clock CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 629 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 629

as much voltage to fire the plug at hi

gh speeds than at idle. The improved

air/fuel ratio control of modern fuel injection combin ed with the higher voltage

output of modern ignition systems will often allow an engine to run significantly

longer on a set of standard spark plugs, but keep in mind that efficiency will

drop as the gap widens (along wit h fuel economy and power).

When you're removing spark plugs, work on one at a time. Don't start by

removing the plug wires all at once, because, unless you number them, they

may become mixed up. Take a minute before you begin and number the wires

with tape.

1. Disconnect the negative battery cabl e, and if the vehicle has been run

recently, allow the engine to thoroughly cool.

2. Carefully twist the spark plug wire boot to loosen it, then pull upward and

remove the boot from the plug. Be su re to pull on the boot and not on the

wire, otherwise the connector locat ed inside the boot may become

separated.

3. Using compressed air, blow any water or debris from the spark plug well

to assure that no harmful contam inants are allowed to enter the

combustion chamber when the spark plug is removed. If compressed air

is not available, use a rag or a brush to clean the area.

Remove the spark plugs when the engine is cold, if possible, to prevent damage

to the threads. If removal of the plugs is difficult, apply a few drops of

penetrating oil or silicone spray to t he area around the base of the plug, and

allow it a few minutes to work.

4. Using a spark plug socket that is equipped with a rubber insert to

properly hold the plug, turn the spar k plug counterclockwise to loosen

and remove the spark pl ug from the bore.

WARNING - Be sure not to use a flexible extension on the socket. Use of a

flexible extension may allow a shear fo rce to be applied to the plug. A shear

force could break the plug off in the cylinder head, leading to costly a\

nd

frustrating repairs.

To install:

5. Inspect the spark plug boot for t ears or damage. If a damaged boot is

found, the spark plug wire must be replaced.

6. Using a wire feeler gauge, check and adjust the spark plug gap. When

using a gauge, the proper size shoul d pass between the electrodes with

a slight drag. The next larger size should not be able to pass while the\

next smaller size should pass freely.

7. Carefully thread the plug into the bor e by hand. If resistance is felt before

the plug is almost completely th readed, back the plug out and begin

threading again. In small, hard to r each areas, an old spark plug wire and

boot could be used as a th reading tool. The boot will hold the plug while

you twist the end of the wire and t he wire is supple enough to twist

before it would allow t he plug to crossthread.

