fuse CHEVROLET CAMARO 1967 1.G Chassis Owner's Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 617 of 659

ACCESSORIES

15-8

BROWN

BRAKE

SWITCH

+12V *

BLACK

CONNECTOR

AT FUSE BLOCK

CRUISE POSITION

BUTTON RELEASED

ENGAGE POSITION

BUTTON PARTIALLY DEPRESSED^ N. ENOAOi SWITCH

TRIM POSITION N. N. I

BUHON FULLY DEPRESSED. \ ^

BROWN

BLUE

ENGAGE SWITCH

CONFIGURATION

BLACK

BLUE

REGULATOR

- SOLENOID COIL

(5 a RESISTANCE)

9 BLACK

BLUE

REGULATOR

Fig.

10 - Wiring Diagram

Replacement

1.

Insert the switch into the turn signal knob, push the

retaining ring firmly against the switch, and push the

operating button onto the switch plunger. " .

SERVO

Service

—

H the Servo unit is found to be defective, re-

placement is required. Note the condition of the hoses

and replace any which are cracked or deteriorated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 618 of 659

ACCESSORIES 15-9

Adjustment- Adjust the bead chain so that it is as tight

as possible without holding the throttle open when the

carburetor is set at its lowest idle throttle position.

When connecting the bead chain (engine stopped) manually

set the fast idle cam at its lowest step and connect the

chain so that it does not hold the idle screw off the cam.

If the chain needs to be cut, cut it three beads beyond the

bead which pulls the linkage.

REGULATOR

Service - A defective regulator, that is one which is not

simply out of adjustment, must be replaced. During re-

placement, check the hoses which connect to the regulator

and replace any which are cracked or deteriorated.

Air Filter

The air filter located in the solenoid cover should be

cleaned and re-oiled at engine oil change intervals.

1.

Snap the solenoid cover off.

2.

Remove the filter and wash it in kerosene or mineral

spirits. Squeeze it dry and wet with SAE 10 engine

oil.

Squeeze out excess oil and reinstall into the

cover.

3.

Attach the cover with neoprene seal to the solenoid

housing. Be certain that the cover fits tightly to the

housing.

One regulator adjustment is possible: Engagement-

Cruising Speed Zeroing (to remove any difference be-

tween engagement and cruising speed).

NOTE:

No regulator adjustment should be

made, however, until the following items have

been checked or serviced:

1.

Bead chain properly adjusted.

2.

All hoses in good condition, properly attached, not

leaking, not pinched or kinked.

3.

Regulator air filter clean and properly oiled.

4.

Electric and vacuum release switches properly

adjusted.

Engagement—Cruising Speed Zeroing

If the cruising speed is lower than the engagement

speed, loosen the orifice tube locknut and turn the tube

outward; if higher, turn the tube inward. Each 1/8 turn

will alter the engagement-cruising speed difference one

mph. Tighten the locknut after adjustment and check the

system operation at 50 mph.

ELECTRICAL SYSTEM CHECK OUT

1.

Check fuse and connector.

2.

Check electric brake switch as follows: Unplug con-

nector at brake switch. Connect ohmmeter at points

A and B on brake switch. The ohmmeter must indi-

cate infinity when the brake pedal is depressed and

continuity when pedal is released. The cruise re-

lease brake switch (electric) is adjusted as is the

standard stop light brake switch. Replace electric

brake switch if needed.

3.

