CHEVROLET CAMARO 1973 2.G Repair Manual

Manufacturer: CHEVROLET, Model Year: 1973, Model line: CAMARO, Model: CHEVROLET CAMARO 1973 2.GPages: 84, PDF Size: 32.64 MB

Page 61 of 84

Downloaded from www.Manualslib.com manuals search engine ... ... ... ...

---",,"'"

-..... .

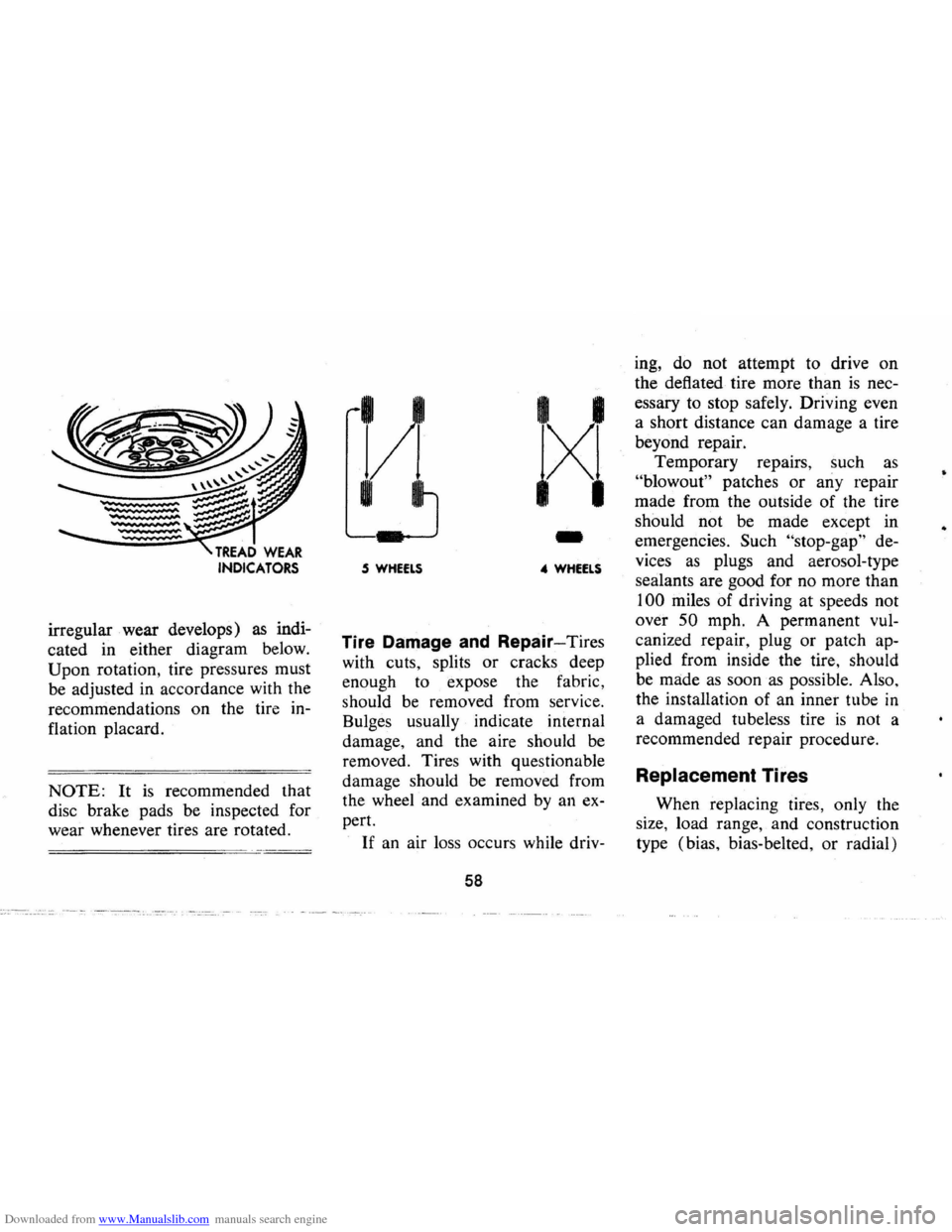

irregular . wear develops) as indi

cated in either diagram below.

Upon rotation, tire pressures must

be adjusted in accordance with the

recommendations on the tire in

flation placard.

NOTE: It is recommended that

disc brake pads be inspected for

wear whenever tires are rotated.

)11

I I

~Xl l.j

-.5 WHEELS 4 WHEELS

Tire Damage and Repair-Tires

with cuts, splits or cracks deep

enough to expose the fabric,

should be removed from service.

Bulges usually indicate internal

damage , and the aire should be

removed. Tires with questionable

damage should be removed from

the wheel and examined

by an ex

pert.

H an air loss occurs while driv-

58

ing, do not attempt to drive on

the deflated tire more than

is nec

essary to stop safely. Driving even

a short distance can damage a tire

beyond repair.