Page 635 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 635

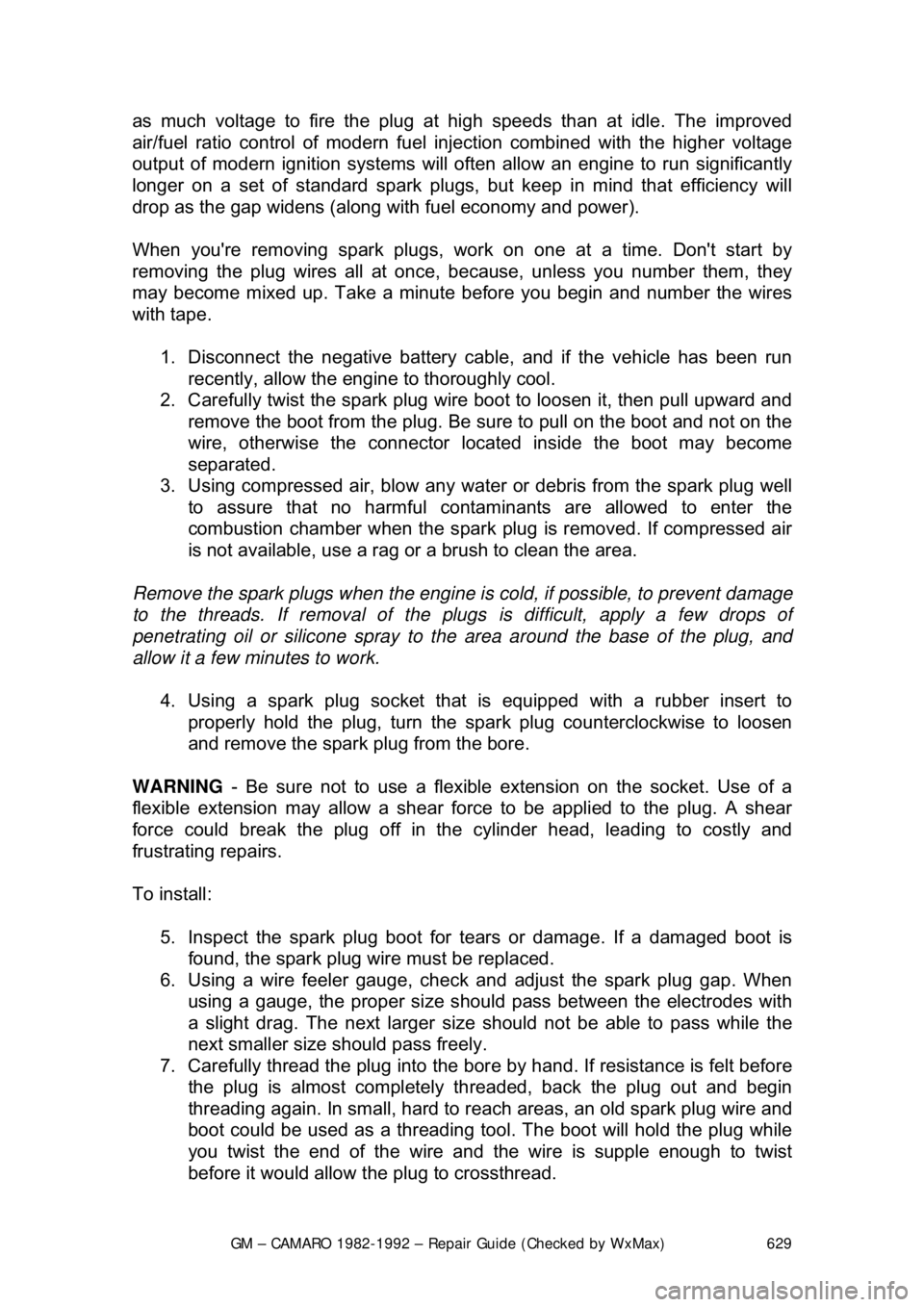

FIRING ORDERS

To avoid confusion, remove and tag th

e spark plug wires one at a time, for

replacement.

If a distributor is not keyed for installati on with only one orientation, it could have

been removed previously and rewired. Th e resultant wiring would hold the

correct firing order, but could change the relative placement of the plug towers

in relation to the engine. Fo r this reason it is imperative that you label all wires

before disconnecting any of them. Also, before removal, compare the current

wiring with the accompanying i llustrations. If the current wiring does not match,

make notes, to reflect how your engine is wired.

Fig. 1: 2.5L Engine - Engine firing or der: 1-3-4-2- Distributor Rotation:

Clockwise

Page 636 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 636

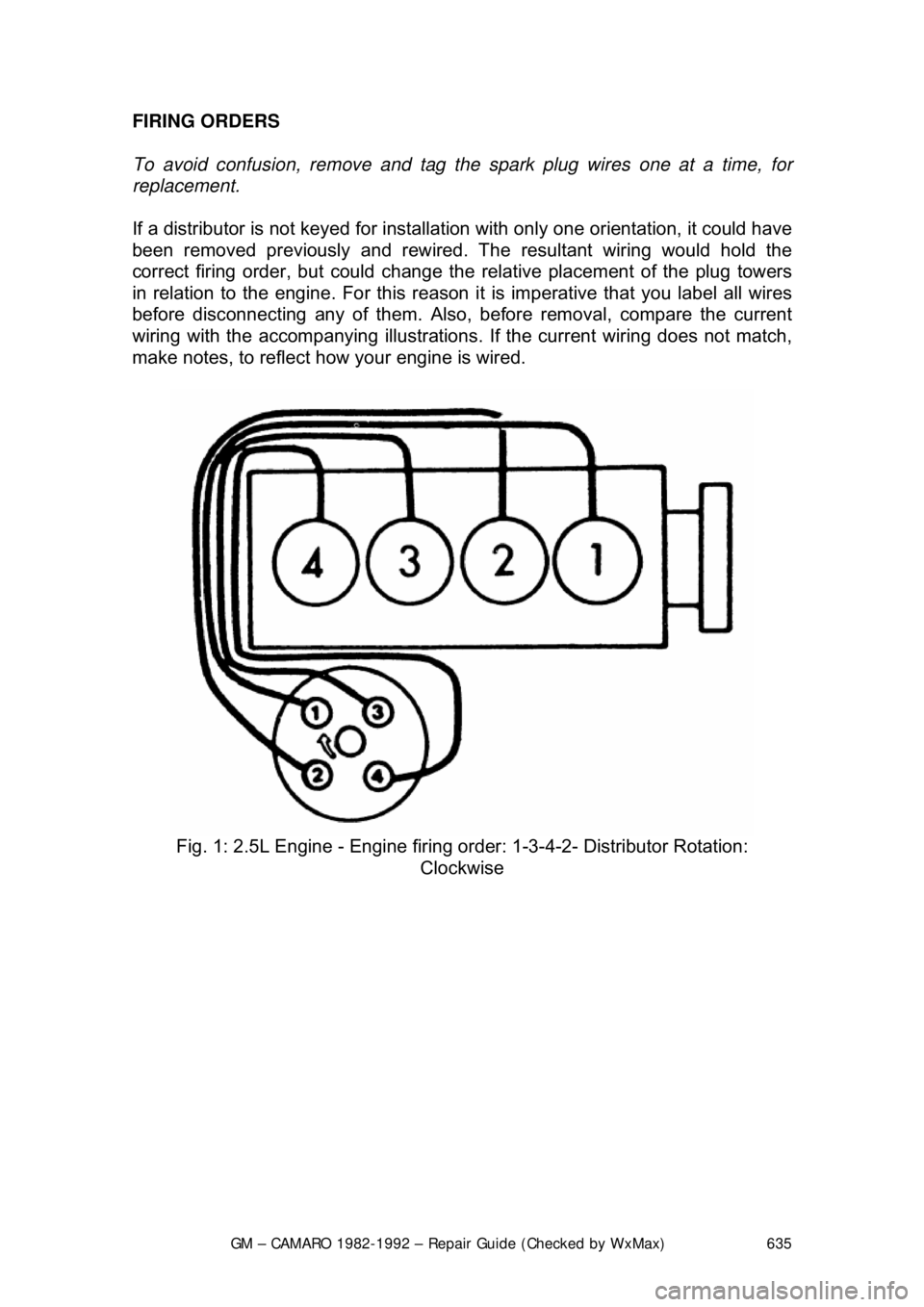

Fig. 2: 2.8L Engine - Engine firing or der: 1-2-3-4-5- Distributor Rotation:

Clockwise

Fig. 3: 3.1L Engine - Engine firing order : 1-2-3-4-5-6- Distributor Rotation:

Clockwise

Page 637 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 637

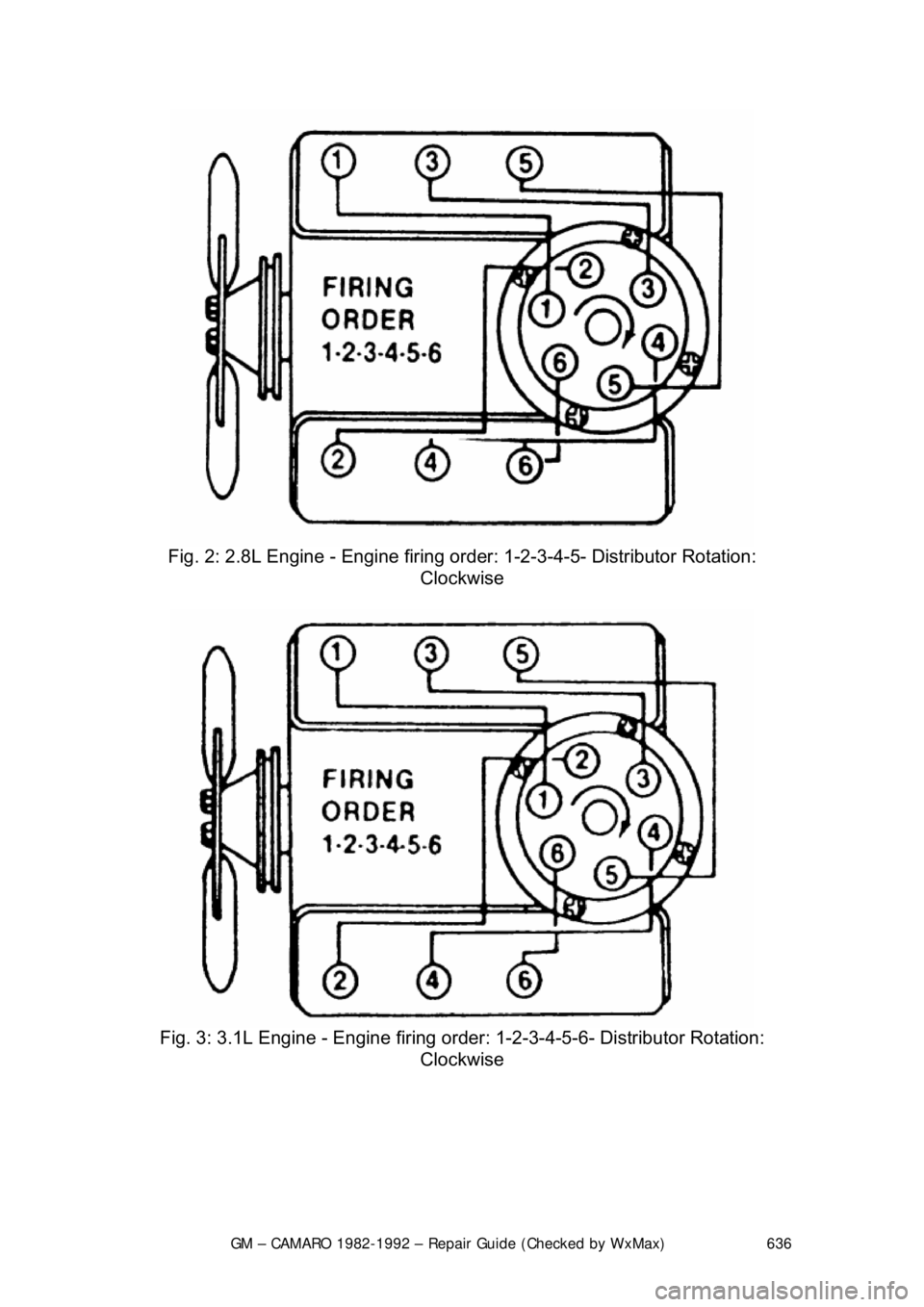

Fig. 4: 5.0L and 5.7L (VIN 8) Engines - Engine firing order: 1-8-4-3-6-5-7-2-

Distributor Rotation: Clockwise

It should be remembered that resistance is also a function of length; the longer

the wire, the greater the re sistance. Thus, if the wires on your car are longer

than the factory originals, resistance will be higher, qui te possibly outside these

limits.

When installing new wires, r eplace them one at a time to avoid mix-ups. If it

becomes necessary to remove all of the wires from the distributor cap or coil

packs at one time, take the time to label the distributor cap/coil pack towers to

denote the cylinder number of the wire fo r that position. When this is done,

incorrect positioning of wires can more eas ily be avoided. Start by replacing the

longest one first. Route the wire over the same path as the original and secure

in place.

