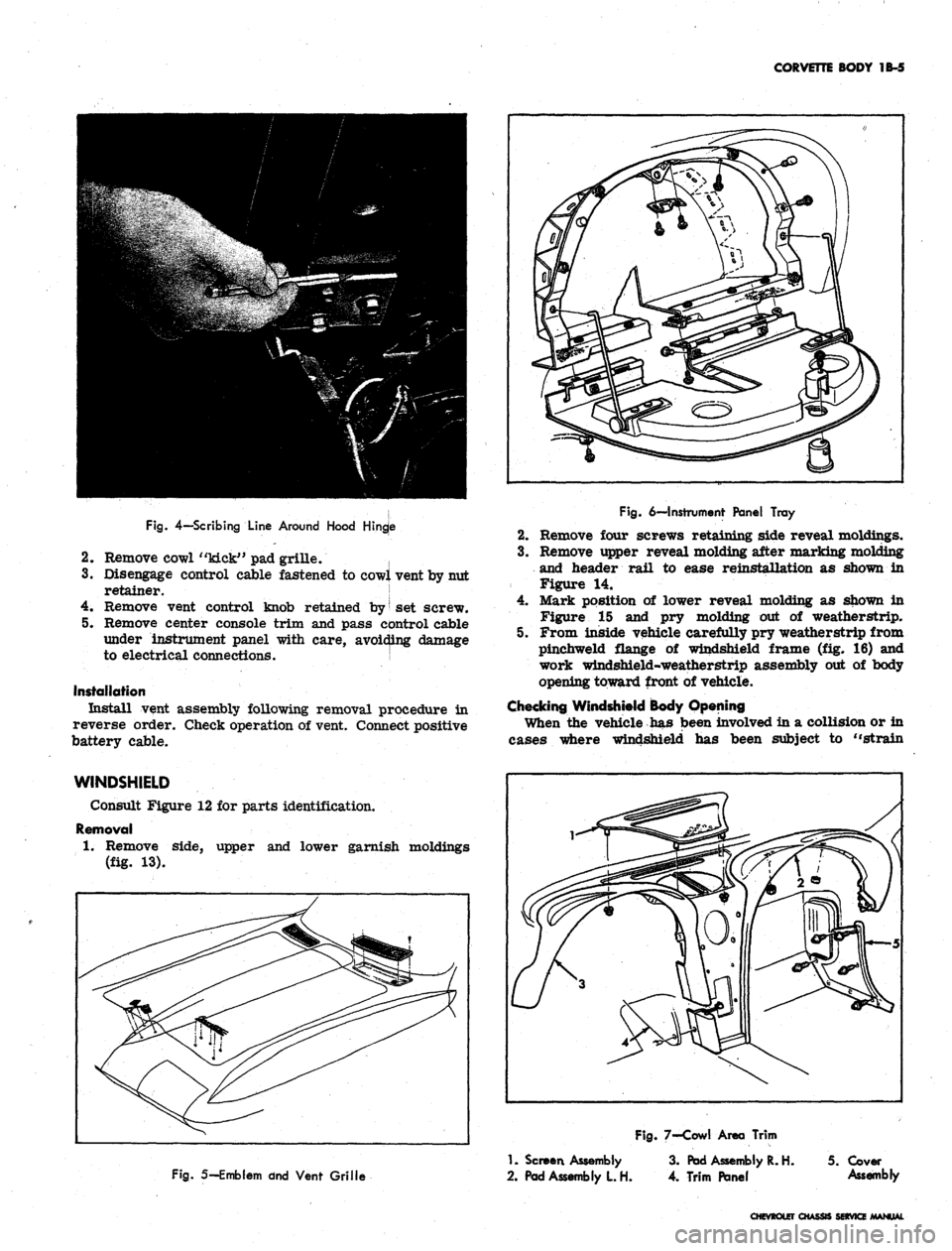

CORVETTE BODY 1B-5

Fig.

4—Scribing

Line

Around

Hood

Hingje

2.

Remove cowl "kick" pad grille. |

3.

Disengage control cable fastened to cowl vent by nut

retainer. !