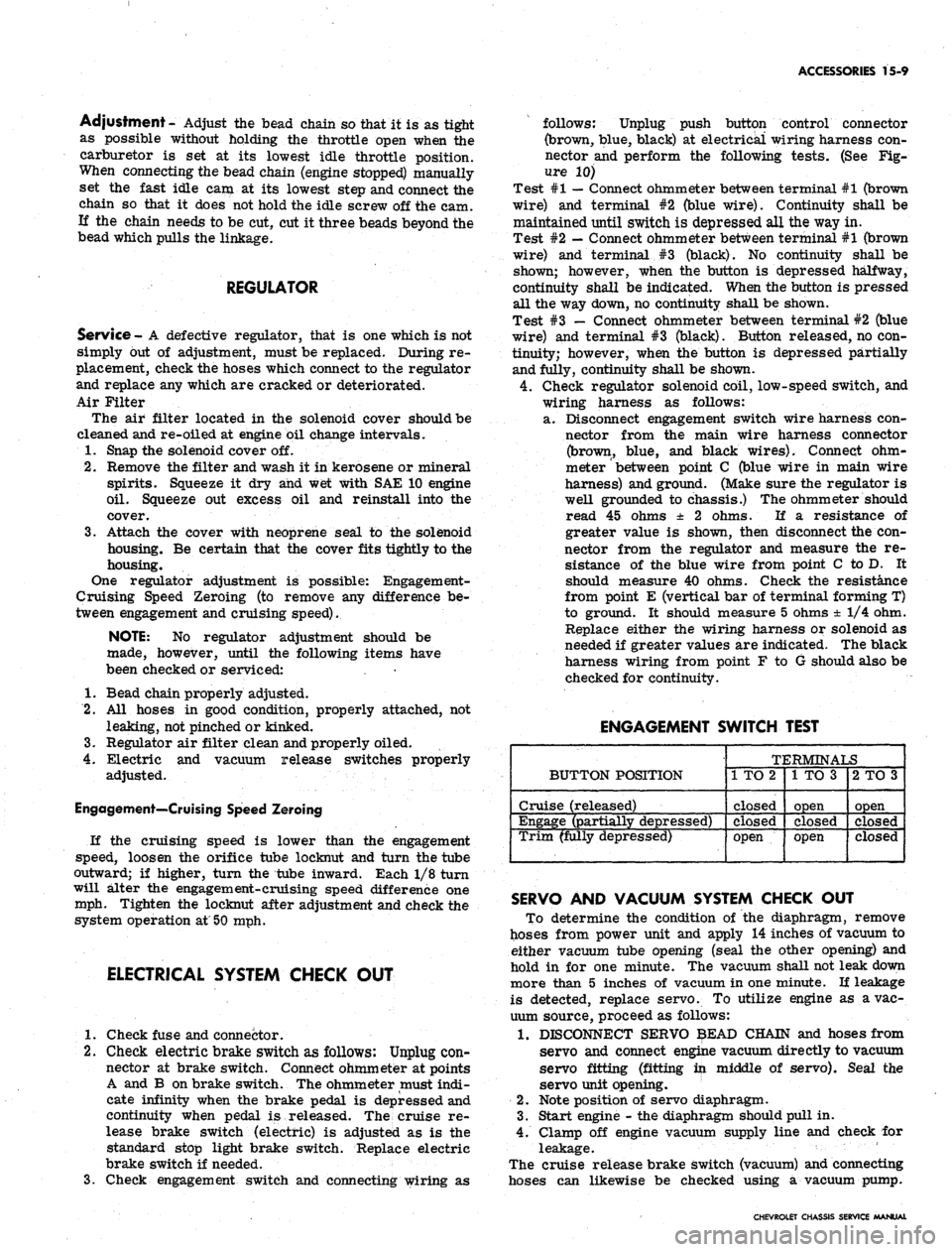

Check engagement switch and connecting wiring as

follows: Unplug push button control connector

(brown, blue, black) at electrical wiring harness con-

nector and perform the following tests. (See Fig-

ure 10)

Test #1

—

Connect ohmmeter between terminal #1 (brown

wire) and terminal #2 (blue wire). Continuity shall be

maintained until switch is depressed all the way in.

Test #2

—

Connect ohmmeter between terminal #1 (brown

wire) and terminal #3 (black). No continuity shall be

shown; however, when the button is depressed halfway,

continuity shall be indicated. When the button is pressed

all the way down, no continuity shall be shown.

Test #3 — Connect ohmmeter between terminal #2 (blue

wire) and terminal #3 (black). Button released, no con-

tinuity; however, when the button is depressed partially

and fully, continuity shall be shown.

