engine CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 151 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 151

ARMING THE SYSTEM

1. Turn the ignition key to the LO CK position and remove the key.

2. On vehicles with a passenger side ai r bag, reconnect the yellow two-way

connector assembly located near the yellow 24-way DERM harness

connector. Install the glov e box door assembly.

3. Connect the yellow two-way connector assembly at the base of the

steering column.

Always be sure to reinstall the Connec tor Position Assurance (CPA) device.

4. Install the left side trim panel and rein stall the fuse in the fuse block.

5. Turn the ignition key to the RUN posit ion and verify that the warning lamp

flashes seven to nine times and then turn s OFF. If it does not operate as

described, have the system repair ed by a qualified technician.

HEATING AND AIR CONDITIONING

BLOWER MOTOR

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable. If necessary, remove the diagonal

fender brace at the right rear corner of the engine compartment to gain

access to the blower motor.

2. Disconnect the electrical wiring fr om the blower motor. If equipped with

air conditioning, remove the blower relay and bracket as an assembly

and swing them aside.

3. Remove the blower motor cooling tube.

4. Remove the blower mo tor retaining screws.

5. Remove the blower motor and fan as an assembly from the case.

To install: 6. Position the blower motor into pl ace and install the retaining screws.

7. Install the blower motor cooling tube.

8. Connect all the electrical connections.

9. Connect the negative battery cable.

Page 158 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 158

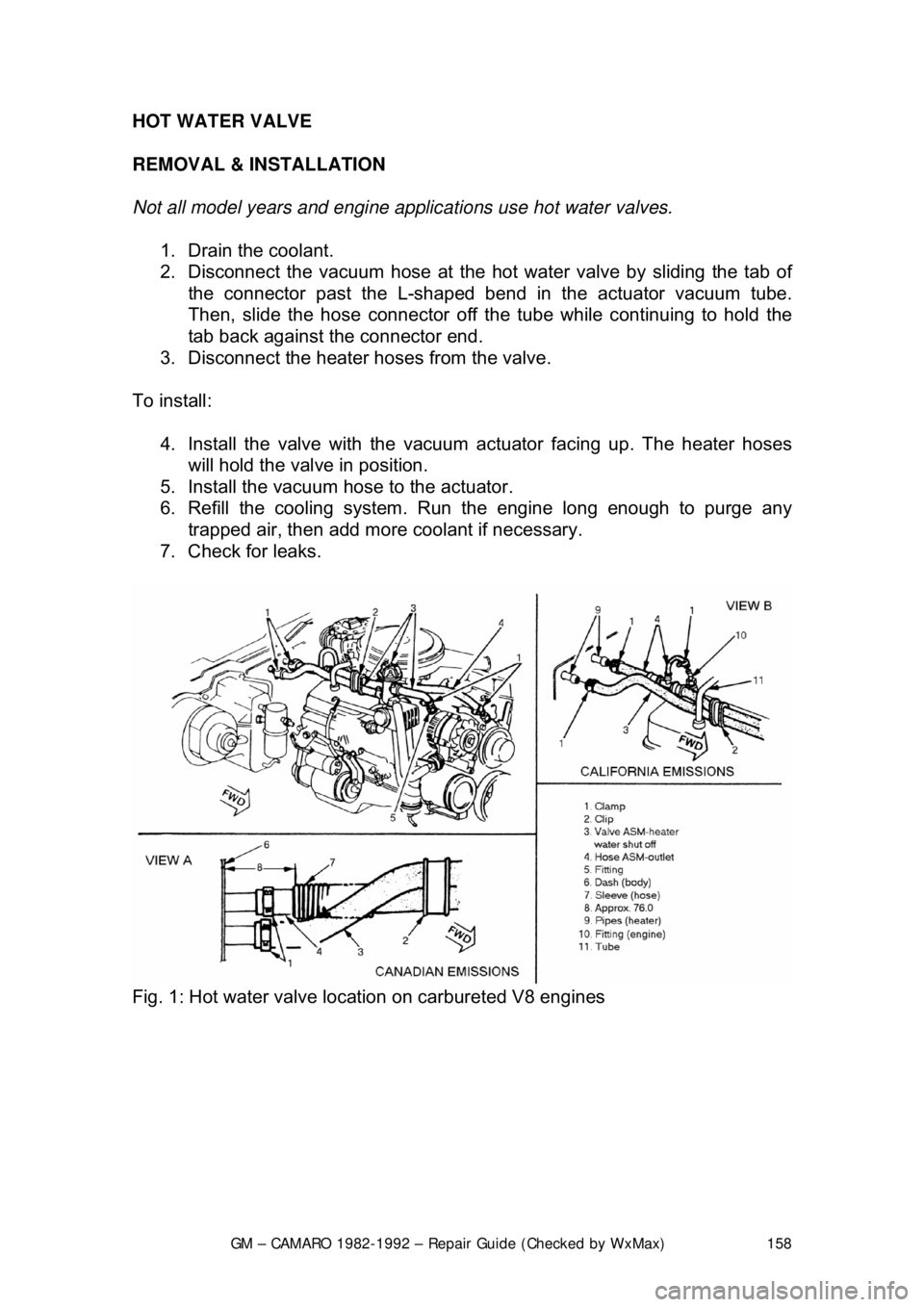

HOT WATER VALVE

REMOVAL & INSTALLATION

Not all model years and engine applic

ations use hot water valves.

1. Drain the coolant.

2. Disconnect the vacuum hose at the hot water valve by sliding the tab of

the connector past the L-shaped bend in the ac tuator vacuum tube.

Then, slide the hose connector off the tube while continuing to hold the

tab back against the connector end.

3. Disconnect the heater hos es from the valve.

To install: 4. Install the valve with the vacuum actuator faci ng up. The heater hoses

will hold the valve in position.

5. Install the vacuum hose to the actuator.

6. Refill the cooling system. R un the engine long enough to purge any

trapped air, then add more coolant if necessary.