4.

Remove vent control knob retained by

|

set screw.

5. Remove center console trim and pass control cable

under instrument panel with care, avoiding damage

to electrical connections. j

Installation

Install vent assembly following removal procedure in

reverse order. Check operation of vent. Connect positive

battery cable.

Fig.

6—Instrument

Panel Tray

2.

Remove four screws retaining side reveal moldings.

3.

Remove upper reveal molding after marking molding

and header rail to ease reinstallation as shown in

Figure 14.

4.

Mark position of lower reveal molding as shown in

Figure 15 and pry molding out of weatherstrip.

5. From inside vehicle carefully pry weatherstrip from

pinchweld flange of windshield frame (fig. 16) and

work windshield-weatherstrip assembly out of body

opening toward front of vehicle.

Checking Windshield Body Opening

When the vehicle has been involved in a collision or in

cases where windshield has been subject to "strain

WINDSHIELD

Consult Figure 12 for parts identification.

Removal

1.

Remove side, upper and lower garnish moldings

(fig. 13).

Fig.

5—Emblem dnd

Vent Grille

1.

Screen

Assembly

2.

Pad

Assembly

L H.

Fig.

7-Cowl

Area Trim

3.

Pad

Assembly

R. H. 5.

Cover

4.

Trim Panel

Assembly

CHEVROLET CHASSIS SERVICE MANUAL

Page 122 of 659

CORVETTE BODY 1B-15

Fig.

32—Removing Regulator

GLASS RUN CHANNEL-REAR

Removal

For parts identification refer to Figure 41.

1.

Remove door trim assembly as outlined in this

section.

2.

Remove window glass assembly as outlined in this

section.

3.

Remove 2 channel retaining screws and pass chan-

nels out through large opening in door inner panel

(fig. 42).

Fig.

33—Removing Ventilator Assembly 19437

Installation

1.

Position run channel in door and install bolts loosely.

2.

Install window glass as outlined in this section.

3.

Make necessary adjustments to channel as outlined

under Doors - Adjustments - Door Windows.

4.

Replace door window and door trim panel.

WINDOW REGULATOR-MANUAL

For parts identification see Figure 41.

Removal

1.

Remove trim panel as outlined in this section.

2.

Remove door window glass as outlined in this

section.

3.

Remove screws retaining regulator assembly to

door panel.

4.

Remove screws holding lower guide rail to door

panel.

5. Remove regulator assembly from large access open-

ing as shown in Figure 43.

Installation

Regulator may be installed by following removal pro-

cedure in reverse order. Always lubricate all guide rails

and rollers when regulator is disassembled. Test regula-

tor thoroughly before installing door trim panel. Adjust

window as outlined in this section.

WINDOW REGULATOR-POWER

In cases where window will not operate, check electri-

cal connections first. Figure 44 illustrates lpcation of

junctions, switches and circuit breaker.

Removal

Perform operations 1 thru 5 under Window Regulator-

Manual Removal. Note, however, that electrical connec-

tors must be removed from motor before performing

any operation on regulator. Figure 44 illustrates in-

stallation of regulator on door and regulator wiring.

Disassembly

NOTE:

Do not attempt to remove motor from

regulator until the following operations are per-

formed. THIS IS A SAFETY ITEM; arm is

spring-loaded and may cause injury if not locked

in position when motor is removed.

Refer to Figure 45.

1.

Place regulator assembly in vise.

2.

Using jumper leads to 12 volt power supply, operate

motor until semi-circular hole in sector gear cen-

ters over one of two weld nuts on mounting plate.

3.

Screw a l/4"-20 x 1" bolt into weld nut so that end

passes through hole in sector gear. It may be neces-

sary to enlarge hole in gear slightly with file or

drill. Install nut on bolt to lock arm in position.

Installation

1.

Be sure lock bolt has been removed if regulator

has been disassembled.

2.

Install lubricated regulator assembly and guide rails

in door in reverse order of removal.

3.

Install window as outlined in this section.

4.

Making sure connectors are securely installed on

motor, test operation of window thoroughly.

5. Install door trim panel and handles as outlined in

this section.