Page 650 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 650

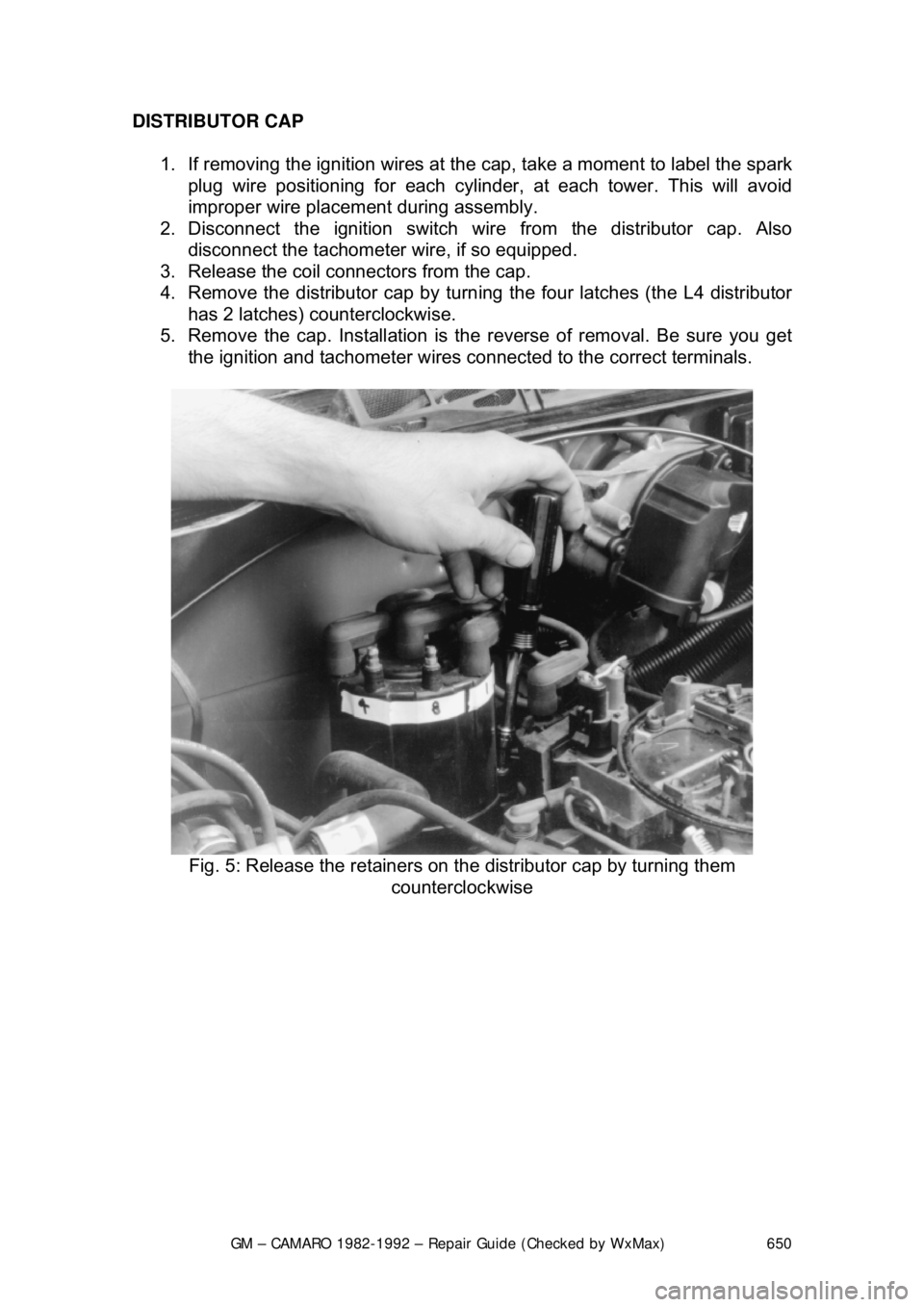

DISTRIBUTOR CAP

1. If removing the ignition wires at the cap, take a moment to label the spark

plug wire positioning for each cylinder, at each tower. This will avoid

improper wire placement during assembly.

2. Disconnect the ignition switch wir e from the distributor cap. Also

disconnect the tachometer wire, if so equipped.

3. Release the coil connec tors from the cap.

4. Remove the distributor cap by turn ing the four latches (the L4 distributor

has 2 latches) counterclockwise.

5. Remove the cap. Installation is the reverse of removal. Be sure you get

the ignition and tachometer wires c onnected to the correct terminals.

