charging CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 334 of 659

ENGINE-ELECTRICAL 6Y-9

63 AMP 1

MODELS ONLY'

BATTERY FUSIBLE

LINK

HORN

FUSIBLE LINK'

TRANSISTOR

FUSIBLE LINK'

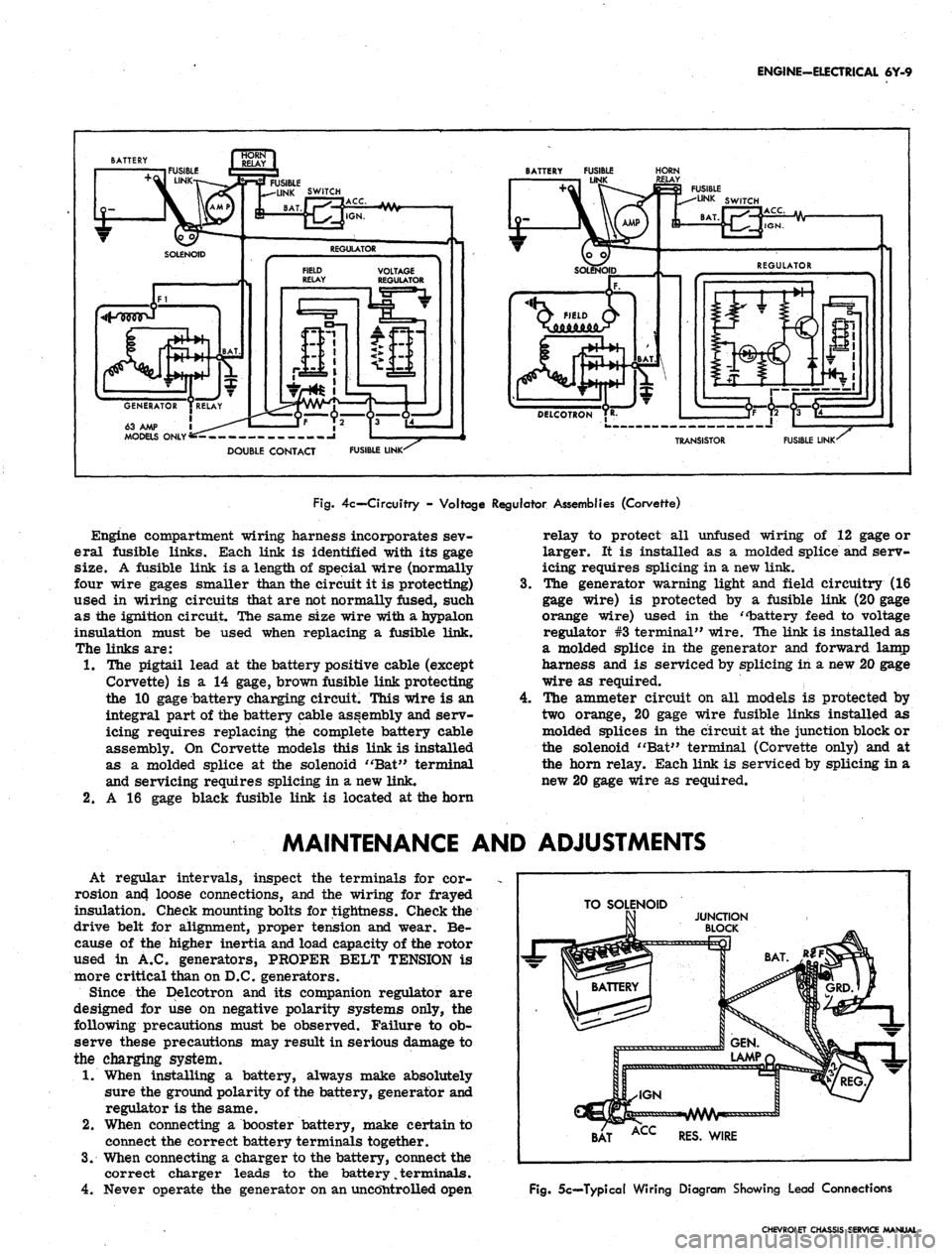

Fig.

4c— Circuitry - Voltage Regulator Assemblies (Corvette)

Engine compartment wiring harness incorporates sev-

eral fusible links. Each link is identified with its gage

size. A fusible link is a length of special wire (normally

four wire gages smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a hypalon

insulation must be used when replacing a fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gage, brown fusible link protecting

the 10 gage battery charging circuit. This wire is an

integral part of the battery cable assembly and serv-

icing requires replacing the complete battery cable

assembly. On Corvette models this link is installed

as a molded splice at the solenoid "Bat" terminal

and servicing requires splicing in a new link.

2.

A 16 gage black fusible link is located at the horn

4.

relay to protect all unfused wiring of 12 gage or

larger. It is installed as a molded splice and serv-

icing requires splicing in a new link.

The generator warning light and field circuitry (16

gage wire) is protected by a fusible link (20 gage

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed as

a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gage

wire as required.

The ammeter circuit on all models is protected by

two orange, 20 gage wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at

the horn relay. Each link is serviced by splicing in a

new 20 gage wire as required.

MAINTENANCE AND ADJUSTMENTS

At regular intervals, inspect the terminals for cor-

rosion an4 loose connections, and the wiring for frayed

insulation. Check mounting bolts for tightness. Check the

drive belt for alignment, proper tension and wear. Be-

cause of the higher inertia and load capacity of the rotor

used in A.C. generators, PROPER BELT TENSION is

more critical than on D.C. generators.