7. Check for leaks.

Fig. 1: Hot water valve loca tion on carbureted V8 engines

Page 159 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 159

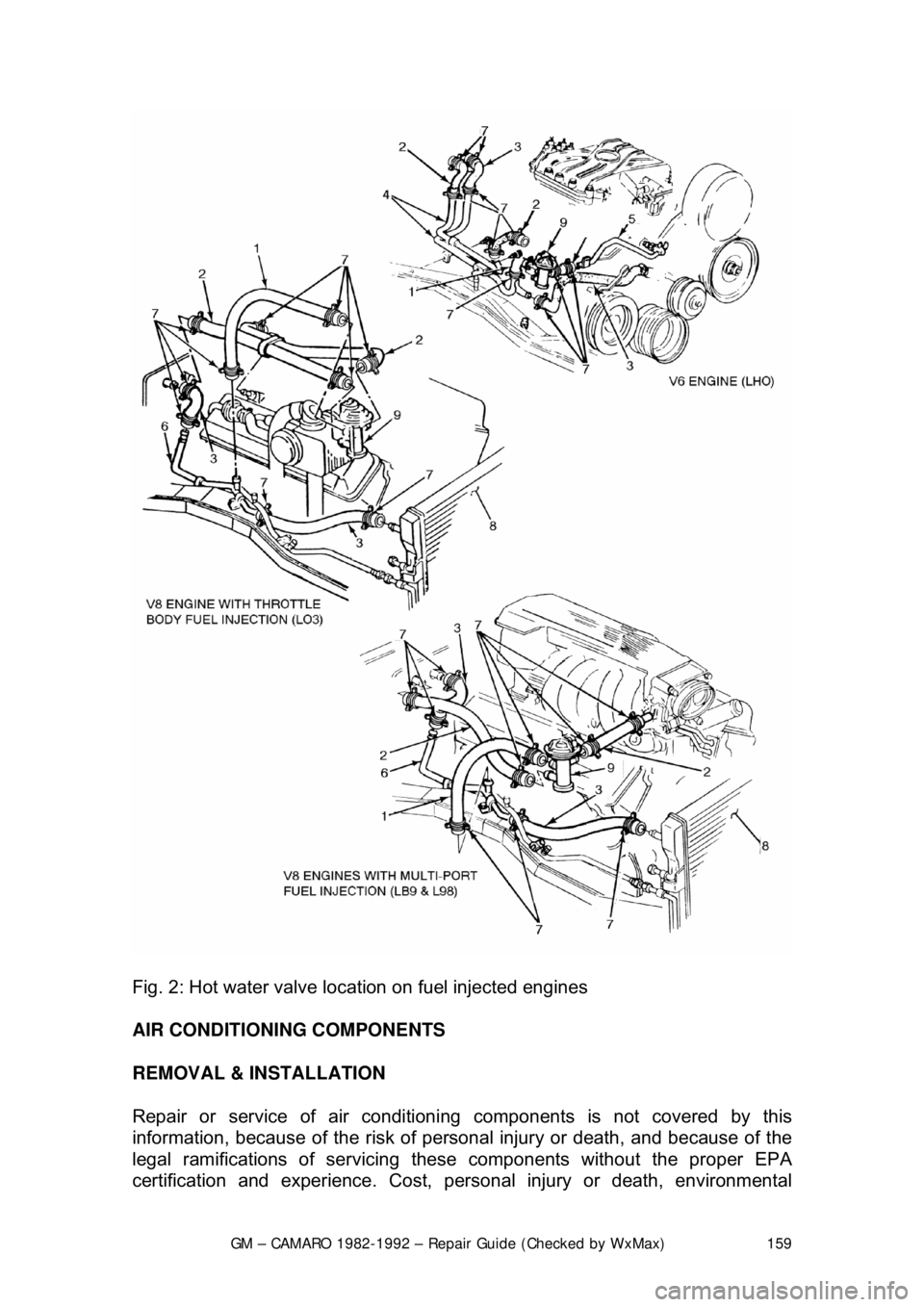

Fig. 2: Hot water valve location on fuel injected engines

AIR CONDITIONING COMPONENTS

REMOVAL & INSTALLATION

Repair or service of air conditioni ng components is not covered by this

information, because of the risk of personal injury or death, and because of the

legal ramifications of servicing these components without the proper EPA