4.

Check regulator solenoid coil, low-speed switch, and

wiring harness as follows:

a. Disconnect engagement switch wire harness con-

nector from the main wire harness connector

(brown, blue, and black wires). Connect ohm-

meter

'

between point C (blue wire in main wire

harness) and ground. (Make sure the regulator is

well grounded to chassis.) The ohmmeter should

read 45 ohms ± 2 ohms. If a resistance of

greater value is shown, then disconnect the con-

nector from the regulator and measure the re-

sistance of the blue wire from point C to D. It

should measure 40 ohms. Check the resistance

from point E (vertical bar of terminal forming T)

to ground. It should measure 5 ohms ± 1/4 ohm.

Replace either the wiring harness or solenoid as

needed if greater values are indicated. The black

harness wiring from point F to G should also be

checked for continuity.

ENGAGEMENT SWITCH TEST

BUTTON POSITION

Cruise (released)

Engage (partially depressed)

Trim (fully depressed)

TERMINALS

1 TO 2

closed

Closed

open

1 TO 3

open

closed

open

2 TO 3

open

closed

closed

SERVO AND VACUUM SYSTEM CHECK OUT

To determine the condition of the diaphragm, remove

hoses from power unit and apply 14 inches of vacuum to

either vacuum tube opening (seal the other opening) and

hold in for one minute. The vacuum shall not leak down

more than 5 inches of vacuum in one minute. If leakage

is detected, replace servo. To utilize engine as a vac-

uum source, proceed as follows:

1.

DISCONNECT SERVO $EAD CHAIN and hoses from

servo and connect engine vacuum directly to vacuum

servo fitting (fitting in middle of servo). Seal the

servo unit opening.

2.

Note position of servo diaphragm.

3.

Start engine - the diaphragm should pull in.

4.

Clamp off engine vacuum supply line and check for

leakage. '

The cruise release brake switch (vacuum) and connecting

hoses can likewise be checked using a vacuum pump.