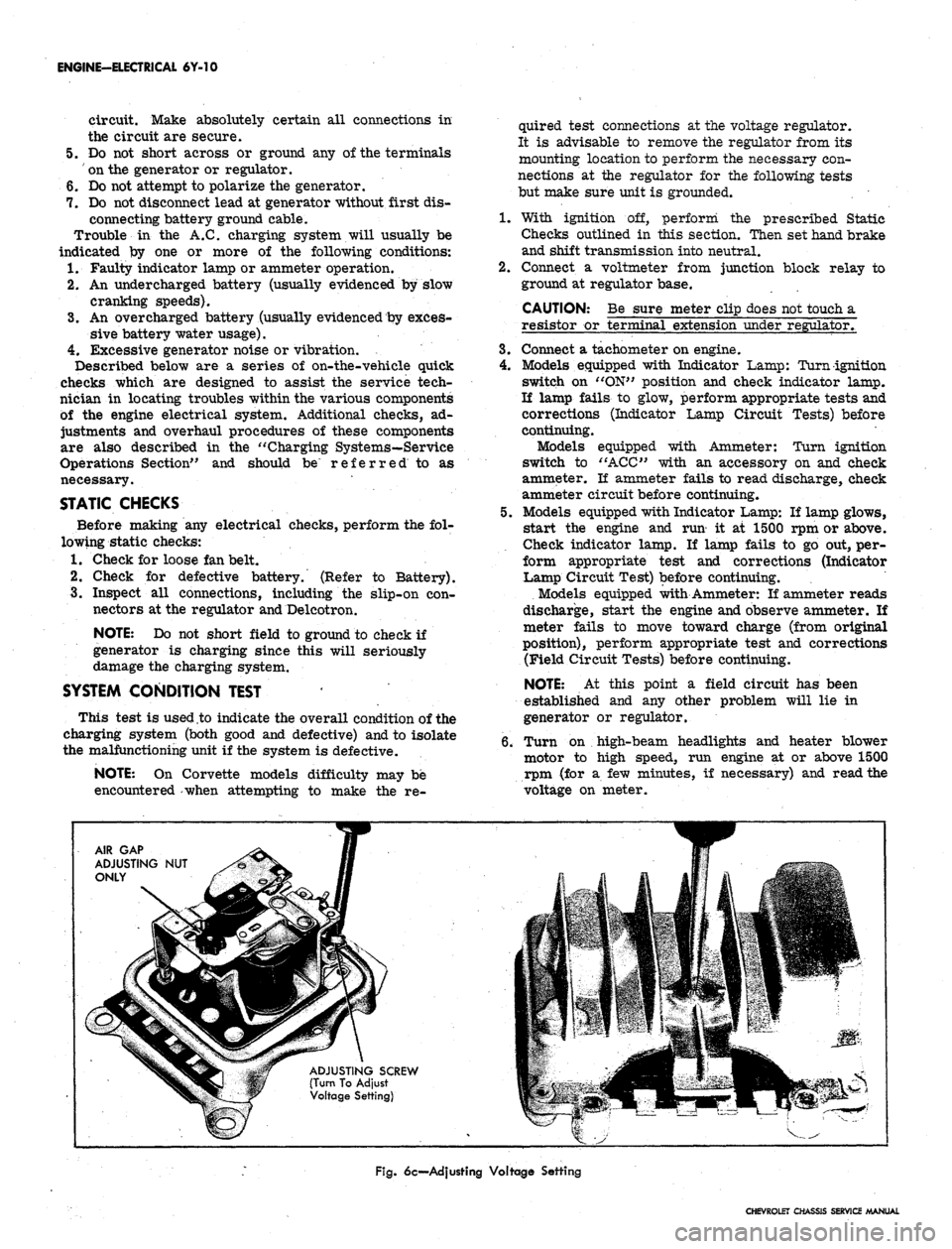

Since the Delcotron and its companion regulator are

designed for use on negative polarity systems only, the

following precautions must be observed. Failure to ob-

serve these precautions may result in serious damage to

the charging system.

1.

When installing a battery, always make absolutely

sure the ground polarity of the battery, generator and

regulator is the same.

2.

When connecting a booster battery, make certain to

connect the correct battery terminals together.

3.

When connecting a charger to the battery, connect the

correct charger leads to the battery

%

terminals.

4.

Never operate the generator on an uncontrolled open

TO SOLENOID

BAT ACC RES. WIRE

Fig.

5c—Typical Wiring Diagram Showing Lead Connections

CHEVROLET CHASSIS SERVICE MANUAL

Page 335 of 659

ENGINE-ELECTRICAL 6Y-10

circuit. Make absolutely certain all connections in

the circuit are secure.

5.

Do not short across or ground any of the terminals

on the generator or regulator.

6. Do not attempt to polarize the generator.

7.

Do not disconnect lead at generator without first dis-

connecting battery ground cable.

Trouble in the A.C. charging system will usually be

indicated by one or more of the following conditions:

1.

Faulty indicator lamp or ammeter operation.

2.

An undercharged battery (usually evidenced by slow

cranking speeds).

3.

An overcharged battery (usually evidenced by exces-

sive battery water usage).

4.

Excessive generator noise or vibration.

Described below are a series of on-the-vehicle quick

checks which are designed to assist the service tech-

nician in locating troubles within the various components

of the engine electrical system. Additional checks, ad-

justments and overhaul procedures of these components

are also described in the "Charging Systems—Service

Operations Section" and should be referred to as

necessary.

STATIC CHECKS

Before making any electrical checks, perform the fol-

lowing static checks:

1.

Check for loose fan belt.

2.

Check for defective battery. (Refer to Battery).

3.

Inspect all connections, including the slip-on con-

nectors at the regulator and Delcotron.

NOTE: Do not short field to ground to check if

generator is charging since this will seriously

damage the charging system.

SYSTEM CONDITION TEST

This test is used .to indicate the overall condition of the

charging system (both good and defective) and to isolate

the malfunctioning unit if the system is defective.

NOTE: On Corvette models difficulty may be

encountered -when attempting to make the re-

quired test connections at the voltage regulator.

It is advisable to remove the regulator from its

mounting location to perform the necessary con-

nections at the regulator for the following tests

but make sure unit is grounded.

1.

With ignition off, perform the prescribed Static

Checks outlined in this section. Then set hand brake

and shift transmission

into

neutral.

2.

Connect a voltmeter from junction block relay to

ground at regulator base.

CAUTION: Be sure meter clip does not touch a

resistor or terminal extension under regulator,

3.

Connect a tachometer on engine.

4.

Models equipped with Indicator Lamp: Turn ignition

switch on "ON" position and check indicator lamp.

If lamp fails to glow, perform appropriate tests and

corrections (Indicator Lamp Circuit Tests) before

continuing.

Models equipped with Ammeter: Turn ignition

switch to "ACC" with an accessory on and check

ammeter. If ammeter fails to read discharge, check

ammeter circuit before continuing.

5.

Models equipped with Indicator Lamp: If lamp glows,

start the engine and run' it at 1500 rpm or above.

Check indicator lamp. If lamp fails to go out, per-

form appropriate test and corrections (Indicator

Lamp Circuit Test) before continuing.

Models equipped with Ammeter: If ammeter reads

discharge, start the engine and observe ammeter. If

meter fails to move toward charge (from original

position), perform appropriate test and corrections

(Field Circuit Tests) before continuing.

NOTE: At this point a field circuit has been

established and any other problem will lie in

generator or regulator.

6. Turn on high-beam headlights and heater blower

motor to high speed, run engine at or above 1500

rpm (for a few minutes, if necessary) and read the

voltage on meter.

AIR GAP

ADJUSTING NUT

ONLY

ADJUSTING SCREW

(Turn To Adjust

Voltage Setting)

Fig.

6c—Adjusting Voltage Setting

CHEVROLET CHASSIS SERVICE MANUAL

Page 336 of 659

ENGINE-ELECTRICAL 6Y-11

I

BAT

JUNCTION BLOCK

DELCOTRON

—GRQ

BATTERY

&HJVVWV

0 VA OHM TEST RELAY >

RESISTOR [ 1 d

FUSIBLE

LINK

TO CRANKING

MOTOR

Ik

REGULATOR

VOLTMETER

FUSIBLE LINK

IGN.