Temporary repairs, such as

"blowout" patches or any repair

made from the outside of the tire

should not be made except in

emergencies.

Such "stop-gap" de

vices

as plugs and aerosol-type

sealants are good for no more than

100 miles of driving at speeds not

over

50 mph. A permanent vul

canized repair, plug or patch ap

plied from inside the tire, should

be

made as soon as possible . Also,

the installation of an inner tube

in

a damaged tubeless tire is not a

recommended repair procedure.

Replacement Tires

When replacing tires, only the

size, load range , and construction

type (bias, bias-belted, or radial)

•

Page 62 of 84

Downloaded from www.Manualslib.com manuals search engine originally installed on your vehi

cle are recommended.

Use of any

other tire size or type tire may

seriously affect ride, handling ,

speedometer / odometer calibration

vehicle ground clearance and tire

clearance to the body and chassis.

The following also should be con

sidered when replacing tires:

• To achieve best all around ve

hicle performance, belted-bias

tires and bias tires should not

be mixed

on the same car.

• Because of possible adverse ef

fects on vehicle handling, do

not mix radial ply tires with

other type tires on the same

vehicle.

• It is recommended that new

tires be installed in pairs on the

same axle.

.. When replacing only one tire, it

should be paired with the tire having

the least wear, to equal

ize braking traction.

• When replacing original tires

with an optional recommended

size of different diameter, the

speedometer must be recali

brated by installing the correct

speedometer driven gear.

Snow Tires

If you equip your vehicle with

snow tires, they should be inflated

4 psi above the recommended

pressures shown on the tire pla

card up to a maximum of 32 psi

( cold) for load range B tires and

40 psi for load range D tires. It is

recommended that vehicle speeds

be limited to a maximum of 75

mph if snow tires are installed.

Replacement Wheels

When replacing wheels for any

reason, care should be taken to in-

59

sure that the wheels are equiva

lent to those removed in diameter,

rim width and off-set.

Warranty

Tires are warranted by the tire

manufacturers

as covered in the

New Vehicle Warranty and Policy

on Owner Service folder furnished

with your vehicle. However, for

the added convenience of owners,

many Chevrolet dealers are

equipped to handle tire warranty

adjustments

on certain makes of

tires provided

on 1973 Chevrolet

cars.

Tire Traction

A decrease in driving, corner

ing, and braking traction occurs

when water, snow, ice, gravel,

or

other material is on the road sur

face. Driving practices and car

speed should be adjusted to the

road conditions.

Page 63 of 84

Downloaded from www.Manualslib.com manuals search engine When driving on wet or slushy

roads, it

is possible for a wedge of

water to build up between the tire

and road surface. This phenom

enon, known

as hydroplaning.

may cause partial

or complete loss

of traction, which adversely affects

vehicle control and stopping abil

ity.

To reduce the possiblity of

traction loss, the following precau

tions should be observed:

1. Slow down during rainstorms or

when roads are slushy.

2. Slow down if road has standing

water

or puddles.

3. Replace tires when tread wear

indicators are visible .

4. Keep tires properly inflated.

For temporary assistance when

traction

is lost on ice or snow. the

use of AC Liquid Tire Chain is

recommended.

Inflation Instructions for

Space Saver Spare Tire

I. Install deflated space saver

spare

on car with valve stem at

the bottom and tighten all

five

lug nuts.

2. Remove valve qp and make

sure valve core is screwed tight

in valve stem.

3. Remove plastic cap from

in

flator.

4 . Place inflator over valve

stern

and push onto stem until sound

of gas entering tire can

be

heard .

5 . Keep pressure against valve and

hold can upright against wheel

to ensure complete draining of

fluid.

60

6 . Hold the inflator in position one

minute. After sound stops. then

remove inflator for disposal

in

proper receptacle.

7 . Replace valve cap.

NOTE: It is recommended that

the inflation pressure be checked

and adjusted to 28 psi

(Space

Saver Spare

only), as soon as pos

sible after installing tire on car.

To stow , deflate tire by remov

ing tire valve stem core with tool

on end of valve cap. Flatten tire

and replace core and cap. Do not

inhale gas.

Store tire in trunk com

partment. The

Space Saver Spare tire has

an approximate tread life of

2,000

miles; therefore, its continued use

other than for emergency purposes

is not recommended. The Space

Saver Spare

has the same warranty

as all original equipment tires.

Page 64 of 84

Downloaded from www.Manualslib.com manuals search engine However, this warranty is void if

any inflator containing sealants

is

used. Approved inflation gases are

air, carbon dioxide, nitrogen, and

Freon 22.

Underbody Maintenance

The effects of salt and other

corrosive materials used for ice

and snow removal and dust con

trol can result in accelerated rust

ing and deterioration of under

body component s such

as brake

and fuel lines, frame, underbody

floor pan, exhaust system, brac

kets, parking brake cables. These

corrosive effects, however , can be

reduced

by periodic flushing of the underbody

with plain water. In

geographic areas having a heavy

concentration of such corrosive

materials, it

is recommended that

the complete underbody be in

spected and flushed at least

once

each year, preferably after a win

ter's exposure.

