service indicator CHEVROLET CAMARO 1967 1.G Chassis Service Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 546 of 659

ELECTRICAL-BODY AND CHASSIS 12-34

5. To replace, reverse the removal procedure.

SPEEDOMETER REPLACEMENT

1.

Remove instrument cluster as previously described

in this section.

2.

Remove clock set shaft knob.

3.

Remove eight screws securing cluster housing to

bezel trim panel. Separate parts carefully observing

stack up of parts.

4.

Remove two screws securing speedometer head to

rear of cluster housing.

NOTE:

Servicing of the speedometer head

should be performed by an authorized AC Speed-

ometer Service Station.

5. To install, reverse the removal procedure..

SPEEDOMETER CABLE

Replacement or Lubricatibn

1.

Disconnect the speedometer cable from the speed-

ometer head. Remove the old cable by pulling it out

from speedometer end of conduit.

NOTE:

If old cable is broken it may be neces-

sary to remove lower piece from transmission

end of conduit.

2.

Lubricate the lower 3/4 of cable with speedometer

cable lubricant and push the cable into the conduit.

Connect the upper end to the speedometer head and

road test vehicle for proper speedometer operation.

INDICATOR LIGHT REPLACEMENT

To replace any indicator or cluster bulb, unsnap the

proper socket from rear of instrument cluster, remove

and replace bulb, and reinsert unit into rear of cluster

housing.

OIL PRESSURE INDICATOR

If the light does not come on when the ignition switch

is turned on, or if the light comes on and remains on

after the engine is started, one or more of the following

conditions is indicated:

• Low oil pressure

• High engine temperature

• Defective wiring or switch

Switch Replacement

1.

Disconnect wiring harness connector from sender

unit terminal (located in block above starter on

L-6 engines and at left front of distributor on V-8

engines).

2.

Remove sender unit, replace with new unit, and

; check operation.

GENERATOR INDICATOR

1.

Ignition on, engine not running and telltale light off.

a. Indicator bulb burned out, replace bulb.

b.

Open circuit or loose connection in the telltale

light circuit.

2.

Telltale light stays on after engine is started.

a. If indicator light does not go out at engine idle

speed, refer to Charging Systems under Engine

Electrical, Section 6Y.

TEMPERATURE (COOLING SYSTEM) INDICATOR

The temperature indicator circuit consists of two re-

motely located units, indicator gauge and engine sender

unit. The indicator gauge on all models uses a single

red light to indicate an overheated engine condition.

Engine Sender Unit Replacement

1.

Drain engine cooling system to a level below unit.

2.

Remove sender unit (located in the inlet manifold

near water pump housing on V-8 engines and in the

cylinder head near an exhaust port on L-6 engines)

and replace with new unit.

3.

Refill cooling system and check operation of unit.

CORVETTE INSTRUMENTS AND GAUGES

INDEX

Page

General Description ., 12-34

Service Operations . 12-35

Instrument Cluster ., 12-35

Fuel Gauge 12-35

Speedometer/Tachometer Service. 12-35

Temperature Gauge 12-35

Ammeter/Oil Pressure Gauges 12-35

GENERAL DESCRIPTION

All Corvette instruments and gauges are conveniently

located in the dash-mounted cluster. The entire cluster

is removable to permit servicing of the various instru-

ments and gauges. The indicator and cluster illuminating

bulbs may be replaced without removing the cluster from

the panel.

Regular maintenance is not required on the instrument

cluster or its components other than maintaining clean

and keeping the speedometer and tachometer cables

properly lubricated.