SWITCH

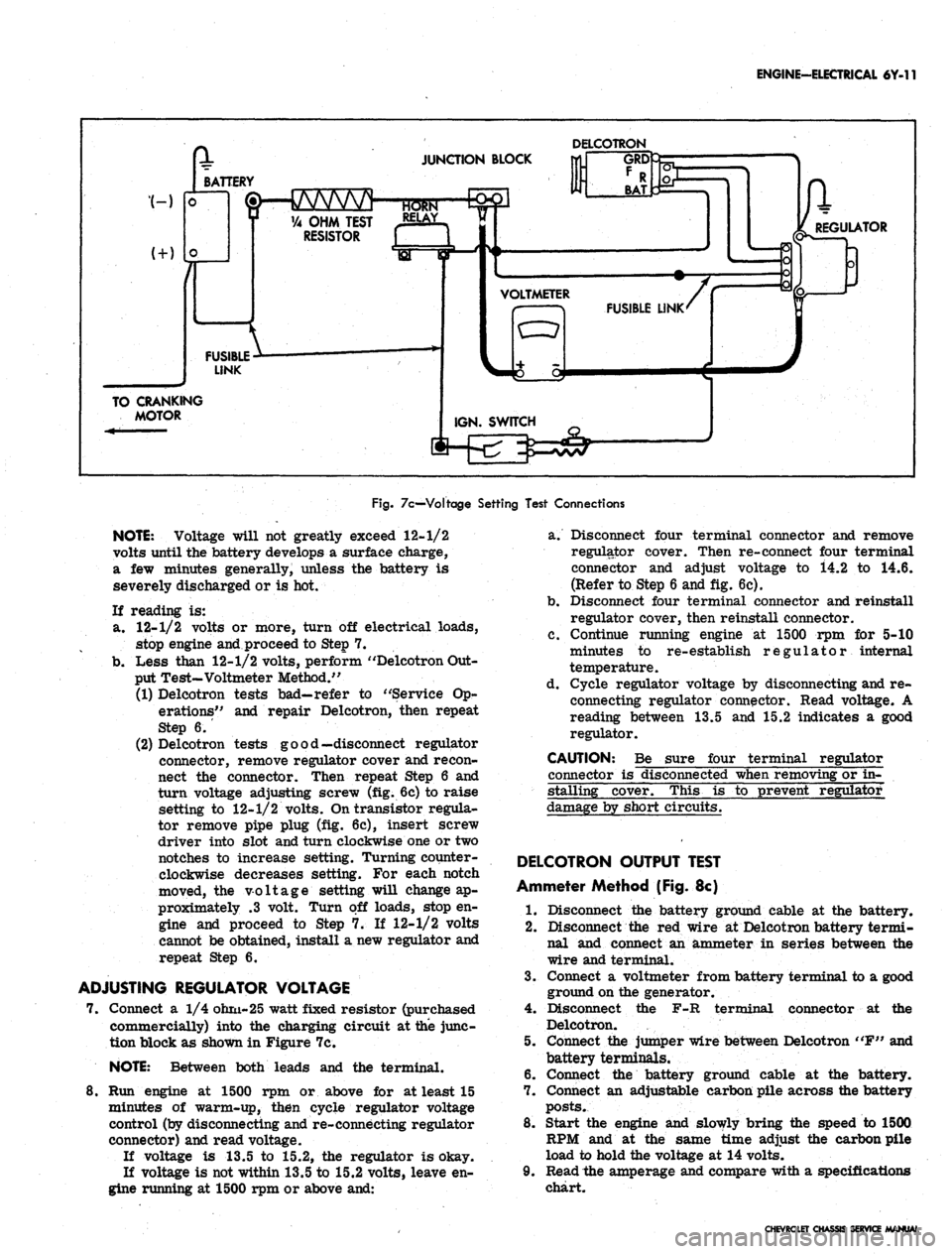

Fig.

7c—Voltage Setting Test Connections

NOTE:

Voltage will not greatly exceed 12-1/2

volts until the battery develops a surface charge,

a few minutes generally, unless the battery is

severely discharged or is hot.

If reading is:

a. 12-1/2 volts or more, turn off electrical loads,

stop engine and proceed to Step 7.

b.

Less than 12-1/2 volts, perform "Delcotron Out-

put Test-Voltmeter Method."

(1) Delcotron tests bad—refer to "Service Op-

erations" and repair Delcotron, then repeat

Step 6.

(2) Delcotron tests good—disconnect regulator

connector, remove regulator cover and recon-

nect the connector. Then repeat Step 6 and

turn voltage adjusting screw (fig. 6c) to raise

setting to 12-1/2 volts. On transistor regula-

tor remove pipe plug (fig. 6c), insert screw

driver into slot and turn clockwise one or two

notches to increase setting. Turning counter-

clockwise decreases setting. For each notch

moved, the voltage setting will change ap-

proximately .3 volt. Turn off loads, stop en-

gine and proceed to Step 7. If 12-1/2 volts

cannot be obtained, install a new regulator and

repeat Step 6.

ADJUSTING REGULATOR VOLTAGE

7. Connect a 1/4 ohm-25 watt fixed resistor (purchased

commercially) into the charging circuit at the junc-

tion block as shown in Figure 7c.

NOTE:

Between both leads and the terminal.

8. Run engine at 1500 rpm or above for at least 15

minutes of warm-up, then cycle regulator voltage

control (by disconnecting and re-connecting regulator

connector) and read voltage.

If voltage is 13.5 to 15.2, the regulator is okay.

If voltage is not within 13.5 to 15.2 volts, leave en-

gine running at 1500 rpm or above and:

a. Disconnect four terminal connector and remove

regulator cover. Then re-connect four terminal

connector and adjust voltage to i4.2 to 14.6.

(Refer to Step 6 and fig. 6c).

b.

Disconnect four terminal connector and reinstall

regulator cover, then reinstall connector.

c. Continue running engine at 1500 rpm for 5-10

minutes to re-establish regulator internal

temperature.

d. Cycle regulator voltage by disconnecting and re-

connecting regulator connector. Read voltage. A

reading between 13.5 and 15.2 indicates a good

regulator.

CAUTION: Be sure four terminal regulator

connector is disconnected when removing or in-

stalling cover. This is to prevent regulator

damage by short circuits.

DELCOTRON OUTPUT TEST

Ammeter Method (Fig. 8c)

1.

Disconnect the battery ground cable at the battery.

2.

Disconnect the red wire at Delcotron battery termi-

nal and connect an ammeter in series between the

wire and terminal.

3.

Connect a voltmeter from battery terminal to a good

ground on the generator.

4.

Disconnect the F-R terminal connector at the

Delcotron.

5. Connect the jumper wire between Delcotron "F" and

battery terminals.

6. Connect the battery ground cable at the battery.

7. Connect an adjustable carbon pile across the battery

posts.

8. Start the engine and slowly bring the speed to 1500

RPM and at the same time adjust the carbon pile

load to hold the voltage at 14 volts.

9. Read the amperage and compare with a specifications

chart.