Particular attention

should be given to cleaning out

underbody members where dirt

and other foreign materials may

have collected .

If desired, your Chevrolet deal

er can perform

this service for

you. In addition , he can provide

recommendations on undercoat

ing materials which will help pro

tect your vehicle from corrosion.

61

Battery Care (Energizer)

Check fluid level monthly utiliz

ing the level indicator cap marked

"Delco Eye". If the transparent eye

within the cap glows, fluid level

is

low. Add only colorless, odorless

drinking water or distilled water to

bring level to split ring in filler

opening.

Page 65 of 84

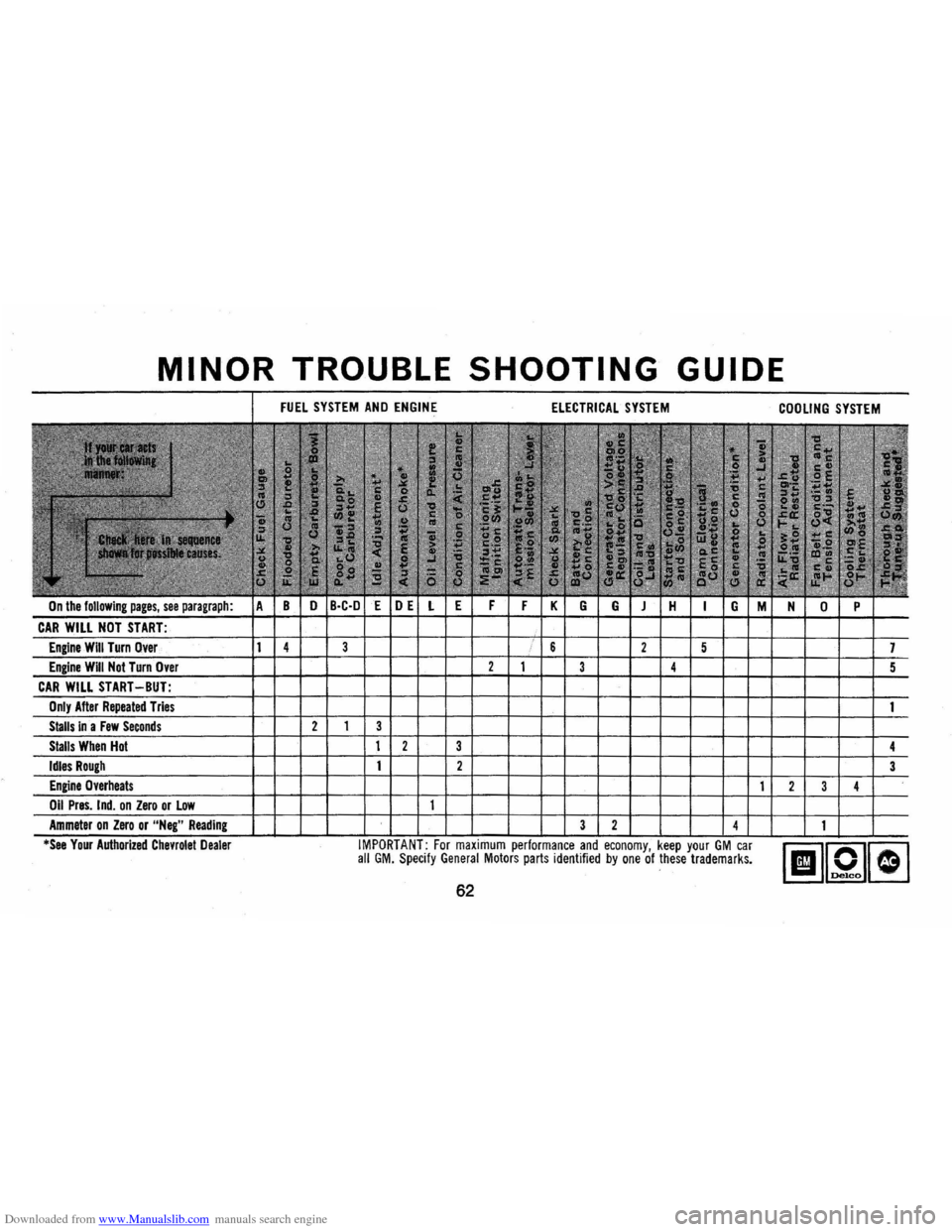

Downloaded from www.Manualslib.com manuals search engine MINOR TROUBLE SHOOTING GUIDE

IMPORTANT: For maximum performance and economy, keep your GM car all GM. Specify General Motors parts identified by one of these trademarks.

62

Page 66 of 84

Downloaded from www.Manualslib.com manuals search engine The chart on the previous page, and the, information on the pages

which follow, contains information designed to aid the average

driver to discover, and possibly correct, conditions resulting in minor

mechanical difficulties

in his car. The chart, designed to point out

possible solutions to several

of the most common automotive malfunctions and point out a logical checking sequence, will lead step

by step to the most

likely causes and corrective procedures. If, after

making the checks and adjustments suggested, the source of the

trouble

has not been found and corrected, it is strongly recom

mended that an Authorized Chevrolet Dealer inspect the vehicle and make whatever repairs or adjustments are necessary.