CHEVROLET CHASSIS SERVICE MANUAL

Page 619 of 659

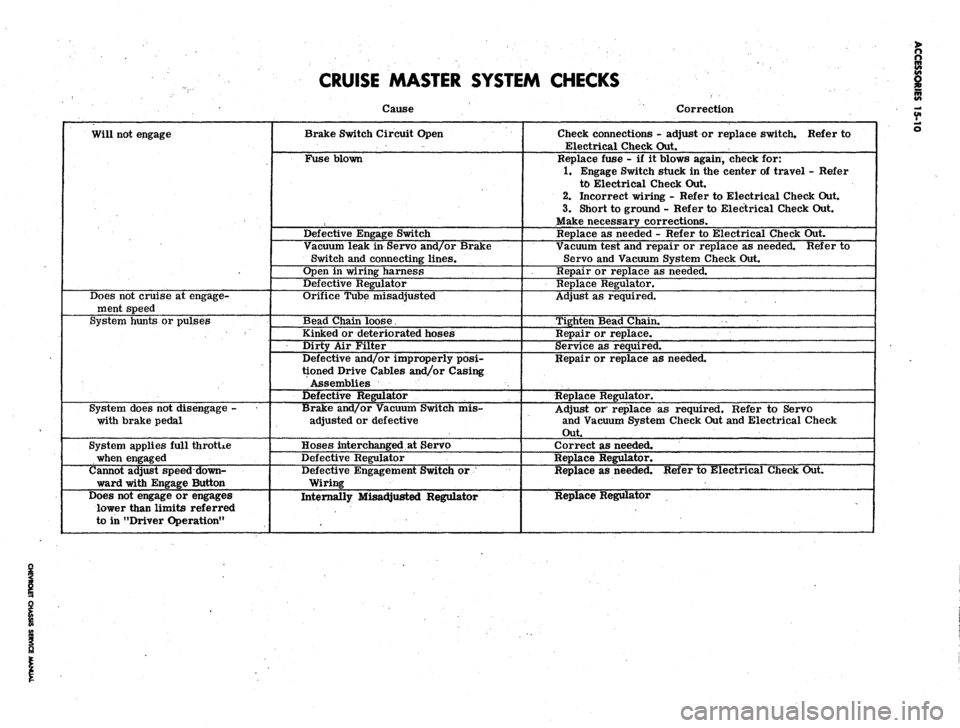

CRUISE MASTER SYSTEM CHECKS

Will not engage

Does not cruise at engage-

ment speed

System hunts or pulses

System does not disengage -

with brake pedal

System applies full throtUe

when engaged

Cannot adjust speed down-

ward with Engage Button

Does not engage or engages

lower than limits referred

to in "Driver Operation"

Cause

Brake Switch Circuit Open

Fuse blown

Defective Engage Switch

Vacuum leak in Servo and/or Brake

Switch and connecting lines.

Open in wiring harness

Defective Regulator

Orifice Tube misadjusted

Bead Chain loose.

Kinked or deteriorated hoses

Dirty Air Filter

Defective and/or improperly posi-

tioned Drive Cables and/or Casing

Assemblies

Defective Regulator

Brake and/or Vacuum Switch mis-

adjusted or defective

Hoses interchanged at Servo

Defective Regulator

Defective Engagement Switch or

Wiring

Internally Misadjusted Regulator

Correction

Check connections - adjust or replace switch. Refer to

Electrical Check Out.

Replace fuse - if it blows again, check for:

1.

Engage Switch stuck in the center of travel - Refer

to Electrical Check Out.

2.

Incorrect wiring - Refer to Electrical Check Out.

3.

Short to ground - Refer to Electrical Check Out.

Make necessary corrections.

Replace as needed - Refer to Electrical Check Out.

Vacuum test and repair or replace as needed. Refer to

Servo and Vacuum System Check Out.

Repair or replace as needed.

Replace Regulator.

Adjust as required.

Tighten Bead Chain.

Repair or replace.

Service as required.

Repair or replace as needed.

Replace Regulator.

Adjust or replace as required. Refer to Servo

and Vacuum System Check Out and Electrical Check

Out.

Correct as needed.

Replace Regulator.

Replace as needed. Refer to Electrical Check Out.