certification and experience. Cost, perso nal injury or death, environmental

Page 170 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 170

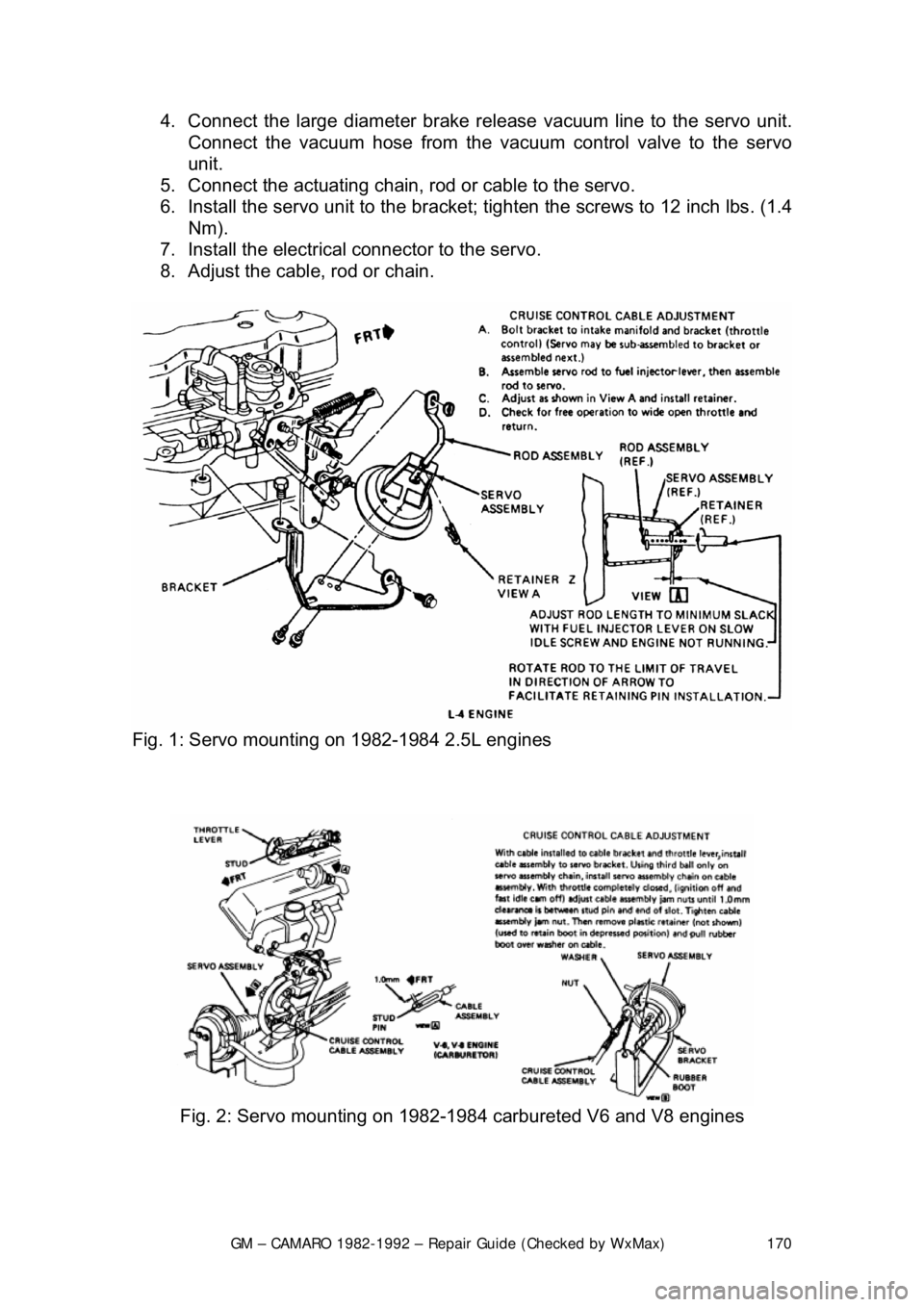

4. Connect the large diamet

er brake release vacuum line to the servo unit.

Connect the vacuum hose from the va cuum control valve to the servo

unit.

5. Connect the actuating chain, rod or cable to the servo.

6. Install the servo unit to the bracket; tighten the screws to 12 inch lbs. (1.4

Nm).

