electrical CHEVROLET CAMARO 1967 1.G Chassis Repair Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 355 of 659

ENGINE-ELECTRICAL-6Y-30

Fig.

2 li—Removing Ignition Switch Nut

4.

Remove heater and/or A/C control panel assembly

retaining screws and push panel assembly from

console.

NOTE: If interference between control panel

and radio is encountered, loosen radio retaining

nuts.

5.

Remove radio control knobs, bezels and retaining

nuts.

6. Disconnect radio wiring harness and antenna lead-in.

7.

Remove radio rear brace attaching screw and re-

move radio from vehicle.

Fig.

231—Switch and Connector Unplugged

8. Remove ignition switch bezel nut using Tool J-7607

and push switch rearward from panel opening.

9. Disconnect wiring connector from rear of switch.

10.

To install, reverse removal procedure.

SPARK PLUGS

CLEANING AND REGAPPING

Clean the spark plugs thoroughly, using an abrasive-

type cleaner. If the porcelains are badly glazed or

blistered, the spark plugs should be replaced. All spark

plugs must be of the same make and number or heat

range. Use a round feeler gauge to adjust the spark plug

gap to specifications (fig. 24i).

Fig.

22i—Unlocking Ignition Switch Connector

Fig.

241—Setting Sfxirk Plug Gap

CHEVROLET CHASSIS SERVICE MANUAL

Page 356 of 659

ENGINE-ELECTRICAL

6Y-31

CAUTION: Before adjusting gap, me center

INSTALLATION

electrode flat. In adjusting the spark pluig Install the spark plugs in the engine with new gaskets

gap,

never bend the center electrode which and tighten to specifications. If torque wrench is not

extends through the porcelain center. Always available, tighten plugs finger tight and 1/2 turn more.

make adjustment by bending the ground or , Plugs are of a 14 millimeter size and care must be

side electrode. exercised when installing or the gap setting may be

changed.

CHEVROLET CHASSIS SERVICE MANUAL

Page 357 of 659

ENGINE-ELECTRICAL 6Y-32

STARTER CIRCUIT

INDEX

Page

General Description 6Y-32

Maintenance and Adjustments . '. . 6Y-32

Resistance Checks 6Y-32

Starting Motor and Solenoid Check 6Y-33

Page

Service Operations 6Y-33

Starter Motor 6Y-33

Removal and Installation 6Y-33

GENERAL DESCRIPTION

The function of the starting system, composed of the

starting motor, solenoid and battery, is to crank the

engine. The battery supplies the electrical energy, the

solenoid completes the circuit to the starting motor, and

the motor then does the actual work of cranking the

engine.

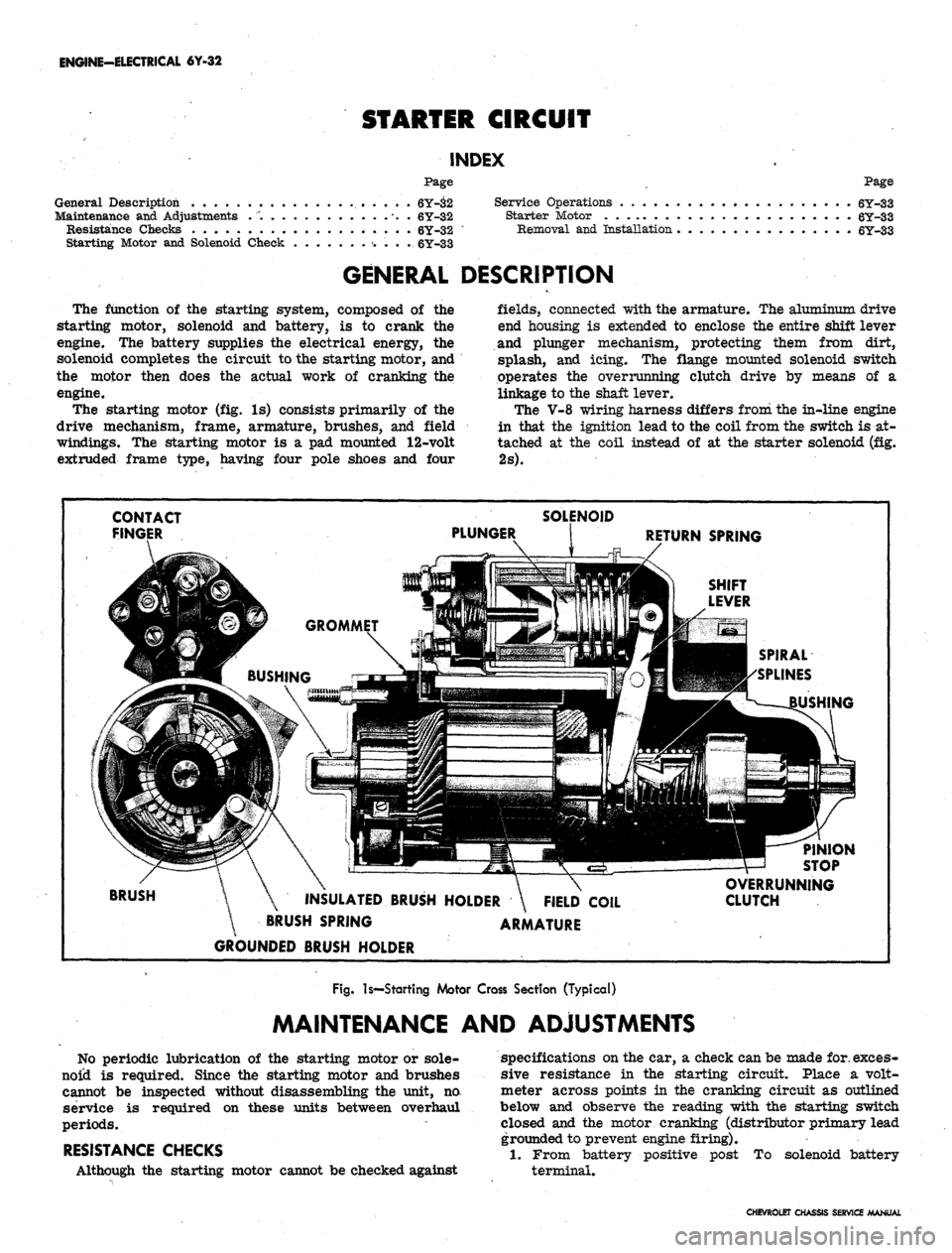

The starting motor (fig. Is) consists primarily of the

drive mechanism, frame, armature, brushes, and field

windings. The starting motor is a pad mounted 12-volt

extruded frame type, having four pole shoes and four

fields,

connected with the armature. The aluminum drive

end housing is extended to enclose the entire shift lever

and plunger mechanism, protecting them from dirt,

splash, and icing. The flange mounted solenoid switch

operates the overrunning clutch drive by means of a

linkage to the shaft lever.

The V-8 wiring harness differs from the in-line engine

in that the ignition lead to the coil from the switch is at-

tached at the coil instead of at the starter solenoid (fig.

2s).

CONTACT

FINGER

PINION

STOP

BRUSH

INSULATED BRUSH HOLDER \ FIELD COIL

BRUSH SPRING ARMATURE

GROUNDED BRUSH HOLDER

OVERRUNNING

CLUTCH

Fig.

