CHEVROLET CAMARO 1973 2.G Workshop Manual

Manufacturer: CHEVROLET, Model Year: 1973, Model line: CAMARO, Model: CHEVROLET CAMARO 1973 2.GPages: 84, PDF Size: 32.64 MB

Page 51 of 84

Downloaded from www.Manualslib.com manuals search engine sert it firmly for an accurate read

ing. The oil gauge rod

is marked

"FULL" and "ADD." The oil level

should be maintained in the safety

margin, neither going above the

"FULL" line nor below the "ADD"

line. Reseat the gauge firmly after

taking the reading.

NOTE: The oil gauge rod is also

marked

"Use SE Engine Oil" as a

reminder to use only

SE oils.

Supplemental Engine Oil

Additives

The regular use of supplemental

additives

is specifically not recom

mended and will increase operat

ing costs. However, supplemental

additives are available that can

effectively and economically solve

certain specific problems without

causing other difficulties. For ex

ample,

if higher detergency is re

quired to reduce varnish and sludge

deposits resulting from

some unusual operational diffi

culty, a thoroughly tested and ap

proved additive -

"Super Engine

Oil Supplement" -is available at

your Chevrolet dealer.

In the event

of an operational problem, consult

your dealer for advice before

us

ing supplemental additives.

Drive Belts

Every 6,000 miles or 4 months

inspect drive belts for wear, fray

ing, cracking, and tension. Belts

which are in poor condition should

be replaced immediately.

Check tension by applying mod

erate thumb pressure midway be

tween pulleys.

If the center-to

center distance between pulleys

is

13 to 16 inches, the belt should

deflect

Y2 inch . If the center-to

center distance

is7 to 10 inches,

the belt should deflect

1.4 inch.

Loose belts should be retensioned

48

to give the correct deflection.

Air Cleaner

Flame Arrester -Every 12,000

miles-Clean the arrester (located

in the base of the air cleaner) with

kerosene

or a suitable solvent. Dry

with compressed air.

Rear Axle

Standard -Every 4 months or

6,000 miles, whichever occurs

first, check lubricant level and add

lubricant, if necessary, to fill to

level of filler plug hole.

Use SAE

80 or SAE 90 GL-5 Gear Lubri

cant.

(For vehicles normally oper

ated in Canada use SAE 80 GL-5

Gear Lubricant.)

Page 52 of 84

Downloaded from www.Manualslib.com manuals search engine Positraction -Drain and refill

after the first

12,000 miles then

maintain same

as standard axle but

use only the special positraction

lubricant available from your

Chevrolet Dealer.

Manual Transmissions

3-Speed and 4-Speed -Every

6,000 miles or 4 months-Check

at operating temperature and

fill

as necessary to level of filler plug

hole with

SAE 80 or SAE 90 GL-

5 Gear Lubricant.

(For vehicles

normally operated in Canada use

SAE 80 GL-5 Gear Lubricant.)

If temperatures of below 3Z°F.

are expected, use SAE 80 GL-5

Gear Lubricant only.

Clutch Cross-Shaft -Every

36,000 miles or sooner if neces

sary -Remove the plug, install a

lubrication fitting and lubricate

with water resistant

EP Chassis

Lubricant which meets GM

Speci

fication 6031 M.

Automatic Transmission

Fluid Recommendations

Use only automatic transmis

sion fluids identified with the

mark

DEXRON. These fluids have

been specially formulated and

tested for

use in your automatic

transmission, and are available

from your Chevrolet dealer or lo

cal service station.

Check the fluid level at each

engine oil change period. To make

an accurate fluid level check:

Check the fluid level at each en

gine oil change period.

To make an

accurate fluid level check:

1. Drive car several miles, making

frequent starts and stops, to

bring transmission up to normal

operating temperature (approxi

mately

180-190° F.).

2. Park car on a level surface.

3.

Place selector level in "Park"

and leave engine running.

49

4. Remove dipstick and wipe clean.

5. Reinsert dipstick until cap seats.

6. Remove dipstick and note read

ing.