FUEL SYSTEM AND ENGINE

If the ignition switch will cause the engine to "turn over" or

"crank" but the car will not start, check Steps A through 0 below.

NOTE: If continual ··f1ooding··, of the carburetor is evidenced by a

carburetor wet with fuel or black exhaust smoke, perform the

operation suggested in paragraph D only.

(A) The first and most obvious, and one of the most frequently

overlooked, items to check when

you have difficulty in starting your car is the amount of fuel in the

tank. Make it a habit to check the

FUEL GAUGE regularly and most

especially at a time when the engine will "turn over" but will not

start.

(8)

If the fuel tank is not empty,

you may check further to see

Checking Fuel Flow

63

whether the fuel is reaching the carburetor. Disconnect .the fuel line at the carburetor and remove the center wire (ground the secondary coil terminal or disconnect the primary wire from the coil to the

distributor at the coil) from the coil tower. Place a jar or cup under

the open line and briefly "crank" the engine by means of the

starter. If fuel spurts from the fitting, you may assume that the FUEL LINES are clear and the FUEL PUMP is operating properly. If no

fuel leaves the line, either the fuel

lines

or fuel pump are at fault.

See your Authorized Chevrolet

Dealer.

(C) Before reconnecting the fuel

line to the carburetor, remove

the

FUEL FILTER from the carburetor

inlet and check its condition. If it

appears to be clean, replace it

and recorinect the fuel line. Re

place the filter if it appears to be

plugged.

(D) If the fuel seems to be

reaching the carburetor properly, Fuel Filter

the problem may be: an EMPTY CARBURETOR BOWL caused by a "stuck shut" carburetor; a FLOODED CARBURETOR caused by a "stuck open" condition and evidenced by gasoline seeping around and down the outside of the carburetor; or a stuck CHOKE valve.

Remove the air cleaner from the carburetor. Check that the choke

valve moves freely and is not stuck. (Don't mistake normal spring

tension for a stuck valve.) Tap the side of the carburetor sharply

several times with a light tool such as a screwdriver handle or pliers. Replace the air cleaner and attempt to start the engine in the normal manner.

I

Page 67 of 84

Downloaded from www.Manualslib.com manuals search engine IE) If the car will start but stalls when hot or has a rough idle,

you can suspect a faulty IDLE ADJUSTMENT, a malfunctioning AUTOMATIC CHOKE or an extremely dirty and blocked AIR CLEANER ELEMENT. Replace paper element air cleaner if necessary. Idle adjustment or automatic choke service (other than that outlined in paragraph 0 above) should be performed by your

Chevrolet Dealer.

If the above Fuel System checks and the checks suggested under the Electrical System following do not correct the malfunction, it is recommended that you return to your Authorized Chevrolet Dealer

for further checks, adjustments or repairs.

ELECTRICAL SYSTEM If, when the ignition key is turned to "Start", the engine will not

turn over, you have good reason to suspect electrical trouble. NOTE: Never remove Delcotron bat lead without first disconnecting

battery ground cable.

IF) When there is no response at all to attempts to start the car, check the obvious-your AUTOMATIC TRANSMISSION SELECTOR LEVER must be in Neutral or Park position (manual transmission

must have clutch depressed all the way to floor) before the engine can be started. Turning the IGNITION SWITCH rapidly back and forth several times will sometimes correct a poor internal switch

contact.

IG) The BATIERY may be discharged. If so, lights will be dim and the horn will have a poor tone if it will blow at all.

Usually a garage recharge will be necessary to return the battery to operation. Occasionally, however, a long drive will recharge the battery. NOTE: If the battery is determined to be dead, and for no apparent reason, have your Authorized Chevrolet Dealer check the

battery, the GENERATOR and the VOLTAGE REGULATOR.

GENERATOR trouble should already have been indicated by the generator indicator light on the instrument panel.

64

POOR BATIERY CONNECTIONS may be suspected if the car has operated properly a short time before and now not even the horn

will operate. Check both ends of both battery cables. If the connections are corroded, a car may sometimes be restored to operation by removing all cable ends, scraping all contacting surfaces

clean with a pen knife, and reassembling. If the cables are broken,

they must be replaced. The power supply should now be restored

unless the battery is dead.

IH) If, however, the lights and horn work properly but the starter will still not turn over, check the STARTER connections. A "click" from the starter solenoid indicates that the wiring to the starter is properly installed. If the wiring seems to be clean and tightly in

stalled, the trouble is probably in the starter itself and should be referred to your Authorized Chevrolet Dealer.

When the engine will

"turn over" but will not start, the foilowing

items may be checked along with the Fuel Systems Checks listed

previously.