Fig. 5: Release the retainers on t he distributor cap by turning them

counterclockwise

Page 672 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 672

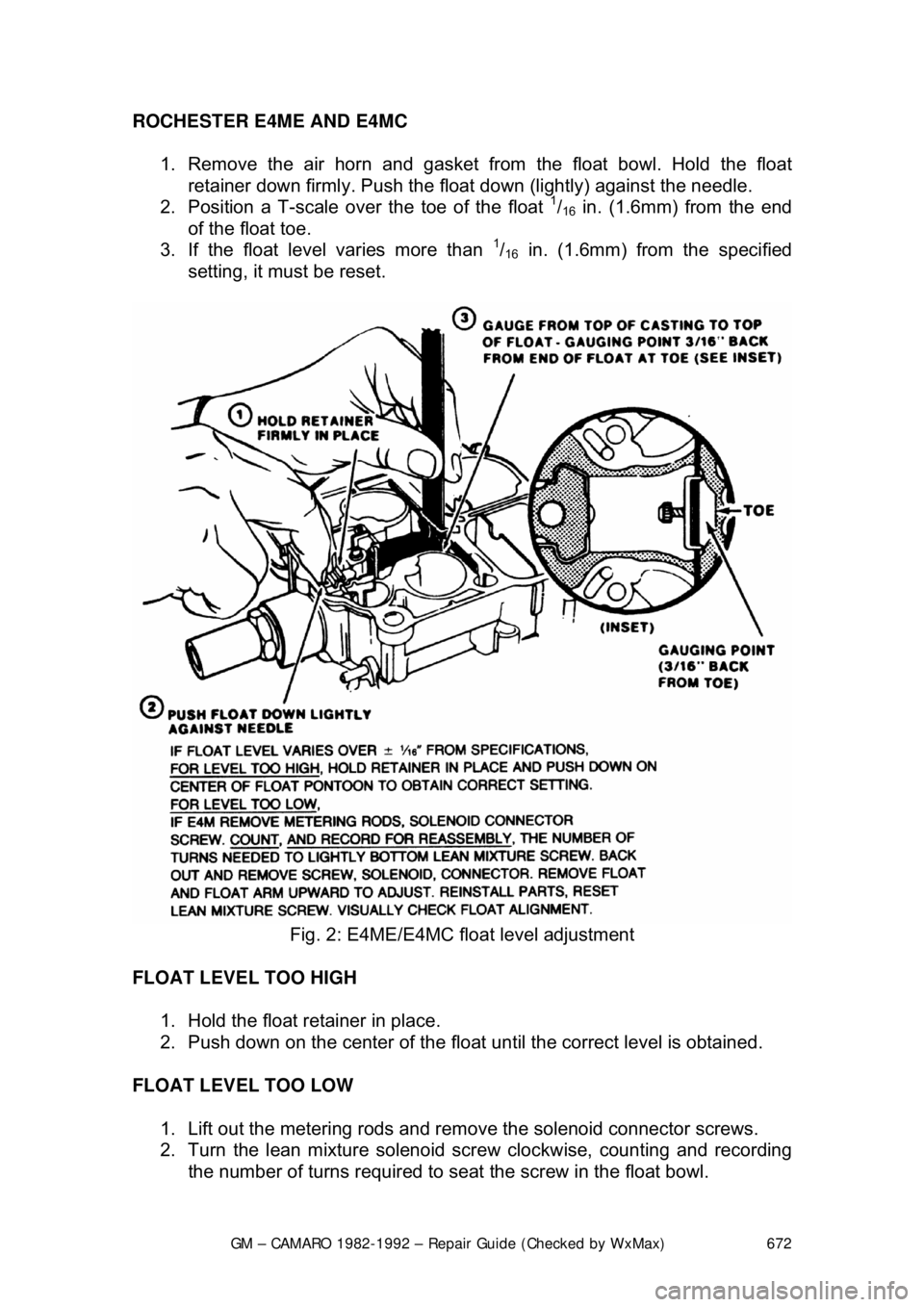

ROCHESTER E4ME AND E4MC

1. Remove the air horn and gasket from the float bowl. Hold the float retainer down firmly. Push the float down (lightly) against the needle.

2. Position a T-scale ov er the toe of the float

1/16 in. (1.6mm) from the end

of the float toe.

3. If the float level varies more than

1/16 in. (1.6mm) from the specified

setting, it must be reset.

Fig. 2: E4ME/E4MC float level adjustment

FLOAT LEVEL TOO HIGH 1. Hold the float retainer in place.

2. Push down on the center of the float until the correct level is obtained.

FLOAT LEVEL TOO LOW 1. Lift out the metering rods and remo ve the solenoid connector screws.

2. Turn the lean mixture solenoid screw clockwise, counting and recording

the number of turns required to seat the screw in the float bowl.

Page 673 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 673

3. Turn the screw counterclockwise and

remove it. Lift the solenoid and the

connector from the float bowl.

4. Remove the float and bend the arm up to adjust. The float must be

correctly aligned after adjustment.

5. To install the components, reverse the order of removal. Back out the

solenoid mixture screw t he number of turns that wa s recorded earlier.

THROTTLE LINKAGE

ROCHESTER E2SE

No adjustment of the thro ttle cable can be made.

ROCHESTER E4ME AND E4MC

Due to the design of the throttle cable, no adjustments of the throttle linkage can

be made.