If fluid level is at or below the

ADD mark, add sufficient fluid to

raise the level to the

FULL mark.

One pint raises the level from ADD

to FULL.

Do not overfill.

Under normal driving condi

tions, the transmission fluid should

be changed every

24,000 miles. If

your car is driven extensively in

heavy city traffic during hot weather,

or

is used to pull a trailer, change

fluid every

12,000 miles. Likewise,

operators of cars in commercial use

(such as taxicab, limousine

or pa

trol car service) where the engine

idles for long periods, should

change fluid every

12,000 miles.

Changing Fluid-For Turbo Hy

dra-Matic

350, remove fluid from

Page 53 of 84

Downloaded from www.Manualslib.com manuals search engine the transmission sump and add ap

proximately 2.5 quarts U.S. Mea

sure

(2.0 quarts Imperial Mea

sure). Operate transmission

through all shift ranges and re

check fluid level as described

above.

Turbo Hydra-Matic 400-Lubri

cation of your Turbo Hydra-matic

400 will, except for fluid capacity

and filter change listed below, fol

low previously stated automatic

transmission recommendations.

After checking transmission fluid

level it

is important that the dip

stick be pushed all the way into

the filler tube.

Every 24,000 miles -After re

moving fluid from the transmission

sump, approximately

71h. pints

U.S. measure (6 pints Imperial

measure) of fresh fluid will be re

quired to return level to proper mark

on the dipstick.

Every 24,000 miles the transmis

sion sump filter should be re

placed.

Transmission Shift and Back

drive Linkage (Manual and

Automatic) -

Every 6,000 miles

or 4 months lubricate shift link

age and on manual transmission

floor controls lever contacting

faces with water

resistantEP chas

sis lubricant which meets GM

Specification 6031M.

Transmission Shift Linkage

(Manual and Automatic)

Every 6,000 miles or 4 months

lubricate shift linkage and on man

ual transmission floor controls

lever contacting faces with water

resistant

EP chassis lubricant

which meets

GM Specification

6031M.

50

Chassis

Front Suspension

Every 6,000 miles or 4 months

-Lubricate 4 fittings · with water

resistant

EP Chassis Lubricant

which meets

GM Specification

6031M.

Ball joints should not be lu

bricated unless their tempera

ture

is 10°F. or higher. During

colder weather, they should be

allowed to warm up as neces

sary before lubrication.

Steering Linkage

Every 6,000 miles or 4 months

-Lubricate 7 fittings, one at each

end of each tie rod, one at each

end of relay rod, and one

at idler

lever with water resistant

EP Chas

sis Lubricant which meets

GM

Specification 6031 M.

Page 54 of 84

Downloaded from www.Manualslib.com manuals search engine Front Wheel Bearings

Every 24,000 miles-clean and

repack with a high melting point

wheel bearing lubricant.

Use wheel

bearing lubricant GM Part No.

1051344 or equivalent. This is a

premium high melting point lubri

cant. When replacement is neces

sary specify Delco parts.

Brakes

Brake linings should. be periodi

cally inspected for wear by a quali

fied technician. The frequency of

thi s inspection depends upon driv

ing conditions such

as traffic or

terrain, and also the driving tech

niques of individual owners.

Your

Chevrolet Dealer is best qualified

to advise you

as to how often this inspection

should be performed.

When replacement

is required ,

specify

GM and Delco parts.

Master Cylinder -Every 6,000

miles or 4 months -Check fluid

level in each reservoir and main

tain

1;4" below lowest edge of each

filler opening with Delco Hydrau

lic Brake Fluid,

Supreme No. 11.

Parking Brake Pulley, Cables

and Linkage-Every 6,000 miles

or 4 months-Apply water resist

ant EP Chassis Lubricant which

meets

GM Specification 6031 M, to

parking brake cable at cable guides

and at all operating links and

levers.

Standard Steering Gear

The steering gear is factory

filled with steering gear lubricant.

Seasonal change of this lubricant

should not be performed and the

housing should not be

drained-no

51

lubrication is required for the life

of the steering gear.