Is—Starting Motor Cross Section (Typical)

MAINTENANCE AND ADJUSTMENTS

No periodic lubrication of the starting motor or sole-

noid is required. Since the starting motor and brushes

cannot be inspected without disassembling the unit, no.

service is required on these units between overhaul

periods.

RESISTANCE CHECKS

Although the starting motor cannot be checked against

specifications on the car, a check can be made for. exces-

sive resistance in the starting circuit. Place a volt-

meter across points in the cranking circuit as outlined

below and observe the reading with the starting switch

closed and the motor cranking (distributor primary lead

grounded to prevent engine firing).

1.

From battery positive post To solenoid battery

terminal.

CHEVROLET CHASSIS SERVICE MANUAL

Page 358 of 659

ENGINE-ELECTRICAL 6Y-33

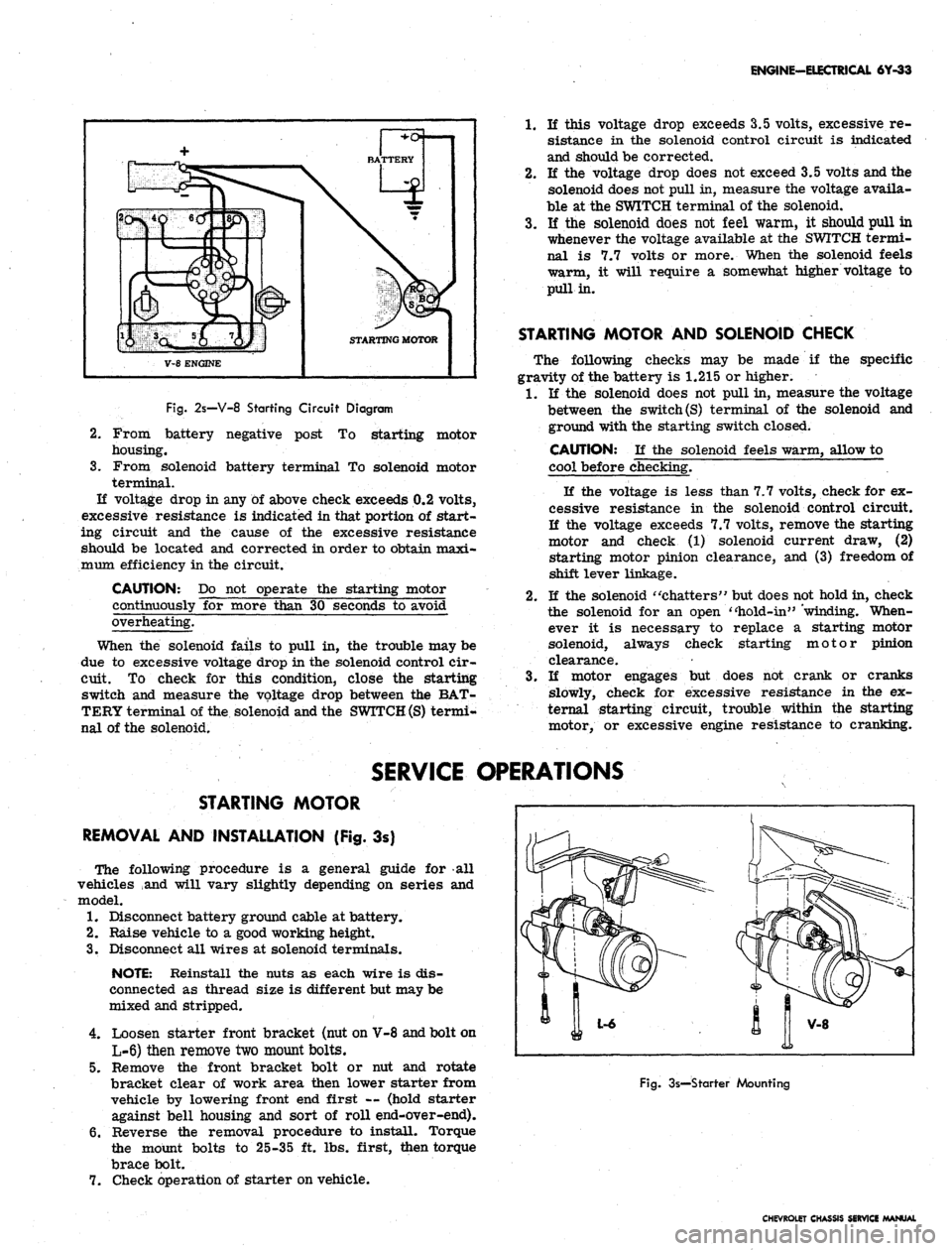

O

V-8 ENGINE

STARTING MOTOR

Fig.

2s—V-8 Starting Circuit Diagram

2.

3.

From battery negative post

To

starting motor

housing.

From solenoid battery terminal

To

solenoid motor

terminal.

If voltage drop

in

any

of

above check exceeds 0.2 volts,

excessive resistance

is

indicated in that portion

of

start-

ing circuit

and the

cause

of the

excessive resistance

should

be

located

and

corrected

in

order to obtain maxi-

mum efficiency in the circuit.

CAUTION:

Do not

operate

the

starting motor

continuously

for

more than

30

seconds

to

avoid

overheating.

When

the

solenoid fails

to

pull

in, the

trouble may be

due

to

excessive voltage drop in the solenoid control cir-

cuit.

To

check

for

this condition, close

the

starting

switch

and

measure

the

voltage drop between

the

BAT-

TERY terminal of the solenoid and the

SWITCH (S)

termi-

nal

of

the solenoid.

1.

If

this voltage drop exceeds 3.5 volts, excessive

re-

sistance

in the

solenoid control circuit

is

indicated

and should be corrected.

2.

If the

voltage drop does not exceed 3.5 volts and the

solenoid does not pull in, measure the voltage availa-

ble

at

the SWITCH terminal

of

the solenoid.

3.

If the

solenoid does

not

feel warm,

it

should pull

in

whenever the voltage available

at

the SWITCH termi-

nal

is 7.7

volts

or

more. When

the

solenoid feels

warm,

it

will require

a

somewhat higher voltage

to

pull in.

STARTING MOTOR AND SOLENOID CHECK

The following checks

may be

made

if the

specific

gravity of the battery

is

1.215

or

higher.

1.

If the

solenoid does

not

pull in, measure the voltage

between

the

switch

(S)

terminal

of the

solenoid

and

ground with the starting switch closed.

CAUTION:

If the

solenoid feels warm, allow

to

cool before checking.

If

the

voltage

is

less than 7.7 volts, check for ex-

cessive resistance

in the

solenoid control circuit.

If

the

voltage exceeds 7.7 volts, remove the starting

motor

and

check

(1)

solenoid current draw,

(2)

starting motor pinion clearance,

and (3)

freedom of

shift lever linkage.

2.

If

the solenoid "chatters" but does not hold in, check

the solenoid

for an

open "hold-in" 'winding. When-

ever

it is

necessary

to

replace

a

starting motor

solenoid, always check starting motor pinion

clearance.

3.

If

motor engages

but

does

not

crank

or

cranks

slowly, check

for

excessive resistance

in the ex-

ternal starting circuit, trouble within

the

starting

motor,

or

excessive engine resistance

to

cranking.

SERVICE OPERATIONS

STARTING MOTOR

REMOVAL AND INSTALLATION (Fig.

3s)

The following procedure

is a

general guide

for all

vehicles

and

will vary slightly depending

on

series

and

model.