CHEVROLET CHASSIS SERVICE MANUAL

Page 339 of 659

ENGINE-ELECTRICAL 6Y-14

VOLTMETER

WIRING HARNESS

CONNECTOR

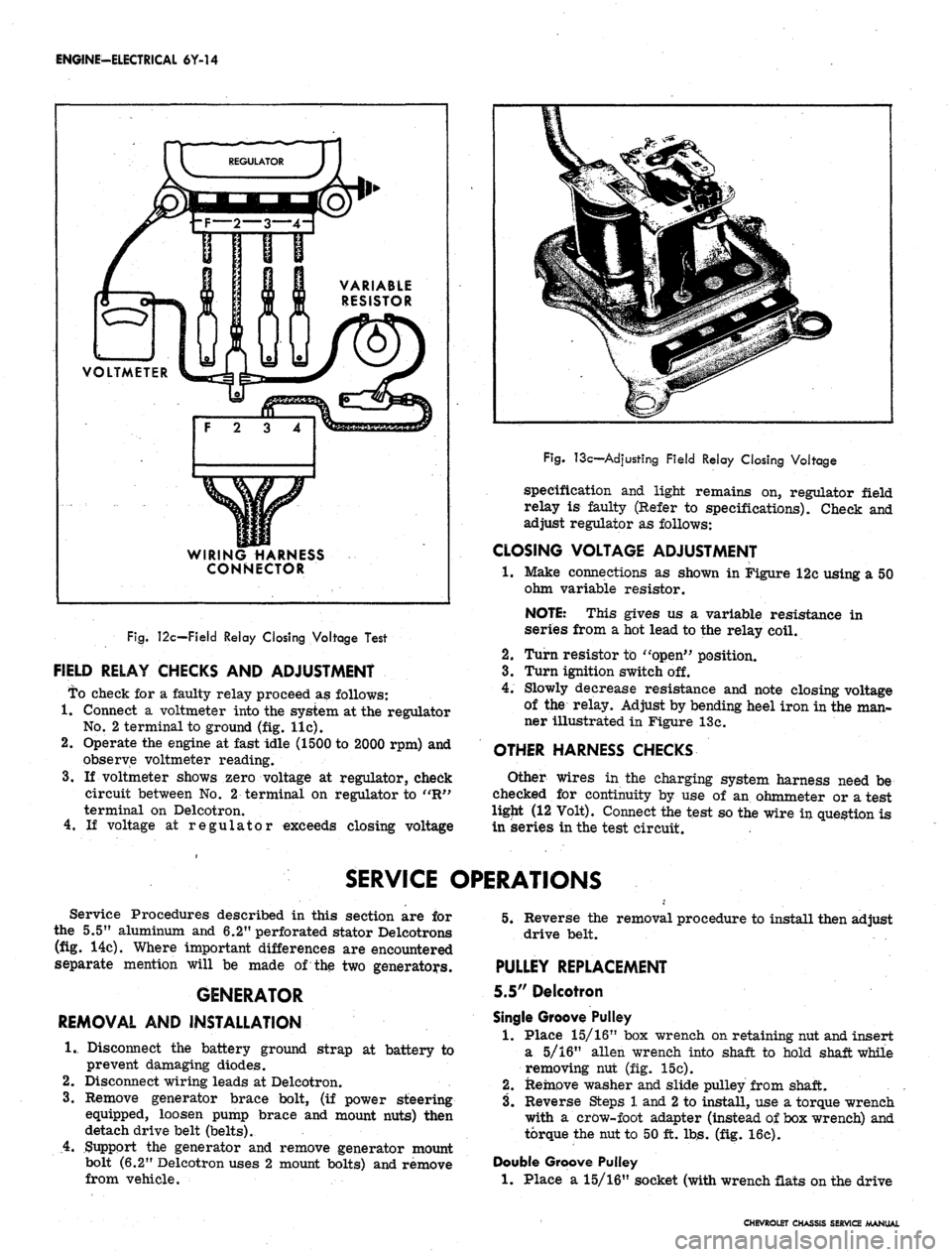

Fig.

12c—Field Relay Closing Voltage Test

FIELD RELAY CHECKS AND ADJUSTMENT

To check for a faulty relay proceed as follows:

1.

Connect a voltmeter into the system at the regulator

No.

2 terminal to ground (fig. lie).

2.

Operate the engine at fast idle (1500 to 2000 rpm) and

observe voltmeter reading.

3.

If voltmeter shows zero voltage at regulator, check

circuit between No. 2 terminal on regulator to "R"

terminal on Delcotron.

4.

If voltage at regulator exceeds closing voltage

Fig.

13c—Adjusting Field Relay Closing Voltage

specification and light remains on, regulator field

relay is faulty (Refer to specifications). Check and

adjust regulator as follows:

CLOSING VOLTAGE ADJUSTMENT

•1.

Make connections as shown in Figure 12c using a 50

ohm variable resistor.

NOTE: This gives us a variable resistance in

series from a hot lead to the relay coil.

2.

Turn resistor to "open" position.

3.

Turn ignition switch off.

4.

Slowly decrease resistance and note closing voltage

of the relay. Adjust by bending heel iron in the man-

ner illustrated in Figure 13c.

OTHER HARNESS CHECKS

Other wires in the charging system harness need be

checked for continuity by use of an ohmmeter or a test

ligjit (12 Volt). Connect the test so the wire in question is

in series in the test circuit.

SERVICE OPERATIONS

Service Procedures described in this section are for

the 5.5" aluminum and 6.2" perforated stator Delcotrons

(fig. 14c). Where important differences are encountered

separate mention will be made of the two generators.

GENERATOR

REMOVAL AND INSTALLATION

1.

Disconnect the battery ground strap at battery to

prevent damaging diodes.

2.

Disconnect wiring leads at Delcotron.

3.

Remove generator brace bolt, (if power steering

equipped, loosen pump brace and mount nuts) then

detach drive belt (belts).

4.

Support the generator and remove generator mount

bolt (6.2" Delcotron uses 2 mount bolts) and remove

from vehicle.

5.

Reverse the removal procedure to install then adjust

drive belt.

PULLEY REPLACEMENT

5.5" Delcotron

Single Groove Pulley

1.

Place 15/16" box wrench on retaining nut and insert

a 5/16" alien wrench into shaft to hold shaft while

removing nut (fig. 15c).

2.

Remove washer and slide pulley from shaft.

3.

Reverse Steps 1 and

2

to install, use a torque wrench

with a crow-foot adapter (instead of box wrench) and

torque the nut to 50 ft. lbs. (fig. 16c).

Double Groove Pulley

1.

Place a 15/16" socket (with wrench flats on the drive

CHEVROLET CHASSIS SERVICE MANUAL

Page 430 of 659

FUEL TANK

AND

EXHAUST SYSTEMS

8-24

EXHAUST SYSTEMS

INDEX

Page

General Description. ..........

8-24

Service Operations

8-24

Muffler Assembly.

8-24

Side Mounted Exhaust.