Every 36,000 miles, the gear

should be inspected for seal leak

age (actual solid

grease-not just

oily film) .

Ifa seal is replaced or

the gear is overhauled, the gear

housing should be refilled with

Part No.

105 1052 (13 oz. con

tainer) Steering Gear Lubricant

which meets GM Specification GM

4673M, or

its equivalent.

NOTE: Do not use EP Chassis

Lube, meeting

GM Specification

GM 603 I M, to lubricate the gear.

DO NOT OVER-FILL the gear

housing.

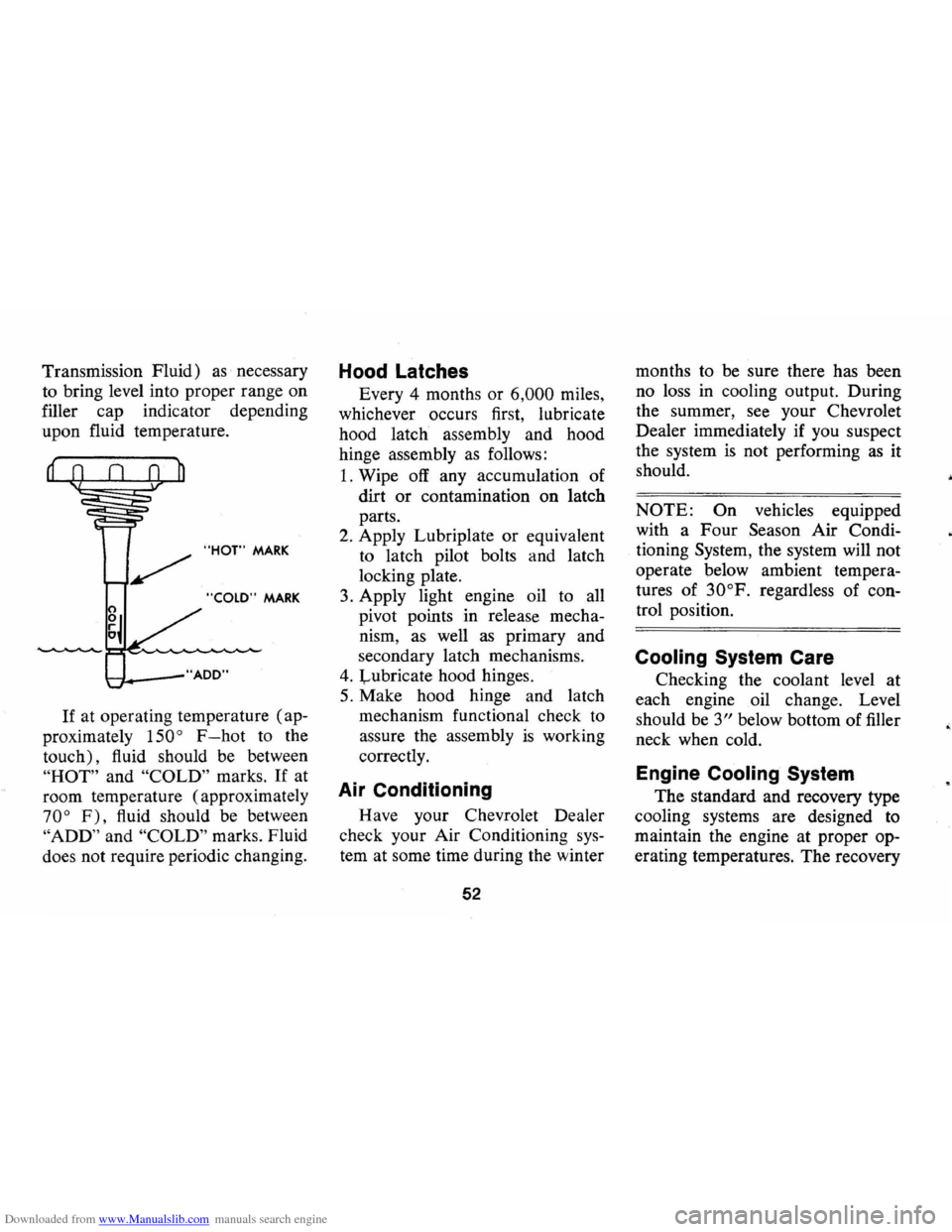

Power Steering System

Check the fluid level in the

pump reservoir at each oil change

period. Add GM Power Steering

Fluid

(or DEXRON Automatic

Page 55 of 84

Downloaded from www.Manualslib.com manuals search engine Transmission Fluid) as necessary

to bring level into proper range on

filler cap indicator depending

upon fluid temperature .