Replace Regulator

Page 628 of 659

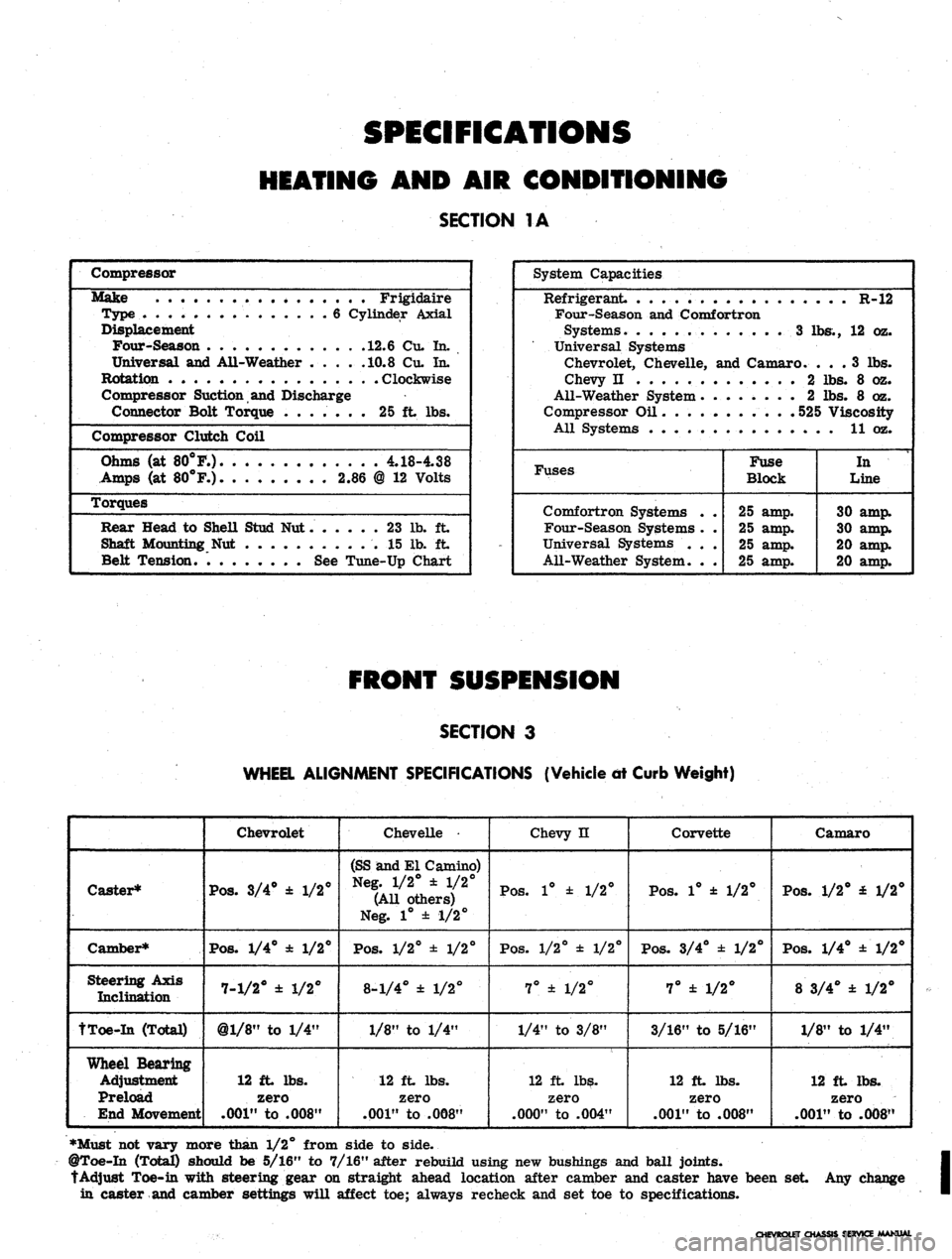

SPECIFICATIONS

HEATING

AND AIR

CONDITIONING

SECTION

1A

Compressor

Make Frigidaire

Type

. 6

Cylinder Axial

Displacement

Four-Season

12.6

Cu.

In.

Universal

and

Ail-Weather

.... .10.8 Cu. In.

Rotation Clockwise

Compressor Suction

and

Discharge

Connector Bolt Torque

.......

25 ft lbs.

Compressor Clutch Coil

Ohms

(at

80°F.).

4.18-4.38

Amps

(at

80°F.)

2.86 @ 12

Volts

Torques

Rear Head

to

SheU Stud

Nut 23 lb. ft

Shaft Mounting

Nut 15 lb. ft

Belt Tension.

See

Tune-Up Chart

System Capacities

Refrigerant

R-12

Four-Season

and

Comfortron

Systems.

............

3 lbs., 12 oz.

Universal Systems

Chevrolet, Chevelle,

and

Camaro.

... 3 lbs.

Chevy

n 2 lbs. 8 oz.

All-Weather System

2 lbs. 8 oz.

Compressor

Oil 525

Viscosity

All Systems

11 oz.

Fuses

Comfortron Systems

.

Four-Season Systems

.

Universal Systems

. .

All-Weather System.

.

Fuse

Block

25

amp.

25

amp.

25

amp.

25

amp.

In

Line

30

amp.

30

amp.

20

amp.

20

amp.

SECTION

3

WHEEL ALIGNMENT SPECIFICATIONS (Vehicle

dt

Curb Weight)

Caster*

Camber*

Steering Axis

Inclination

tToe-In (Total)

Wheel Bearing

Adjustment

Preload

End Movement

Chevrolet

Pos.

3/4° ± 1/2°

Pos.