7. Install the electrical connector to the servo.

8. Adjust the cable, rod or chain.

Fig. 1: Servo mounting on 1982-1984 2.5L engines

Fig. 2: Servo mounting on 1982-1984 carbureted V6 and V8 engines

Page 171 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 171

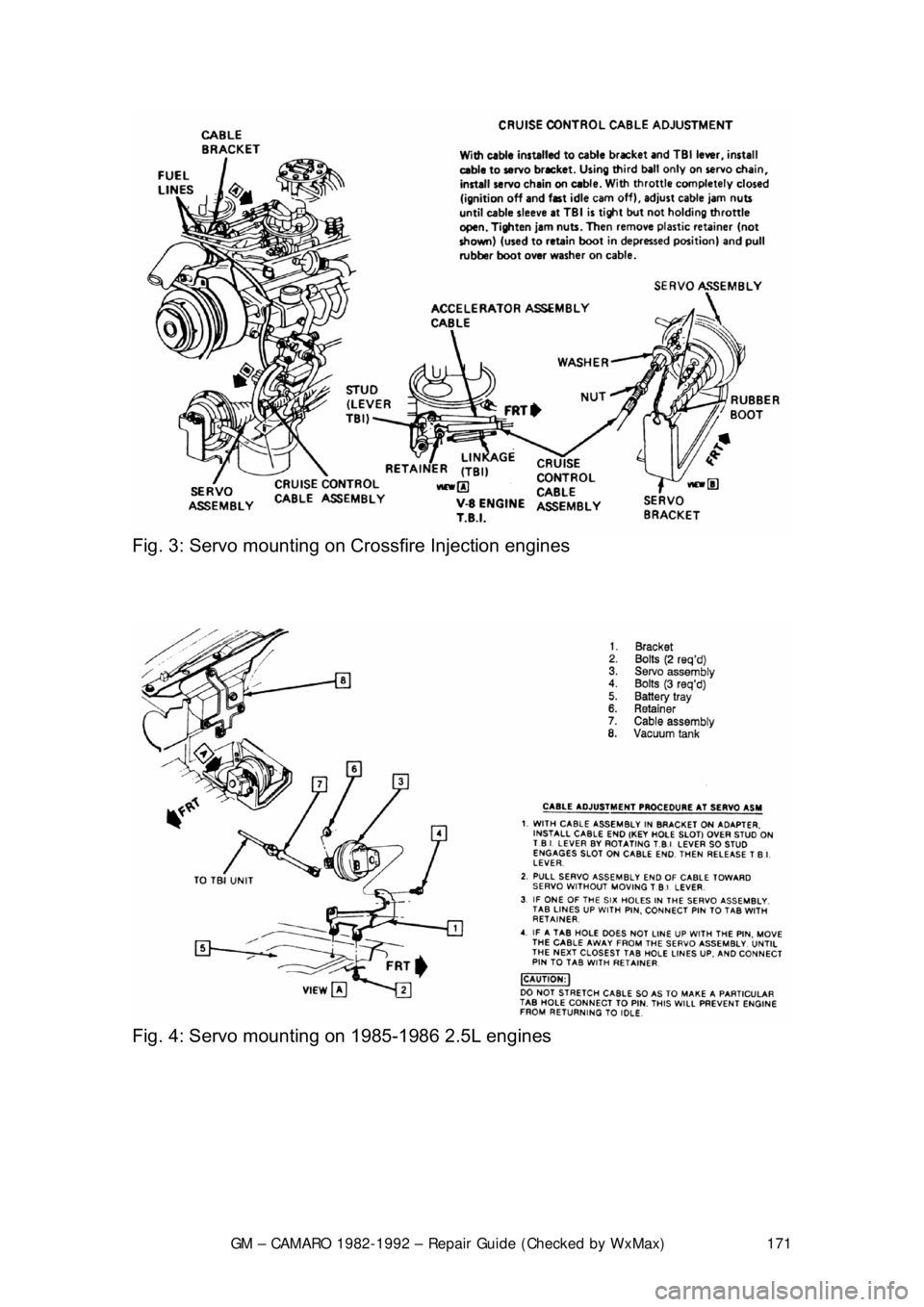

