fuse CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 219 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 219

FUSE BLOCK

The fuse block on some models is loca

ted under the instrument panel next to

the steering wheel an d is a swing down unit. Other models have the fuse block

located on the left side of the dash.

Each fuse block uses miniature fuse s which are designed for increased circuit

protection and greater reliabi lity. The compact fuse is a blade terminal design

which allows easy pull-out/push- in removal and replacement.

Although the fuses are interchangeable , the amperage values are not. The

values are usually molded in bold, color coded, easy to read numbers on the

fuse body. Use only fuses of equal replacement valve.

A blown fuse can easily be checked by visual inspection or by continuity

checking.

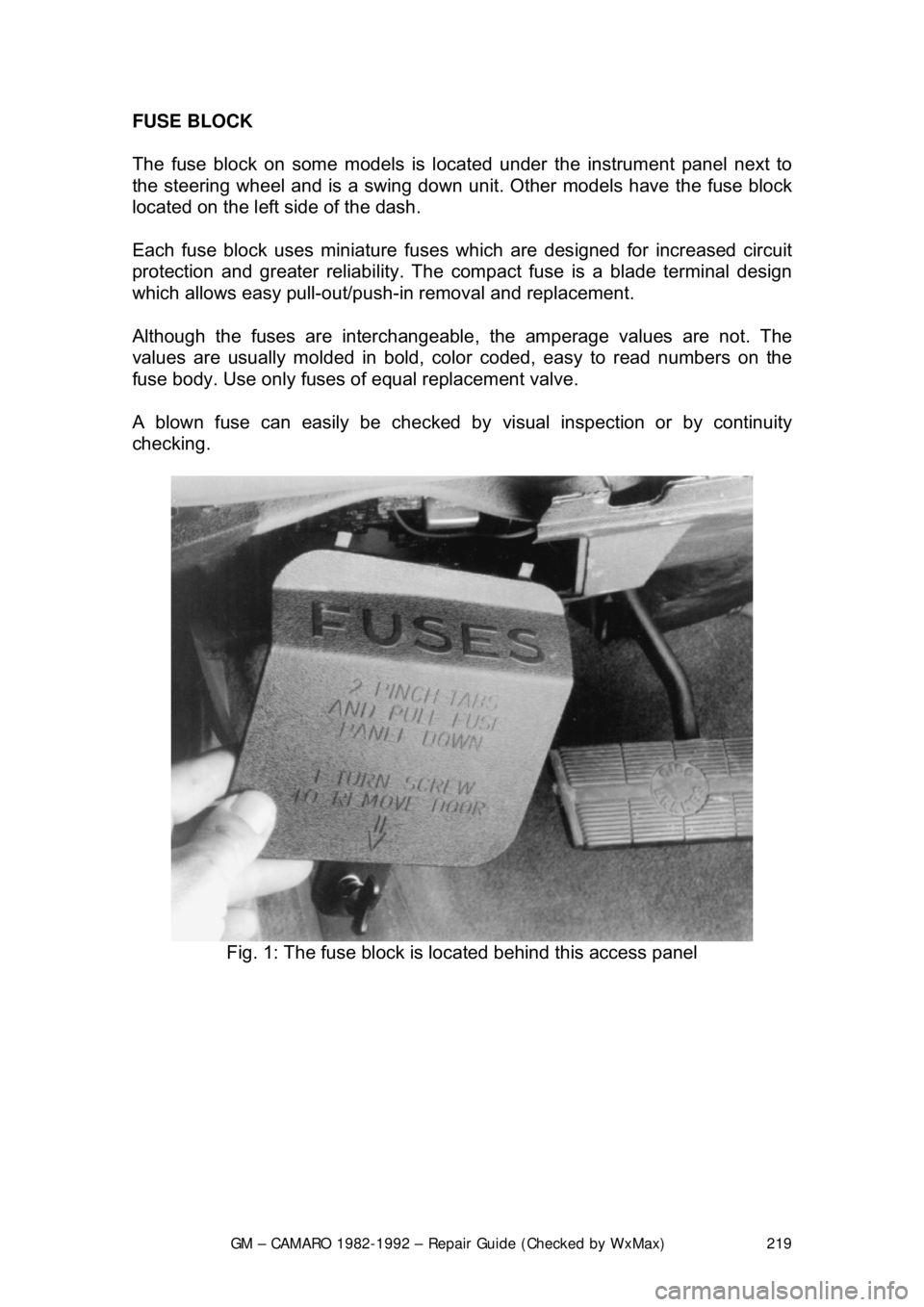

Fig. 1: The fuse block is located behind this access panel

Page 220 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 220

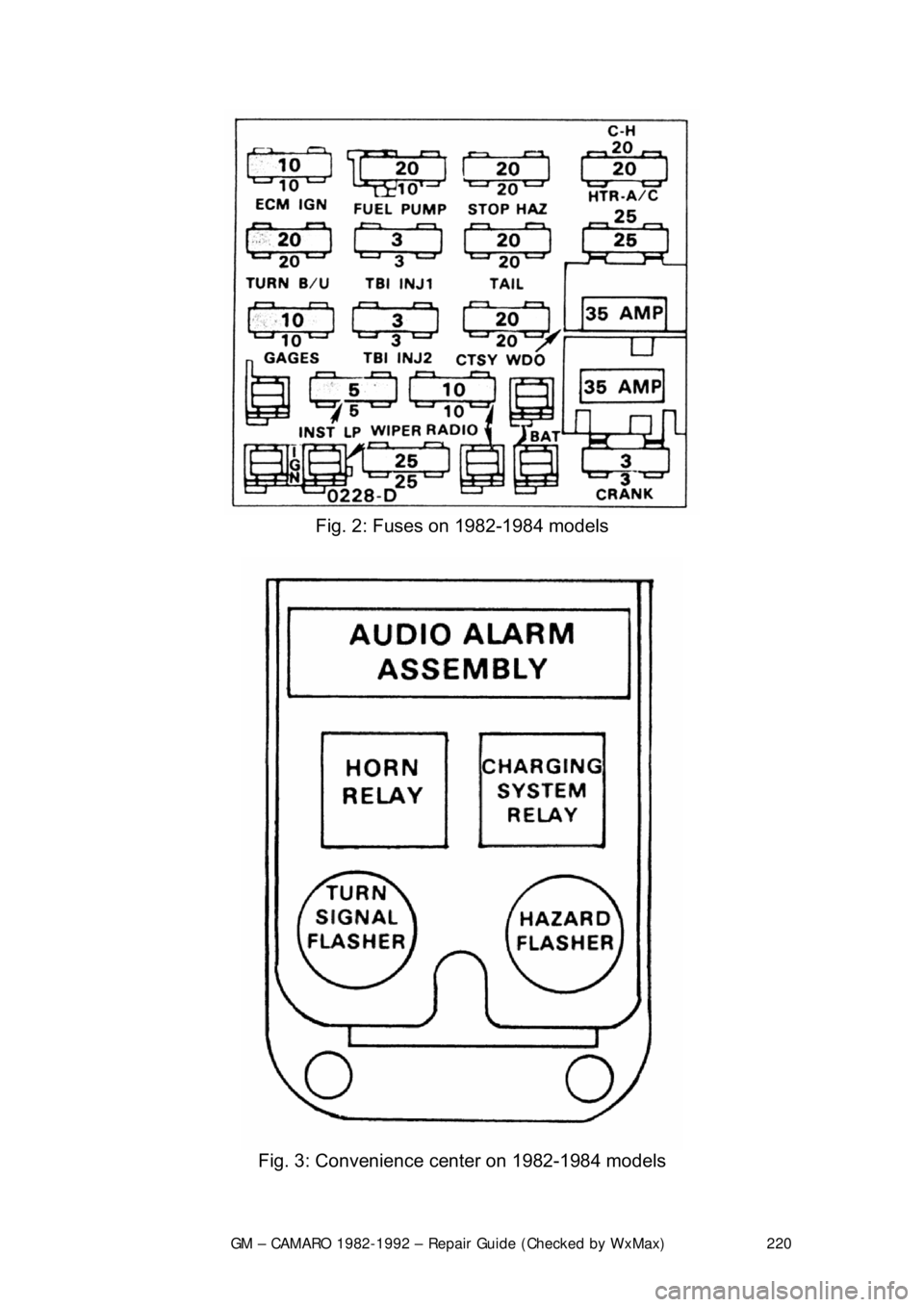

Fig. 2: Fuses on 1982-1984 models