II) With a clean dry cloth, wipe the ceramic portions of the spark plugs dry. In particularly damp or rainy weather dampness may be

the cause of not sta rting, especi

ally when the engine is cold.

IJ) Check the cables at the top of the distributor and coil as well as each spark plug cable for

tightness.

IK) If the co r will still not sta rt,

check for spark at the spark plugs in the following manner:

Pull one of the spark plug

wires off its spark plug. Insert a

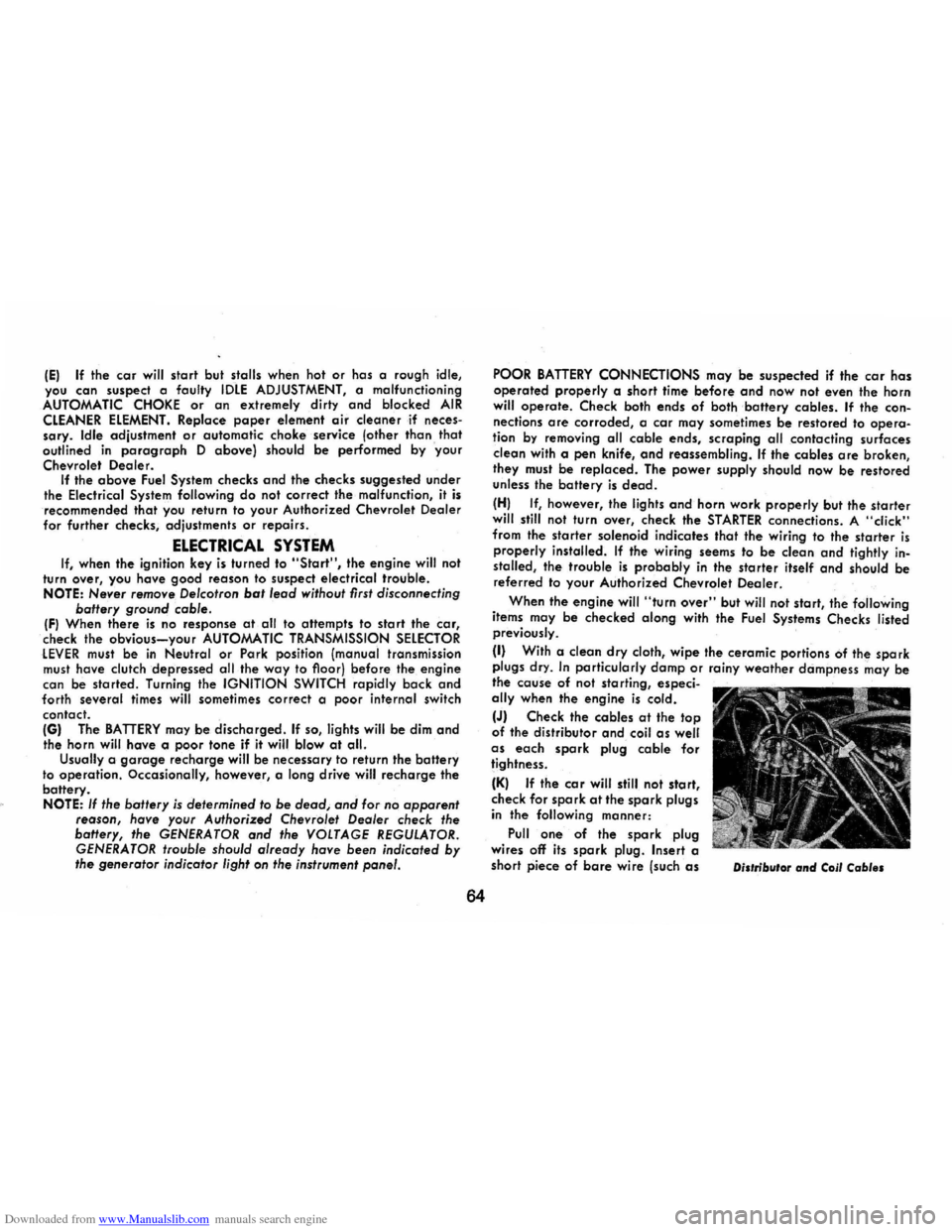

short piece of bare wire (such as Di.,ribu'or and Coil Cab I ••

Page 68 of 84

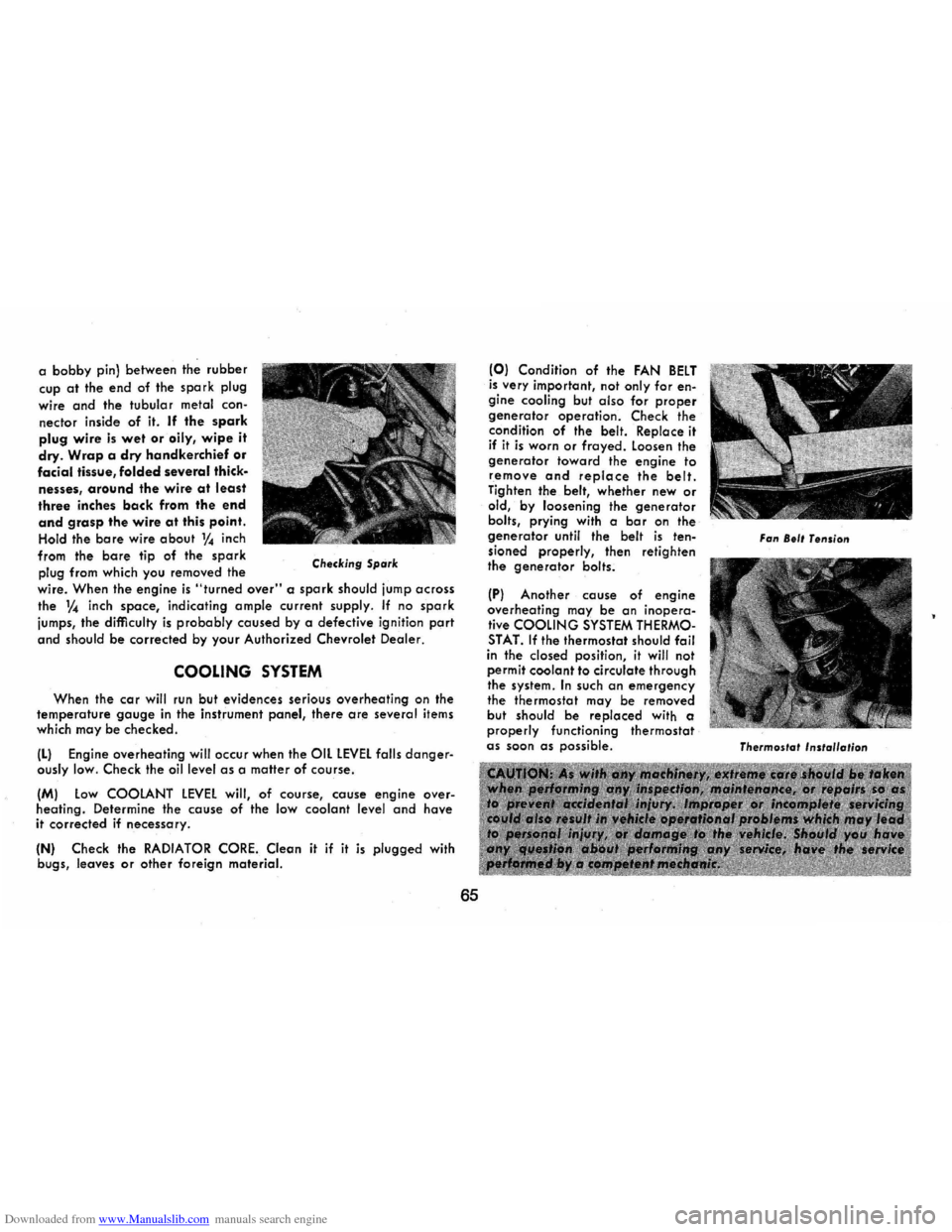

Downloaded from www.Manualslib.com manuals search engine a bobby pin) between the rubber

cup at the end of the spark plug

wire and the tubular metal con

nector inside of it. If the spark

plug wire is wet or oily, wipe it

dry. Wrap a dry handkerchief or facial tissue, folded several thick.

nesses, around the wire at least three inches back from the end

and grasp the wire at this point.

Hold the bare wire about 1f4 inch

from the

bare tip of the spark

plug from which you removed the Checking Spark

wire. When the engine is "turned over" a spark should jump across

the V" inch space, indicating ample current supply. If no spark

jumps, the difficulty is probably caused by a defective ignition port

and should be corrected by your Authorized Chevrolet Dealer.

COOLING SYSTEM

When the cor will run but evidences serious overheating on the temperature gauge in the instrument panel, there are several items

which may be checked .

(L) Engine overheating will occur when the OIL lEVEL falls dangerously low. Check the oil level as a matter of course.

(M) Low COOLANT LEVEL will , of course, couse engine overheating. Determine . the cause of the low coolant level and have

it corrected if necessary.

(N) Check the RADIATOR CORE. Clean it if it is plugged with

bugs, leaves or other foreign material.