Fig. 3: Servo mounting on Cr ossfire Injection engines

Fig. 4: Servo mounting on 1985-1986 2.5L engines

Page 172 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 172

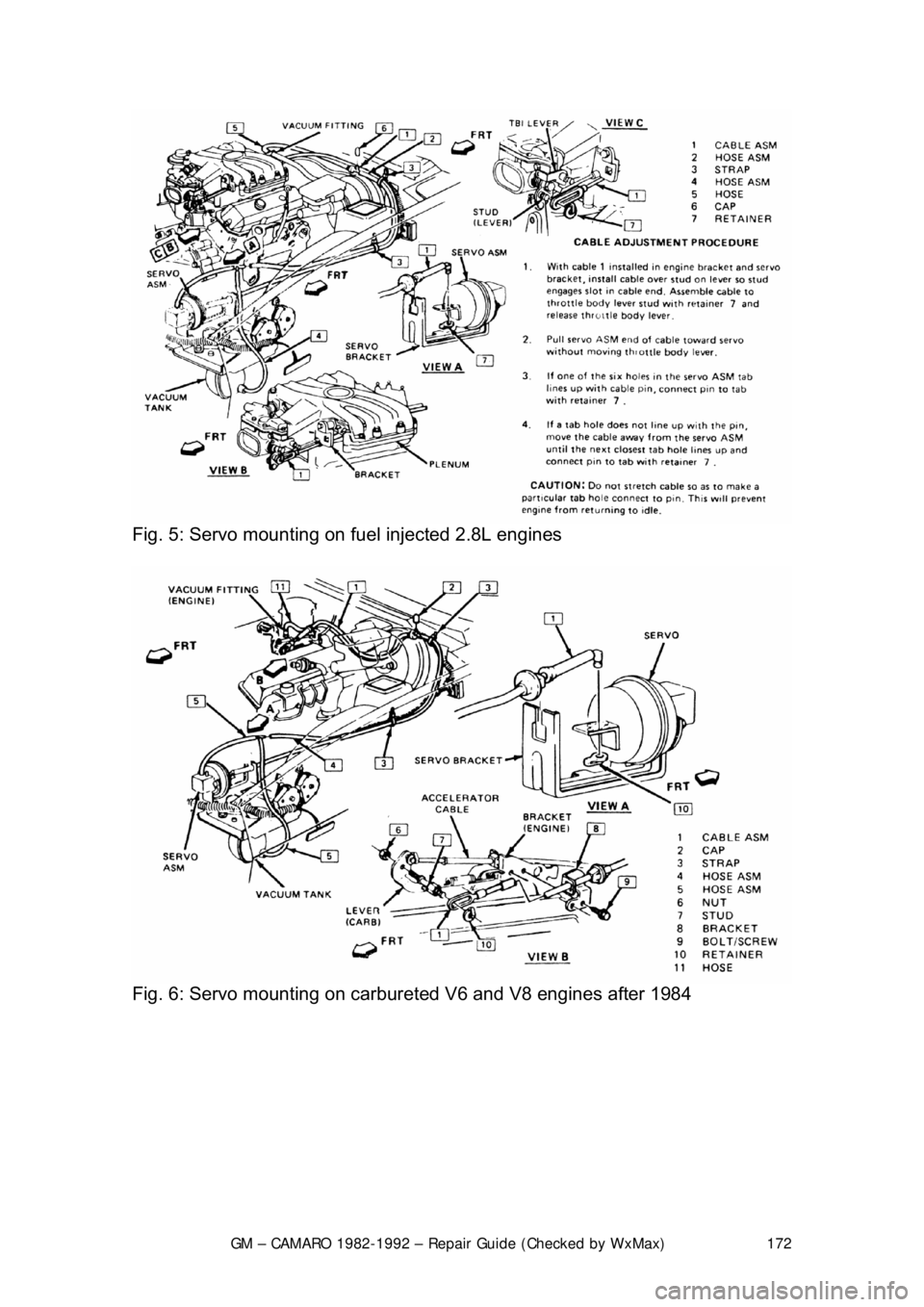

Fig. 5: Servo mounting on fuel injected 2.8L engines