CHEVROLET CHASSIS SERVICE MANUAL

Page 547 of 659

ELECTRICAL-BODY AND CHASSIS 12-35

SERVICE OPERATIONS

INSTRUMENT CLUSTER

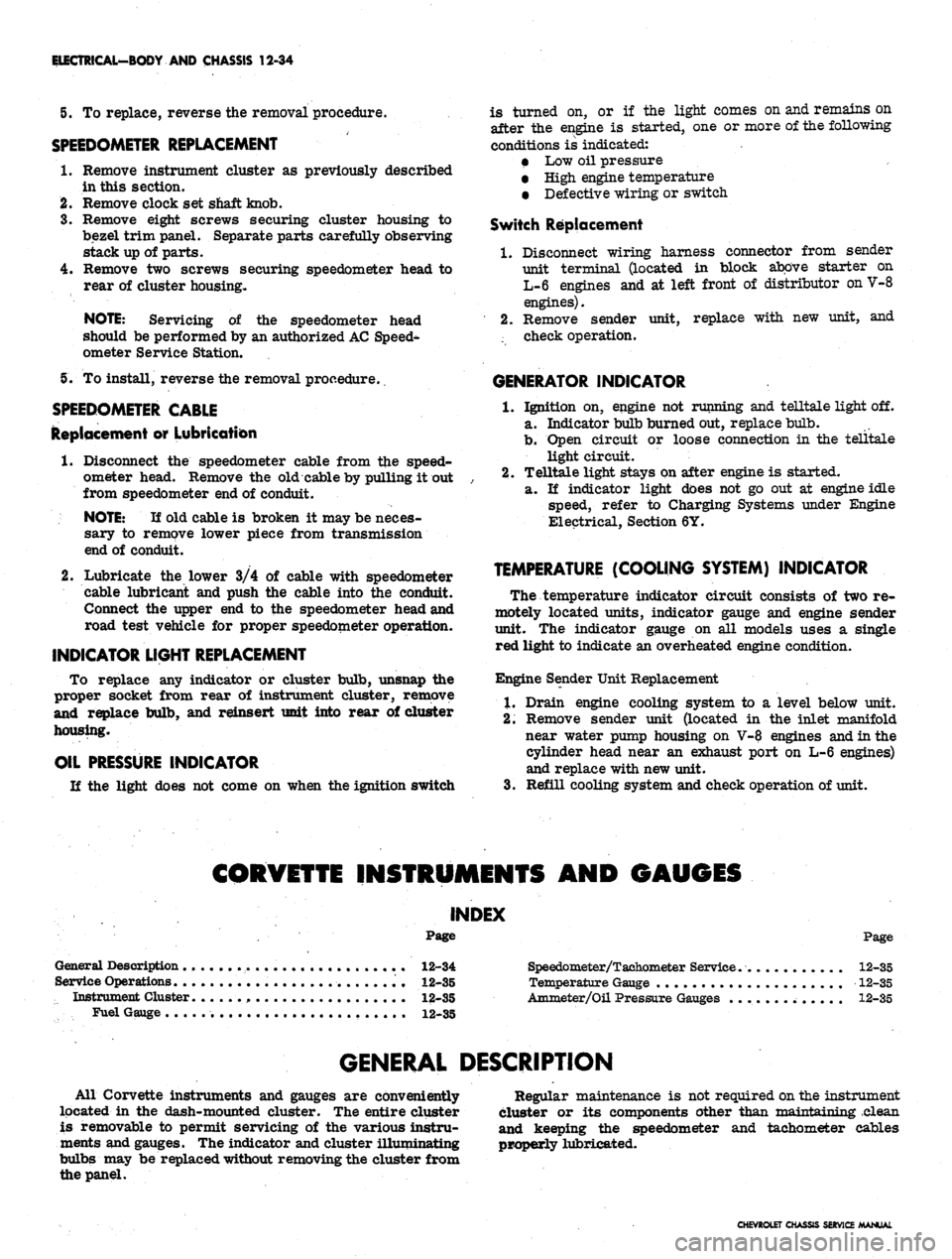

REMOVAL AND INSTALLATION (Fig. 49)

1.

Remove mast jacket assembly. Refer to Section 9

for removal procedures.

2.

Disconnect tachometer drive cable at distributor.

3.

Disconnect the headlamp panel control switch from

instrument cluster.

4.

Remove lighting switch as outlined in this section.

10 10-A 1112 13

14

15 16 17 18 19

Fig.

49- Instrument Cluster Connections

1.

Cluster Illuminating

Bulbs

2.

Direction Signal Indicator

Bulb L.H.

3. Direction Signal Indicator

BulbR.H.

4.

Headlamp Actuating Motor

Indicator

5. Headlamp Hi Beam

Indicator

6. Parking Brake Alarm

Indicator

7. Ground Lead Attaching

Point

8. Temperature Indicator

"1"

Terminal

9.

10.

10A.

11.

12.

13.

14.

]5.

16.

17.

18.

19.

20.

21.

Temperature Indicator "S"

Terminal

Ignition Switch Receptacle

ignition Switch Illuminating

Bulb

Oil Pressure Indicator

Tachometer

Lighter Receptacle

Trip Odometer

Wiper Switch Receptacle

Speedometer

Ammeter "Gen" Terminal

Ammeter "Battery" Terminal

Lighting Switch Receptacle

Fuel Gauge

"1"

Terminal

Fuel Gauge "S" Terminal

5. Remove the ignition switch. Refer to Section 6Y

for removal procedure. Then disconnect ignition

switch lamp support at instrument panel.

6. Disconnect oil pressure line at oil pressure gauge

then remove the lead wires from ammeter, wiper

switch and cigarette lighter. Disconnect trip odom-

eter at mast jacket support.

7. Remove the instrument cluster-to-dash retaining

screws and pull cluster assembly slightly forward

to obtain clearance for removal of speedometer

cable, tachometer cable, cluster ground wire, fuel

gauge lead wires and remaining indicator and cluster

illuminating lamps.

8. To install cluster in dash panel, reverse removal

procedure.

FUEL GAUGE

The gasoline fuel gauge circuit consists of an electri-

cal indicator in the instrument cluster and a float-

controlled rheostat in the fuel tank.

Since the fuel gauge consists of two remotely located

units and connecting wires, it is sometimes difficult to

determine which unit is at fault when the gauge fails to

operate properly. Cluster removal is necessary to re-

place the fuel gauge.

NOTE:

Be sure to check gas gauge fuse in fuse

panel before attempting to trouble shoot for

inoperative gauge or tank sending unit.

SPEEDOMETER AND/OR TACHOMETER

Removal and Installation

Cluster must be removed from vehicle to service

speedometer head assembly (see Cluster Removal pro-

cedure)

.

With cluster removed from vehicle:

1.

Remove five screws securing cluster back panel to

cluster assembly; separate the parts carefully.