"HOT" MARK

"COLD" MARK

t-"f. __ -"AOO"

If at operating temperature (ap

proximately

150 ° F-hot to the

touch), fluid should be between

"HOT" and "COLD" marks. If at

room temperature (approximately

70° F), fluid should be between

"ADD" and "COLD" marks . Fluid

does not require periodic changing.

Hood Latches

Every 4 months or 6,000 miles,

whichever occurs first, lubricate

hood latch assembly and hood

hinge assembly

as follows:

1. Wipe off any accumulation of

dirt

or contamination on latch

parts.

2. Apply Lubriplate or equivalent

to latch pilot bolts and latch

locking plate.

3. Apply light engine oil to all

pivot points in release mecha

nism,

as well as primary and

secondary latch mechanisms.

4. Lubricate hood hinges.

5. Make hood hinge and latch

mechanism functional check to

assure the assembly

is working

correctly.

Air Conditioning

Have your Chevrolet Dealer

check your Air Conditioning

sys

tem at some time during the winter

52

months to be sure there has been

no loss

in cooling output. During

the summer,

see your Chevrolet

Dealer immediately if you suspect

the system

is not performing as it

should.

NOTE: On vehicles equipped

with a Four

Season Air Condi

tioning

System, the system will not

operate below ambient tempera

tures of

30°F. regardless of con

trol position.

Cooling System Care

Checking the coolant level at

each engine oil change. Level

should be

3" below bottom of filler

neck when cold.

Engine Cooling System

The standard and recovery type

cooling systems are designed

to

maintain the engine at proper op

erating temperatures. The recovery

•

Page 56 of 84

Downloaded from www.Manualslib.com manuals search engine type cooling system is used on all

1973 Camaro air conditioned and

heavy duty cooling systems. It has

been filled at the factory with a

high-quality, inhibited, year-around

coolant that meets the standards

of General Motors Specification

1899-M. This coolant solution pro

vides freezing protection to

-20 0 F

(-32°F in Canada), and it has

been formulated to be used for

two full calendar years

or 24,000

miles, whichever first occurs, of

normal operation without draining,

provided the proper concentration

of coolant

is maintained.

• For Recovery Systems Only

Check the coolant level visually

at the see-through coolant reser

voir at each oil change interval

while the engine

is at normal

operating temperature. Do not

remove radiator cap except for

draining and refilling the system.

Coolant level should be at the

"Full Hot" mark on the reservoir.

If system is checked cold, the

coolant level should be at the

"Full Cold" mark on the reser

voir.

• For Other Than Recovery Sys

tems-Check the coolant level

only at oil change intervals, un

less there

is evidence of leaking

or overheating. Do not remove

radiator cap when solution

is

hot and under pressure. Coolant

level should be a maximum of

three inches below the level of

the filler neck when the engine

is cold.

• All Systems-Add a 50/50 mix

ture of high-quality ethylene

glycol antifreeze and water if

coolant additions are necessary.

Do not overfill.

NOTE: If recommended quality

antifreeze

is used, supplemental

inhibitors or additives claiming to

53

provide increased cooling capabil

ity are not necessary. They may be

detrimental to the efficient opera

tion of the system, and represent

an unnecessary operating expense.

Every year, the cooling system

should be serviced

as follows:

1. Wash radiator cap and filler

neck with clean water.

2. Check coolant for proper level

and freeze protection.

3. Pressure test system and radia

tor cap for proper pressure hold

ing capacity (15 psi).

If re

placement

of cap is required,

use the proper AC cap specified

for your car model.

