check engine CHEVROLET CAMARO 1967 1.G Chassis Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 276 of 659

ENGINE 6-11

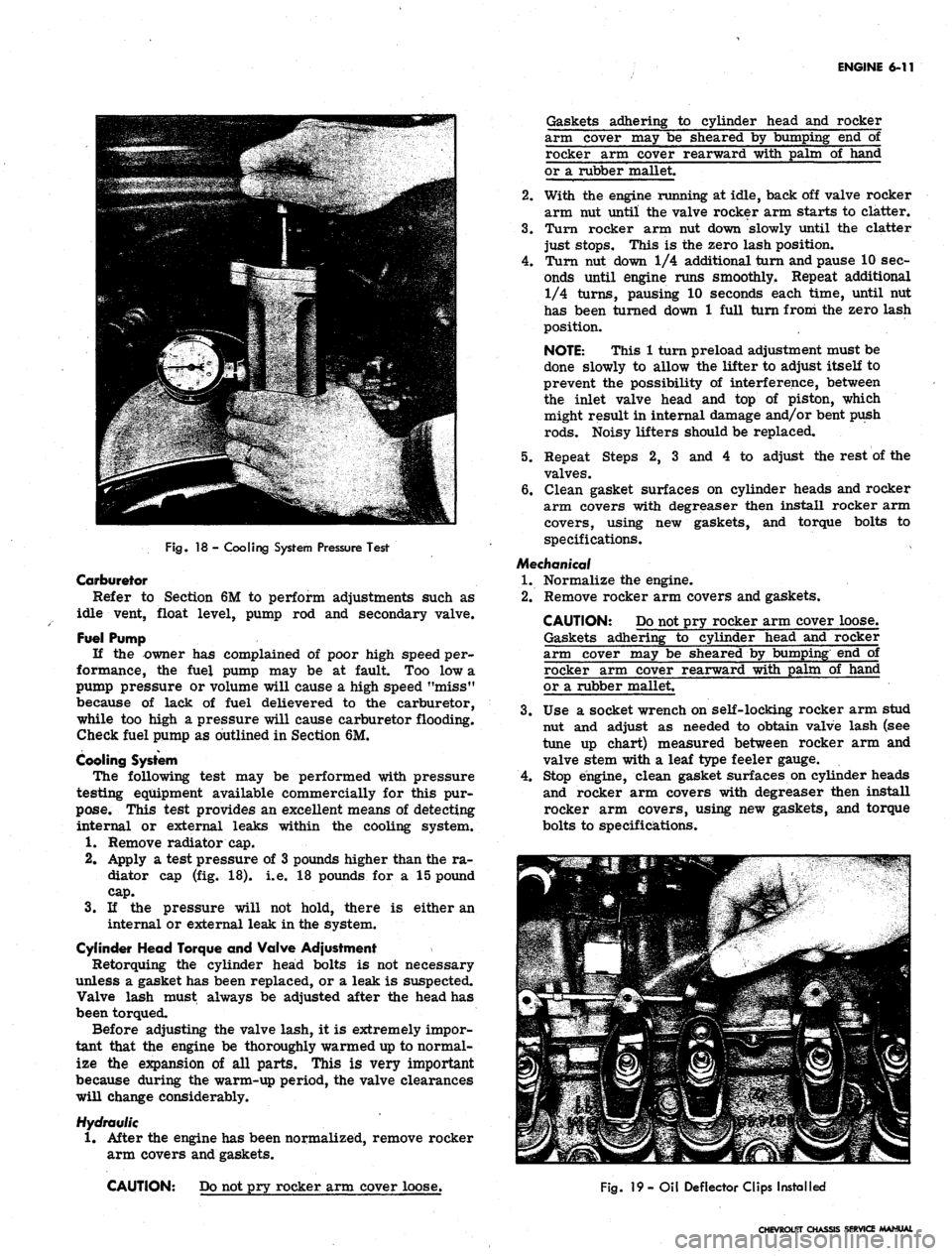

Fig.

18 - Cooling System Pressure Test

Carburetor

Refer to Section 6M to perform adjustments such as

idle vent, float level, pump rod and secondary valve.

Fuel Pump

If the owner has complained of poor high speed per-

formance, the fuel pump may be at fault. Too low a

pump pressure or volume will cause a high speed "miss"

because of lack of fuel delievered to the carburetor,

while too high a pressure will cause carburetor flooding.

Check fuel pump as outlined in Section 6M.

Cooling System

The following test may be performed with pressure

testing equipment available commercially for this pur-

pose.

This test provides an excellent means of detecting

internal or external leaks within the cooling system.

1.

Remove radiator cap.

2.

Apply a test pressure of 3 pounds higher than the ra-

diator cap (fig. 18). i.e. 18 pounds for a 15 pound

cap.

3.

If the pressure will not hold, there is either an

internal or external leak in the system.

Cylinder Head Torque and Valve Adjustment

Retorquing the cylinder head bolts is not necessary

unless a gasket has been replaced, or a leak is suspected.

Valve lash must always be adjusted after the head has

been torqued.

Before adjusting the valve lash, it is extremely impor-

tant that the engine be thoroughly warmed up to normal-

ize the expansion of all parts. This is very important

because during the warm-up period, the valve clearances

will change considerably.

Hydraulic

1.

After the engine has been normalized, remove rocker

arm covers and gaskets.

CAUTION: Do not pry rocker arm cover loose.

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand

or a rubber mallet.

2.

With the engine running at idle, back off valve rocker

arm nut until the valve rocker arm starts to clatter.

3.

Turn rocker arm nut down slowly until the clatter

just stops. This is the zero lash position.

4.

Turn nut down 1/4 additional turn and pause 10 sec-

onds until engine runs smoothly* Repeat additional

1/4 turns, pausing 10 seconds each time, until nut

has been turned down 1 full turn from the zero lash

position.

NOTE: This 1 turn preload adjustment must be

done slowly to allow the lifter to adjust itself to

prevent the possibility of interference, between

the inlet valve head and top of piston, which

might result in internal damage and/or bent push

rods.

Noisy lifters should be replaced.

5.

Repeat Steps 2, 3 and 4 to adjust the rest of the

valves.

6. Clean gasket surfaces on cylinder heads and rocker

arm covers with degreaser then install rocker arm

covers, using new gaskets, and torque bolts to

specifications.

Mechanical

1.

Normalize the engine.

2.

Remove rocker arm covers and gaskets.

CAUTION: Do not pry rocker arm cover loose.

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand

or a rubber mallet.

