service indicator CHEVROLET CAMARO 1967 1.G Chassis Owner's Manual

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1967, Model line: CAMARO, Model: CHEVROLET CAMARO 1967 1.GPages: 659, PDF Size: 114.24 MB

Page 392 of 659

CLUTCH AND TRANSMISSIONS 7-33

from rolling. The pointer on the indicator quadrant

should line up properly with the range indicators in all

ranges.

OIL LEAKS

Before attempting to correct an oil leak, the actual

source of the leak must be determined. In many cases

the source of the leak can be deceiving due to "wind flow1 f

around the engine and transmission.

The suspected area should be wiped clean of all oil

before inspecting for the source of the leak. Red dye is

used in the transmission oil at the assembly plant and

will indicate if the oil leak is from the transmission.

The use of a "black light"* to identify the oil at the

source of leak is also helpful. Comparing the oil from

the leak to that on the engine or transmission dip stick

(when viewed by black light) will determine the source

of the leak.

Oil leaks around the engine and transmission are gen-

erally carried toward the rear of the car by the air

stream. For example, a transmission "oil filter tube

to case leak" will sometimes appear as a leak at the

rear of the transmission. In determining the source of

an oil leak it is most helpful to keep the engine running.

The mating surfaces of servo cover, converter housing,

transmission case and transmission case extension

should be carefully examined for signs of leakage. The

vacuum modulator must also be checked to insure that

the diaphragm has not ruptured as this would allow trans-

mission oil to be drawn into the intake manifold. Us-

ually, the exhaust will be excessively smoky if the

diaphragm ruptures due to the transmission oil added to

the combustion. The transmission case extension rear

oil seal should also be checked. All test plugs should be

checked to make sure that they are tight and that there

is no sign of leakage at these points. The converter

underpan should also be removed. Any appreciable quan-

tity of oil in this area would indicate leakage at the pump

square seal ring, pump seal assembly, or pump bolt

sealing washers.

BASIC PRESSURE CHECKS

Four basic pressure checks are used for diagnosis and

operational checks for the Aluminum Powerglide trans-

mission. All checks should be made only after thoroughly

warming up the transmission.

• Wide Open Throttle Upshift Pressure.

• Idle Pressure in "Drive" Range.

• Manual "Low" Range Pressure.

• "Drive" Range Overrun (Coast) Pressure.

It is not recommended that stall tests be conducted

which would result in engine vacuum falling below 10" Hg.

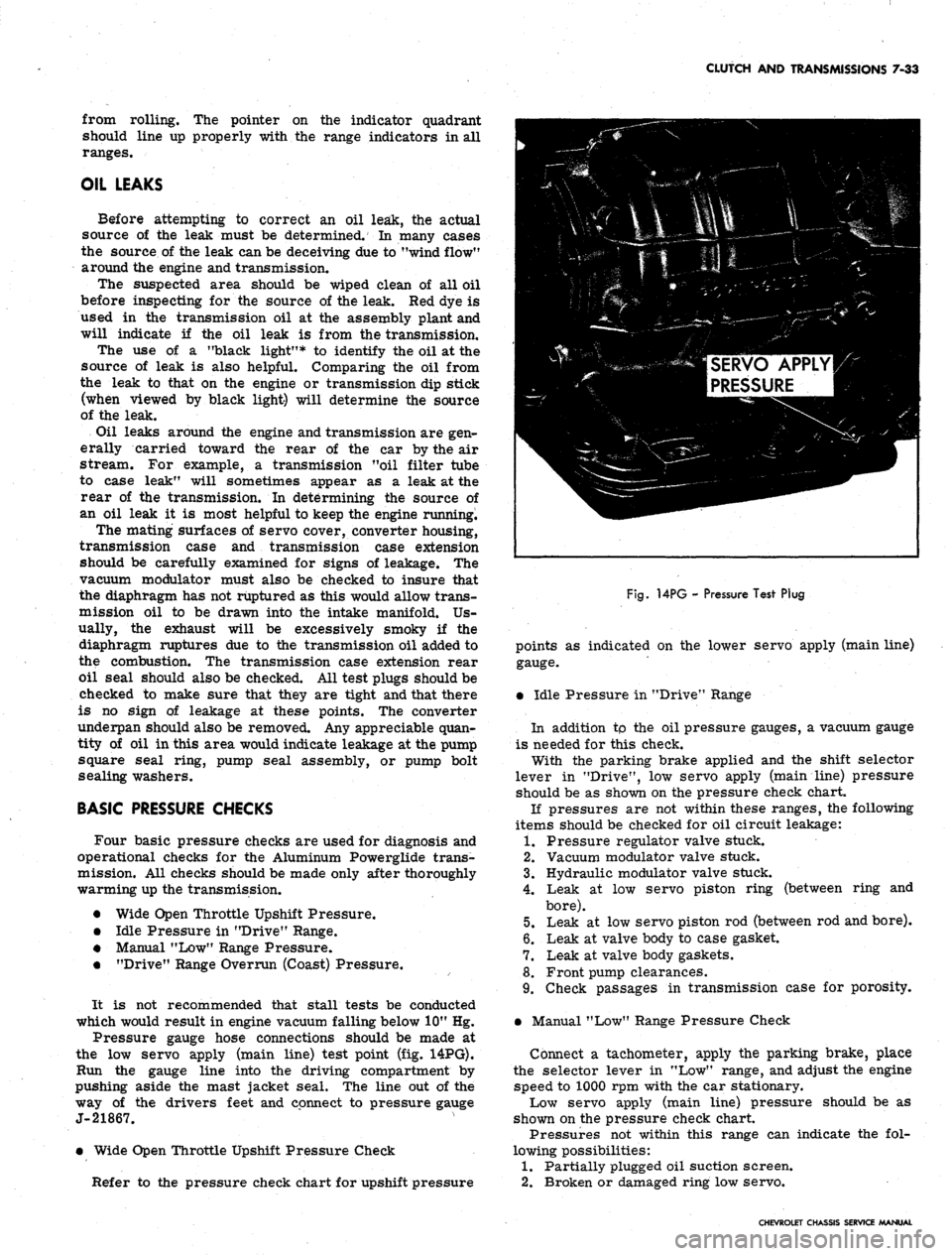

Pressure gauge hose connections should be made at

the low servo apply (main line) test point (fig. 14PG).