4. Tighten hose clamps and inspect

all hoses. Replace hoses when

ever checked, swollen

or other

wise deteriorated.

5. Clean frontal area of radiator

core and air conditioning con

denser.

Page 57 of 84

Downloaded from www.Manualslib.com manuals search engine Every two years or 24,000 miles,

whichever first occurs, the cooling

system should be drained by si

phoning

and refilled as follows :

1 . Run engine, with radiator cap

removed , until normal operat

ing temperature

is reached

and upper radiator

is hot (in

dicates thermostat

is open).

2. With engine stopped, insert

one end

of a 5-foot length of

¥s inch tubing into the filler

neck until it touches the bot

tom of the radiator.

3. Insert any type of large sy

ringe into the open end of the

tubing and initiate the siphon

ing process by squeezing and

releasing the ball.

4. Completely drain radiator

coolant through the siphon

tube.

(To speed this opera

. tion the drain plugs in block

can also be removed.)

4A. For recovery systems use

same method to siphon all

coolant from reservoir.

5. Remove tubing (install block

drain plugs, if removed) and

add sufficient water to fill

system.

6. Run engine, drain and refill

the system, as described in

steps

1 thru 5, a sufficient

number of times until the

drained liquid

is nearly color

less.

7. Allow system to drain com

pletely and install block drain

plugs, if removed.

8. Coolant Recovery Systems

Only

- Flush reservoir with

clean water,

and drain.

54

9. Add sufficient ethylene glycol

coolant, meeting

GM Specifi

cation 1899-M, to provide

the required freezing and

corrosion

protection-at least

a

44 percent solution (-200

F). For both standard and

recovery systems, fill radiator

to the cold fill level

(3" be

low bottom

of filler neck).

For recovery systems, add

sufficient coolant to reservoir

to raise level to

"Full Hot"

mark.

I O. Run engine, with radiator cap

removed, until normal oper

ating temperature

is reached.

(Radiator upper hose be

comes

hot.)

11. With engine idling, add cool

ant to within 1 V:z " below bot

tom of filler neck and install

radiator cap making certain

arrows line

up with overflow

tube.

Page 58 of 84

Downloaded from www.Manualslib.com manuals search engine It is the owner's responsibility

to keep the freeze protection at a

level commensurate with the tem

peratures which may occur

in the

area of vehicle operation.

• Maintain cooling system freeze

protection at

_200 F or below

to ensure protection against cor

rosion and loss of coolant from

boiling, even though freezing

temperatures are not expected.

• Add ethylene glycol base cool

ant that meets GM Specification

1899-M when coolant additions

are required because of coolant

loss or to provide additional

protection against freezing at

temperatures lower than

_200

F (_320 F in Canada).

NOTE: Alcohol or methanol base

coolants

or plain water are not

recommended for your Camaro at

any time.

Radiator Pressure Cap

The radiator cap, a 15 lb. pres

sure type, must be installed tightly,

otherwise coolant may be lost and

damage to engine may result from

overheating. Radiator pressure

caps should be checked periodi

cally for proper operation.

If re

placement

is required specify AC.

Thermostat

The cooling system is protected

and controlled by a thennostat

in

stalled in the engine coolant outlet

to maintain a satisfactory operat

ing temperature of the engine. This

thermostat

is designed forcontinu

ous use through both winter and summer

and need not be changed

seasonally . When replacement

is

necessary, Delco parts are recom~

mended.

Tires

The factory installed tires on

your car

as shown in the Tire

Usage chart below are designed to

provide the best all around per

formance for normal vehicle oper

ation. When inflated

as recom

mended on the tire pressure plac

ard, located

on the left door of

your vehicle, they have the load

carrying capacity to operate satis

factorily at all normal highway

speeds.