1.

Disconnect battery ground cable at battery.

2.

Raise vehicle

to a

good working height.

3.

Disconnect all wires

at

solenoid terminals.

NOTE: Reinstall

the

nuts

as

each wire

is

dis-

connected

as

thread size

is

different but may be

mixed and stripped.

4.

Loosen starter front bracket (nut on V-8 and bolt on

L-6) then remove two mount bolts.

5.

Remove

the

front bracket bolt

or nut and

rotate

bracket clear

of

work area then lower starter from

vehicle

by

lowering front end first

—

(hold starter

against bell housing

and

sort

of

roll end-over-end).

6. Reverse

the

removal procedure

to

install. Torque

the mount bolts

to

25-35

ft.

lbs. first, then torque

brace bolt.

7.

Check operation

of

starter on vehicle.

Fig.

3s—Starter Mounting

CHEVROLET CHASSIS SERVICE MANUAL

Page 359 of 659

ENGINE-ELECTRICAL 6Y-34

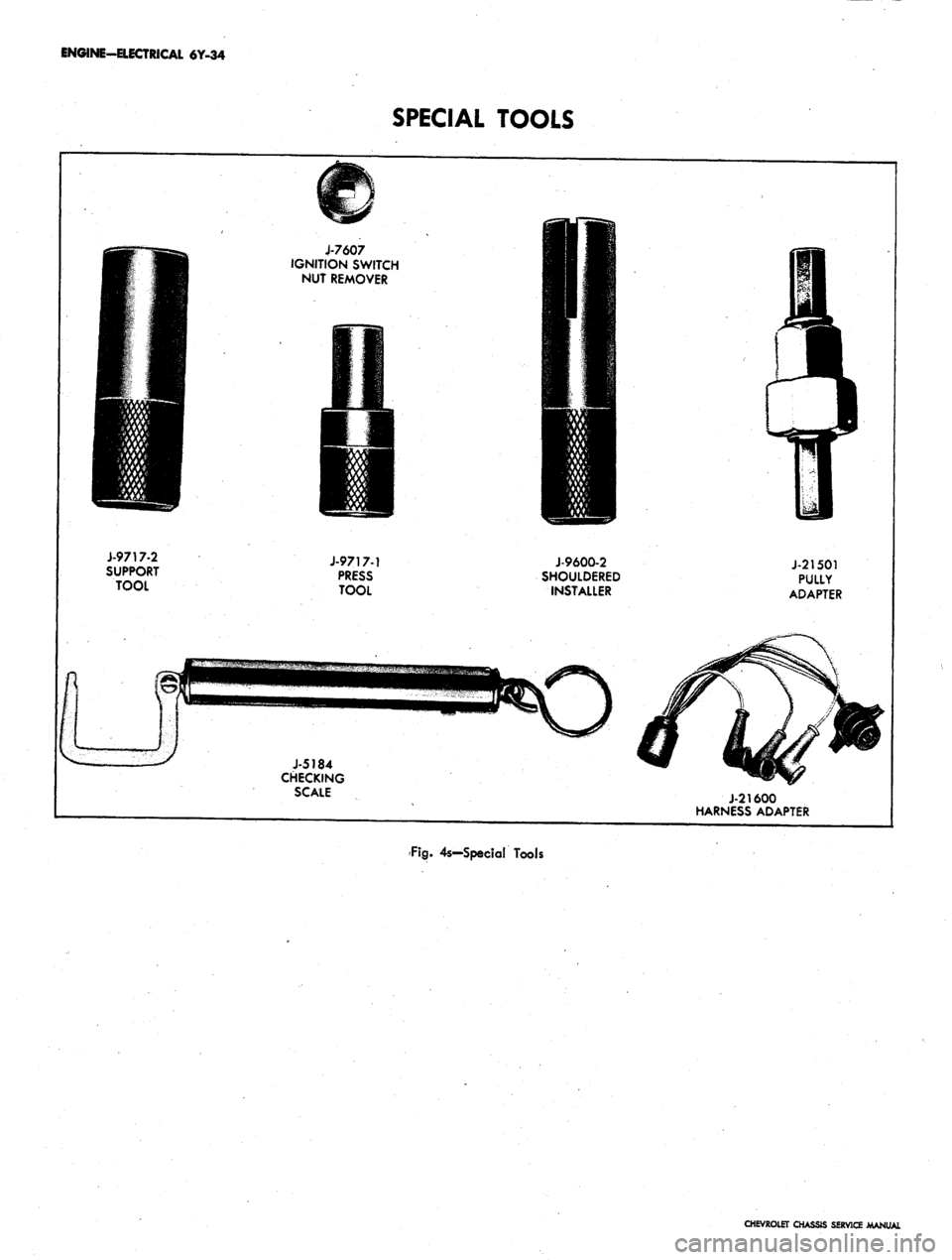

SPECIAL TOOLS

J-7607

IGNITION SWITCH

NUT REMOVER

J-9717-2

SUPPORT

TOOL

J-9717-1

PRESS

TOOL

J-9600-2

SHOULDERED

INSTALLER

J-21501

PULLY

ADAPTER

J-5184

CHECKING

SCALE

J-21600

HARNESS ADAPTER

Fig. 4s-Specia! Tools

CHEVROLET CHASSIS SERVICE MANUAL

Page 368 of 659

CLUTCH AND TRANSMISSIONS 7-9

6. Connect speedometer cable.

7. Install propeller shaft assembly.

8. Fill transmission with lubricant specified in Section

O.

CORVETTE TRANSMISSION REPLACEMENT

, 1. Disconnect battery ground cable.

2.

Pisassemble transmission shift control lever by un-

screwing ball from lever, lifting out

"T"

handle re-

turn spring and "T" handle, then remove the anti-

rattle bushings.

3.

Raise front and rear of vehicle.

4.

Insert a block of wood between the top of the dif-

ferential carrier housing and the underbody (to pre-

vent upward travel of the carrier when the carrier

front support is disconnected).

5. Disconnect the differential carrier front supportfrom

its frame bracket, by removing the nut on the under-

side of the biscuit mount.

6. Pry the carrier downward to relieve load while re-

moving the two center mounting bolts from the car-

rier front support. (To pry carrier downward insert

crowfoot end of a pry bar through the opening in the

carrier front support, hooking end of bar over top of

the center mounting bolt pad cast in the underside of

the carrier.)

7. Pivot carrier support downward for access to prop

shaft "U" joint.

8.

.

Disconnect prop shaft front and then rear "U" bolts.

9. Disconnect parking brake cable from ball socket at

idler lever located near center of underbody.

10.

Remove prop shaft by moving shaft forward.

11.

Remove heat deflectors from the right and left ex-

haust pipe.

12.

Remove left bank exhaust pipe.

13.

Remove right bank exhaust pipe and heat riser.

14.

Disassemble the transmission mount, as follows:

a. Remove the two bolts that attach rear mount

cushion to the rear mount bracket.

b.

Support engine under oil pan and raise engine to

remove load from rear mount cushion.

CAUTION: To avoid damage to oil pan, a suit-

able wide base, heavy wood platform should be

placed between the jack pad and the oil pan.

c. Remove the three transmission mount bracket-

to-

crossm ember bolts and remove mount bracket.

d. Remove the two bolts from mount pad to trans-

mission case and remove rubber mount cushion

and exhaust pipe "yoke".