1/4° ± 1/2°

7-1/2° ± 1/2°

@l/8"

to 1/4"

12 ft lbs.

zero

.001"

to .008"

Chevelle •

(SS and El Camino)

Neg. 1/2° ± 1/2°

(All others)

Neg. 1° ± 1/2°

Pos.

1/2° ± 1/2°

8-1/4° ± 1/2°

1/8" to 1/4"

12 ft lbs.

zero

.001"

to .008"

Chevy n

Pos.

1° ± 1/2°

Pos.

1/2° ± 1/2°

7° ± 1/2°

1/4" to 3/8"

12 ft lbs.

zero

.000"

to .004"

Corvette

Pos.

1° ± 1/2°

Pos.

3/4° ± 1/2°

7° ± 1/2°

3/16" to 5/16"

12 ft lbs.

zero

.001"

to .008"

Camaro

Pos.

1/2° £ 1/2°

Pos.

1/4° ±1/2°

8 3/4° ± 1/2°

1/8" to 1/4"

12 ft lbs.

zero

.001"

to .008"

•Must not vary more than 1/2° from side to side.

@Toe-In (Total) should be 5/16" to 7/16" after rebuild using new bushings and ball joints.

tAdjust Toe-in with steering gear on straight ahead location after camber and caster have been set Any change

in caster and camber settings will affect toe; always recheck and set toe to specifications.

