boot CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 300 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 300

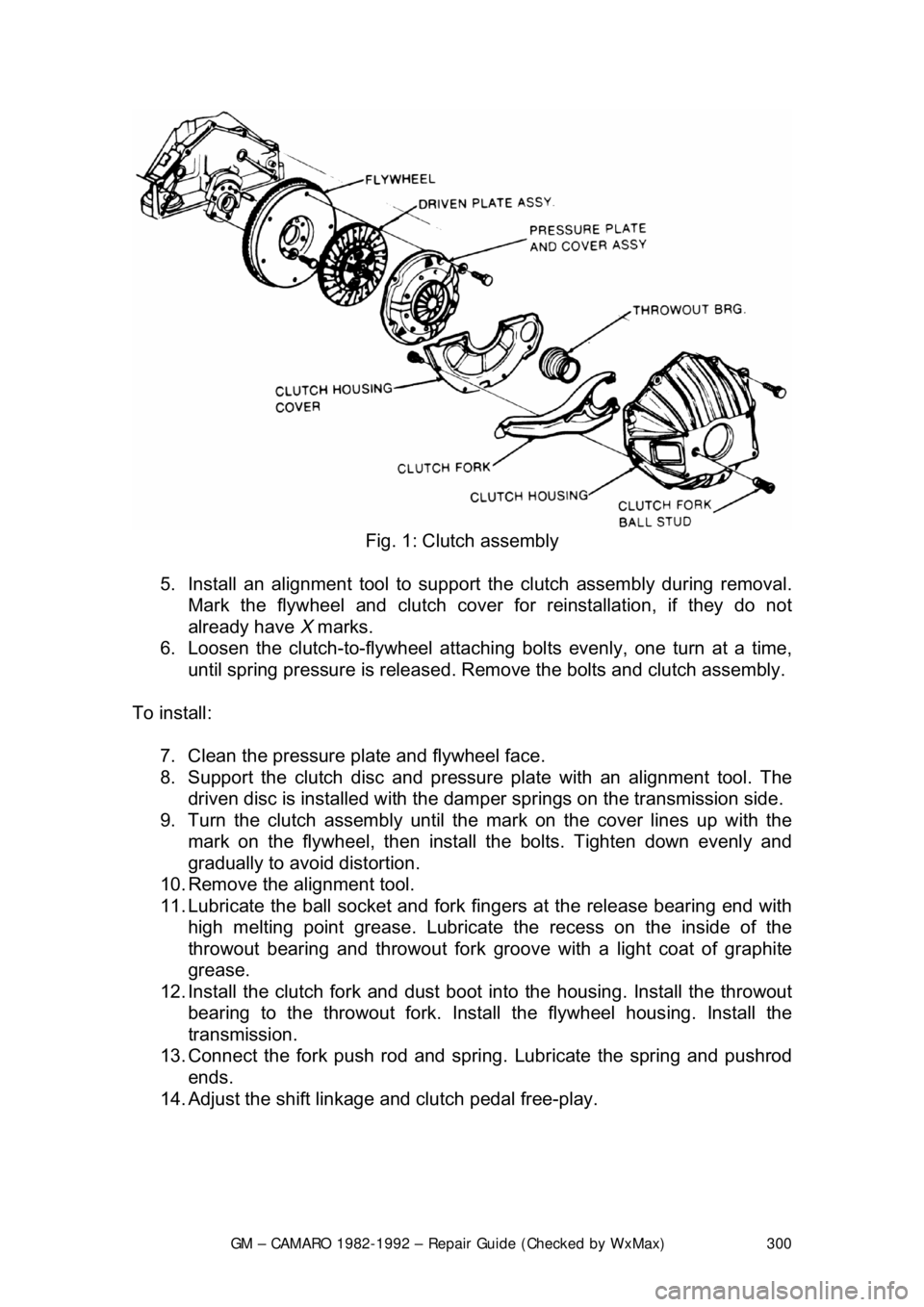

Fig. 1: Clutch assembly

5. Install an alignment tool to support the clutch assembly during removal.

Mark the flywheel and clutch cover for reinstallation, if they do not

already have X marks.

6. Loosen the clutch-to-flywheel attachi ng bolts evenly, one turn at a time,

until spring pressure is released. Remo ve the bolts and clutch assembly.

To install: 7. Clean the pressure plate and flywheel face.

8. Support the clutch di sc and pressure plate with an alignment tool. The

driven disc is installed with the damper springs on the transmission side.

9. Turn the clutch assembly until t he mark on the cover lines up with the

mark on the flywheel, then install t he bolts. Tighten down evenly and

gradually to avoid distortion.

10. Remove the alignment tool.

11. Lubricate the ball socket and fork fi ngers at the release bearing end with

high melting point greas e. Lubricate the recess on the inside of the

throwout bearing and throwout fork groove with a light coat of graphite

grease.