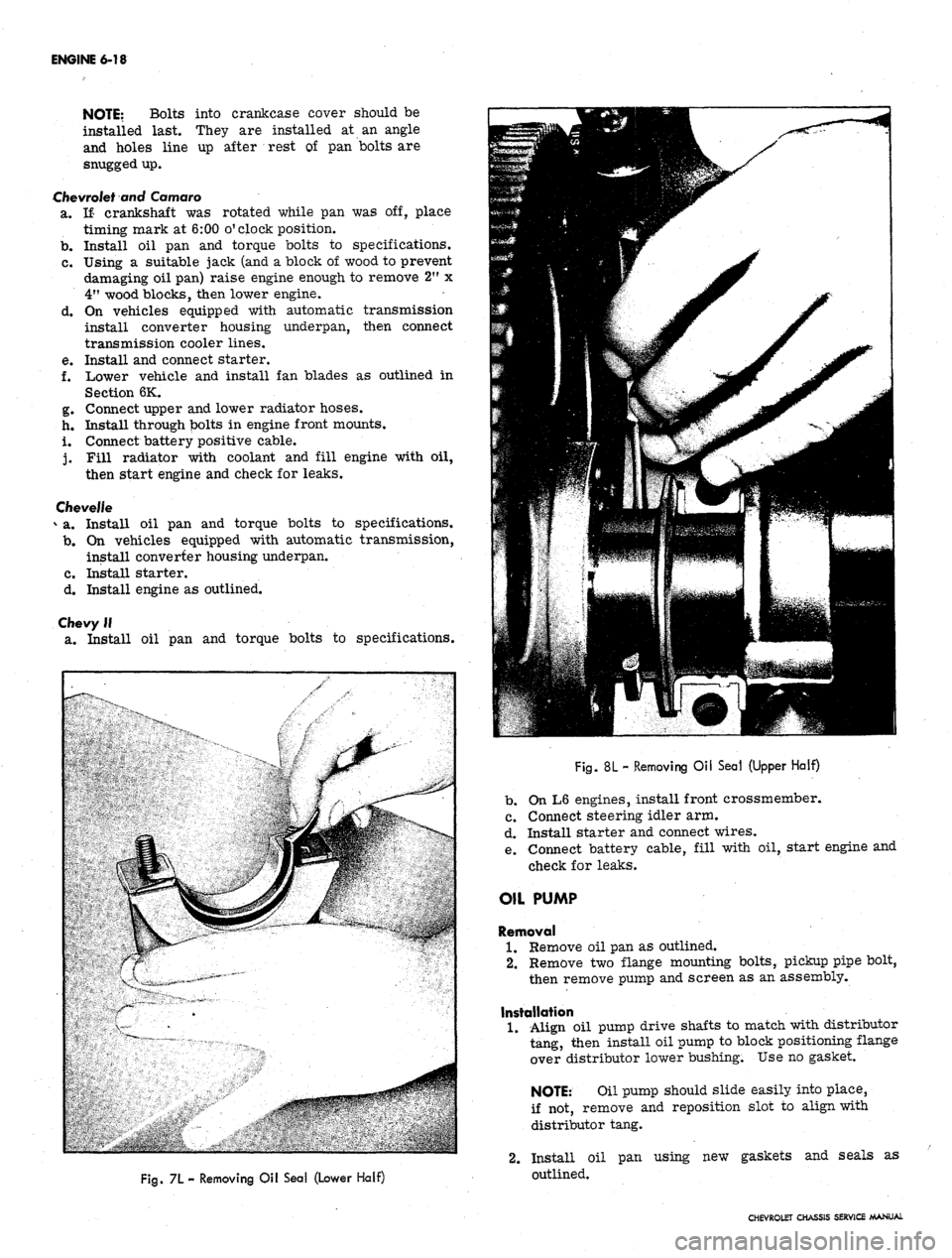

3.

Use a socket wrench on self-locking rocker arm stud

nut and adjust as needed to obtain valve lash (see

tune up chart) measured between rocker arm and

valve stem with a leaf type feeler gauge.

4.

Stop engine, clean gasket surfaces on cylinder heads

and rocker arm covers with degreaser then install

rocker arm covers, using new gaskets, and torque

bolts to specifications.

Fig.

19

- Oil Deflector Clips Installed

CHEVROLET CHASSIS SERVICE MANUAL

Page 279 of 659

ENGINE 6-14

b.

Bolt transmission to engine, then raise engine and

transmission assembly and install flywheel to

converter attaching bolts.

c. Install converter

housing*

underpan and starter.

3.

Tilt and lower engine and transmission assembly into

the chassis as a unit, guiding engine to align front

mounts with frame supports.

4.

Install front mount through bolts and torque to

specifications.

5.

Raise engine enough to install rear crossmember,

then install crossmember, install rear mount, lower

engine and torque bolts to specifications.

6. Remove lifting device and lifting adapter then install

rocker arm cover as outlined.

7.

On synchromesh equipped vehicles, install clutch

cross shaft engine bracket, then adjust and connect

clutch as outlined in Section 7.

8. Connect:

• Speedometer cable.

• Shift linkage at transmission.

9; Install propeller shaft.

10.

Remove jack stands and lower vehicle.

11.

Connect:

Power steering pump lines (if disconnected).

Vacuum line to power brake unit (if disconnected).

Fuel line at fuel pump.

Exhaust pipe at manifold flange.

Accelerator linkage at manifold bellcrank.

12.

Connect wires at:

Coil

Oil pressure switch

Temperature switch

Delcotron

Starter solenoid

13.

Install pulley, fan blade and fan belt as outlined in

Section 6K.

14.

Install radiator and shroud as outlined in Section 13.

15.

Install and adjust hood as outlined in Section 11.

16.

Connect battery cables.

17.

Fill with coolant, engine oil and transmission oil,

then start engine and check for leaks.

18.

Perform necessary adjustments and install air

cleaner.

MANIFOLD ASSEMBLY

Removal

1.

Remove air cleaner.

2.

Disconnect both throttle rods at bellcrank and re-

move throttle return spring.

3.

Disconnect fuel and vacuum lines at carburetor.

Disconnect choke cable on \A engines.

4.

Disconnect crankcase ventilation hose at rocker arm

cover.

5.

Disconnect exhaust pipe at manifold flange and dis-

card packing.

6. Remove manifold attaching bolts and clamps then

remove manifold assembly and discard gaskets.

7.

Check for cracks in manifold castings.

8. If necessary to replace either intake or exhaust

manifolds, separate them by removing one bolt and

two nuts at center of assembly. Reassemble mani-

folds using a new gasket. Tighten finger tight and

torque to specifications after assembly to cylinder

head. Transfer all necessary parts.

Installation

1.

Clean gasket surfaces on cylinder head and

manifolds*

2.

Position new gasket over manifold end studs on head

and carefully install the manifold in position making

sure the gaskets are in place.

3.

Install bolts and clamps while holding manifold in

place with hand.

4.

Torque bolts to specifications.

NOTE: On L6 engines center bolt and end bolt

torque differ.

5.

Connect exhaust pipe to manifold using a new

packing.

6. Connect crankcase ventilation hose at rocker arm

cover.

7.

Connect fuel and vacuum lines at carburetor.

8. On L4 engines connect choke cable and adjust as out-

lines in Section 6M.

9. Connect throttle rods at bellcrank and install throttle

return spring.

10.

Install air cleaner, start engine, check for leaks and

adjust carburetor idle speed and mixture.

ROCKER ARM COVER

Removal

1.

Disconnect crankcase ventilation hose(s) at rocker

arm cover.

2.

Remove air cleaner.

3.

Disconnect temperature wire from rocker arm cover

clips.

4.

Remove rocker arm cover. '

CAUTION: Do Not pry rocker arm cover loose

Gaskets adhering to cylinder head and rocker

arm cover may be sheared by bumping end of

rocker arm cover rearward with palm of hand or

a rubber mallet.

Installation

1.

Clean gasket surfaces on cylinder head and rocker

arm cover with degreaser then, using anew gasket,

install rocker arm cover and torque bolts to

specifications.

2.

Connect temperature wire at rocker arm cover clips.

3.

Install air cleaner.

4.

Connect crankcase ventilation hoses.

VALVE MECHANISM

Removal

1.

Remove rocker arm cover as outlined.

2.

Remove rocker arm nuts, rocker arm

balls,

rocker

arms and push rods.

NOTE:

Place rocker arms, rocker arm balls

and push rods in a rack so they may be rein-

stalled in the same location.

Installation and Adjustment

NOTE:

Whenever new rocker arms and/or

rocker arm balls are being installed, coat bear-

ing surfaces of rocker arms and rocker arm

balls with Molykote or its equivalent.

1.

Install push rods,

socket.

Be sure push rods seat in lifter

CHEVROLET CHASSIS SERVICE MANUAL

Page 280 of 659

ENGINE 6-15

2.

Install rocker arms, rocker arm balls and rocker

arm

nuts.

\

Tighten rocker arm nuts until all lash is

eliminated. .

3.

Adjust valves when lifter is on base circle of cam-

shaft lobe as follows:

a. Mark distributor housing, with chalk, at each cyl-

inder position (plug wire) then disconnect plug

wires at spark plugs and coil and remove distri-

butor cap and plug wire assembly (if not previ-

ously done).

b.

Crank engine until distributor rotor points to

number one cylinder position and breaker points

are open. Both valves on number one cylinder

may now be adjusted.