Run the gauge line into the driving compartment by

pushing aside the mast jacket seal. The line out of the

way of the drivers feet and connect to pressure gauge

J-21867.

• Wide Open Throttle Upshift Pressure Check

Refer to the pressure check chart for upshift pressure

SERVO APPLY

PRESSURE

Fig.

14PG - Pressure Test Plug

points as indicated on the lower servo apply (main line)

gauge.

• Idle Pressure in "Drive" Range

In addition tp the oil pressure gauges, a vacuum gauge

is needed for this check.

With the parking brake applied and the shift selector

lever in "Drive", low servo apply (main line) pressure

should be as shown on the pressure check chart.

If pressures are not within these ranges, the following

items should be checked for oil circuit leakage:

1.

Pressure regulator valve stuck.

2.

Vacuum modulator valve stuck.

3.

Hydraulic modulator valve stuck.

4.

Leak at low servo piston ring (between ring and

bore).

5.

Leak at low servo piston rod (between rod and bore).

6. Leak at valve body to case gasket.

7.

Leak at valve body gaskets.

8. Front pump clearances.

9. Check passages in transmission case for porosity.

• Manual "Low" Range Pressure Check

Connect a tachometer, apply the parking brake, place

the selector lever in "Low" range, and adjust the engine

speed to 1000 rpm with the car stationary.

Low servo apply (main line) pressure should be as

shown on the pressure check chart.

Pressures not within this range can indicate the fol-

lowing possibilities:

1.

Partially plugged oil suction screen.

2.

Broken or damaged ring low servo.

CHEVROLET CHASSIS SERVICE MANUAL

Page 395 of 659

CLUTCH AND TRANSMISSIONS 7-36

TURBO HYDRA-MATIC TRANSMISSION

INDEX

Page

General Description . . , . 7-36

Maintenance and Adjustments . 7-37

Transmission Fluid 7-37

Fluid Level Indicator 7-37

Shift Control Linkage Adjustment ........... 7-37

Neutral Safety Switch Adjustment 7-37

Draining and Refilling Transmission . . . 7-37

Pressure Regulator Valve 7-38

Control Valve Body . 7-39

Governor ..'.... 7-40

Modulator and Modulator Valve 7-40

Parking Linkage . . 7-40

Page

Rear Seal -. 7-40

Other Service Operations . . 7-40

Transmission Replacement 7-40

Turbo Hydra-Matic Diagnosis Procedure. ......... 7-41

Sequence . ; ; 7-41

Oil Level and Condition Check 7-41

Manual Linkage 7-41

Oil Leaks .' 7-41

Case Porosity - Repair ................ 7-42

Oil Pressure Check 7-42

Transmission Shift Points 7-42

Special Tools 7-43

GENERAL DESCRIPTION

The Turbo Hydra-Matic transmission is a fully auto-

matic unit consisting primarily of a 3-element hydraulic

torque converter and a compound planetary gear set.

Three multiple-disc clutches, one sprag unit, one roller

clutch and two bands provide the friction elements re-

quired to obtain the desired function of the compound

planetary gear set.

The torque converter couples the engine to the plane-

tary gears through oil and provides hydraulic torque

multiplication when required. The compound planetary

gear set produces three forward speeds and reverse.

The

3-

element torque converter consists of a pump or

driving member, a turbine or driven member, and a

stator assembly. The stator is mounted on a one-way

roller clutch which will allow the stator to turn clock-

wise but not counter-clockwise.

The torque converter housing is filled with oil and

is attached to the engine crankshaft by a flex plate and

always rotates at engine speed. The converter pump is

an integral part of the converter housing, therefore the

pump blades, rotating at engine speed, set the oil within

the converter into motion and direct it to the turbine,

causing the turbine to rotate.

As the oil passes through the turbine it is traveling in

such a direction that if it were not re-directed by the

stator it would hit the rear of the converter pump blades

and impede its pumping action. So at low turbine speeds,

the oil is re-directed by the stator to the converter pump

in such a manner that it actually assists the converter

pump to deliver power or multiply engine torque.

As turbine speed increases, the direction of the oil

leaving the turbine changes and flows against the rear

side of the stator vanes in a clockwise direction. Since

the stator is now impeding the smooth flow of oil, its

roller clutch releases and it revolves freely on its shaft.

Once the stator becomes inactive, there is no further

multiplication of engine torque within the converter. At

this point, the converter is merely acting as a fluid

coupling as both the converter pump and turbine are

being driven at approximately the same speed - or at a

one-to-one ratio.

A hydraulic system pressurized by a gear type pump

provides the working pressure required to operate the

friction elements and automatic controls.

External control connections to transmission are:

Manual Linkage

Engine Vacuum

12 Volt Electrical

Signal

To select the desired op-

erating range.

To operate a vacuum mod-

ulator unit.

To operate an electrical

detent solenoid.

A vacuum modulator is used to automatically sense

any change in the torque input to the transmission. The

vacuum, modulator transmits this signal to the pressure

regulator for line pressure control, to the 1-2 accumula-

tor valve, and to the shift valves so that all torque re-

quirements of the transmission are met and smooth

shifts are obtained at all throttle openings.

The detent solenoid is activated by an alectric switch

on the carburetor. When the throttle is fully opened, the

switch on the carburetor is closed, activating the detent

solenoid and. causing the transmission to downshift at

speeds below approximately 70 MPH.

The selector quadrant has six selector positions: P,R,

N,D,

L2,L1.

P.