Fig. 3: Convenience center on 1982-1984 models

Page 221 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 221

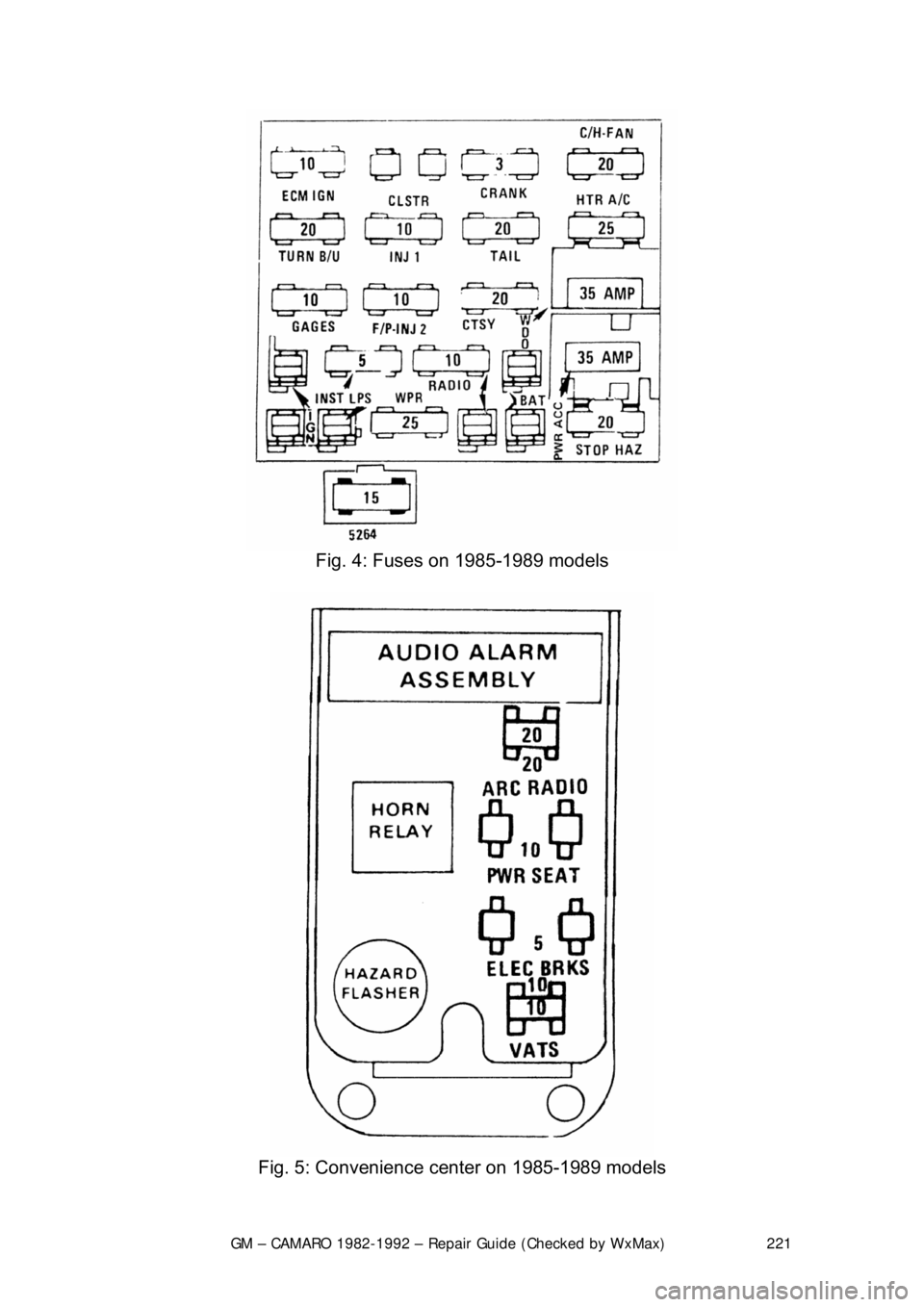

Fig. 4: Fuses on 1985-1989 models

Fig. 5: Convenience center on 1985-1989 models

Page 222 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 222

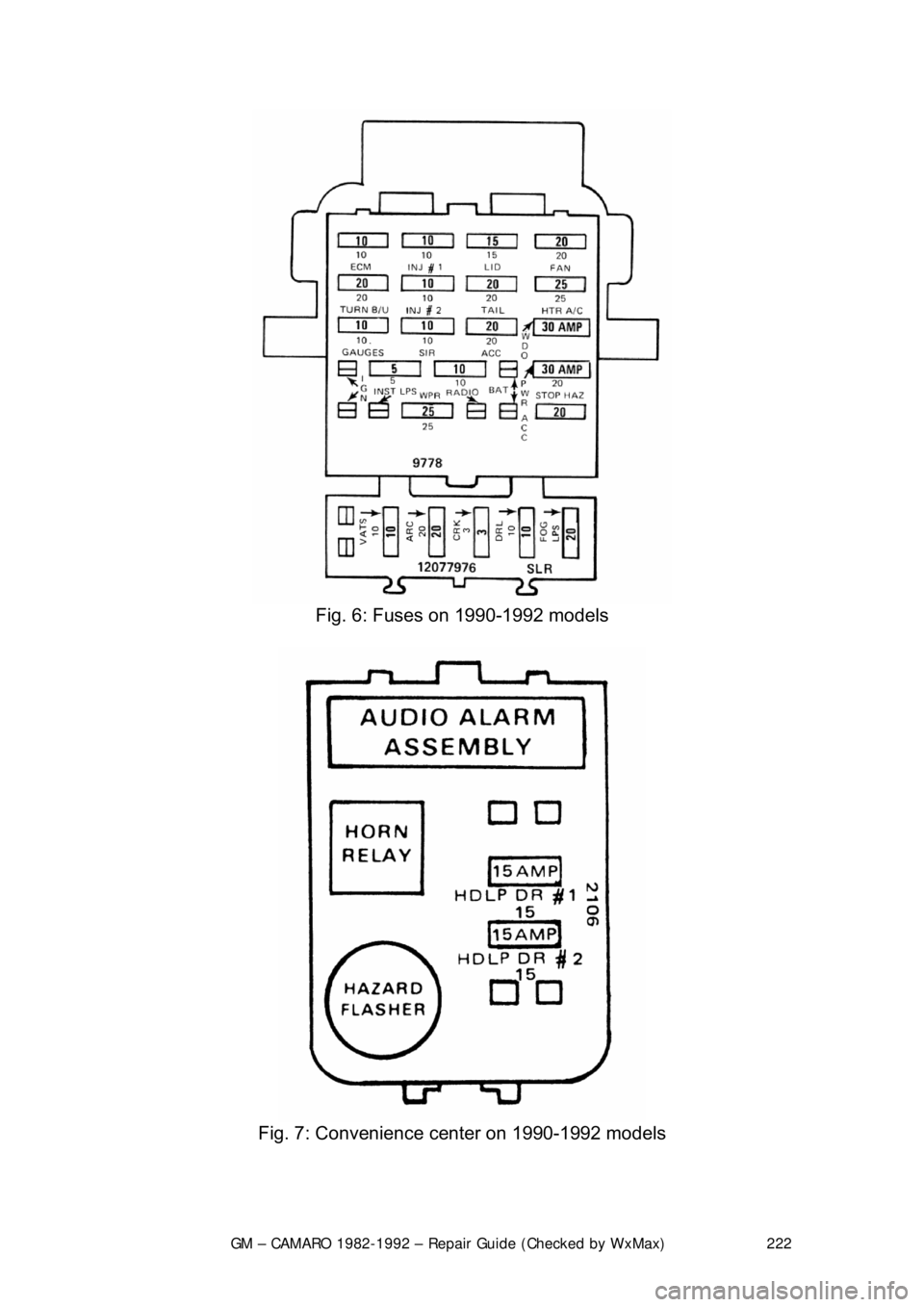

Fig. 6: Fuses on 1990-1992 models

Fig. 7: Convenience center on 1990-1992 models

Page 223 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 223

FUSIBLE LINKS

In addition to circuit breakers and fuses,

the wiring harness incorporates fusible

links to protect the wiring. Links are used rather than a fuse, in wiring circuits

that are not normally fused, such as th e ignition circuit. The fusible links are

color coded red in the charging and load circuits to match the color coding of

the circuits they protect. Each link is four gauges smaller than the cable it

protects, and is marked on the insulation with the gauge size because the

insulation makes it appear heavier than it really is. The engine compartment