LET CHASSIS SERVICE MANUAL

Page 653 of 659

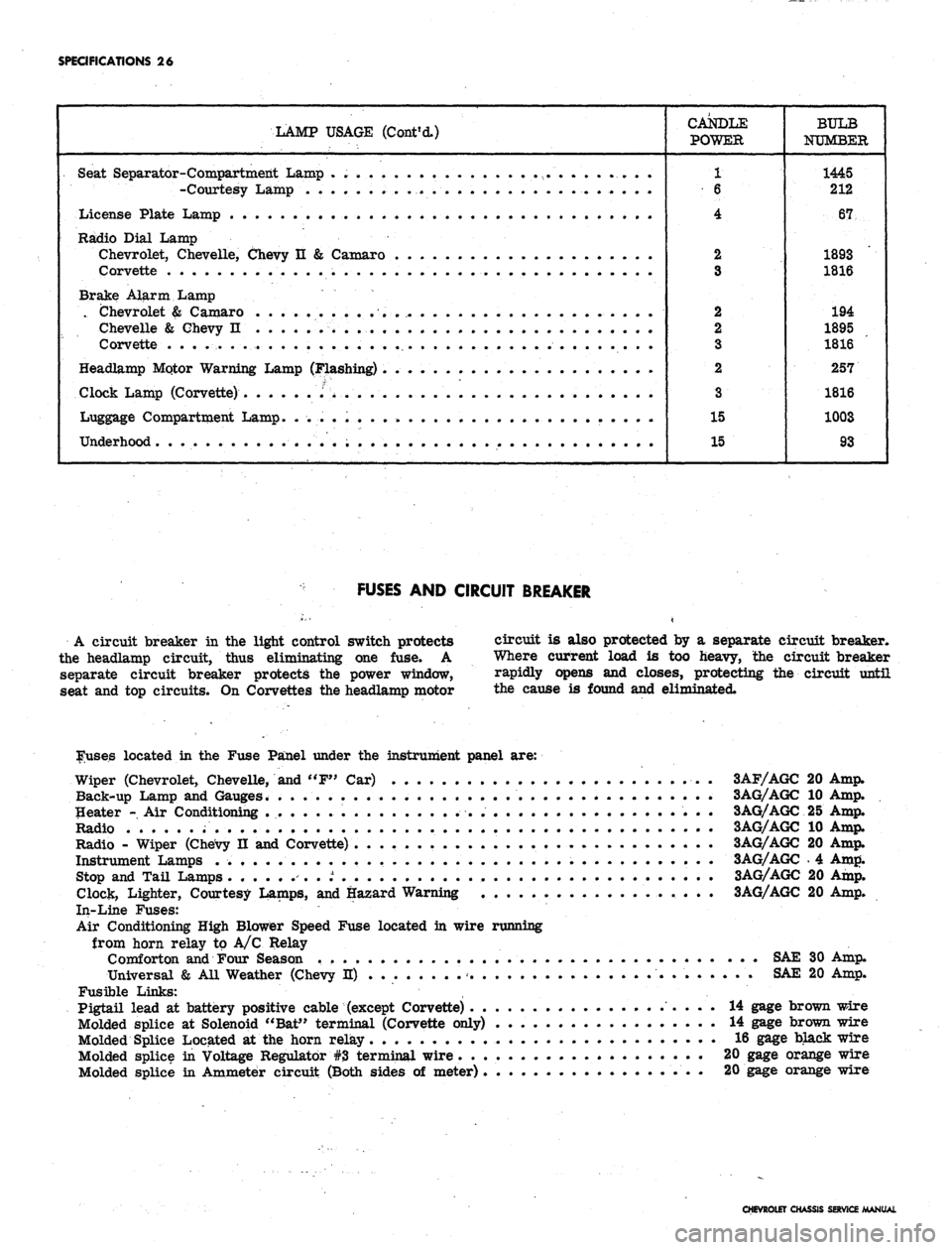

SPECIFICATIONS 26

LAMP USAGE (Cont'd.)

CANDLE

POWER

1

6

4

2

3

2

2

3

2

3

15

15

BULB

NUMBER

1445

212

67

1893

1816

194

1895

1816

257

1816

1003

93

Seat Separator-Compartment Lamp . . . . .

-Courtesy Lamp •

License Plate Lamp . .

Radio Dial Lamp

Chevrolet, Chevelle, Chevy n & Camaro

Corvette

Brake Alarm Lamp

. Chevrolet & Camaro . . .... . .

Chevelle & Chevy n . . . . .'. ;v . . . .

Corvette . . . . . . . .

Headlamp Mqtor Warning Lamp (Flashing) .

Clock Lamp (Corvette) .''> ....

Luggage Compartment Lamp. . ... . . . •

Underhood

FUSES AND CIRCUIT BREAKER

A circuit breaker in the light control switch protects

the headlamp circuit, thus eliminating one fuse. A

separate circuit breaker protects the power window,

seat and top circuits. On Corvettes the headlamp motor

circuit is also protected by a separate circuit breaker.

Where current load is too heavy, the circuit breaker

rapidly opens and closes, protecting the circuit until

the cause is found and eliminated.

louses located in the Fuse Panel under the instrument panel are:

Wiper (Chevrolet, Chevelle, and "F" Car) 3AF/AGC 20 Amp.

Back-up Lamp and Gauges. . . 3AG/AGC 10 Amp.

Heater - Air Conditioning 3AG/AGC 25 Amp.

Radio 3AG/AGC 10 Amp.

Radio - Wiper (Chevy II and Corvette) 3AG/AGC 20 Amp.

Instrument Lamps 3AG/AGC . 4 Amp.

Stop and Tail Lamps ........ t 3AG/AGC 20 Amp.

Clock, Lighter, Courtesy Lamps, and Hazard Warning 3AG/AGC 20 Amp.

In-Line Fuses:

Air Conditioning High Blower Speed Fuse located in wire running

from horn relay to A/C Relay

Comforton and Four Season SAE 30 Amp.

Universal & All Weather (Chevy H) SAE 20 Amp.

Fusible Links: ,

Pigtail lead at battery positive cable (except Corvette) 14 gage brown wire

Molded splice at Solenoid "Bat" terminal (Corvette only) 14 gage brown wire

Molded Splice Located at the horn relay 16 gage black wire

Molded splice in Voltage Regulator #3 terminal wire 20 gage orange wire

Molded splice in Ammeter circuit (Both sides of meter) 20 gage orange wire

CHEVROLET CHASSIS SERVICE MANUAL