*

- Park position positively locks the output shaft to

the transmission case by means of a locking pawl

to prevent the vehicle from rolling in either di-

rection. The engine may be started in Park

position.

R. - Reverse enables the vehicle to be operated in a

reverse direction.

N.

- Neutral position enables the engine to be started

and run without driving the vehicle.

D,

- Drive Range is used for all normal driving condi-

tions and maximum economy. Drive Range has

three gear ratios, from the starting ratio to

direct drive. Detent downshifts are available by

depressing the accelerator to the floor.

L2.

- L2 Range has the same starting ratio as Drive

Range, but prevents the transmission from shift-

ing above second speed to retain second speed

acceleration when extra performance is desired.

L2 Range can also be used for engine braking.

L2 Range can be selected at any vehicle speed,

and the transmission will shift to second gear and

remain in second until the vehicle speed or the

throttle are changed to obtain first gear operation

in the same manner as in D Range.

CHIVROLET CHASSIS SERVICE MANUAL

Page 396 of 659

CLUTCH AND TRANSMISSIONS 7-37

LI.

- LI Range can be selected at any vehicle speed,

and the transmission will shift to second gear

and remain in second until vehicle speed is re-

duced to approximately 40 MPH, .depending on

axle ratio. LI Range position prevents the trans-

mission from shifting out of first gear.

It is very important that any communication concerning

the Turbo Hydra-Matic always contain the transmission

serial number and that all transmission parts returned

to Chevrolet Motor Division always be tagged with the

transmission serial number.

MAINTENANCE AND ADJUSTMENTS

TRANSMISSION FLUID

Transmission fluid level should be checked with trans-

mission warm and selector lever in "P" Park position,

every time engine oil level is checked or as specified in

Section 0 when engine oil is changed.

CAUTION: Since the Turbo Hydra-Matic trans-

mission is very sensitive to oil level, special

precautions should be taken when checking the

oil level, to insure against an overfifE

Transmission fluid should be changed as specified in

Section 0.

FLUID LEVEL INDICATOR

The fluid level indicator is located in the filler pipe at

the right rear corner of the engine. To bring the fluid

level from the add mark to the full mark add 1 pint.

Fluid level should be to the full mark with transmission

at normal operating temperature. With cold fluid the

level should be at the add mark or slightly below.

SHIFT CONTROL LINKAGE ADJUSTMENT

Adjust linkage as shown below and in Figure 2.

1.

The shift tube and lever assembly must be free in the

mast jacket See Section 9 for alignment of steering

column assembly if necessary.

2.

To check for proper shift linkage adjustment, lift the

transmission selector lever towards the steering

wheel. Allow the selector lever to be positioned in

drive (D) by the transmission detent.

NOTE: Do not use the indicator pointer as a

reference to position the selector lever. When

performing linkage adjustment, pointer is ad-

justed last.

3.

Release the selector lever. The lever should be in-

hibited from engaging low range unless the lever is

lifted.

4.

Lift the selector lever towards the steering wheel,

and allow the lever to be positioned in neutral (N) by

the transmission detent.

5.

Release the selector lever. The lever should now be

inhibited from engaging reverse range unless the

lever is lifted.

6. A properly adjusted linkage will prevent the selector

lever from moving beyond both the neutral detent,

and the drive detent unless the lever is lifted to pass

over the mechanical stop in the steering column.

See schematic diagram.

7.

In the event that an adjustment is required, place the

selector lever in drive (D) position as determined by

the transmission detent. See Steps 2 and 3.

8. Loosen the adjustment swivel at the cross-shaft, and

rotate the transmission lever so that it contacts the

drive stop in the steering column.

9. Tighten the swivel and recheck the adjustment. See

Steps 2 and 6. -

l(h Readjust indicator needle if necessary to agree with

the transmission detent" positions. See Section 9.

11.

Readjust neutral safety switch if necessary to pro-

vide the correct relationship to the transmission de-

tent positions. See Section 12.

12.

When properly adjusted the following conditions must

be met by manual operation of the steering column

shift lever:

a. From reverse to drive position travel, the trans-

mission detent feel must be noted and related to

indicated position on dial.

b.

When in drive and reverse positions, pull lever

rearward (towards steering wheel) and then re-

lease. It must drop back into position with no

restrictions.

NEUTRAL SAFETY SWITCH ADJUSTMENT

The neutral safety switch must be adjusted so that the

car will start in the park or neutral position, but will not

start in the other positions. For replacement refer to

Section 12 of this Manual.

DRAINING AND REFILLING TRANSMISSION

Drain oil immediately after operation before it has had

an opportunity to cool.

To drain oil proceed as follows:

1.

Remove bottom pan attaching screws, pan, and gas-

ket.

2.

Remove oil strainer. Remove "O" ring seal from

pick-up pipe and discard.

3.

Discard strainer if dirty.

4.

Install new "O" ring seal on pick-up pipe and install

strainer and pipe assembly.

5.

Thoroughly clean bottom pan.

6.. Affix new gasket to bottom pan with petroleum jelly.

7.

Install bottom pan with attaching screws and torque

to specifications;

8. If only the pan has been removed, pour approximately

7-1/2 pints of fluid into the transmission. If the

valve body has also been removed use 9-1/2 pints.

After a complete overhaul approximately 19 pints

are required. Be sure container, spout, or funnel is

clean.

9. Start engine and let idle (carburetor off fast idle

step).

Place selector lever in P position and apply

hand brake.

10.

With transmission warm (approximately 150°F), add

fluid to bring level to full mark on indicator.

CAUTION: Do not overfill. Foaming will re-

sult.

CHEVROLET CHASSIS SERVICE MANUAL

Page 400 of 659

CLUTCH AND TRANSMISSIONS 7-41

CAUTION: Use converter holding ToolJ-5384

when lowering transmission or keep rear of

transmission lower than front so as not to lose

converter.

The installation of the transmission is the reverse of

the removal.