Fig. 6: Servo mounting on carbur eted V6 and V8 engines after 1984

Page 173 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 173

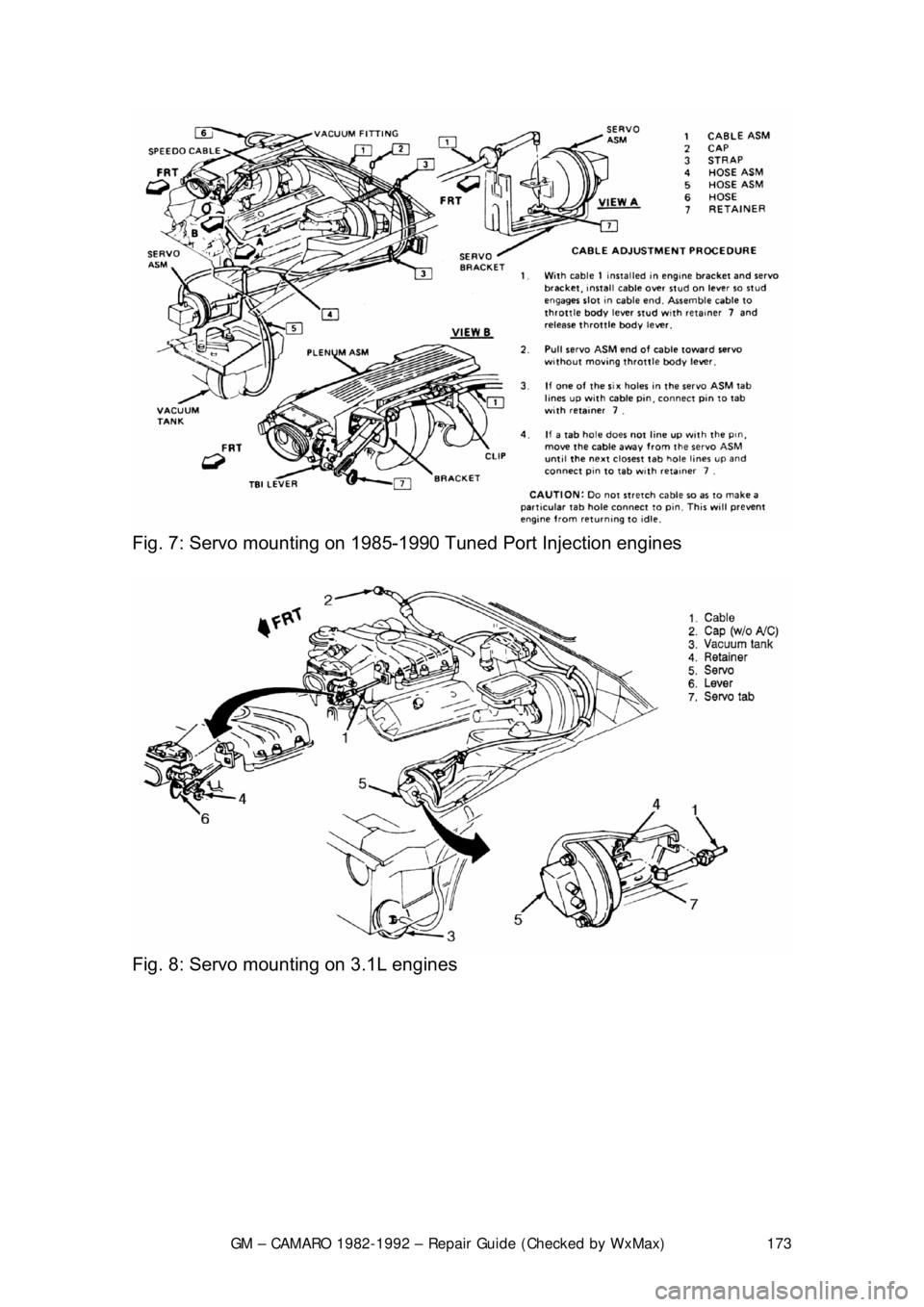

Fig. 7: Servo mounting on 1985-1990 Tuned Port Injection engines

Fig. 8: Servo mounting on 3.1L engines

