fuse CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 126 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 126

CHASSIS ELECTRICAL

UNDERSTANDING AND TROUBLESHOOTING ELECTRICAL SYSTEMS

BASIC ELECTRICAL THEORY

For any 12 volt, negative ground, electrical system to operate, the electricity

must travel in a complete circuit. This simply means that current (power) from

the positive (+) terminal of the battery must eventually return to the negative (—

) terminal of the battery. Along the way, this current will travel through wires,

fuses, switches and components. If, for any reason, the flow of current through

the circuit is interrupted, the component f ed by that circuit will cease to function

properly.

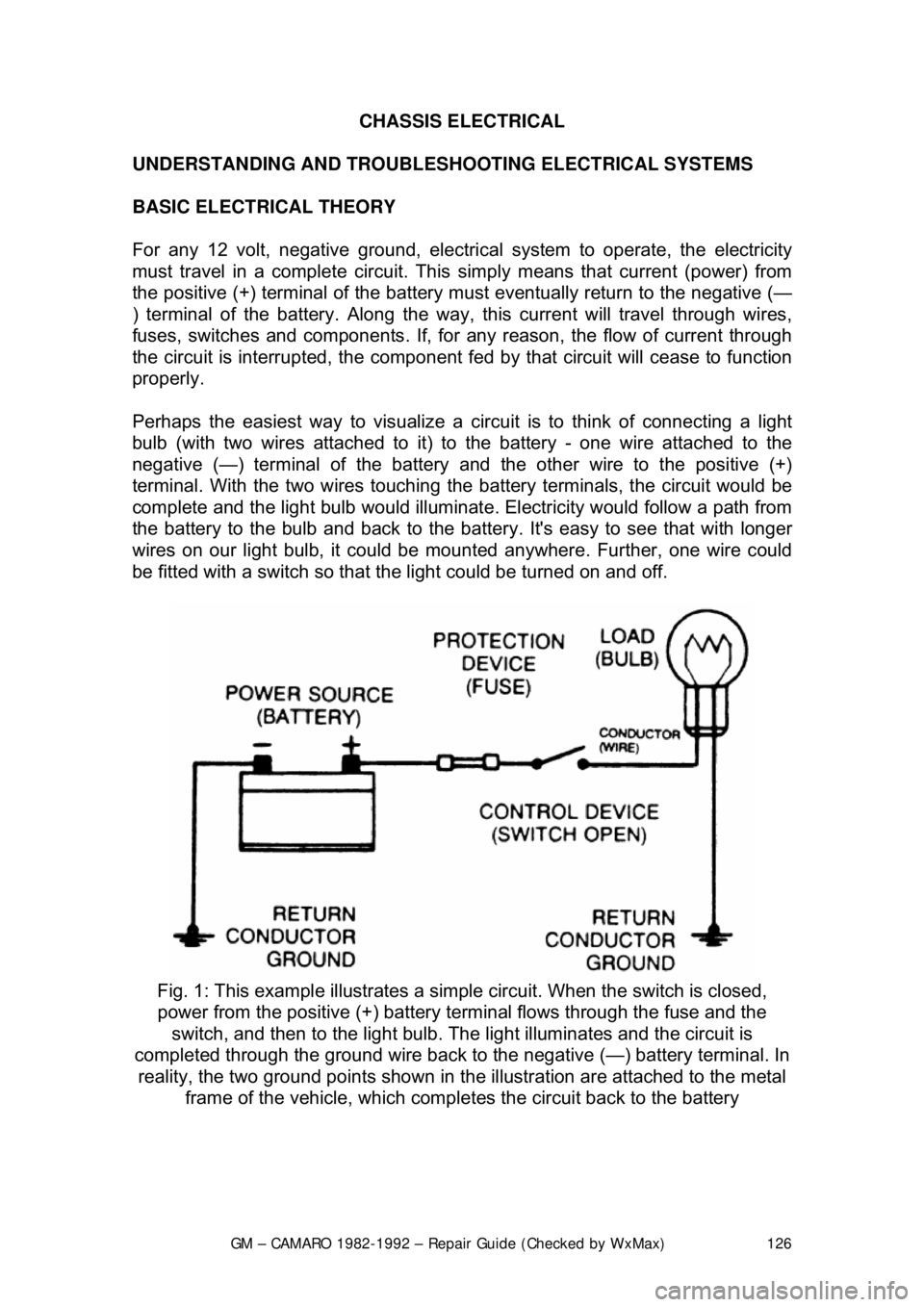

Perhaps the easiest way to visualize a circ uit is to think of connecting a light