TURBO HYDRA-MATIC DIAGNOSIS PROCEDURE

Accurate diagnosis of transmission problems begins

with a thorough understanding of normal transmission

operation. In particular, knowing which units are in-

volved in the various speeds or shifts so that the specific

units or circuits involved in the problem can be isolated

and investigated further. Analytical diagnosis will pro-

tect the technician from come backs and certainly will

improve owner satisfaction.

An important and often overlooked aspect of diagnosis

is finding out specifically what the customer is com-

plaining of. For this purpose a short ride with the cus-

tomer will often prove beneficial. It may be found that

the condition the customer wants corrected is standard

and should not be altered.

The following sequence, based on field experience, pro-

vides the desired information quickly and in most cases

actually corrects the malfunction without requiring the

removal of the transmission. Details of the items listed

in this sequence are covered further in the text.

SEQUENCE FOR TURBO HYDRA-MATIC

DIAGNOSIS PROCEDURE

1.

Check oil level and condition.

2.

Check and correct detent switch.

3.

Check and correct vacuum line and fittings.

4.

Check and correct manual linkage.

OIL LEVEL AND CONDITION CHECK

Always check the oil level before road testing. Oil

must be visible on dip stick prior to operating the ve-

hicle. Erratic shifting, pump noise, or other malfunc-

tions can in some cases be traced to improper oil level.

Oil level should be checked with the selector lever in

the Park (P) position, engine running, and the vehicle on

level pavement.

Fluid level should be to the FULL mark with the trans-

mission at normal operating temperature (170°-190°

F.).

With warm fluid (room temperature), the level should be

at or slightly below the ADD mark.

If oil level was low, refer to Oil Leaks.

The condition of the oil is often an indication of whether

the transmission should be removed from the vehicle, or

to make further tests. When checking oil level, a burned

smell and discoloration indicate burned clutches or bands

and the transmission will have to be removed.

MANUAL LINKAGE

Manual linkage adjustment and the associated neutral

safety switch are important from a safety standpoint

The neutral safety switch should be adjusted so that the

engine will start in the Park and Neutral positions only.

With the selector lever in the Park position, the park-

ing pawl should freely engage and prevent the vehicle

from rolling. The pointer on the indicator quadrant

should line up properly with the range indicators in all

ranges.

OIL LEAKS

Before attempting to correct an oil leak, the actual

source of the leak must be determined. In many cases,

the source of the leak can be deceiving due to "wind flow"

around the engine and transmission.

The suspected area should be wiped clean of all oil be-

fore inspecting for the source of the leak. Red dye is

used in the transmission oil at the assembly plant and

will indicate if the oil leak is from the transmission.

. The use of a "black light"* to identify the oil at the

source of leak is also helpful. Comparing the oil from

the leak to that on the engine or transmission dip stick

(when viewed by black light) will determine the source

of the leak.

Oil leaks around the engine and transmission are gen-

erally carried toward the rear of the car by the air

stream. For example, a transmission "oil filler tube to

case leak" will sometimes appear as a leak at the rear of

the transmission. In determining the source of an oil

leak it is most helpful to keep the engine running.

POSSIBLE POINTS OF OIL LEAKS

• 1. TRANSMISSION OIL PAN LEAK

a. Attaching bolts not correctly torqued.

b.

Improperly installed or damaged pan gasket.

c. Oil pan gasket mounting face not flat.

2.

REAR EXTENSION LEAK

a. Attaching bolts not correctly torqued.

b.

Rear seal assembly — damaged or improperly

installed.

c. Gasket seal — (extension to case) damaged or

improperly installed.

d. Porous casting.

3.

CASE LEAK

a. Filler pipe "O" ring seal damaged or missing;

misposition of filler pipe bracket to engine —

"loading" one side of

"O"

ring.

b.

Modulator assembly "O" ring seal

—

damaged or

improperly installed.

c. Governor cover, gasket and bolts — damaged,

loose; case face leak.

d. Speedo gear

—

"O" ring damaged.

e. Manual shaft seal — damaged, improperly in-

stalled.

f. line pressure tap plug — stripped, shy sealer

compound.

g. Parking pawl shaft cup plug

—

damaged, improp-

erly installed.

h. Vent pipe (refer to Item 5).

i. Porous case.

4.

FRONT END LEAK

a. Front seal - damaged (check converter neck for

nicks,

etc., also for pump bushing moved for-

ward);

garter spring missing from pump to con-

verter seaL

b.

Pump attaching bolts and seals

—

damaged, miss-

ing, bolts loose.

CHEVROLET a

SERVICE

Page 404 of 659

CLUTCH AND TRANSMISSIONS 7-45

23

Fig.

5T - Aluminum Powerglide Special Tools

1. J-9506

2.

J-3289-01

3.

J-9549

4.

J-21867

5.

J-4264

6. J-3387

7.

J-9539

8. J-6839

9. J-9546

10.

J-7782

11.

J-5133

12.

J-4599

13.

J-9542

14.

J-9557

Holding Fixture Adapters

Holding Fixture (Use with J-3289-20 Base)

Converter Safety Strap

Transmission Pressure Gauge and Hose

Oil Filler Tube and Funnel

Pilot Stud Set

Front Pump Puller Bolts (Use with weights

from Slide Hammers J-6585)

Front Pump Seal Driver

Clutch Drum Bushing Remover and Installer

Clutch Spring Compressor Adapter Plate

Clutch Spring Compressor

Planet Pinion Assembly Tool Set

Reverse Piston Spring Compressor

Transmission Case Rear Bushing Remover and

Installer and Rear Pump Bushing Remover

15.

J-7079

16.

J-6582

17.

J-9543

18.

J-5778

19.

J-5154

20.

J-5403

21.

J-5814

22.

J-5853

23.

J-8039

24.