CAUTION: Care must be used to avoid marring

instrument cluster face.

2.

Remove two screws securing speedometer or ta-

chometer head to cluster back panel; carefully re-

move speedometer or tachometer head.

NOTE:

Servicing of speedometer or tachom-

eter head should be performed by an authorized

AC service station.

3.

Reverse above procedure to install speedometer.

Cable Replacement or Lubrication

1.

Disconnect the. cable from the speedometer or ta-

chometer head. Remove the old cable by pulling it

out from speedometer end of conduit.

NOTE:

If old cable is broken it may be nec-

essary to remove lower piece from transmission

or distributor end of conduit as applicable.

2.

Lubricate the lower 3/4 of cable with

AC

speedom-

eter cable lubricant and push the cable into the con-

duit. Connect the upper end to the speedometer or

tachometer head and road test vehicle for proper

operation.

TEMPERATURE GAUGE

The temperature indicator requires very little service

other than testing for malfunctioning and replacing de-

fective units. Cluster must be removed to service tem-

perature gauge.

Do not attempt to repair either the engine unit or the

gauge. When installing new engine unit, do not use

thread compound on unit threads, as this will increase

electrical resistance of unit and cause faulty reading

on gauge.

AMMETER OR OIL PRESSURE GAUGE

The ammeter or oil pressure gauge requires very

little attention other than keeping ammeter terminals

clean and tight. If the oil pressure control line should

become restricted it should be blown out or replaced.

Cluster must be removed to service these gauges.

HftVKI MANUAL

Page 548 of 659

ELECTRICAL-BODY

AND

CHASSIS

12-36

CAMARO INSTRUMENTS AND GAUGES

INDEX

Page

General Description

12-36

Service Operations

12-36

Instrument Cluster

. . . 12-36

Instrument Lamps

12-36

Printed Circuit

12-36

Fuel Gauge

12-37

Tachometer

. . 12-37

Seat Separator Instrument Console

12-37

Page

Fuel Gauge

12-37

Ammeter

12-37

Temperature Gauge

12-37

Oil Pressure Gauge

. 12-37

Fuel Warning Unit

12-37

Clock.

... 12-37

Oil Pressure Indicator

12-37

Generator Indicator

12-38

Temperature Indicator

12-38

GENERAL DESCRIPTION

The standard Camaro instrument cluster assembly con-

sists

of two

circular units which house

the

speedometer

and fuel gauge assemblies.

The oil

pressure, left-hand

directional

and

brake warning indicators

are

located

in

the face

of the

speedometer bezel while generator,

tem-

perature

and

right-hand directional indicators are grouped

with

the

fuel gauge unit.

The

high beam indicator

is

located between

the

cluster bezels.

A special instrumentation package

is

available with

the

eight-cylinder engine

and

center floor console combina-

tion.

The

special cluster includes:

a

clock; coolant

temperature,

oil

pressure, fuel

and

ammeter gauges,

mounted forward

on the

seat separator console;

a ta-

chometer

in the

right circular housing

of the

dash

in-

strument cluster; and

a low

fuel level indicator replacing

the

oil

pressure indicator lamp

in the

instrument cluster.

The instruments

and

gauges,

may be

serviced only

after

the

instrument cluster

is

removed from

the

vehicle.

Indicator

and

cluster lamps except

for the

high beam

indicator

may be

replaced without removing

the

cluster

assembly. Partial cluster removal

is

necessary when

replacing

the

high beam indicator due

to its

proximity

to

the upper brace

rod

anchor plate.

The

bulbs

are in-

stalled

in

plastic sockets which lock into

the

cluster

housing and make contact with

the

printed circuit.

A

low

level fuel warning system

is a

special feature

available with

the

floor console gauge pack. This

sys-

tem includes

an

indicator lamp

in the

dash cluster and

a

semi-conductor unit senses

the

change

in

electrical

re-

sistance

of the

fuel system circuitry

as

variations

in

fuel level occur.

The

sensing device

is

replaced

as a

unit

if

found defective.

The brake warning light serves

a

dual purpose.

It

functions

as an

indicator when

the

parking brake

is ap-

plied

and

also

if

there

is a

malfunction (loss

of

hydraulic

pressure)

in the

brake system. Switches which provide

the signal

to

operate

the

light

are

located

at the

parking

brake assembly

and at the

brake master cylinder

in the

hydraulic lines. Service

of the

brake pressure differ-

ential switch unit

is

covered

in

Section

5 of

this manual.

Regular maintenance

is not

required on

the

instrument

cluster

or its

components other than maintaining clean,

tight electrical connections, replacing defective parts

and keeping

the

speedometer properly lubricated.

SERVICE OPERATIONS

INSTRUMENT CLUSTER (Figs.

50

thru

53)

Removal

and

Installation

1.

Disconnect battery ground cable.

2.

Remove mast jacket lower support screws

at toe

pan.

3.

Remove mast jacket upper support bolts

and

allow

steering wheel

to

rest

on

seat cushion.

CAUTION: Both supports must

be

detached

to

prevent distortion

of

mast jacket.

4.

Remove cluster attaching screws from face

of

panel

and partially remove assembly from console opening.

