fuse CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 528 of 659

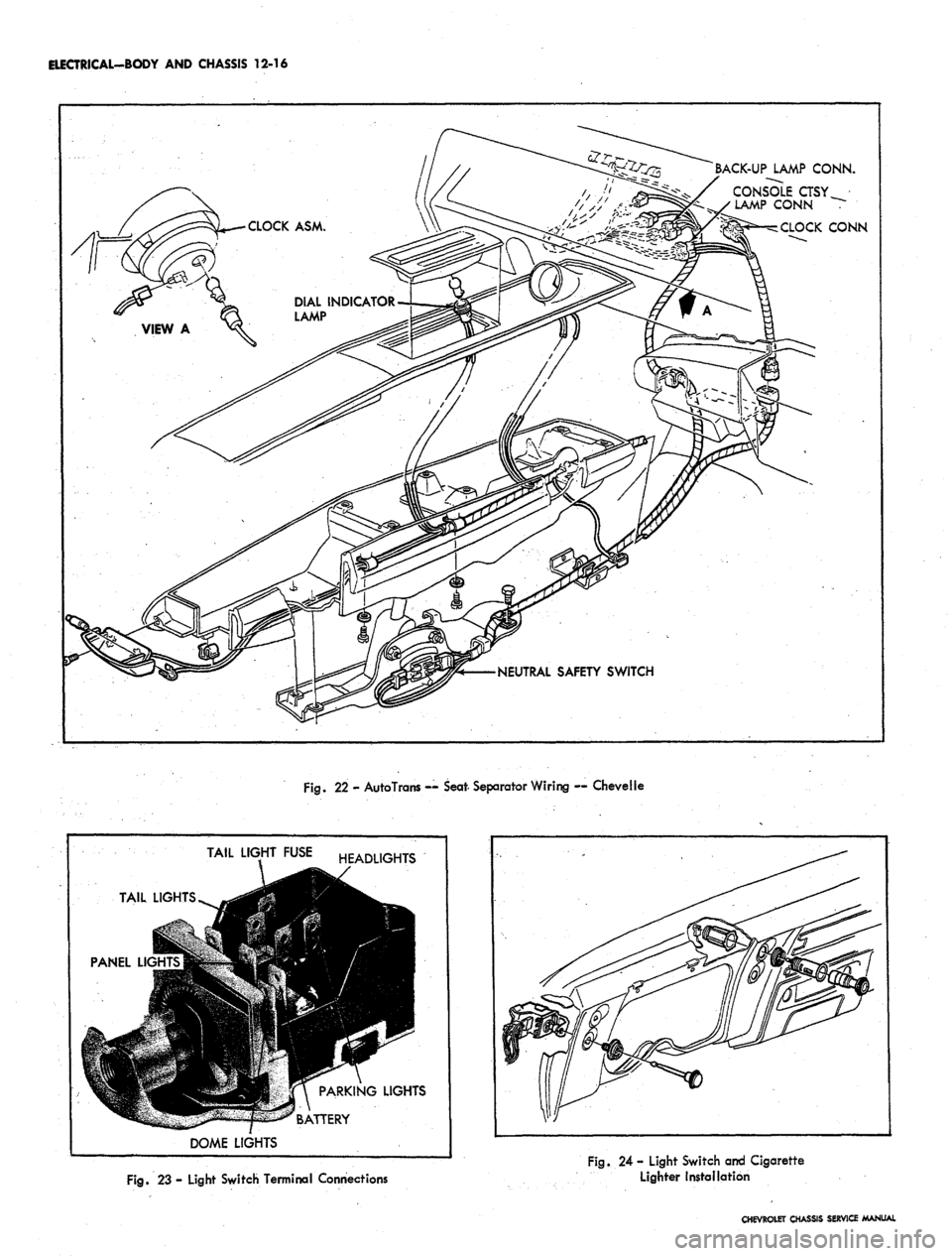

ELECTRICAL-BODY AND CHASSIS 12-16

BACK-UP LAMP CONN.

CONSOLE CTSY

LAMP CONN

CLOCK CONN

NEUTRAL SAFETY SWITCH

Fig.

22 - AutoTrans — Seat- Separator Wiring — Chevelle

TAIL

PANEL Ll<

J

TAIL

LIGHTS ^^g

9

""TUtflll -^ ""

DOME

LIGHT

r

•I

m

/

LIGHTS

FUSE HEADLIGHTS

9R

jl PARKING LIGHTS

*^ R ATTPRY

Fig.

23 - Light Switch Terminal Connections

Fig.