bulb (with two wires attac hed to it) to the battery - one wire attached to the

negative (—) terminal of the battery and the other wire to the positive (+)

terminal. With the two wires touching the battery terminals, the circuit would be

complete and the light bulb would illuminat e. Electricity would follow a path from

the battery to the bulb and back to the bat tery. It's easy to see that with longer

wires on our light bulb, it could be mounted anywhere. Further, one wire could

be fitted with a switch so that t he light could be turned on and off.

Fig. 1: This example illu strates a simple circuit. Wh en the switch is closed,

power from the positive (+) battery te rminal flows through the fuse and the

switch, and then to the light bulb. The light illuminates and the circuit is

completed through the ground wire back to the negative (—) battery terminal. In

reality, the two ground point s shown in the illustration are attached to the metal

frame of the vehicle, which comple tes the circuit back to the battery

Page 129 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 129

THE BATTERY

In most modern vehicles, the battery is

a lead/acid electrochemical device

consisting of six 2 volt subs ections (cells) connected in se ries, so that the unit is

capable of producing approximately 12 volt s of electrical pressure. Each

subsection consists of a series of positive and negative plates held a short

distance apart in a solution of sulfuric acid and water.

The two types of plates are of dissim ilar metals. This sets up a chemical

reaction, and it is this r eaction which produces current flow from the battery

when its positive and negative terminals are connected to an electrical \

load .

The power removed from the battery is r eplaced by the alternator, restoring the

battery to its original chemical state.

THE ALTERNATOR

On some vehicles there isn't an alter nator, but a generator. The difference is

that an alternator supplies alternating current which is then changed to direct

current for use on the vehicle, while a generator produces direct current.

Alternators tend to be more efficient and that is why they are used.

Alternators and generators are devices t hat consist of coils of wires wound

together making big electrom agnets. One group of coils spins within another set

and the interaction of the magnetic fields causes a current to flow. This current

is then drawn off the coils and fed into the vehicles electrical system.

GROUND

Two types of grounds are used in automot ive electric circuits. Direct ground

components are grounded to the frame thr ough their mounting points. All other

components use some sort of ground wire which is attached to the frame or

chassis of the vehicle. The electrical current runs through the chassis of the

vehicle and returns to the battery thr ough the ground (—) cable; if you look,

you'll see that the battery ground cabl e connects between the battery and the

frame or chassis of the vehicle.

It should be noted that a good percentage of electrical problems can be traced

to bad grounds.

PROTECTIVE DEVICES

It is possible for large surges of current to pass through the electrical system of

your vehicle. If this surge of current we re to reach the load in the circuit, the

surge could burn it out or severely dam age it. It can also overload the wiring,

causing the harness to get hot and melt t he insulation. To prevent this, fuses,

circuit breakers and/or fusible links are connected into the supply wires of the

electrical system. These items are nothing more than a built-in weak spot in the

system. When an abnormal amount of curr ent flows through the system, these

protective devices work as fo llows to protect the circuit:

Page 130 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 130

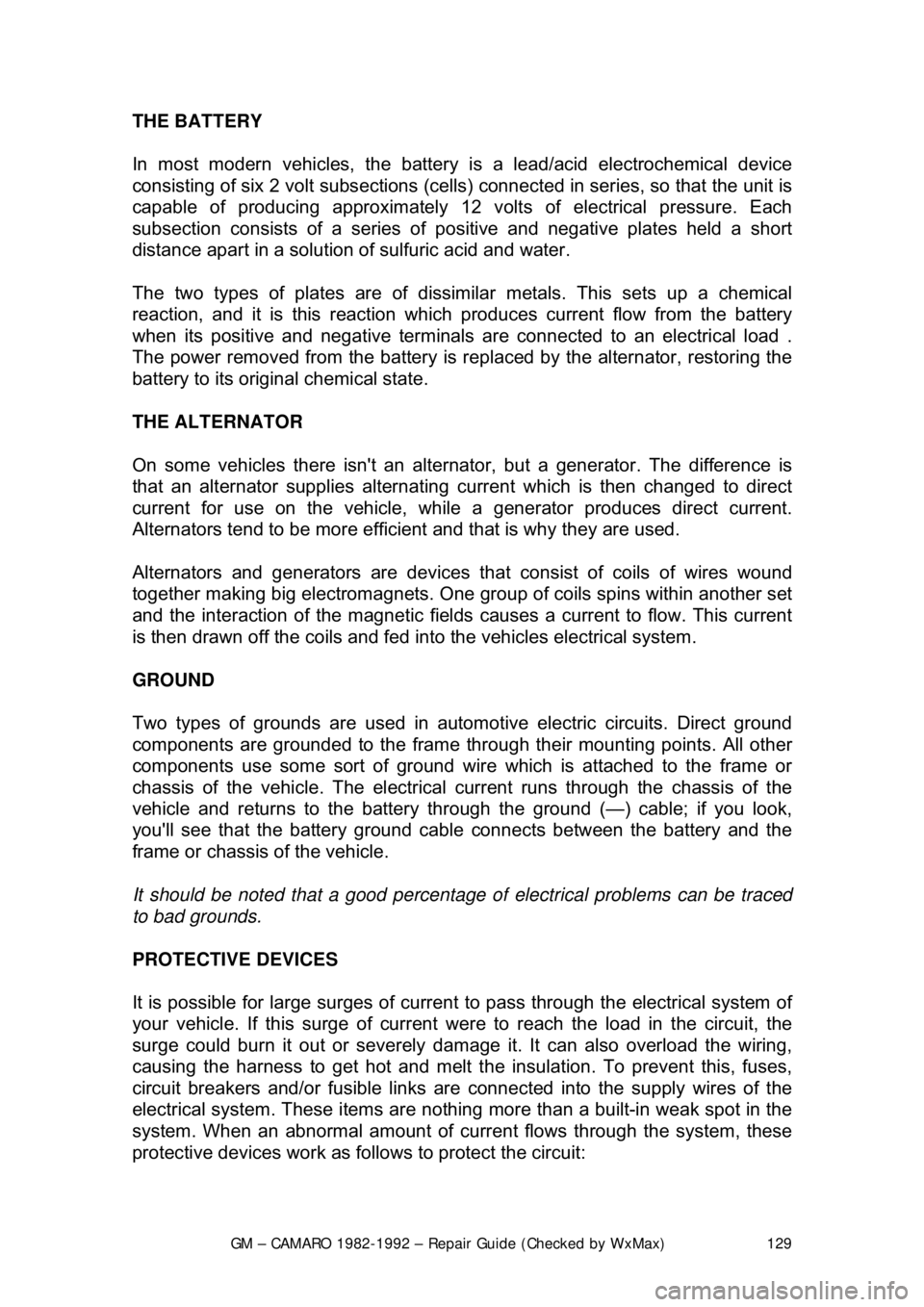

•

Fuse - when an excessive electrical current passes through a fuse, the

fuse "blows" (the conductor melts) and opens the circuit, preventing the

passage of current.

Fig. 1: Most vehicles use one or more fuse panels. This one is located on the

driver's side kick panel

Page 131 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 131

•

Circuit Breaker - a circuit breaker is basically a self-repairing fuse. It will

open the circuit in the same fashio n as a fuse, but when the surge

subsides, the circuit breaker can be reset and does not need

replacement.

• Fusible Link - a fusible link (fuse link or main link) is a short length of

special, high temperatur e insulated wire that acts as a fuse. When an

excessive electrical current passes th rough a fusible link, the thin gauge

wire inside the link melt s, creating an intentional open to protect the

circuit. To repair the circuit, the link must be replaced. Some newer type

fusible links are housed in plug-in modules, which are simply replaced

like a fuse, while older type fusible lin ks must be cut and spliced if they

melt. Since this link is very early in the electrical path, it's the first place to

look if nothing on the vehicle works, yet the battery seems to be charged

and is properly connected.