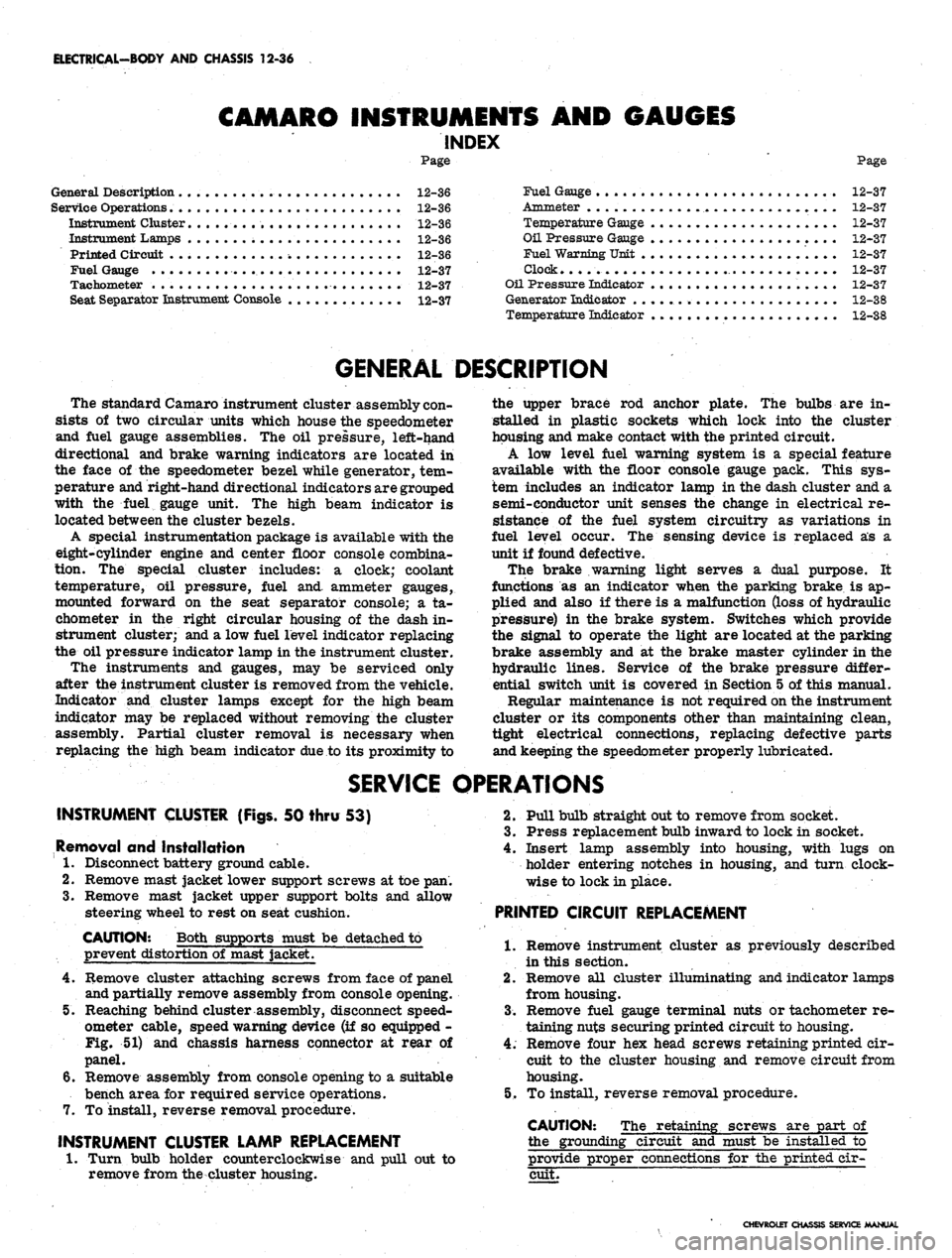

5. Reaching behind cluster assembly, disconnect speed-

ometer cable, speed warning device

(if so

equipped

-

Fig.

51) and

chassis harness connector

at

rear

of

panel.

6. Remove assembly from console opening to

a

suitable

bench area

for

required service operations.

7.

To

install, reverse removal procedure.

INSTRUMENT CLUSTER LAMP REPLACEMENT

1.

Turn bulb holder counterclockwise

and

pull

out to

remove from

the

cluster housing.

2.

Pull bulb straight out

to

remove from socket.

3.

Press replacement bulb inward

to

lock

in

socket.

4.

Insert lamp assembly into housing, with lugs

on

holder entering notches

in

housing,

and

turn clock-

wise

to

lock

in

place.

PRINTED CIRCUIT REPLACEMENT

1.

Remove instrument cluster

as

previously described

in this section.

2.

Remove

all

cluster illuminating and indicator lamps

from housing.

3.

Remove fuel gauge terminal nuts

or

tachometer

re-

taining nuts securing printed circuit

to

housing.

4.

Remove four

hex

head screws retaining printed

cir-

cuit

to the

cluster housing

and

remove circuit from

housing.

5.

To

install, reverse removal procedure.

CAUTION:

The

retaining screws

are

part

of

the grounding circuit

and

must

be

installed

to

provide proper connections

for the

printed

eir-

cuit.