15.

Disconnect transmission linkage by removing the

shift levers at the transmission side cover.

16.

Disconnect speedo cable at transmission extension.

17.

Remove transmission output shaft slip yoke.

NOTE:

The yoke is removed to avoid tearing

the heat reflecting pad on the underbody, when

the transmission is being removed.

18.

Remove two bolts to disconnect the transmission

gearshift control lever and bracket assembly from

its adapter plate on side of transmission. Lower

transmission assembly from the vehicle, letting the

gearshift lever slide down and through the dust boot

in the console.

19.

Remove transmission-to-clutch housing attaching

bolts.

20.

Slide transmission assembly rearward from clutch

and rotate transmission for access to the three flat

head machine screws in the control lever bracket

adapter plate. Remove adapter plate. Rotate trans-

mission back to the upright position.

21.

To allow room for transmission removal slowly

lower the rear of engine until the tachometer drive

cable at the distributor just clears the horizontal

ledge across the front of dash.

CAUTION: The tachometer cable can be easily

damaged by heavy contact with the dash. Slide

transmission rearward out of the clutch, then

tip front end of transmission downward and

lower the assembly from vehicle.

22.

Reinstall transmission assembly by performing above

steps in reverse order.

TRANSMISSION OVERDRIVE

INDEX

Page

General

Description 7-10

Maintenance

and Adjustments 7—10

Governor

Switch and Pinion .............. 7-10

Sun

Gear Solenoid Oil Seal and Control

Cable

Bracket 7-10

Case

Rear Oil Seal 7-10

Removal

7-10

Installation

. . . . . 7-10

Control

Shaft Lever and Oil Seal 7-10

Speedometer

Driven Gear 7-10

Electrical

Unit Checks 7-11

Overdrive

Relay . 7-11

Page

Air

Gap 7-11

Point

Opening 7-11

Closing

Voltage 7-11

Solenoid

. 7-11

Closing

Coil 7-11

Engaging

Spring . - 7-11

Ignition

Grounding Contact . 7-11

Governor

Switch 7-11

Kickdown

Switch 7-11

Diagnosis

- Overdrive 7-12

Mechanical

. 7-12

Electrical

7-13

CHEVROLET CHASSIS SERVICE MANUAL

Page 369 of 659

CLUTCH AND TRANSMISSIONS 7-10 ,

GENERAL DESCRIPTION

The overdrive unit is essentially a two-speed planetary-

transmission attached to the rear of a conventional three-

speed transmission. In overdrive, engine speed is ap-

proximately 30 per cent slower at a given road speed

since the drive train includes planetary gears which pro-

vide a lower overall gear ratio than that obtained in high

gear with the conventional transmission.

The electrical equipment which controls the automatic

action of the mechanical portion of the overdrive unit

consists of a solenoid, a speed-sensitive governor switch,

a relay and a kickdown switch. The circuit including this

equipment makes it possible to operate in overdrive above

a pre-set cut-in speed, or in .conventional drive at any

speed.

With the overdrive unit engaged, the transmission

should not be left in any forward gear with intent of lock-

ing the drive-line as the overrunning clutch is a free-

wheeling condition.

SERVICING THE OVERDRIVE

With the,overdrive assembly removed from the trans-

mission, service operations on the transmission proper

are the same as for the standard three-speed trans-

mission.

Repairs to the overdrive housing, output shaft, ring

gear assembly, clutch cam, roller retainer, pinion cage,

sun gear, shift rail, sun gear control plate, output shaft

bearing, oil seal, speedometer drive gear, solenoid pawl

and interlock plunger may be performed underneath the

car, if so desired, by removing the overdrive housing

without disturbing the transmission. Refer to Overhaul

Manual for Service Procedure.

If the transmission mainshaft, overdrive adapter or

transmission rear bearing which is retained in adapter

require replacement, the entire transmission and over-

drive assembly should be removed and overhauled on the

bench.

MAINTENANCE AND ADJUSTMENTS

Servicing of the overdrive governor switch and pinion,

the sun gear solenoid, oil seal and cable bracket, the out-

put shaft rear oil seal, the control shaft lever, and the

speedometer driven gear may be accomplished without

removing the overdrive from the vehicle, as discussed

in the following paragraphs:

GOVERNOR SWITCH AND PINION

To remove governor switch, disconnect wires at gover-

nor switch and screw governor

out

of housing, using Tool

J-4653 on the flat hexagonal surface of governor case.

The pinion may be separated from the governor by re-

moving the snap ring on the shaft.

SUN GEAR SOLENOID, OIL SEAL AND

CONTROL CABLE BRACKET

Remove the solenoid by taking out the two mounting

bolts and lock washers, removing

the.

cable bracket with

the lower bolt. Turn the solenoid 1/4 turn and

pull,

sole-

noid plunger out of adapter. The oil seal may be pried

out of the adapter.

CASE REAR OIL SEAL

Removal

1.

Remove propeller shaft as outlined in Section 4.

2.

Using a punch against seal in housing, pry out seal

from housing.

Installation

1.

Prelubricate between sealing lips and coat outside of

new oil seal with a suitable sealant, then start seal

into bore in overdrive housing.

2.

Using Tool J-5154 drive oil seal into counterbore.

3.

Install propeller shaft as outlined in Section 4.

CONTROL SHAFT LEVER AND/OR "O" RING

OIL SEALS

To remove- the control shaft, disconnect the cpntrol

cable, remove tapered pin and pull lever out. Replace

the two "0" ring seals on the control shaft. Insert shaft

and new "O" ring seals into housing and install tapered

pin. Connect control wire to lever.

SPEEDOMETER DRIVEN GEAR

Disconnect speedometer cable, remove lock plate to

housing bolt and lock washer and remove lock plate. In-

sert screw driver in lock plate slot in fitting and pry

fitting, gear and shaft from housing. Pry "O" ring from

groove in guide.

Install new "O" ring in groove in fitting and insert

shaft.

Hold the assembly so slot in fitting is toward lock plate

boss on housing and install in housing. Push fitting into

housing until lock plate can be inserted in groove and

attached to housing.

L

dl

ZAIR GAP

km (CHECK WITH

M*= POINTS BARELY

'A

AoWER

|^

POINT

0 ADJUST

=^ i

SUPPORT

Fig. IB - Checking Relay Air Gap

CHEVROLET CHASSIS SERVICE MANUAL

Page 370 of 659

CLUTCH AND TRANSMISSIONS 7-11

UPPER ARMATURE STOP

(BEND TO ADJUST POINT OPENING)

Fig.