CAUTION - Always replace fuses, circ uit breakers and fusible links with

identically rated component s. Under no circumstances should a component of

higher or lower amperage rating be substituted.

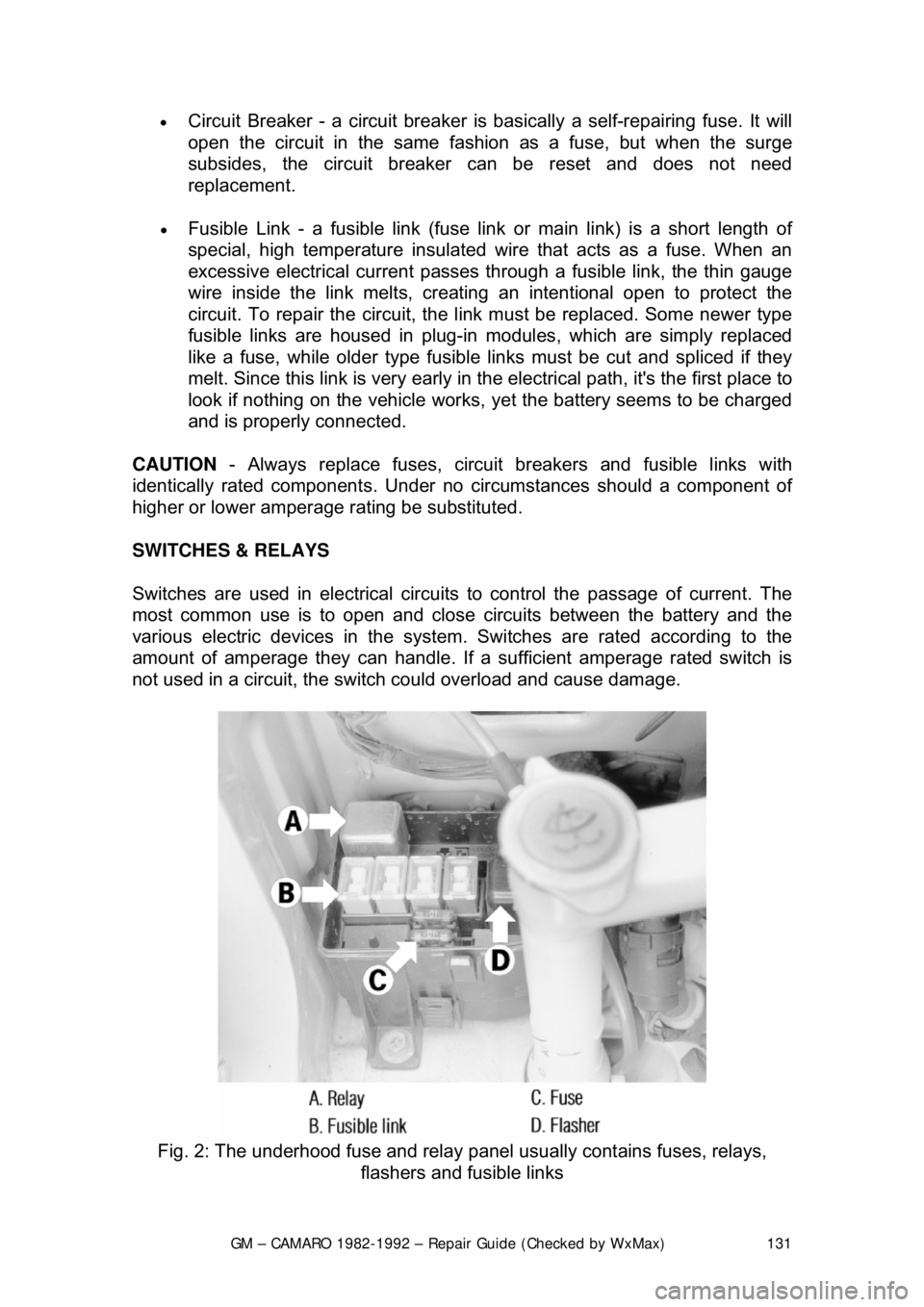

SWITCHES & RELAYS

Switches are used in electrical circuits to control the passage of current. The

most common use is to open and close circuits between the battery and the

various electric devices in the system. Switches are rated according to the

amount of amperage they c an handle. If a sufficient amperage rated switch is

not used in a circuit, the switch could overload and cause damage.