65

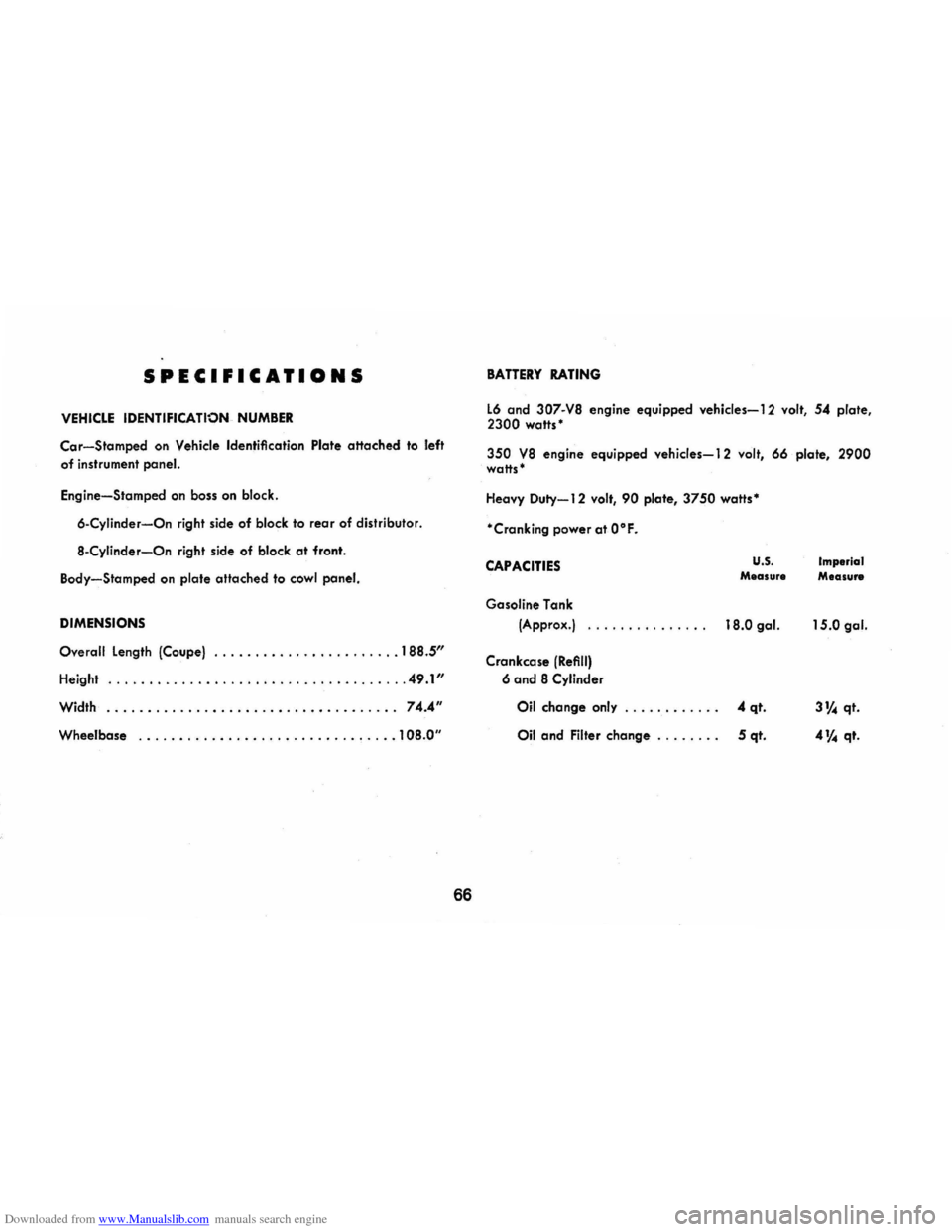

(0) Condition of the FAN BELT is very important, not only for engine cooling but also for proper generator operation. Check the

condition of the belt. Replace it if it is worn or frayed. Loosen the generator toward the engine to remove and replace the belt. Tighten the belt, whether new or old, by loosening the generator bolts, prying with a bar on the generator until the belt is tensioned properly, then retighten

the generator bolts.