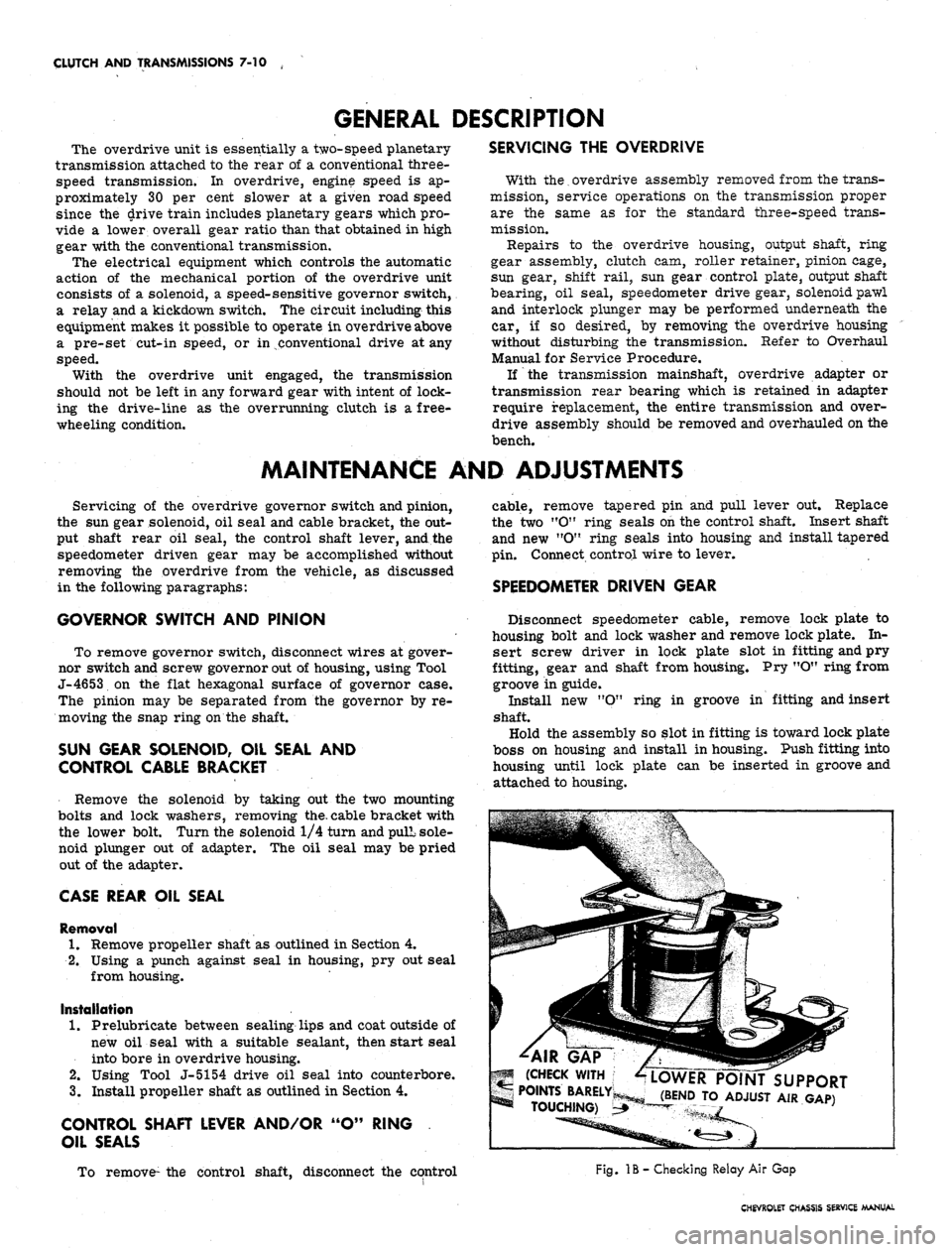

2B-Adjusting Relay Point Opening

ELECTRICAL UNIT CHECKS

Overdrive Relay

Specifications and checking procedures for this relay

are as follows:

Specifications

Air Gap Oil inch minimum

Point Opening .025 inch

Closing Voltage

8.3-10.2

volts

Armature Sealing Voltage. ..... 11.2 volts maximum

Three checks and adjustments are required on the

overdrive relay; air gap, point opening and closing volt-

age.

The air gap contact point opening checks and adjust-

ments should be made with the battery disconnected.

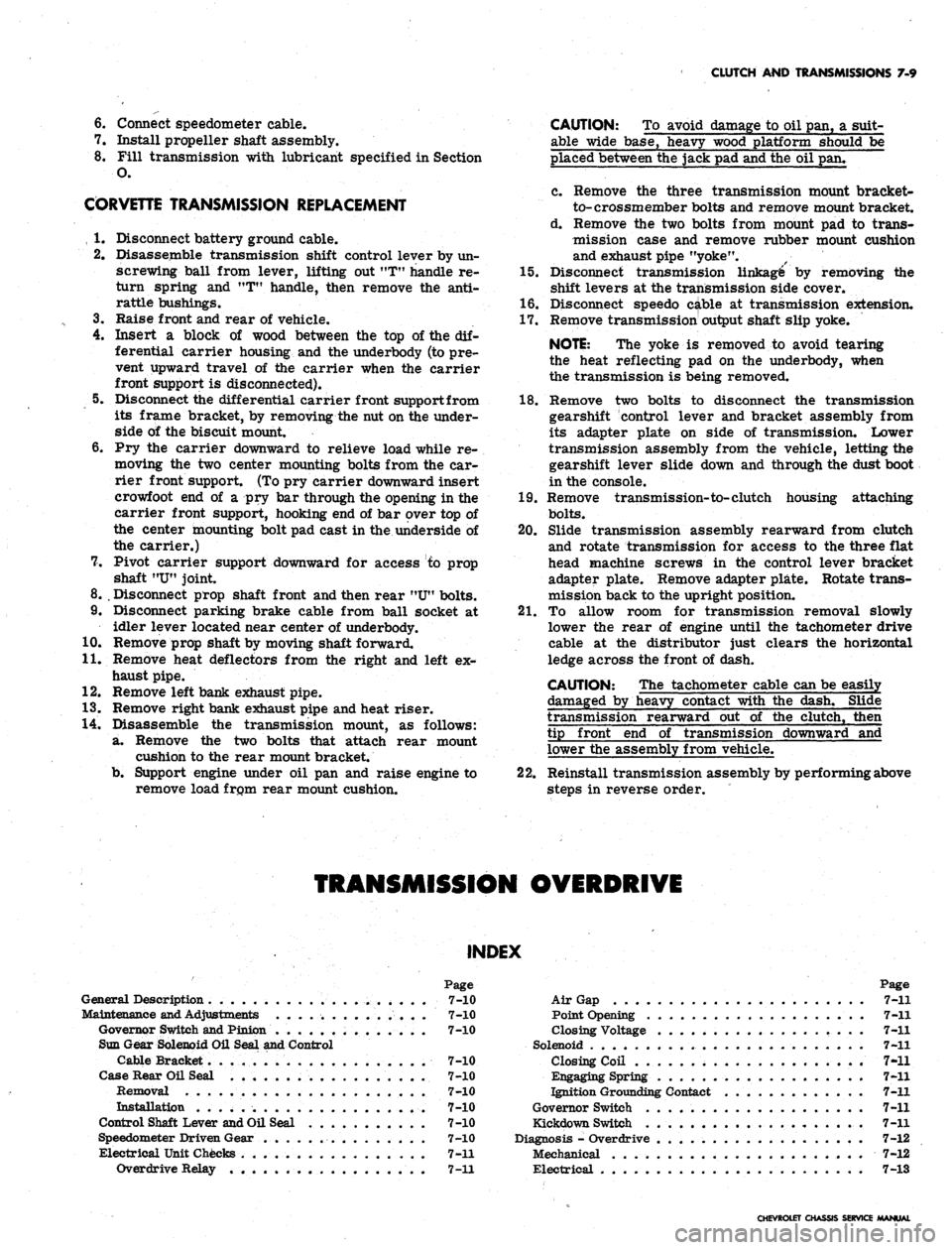

Air Gap

The air gap should not normally require adjustment

unless the relay has been misadjusted. Check the air gap

with the points barely touching and adjust if necessary by

bending the lower point support (fig, IB).