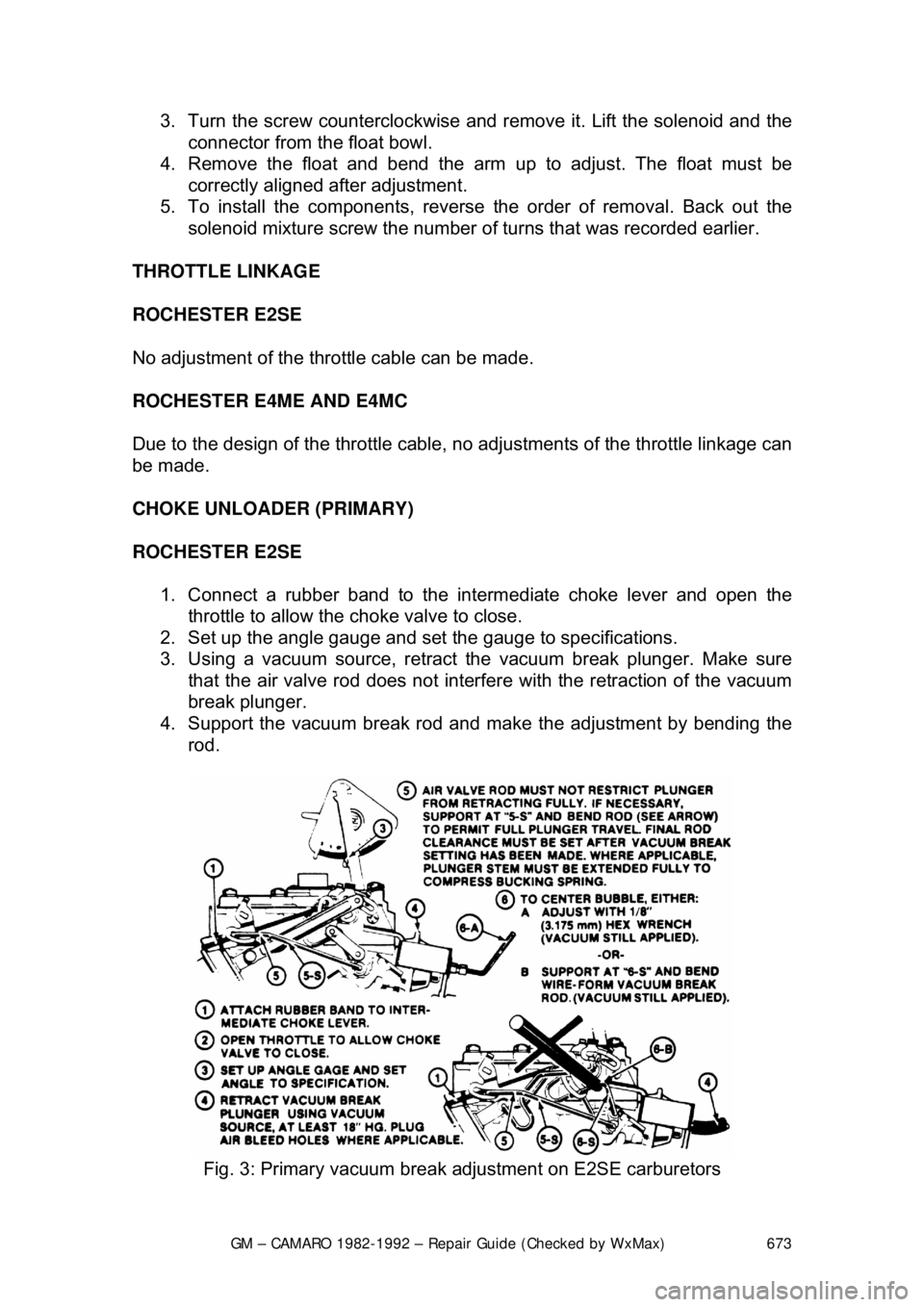

CHOKE UNLOADER (PRIMARY)

ROCHESTER E2SE

1. Connect a rubber band to the in termediate choke lever and open the

throttle to allow the choke valve to close.

2. Set up the angle gauge and set the gauge to specifications.

3. Using a vacuum source, retract the vacuum break plunger. Make sure

that the air valve rod does not interf ere with the retraction of the vacuum

break plunger.

4. Support the vacuum br eak rod and make the adjustment by bending the

rod.