wiring harness has several fusible links. The same size wire with a special

Hypalon insulation must be used w hen replacing a fusible link.

For more details, see the information on fusible links at the beginning of this

section.

The links are located in the following areas:

1. A molded splice at the starter solenoid Bat terminal, a 14 gauge red wire.

2. A 16 gauge red fusible link at the j unction block to protect the unfused

wiring of 12 gauge or larger wire. This link stops at the bulkhead

connector.

3. The alternator warning light and fiel d circuitry is protected by a 20 gauge

red wire fusible link used in the batte ry feed-to-voltage regulator number

3 terminal. The link is installed as a molded splice in the circuit at the

junction block.

4. The ammeter circuit is protected by two 20 gauge fusible links installed

as molded splices in the circuit at t he junction block and battery to starter

circuit.

REPLACEMENT 1. Determine the circuit that is damaged.

2. Disconnect the negative battery terminal.

3. Cut the damaged fuse link from the harness and discard it.

4. Identify and procure the proper fuse link and butt connectors.

5. Strip the wire about

1/2 in. (13mm) on each end.

6. Connect the fusible link and crimp the butt connectors making sure that the wires are secure.

7. Solder each connection with resin core solder, and wrap the connections

with plastic electrical tape.

8. Reinstall the wir e in the harness.

9. Connect the negative battery terminal and test the system for proper

operation.

CIRCUIT BREAKERS

Various circuit breakers are located under the instrument panel. In order to gain

access to these components, it may be ne cessary to first remove the under

dash padding. Most of the circuit breakers are located in the convenience

center or the fuse panel.

Page 351 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 351

alternating current developed

within the stator windings to a direct (DC) current

at the output (BAT) terminal. Three of these diodes are negative and are

mounted flush with the end frame while t he other three are positive and are

mounted into a strip called a heat sink. The positive diodes are easily identified

as the ones within small cavities or depressions.

The alternator charging system is a negative (-) ground system which consists

of an alternator, a regulat or, a charge indicator, a storage battery and wiring

connecting the components, and fuse link wire.

The alternator is belt-driven from t he engine. Energy is supplied from the

alternator/regulator system to the rotati ng field through two brushes to two slip-

rings. The slip-rings are mounted on the rotor shaft and are connected t\

o the

field coil. This energy supplied to the ro tating field from the battery is called

excitation current and is used to init ially energize the field to begin the

generation of electricity. Once the alter nator starts to generate electricity, the

excitation current comes from its ow n output rather than the battery.

The alternator produces power in the form of alternating current. The alternating

current is rectified by 6 diodes into dire ct current. The direct current is used to

charge the battery and power the rest of the electrical system.