24 - Light Switch and Cigarette

Lighter Installation

CHEVROLET CHASSIS SERVICE MANUAL

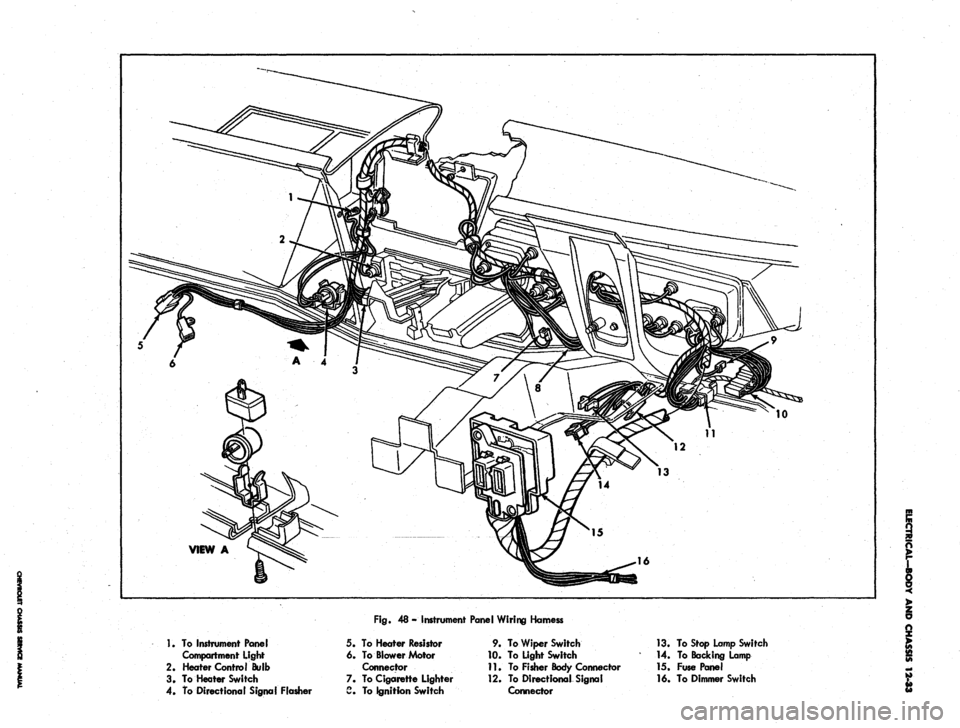

Page 545 of 659

Fig.

48 - Instrument Panel Wiring Hamess

1.

To Instrument Panel

Compartment light

2.

Heater Control Bulb

3. To Heater Switch

4.

To Directional Signal Flasher

5.

6.

7.

a

To Heater Resistor

To Blower Motor

Connector

To Cigarette Lighter

To Ignition Switch

9.

10.

11.

12.

To Wiper Switch

To Light Switch

To Fisher Body Connector

To Directional Signal

Connector

13.

To Stop Lamp Switch

14.

To Backing Lamp

15.

Fuse Panel

16.

To Dimmer Switch

Page 547 of 659

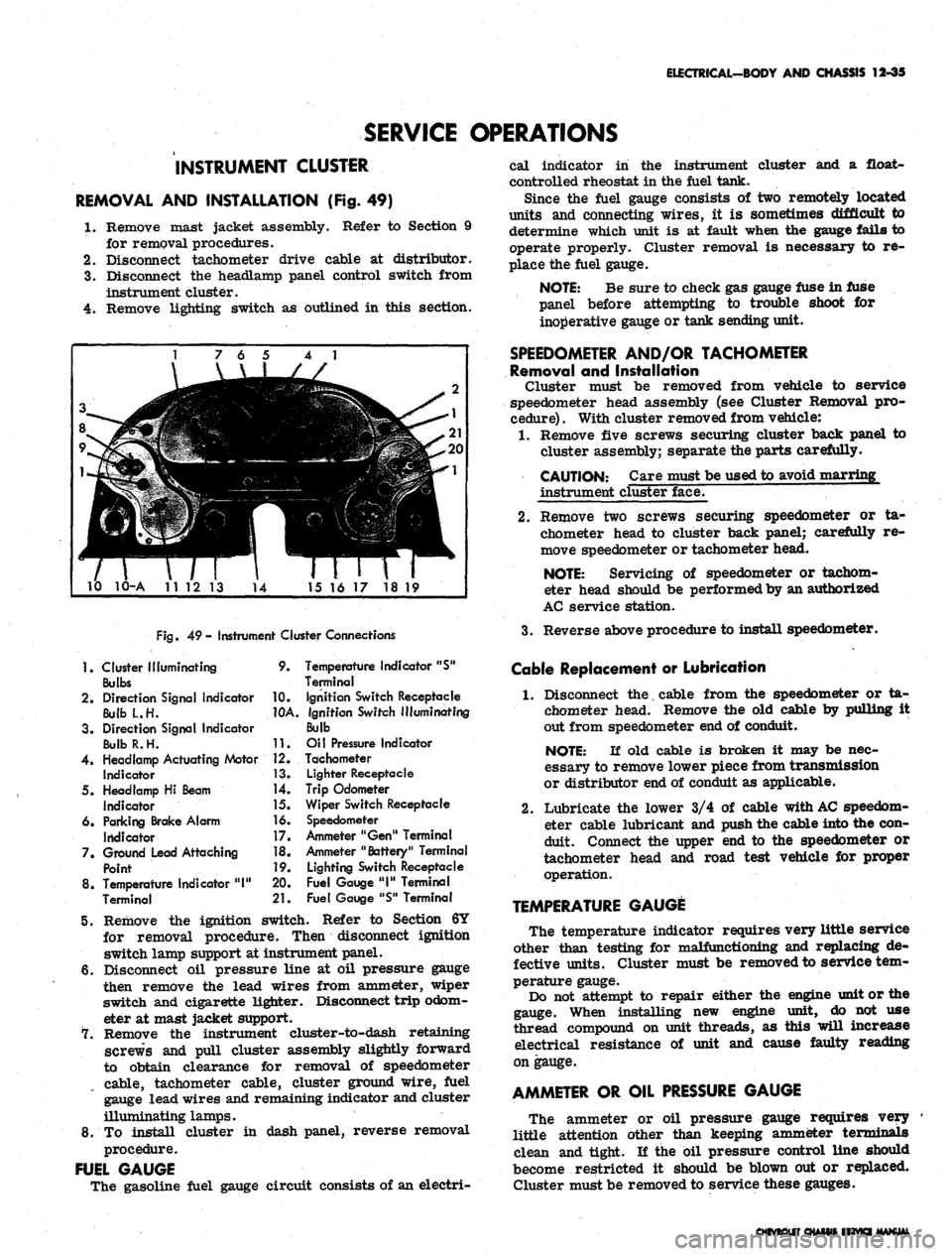

ELECTRICAL-BODY AND CHASSIS 12-35

SERVICE OPERATIONS

INSTRUMENT CLUSTER

REMOVAL AND INSTALLATION (Fig. 49)

1.