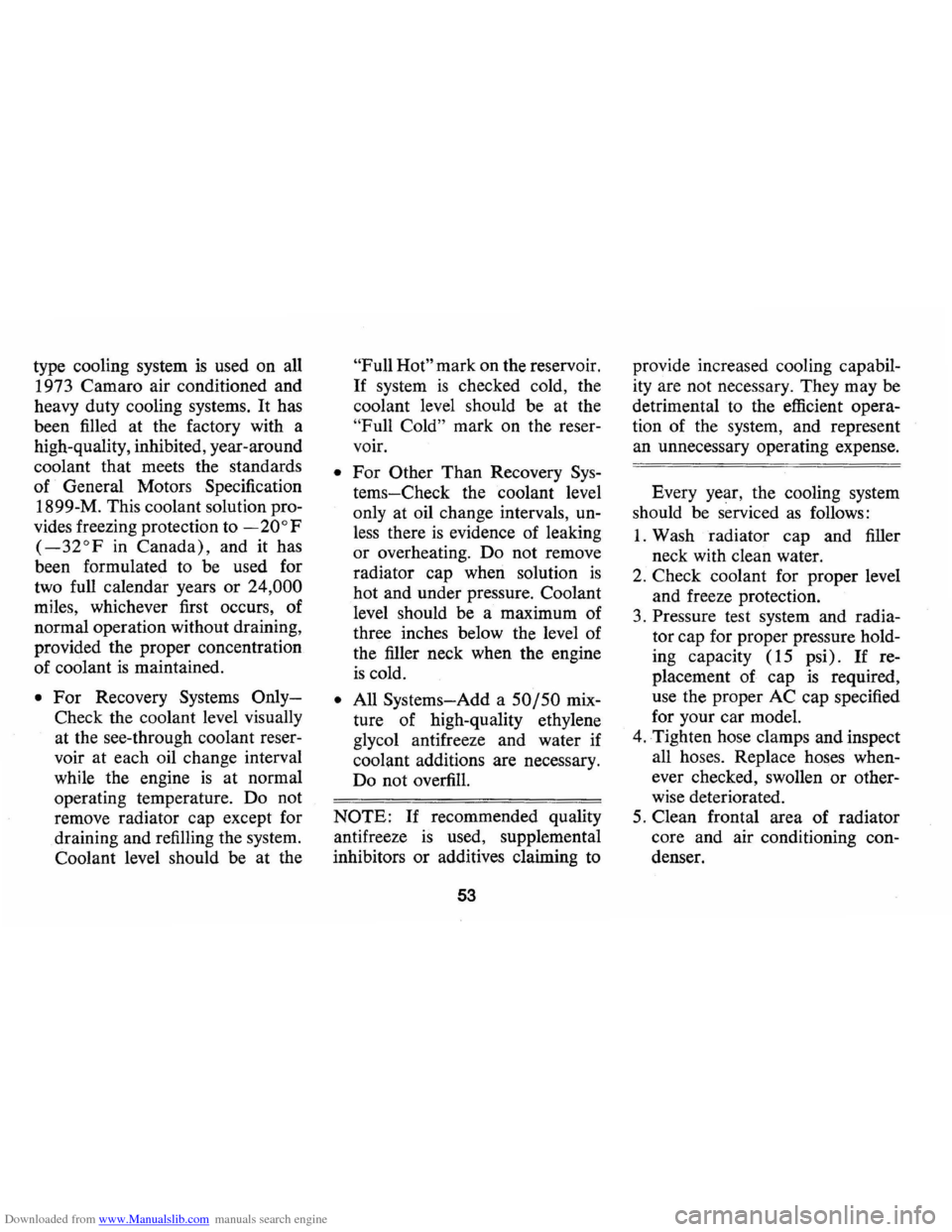

CAMARO TIRE USAGE

ENGINE AND BODY STANDARD OPTIONAL

All (Except Type l T or Z28 Models) E78·14 F70·14 G70·14

Type lT Space Saver Tire E78·14 F70·14

Z28 F60·15 White letters Space Saver Tire -

All standard tires are blackwall with whitewall optional. All tires are bias-belted, load

range B unless otherwise specified. .