When the ignition key is turned ON, current flows from the battery, through the

charging system indicator light on the in strument panel, to the voltage regulator,

and to the alternator. Since the alternat or is not producing any current, the

alternator warning light comes on. When the engine is started, the alternator

begins to produce current and turns the alte rnator light off. As the alternator

turns and produces current, the current is divided in two ways: part to the

battery(to charge the battery and power the electrical components of the

vehicle), and part is returned to the alte rnator (to enable it to increase its

output). In this situation, the alternator is receiving current from the battery and

from itself. A voltage regulat or is wired into the current supply to the alternator

to prevent it from receiving too much cu rrent which would cause it to put out too

much current. Conversely, if the voltage regulator does not allow the alternator

to receive enough current, the battery will not be fully charged and will

eventually go dead.

The battery is connected to the alternator at all times, whether the ignition key is

turned ON or not. If the battery were shorted to ground, the alternator would

also be shorted. This woul d damage the alternator. To prevent this, a fuse link

is installed in the wiring between the battery and the alternator. If the battery is

shorted, the fuse link melts, protecting the alternator.

An alternator is better that a convent ional, DC shunt generator because it is

lighter and more compact, because it is designed to supply the battery and

accessory circuits through a wide range of engine speeds, and because it

eliminates the necessary maintenance of replacing brushes and servicing

commutators.

PRECAUTIONS

Page 596 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 596

recommended to have a qualified technici

an perform any further testing, if

needed.

FIELD SERVICE MODE

On fuel injected models, if the ALDL terminal B is grounded to terminal A with

the engine running, the system enters the Field Service Mode. In this mode, the

MIL will indicate whether the system is operating in open loop or closed loop.

If working in open loop, t he MIL will flash rapidly 2

1/2 times per second. In

closed loop, the flash rate slows to once per second. Additionally, if the system

is running lean in closed loop, the lamp will be off most of the cycle. A rich

condition in closed loop will cause the lamp to remain lit for most of the one

second cycle.

When operating in the Field Service M ode, additional codes cannot be stored

by the ECM. The closed loop timer is bypassed in this mode.

CLEARING CODES

Stored fault codes may be erased from me mory at any time by removing power

from the ECM for at least 30 seconds. It may be necessary to clear stored

codes during diagnosis to check for any re currence during a test drive, but the

stored should be written dow n when retrieved. The codes may still be required

for subsequent troubleshooting. Whenever a repair is complete, the stored

codes must be erased and the vehicle te st driven to confirm correct operation

and repair.

The ignition switch must be OFF any ti me power is disconnected or restored to

the ECM. Severe damage may result if this precaution is not observed.

Depending on the electric di stribution of the particular vehicle, power to the

ECM may be disconnected by removing the ECM fuse in the fusebox or

disconnecting the inline EC M power lead at the positive battery terminal.

Disconnecting the negative battery cable to clear codes will achieve the desired

result, but this will also clear other me mory data in the vehicle such as radio

presets or seat memory.

Page 638 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 638

ELECTRONIC IGNITION SYSTEM

GENERAL INFORMATION

The High Energy Ignition (HEI) system

controls the fuel combustion by

providing a spark to ignite the compress ed air/fuel mixture at the correct time.

To provide improved engine performance, fuel economy, and control of exhaust

emissions, the engine contro l module (ECM) controls distributor spark advance

(timing) with an ignition control system.

The distributor may have an internal, or ex ternal ignition coil. To be certain of

the type coil used for your vehicle, vis ually inspect the ignition system. If the

ignition coil is inside the distributor c ap, it connects through a resistance brush

to the rotor. If your vehicle is equipped with an external ignition coil, it connects

to the rotor through a high tension wire.

Fig. 1: Distributor with exterior ignition coil - 1987 vehicle shown

The distributor contains the ignition c ontrol module, and the magnetic triggering

device. The magnetic pickup assembly contains a permanent magnet, a pole

piece with internal "teeth", and a pickup co il (not to be confused with the ignition

coil).

All spark timing changes are done electr onically by the engine control module

(ECM) which monitors information from various engine sensors. The ECM

computes the desired spark timing and t hen signals the distributor ignition

module to change the timing accordingly. No vacuum or mechanical advance

systems are used.