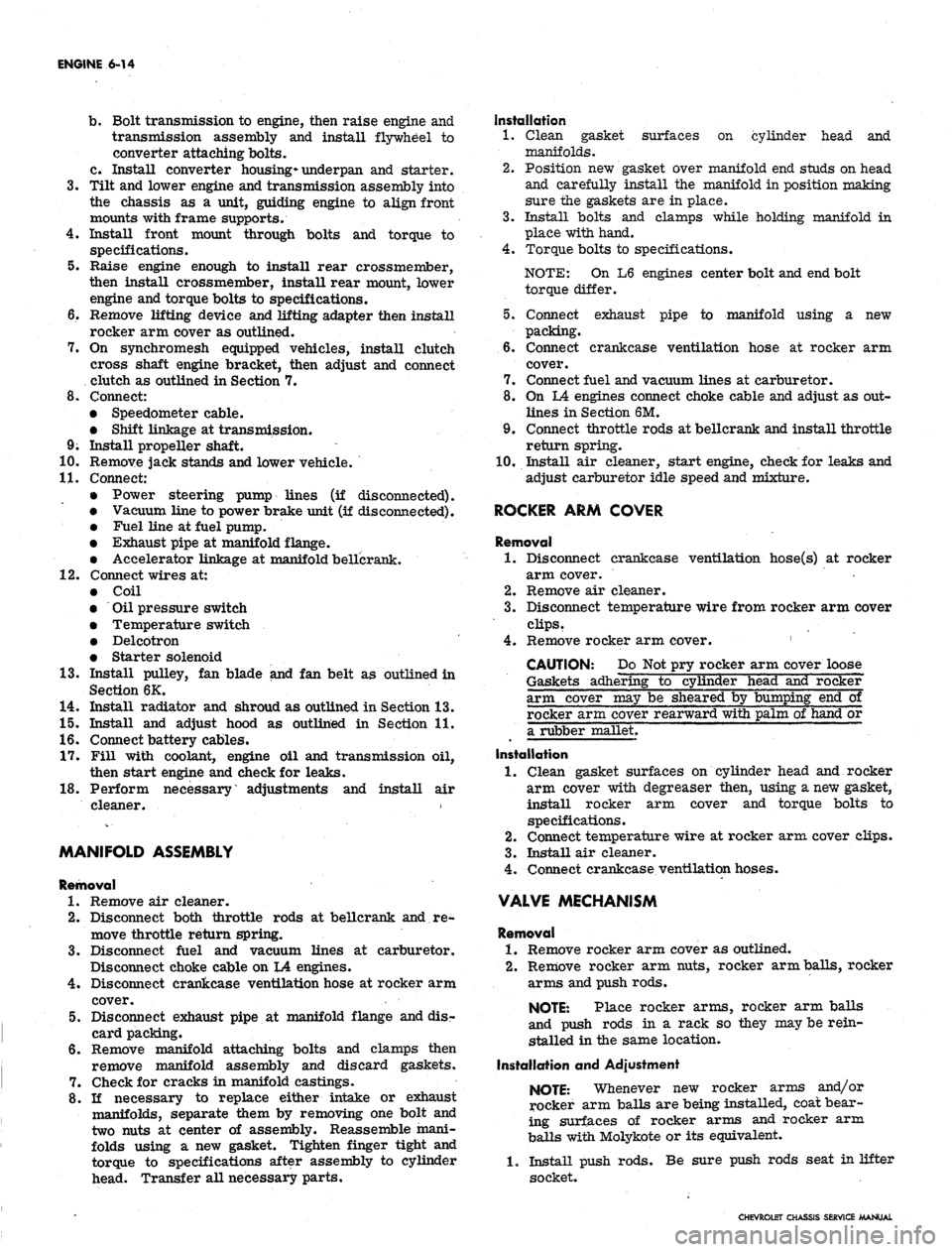

c. Back out adjusting nut until lash is felt at the push

rod then turn in adjusting nut until all lash is re-

moved. This can be determined by checking push

rod side play while turning adjusting nut (fig. 2L).

When play has been removed, turn adjusting nut

in one full additional turn (to center lifter

plunger).

d. Adjust the remaining valves, one cylinder at a

time,

in the same manner.

4.

Install distributor cap and spark plug wire assembly.

5.

Install rocker arm cover as outlined.

6. Adjust carburetor idle speed and mixture.

VALVE LIFTERS

Hydraulic valve lifters very seldom require attention.

The lifters are extremely simple in design readjustments

are not necessary, and servicing of the lifters requires

only that care and cleanliness be exercised in the han-

dling of parts.

Locating Noisy Lifters

Locate a noisy valve lifter by using a piece of garden

Fig.

2L - Valve Adjustment

hose approximately four feet in length. Place one end of

the hose near the end of each intake and exhaust valve

with the other end of the hose to the ear. In this manner,

the sound is localized making it easy to determine which

lifter is at fault.

Another method is to place a finger on the face of the

valve spring retainer. If the lifter is not functioning

properly, a distinct shock will be felt when the valve

returns to its seat.

The general types of valve lifter noise are as follows:

1.

Hard Rapping Noise--Usually caused by the plunger

becoming tight in the bore of the lifter body to such

an extent that the return spring can no longer push

the plunger back up to working position. Probable

causes are:

a. Excessive varnish or carbon deposit causing

abnormal stickiness.

b.

Galling or "pickup" between plunger and bore of

lifter body, usually caused by an abrasive piece

of dirt or metal wedging between plunger and

lifter body.

2.

Moderate Rapping Noise--Probable causes are:

a. Excessively high leakdown rate.

b.

Leaky check valve seat.

c. Improper adjustment.

3.

General Noise Throughout the Valve Train—This

will, in almost all cases, be a definite indication of

insufficient oil supply, or improper adjustment.

4.

Intermittent Clicking—Probable causes are:

a. A microscopic piece of dirt momentarily caught

between ball seat and check valve ball.

b.

In rare cases, the ball itself may be

out-of-

round or have a flat spot.

c. Improper adjustment.

In most cases where noise exists in one or more lifters

all lifter units should be removed, disasssmbled, cleaned

in a solvent, reassembled, and reinstalled in the engine.

If dirt, varnish, carbon, etc. is shown to exist in one unit,

it more than likely exists in all the units, thus it would

only be, a matter of time before all lifters caused trouble.

Removal

1.

Remove valve mechanism as outlined.

2.

Mark distributor housing, with chlak, at each cylin-

der position (plug wire) then disconnect plug wires at

spark plugs and coil and remove distributor cap and

plug wire assembly.

3.

Crank engine until distributor rotor points to number

one position, then disconnect distributor primary lead

at coil and remove distributor.

4.

Remove push rod covers (discard gaskets).

5.

Remove valve lifters.

NOTE: Place valve lifters in a rack so they

may be reinstalled in the same location.

Installation

1.

Install valve lifters.

NOTE:

Whenever new valve lifters are being

installed, coat foot of valve lifters with Molykote

or its equivalent.

2.

Install push rod covers, using new gaskets, and

torque bolts to specifications.

3.

Install distributor, positioning rotor to number one

cylinder position, then connect primary lead at coil.

4.

Install and adjust valve mechanism as outlined.