J-21848

J-8001

J-5492

J-6585

J-6585-3

J-9534

Handle

Rear Pump Bushing Installer

Vacuum

Modu

lator Wrench

Extension Bushing Remover and Installer

Extension Oil Seal Installer

Snap Ring Pliers

Speedometer Drive Gear Remover and

Installer

Torque Wrench

Snap Ring Pliers

Low Band Adjusting Tool

Dial Indicator (Not Illustrated)

Dial Indicator Support Strap (Not Illustrated)

Slide Hammers (Not Illustrated)

Slide Hammer Adapters (Not Illustrated)

Bushing Remover (Not Illustrated)

CHEVROLET CHASSIS SERVICE MANUAL

Page 448 of 659

STEERING 9-8

DIAL

UPPER COVER

FASTENER

CHEVROLET

SCREW

CHEVELLE

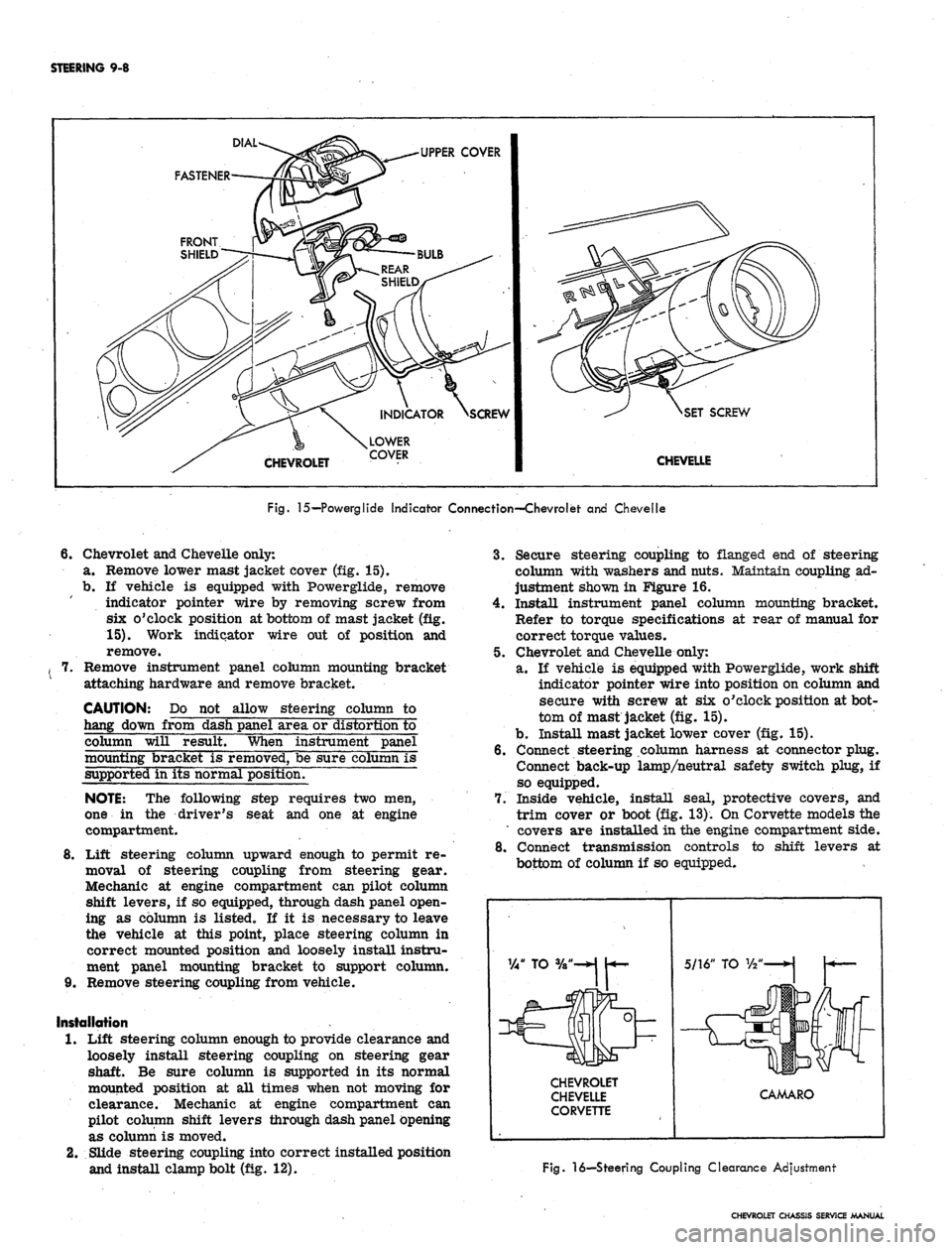

Fig.

15—Powerglide Indicator Connection—Chevrolet and Chevelle

6.

Chevrolet and Chevelle only:

a. Remove lower mast jacket cover (fig. 15).

b.

If vehicle is equipped with Powerglide, remove

indicator pointer wire by removing screw from

six o'clock position at bottom of mast jacket (fig.

15).

Work indicator wire out of position and

remove.

Remove instrument panel column mounting bracket

attaching hardware and remove bracket.

CAUTION: Do not allow steering column to

hang down from dash panel area or distortion to

column will result. When instrument panel

mounting bracket is removed, be sure column is

supported in its normal position.

NOTE:

The following step requires two men,

one in the driver's seat and one at engine

compartment.

8

Lift steering column upward enough to permit re-

moval of steering coupling from steering gear.

Mechanic at engine compartment can pilot column

shift levers, if so equipped, through dash panel open-

ing as column is listed. If it is necessary to leave

the vehicle at this point, place steering column in

correct mounted position and loosely install instru-

ment panel mounting bracket to support column.

9. Remove steering coupling from vehicle.

Installation

1.

Lift steering column enough to provide clearance and

loosely install steering coupling on steering gear

shaft. Be sure column is supported in its normal

mounted position at all times when not moving for

clearance. Mechanic at engine compartment can

pilot column shift levers through dash panel opening

as column is moved.

2.

Slide steering coupling into correct installed position

and install clamp bolt (fig. 12).