Remove mast jacket assembly. Refer to Section 9

for removal procedures.

2.

Disconnect tachometer drive cable at distributor.

3.

Disconnect the headlamp panel control switch from

instrument cluster.

4.

Remove lighting switch as outlined in this section.

10 10-A 1112 13

14

15 16 17 18 19

Fig.

49- Instrument Cluster Connections

1.

Cluster Illuminating

Bulbs

2.

Direction Signal Indicator

Bulb L.H.

3. Direction Signal Indicator

BulbR.H.

4.

Headlamp Actuating Motor

Indicator

5. Headlamp Hi Beam

Indicator

6. Parking Brake Alarm

Indicator

7. Ground Lead Attaching

Point

8. Temperature Indicator

"1"

Terminal

9.

10.

10A.

11.

12.

13.

14.

]5.

16.

17.

18.

19.

20.

21.

Temperature Indicator "S"

Terminal

Ignition Switch Receptacle

ignition Switch Illuminating

Bulb

Oil Pressure Indicator

Tachometer

Lighter Receptacle

Trip Odometer

Wiper Switch Receptacle

Speedometer

Ammeter "Gen" Terminal

Ammeter "Battery" Terminal

Lighting Switch Receptacle

Fuel Gauge

"1"

Terminal

Fuel Gauge "S" Terminal

5. Remove the ignition switch. Refer to Section 6Y

for removal procedure. Then disconnect ignition

switch lamp support at instrument panel.

6. Disconnect oil pressure line at oil pressure gauge

then remove the lead wires from ammeter, wiper

switch and cigarette lighter. Disconnect trip odom-

eter at mast jacket support.

7. Remove the instrument cluster-to-dash retaining

screws and pull cluster assembly slightly forward

to obtain clearance for removal of speedometer

cable, tachometer cable, cluster ground wire, fuel

gauge lead wires and remaining indicator and cluster

illuminating lamps.

8. To install cluster in dash panel, reverse removal

procedure.

FUEL GAUGE

The gasoline fuel gauge circuit consists of an electri-

cal indicator in the instrument cluster and a float-

controlled rheostat in the fuel tank.

Since the fuel gauge consists of two remotely located

units and connecting wires, it is sometimes difficult to

determine which unit is at fault when the gauge fails to

operate properly. Cluster removal is necessary to re-

place the fuel gauge.

NOTE:

Be sure to check gas gauge fuse in fuse

panel before attempting to trouble shoot for

inoperative gauge or tank sending unit.

SPEEDOMETER AND/OR TACHOMETER

Removal and Installation

Cluster must be removed from vehicle to service

speedometer head assembly (see Cluster Removal pro-

cedure)

.

With cluster removed from vehicle:

1.

Remove five screws securing cluster back panel to

cluster assembly; separate the parts carefully.

CAUTION: Care must be used to avoid marring

instrument cluster face.

2.

Remove two screws securing speedometer or ta-

chometer head to cluster back panel; carefully re-

move speedometer or tachometer head.

NOTE:

Servicing of speedometer or tachom-

eter head should be performed by an authorized

AC service station.

3.

Reverse above procedure to install speedometer.

Cable Replacement or Lubrication

1.

Disconnect the. cable from the speedometer or ta-

chometer head. Remove the old cable by pulling it

out from speedometer end of conduit.

NOTE:

If old cable is broken it may be nec-

essary to remove lower piece from transmission

or distributor end of conduit as applicable.

2.

Lubricate the lower 3/4 of cable with

AC

speedom-

eter cable lubricant and push the cable into the con-

duit. Connect the upper end to the speedometer or

tachometer head and road test vehicle for proper

operation.

TEMPERATURE GAUGE

The temperature indicator requires very little service

other than testing for malfunctioning and replacing de-

fective units. Cluster must be removed to service tem-

perature gauge.

Do not attempt to repair either the engine unit or the

gauge. When installing new engine unit, do not use

thread compound on unit threads, as this will increase

electrical resistance of unit and cause faulty reading

on gauge.

AMMETER OR OIL PRESSURE GAUGE

The ammeter or oil pressure gauge requires very

little attention other than keeping ammeter terminals

clean and tight. If the oil pressure control line should

become restricted it should be blown out or replaced.

Cluster must be removed to service these gauges.

HftVKI MANUAL

Page 551 of 659

17-

VIEW A

Fig.

53 - Instrument Panel Wiring Harness

1.

To Glove Box Light

2.

To Heater Control

3. Heater Control Lamp

4. To Cigarette Lighter

5. To Ignition Switch

6. To Instrument Cluster

7. To Wiper Switch

8. To Light Switch

9.

To Directional Signal Switch

10.

To Stop Lamp Switch

11.

To Backing Lamp Switch

12.

Fuse Panel

13.

To Dimmer Switch

14.

To Fisher Body Connector

15.

To Directional Signal Flasher

16.

To Heater Resistor

17.