Point Opening

Check the contact point opening and adjust by bending

the upper armature stop (fig. 2B).

Closing Voltage

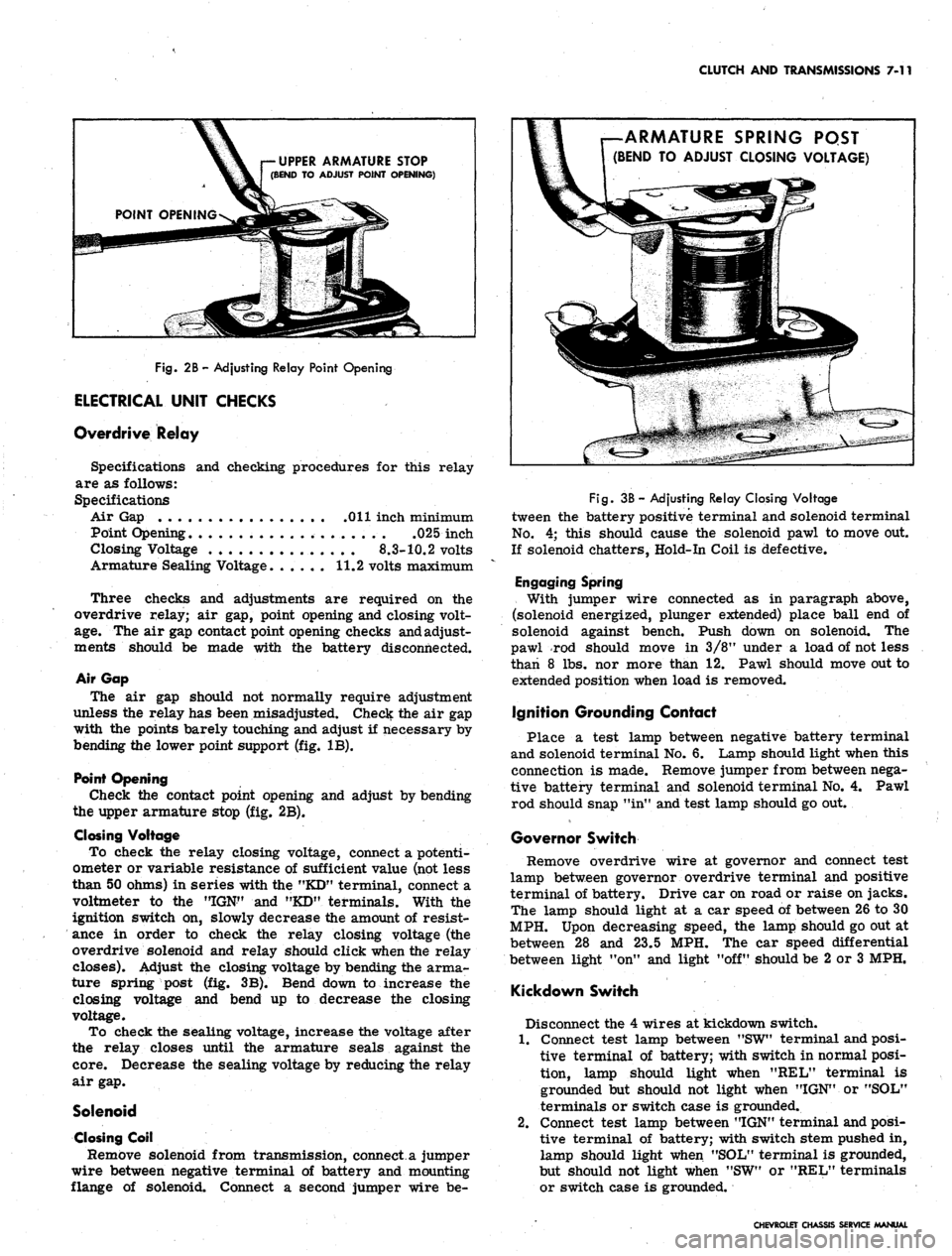

To check the relay closing voltage, connect a potenti-

ometer or variable resistance of sufficient value (not less

than 50 ohms) in series with the "KD" terminal, connect a

voltmeter to the "IGN" and "KD" terminals. With the

ignition switch on, slowly decrease the amount of resist-

ance in order to check the relay closing voltage (the

overdrive solenoid and relay should click when the relay

closes). Adjust the closing voltage by bending the arma-

ture spring post (fig. 3B). Bend down to increase the

closing voltage and bend up to decrease the closing

voltage.

To check the sealing voltage, increase the voltage after

the relay closes until the armature seals against the

core.

Decrease the sealing voltage by reducing the relay

air gap.

Solenoid

Closing Coil

Remove solenoid from transmission, connect a jumper

wire between negative terminal of battery and mounting

flange of solenoid. Connect a second jumper wire be-

ARMATURE SPRING PQST

(BEND TO ADJUST CLOSING VOLTAGE)

Fig.

3B - Adjusting Relay Closing Voltage

tween the battery positive terminal and solenoid terminal

No.

4; this should cause the solenoid pawl to move out.

If solenoid chatters, Hold-In Coil is defective.

Engaging Spring

With jumper wire connected as in paragraph above,

(solenoid energized, plunger extended) place ball end of

solenoid against bench. Push down on solenoid. The

pawl rod should move in 3/8M under a load of not less

than 8 lbs. nor more than 12. Pawl should move out to

extended position when load is removed.

Ignition Grounding Contact

Place a test lamp between negative battery terminal

and solenoid terminal No. 6. Lamp should light when this

connection is made. Remove jumper from between nega-

tive battery terminal and solenoid terminal No. 4. Pawl

rod should snap "in" and test lamp should go out.

Governor Switch

Remove overdrive wire at governor and connect test

lamp between governor overdrive terminal and positive

terminal of battery. Drive car on road or raise on jacks.

The lamp should light at a car speed of between 26 to 30

MPH. Upon decreasing speed, the lamp should go out at

between 28 and 23.5 MPH. The car speed differential

between light "on" and light "off" should be 2 or 3 MPH.

Kickdown Switch

Disconnect the 4 wires at kickdown switch.

1.

Connect test lamp between "SW" terminal and posi-

tive terminal of battery; with switch in normal posi-

tion, lamp should light when "REL" terminal is

grounded but should not light when "IGN" or "SOL"

terminals or switch case is grounded.

2.

Connect test lamp between "IGN" terminal and posi-

tive terminal of battery; with switch stem pushed in,

lamp should light when "SOL" terminal is grounded,

but should not light when "SW" or "REL" terminals

or switch case is grounded.

CHEVROLET CHASSIS SERVICE MANUAL

Page 372 of 659

CLUTCH AND TRANSMISSIONS 7-13

PULL-IN

WINDING

li

HOLD-IN

WINDING

Fig.