Page 174 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 174

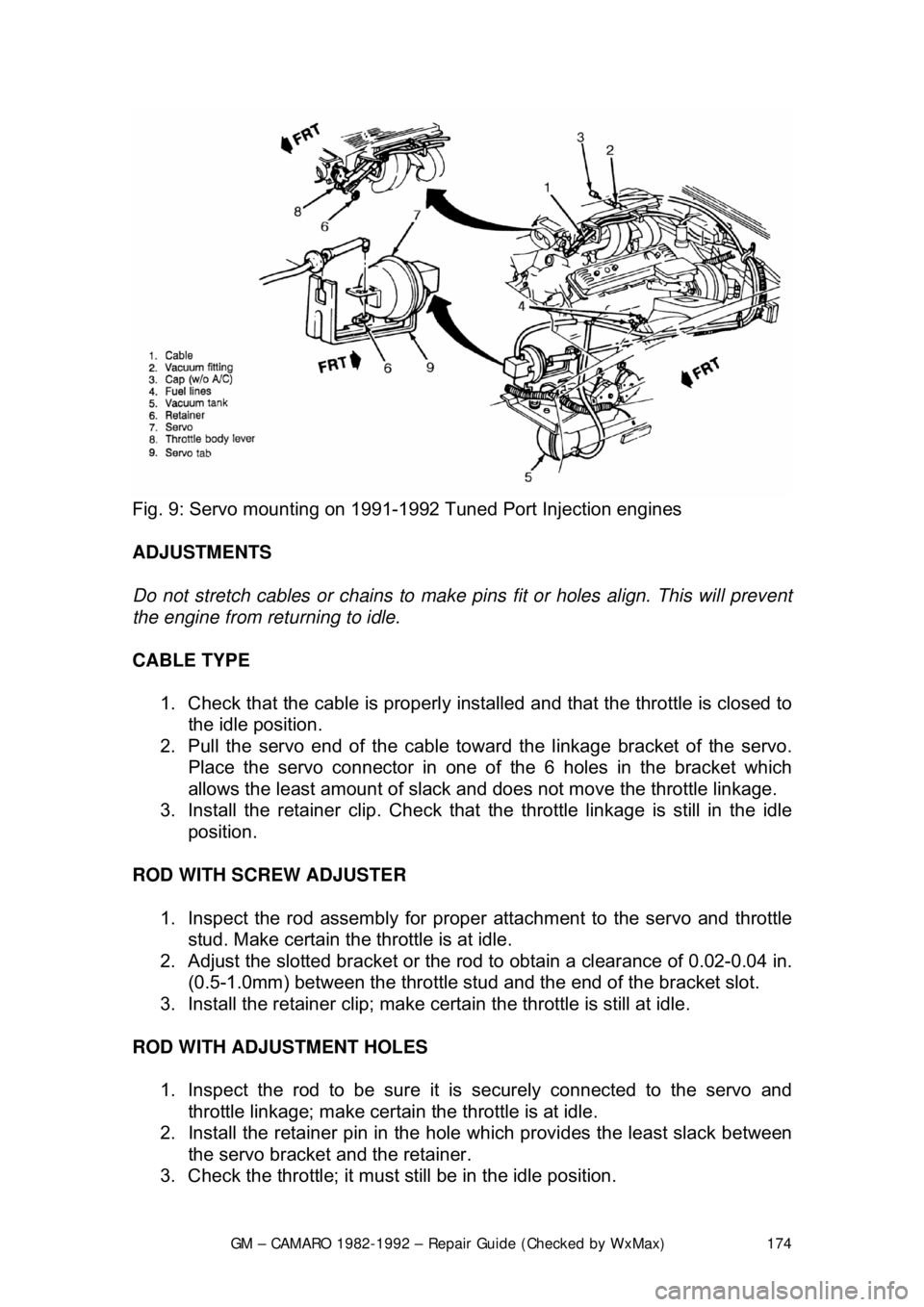

Fig. 9: Servo mounting on 1991-1992 Tuned Port Injection engines

ADJUSTMENTS

Do not stretch cables or chains to make pins fit or holes align. This will prevent

the engine from returning to idle.