CHEVROLET CHASSIS SERVICE MANUAL

Page 549 of 659

ELECTRICAL-BODY AND CHASSIS 12-37

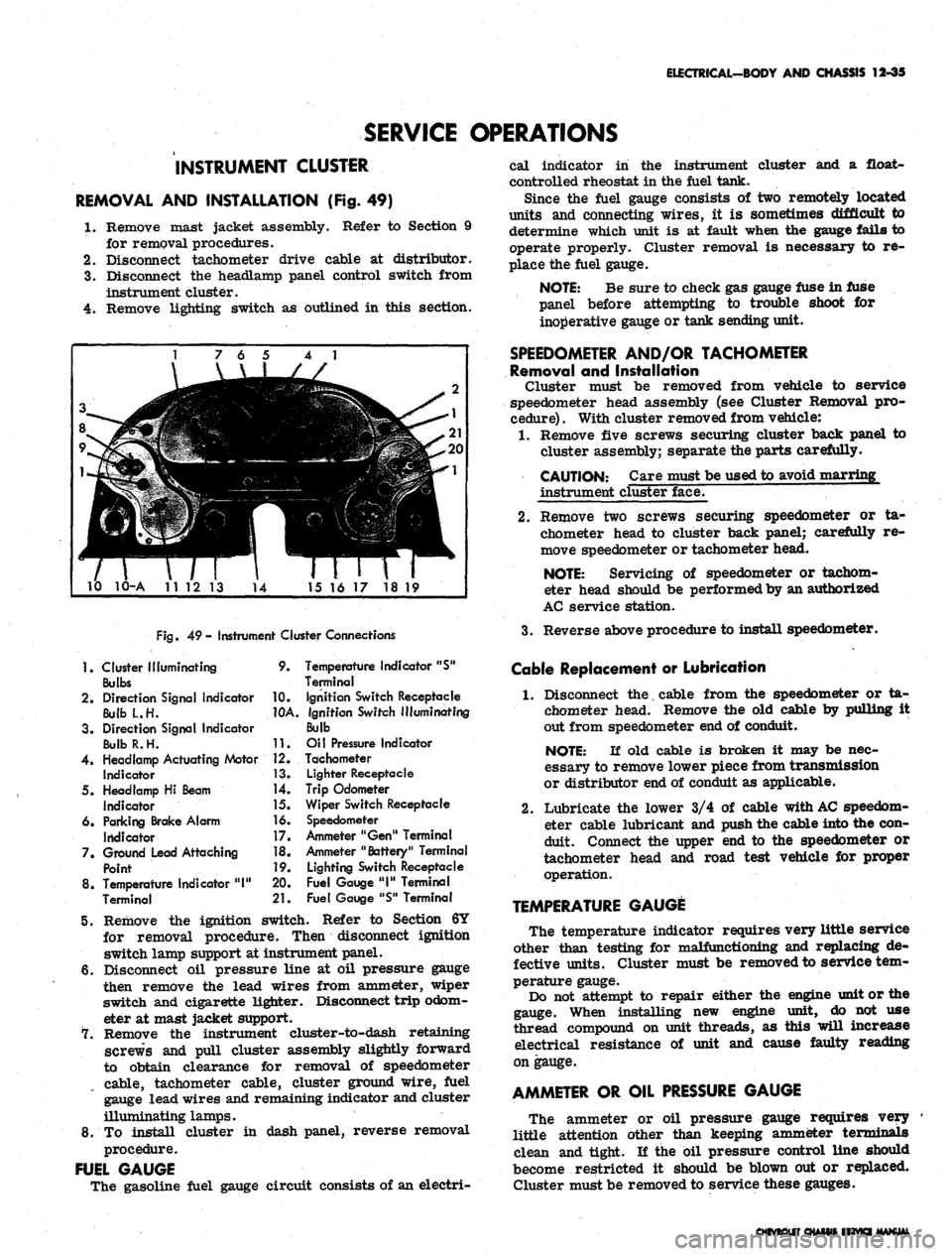

Fig.

50 - Instrument Cluster Installation — Camaro

FUEL GAUGE REPLACEMENT

1.

Remove instrument cluster assembly as previously

described.

2.

Remove cluster lamps from gauge cover plate,

ground screw and terminal nuts attaching printed

circuit to fuel gauge.

3.

Remove three screws retaining gauge assembly to

cluster housing.

4.

Carefully move printed circuit away from gauge and

remove gauge assembly from cluster housing.

5. Remove terminal nuts securing gauge to cover plate,

and detach gauge unit.

6. To install, reverse removal procedure.

TACHOMETER

NOTE:

The tachometer is a self-contained, all

transistor unit requiring very little service

other than keeping the terminal nuts clean and

tight. The unit is not serviceable and must be

replaced, if defective.

1.

Remove instrument cluster as previously described

in this section.

2.

Remove cluster lamps from rear of gauge cover and

disconnect harness wiring connections from gauge

terminals.

3.

Remove three screws retaining gauge to cluster

housing.

4.

Move printed circuit away from gauge area and re-

move gauge unit from housing.

5. Remove terminal nuts securing gauge to cover

detach unit.

6. To install, reverse removal procedure.

SEAT SEPARATOR INSTRUMENT CONSOLE

(Fig.