Page 726 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 726

RELIEVING FUEL SYSTEM PRESSURE

1. Remove the fuse marked "Fuel Pu mp" from the fuse block in the

passenger compartment.

2. Crank the engine. Th e engine will start and run until the fuel supply

remaining in the lines is exhauste d. When the engines stops, engage the

starter again for three seconds to a ssure dissipation of any remaining

pressure.

3. With the ignition OFF, disconnect the negative battery cable to prevent

fuel discharge if the key is accidentally turned to the ON position.

Replace the fuse with the ignition OFF.

When disconnecting fuel lines, there ma y still be a small amount of fuel

released. Cover the fuel line connection wi th a shop cloth to collect the fuel,

then place the cloth in an approved container.

ELECTRIC FUEL PUMP

REMOVAL & INSTALLATION

The removal and installation procedures fo r the Crossfire injection system fuel

pump is identical to the Throttle Body In jection (TBI) system. Please refer to the

TBI fuel pump procedures earlier in this repair guide.

TESTING

The testing procedures for the Crossfire in jection system fuel pump is identical

to the Throttle Body Injection (TBI) syst em. Please refer to the TBI fuel pump

procedures earlier in this repair guide.

THROTTLE BODY

REMOVAL & INSTALLATION

FRONT UNIT

1. Relieve the fuel system pressure.

2. Remove the air cleaner assembly, noting the connection points of the

vacuum lines.

3. Detach the electrical connectors at the injector and the idle air control

motor.

4. Disconnect the vacuum lines from the TBI unit, noting the connection

points. During installation, refer to the underhood emission control

information decal for vacuum line routing information.

5. Disconnect the transmission det ent cable from the TBI unit.

6. Disconnect the fuel inlet (feed) and fuel balance line connections at the

front TBI unit.

7. Remove and discard the throttle cont rol rod retaining clip from the front

TBI throttle lever stud. A new clip must be used during reassembly.

8. Unbolt and remove the TBI unit.

Page 847 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 847

DISARMING

1. Turn the steering wheel to align the w heels in the straight-ahead position.

2. Turn the ignition switch to the LOCK position.

3. Remove the SIR air bag fuse from the fuse block.

4. Remove the left side trim panel and disconnect the yellow 2-way SIR

harness wire connector at the bas e of the steering column.

To enable system: 5. Turn the ignition switch to the LOCK position.

6. Reconnect the yello w 2-way connector at the base of the steering

column.

7. Reinstall the SIR fuse and the left side trim panel.

8. Turn the ignition switch to the RUN position.

9. Verify the SIR indicator light flashes 7-9 times, if not as specified, inspect

system for malfunction or c ontact the manufacturer.

For more details on the SIR system - including disarming instructions for

passenger bags - please refer to Chassis Electrical in this repair guide.

SUPPLEMENTAL INFLATABLE REST RAINT (SIR) COIL ASSEMBLY

After performing repairs on the inter nals of the steering column the coil

assembly must be centered in order to avoid damaging the coil or accidental

deployment of the air bag. There are 2 different styles of coils, one rotates

clockwise and the other rotates counterclockwise.

ADJUSTMENT (CENTERING THE COIL) 1. With the system properly disarmed, hold the coil assembly with the clear

bottom up to see the coil ribbon.

2. While holding the coil assembly, depr ess the lock spring and rotate the

hub in the direction of the arrow until it stops. The coil should now be

wound up snug against the center hub.

3. Rotate the coil assembly in the opposite direction approximately 2

1/2

turns and release the lock spring between the locking tabs in front of the

arrow.

4. Install the coil assembly onto the steering shaft.

STEERING WHEEL

WARNING - Before attempting any repairs involving the steering wheel or

disassembly of it, ensure that the Supple mental Inflatable Restraint (Air Bag)

system is properly disarmed.

REMOVAL & INSTALLATION

If the vehicle is equipped with a SIR (A ir Bag) system, ensure that the proper

disarming procedure is followed.