Fig. 2: The underhood fuse and relay panel usually contains fuses, relays,

flashers and fusible links

Page 136 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 136

accidental grounding. It is al

so advisable to include a standard automotive fuse

in any jumper wire. This is commonly referred to as a "fused jumper". By

inserting an in-line fuse holder between a set of test leads, a fused jumper wire

can be used for bypassing open circuits. Use a 5 amp fuse to provide protection

against voltage spikes.

Jumper wires are used primarily to locate open electrical circuits, on either the

ground (—) side of the circuit or on the power (+) side. If an electrical

component fails to operate, connect t he jumper wire between the component

and a good ground. If the component operates only with the jumper installed,

the ground circuit is open. If the ground circuit is good, but the component does

not operate, the circuit between the power feed and component may be open.

By moving the jumper wire successively back from the component toward the

power source, you can isolate the area of the circuit where the open is located.

When the component stops func tioning, or the power is cut off, the open is in

the segment of wire between the jumper and the point previously tested.

You can sometimes connect the jumper wir e directly from the battery to the

"hot" terminal of the component, but firs t make sure the component uses 12

volts in operation. Some electrical components, such as fuel injectors or

sensors, are designed to operate on about 4 to 5 volts, and running 12 volts

directly to these components will cause damage.

TEST LIGHTS

Fig. 1: A 12 volt test light is used to detect the presence of voltage in a circuit

The test light is used to check circuits and components while electrical current is

flowing through them. It is used for volt age and ground tests. To use a 12 volt

test light, connect the ground clip to a good ground and probe wherever

necessary with the pick. The test light will illuminate when voltage is detected.

This does not necessarily mean that 12 volts (or any particular amount of

Page 138 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 138

the ground side of the circuit) and

connect the positive lead to the

positive (+) side of the circuit (to t he power source or the nearest power

source). Note that the negative voltme ter lead will always be black and

that the positive voltmeter will alwa ys be some color other than black

(usually red).

• Ohmmeter - the ohmmeter is designed to read resistance (measured in

ohms) in a circuit or component. Mo st ohmmeters will have a selector

switch which permits the measurement of different ranges of resistance

(usually the selector swit ch allows the multiplication of the meter reading

by 10, 100, 1,000 and 10,000). Some ohmmeters are "auto-ranging"

which means the meter itself will dete rmine which scale to use. Since the

meters are powered by an internal battery, the ohmmeter can be used

like a self-powered test light. When the ohmmeter is connected, current

from the ohmmeter flows through the ci rcuit or component being tested.

Since the ohmmeter's internal resi stance and voltage are known values,

the amount of current flow throug h the meter depends on the resistance

of the circuit or component being test ed. The ohmmeter can also be used

to perform a continuity test for suspected open circuits. In using the

meter for making continuity checks, do not be concerned with the actual

resistance readings. Zero resistance, or any ohm reading, indicates

continuity in the circui t. Infinite resistance indi cates an opening in the

circuit. A high resistance reading w here there should be none indicates a

problem in the circuit. Checks for s hort circuits are made in the same

manner as checks for open circuits, ex cept that the circuit must be

isolated from both power and normal gr ound. Infinite resistance indicates

no continuity, while zero resi stance indicates a dead short.

WARNING - Never use an ohmmeter to check the resistance of a component or

wire while there is volt age applied to the circuit

• Ammeter - an ammeter measures the am ount of current flowing through

a circuit in units called amperes or amps. At normal operating voltage,

most circuits have a characteristic amount of amperes, called "current

draw" which can be measured usi ng an ammeter. By referring to a

specified current draw rating, then measuring the amperes and

comparing the two values, one can det ermine what is happening within

the circuit to aid in diagnosis. An open circuit, for example, will not allow

any current to flow, so the amme ter reading will be zero. A damaged

component or circuit will have an incr eased current draw, so the reading

will be high. The ammeter is always connected in series with the circuit\

being tested. All of the current that normally flows through the circuit

must also flow through the ammeter; if there is any other path for the

current to follow, the ammeter readi ng will not be accurate. The ammeter

itself has very little resistance to curr ent flow and, therefore, will not affect

the circuit, but it will measure current draw only when the circuit is closed

and electricity is flowing. Excessive current draw can blow fuses and

drain the battery, while a reduced current draw can cause motors to run \

slowly, lights to dim and other components to not operate properly.