4B -

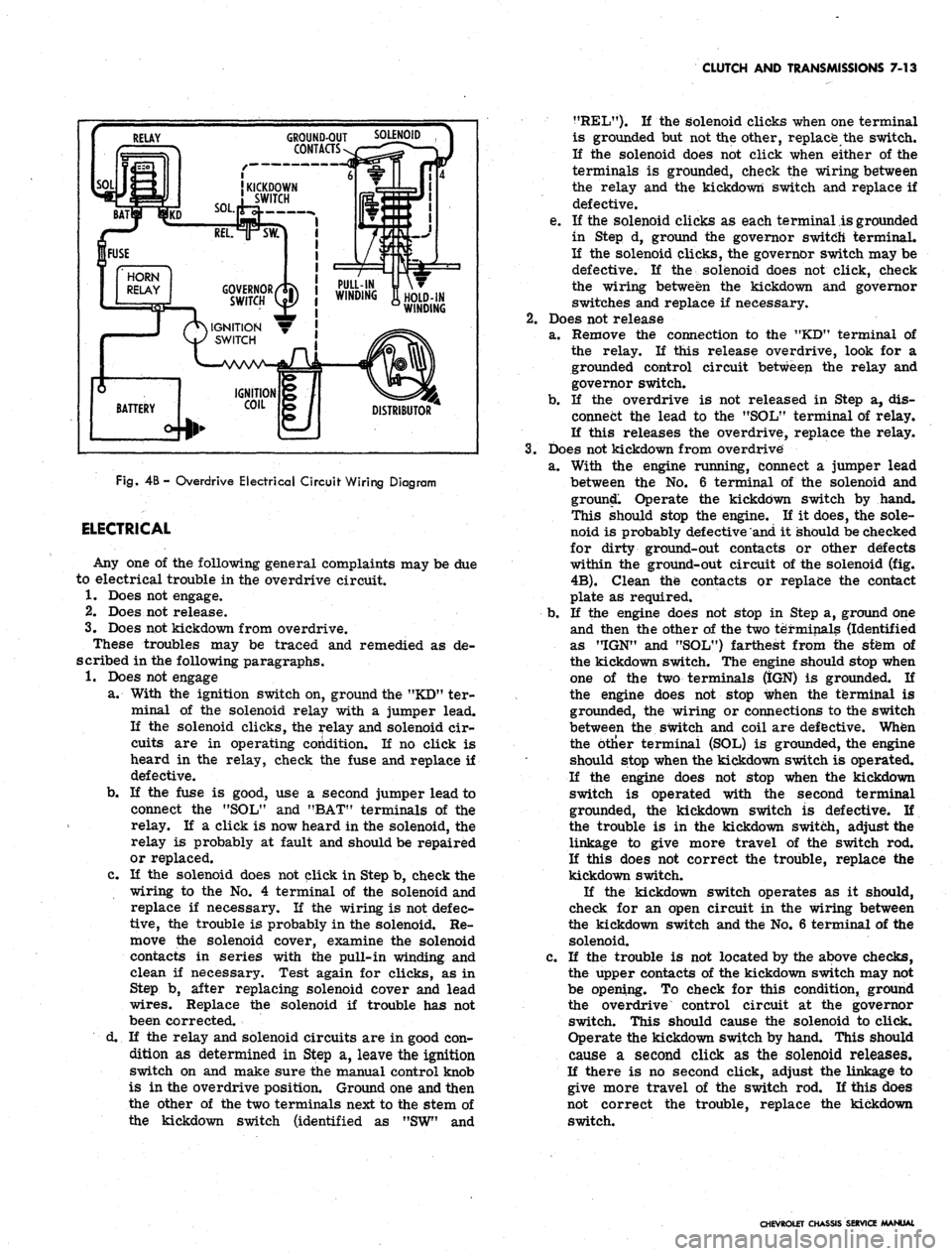

Overdrive Electrical Circuit Wiring Diagram

ELECTRICAL

Any one of the following general complaints may be due

to electrical trouble in the overdrive circuit.

1.

Does not engage.

2.

Does not release.

3.

Does not kickdown from overdrive.

These troubles may be traced and remedied as de-

scribed in the following paragraphs.

1.

Does not engage

a. With the ignition switch on, ground the "KD" ter-

minal of the solenoid relay with a jumper lead.

If the solenoid clicks, the relay and solenoid cir-

cuits are in operating condition. If no click is

heard in the relay, check the fuse and replace if

defective.

b.

If the fuse is good, use a second jumper lead to

connect the "SOL" and "BAT" terminals of the

relay. If a click is now heard in the solenoid, the

relay is probably at fault and should be repaired

or replaced.

c. If the solenoid does not click in Step b, check the

wiring to the No. 4 terminal of the solenoid and

replace if necessary. If the wiring is not defec-

tive,

the trouble is probably in the solenoid. Re-

move the solenoid cover, examine the solenoid

contacts in series with the pull-in winding and

clean if necessary. Test again for clicks, as in

Step b, after replacing solenoid cover and lead

wires.

Replace the solenoid if trouble has not

been corrected.

d. If the relay and solenoid circuits are in good con-

dition as determined in Step a, leave the ignition

switch on and make sure the manual control knob

is in the overdrive position. Ground one and then

the other of the two terminals next to the stem of

the kickdown switch (identified as "SW" and

?fREL"). K the solenoid clicks when one terminal

is grounded but not the other, replace the switch.

If the solenoid does not click when either of the

terminals is grounded, check the wiring between

the relay and the kickdown switch and replace if

defective.

e. If the solenoid clicks as each terminal is grounded

in Step d, ground the governor switch terminal.

If the solenoid clicks, the governor switch may be

defective. If the solenoid does not click, check

the wiring between the kickdown and governor

switches and replace if necessary.

2.

Does not release

a. Remove the connection to the "KD" terminal of

the relay. If this release overdrive, look for a

grounded control circuit between the relay and

governor switch.

b.

If the overdrive is not released in Step a, dis-

connect the lead to the "SOL" terminal of relay.

If this releases the overdrive, replace the relay.

3.

Does not kickdown from overdrive

a. With the engine running, connect a jumper lead

between the No. 6 terminal of the solenoid and

ground. Operate the kickdown switch by hand.

This should stop the engine. If it does, the sole-

noid is probably defective and it should be checked

for dirty ground-out contacts or other defects

within the ground-out circuit of the solenoid (fig.

4B).

Clean the contacts or replace the contact

plate as required.

b.

If the engine does not stop in Step a, ground one

and then the other of the two terminals (Identified

as "IGN" and "SOL") farthest from the sfem of

the kickdown switch. The engine should stop when

one of the two terminals (IGN) is grounded. If

the engine does not stop when the terminal is

grounded, the wiring or connections to the switch

between the switch and coil are defective. When

the btlier terminal (SOL) is grounded, the engine

should stop when the kickdown switch is operated.

If the engine does not stop when the kickdown

switch is operated with the second terminal

grounded, the kickdown switch is defective. If

the trouble is in the kickdown switch, adjust the

linkage to give more travel of the switch rod.

If this does not correct the trouble, replace the

kickdown switch.

If the kickdown switch operates as it should,

check for an open circuit in the wiring between

the kickdown switch and the No. 6 terminal of the

solenoid.

c. If the trouble is not located by the above checks,

the upper contacts of the kickdown switch may not

be opening. To check for this condition, ground

the overdrive control circuit at the governor

switch. This should cause the solenoid to click.

Operate the kickdown switch by hand. This should

cause a second click as the solenoid releases.

If there is no second click, adjust the linkage to

give more travel of the switch rod. If this does

not correct the trouble, replace the kickdown

switch.

CHEVROLET CHASSIS SERVICE MANUAL

Page 389 of 659

CLUTCH AND TRANSMISSIONS

7*30

V-8 Models-With Uni-Directional Linkage

1.