Directional Signal Flasher

Page 552 of 659

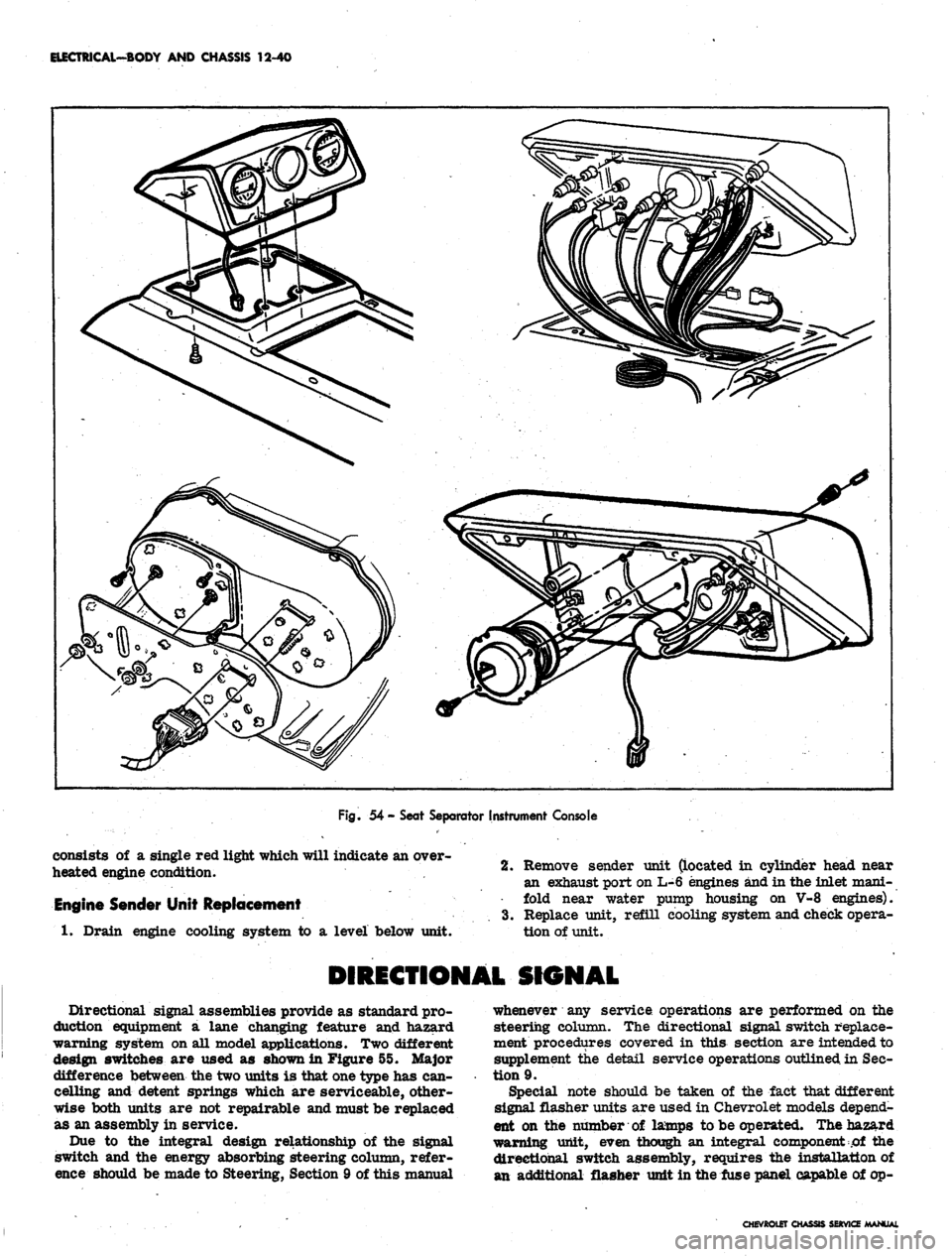

ELECTRICAL-BODY AND CHASSIS 12-40

Fig.

54 - Seat Separator Instrument Console

consists of a single red light which will indicate an over-

heated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system to a level below unit.

2.

Remove sender unit (located in cylinder head near

an exhaust port on L-6 engines and in the inlet mani-

fold near water pump housing on V-8 engines).

3.

Replace unit, refill cooling system and check opera-

tion of unit.

DIRECTIONAL SIGNAL

Directional signal assemblies provide as standard pro-

duction equipment a lane changing feature and hazard

warning system on all model applications. Two different

design switches are used as shown in Figure 55. Major

difference between the two units is that one type has can-

celling and detent springs which are serviceable, other-

wise both units are not repairable and must be replaced

as an assembly in service.

Due to the integral design relationship of the signal

switch and the energy absorbing steering column, refer-

ence should be made to Steering, Section 9 of this manual

whenever any service operations are performed on the

steering column. The directional signal switch replace-

ment procedures covered in this section are intended to

supplement the detail service operations outlined in Sec-

tion 9.