Page 139 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 139

TROUBLESHOOTING ELECTRICAL SYSTEMS

When diagnosing a specific problem, or

ganized troubleshooting is a must. The

complexity of a modern automotive v ehicle demands that you approach any

problem in a logical, organized m anner. There are certain troubleshooting

techniques, however, which are standard:

• Establish when the problem occurs. D oes the problem appear only under

certain conditions? Were there any noises, odors or other unusual

symptoms? Isolate the problem area. To do this, make some simple tests

and observations, then eliminate the syst ems that are working properly.

Check for obvious problems, such as broken wires and loose or dirty

connections. Always check the obvious before assuming something

complicated is the cause.

• Test for problems systematically to determine the cause once the

problem area is isolated. Are all t he components functioning properly? Is

there power going to electrical switc hes and motors. Performing careful,

systematic checks will often turn up mo st causes on the first inspection,

without wasting time checking co mponents that have little or no

relationship to the problem.

• Test all repairs after the work is done to make sure that the problem is

fixed. Some causes can be traced to more than one component, so a

careful verification of repair work is important in order to pick up

additional malfunctions that may cause a problem to reappear or a

different problem to arise. A blown fu se, for example, is a simple problem

that may require more than another fuse to repair. If you don't look for a

problem that caused a fuse to blow, a shorted wire (for example) may go

undetected.

Experience has shown that most problem s tend to be the result of a fairly

simple and obvious cause, such as loose or corroded connectors, bad grounds

or damaged wire insulation which causes a short. This makes careful visual

inspection of components during testing essential to quick and accurate

troubleshooting.