55

Page 59 of 84

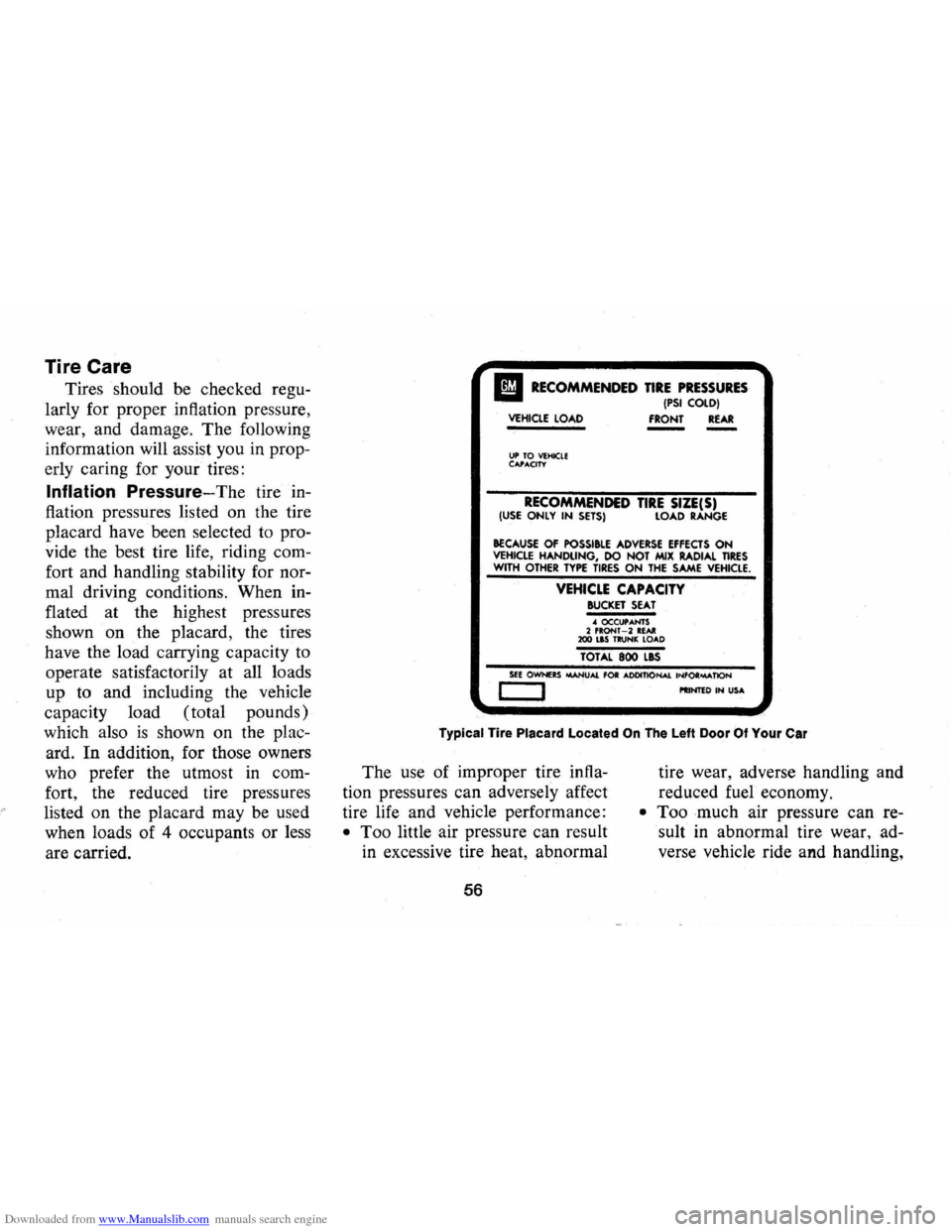

Downloaded from www.Manualslib.com manuals search engine Tire Care

Tires should be checked regu

larly for proper inflation pressure,

wear, and damage. The following

information will assist you in prop

erly caring for your tires:

Inflation

Pressure-The tire in

flation pressures listed on the tire

placard have been selected to pro

vide the best tire life, riding com

fort and handling stability for nor

mal driving conditions. When in

flated at the highest pressures

shown

on the placard, the tires

have the load carrying capacity to

operate satisfactorily at all loads

up to and including the vehicle

capacity load (total pounds)

which also

is shown on the plac

ard.