Fig. 3: Primary vacuum break adjustment on E2SE carburetors

Page 676 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 676

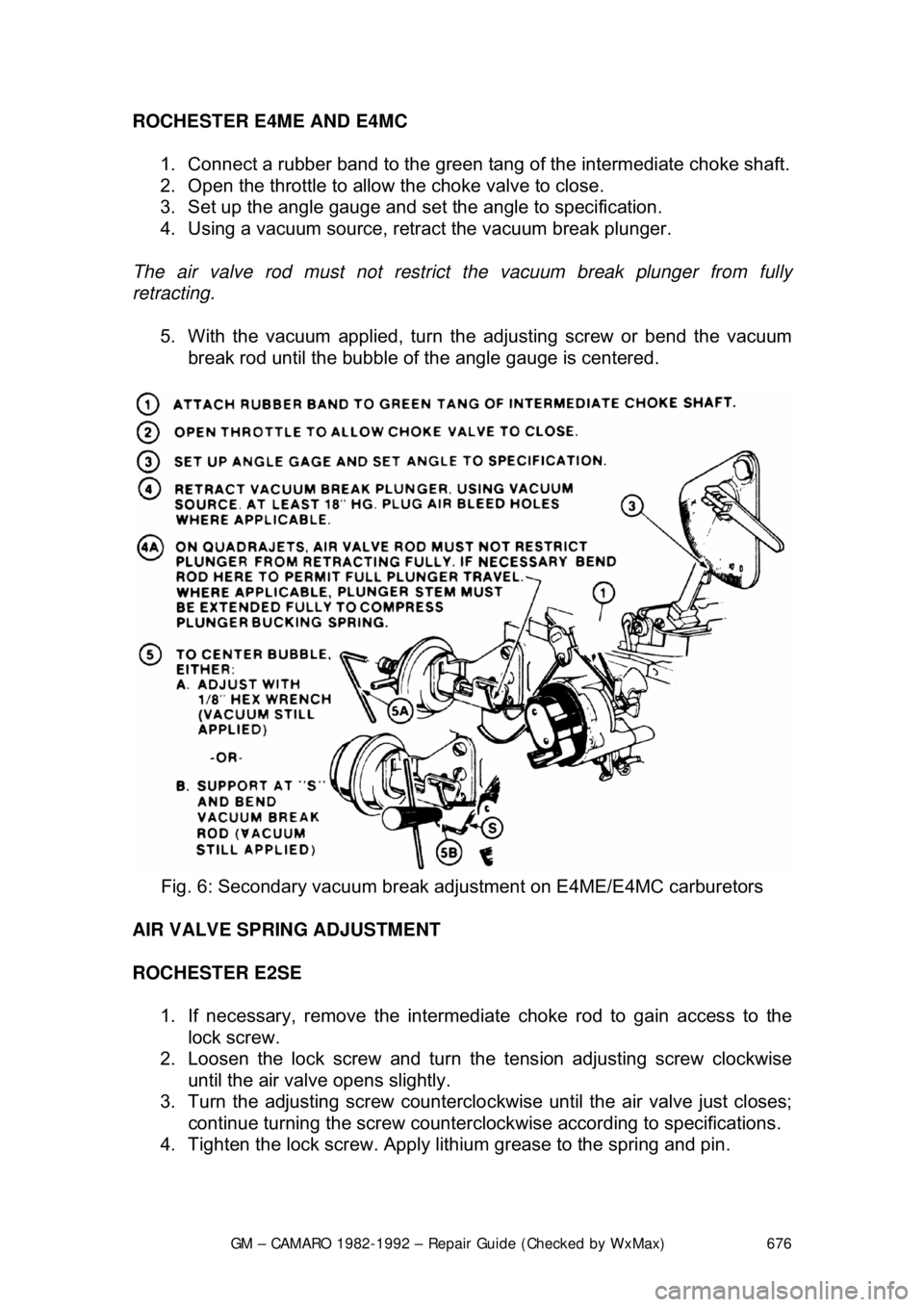

ROCHESTER E4ME AND E4MC

1. Connect a rubber band to the green tang of the intermediate choke shaft.

2. Open the throttle to allow the choke valve to close.

3. Set up the angle gauge and set the angle to specification.

4. Using a vacuum source, retr act the vacuum break plunger.

The air valve rod must not restrict the vacuum break plunger from fully

retracting.

5. With the vacuum applied, turn t he adjusting screw or bend the vacuum

break rod until the bubble of t he angle gauge is centered.

Fig. 6: Secondary vacuum break adj ustment on E4ME/E4MC carburetors

AIR VALVE SPRING ADJUSTMENT

ROCHESTER E2SE 1. If necessary, remove the intermediat e choke rod to gain access to the

lock screw.

2. Loosen the lock screw and turn t he tension adjusting screw clockwise

until the air valve opens slightly.

3. Turn the adjusting screw counterclo ckwise until the air valve just closes;

continue turning the screw counterclock wise according to specifications.