Page 149 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 149

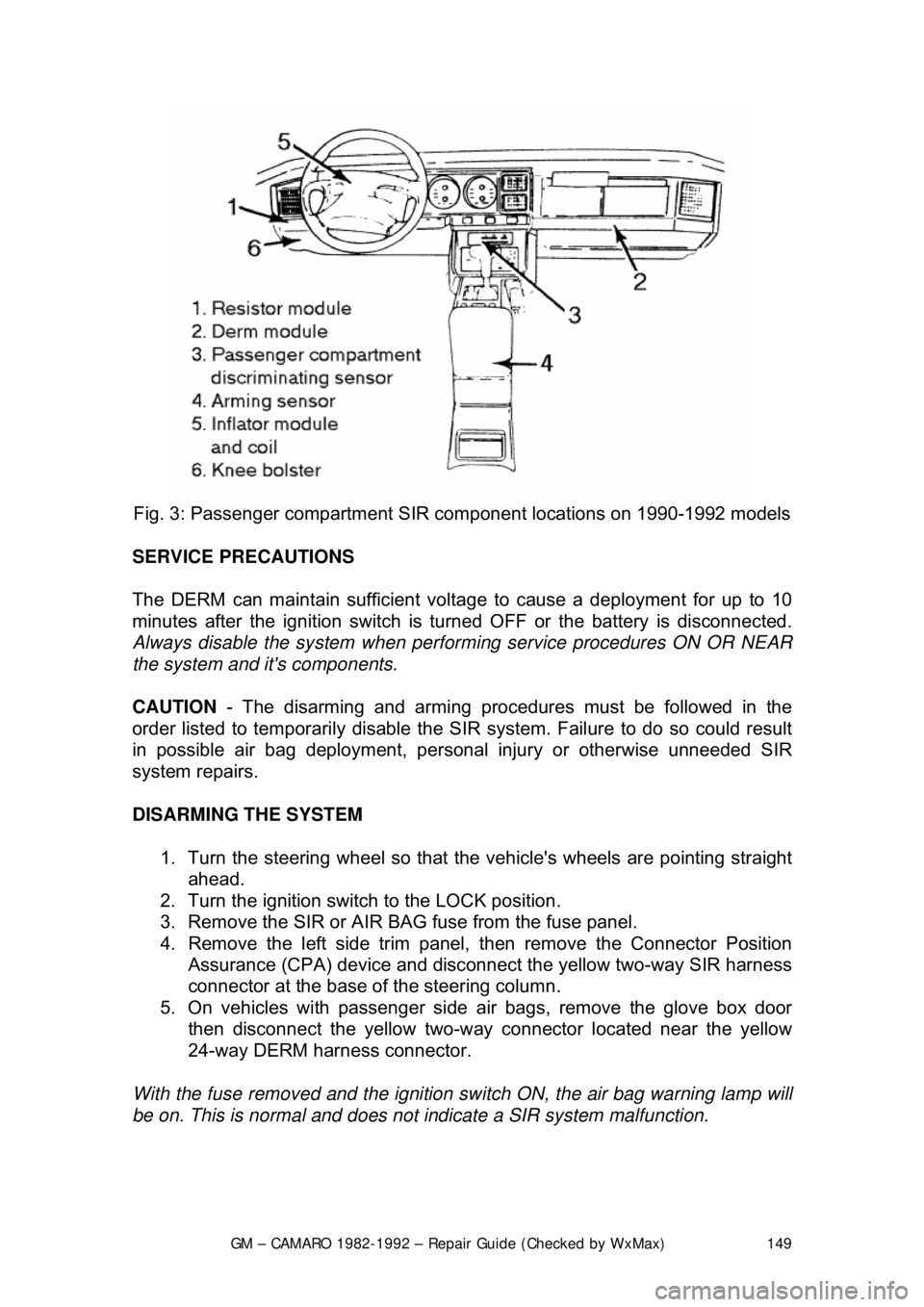

Fig. 3: Passenger com partment SIR component lo cations on 1990-1992 models

SERVICE PRECAUTIONS

The DERM can maintain sufficient volt age to cause a deployment for up to 10

minutes after the ignition switch is tur ned OFF or the battery is disconnected.

Always disable the system when perfo rming service procedures ON OR NEAR

the system and it's components.

CAUTION - The disarming and arming procedures must be followed in the

order listed to temporarily disable the SI R system. Failure to do so could result

in possible air bag deployment, pers onal injury or otherwise unneeded SIR

system repairs.

DISARMING THE SYSTEM

1. Turn the steering wheel so that t he vehicle's wheels are pointing straight

ahead.

2. Turn the ignition switch to the LOCK position.

3. Remove the SIR or AIR BAG fuse from the fuse panel.

4. Remove the left side trim panel, t hen remove the Connector Position

Assurance (CPA) device and disconnec t the yellow two-way SIR harness

connector at the base of the steering column.

5. On vehicles with passenger side air bags, remove the glove box door

then disconnect the yellow two-way c onnector located near the yellow

24-way DERM harness connector.

With the fuse removed and the ignition sw itch ON, the air bag warning lamp will

be on. This is normal and does not indicate a SIR system malfunction.

Page 151 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 151

ARMING THE SYSTEM

1. Turn the ignition key to the LO CK position and remove the key.

2. On vehicles with a passenger side ai r bag, reconnect the yellow two-way

connector assembly located near the yellow 24-way DERM harness

connector. Install the glov e box door assembly.

3. Connect the yellow two-way connector assembly at the base of the

steering column.

Always be sure to reinstall the Connec tor Position Assurance (CPA) device.

4. Install the left side trim panel and rein stall the fuse in the fuse block.

5. Turn the ignition key to the RUN posit ion and verify that the warning lamp

flashes seven to nine times and then turn s OFF. If it does not operate as

described, have the system repair ed by a qualified technician.

HEATING AND AIR CONDITIONING

BLOWER MOTOR

REMOVAL & INSTALLATION 1. Disconnect the negative battery cable. If necessary, remove the diagonal

fender brace at the right rear corner of the engine compartment to gain

access to the blower motor.

2. Disconnect the electrical wiring fr om the blower motor. If equipped with

air conditioning, remove the blower relay and bracket as an assembly

and swing them aside.

3. Remove the blower motor cooling tube.

4. Remove the blower mo tor retaining screws.

5. Remove the blower motor and fan as an assembly from the case.

To install: 6. Position the blower motor into pl ace and install the retaining screws.