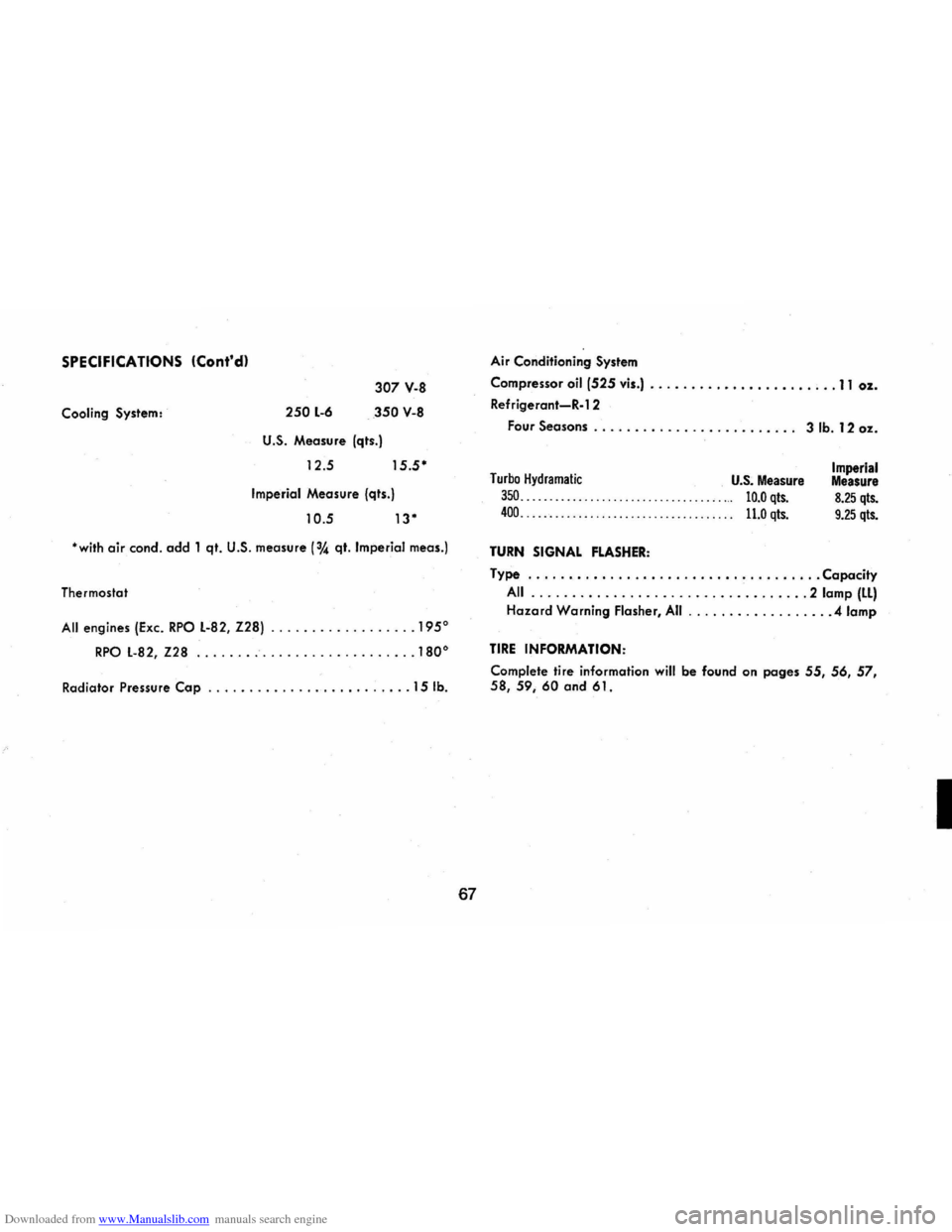

(PI Another couse of engine ove rheating may be on inopera

tive COOLING SYSTEM THERMOSTAT. If the thermostat should foil in the closed position, it will not

perm it coolant to circulate through

the system . In such on emergency the thermostat may be removed

but should be replaced with a properly functioning thermostat as soon as possible.

Fan 8.11 Tension

Thermoslal Inslollo/ion

Page 69 of 84

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS

VEHICLE IDENTIFICATION NUMBER

Car-Stamped on Vehicle Identification Plate attached to left

of instrument panel.

Engine-Stamped on boss on block.

6-Cylinder-On right side of block to rear of distributor.

S-Cylinder-On right side of block at front.

Body-Stamped

on plate attached to cowl panel.

DIMENSIONS

Overall Length (Coupe) ....................... 1 SS.5"

Height ..................................... 49.1"

Width .............•............•......... 74.4"

Wheelbase ................................ 10S.0"

66

BATTERY RATING

L6 and 307-VS engine equipped vehicles-I 2 volt, 54 plate, 2300 watts'

350 VS engine equipped vehicles-12 volt, 66 plate, 2900 watts'

Heavy Duty-I 2 volt, 90 plate, 3750 watts'

'Cranking power at O°F.

CAPACITIES

Gasoline Tank

(Approx.)

Crankcase

(Refill)

6 and S Cylinder

U.S. Measure

IS.O gal.

Oil

change only . . . . . . . . . . .. 4 qt.

Oil and Filter change . . . . . . .. 5 qt.

Imperial Measure

15.0 gal.

3% qt.

4% qt.

Page 70 of 84

Downloaded from www.Manualslib.com manuals search engine SPECIFICATIONS (Cont'dl

Cooling System: 250 L-6

307 V-8

350 V-8

U.S. Measure (qts.)

12.5

15.5·

Imperial Measure (qts.)

10.5 13·

·with air condo add 1 qt. U.S. measure (3,4 qt. Imperial meas.)

Thermostat

All engines (Exc. RPO L-82, Z28) .............. .... 1950

RPO L-82, Z28 ........................... 1800

Radiator Pressure Cap ......................... 15 lb.

67

Air Conditioning System

Compressor

oil (525 vis.) .................... , .. 11 oz.

Refrigerant-R-l 2

Four

Seasons . . . . . . . . . . . . . . . . . . . . . . . .. 3 lb. 12 oz.

Turbo Hydramatic U.S. Measure

350. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ... 10.0 qts.

400. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.0 qts.

TURN SIGNAL FLASHER:

Imperial Measure

8.25 qts.

9.25 qts.

Type .................................... Capacity

All .................................. 2 lamp (LL)

Hazard Warning Flasher, All ................. .4 lamp

TIRE INFORMATION:

Complete tire information will be found on pages 55, 56, 57, 58,59,60 and 61.

I