54)

(Fuel,

Ammeter, Temperature, Oil Pressure Gauges,

Low Fuel Warning Unit, and Clock)

1.

Disconnect battery ground cable.

2.

Remove clock shaft knob from face of cluster.

3.

Remove cover retaining screws (4) and cover from

cluster assembly.

NOTE:

Use an alien wrench to remove the two

screws located in the top of the cover below the

instrument console.

4.

Remove four screws retaining gauge mounting plate

to cluster housing.

5. Carefully disengage gauge plate from housing and

disconnect oil pipe and all electrical connections at

rear of gauges.

NOTE:

At this point, with gauge package re-

moval from housing all gauges including the low

fuel warning system may easily be serviced.

6. To install assembly, use reverse of removal

procedure.

OIL PRESSURE INDICATOR

If the light does not come on when the ignition switch

is turned on, or if the light comes on and remains on

after the engine is started, one or more of the following

conditions is indicated.

• Low oil pressure

• Defective wiring or switch

Sending Unit Replacement

1.

Disconnect wiring harness connector from sender

unit terminal (located in block above starter on L-6

engines and at left front of distributor on V-8

engines).

Fig.

51 - Speed Warning Device

CHEVROLET CHASSIS SERVICE MANUAL

Page 555 of 659

ELECTRICAL-BODY AND CHASSIS 12-43

23.

Install

MCtT

ring over steering shaft using snap ring

installer J-22659 (refer to Section 9).

NOTE: Be sure retaining ring is completely

seated into groove.

24.

Install dial pointer on Chevrolet and Chevelle models

equipped with automatic transmission (if applicable).

25.

Install dial indicator and lamp assembly on Camaro

and Chevy n models equipped with automatic

transmission.

26.

Install mast jacket lower trim covers (if applicable).

27.

Install hazard warning knob and turn signal lever.

28.

Install shift lever.

29.

Install steering wheel.

30.

Install multiple connector to switch wiring using old

harness for wire color guide and connect to body

harness connector.

31.

Connect battery ground cable and check operation of

assembly.

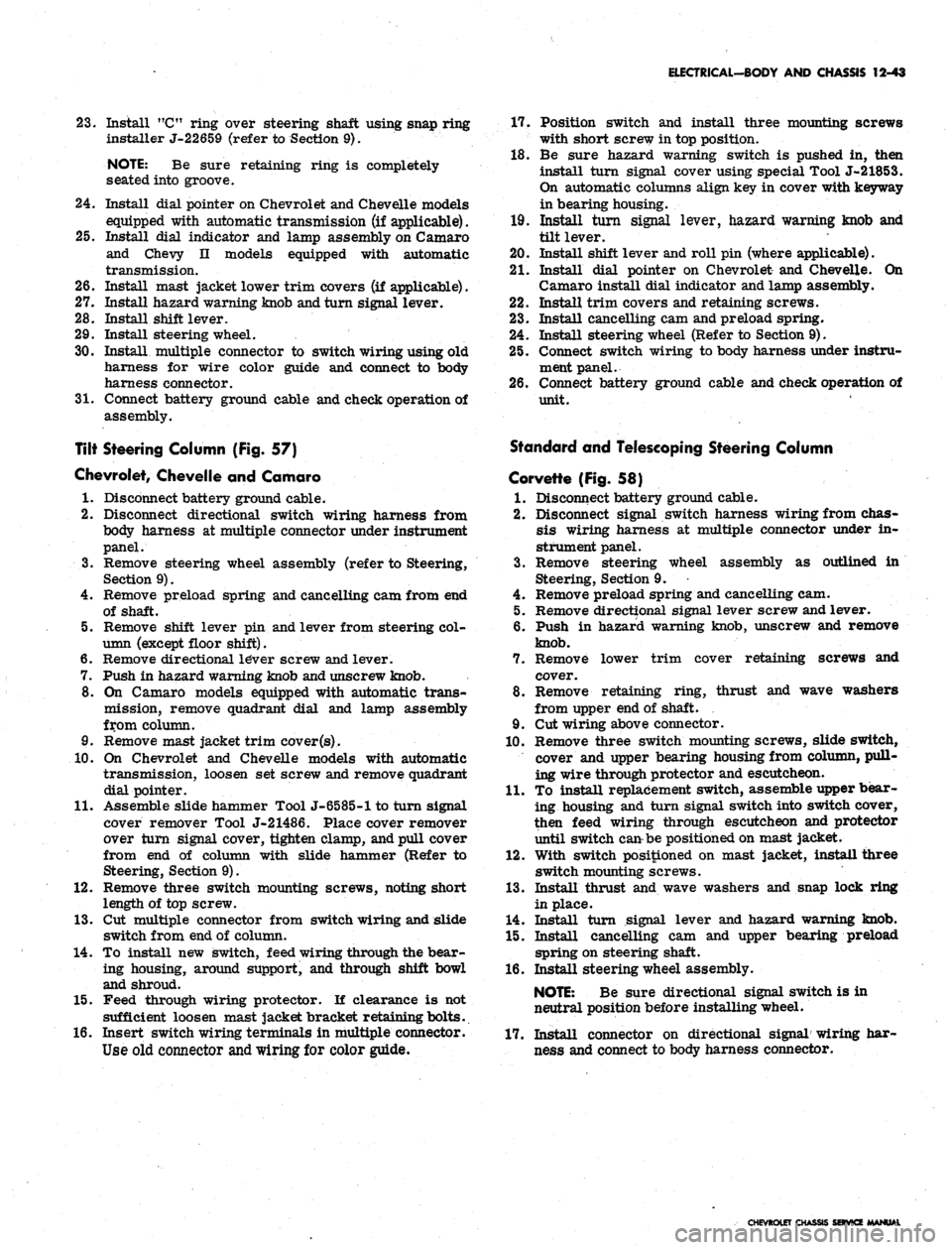

Tilt Steering Column (Fig. 57)