3.

Secure steering coupling to flanged end of steering

column with washers and nuts. Maintain coupling ad-

justment shown in Figure 16.

4.

Install instrument panel column mounting bracket.

Refer to torque specifications at rear of manual for

correct torque values.

5. Chevrolet and Chevelle only:

a. If vehicle is equipped with Powerglide, work shift

indicator pointer wire into position on column and

secure with screw at six o'clock position at bot-

tom of mast jacket (fig. 15).

b.

Install mast jacket lower cover (fig. 15).

6. Connect steering column harness at connector plug.

Connect back-up lamp/neutral safety switch plug, if

so equipped.

7. Inside vehicle, install seal, protective covers, and

trim cover or boot (fig. 13). On Corvette models the

' covers are installed in the engine compartment side.

8. Connect transmission controls to shift levers at

bottom of column if so equipped.

CHEVROLET

CHEVELLE

CORVETTE

CAMARO

Fig.

16—Steering Coupling Clearance Adjustment

CHEVROLET CHASSIS SERVICE MANUAL

Page 450 of 659

STEERING 9-10

SECTOR SHAFT SEAL REPLACEMENT

A faulty seal may be replaced without removal of

steering gear from car by removing pitman arm as out-

lined under Maintenance and Adjustments--Steering Gear

Adjustments and proceed as follows:

1.

Loose lash adjuster lock nut and turn lash adjuster

screw several turns counterclockwise.

2.

Remove three cap screws holding side cover to gear

bushing.

3.

Pull side cover and sector shaft from gear housing

as a unit. Do not separate side cover from sector

shaft.

4.

Pull sector shaft seal from gear housing using

hooked tool or pliers.

5. Coat new seal with chassis grease and position in

sector shaft bore.

6. Place a socket or piece of pipe of suitable diameter

on top of seal and drive seal into bore by tapping

pipe or socket with soft hammer.

7. Install sector shaft side cover assembly, being care-

ful not to damage new seal with splines on end of

shaft; splines may be wrapped with a few turns of

tape to prevent this.

8. Install new side cover gasket and align side cover on

gear housing and install cap screw.

9. Perform steering gear adjustment and install pitman

arm as outlined under Maintenance and Adjustments.

STEERING COLUMN

All models are equipped with new energy absorbing

steering columns. The columns are of five basic designs

as follows:

1.

Syncromesh. The syncromesh column is used on

models with standard, column mounted, conventional

shift levers. The shift tube, within the outer mast

jacket, includes two lower shift levers for connection

to the transmission control linkage.

2.

Automatic and floor shift. This column is used on

models equipped with column mounted powerglide

shift levers, or models with floor shift. If the ve-

hicle has the column mounted powerglide shift con-

trol, the inner shift tube has a single lower shift

lever for connection to the transmission control

linkage. On floor shift models, no lower shift levers

are present on the shift tube.

3.

Tilt wheel option. The upper end and steering shaft

of this column is specially designed to accommodate

the optional tilt steering wheel.

4.

Standard Corvette Column. The standard Corvette

column is similar in design to the Automatic and

Floor Shift column used on other models, except

no shift tube is used. Other differences are pointed

out in the disassembly and assembly procedures for

Standard Corvette column.

5. Telescopic wheel option. The upper end and steering

shaft of this column is specially designed to ac-

commodate the optional telescoping steering wheel.

To perform service procedures on steering column

upper end components, it is not necessary to remove the

column from the vehicle. The steering wheel, horn com-

ponents, turn signal switch, upper housing with bearing,

shift control lever, hazard warning knob, and upper shift

bowl may all be removed with the column remaining in

the vehicle. When servicing the above components, omit

the removal procedure and proceed with the applicable

disassembly procedures. Because of the numerous dif-

ferences in steering column types, be sure to refer to the

set of instructions below which apply to the exact column

to be serviced:

CAUTION: The outer mast jacket, shift tube, _

steering shaft, and instrument panel column

mounting b

racket

are designed as energy ab-

sorbing units. Because of the design of these

components, it is absolutely necessary to handle

the column with care when performing any serv-

ice operation required. Avoid hammering, jar-

ring, dropping, or leaning on any portion of the

column.

Removal

1.

Disconnect steering column harness at connector.

Disconnect neutral safety switch and back-up lamp

switch connectors if so equipped.

Remove steering wheel as outlined in this section.

Remove nuts and washers securing flanged end of

column to steering gear. On Chevy H models, re-

move nut and clamp bolt securing lower end of steer-

ing column to steering gear.

Disconnect transmission control linkage, if so

equipped, from lower column shift tube, levers.

Chevrolet and Chevy II only: Remove screws at-

taching upper and lower mast jacket covers together.

On Chevrolet, remove screws attaching lower cover

to instrument panel (figs. 15 and 18). Remove lower

cover.

Chevelle only: Remove screws securing mast jacket

trim cover to instrument panel and remove cover

(fig. 15).

Corvette, only: Remove screws securing escutcheon

to instrument panel. Remove screws securing upper

and lower covers together and remove covers.

On Chevrolet and Chevelle columns with Powerglide

shift levers, loosen set screw at six o'clock position

at bottom of column and remove the transmission

shift indicator pointer (fig. 15).

9. Chevrolet only (fig. 19):

a. Remove screws securing cover trim to dash

panel and remove cover trim.

2.

3.

4.

5.

6.

7.

8.

Fig.

18—Mast Jacket Cover Attachments—Chevy II

CHEVROLET CHASSIS SERVICE MANUAL

Page 456 of 659

STEERING 9-16

new upper shift lever spring into bowl pocket. Be

sure spring is seated in bowl pocket. Install bowl

washer (fig. 30).

12.

Insert the upper bearing housing assembly and the

turn signal switch assembly into the cover, feeding

the signal switch wires through the back of the

cover.

13.

Align the signal switch and bearing housing holes

with the holes in the cover. Install three mounting

screws through the holes.