CHEVROLET CHASSIS SERVICE MANUAL

Page 234 of 659

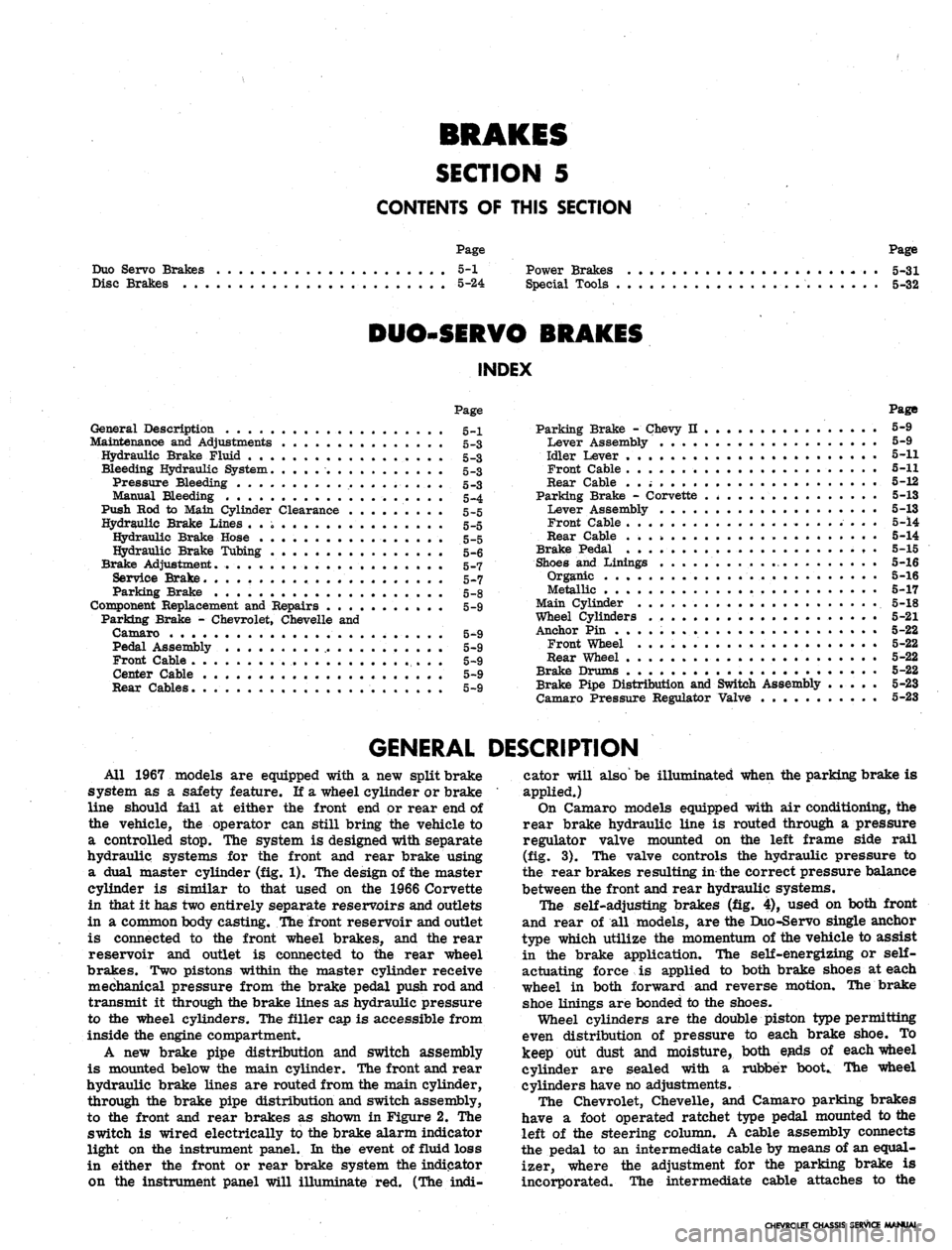

BRAKES

SECTION 5

CONTENTS OF THIS SECTION

Duo Servo Brakes

Disc Brakes

Page

5-1 Power Brakes

5-24 Special Tools

Page

5-31

5-32

DUO-SERVO BRAKES

INDEX

Page

General Description 5-1

Maintenance and Adjustments 5-3

Hydraulic Brake Fluid .. . 5-3

Bleeding Hydraulic System 5-3

Pressure Bleeding 5-3

Manual Bleeding 5_4

Push Rod to Main Cylinder Clearance 5-5

Hydraulic Brake Lines 5-5

Hydraulic Brake Hose 5-5

Hydraulic Brake Tubing 5-6

Brake Adjustment. .................... 5-7

Service Brake 5-7

Parking Brake 5-8

Component Replacement and Repairs 5-9

Parking Brake - Chevrolet, Chevelle and

Camaro 5^9

Pedal Assembly 5-9

Front Cable ,. . . 5-9

Center Cable 5-9

Rear Cables. . 5-9

Parking Brake - Chevy n 5-9

Lever Assembly 5-9

Idler Lever 5-11

Front Cable 5-11

Rear Cable . . ; 5-12

Parking Brake - Corvette 5-13

Lever Assembly . . . . 5-13

Front Cable 5-14

Rear Cable . . 5-14

Brake Pedal 5-15

Shoes and Linings 5-16

Organic 5-16

Metallic 5-17

Main Cylinder 5-18

Wheel Cylinders 5-21

Anchor Pin 5-22

Front Wheel 5-22

Rear Wheel 5-22

Brake Drums • 5-22

Brake Pipe Distribution and Switch Assembly . . . . . 5-23

Camaro Pressure Regulator Valve 5-23

GENERAL DESCRIPTION

All 1967 models are equipped with a new split brake

system as a safety feature. If a wheel cylinder or brake

line should fail at either the front end or rear end of

the vehicle, the operator can still bring the vehicle to

a controlled stop. The system is designed with separate

hydraulic systems for the front and rear brake using

a dual master cylinder (fig. 1). The design of the master

cylinder is similar to that used on the 1966 Corvette

in that it has two entirely separate reservoirs and outlets

in a common body casting. The front reservoir and outlet

is connected to the front wheel brakes, and the rear

reservoir and outlet is connected to the rear wheel

brakes. Two pistons within the master cylinder receive