CHEVROLET CHASSIS SERVICE MANUAL

Page 283 of 659

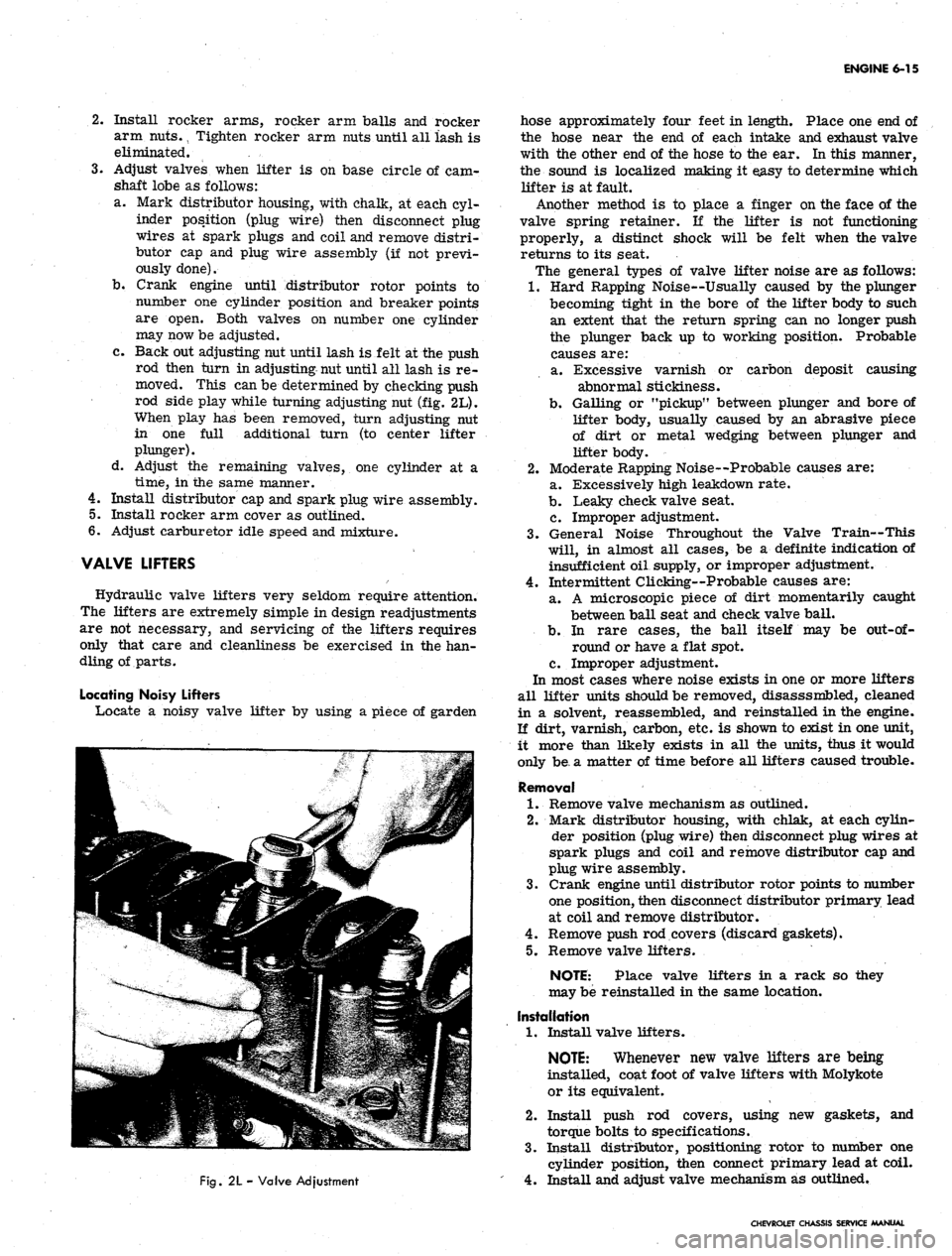

ENGINE 6-18

NOTE:

Bolts into crankcase cover should be

installed last. They are installed at an angle

and holes line up after rest of pan bolts are

snugged up.

Chevrolet and Camaro

a. If crankshaft was rotated while pan was off, place

timing mark at 6:00 o'clock position.

b.

Install oil pan and torque bolts to specifications.

c. Using a suitable jack (and a block of wood to prevent

damaging oil pan) raise engine enough to remove 2" x

4"

wood blocks, then lower engine.

d. On vehicles equipped with automatic transmission

install converter housing underpan, then connect

transmission cooler lines.

e. Install and connect starter.

f. Lower vehicle and install fan blades as outlined in

Section 6K.

g. Connect upper and lower radiator hoses.

h. Install through bolts in engine front mounts.

i. Connect battery positive cable.

j.

Fill radiator with coolant and fill engine with oil,

then start engine and check for leaks.

Chevelie

* a. Install oil pan and torque bolts to specifications.

b.

On vehicles equipped with automatic transmission,

install converter housing underpan.

c. Install starter.

d. Install engine as outlined.

Chevy II

a. Install oil pan and torque bolts to specifications.

Fig.

7L- Removing Oil Sea! (Lower Half)

Fig.

8L - Removing Oil Seal (Upper Half)

b.

On L6 engines, install front crossmember.

c. Connect steering idler arm.

d. Install starter and connect wires.

e. Connect battery cable, fill with oil, start engine and

check for leaks.

OIL PUMP

Removal

1.

Remove oil pan as outlined.

2.

Remove two flange mounting bolts, pickup pipe bolt,

then remove pump and screen as an assembly.

Installation

1.

Align oil pump drive shafts to match with distributor

tang, then install oil pump to block positioning flange

over distributor lower bushing. Use no gasket.

NOTE:

Oil pump should slide easily into place,

if not, remove and reposition slot to align with

distributor tang.

2.

Install oil pan using new gaskets and seals as

outlined.

CHEVROLET CHASSIS SERVICE MANUAL

Page 285 of 659

ENGINE 6-20

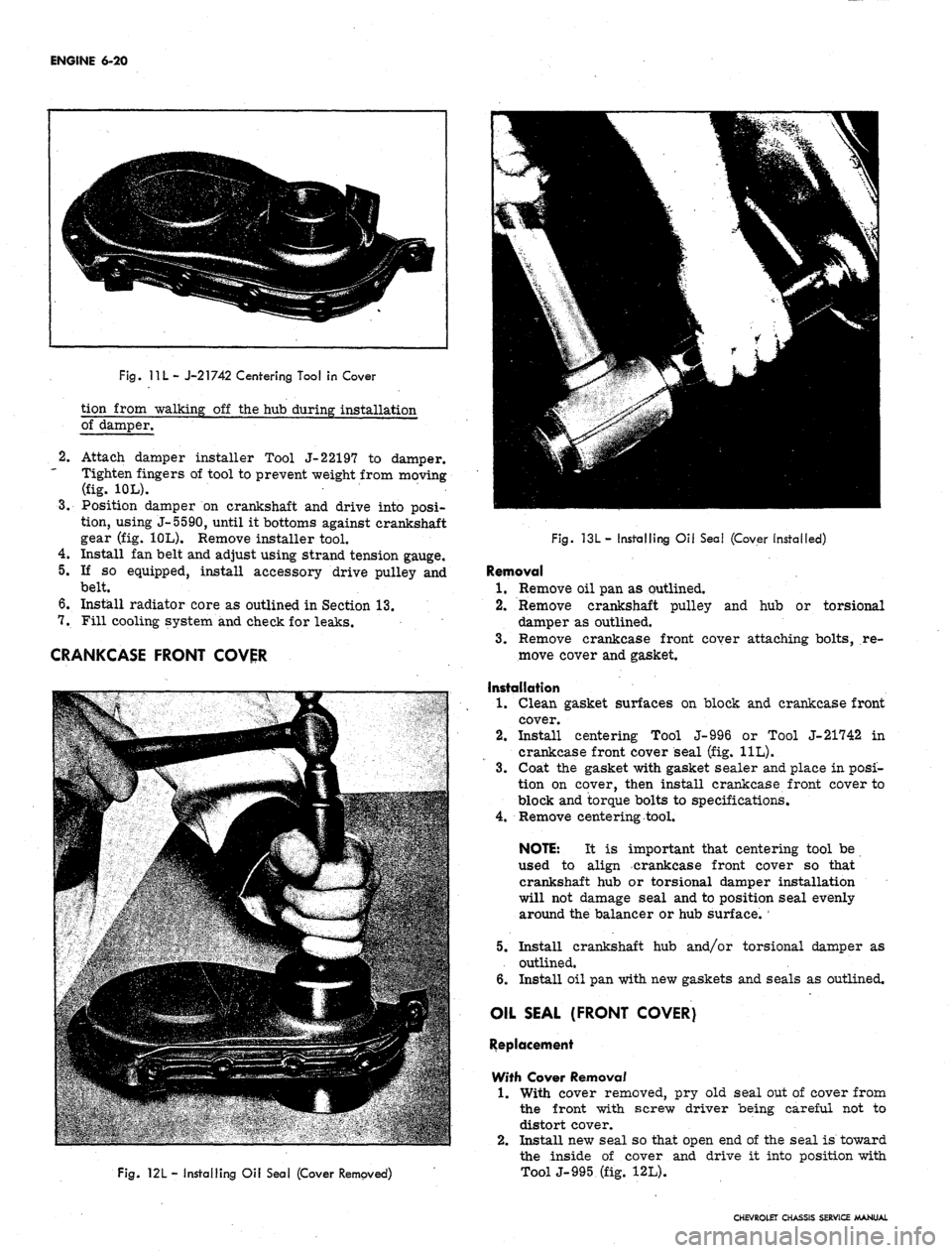

Fig.

11 L

- J-21742 Centering Tool in Cover

tion from walking off the hub during installation

of damper.

2.

3.

Attach damper installer Tool J-22197 to damper.

Tighten fingers of tool to prevent weight from moving

(fig. 10L).

Position damper on crankshaft and drive into posi-

tion, using J-5590, until it bottoms against crankshaft

gear (fig. 10L). Remove installer tool.

4.

Install fan belt and adjust using strand tension gauge.

5.

If so equipped, install accessory drive pulley and

belt.

6. Install radiator core as outlined in Section 13.

7.

Fill cooling system and check for leaks.

CRANKCASE FRONT COVER

Fig.