. . . 8-25

GENERAL DESCRIPTION

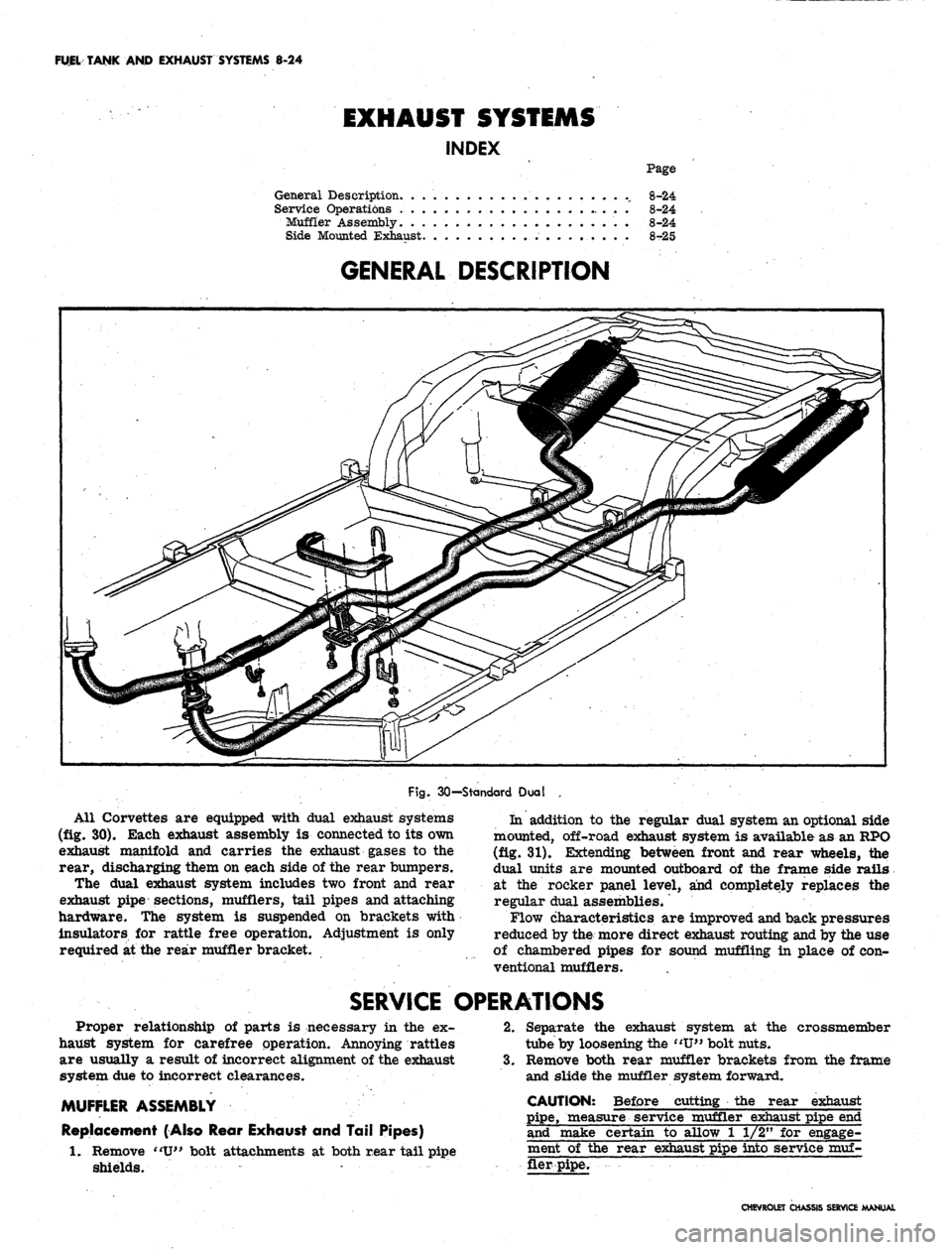

Fig.

30—Standard Dual

All Corvettes

are

equipped with dual exhaust systems

(fig.

30).

Each exhaust assembly

is

connected

to its own

exhaust manifold

and

carries

the

exhaust gases

to the

rear, discharging them

on

each side

of

the rear bumpers.

The dual exhaust system includes

two

front

and

rear

exhaust pipe sections, mufflers, tail pipes and attaching

hardware.

The

system

is

suspended

on

brackets with

insulators

for

rattle free operation. Adjustment

is

only

required

at the

rear muffler bracket.

In addition

to the

regular dual system

an

optional side

mounted, off-road exhaust system

is

available

as an

RPO

(fig.

31).

Extending between front

and

rear wheels,

the

dual units

are

mounted outboard

of the

frame side rails

at

the

rocker panel level,

and

completely replaces

the

regular dual assemblies*

Flow characteristics

are

improved and back pressures

reduced

by

the more direct exhaust routing and

by the use

of chambered pipes

for

sound muffling

in

place

of con-

ventional mufflers.

SERVICE OPERATIONS

Proper relationship

of

parts

is

necessary

in the ex-

haust system

for

carefree operation. Annoying rattles

are usually

a

result

of

incorrect alignment

of

the exhaust

system

due to

incorrect clearances.

MUFFLER ASSEMBLY

Replacement (Also Rear Exhaust

and

Tail Pipes)

Remove

"U"

bolt attachments

at

both rear tail pipe

shields.

2.

crossmember

1.

Separate

the

exhaust system

at the

tube

by

loosening the

"IT"

bolt nuts.

3.

Remove both rear muffler brackets from

the

frame

and slide

the

muffler system forward.

CAUTION: Before cutting

the

rear exhaust

pipe, measure service muffler exhaust pipe

end

and make certain

to

allow

1 1/2" for

engage-

ment

of the

rear exhaust pipe into service

muf-

fler pipe.

CHEVROLET CHASSIS SERVICE MANUAL

Page 514 of 659

ELECTRICAL-BODY AND CHASSIS 12-2

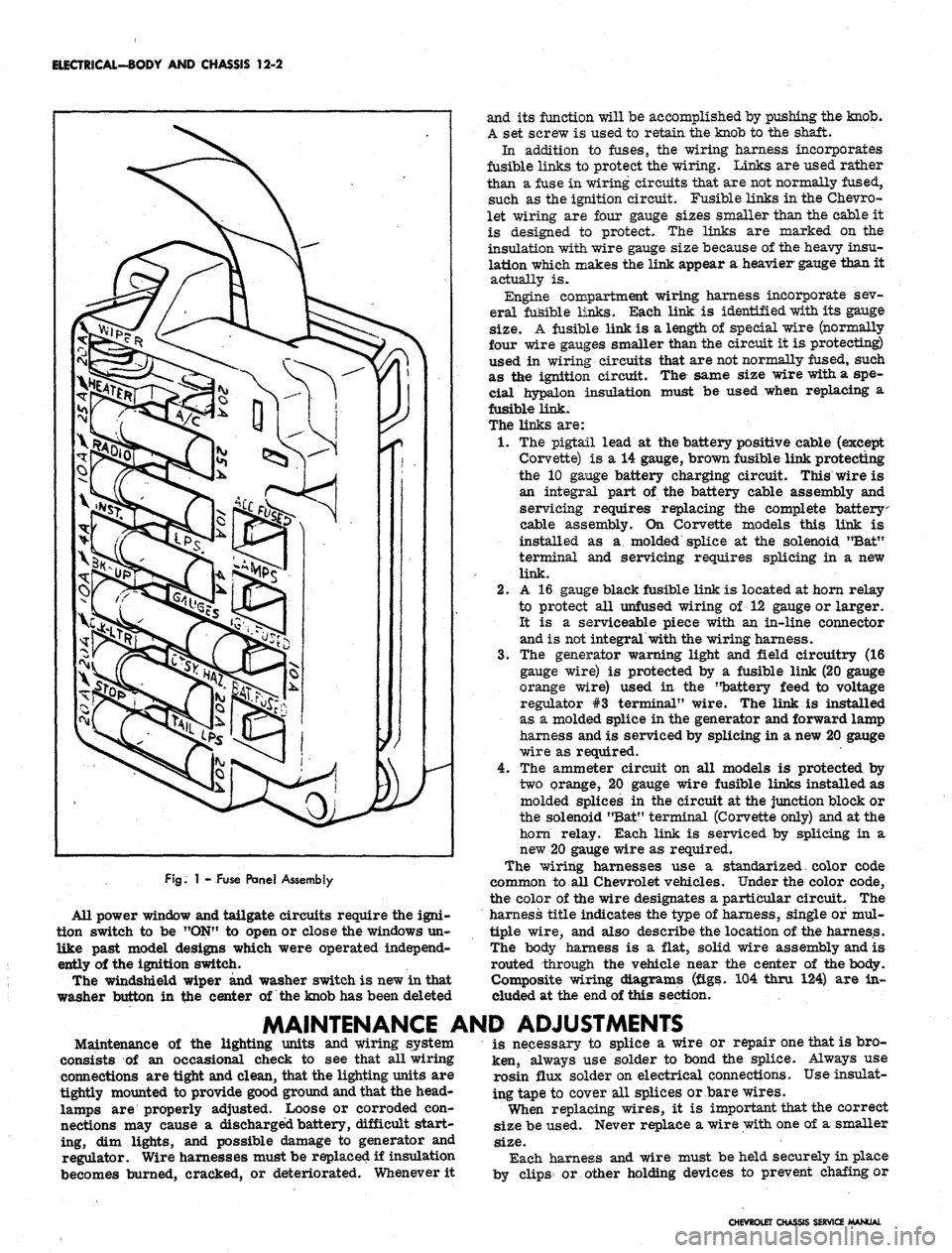

FJg.