Special note should be taken of the fact that different

signal flasher units are used in Chevrolet models depend-

ent on the number of lamps to be operated. The hazard

warning unit, even though an integral component of the

directional switch assembly, requires the installation of

an additional flasher unit in the fuse panel capable of op-

CHEVROtET CHASSIS SERVICE MANUAL

Page 574 of 659

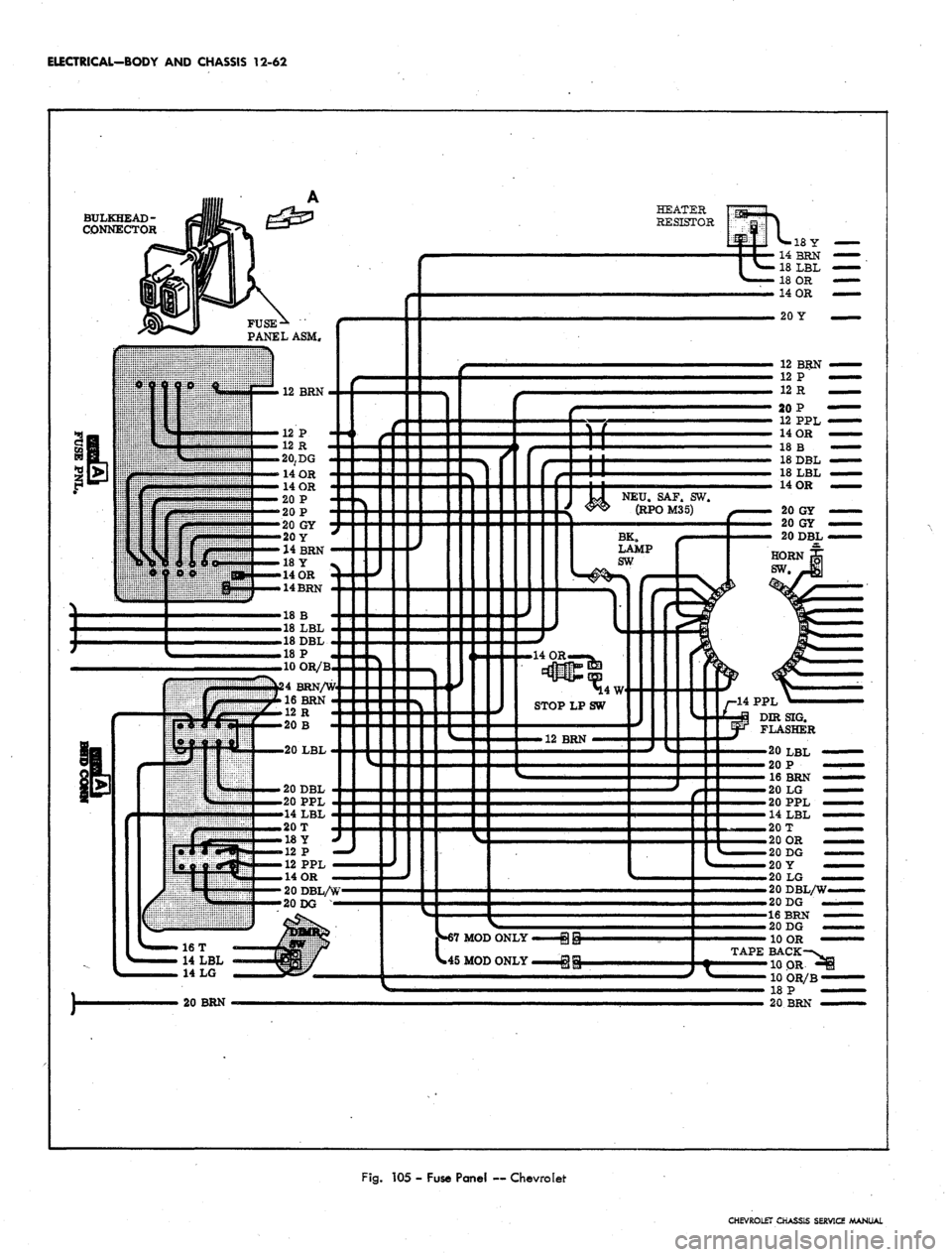

ELECTRICAL-BODY

AND

CHASSIS

12-62

BULKHEAD-

CONNECTOR

HEATER

RESISTOR

PANEL ASM.

12 BRN

20

Y

12 BRN

»-67 MOD ONLY

*45 MOD ONLY

14 PPL

DIRSIG.

FLASHER

20 BRN

'20 LBL

20

P

16 BRN

>20

LG

• 20 PPL

•

14 LBL

• 20

T

.20 OR

-20 DG

20

Y

20

LG

—

20DBL/W.

20

DG

—16 BRN

20 DG

10

OR

TAPE BACK

'10 OR

10 OR/B

18

P

20 BRN

Fig.