Remove air cleaner.

2.

Disconnect accelerator linkage at carburetor.

3.

Disconnect accelerator return and TV rod return

springs.

4.

With right hand, pull TV upper rod forward until

transmission is through detent. With left hand, open

carburetor to wide open throttle position. Carbure-

tor must reach wide open throttle position at the

same time the ball stud contacts end of slot in upper

TV rod.

5. Adjust swivel on end of upper TV rod to obtain set-

ting described in Step 4. Allowable tolerance is

approximately 1/32".

6. Connect and adjust accelerator linkage as described

in Section 6.

7. Check for throttle linkage freedom.

Neutral Safety Switch Adjustment

The adjustment at the neutral safety switch is de-

scribed in the Electrical Section 12.

Throttle Return Check Valve (Dashpot) Adjustment

The adjustment of the throttle return check valve is

described in Section 6M for each carburetor installation.

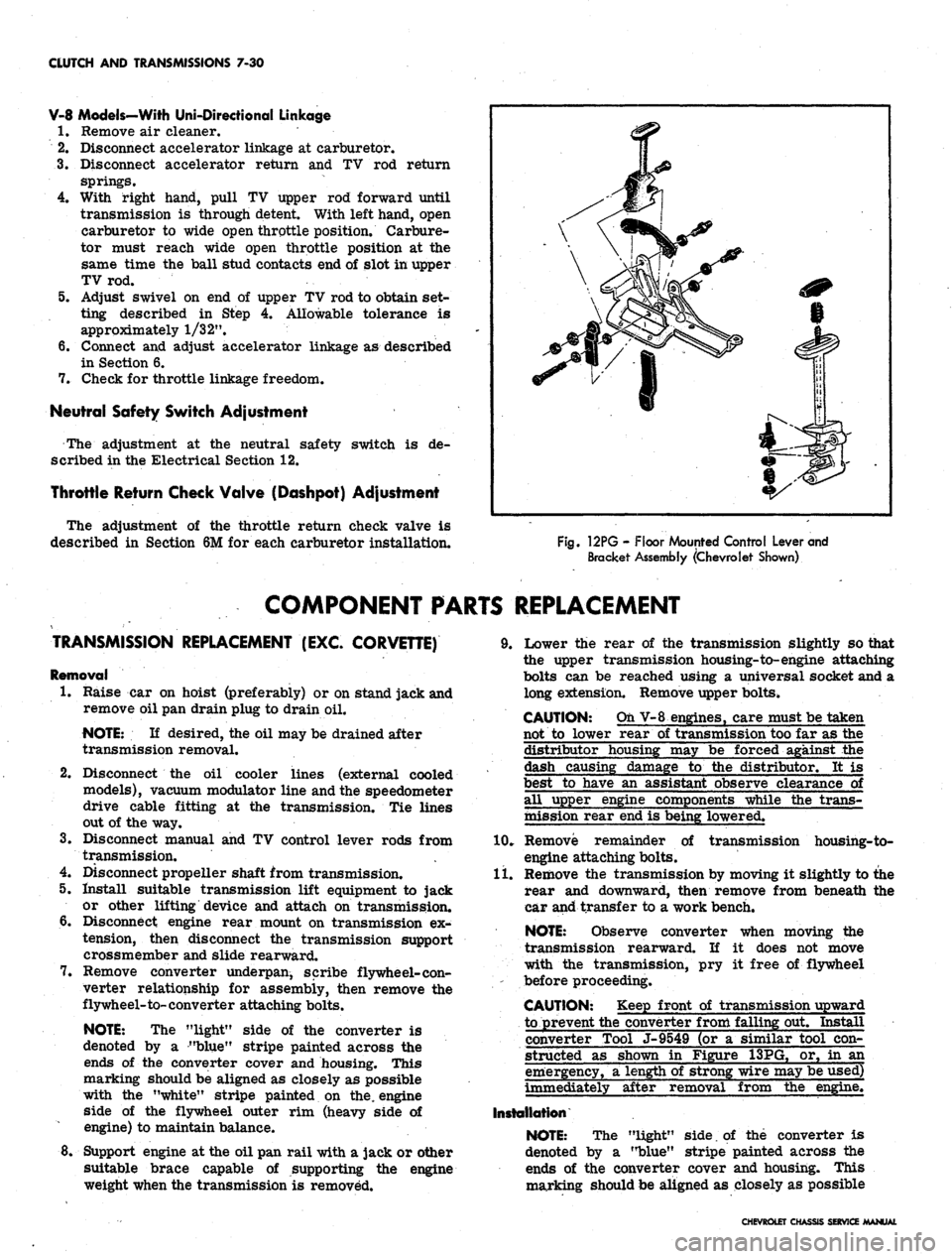

Fig.

12PG - Floor Mounted Control Lever and

Bracket Assembly (Chevrolet Shown)

COMPONENT PARTS REPLACEMENT

TRANSMISSION REPLACEMENT (EXC. CORVETTE)

Removal

1.

Raise car on hoist (preferably) or on stand jack and

remove oil pan drain plug to drain oil.

NOTE:

If desired, the oil may be drained after

transmission removal.

2.

Disconnect the oil cooler lines (external cooled

models), vacuum modulator line and the speedometer

drive cable fitting at the transmission. Tie lines

out of the way.

3.

Disconnect manual and TV control lever rods from

transmission.

4.

Disconnect propeller shaft from transmission.

5. Install suitable transmission lift equipment to jack

or other lifting device and attach on transmission.

6. Disconnect engine rear mount on transmission ex-

tension, then disconnect the transmission support

crossmember and slide rearward.

7. Remove converter underpan, scribe flywheel-con-

verter relationship for assembly, then remove the

flywheel-to-converter attaching bolts.

NOTE:

The "light" side of the converter is

denoted by a "blue" stripe painted across the

ends of the converter cover and housing. This

marking should be aligned as closely as possible

with the "white" stripe painted on the. engine

side of the flywheel outer rim (heavy side of

engine) to maintain balance.

8. Support engine at the oil pan rail with a jack or other

suitable brace capable of supporting the engine

weight when the transmission is removed.

9. Lower the rear of the transmission slightly so that

the upper transmission housing-to-engine attaching

bolts can be reached using a universal socket and a

long extension. Remove upper bolts.

CAUTION: Oh V-8 engines, care must be taken

not to lower rear of transmission too far as the

distributor housing may be forced against the

dash causing damage to the distributor. It is

best to have an assistant observe clearance of

all upper engine components while the trans-

mission rear end is being lowered.

10.

Remove remainder of transmission housing-to-

engine attaching bolts.

11.

Remove the transmission by moving it slightly to the

rear and downward, then remove from beneath the

car and transfer to a work bench.

NOTE:

Observe converter when moving the

transmission rearward. If it does not move

with the transmission, pry it free of flywheel

before proceeding.

CAUTION: Keep front of transmission upward

to prevent the converter from falling out. Install

converter Tool J-9549 (or a similar tool con-

structed as shown in Figure 13PG, or, in an

emergency, a length of strong wire may be used)

immediately after removal from the engine.

Installation

NOTE:

The "light" side, of the converter is

denoted by a "blue" stripe painted across the

ends of the converter cover and housing. This

marking should be aligned as closely as possible

CHEVROLET CHASSIS SERVICE MANUAL