121

- Installing Oil Seal (Cover Removed)

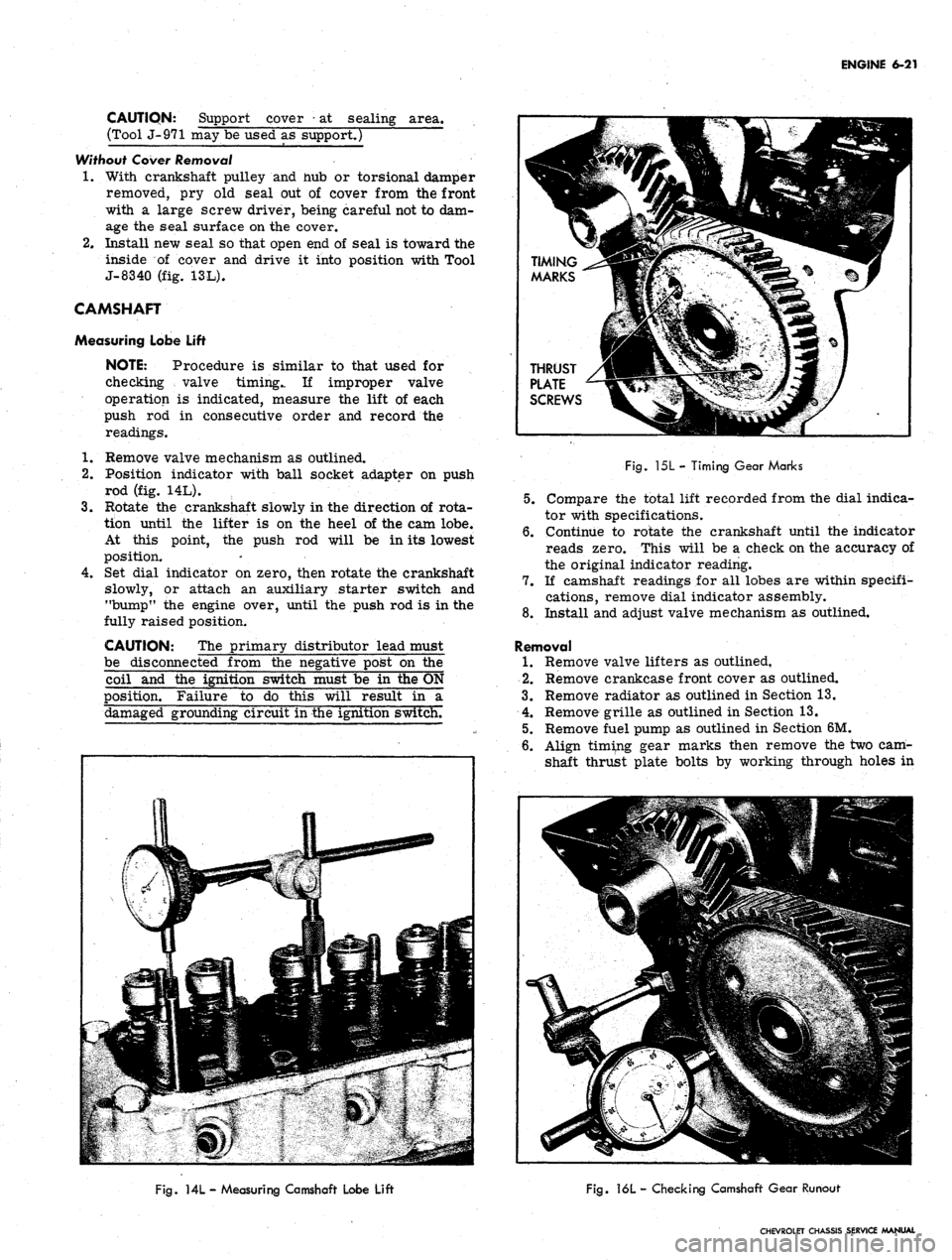

Fig. 13L- Installing Oil Seal (Cover installed)

Removal

1.

Remove oil pan as outlined.

2.

Remove crankshaft pulley and hub or torsional

damper as outlined.

3.

Remove crankcase front coyer attaching bolts, re-

move cover and gasket.

Installation

1.

Clean gasket surfaces on block and crankcase front

cover.

2.

Install centering Tool J-996 or Tool J-21742 in

crankcase front cover seal (fig. 11L).

3.

Coat the gasket with gasket sealer and place in posi-

tion on cover, then install crankcase front cover to

block and torque bolts to specifications.

4.

Remove centering tool.

NOTE: It is important that centering tool be

used to align crankcase front cover so that

crankshaft hub or torsional damper installation

will not damage seal and to position seal evenly

around the balancer or hub surface.

5.

Install crankshaft hub and/or torsional damper as

outlined.

6. Install oil pan with new gaskets and seals as outlined.

OIL SEAL (FRONT COVER)

Replacement

With Cover Removal

1.

With cover removed, pry old seal out of cover from

the front with screw driver being careful not to

distort cover.

2.

Install new seal so that open end of the seal is toward

the inside of cover and drive it into position with

ToolJ-995 (fig. 12L).

CHEVROLET CHASSIS SERVICE MANUAL

Page 286 of 659

ENGINE 6-21

CAUTION: Support cover

•

at sealing area.

(Tool J-971 may be used as support.)

Without Cover

Removal

1.

With crankshaft pulley and nub or torsional damper

removed, pry old seal out of cover from the front

with a large screw driver, being careful not to dam-

age the seal surface on the cover.

2.

Install new seal so that open end of seal is toward the

inside of cover and drive it into position with Tool

J-8340 (fig. 13L).

CAMSHAFT

Measuring Lobe Lift

NOTE: Procedure is similar to that used for

checking valve timing.. If improper valve

operation is indicated, measure the lift of each

push rod in consecutive order and record the

readings.

1.

Remove valve mechanism as outlined.

2.

Position indicator with ball socket adapter on push

rod (fig. 14L).

3.

Rotate the crankshaft slowly in the direction of rota-

tion until the lifter is on the heel of the cam lobe.

At this point, the push rod will be in its lowest

position.

4.

Set dial indicator on zero, then rotate the crankshaft

slowly, or attach an auxiliary starter switch and

"bump" the engine over, until the push rod is in the

fully raised position.

CAUTION: The primary distributor lead must

be disconnected from the negative post on the

coil and the ignition switch must be in the ON

position. Failure to do this will result in a

damaged grounding circuit in the ignition switch.

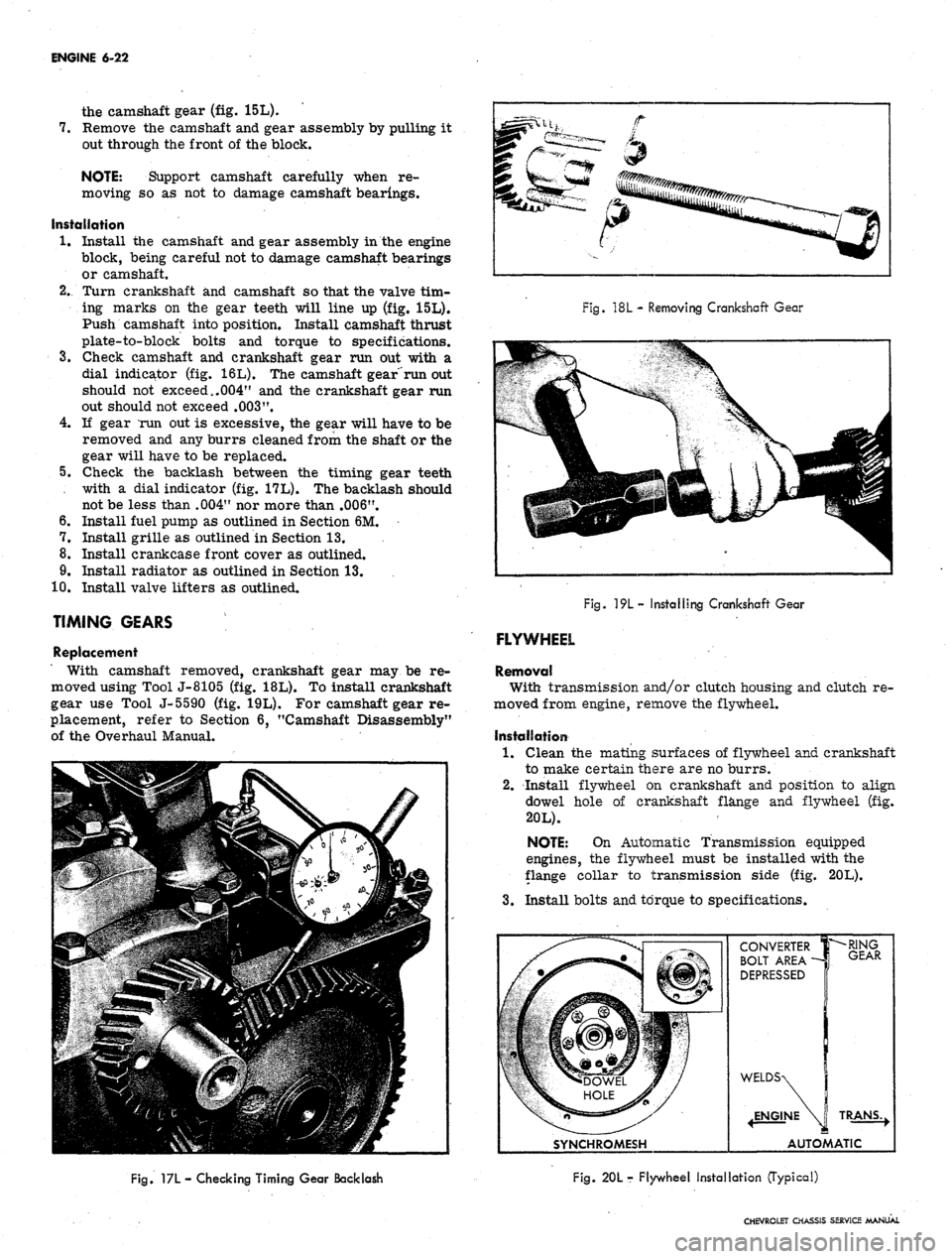

Fig.