1 - Fuse Panel Assembly

All power window and tailgate circuits require the igni-

tion switch to be "ON" to open or close the windows un-

like past model designs which were operated independ-

ently of the ignition switch.

The windshield wiper and washer switch is new in that

washer button in the center of the knob has been deleted

and its function will be accomplished by pushing the knob.

A set screw is used to retain the knob to the shaft.

In addition to fuses, the wiring harness incorporates

fusible links to protect the wiring. Links are used rather

than a fuse in wiring circuits that are not normally fused,

such as the ignition circuit. Fusible links in the Chevro-

let wiring are four gauge sizes smaller than the cable it

is designed to protect. The links are marked on the

insulation with wire gauge size because of the heavy insu-

lation which makes the link appear a heavier gauge than it

actually is.

Engine compartment wiring harness incorporate sev-

eral fusible links. Each link is identified with its gauge

size.

A fusible link is a length of special wire (normally

four wire gauges smaller than the circuit it is protecting)

used in wiring circuits that are not normally fused, such

as the ignition circuit. The same size wire with a spe-

cial hypalon insulation must be used when replacing a

fusible link.

The links are:

1.

The pigtail lead at the battery positive cable (except

Corvette) is a 14 gauge, brown fusible link protecting

the 10 gange battery charging circuit. This wire is

an integral part of the battery cable assembly and

servicing requires replacing the complete battery

cable assembly. On Corvette models this link is

installed as a molded splice at the solenoid "Bat"

terminal and servicing requires splicing in a new

link.

2.

A 16 gauge black fusible link is located at horn relay

to protect all unfused wiring of 12 gauge or larger.

It is a serviceable piece with an in-line connector

and is not integral with the wiring harness.

3.

The generator warning light and field circuitry (16

gauge wire) is protected by a fusible link (20 gauge

orange wire) used in the "battery feed to voltage

regulator #3 terminal" wire. The link is installed

as a molded splice in the generator and forward lamp

harness and is serviced by splicing in a new 20 gauge

wire as required.

4.

The ammeter circuit on all models is protected by

two orange, 20 gauge wire fusible links installed as

molded splices in the circuit at the junction block or

the solenoid "Bat" terminal (Corvette only) and at the

horn relay. Each link is serviced by splicing in a

new 20 gauge wire as required.

The wiring harnesses use a standarized. color code

common to all Chevrolet vehicles. Under the color code,

the color of the wire designates a particular circuit. The

harness title indicates the type of harness, single of mul-

tiple wire, and also describe the location of the harness.

The body harness is a flat, solid wire assembly and is

routed through the vehicle near the center of the body.

Composite wiring diagrams (figs. 104 thru 124) are in-

cluded at the end of this section.

MAINTENANCE AND ADJUSTMENTS

Maintenance of the lighting units and wiring system

consists of an occasional check to see that all wiring

connections are tight and clean, that the lighting units are

tightly mounted to provide good ground and that the head-

lamps are properly adjusted. Loose or corroded con-

nections may cause a discharged battery, difficult start-

ing, dim lights, and possible damage to generator and

regulator. Wire harnesses must be replaced if insulation

becomes burned, cracked, or deteriorated. Whenever it

is necessary to splice a wire or repair one that is bro-

ken, always use solder to bond the splice. Always use

rosin flux solder on electrical connections. Use insulat-

ing tape to cover all splices or bare wires.

When replacing wires, it is important that the correct

size be used. Never replace a wire with one of a smaller

size.

Each harness and wire must be held securely in place

by clips or other holding devices to prevent chafing or

CHEVROLET CHASSIS SERVICE MANUAL

Page 538 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-26

•

Low oil

pressure

• High engine temperature

• Defective wiring

or

switch

connector from sender

in block above starter

on

and

at

left front

of

distributor

on V-8

Sending Unit Replacement

1.

Disconnect wiring harness

unit terminal (located

L-6 engines

engines).

2.

Remove sender unit using Tool J-21757

or 12

point

socket, replace with

new

unit

and

check operation.

GENERATOR INDICATOR

1.

Ignition

on,

Engine

not

Running

and

Telltale Light

Off.

• Indicator bulb burned out, replace bulb.

• Open circuit

or

loose connection

in the

telltale

light circuit.

2.

telltale Light Stays

on

after Engine

is

Started.

If indicator light does

not go out at

engine idle

speed, refer

to

Charging Systems under Engine

Electrical, Section

6Y.

TEMPERATURE (COOLING SYSTEM) INDICATOR

The temperature indicator circuit consists

of two re-

motely located units, indicator gauge

and

engine sender

unit.

The

indicator gauge, located

in the

instrument

panel, consists

of a

red light which will indicate

an

over-

heated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system

to a

level below unit.

2.

Remove sender unit (located

in the

inlet manifold

near water pump housing

on V-8

engines and

in the

cylinder head near

an

exhaust port

oh L-6

engines)

and replace with new unit.

3.

Refill cooling system

and

check operation

of

unit.

CHEVELLE INSTRUMENTS AND GAUGES

INDEX

Page

General Description

* *

i2-26

Service Operations

12-26

Instrument Panel

12-26

Instrument Cluster.

12-26

Fuel Gauge and/or Ammeter

12-27

Clock,

i 12-27

Speedometer

12-27

Page

Speedometer Cable

.

. 12-27

Temperature Gauge

12-29

Oil Pressure Gauge

12-29

Indicator Lights.

. 12-29

Oil Pressure Indicator

12-29

Generator Indicator

. . 12-29

• Temperature Indicator

12-29

GENERAL DESCRIPTION

The Chevelle instrument cluster assembly consists

of:

a speedometer;

a

fuel gauge;

a

generator,

an

engine

tem-

perature and an

oil

pressure indicator lamp, and includes

a clock

on

deluxe models.

On

super sport models,

am-

meter, coolant temperature

and oil

pressure gauges

re-

place

the

appropriate indicator lights. Except

for the

speedometer,

all of the

indicator lamps, instruments

and

gauges

of

these clusters may

be

serviced without remov-

ing

the

instrument cluster assembly from

the

vehicle.

In addition

to the

instrument indicator lamps,

a

brake

warning lamp

is

included

in the

cluster

as

standard

equipment.

The

indicator

is

connected

to the

parking

brake

and

brake pressure differential switches

and

serves

a

dual function.

It

lights when the parking brake

is applied

and

also when

the

brake pedal

is

applied,

if a

malfunction should occur

in the

brake system

due to a

loss

of

hydraulic pressure. Servicing

of the

hydraulic

pressure differential switch

is

covered

in

Section

5 of

this manual.

Regular maintenance

is not

required on the instrument

cjLuster

or its

components other than maintaining dean

and tight electrical connections, replacing defective parts

and keeping

the

speedometer cable properly lubricated.

SERVICE OPERATIONS

INSTRUMENT PANEL ASSEMBLY

INSTRUMENT CLUSTER (Figs.

41

thru

44)

Removal

1.

Disconnect battery ground cable.

2.

Remove steering coupling bolt and disconnect steer-

ing shaft from coupling.

3.

Loosen mast jacket lower clamp.

4.

Remove

air

conditioning center distributor duct

(if

so equipped).

5. Remove radio rear support bracket screw.

6. Remove mast jacket upper support clamp and retain-

ing bolts from lower support (refer

to

Section

9,

Steering).