CABLE TYPE 1. Check that the cable is properly installed and that the throttle is closed to

the idle position.

2. Pull the servo end of the cable towa rd the linkage bracket of the servo.

Place the servo connector in one of the 6 holes in the bracket which

allows the least amount of slack and does not move the throttle linkage.

3. Install the retainer clip. Check that the throttle linkage is still in the idle

position.

ROD WITH SCREW ADJUSTER 1. Inspect the rod assembly for proper attachment to the servo and throttle\

stud. Make certain the throttle is at idle.

2. Adjust the slotted bra cket or the rod to obtain a clearance of 0.02-0.04 in.

(0.5-1.0mm) between the throttle stud and the end of the bracket slot.

3. Install the retainer clip; make certain the throttle is still at idle.

ROD WITH ADJUSTMENT HOLES 1. Inspect the rod to be sure it is securely connected to the servo and

throttle linkage; make certain the throttle is at idle.

2. Install the retainer pin in the hole which provides the least slack between

the servo bracket and the retainer.

3. Check the throttle; it must still be in the idle position.

Page 175 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 175

CHAIN AND CABLE

CHAIN AT THROTTLE

1. Check for proper installation of cabl e assembly. Inspect the throttle; it

must be in the idle position.

2. Install the chain in the swivel so that the slack does not exceed

1/2 the

diameter of the ball stud.

3. Install the retainer on the swivel and make sure the throttle has not

moved from idle.

CHAIN AT SERVO 1. Check for proper installation of cabl e assembly. Inspect the throttle; it

must be in the idle position.

2. Install the cable on the third link of the chain; adjust the jam nuts of the

servo until there is no noticeab le slack in the chain.

3. Tighten the jam nuts and check that the throttle has not moved out of the

idle position.

MODULE

REMOVAL & INSTALLATION

1984-1992 MODELS

The module is mounted next to the heater and A/C duct on most models, but is

integral with the ECM on certain late-model engines.

1. Disconnect the negative battery cable.

2. Remove the right side sound insulator.

3. Remove the module attaching screws and remove the module.

4. Disconnect the electrical connector.

To install: 5. Connect the electrical connector.

6. Install the cruise control module and the attaching screws.

7. Install the right side sound insulator.

8. Connect the negative battery cable.

Page 223 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 223

FUSIBLE LINKS

In addition to circuit breakers and fuses,

the wiring harness incorporates fusible

links to protect the wiring. Links are used rather than a fuse, in wiring circuits

that are not normally fused, such as th e ignition circuit. The fusible links are

color coded red in the charging and load circuits to match the color coding of

the circuits they protect. Each link is four gauges smaller than the cable it

protects, and is marked on the insulation with the gauge size because the

insulation makes it appear heavier than it really is. The engine compartment

wiring harness has several fusible links. The same size wire with a special

Hypalon insulation must be used w hen replacing a fusible link.

For more details, see the information on fusible links at the beginning of this

section.

The links are located in the following areas:

1. A molded splice at the starter solenoid Bat terminal, a 14 gauge red wire.

2. A 16 gauge red fusible link at the j unction block to protect the unfused

wiring of 12 gauge or larger wire. This link stops at the bulkhead

connector.

3. The alternator warning light and fiel d circuitry is protected by a 20 gauge

red wire fusible link used in the batte ry feed-to-voltage regulator number

3 terminal. The link is installed as a molded splice in the circuit at the

junction block.

4. The ammeter circuit is protected by two 20 gauge fusible links installed

as molded splices in the circuit at t he junction block and battery to starter

circuit.

REPLACEMENT 1. Determine the circuit that is damaged.

2. Disconnect the negative battery terminal.

3. Cut the damaged fuse link from the harness and discard it.

4. Identify and procure the proper fuse link and butt connectors.

5. Strip the wire about

1/2 in. (13mm) on each end.

6. Connect the fusible link and crimp the butt connectors making sure that the wires are secure.

7. Solder each connection with resin core solder, and wrap the connections

with plastic electrical tape.

8. Reinstall the wir e in the harness.

9. Connect the negative battery terminal and test the system for proper

operation.

CIRCUIT BREAKERS

Various circuit breakers are located under the instrument panel. In order to gain

access to these components, it may be ne cessary to first remove the under

dash padding. Most of the circuit breakers are located in the convenience

center or the fuse panel.