15L - Timing Gear Marks

5.

Compare the total lift recorded from the dial indica-

tor with specifications.

6. Continue to rotate the crankshaft until the indicator

reads zero. This will be a check on the accuracy of

the original indicator reading.

7.

If camshaft readings for all lobes are within specifi-

cations, remove dial indicator assembly.

8. Install and adjust valve mechanism as outlined.

Removal

1.

Remove valve lifters as outlined,

2.

Remove crankcase front cover as outlined.

3.

Remove radiator as outlined in Section 13.

4.

Remove grille as outlined in Section 13.

5.

Remove fuel pump as outlined in Section 6M.

6. Align timing gear marks then remove the two cam-

shaft thrust plate bolts by working through holes in

Fig.

ML - Measuring Camshaft Lobe Lift

Fig.

16L - Checking Camshaft Gear Runout

CHEVROLET CHASSIS SERVICE MANUAL

Page 287 of 659

ENGINE 6-22

the camshaft gear (fig. 15L).

7.

Remove the camshaft and gear assembly by pulling it

out through the front of the block.

NOTE: Support camshaft carefully when re-

moving so as not to damage camshaft bearings.

Installation

1.

Install the camshaft and gear assembly in the engine

block, being careful not to damage camshaft bearings

or camshaft.

2.

Turn crankshaft and camshaft so that the valve tim-

ing marks on the gear teeth will line up (fig. 15L).

Push camshaft into position. Install camshaft thrust

plate-to-block bolts and torque to specifications.

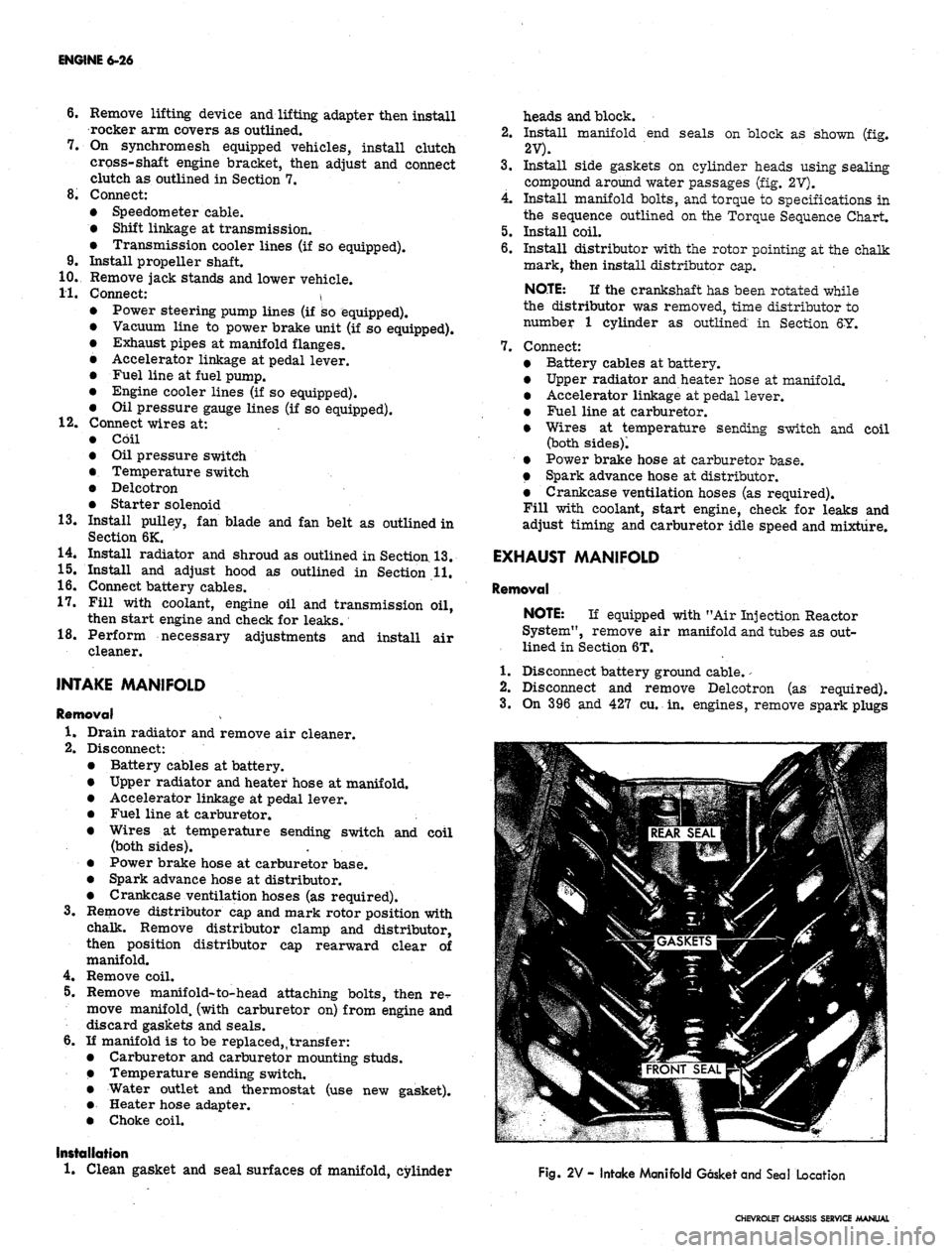

3.

Check camshaft and crankshaft gear run out with a

dial indicator (fig. 16L). The camshaft gear"run out

should not exceed,.004" and the crankshaft gear run

out should not exceed

.003".

4.

If gear mm out is excessive, the gear will have to be

removed and any burrs cleaned from the shaft or the

gear will have to be replaced.

5.

Check the backlash between the timing gear teeth

with a dial indicator (fig. 17L). The backlash should

not be less than .004" nor more than .006".

6. Install fuel pump as outlined in Section 6M.

7.

Install grille as outlined in Section 13.

8. Install crankcase front cover as outlined.

9. Install radiator as outlined in Section 13.

10.

Install valve lifters as outlined.

TIMING GEARS

Replacement

With camshaft removed, crankshaft gear may be re-

moved using Tool J-8105 (fig. 18L). To install crankshaft

gear use Tool J-5590 (fig. 19L). For camshaft gear re-

placement, refer to Section 6, "Camshaft Disassembly"

of the Overhaul Manual.

Fig.

18L

- Removing Crankshaft Gear

Fig.

19L- Installing Crankshaft Gear

FLYWHEEL

Removal

With transmission and/or clutch housing and clutch re-

moved from engine, remove the flywheel.

Installation

1.

Clean the mating surfaces of flywheel and crankshaft

to make certain there are no burrs.

2.

Install flywheel on crankshaft and position to align

dowel hole of crankshaft flange and flywheel (fig.

20L).

NOTE: On Automatic Transmission equipped

engines, the flywheel must be installed with the

flange collar to transmission side (fig. 20L).

3.

Install bolts and torque to specifications.

SYNCHROMESH

CONVERTER

BOLT AREA -

DEPRESSED

•RING

GEAR

TRANS.,

AUTOMATIC

Fig. 17L

—

Checking Timing Gear Backlash

Fig. 20L r Flywheel Installation (Typical)

CHEVROLET CHASSIS SERVICE MANUAL

Page 291 of 659

ENGINE 6-26

6. Remove lifting device and lifting adapter then install

rocker arm covers as outlined.

7.

On synchromesh equipped vehicles, install clutch

cross-shaft engine bracket, then adjust and connect

clutch as outlined in Section 7.

8. Connect:

• Speedometer cable.