Chevrolet, Chevelle and Camaro

1.

Disconnect battery ground cable.

2.

Disconnect directional switch wiring harness from

body harness at multiple connector under instrument

panel.

3.

Remove steering wheel assembly (refer to Steering,

Section 9).

4.

Remove preload spring and cancelling cam from end

of shaft.

5.

Remove shift lever pin and lever from steering col-

umn (except floor shift).

6. Remove directional le*ver screw and lever.

7.

Push in hazard warning knob and unscrew knob.

8. On Camaro models equipped with automatic trans-

mission, remove quadrant dial and lamp assembly

from column.

9. Remove mast jacket trim cover

(s).

10.

On Chevrolet and Chevelle models with automatic

transmission, loosen set screw and remove quadrant

dial pointer.

11.

Assemble slide hammer Tool J-6585-1 to turn signal

cover remover Tool J-21486. Place cover remover

over turn signal cover, tighten clamp, and pull cover

from end of column with slide hammer (Refer to

Steering, Section 9).

12.

Remove three switch mounting screws, noting short

length of top screw.

13.

Cut multiple connector from switch wiring and slide

switch from end of column.

14.

To install new switch, feed wiring through the bear-

ing housing, around support, and through shift bowl

and shroud.

15.

Feed through wiring protector. If clearance is not

sufficient loosen mast jacket bracket retaining bolts.

16.

Insert switch wiring terminals in multiple connector.

Use old connector

and

wiring for color guide.

17.

Position switch and install three mounting screws

with short screw in top position.

18.

Be sure hazard warning switch is pushed in, then

install turn signal cover using special Tool J-21853.

On automatic columns align key in cover with keyway

in bearing housing.

19.

Install turn signal lever, hazard warning knob and

tilt lever.

20.

Install shift lever and roll pin (where applicable).

21.

Install dial pointer on Chevrolet and Chevelle. On

Camaro install dial indicator and lamp assembly.

22.

Install trim covers and retaining screws.

23.

Install cancelling cam and preload spring.

24.

Install steering wheel (Refer to Section 9).

25.

Connect switch wiring to body harness under instru-

ment panel.

26.

Connect battery ground cable and check operation of

unit.

Standard and Telescoping Steering Column

Corvette (Fig. 58)

1.

Disconnect battery ground cable.

2.

Disconnect signal switch harness wiring from chas-

sis wiring harness at multiple connector under in-

strument panel.

3.

Remove steering wheel assembly as outlined in

Steering, Section 9.

4.

Remove preload spring and cancelling cam.

5.

Remove directional signal lever screw and lever.

6. Push in hazard warning knob, unscrew and remove

knob.

7.

Remove lower trim cover retaining screws and

cover.

8. Remove retaining ring, thrust and wave washers

from upper end of shaft.

9. Cut wiring above connector.

10.

Remove three switch mounting screws, slide switch,

cover and upper bearing housing from column, pull-

ing wire through protector and escutcheon.

11.

To install replacement switch, assemble upper bear-

ing housing and turn signal switch into switch cover,

then feed wiring through escutcheon and protector

until switch can be positioned on mast jacket.

12.

With switch positioned on mast jacket, install three

switch mounting screws.

13.

Install thrust and wave washers and snap lock ring

in place.

14.

Install turn signal lever and hazard warning knob.

15.

Install cancelling cam and upper bearing preload

spring on steering shaft.

16.

Install steering wheel assembly.

NOTE:

Be sure directional signal switch is in

neutral position before installing wheel.

17.

Install connector on directional signal wiring har-

ness and connect to body harness connector.