14.

Slide three springs onto screw ends at rear of cover

and place lockplate in position over screws and

springs. Turn screws three turns into lockplate.

15.

Feed switch wire through the shift lever bowl and

place upper end assembly on top of bowl.

16.

Place the shift lever bowl and signal switch cover

assembly on top of jacket, aligning the tangs on the

I.D. of the lockplate with the slots in the top of the

jacket. Shift tube key should align in bowl keyway as

bowl is pushed ono

17.

Lock upper end assembly into position by pushing

down on the cover assembly and rotating assembly

fully clockwise. Tangs of lock plate must engage

slots in jacket.

18.

Tighten three turn signal switch mounting screws in

a gradual criss-cross sequence to avoid cocking the

lockplate.

19.

Slide wave washer and thrust washer over steering

shaft and against upper bearing housing.

20.

Start "C" retaining ring over steering shaft taper.

Complete installation of. retaining ring using snap

ring installer J-22659 as shown in Figure 28. Be

sure "C" retaining ring is completely seated into

steering shaft groove.

21.

-Place turn signal switch lever in position and secure

with screw. Screw hazard warning knob into position.

22.

Remove column from vise and pull wires flat against

jacket. Snap wire protector into place.

23.

If mesh cover was removed, wrap mesh cover around

jacket and secure with electricians or friction tape.

24.

Slide cancelling cam and upper bearing preload

spring onto end of shaft.

Disassembly—Column Mounted Power glide Lever or

Floor Shift Column (Fig. 32)

NOTE: In this procedure, automatic refers to a

column with a column mounted, Powerglide shift-

ing lever. Floor shift refers to a column taken

from a vehicle with conventional or Powerglide

floor shift controls.

1.

Unsnap and remove wiring protector and wiring clip.

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

will damage the column. If support fixture

J^22573 is not used, frequently check position of

column in vise jaws to insure column is not

working free of jaws.

2.

Clamp column in a bench vise as shown in Figure 26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft.

4.

On automatic columns removed from Chevy II or

Camaro, remove screws securing dial retainer to

column and remove retainer and dial (fig. 33). Slide

Fig.

33—Powerglide Dial Indicator Assembly—Chevy II

and Camaro

indicator out of shift bowl and remove indicator. Re-

move cap and bulb from turn signal switch housing.

5.

Remove turn signal lever retaining screw and re-

move lever. Push hazard warning knob in; unscrew

and remove knob.

6. On automatic columns, drive'out shift control lever

retaining pin and remove shift lever.

7.

Remove "C" retaining ring from upper steering

shaft using snap ring remover Tool J-22569 (fig. 28).

8. Slide thrust washer and wave washer off upper steer-

ing shaft (fig. 28).

9. Loosen three turn signal switch mounting screws

until the switch cover can be rotated counterclock-

wise.

It may be necessary to push on top of screws

to loosen the cover assembly. ,

NOTE: Do not remove the three turn signal

switch screws completely unless it is necessary

to replace the turn signal switch, lockplate, or

upper bearing housing and bearing.

10.

Rotate turn signal switch cover counterclockwise

and pull cover off top of jacket (fig. 29).

11.

If necessary, pry upper shift lever spring (fig. 30)

from bowl and discard spring.

12.

Remove shift lever bowl from top of jacket.

13.

If necessary to service components within the signal

switch cover, remove the three signal switch covers,

remove the three signal switch mounting screws

completely from engagement with the lockplate. Use

care to control three springs as screws are removed.

14.

Remove turn signal switch and upper bearing housing

assembly from cover.

15.

Carefully pull steering shaft assembly from bottom

of column.

16.

Remove securing back-up lamp/neutral start switch

to column, if so equipped, and remove switch. Retain

these mounting nuts.

CHEVROLET CHASSIS SERVICE MANUAL

Page 459 of 659

STEERING 9-19

20.

21.

22.

23.

24.

25.

26.

27.

28.

Start "C" retaining ring over steering shaft taper.

Complete installation of retaining ring using snap

ring installer J-22659 as shown in Figure 28. Be

sure "C" retaining ring is completely seated into

steering shaft groove.

Remove any remaining looseness from internal col-

umn stack-up by unscrewing inner tolerance kit ring

section; then screw inner kit ring section back in

1/8 to 1/4 turn (fig. 36).

Touch the outer surface of the tolerance ring kit

.at

several locations with a hot soldering iron to melt

the threads of the inner and outer ring sections

together.

Place turn signal switch lever in position and se-

cure with screw. Screw hazard warning knob into

position.

If column is automatic and to be installed in a Chevy

II or Camaro, install the bulb and cap (fig. 33). Slide

the indicator into the 'shift bowl. Install dial and re-

tainer with screws removed during disassembly.

Install flange and clamp bolt at bottom of steering

shaft, if so equipped.

Remove column from vise and pull wires flat against

bottom of jacket. Snap wire protector and clip into

place.

If mesh cover was removed, wrap mesh cover around

jacket and secure with electricians or friction tape

/**% • *t 1*1* i '% •< n

Slide cancelling cam and

spring onto end of shaft.

upper bearing preload

Disassembly-Til* Column (Fig. 37)

NOTE:

This procedure covers disassembly and

assembly instructions for all tilt columns. Auto-

matic refers to a tilt column with a column

mounted, Powerglide shifting lever. Floor shift

. refers to' a tilt column taken from a vehicle with

conventional or Powerglide floor shift controls.

1.

Unsnap and remove wiring protector.

CAUTION: Secure column in bench vise for

service one of two ways shown in Figure 26.

Clamping column in vise in any other manner

will damage the column. If support fixture

J-22573 is not used, frequently check position

of column in vise jaws to insure column is not

working free of jawsT

2.

Clamp column in a bench vise as shown in Figure 26.

3.

Slide upper bearing preload spring and cancelling

cam off end of shaft.