105 -

Fuse Panel

—

Chevrolet

CHEVROLET CHASSIS SERVICE MANUAL

Page 579 of 659

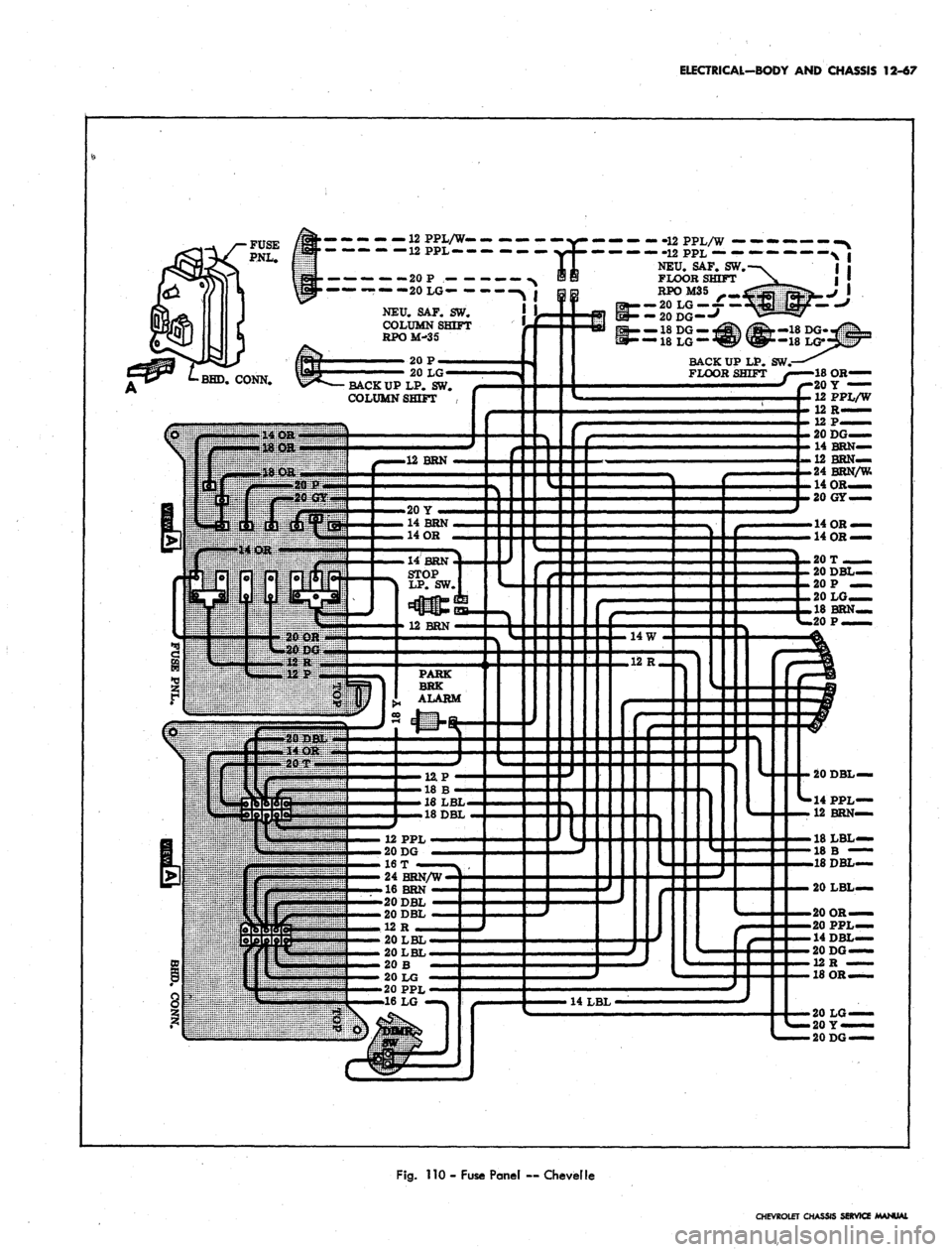

ELECTRICAL-BODY AND CHASSIS 12-67

NEU. SAF. SW.

COLUMN SHIFT

RPOM-35

BHD.

CONN.

__ 20 P

1 20 LG<

BACK UP LP. SW.

COLUMN SHIFT

.12 BRN

8

12.P —

is fi-

le LBL.

.18 DBL

. 12 PPL —

.

20

DG —

>16T —

-24 BRN/W-

• 16 BRN —

•20 DBL —

. 20

DBL —

.12R

•20 LBL

, 20 LBL

.20 B

20 LG

•20 PPL

-16 LG

• -12 PPL/W

•

-12 PPL

NEU. SAF. SW.

FLOOR SHIFT

RPOM35

.20 LG—-f

—

20 DG—^

.

18 DG —

'18 LG~

BACKUP LP. SW>

FLOOR SHIFT /—18 OR—

/-20Y —

. 12 PPL/W

12 R—

12 P_

20 DG—

14 BRN—

,12 BRN—

.24 BRN/W

,14OR—.

20 GY —

14 W

.12 R

.14OR —

14OR —

20T-_

20 DBL—

20 P _

20 LG-—.

,18 BRN—.

L.20P

14 LBL

20 DBL—

•14 PPL—

12 BRN—

>

18 LBL—

18 B ——

.18 DBL—

20 LBL—

20 LG.

»20Y-

•

20DG<

Fig.