• Shift linkage at transmission.

• Transmission cooler lines (if so equipped).

9. Install propeller shaft.

10.

Remove jack stands and lower vehicle.

11.

Connect: \ '

Power steering pump lines (if so equipped).

Vacuum line to power brake unit (if so equipped).

Exhaust pipes at manifold flanges.

Accelerator linkage at pedal lever.

Fuel line at fuel pump.

Engine cooler lines (if so equipped).

Oil pressure gauge lines (if so equipped).

12.

Connect wires at:

Coil

Oil pressure switch

Temperature switch

Delcotron

Starter solenoid

13.

Install pulley, fan blade and fan belt as outlined in

Section 6K.

14.

Install radiator and shroud as outlined in Section 13.

15.

Install and adjust hood as outlined in Section 11.

16.

Connect battery cables.

17.

Fill with coolant, engine oil and transmission oil,

then start engine and check for leaks.

18.

Perform necessary adjustments and install air

cleaner.

INTAKE MANIFOLD

Removal

1.

Drain radiator and remove air cleaner.

2.

Disconnect:

Battery cables at battery.

Upper radiator and heater hose at manifold.

Accelerator linkage at pedal lever.

Fuel line at carburetor. ;

Wires at temperature sending switch and coil

(both sides).

Power brake hose at carburetor base.

Spark advance hose at distributor.

Crankcase ventilation hoses (as required).

3.

Remove distributor cap and mark rotor position with

chalk. Remove distributor clamp and distributor,

then position distributor cap rearward clear of

manifold.

4.

Remove coil.

5.

Remove manifold-to-head attaching bolts, then re^

move manifold, (with carburetor on) from engine and

discard gaskets and seals.

6. If manifold is to be replaced,,transfer:

Carburetor and carburetor mounting studs.

Temperature sending switch.

Water outlet and thermostat (use new gasket).

Heater hose adapter.

Choke coil.

Installation

1.

Clean gasket and seal surfaces of manifold, cylinder

heads and block.

2.

Install manifold end seals on block as shown (fig.

2V).

3.

Install side gaskets on cylinder heads using sealing

compound around water passages (fig. 2V).

4.

Install manifold bolts, and torque to specifications in

the sequence outlined on the Torque Sequence Chart.

5.

Install coil.

6. Install distributor with the rotor pointing at the chalk

mark, then install distributor cap.

NOTE:

If the crankshaft has been rotated while

the distributor was removed, time distributor to

number 1 cylinder as outlined in Section 6Y.

7.

Connect:

Battery cables at battery.

Upper radiator and heater hose at manifold.

Accelerator linkage at pedal lever.

Fuel line at carburetor.

Wires at temperature sending switch and coil

(both sides)!

Power brake hose at carburetor base.

Spark advance hose at distributor.

Crankcase ventilation hoses (as required).

Fill with coolant, start engine, check for leaks and

adjust timing and carburetor idle speed and mixture.

EXHAUST MANIFOLD

Removal

NOTE:

If equipped with "Air Injection Reactor

System", remove air manifold and tubes as out-

lined in Section 6T.

1.

Disconnect battery ground cable.

-

2.

Disconnect and remove Delcotron (as required).

3.

On 396 and 427 cu. in. engines, remove spark plugs

Fig. 2V - Intake Manifold Gasket and Seal Location

CHEVROLET CHASSIS SERVICE MANUAL

Page 292 of 659

ENGINE 6-27

and spark plug shields.

4.

Remove exhaust manifold flange nuts, then lower ex-

haust pipe assembly (hang exhaust pipe from frame

with wire).

5.

Bend french lock tabs (fig. 3V), remove end bolts

then remove center bolts and remove manifold from

engine.

NOTE: A 9/16 thin-wall 6 point socket, sharp-

ened at the leading edge, then started on the head

of the bolt and tapped in place with a hammer,

simplifies bending of french locks.

Installation

1.

Clean mating surfaces on manifold and head, then

install manifold in position and install center bolts.

2.

Install end bolts with french locks under them.

3.

Torque center bolts to specifications, then torque end

bolts to specifications, and bend french lock tabs to

lock end bolts.

4.

Using a new flange gasket install exhaust pipe to

manifold flange.

5.

On 396 and 427 cu. in. engines, clean and install

spark plugs using new gaskets. (Torque spark plugs

to specifications.)

6. Install and connect Delcotron.

7.

Connect the battery ground cable.

8. Start engine and check for leaks.

ROCKER ARM COVER

Removal

1.

Remove air cleaner.

2.

Disconnect crankcase ventilation hoses (as required).

3.

Disconnect temperature wire from rocker arm cover

clips.

4.

Remove rocker arm cover.

CAUTION: DO NOT pry rocker arm cover

loose. Gaskets adhering to cylinder head and

Installation

1.

.Clean gasket surfaces on cylinder head and rocker

arm cover with degreaser then, using a new gasket,

install rocker arm cover and torque bolts to

specifications. .

2.

Connect crankcase ventilation hoses (if disconnected).

3.

Connect temperature wire at rocker arm cover clips.

4.

Install air cleaner.

VALVE MECHANISM

Removal

1.

Remove rocker arm covers as outlined.

2.

Remove rocker arm nuts, rocker arm balls, rocker

arms and push rods.

NOTE: Place rocker arms, rocker arm balls

and push rods in a rack so they may be rein-

stalled in the same location.

Installation and Adjustment

NOTE: Whenever new rocker arms and/or

rocker arm balls are being installed, coat bear-

ing surfaces of rocker arms and rocker arm

balls with Molykote or its equivalent.

1.

Install push rods; Be sure push rods seat in lifter

socket.

2.

Install rocker arms, rocker arm balls and rocker

arm nuts.

3.

Adjust valves when lifter is on base circle of cam-

shaft lobe as follows:

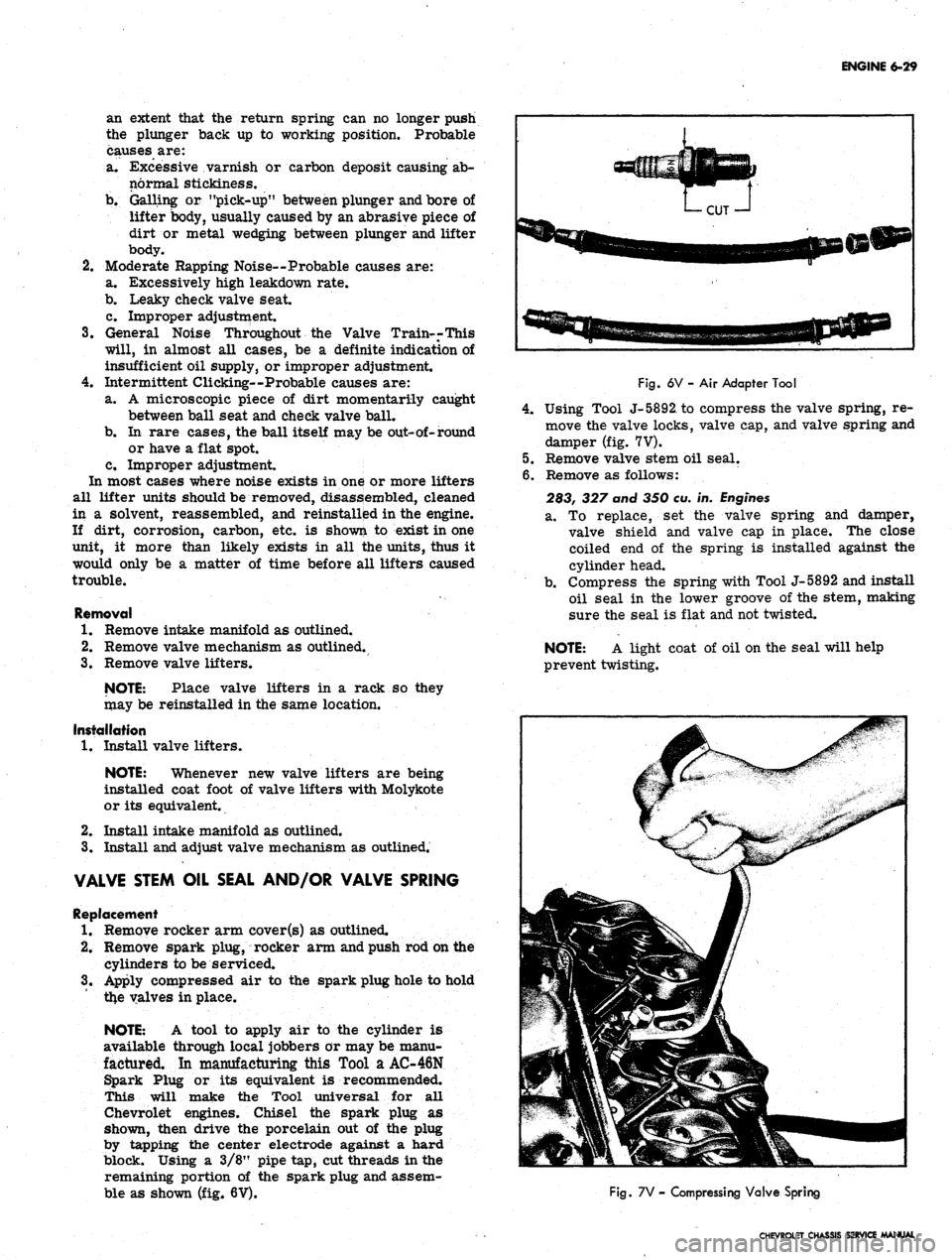

With Hydraulic Valve

Lifters

2L.