Fig,

38—Removing Turn Signal Cover Using Tools

J-21486 and J-6585-1

Fig.

39—Removing Steering Shaft Bearing Lock Nut

Using Lock Nut Wrench j-22599

4.

On automatic columns removed from a Camaro, re-

move screws securing dial retainer to column and

remove retainer and dial (fig. 33). Slide pointer out

of bowl and remove pointer. Remove cap and bulb

from turn signal switch housing.

5. Remove turn signal lever retaining screw and re-

move lever. Unscrew and remove tilt release lever.

Push hazard warning knob in, unscrew and remove

knob.

6. On Automatic columns, drive out shift control lever

retaining pin and remove shift lever.

7. Assemble slide hammer Tool J-6585-1 to turn signal

cover remover Tool J-21486. Place cover remover

over turn signal cover, tighten clamp, and pull

cover from end of column with slide hammer (fig.

38).

8. Remove three turn signal switch mounting screws.

Note short length of secure removed from top

position.

9. Lift signal switch assembly off bearing housing and

allow to hang by the wires. On some columns, the

switch and wires can be removed at this time; re-

move switch and wires if possible. If switch and

wires cannot be removed, allow assembly to hang

by wires.

10.

Install tilt release lever and place column in full up

position. Remove tilt spring retainer using screw-

driver blade that just fits into slot opening. Insert

screwdriver in slot, press in approximately 3/16-

inch;

rotate retainer approximately 1/8 turn clock-

wise until ears align with grooves in housing, and

remove retainer and spring. Use care when remov-

ing spring, it is tightly compressed.

11.

Remove steering shaft bearing lock nut using lock nut

wrench Tool J-22599 (fig. 39). Remove inner race

•seat and inner "race.

12.

Remove two pivot pins from bearing housing using

pivot pin remover Tool J-21854 (fig. 40).

CHEVROLET CHASSIS SERVICE MANUAL

Page 469 of 659

STEERING 9-29

column mounting bracket, and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws and bracket to instrument panel

washers and bolts.

NOTE: Steering shaft to gear clamp must be

tightened before column attaching bolts are

torqued. Refer to "Steering Gear-Chevy n",

installation procedure, for correct Chevy II

steering column alignment procedure.

5.

Camaro only (fig. 60):

Lay wedge shim in position on instrument panel

column mounting bracket and place bracket in cor-

rect position on underside of instrument panel.

Loosely install bracket using bracket to column

mounting screws, nuts, and washer and bolt as shown

in Figure 60.

6. Corvette only (fig. 61):

Loosely secure column mounting bracket to sup-

port plate and instrument panel with washers and

bolts.

7.

Secure flanged end of column to steering coupling

with lockwashers and nuts. On Chevy n, connect col-

umn to steering gear with clamp, clamp bolt, and

nut. On Corvette, slide steering shaft flange into

lower coupling

half,

and install upper clamp bolt

loosely; also secure support, seal and clamp loosely

at dash on engine side.

8. Tighten instrument panel mounting bracket bolts and

nuts.

Refer to torque specifications at rear of manual

for correct torque values.

9. Chevrolet only (fig. 15):

Place upper and lower mast jacket covers in po-

sition and secure covers together and to instrument

panel using nuts and screws as shown in Figure 15.

10.

Chevy H only (fig. 18):

Place lower mast jacket cover in position under

mast jacket and secure to upper cover with screws.

11.

CheveUe only (fig. 15):

Place mast jacket trim cover in position over col-

Fig.

61—Instrument Panel Mounting Bracket and

Support Plqte—Corvette

umn on underside of instrument panel and secure

with screws.

12.

Corvette only (fig. 14):

Slide escutcheon into position at instrument panel

and secure with screws. Place upper end lower

covers in position and secure with screws.

13.

On Chevrolet and CheveUe models with column

mounted powerglide controls, secure transmission

shift indicator pointer into position with set screw

(fig. 15). ,

14.

Chevrolet only (fig. 19):

a. Secure seal and cover to dash panel with screws.

b.

Place clamp assembly in position and install

clamp screw.

c. Install dash panel trim cover with mounting

screws.

15.

Chevelle only (fig. 20):

a. Secure seal and inner and outer covers to dash

panel with screws.

b.

Secure inner and outer covers together with

screws.

c. Install trim cover to dash panel with two

retainers.

16.

Chevy H only (fig. 21):

a. Secure seal, retainer, and clamp to dash panel

with screws.

b.

Install clamp screw.

c. Slide collar into position. Pinch and staple upper

tabs together.

17.

Camaro only (fig. 22):

a. Secure seal, upper cover, and lower cover to

dash panel with screws.

b.

Secure upper and lower cover together with

screws.

c. Fold rubber boot over securely against dash panel

to conceal covers.

18.

Corvette only (fig. 23):

a. Secure seal and support assembly to dash panel

on engine compartment side.

b.

Tighten clamp, washer, and clamp bolt on engine

compartment side.

19.

Connect transmission linkage to lower shift tube

levers in engine compartment, if column is so

equipped. Adjust levers as outlined in Section 7.

20.

Install steering wheel as outlined in this section.

21.

Connect directional signal, horn, back-up lamp, and

neutral start switch at wiring harness plugs. Adjust

back-up lamp, neutral start switch as outlined in

Section 12.

22.

Adjust steering gear and align and center steering

wheel as outlined in this section.

STEERING LINKAGE (Fig. 62)

TIE RODS

There are two tie rod assemblies used on all models.

Each assembly is of three piece construction, consisting

of a sleeve and two tie rod ends. The ends are threaded

into the sleeve and locked with clamps. Right and left

hand threads are provided to facilitate toe-in adjustment

and steering gear centering.

The tie rod ends are self-adjusting for wear and re-

quire no attention in service other than periodic lubrica-

tion and occasional inspection to see that ball studs are

tight. Replacement of tie rod ends should be made when

CHEVROLET CHASSIS SERVICE MANUAL