CHEVROLET CHASSIS SERVICE

Page 652 of 659

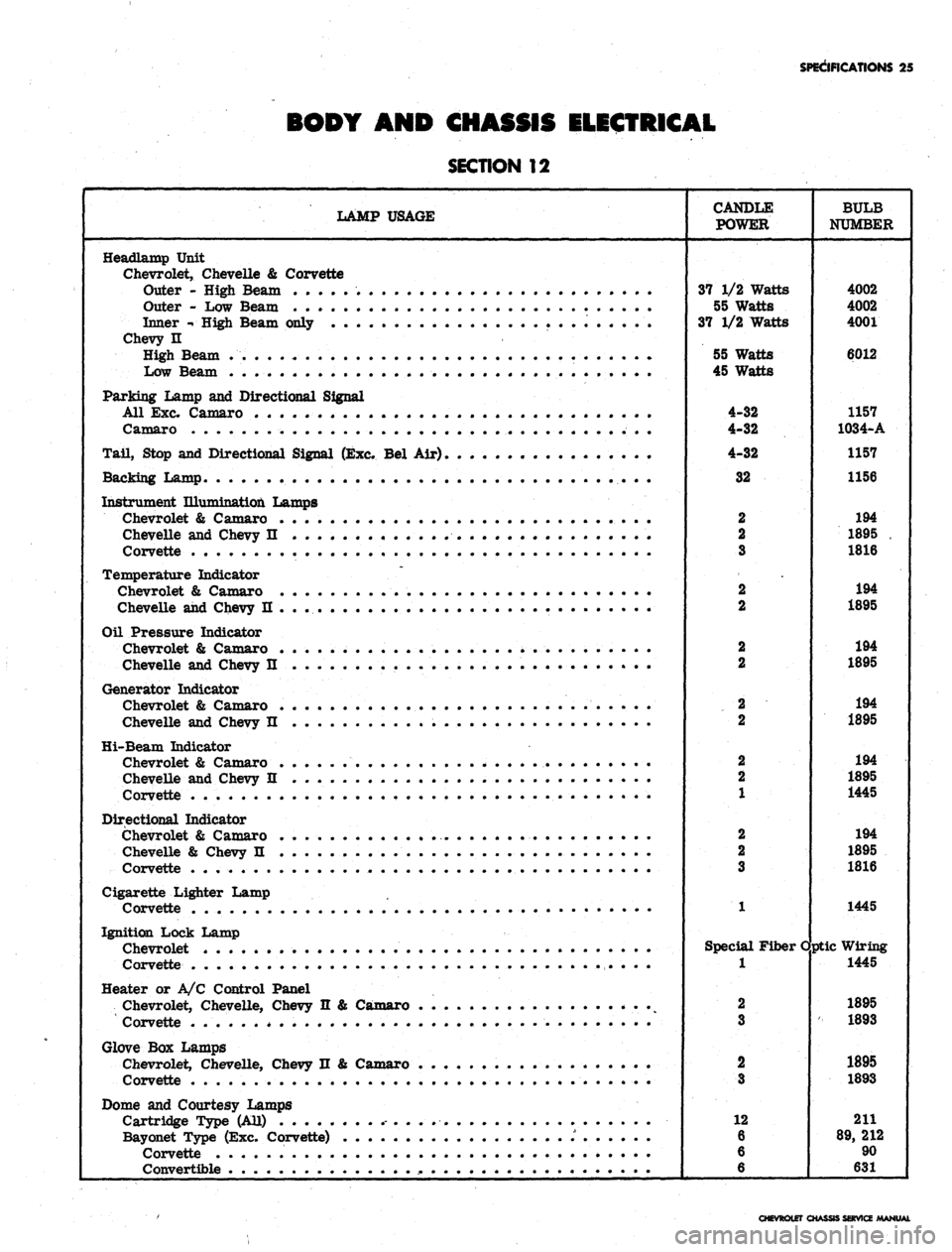

SPECIFICATIONS 25

BODY AND CHASSIS ELECTRICAL

SECTION

12

LAMP USAGE

CANDLE

POWER

BULB

NUMBER

Headlamp Unit

Chevrolet, Chevelle & Corvette

Outer - High Beam

Outer - Low Beam

Inner -• High Beam only

Chevy H

High Beam . .

Low Beam

Parking Lamp and Directional Signal

All Exc. Camaro

Camaro

Tail, Stop and Directional Signal (Exc. Bel Air)

Backing Lamp ••...,

Instrument Illumination Lamps

Chevrolet & Camaro ,

Chevelle and Chevy n

Corvette

Temperature Indicator

Chevrolet & Camaro

Chevelle and Chevy II .............

Oil Pressure Indicator

Chevrolet & Camaro .............

Chevelle and Chevy II

Generator Indicator

Chevrolet & Camaro .

Chevelle and Chevy n ,

Hi-Beam Indicator

Chevrolet & Camaro <

Chevelle and Chevy II

Corvette , . • . ,

Directional Indicator

Chevrolet & Camaro

Chevelle & Chevy II . .

Corvette . .

Cigarette Lighter Lamp

Corvette .

Ignition Lock Lamp

Chevrolet . . .

Corvette . . .

Heater or A/C Control Panel

Chevrolet, Chevelle, Chevy n & Camaro . . .

Corvette . . .

Glove Box Lamps

Chevrolet, Chevelle, Chevy n & Camaro . . .

Corvette . . . . .

Dome and Courtesy Lamps

Cartridge Type (AU)

Bayonet Type (Exc. Corvette) . . .

Corvette ,

Convertible . .

37 1/2 Watts

55 Watts

37 1/2 Watts

55 Watts

45 Watts

4-32

4-32

4-32

Special Fiber

1

2

3

2

3

12

6

6

6

Optic

4002

4002

4001

6012

1157

1034-A

1157

1156

194

1895

.

1816

194

1895

194

1895

194

1895

194

1895

1445

194

1895

1816

1445

Wiring

1445

1895

1893

1895

1893

211

89,

212

90

631

CHEVROLET CHASSIS SERVICE MANUAL