Crank engine until

mark on torsional damper

lines up with center or "0M mark on the timing

tab and the engine is in the number 1 firing posi-

tion. This may be determined by placing fingers

on the number 1 cylinder valve as the mark on the

rocker arm cover may be sheared by bumpii

end of rocker arm cover rearward with palm

hand or a rubber mallet.

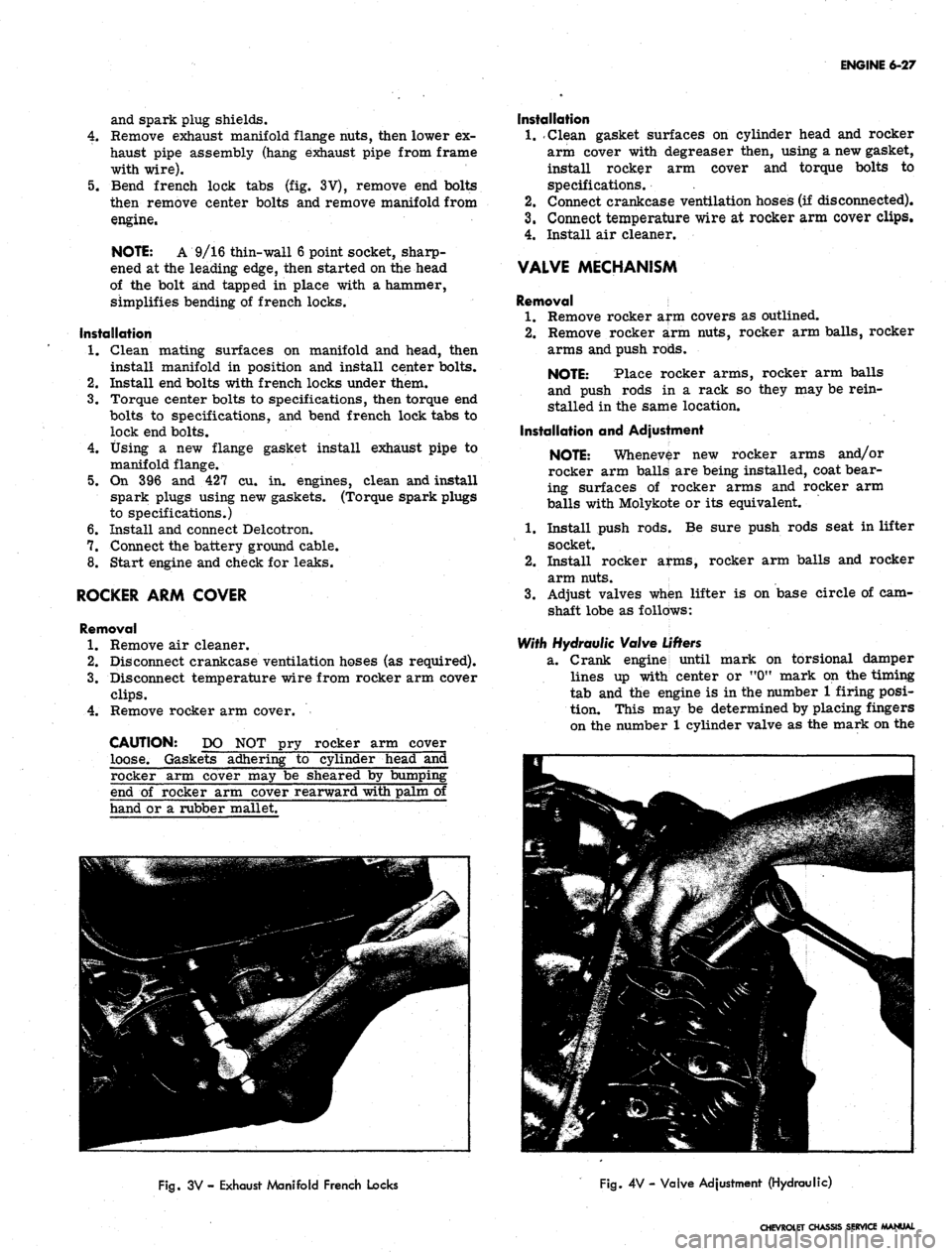

Fig.

3V - Exhaust Manifold French Locks

Fig.

4V - Valve Adjustment (Hydraulic)

CHEVROLET CHASSIS SERVICE MANUAL

Page 294 of 659

ENGINE 6-29

an extent that the return spring can no longer push

the plunger back up to working position. Probable

causes are:

a. Excessive varnish or carbon deposit causing ab-

normal stickiness.

b.

(Sailing or "pick-up" between plunger and bore of

lifter body, usually caused by an abrasive piece of

dirt or metal wedging between plunger and lifter

body.

2.

Moderate Rapping Noise--Probable causes are:

a. Excessively high leakdown rate.

b.

Leaky check valve seat.

c. Improper adjustment.

3.

General Noise Throughout the Valve Train-rThis

will, in almost all cases, be a definite indication of

insufficient oil supply, or improper adjustment.

4.

Intermittent Clicking—Probable causes are:

a. A microscopic piece of dirt momentarily caught

between ball seat and check valve ball.

b.

In rare cases, the ball itself may be out-of-round

or have a flat spot.

c. Improper adjustment.

In most cases where noise exists in one or more lifters

all lifter units should be removed, disassembled, cleaned

in a solvent, reassembled, and reinstalled in the engine.

If dirt, corrosion, carbon, etc. is shown to exist in one

unit, it more than likely exists in all the units, thus it

would only be a matter of time before all lifters caused

trouble.

Removal

1.

Remove intake manifold as outlined.

2.

Remove valve mechanism as outlined.

3.

Remove valve lifters.

NOTE: Place valve lifters in a rack so they

may be reinstalled in the same location.

Installation

1.

Install valve lifters.

NOTE: Whenever new valve lifters are being

installed coat foot of valve lifters with Molykote

or its equivalent.

2.

Install intake manifold as outlined.

3.

Install and adjust valve mechanism as outlined.

VALVE STEM OIL SEAL AND/OR VALVE SPRING

Replacement

1.

Remove rocker arm cover(s) as outlined.

2.

Remove spark plug, rocker arm and push rod on the

cylinders to be serviced.

3.

Apply compressed air to the spark plug hole to hold

tl*e valves in place.

NOTE: A tool to apply air to the cylinder is

available through local jobbers or may be manu-

factured. In manufacturing this Tool a AC-46N

Spark Plug or its equivalent is recommended.

This will make the Tool universal for all

Chevrolet engines. Chisel the spark plug as

shown, then drive the porcelain out of the plug

by tapping the center electrode against a hard

block. Using a 3/8" pipe tap, cut threads in the

remaining portion of the spark plug and assem-

ble as shown (fig. 6V).

Fig.

6V - Air Adapter Tool

4.

Using Tool J-5892, to compress the valve spring, re-

move the valve locks, valve cap, and valve spring and

damper (fig. 7V).

5.

Remove valve stem oil seal.

6. Remove as follows:

283, 327 and 350 eu. in.

Engines

a. To replace, set the valve spring and damper,

valve shield and valve cap in place. The close

coiled end of the spring is installed against the

cylinder head.

b.

Compress the spring with Tool J-5892 and install

oil seal in the lower groove of the stem, making

sure the seal is flat and not twisted.

NOTE: A light coat of oil on the seal will help

prevent twisting.

Fig.

7V - Compressing Valve Spring

CHEVROLET CHASSIS SERVICE MANUAL