CAUTION: Cover mast jacket

and

parl

brake handle with

a

suitable material

to

prevc

scratching.

7.

Disconnect speedometer cable

at

rear

of

cluster

housing

and

speed warning control knob

at

panel

(if

so equipped).

8. Remove instrument panel retaining screws (nine

upper and five lower).

.

9. Working under the console remove four lower retain-

ing screws from instrument cluster housing.

10.

Pull instrument panel assembly from console and

lay

forward on mast jacket.

11.

Disconnect wiring harness, cluster lamps and wiring

CHEVROLET CHASSIS SERVICE MANUAL

Page 541 of 659

ELECTRICAL-BODY AND CHASSIS 12-29

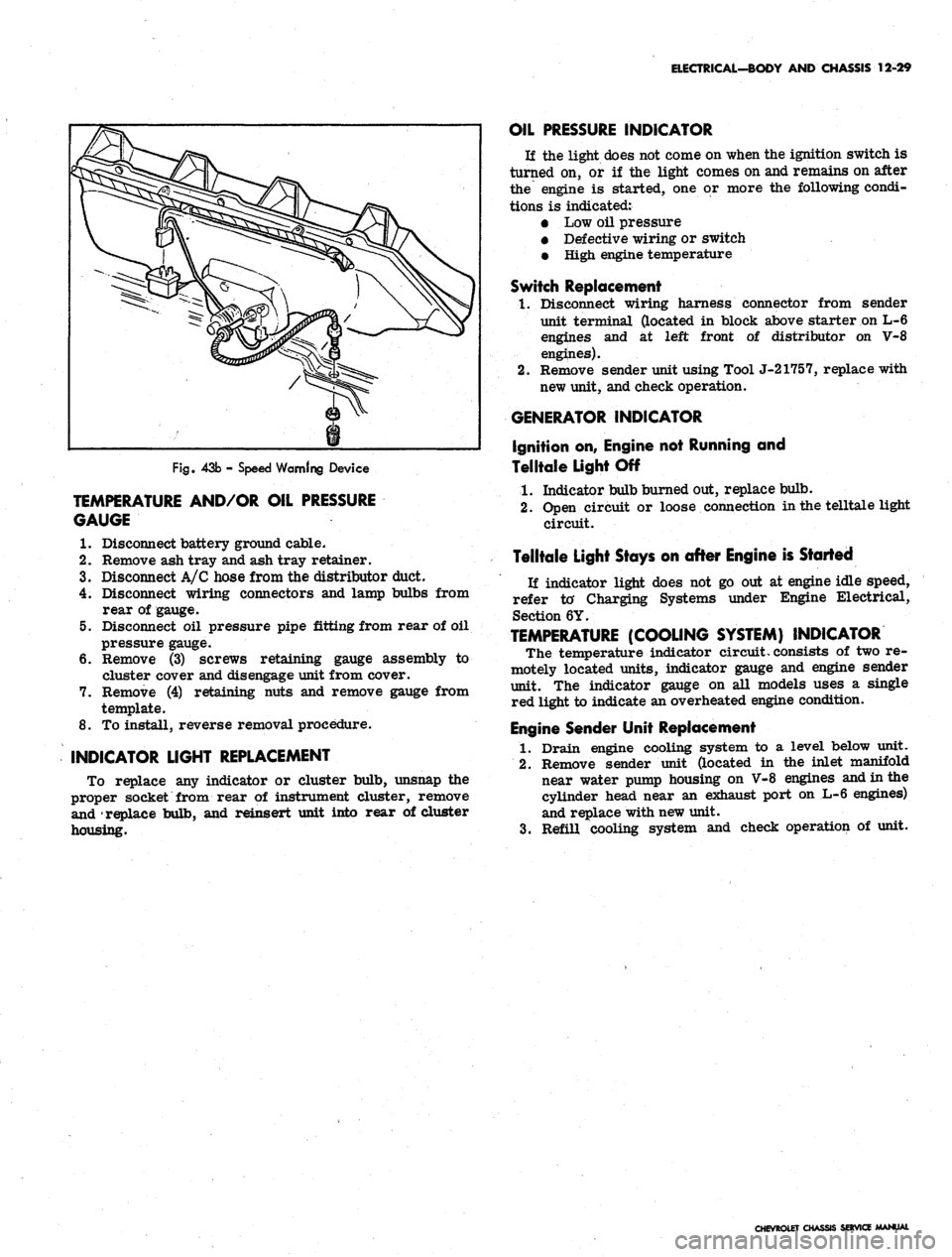

Fig.

43b - Speed Warning Device

TEMPERATURE AND/OR OIL PRESSURE

GAUGE

1.

Disconnect battery ground cable.

2.

Remove ash tray and ash tray retainer.

3.

Disconnect A/C hose from the distributor duct.

4.

Disconnect wiring connectors and lamp bulbs from

rear of gauge.

5. Disconnect oil pressure pipe fitting from rear of oil

pressure gauge.

6. Remove (3) screws retaining gauge assembly to

cluster cover and disengage unit from cover.

7. Remove (4) retaining nuts and remove gauge from

template.

8. To install, reverse removal procedure.

INDICATOR LIGHT REPLACEMENT

To replace any indicator or cluster bulb, unsnap the

proper socket from rear of instrument cluster, remove

and replace bulb, and reinsert unit into rear of cluster

housing.

OIL PRESSURE INDICATOR

If the light does not come on when the ignition switch is

turned on, or if the light comes on and remains on after

the engine is started, one or more the following condi-

tions is indicated:

• Low oil pressure

• Defective wiring or switch

• High engine temperature

Switch Replacement

1.

Disconnect wiring harness connector from sender

unit terminal (located in block above starter on L-6

engines and at left front of distributor on V-8

engines).

2.

Remove sender unit using Tool J-21757, replace with

new unit, and check operation.

GENERATOR INDICATOR

Ignition on, Engine not Running and

Telltale Light Off

1.

Indicator bulb burned out, replace bulb.

2.

Open circuit or loose connection in the telltale light

circuit.

Telltale Light Stays on after Engine is Started

If indicator light does not go out at engine idle speed,

refer to' Charging Systems under Engine Electrical,

Section 6Y.

TEMPERATURE

(COOLING

SYSTEM)

INDICATOR

The temperature indicator circuit, consists of two re-

motely located units, indicator gauge and engine sender

unit. The indicator gauge on all models uses a single

red light to indicate an overheated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system to a level below unit.

2.

Remove sender unit (located in the inlet manifold

near water pump housing on V-8 engines and in the

cylinder head near an exhaust port on L-6 engines)

and replace with new unit.

3.

Refill cooling system and check operation of unit.

CHEVROLET CHASSIS SERVICE MANUAL

Page 546 of 659

ELECTRICAL-BODY AND CHASSIS 12-34

5. To replace, reverse the removal procedure.

SPEEDOMETER REPLACEMENT

1.

Remove instrument cluster as previously described

in this section.

2.

Remove clock set shaft knob.

3.

Remove eight screws securing cluster housing to

bezel trim panel. Separate parts carefully observing

stack up of parts.

4.

Remove two screws securing speedometer head to

rear of cluster housing.

NOTE:

Servicing of the speedometer head

should be performed by an authorized AC Speed-

ometer Service Station.

5. To install, reverse the removal procedure..

SPEEDOMETER CABLE

Replacement or Lubricatibn

1.

Disconnect the speedometer cable from the speed-

ometer head. Remove the old cable by pulling it out

from speedometer end of conduit.