7. Install the blower motor cooling tube.

8. Connect all the electrical connections.

9. Connect the negative battery cable.

Page 215 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 215

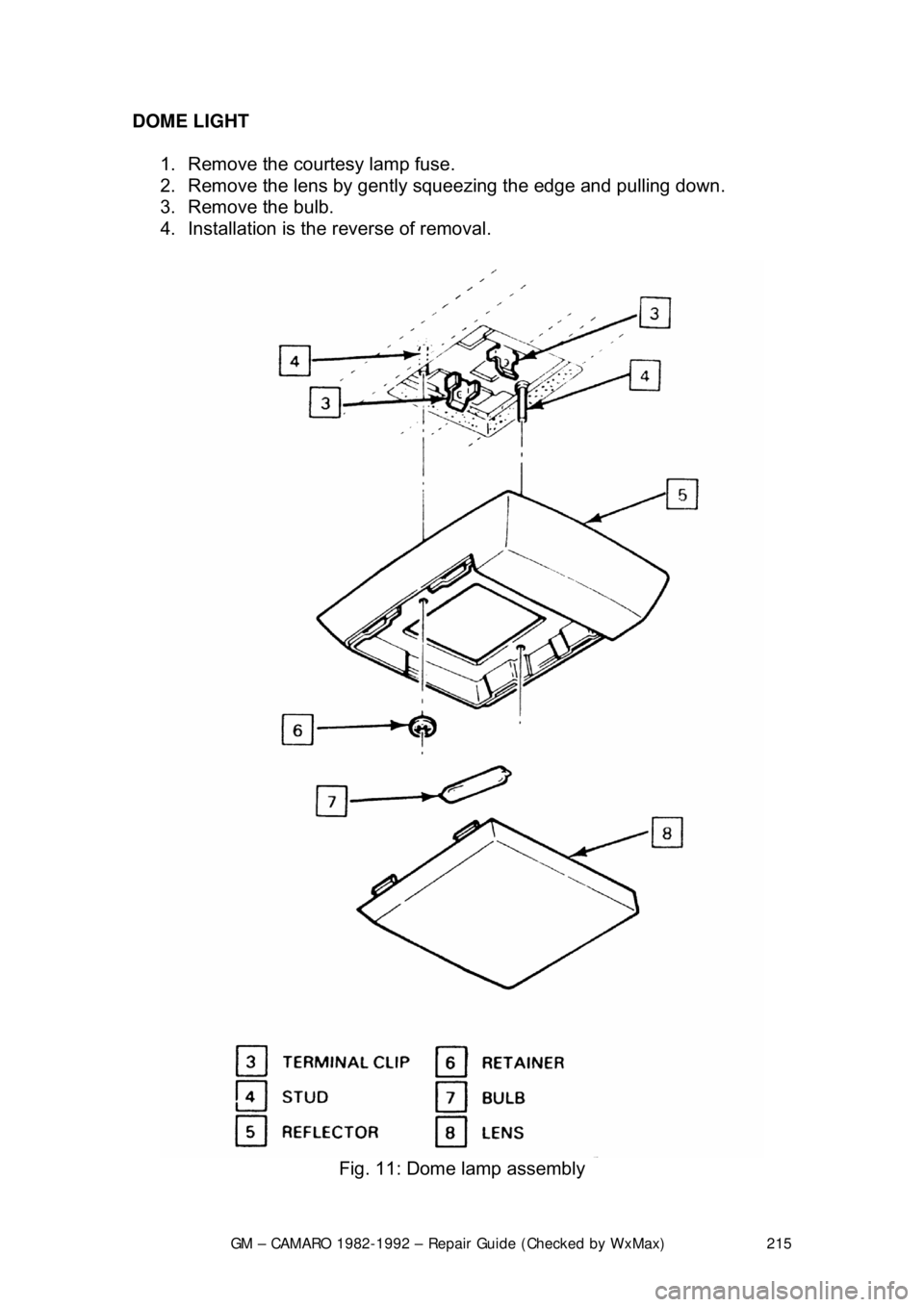

DOME LIGHT

1. Remove the courtesy lamp fuse.

2. Remove the lens by gently squeezing the edge and pulling down.

3. Remove the bulb.

4. Installation is the reverse of removal.

Fig. 11: Dome lamp assembly