110 - Fuse Panel — Chevelle

CHEVROLET CHASSIS SERVICE MANUAL

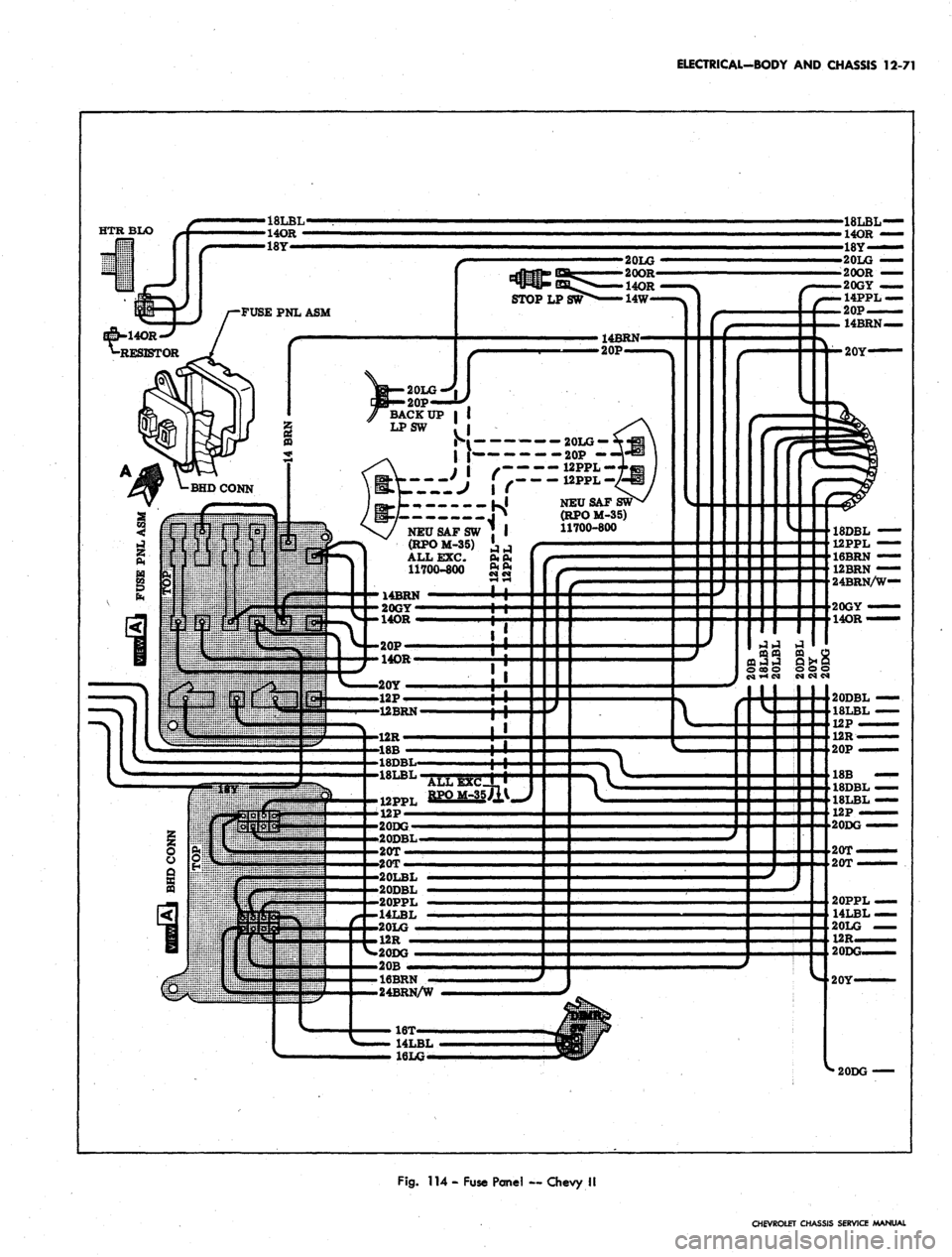

Page 583 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-71

HTRBIiO

20LG

20OR

14OR

14W-

FUSE

PNL

ASM

20LG

—

20P

—

12PPL —

12PPL

—

NEUSAF

(RPO M-35)

11700-800

18DBL

12PPL

—

16BRN

—

12BRN—•

24BRN/W—

NEUSAFSW

(RPO

M-35)

ALLEXC.

11700-800

§§

7T

RPO

M-35

20LBL

20DBL

20PPL

14LBL

20PPL

14LBL

20LG

12R

20DG—

C,

Fig.