In addition, for those owners

who prefer the utmost

in com

fort , the reduced tire pressures

listed on the placard may be used

when loads of 4 occupants or less

are carried.

II RECOMMENDED TIRE PRESSURES . (PSI COlD) VEHICLE LOAD

FRONT REAR

UP TO VEHICLE C"',"'CITY

RECOMMENDED TIRE SIZE(S) (USE ONLY IN SETS) LOAD RANGE

BECAUSE OF POSSI&lE ADVERSE EFFECTS ON VEHICLE HANDliNG, DO NOT MIX RADIAL TIRES WITH OTHER TYPE TIRES ON THE SAME VEHICLE.

VEHICLE CAPACITY BUCKET SEAT ~ OCCU,""NTS 2 fRONT -2 RE .... 200 lIS TRUNK lO ... D

TOTAL 800 lIS

SEE OWNERS oAANU"" fOR ... OOITlONAl INfOR""'TlON c::=:J I'IINTED IN US ...

Typical Tire Placard Located On The Left Door Of Your Car

The use of improper tire infla

tion pressures can adversely affect

tire life and vehicle performance:

• Too little air pressure can result

in excessive tire heat, abnormal

56 tire

wear, adverse handling and

reduced fuel economy.

• Too much air pressure can re

sult in abnormal tire wear, ad

verse vehicle ride and handling,

Page 60 of 84

Downloaded from www.Manualslib.com manuals search engine and increased susceptibility to

damage by road impacts.

Tire pressures should be

checked when the tires are

"cold"

at least once a month (and pref

erably oftener) or before long

trips

or when heavily loaded. The

following points should be ob

served when checking and setting

tire pressures:

1. Cold tire pressure ratings are applic

able when a vehicle has been inopera

tive for 3 hours or more, or driven less than 1 mile.

2. Tire Inflation pressure may increase as

much as 6 pounds per square inch (psi)

when hot (after

vehicle has been driven 10 miles or at speeds of more than 60 miles per hour). Do not "bleed" or re

duce pressures when tires are hot from

driving.

3. For continuous high speed operation

(over 75 mph), Increase tire Inflation pressure 4 psi above the recommended

pressures up to a maximum of 32 psi cold pressure for load range B tires, or 40 psi for 0 load range tires. Sustained

speeds above 75 mph are not recommended when the 4 psi adjustment ,

would require pressures greater than

the above maximum pressures.

4. Always use a tire pressure gauge when

checking pressures as t,he appearance of a tire can be deceiving. For example,

radial ply fires, In comparison with bias ply tires at the same pressure, may have

the appearance of being under-inflated.

Vehicle Loading -Do not load

your vehicle beyond the vehicle

capacity (total pounds) shown on

the tire placard. This figure repre

sents the design capacity of the

ve

hicle, not merely of the tires.

When towing trailers, the allow

able pasenger and cargo load

must be reduced by an amount

equal to the trailer tongue load on

the trailer hitch.

(See "Trailer

Hauling"

in Section 1 of this man

ual.) Station wagon loads should

be distributed

as far forward as

possible. Vehicles equipped with

luggage racks do not have a

ve

hicle load capacity greater than

specified on the tire placard.

57

Tire Wear and Rotation -Un

even or abnormal tire wear is usu

ally the result of incorrect inflation

pressure, improper wheel align

ment, wheels being out-of-balance,

or poor driving habits. Underin

flation, incorrect toe or camber

and fast cornering produce differ

ent types of abnormal wear which

can be diagnosed by your dealer.

The original equipment tires in

corporate built-in tread wear

in

dicators to assist you in determin

ing when your tires ,have been

worn to the point of needing re

placement. These indicators ap

pear

as Ij2 inch wide bands when

tire tread depth

is 1/16 inch or

less. When the indicators appear

in two or more adjacent grooves,

tire replacement due to tread wear

is recommended.

To equalize wear, it

is recom

mended that the tires be rotated

every

6,000 miles (or sooner if