mechanical pressure from the brake pedal push rod and

transmit it through the brake lines as hydraulic pressure

to the wheel cylinders. The filler cap is accessible from

inside the engine compartment.

A new brake pipe distribution and switch assembly

is mounted below the main cylinder. The front and rear

hydraulic brake lines are routed from the main cylinder,

through the brake pipe distribution and switch assembly,

to the front and rear brakes as shown in Figure 2. The

switch is wired electrically to the brake alarm indicator

light on the instrument panel. In the event of fluid loss

in either the front or rear brake system the indicator

on the instrument panel will illuminate red. (The indi-

cator will also' be illuminated when the parking brake is

applied.)

On Camaro models equipped with air conditioning, the

rear brake hydraulic line is routed through a pressure

regulator valve mounted on the left frame side rail

(fig. 3). The valve controls the hydraulic pressure to

the rear brakes resulting in the correct pressure balance

between the front and rear hydraulic systems.

The self-adjusting brakes (fig. 4), used on both front

and rear of all models, are the Duo-Servo single anchor

type which utilize the momentum of the vehicle to assist

in the brake application. The self-energizing or

self-

actuating force is applied to both brake shoes at each

wheel in both forward and reverse motion. The brake

shoe linings are bonded to the shoes.

Wheel cylinders are the double piston type permitting

even distribution of pressure to each brake shoe. To

keep out dust and moisture, both ejads of each wheel

cylinder are sealed with a rubber booC The wheel

cylinders have no adjustments.

The Chevrolet, Chevelle, and Camaro parking brakes

have a foot operated ratchet type pedal mounted to the

left of the steering column. A cable assembly connects

the pedal to an intermediate cable by means of an equal-

izer, where the adjustment for the parking brake is

incorporated. The intermediate cable attaches to the

CHEVROLET CHASSIS SERVICE MANUAL