114 -

Fuse Panel

—

Chevy

II

CHEVROLET CHASSIS SERVICE MANUAL

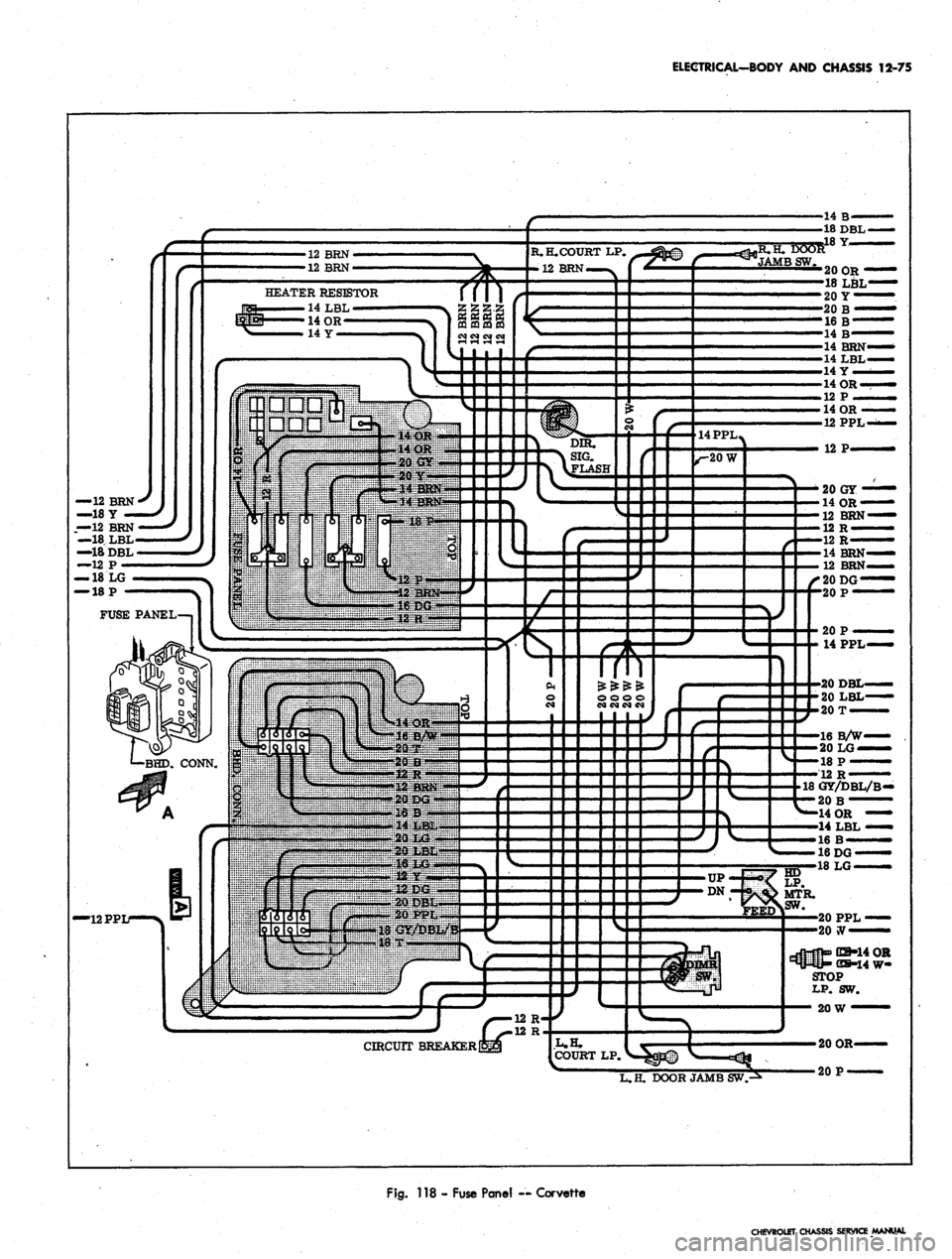

Page 587 of 659

ELECTRICAL-BODY AND CHASSIS 12-75

12 BRN

12 BRN

HEATER RESISTOR

14 LBL—

14 OR

14 Y

—12PPL—*\

/

^.LG

R. H. COURT LP.

-12 BRN —

cmcurr

BREAKER!

.R.H. DOOR

JAMB SW.

20OR-

18 LBL'

20 Y

14PPL%

•-20

W

X

/-20DG'

20 P

—

18 CfY/DBL/B

— 20 B

•^-14

OR

——

-—14 LBL —

L,

H.

DOOR JAMB SW.-

20 P

Fig.

118 - Fuse Panel — Corvette

CHEVROLET CHASSIS SERVICE MANUAl

Page 591 of 659

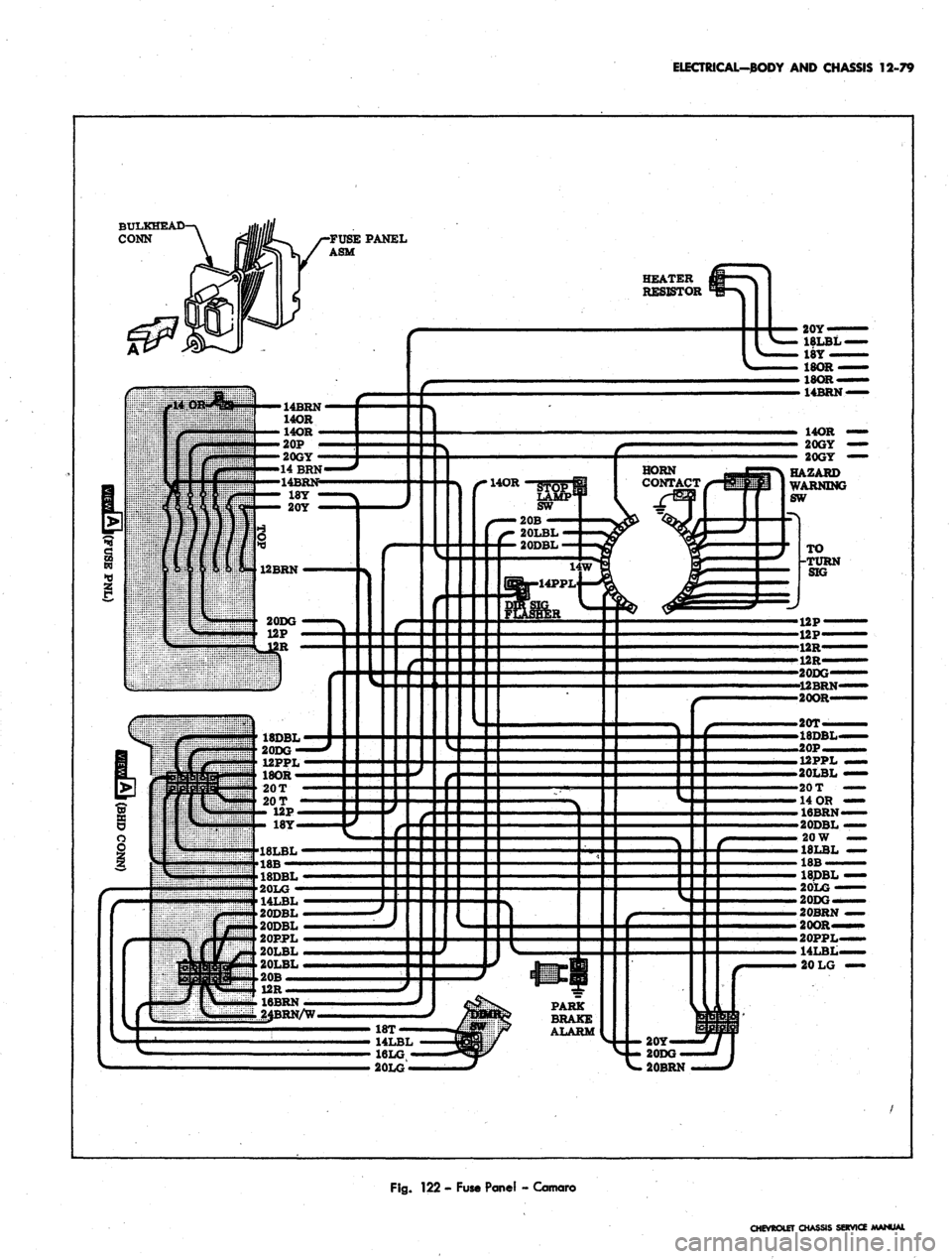

ELECTRICAL-BODY AND CHASSIS 12-79

14LBL

20DBL

20DBL

20PPL

20LBL

20LBL

20B —

12R

—

Fig.

122 - Fuse Panel - Camaro

CHEVROLET at

SERVICE MANUAL