NOTE:

If old cable is broken it may be neces-

sary to remove lower piece from transmission

end of conduit.

2.

Lubricate the lower 3/4 of cable with speedometer

cable lubricant and push the cable into the conduit.

Connect the upper end to the speedometer head and

road test vehicle for proper speedometer operation.

INDICATOR LIGHT REPLACEMENT

To replace any indicator or cluster bulb, unsnap the

proper socket from rear of instrument cluster, remove

and replace bulb, and reinsert unit into rear of cluster

housing.

OIL PRESSURE INDICATOR

If the light does not come on when the ignition switch

is turned on, or if the light comes on and remains on

after the engine is started, one or more of the following

conditions is indicated:

• Low oil pressure

• High engine temperature

• Defective wiring or switch

Switch Replacement

1.

Disconnect wiring harness connector from sender

unit terminal (located in block above starter on

L-6 engines and at left front of distributor on V-8

engines).

2.

Remove sender unit, replace with new unit, and

; check operation.

GENERATOR INDICATOR

1.

Ignition on, engine not running and telltale light off.

a. Indicator bulb burned out, replace bulb.

b.

Open circuit or loose connection in the telltale

light circuit.

2.

Telltale light stays on after engine is started.

a. If indicator light does not go out at engine idle

speed, refer to Charging Systems under Engine

Electrical, Section 6Y.

TEMPERATURE (COOLING SYSTEM) INDICATOR

The temperature indicator circuit consists of two re-

motely located units, indicator gauge and engine sender

unit. The indicator gauge on all models uses a single

red light to indicate an overheated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system to a level below unit.

2.

Remove sender unit (located in the inlet manifold

near water pump housing on V-8 engines and in the

cylinder head near an exhaust port on L-6 engines)

and replace with new unit.

3.

Refill cooling system and check operation of unit.

CORVETTE INSTRUMENTS AND GAUGES

INDEX

Page

General Description ., 12-34

Service Operations . 12-35

Instrument Cluster ., 12-35

Fuel Gauge 12-35

Speedometer/Tachometer Service. 12-35

Temperature Gauge 12-35

Ammeter/Oil Pressure Gauges 12-35

GENERAL DESCRIPTION

All Corvette instruments and gauges are conveniently

located in the dash-mounted cluster. The entire cluster

is removable to permit servicing of the various instru-

ments and gauges. The indicator and cluster illuminating

bulbs may be replaced without removing the cluster from

the panel.

Regular maintenance is not required on the instrument

cluster or its components other than maintaining clean

and keeping the speedometer and tachometer cables

properly lubricated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 550 of 659

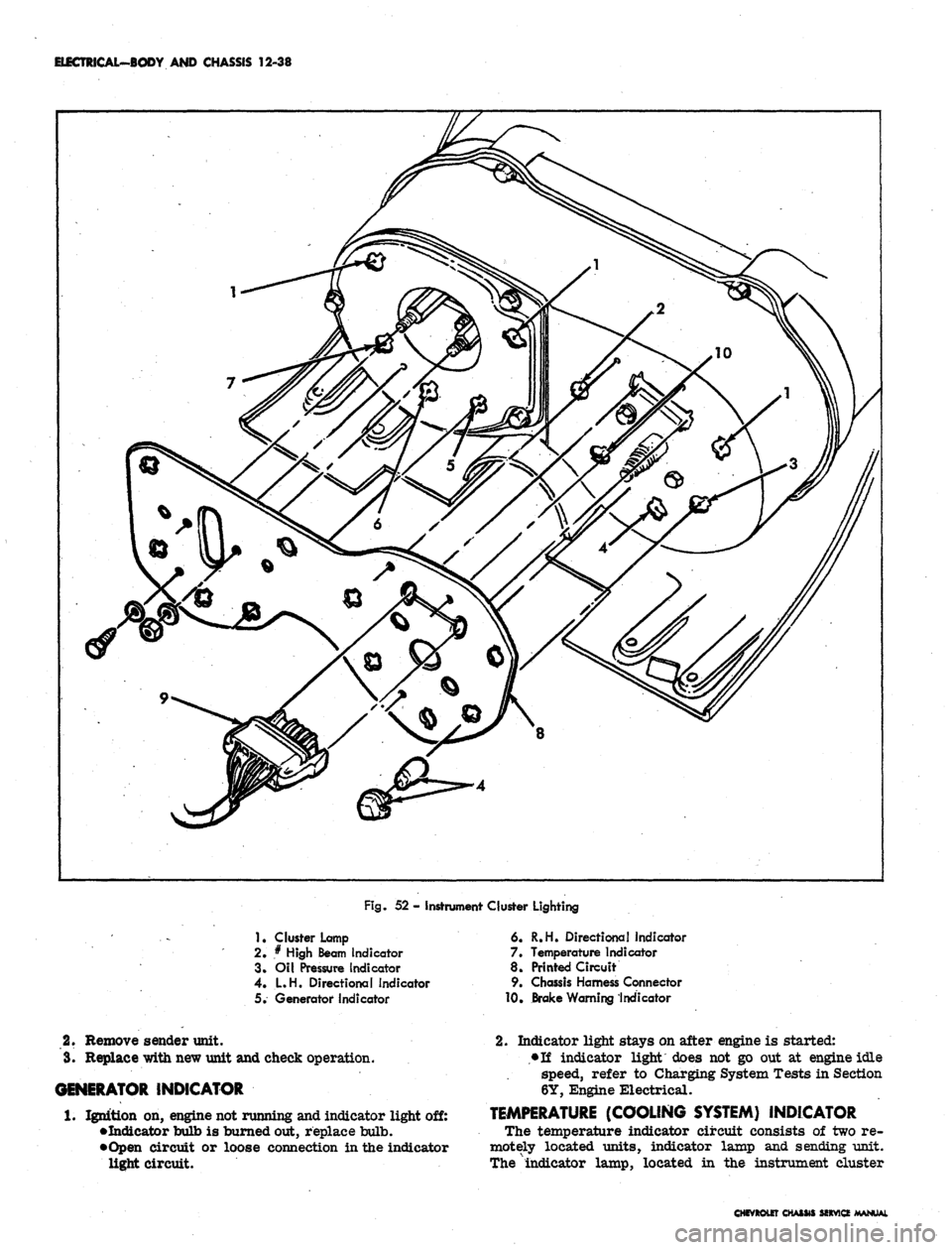

ELECTRICAL-BODY AND CHASSIS 12-38

Fig.

52 - Instrument Cluster Lighting

1

• Cluster Lamp

2.

* High Beam Indicator

3. Oil Pressure Indicator

4.

L.H. Directional Indicator

5. Generator indicator

6. R.H. Directional indicator

7. Temperature Indicator

8. Printed Circuit

9. Chassis Harness Connector

10,

Brake Warning Indicator

2.

Remove sender unit.

3.

Replace with new unit and check operation.

GENERATOR INDICATOR

1.

Ignition on, engine not running and indicator light off:

•Indicator bulb is burned out, replace bulb.

•Open circuit or loose connection in the indicator

light circuit.

2.

Indicator light stays on after engine is started:

•Ti indicator light does not go out at engine idle

speed, refer to Charging System Tests in Section

6Y, Engine Electrical.

TEMPERATURE (COOLING SYSTEM) INDICATOR

The temperature indicator circuit consists of two re-

motely located units, indicator lamp and sending unit.

The "indicator lamp, located in the instrument cluster

CHfVROtEr CHASM SfXVICf