4. Tighten the lock screw. Apply lithium grease to the spring and pin.

Page 678 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 678

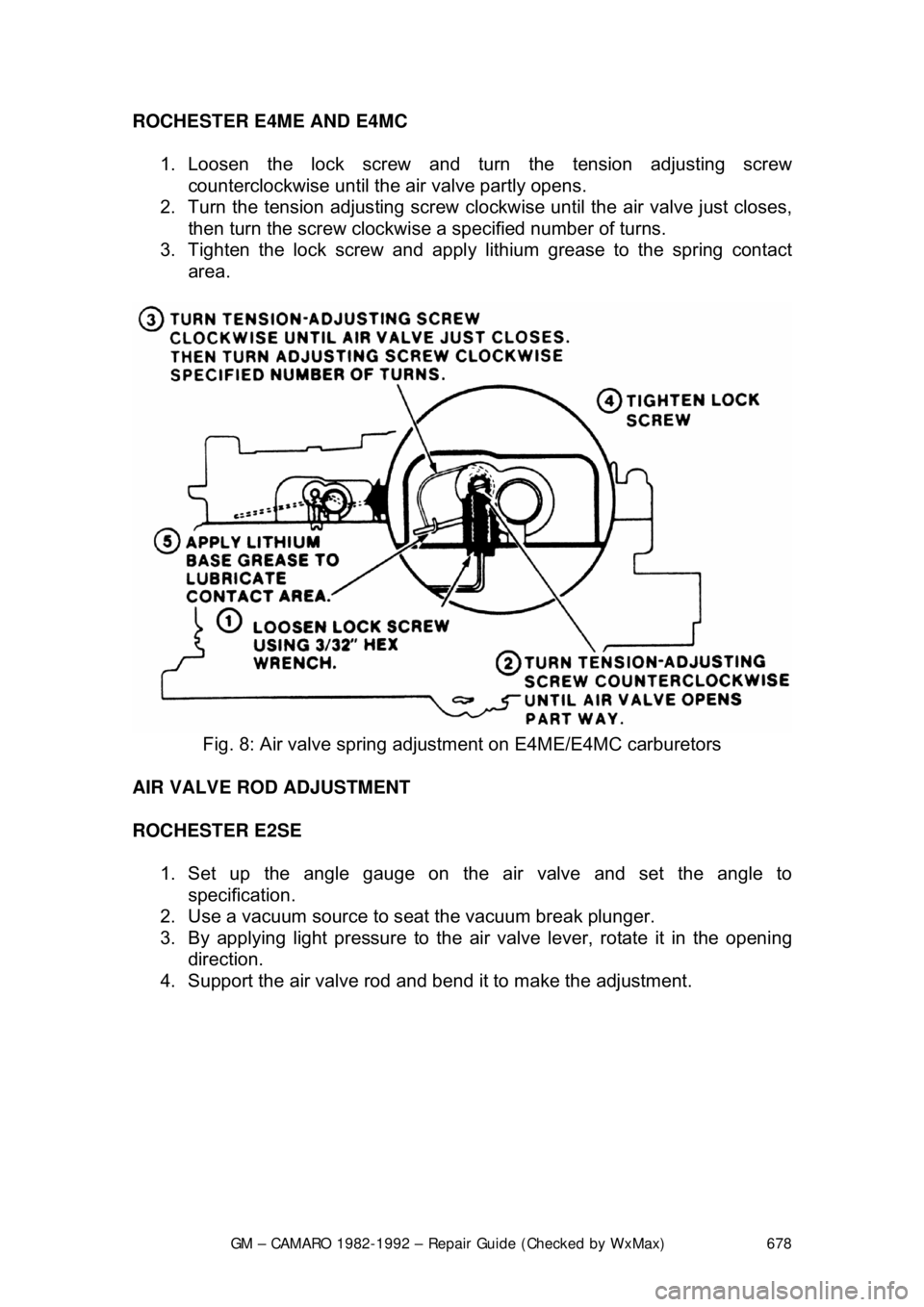

ROCHESTER E4ME AND E4MC

1. Loosen the lock screw and turn the tension adjusting screw counterclockwise until the air valve partly opens.

2. Turn the tension adjus ting screw clockwise until t he air valve just closes,

then turn the screw clockwise a specified number of turns.

3. Tighten the lock screw and apply lithium grease to the spring contact

area.

Fig. 8: Air valve spring adjus tment on E4ME/E4MC carburetors

AIR VALVE ROD ADJUSTMENT

ROCHESTER E2SE 1. Set up the angle g auge on the air valve and set the angle to

specification.

2. Use a vacuum source to s eat the vacuum break plunger.

3. By applying light pressure to the ai r valve lever, rotate it in the opening

direction.

4. Support the air valve rod and bend it to make the adjustment.

Page 689 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 689

c. Foreign material in jets

3. Remove throttle side metering rod. Install mixture control solenoid

gauging tool, J-33815-1, BT-8253-A, or equi valent, over the throttle side

metering jet rod guide and temporarily reinstall the solenoid plunger into

the solenoid body.

4. Holding the solenoid plunger in the DOWN position, use tool J-28696-10,

BT-7928, or equivalent, to turn lean mixture solenoid screw

counterclockwise until the plunger br eaks contact with the gauging tool.

Turn slowly clockwise until the pl unger makes contact with the gauging

tool. The adjustment is correct when t he solenoid plunger is contacting

both the solenoid stop and the gauging tool.

If the total difference in adjustment required less than

3/4 turn of the lean mixture

solenoid screw, the original setting was within the manufacturer's specifications.

5. Remove solenoid plunger and gaugi ng tool and reinstall metering rod

and plastic filler block.

6. Invert air horn and remove rich mixt ure stop screw from bottom side of

air horn, using tool J-28696-4, BT-7967-A, or equivalent.

7. Remove lean mixture screw plug and the rich mixture stop screw plug

from air horn, using a punch.

8. Reinstall rich mixtur e stop screw in air horn and bottom lightly, then back

screw out

1/4 turn.

9. Reinstall air horn gasket, mixture c ontrol solenoid plunger and air horn to

carburetor.

10. Adjust the M/C solenoid pl unger travel as follows:

a. Insert float gauge down D- shaped vent hole. Press down on

gauge and release, observing th at the gauge moves freely and

does not bind. With gauge released, (plunger UP position), read at

eye level and record the reading of the gauge mark (in

inches/millimeters) that lines up with the top of air horn casting,

(upper edge).

b. Lightly press dow n on gauge until bottomed, (plunger DOWN

position). Read and record (in inc hes/millimeters) the reading of

the gauge mark that lines up with top of air horn casting.

c. Subtract gauge UP position from the gauge DOWN position and

record the difference. This difference is the total plunger travel.

Insert external float gauge in vent hole and, with tool J-28696-10,

BT-7928, or equivalent, adjust rich mixture stop screw to obtain

5/32 in. (3.9mm) total plunger travel.

11. With solenoid plunger travel corre ctly set, install plugs (supplied in

service kits) in the air horn, as follows:

a. Install plug, hollow end down, into the access hole for the lean

mixture (solenoid) screw. Use suit ably sized punch to drive plug

into the air horn until t he top of plug is even with the lower. Plug

must be installed to retain the sc rew setting and to prevent fuel

vapor loss.