12. Install the clutch fork and dust boot into the housing. Install the throwout

bearing to the throwout fork. Insta ll the flywheel housing. Install the

transmission.

13. Connect the fork push rod and spri ng. Lubricate the spring and pushrod

ends.

14. Adjust the shift linkage and clutch pedal free-play.

Page 580 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 580

4. Spray a commercial solvent onto the sensor threads and allow it to soak

in for at least five minutes.

5. Carefully remove the sensor wit h a special oxygen sensor socket.

To install: 6. First coat the new sensor's th reads with GM anti-seize compound No.

5613695 or the equivalent. This is not a conventional anti-seize paste.

The use of a regular compound may el ectrically insulate the sensor,

rendering it inoperative. Y ou must coat the threads with an electrically

conductive anti-seize compound. Installati on torque is 30 ft. lbs. (41 Nm).

Do not overtighten.

7. Reconnect the electric al wiring. Be careful not to damage the electrical

pigtail. Check the sensor boot fo r proper fit and installation.

8. Reconnect the negative battery cable.

COOLANT TEMPERATURE SENSOR

OPERATION

Most engine functions are affected by the coolant temperature. Determining

whether the engine is hot or cold is largely dependent on the temperature of the

coolant. An accurate temperature signal to the ECM is supplied by the coolant

temperature sensor. The coolant temperatur e sensor is a thermistor mounted in

the engine coolant stream. A thermistor is an electrical device that varies its

resistance in relation to changes in temperature. Low coolant temperature

produces a high resistance and high coolant temperature produces low

resistance. The ECM supplies a signal of 5 volts to the coolant temperature

sensor through a resistor in the ECM and measures the voltage. The voltage

will be high when the engine is cold and low when the engine is hot.

REMOVAL & INSTALLATION

1. Disconnect the negative battery cable.

2. Drain the cooling system to an appropr iate and clean container for reuse.

3. Disconnect the electrical wiring fr om the coolant temperature sensor.

4. Remove the coolant temperature sensor.

To install: 5. Install the coolant temperature sensor.

6. Connect the electrical wiring.

7. Fill the cooling system.

8. Connect the negative battery cable.

9. Start the engine and check for leaks.

Page 629 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 629

as much voltage to fire the plug at hi

gh speeds than at idle. The improved

air/fuel ratio control of modern fuel injection combin ed with the higher voltage

output of modern ignition systems will often allow an engine to run significantly

longer on a set of standard spark plugs, but keep in mind that efficiency will

drop as the gap widens (along wit h fuel economy and power).

When you're removing spark plugs, work on one at a time. Don't start by

removing the plug wires all at once, because, unless you number them, they

may become mixed up. Take a minute before you begin and number the wires

with tape.

1. Disconnect the negative battery cabl e, and if the vehicle has been run

recently, allow the engine to thoroughly cool.

2. Carefully twist the spark plug wire boot to loosen it, then pull upward and

remove the boot from the plug. Be su re to pull on the boot and not on the

wire, otherwise the connector locat ed inside the boot may become

separated.

3. Using compressed air, blow any water or debris from the spark plug well

to assure that no harmful contam inants are allowed to enter the

combustion chamber when the spark plug is removed. If compressed air

is not available, use a rag or a brush to clean the area.

Remove the spark plugs when the engine is cold, if possible, to prevent damage

to the threads. If removal of the plugs is difficult, apply a few drops of

penetrating oil or silicone spray to t he area around the base of the plug, and

allow it a few minutes to work.

4. Using a spark plug socket that is equipped with a rubber insert to

properly hold the plug, turn the spar k plug counterclockwise to loosen

and remove the spark pl ug from the bore.

WARNING - Be sure not to use a flexible extension on the socket. Use of a

flexible extension may allow a shear fo rce to be applied to the plug. A shear

force could break the plug off in the cylinder head, leading to costly a\

nd

frustrating repairs.

To install:

5. Inspect the spark plug boot for t ears or damage. If a damaged boot is

found, the spark plug wire must be replaced.

6. Using a wire feeler gauge, check and adjust the spark plug gap. When

using a gauge, the proper size shoul d pass between the electrodes with

a slight drag. The next larger size should not be able to pass while the\

next smaller size should pass freely.

7. Carefully thread the plug into the bor e by hand. If resistance is felt before

the plug is almost completely th readed, back the plug out and begin

threading again. In small, hard to r each areas, an old spark plug wire and

boot could be used as a th reading tool. The boot will hold the plug while

you twist the end of the wire and t he wire is supple enough to twist

before it would allow t he plug to crossthread.

Page 630 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 630

WARNING

- Do not use the spark plug socke t to thread the plugs. Always

carefully thread the plug by hand or us ing an old plug wire to prevent the

possibility of crossthreading and damaging the cylinder head bore.

8. Carefully tighten the spark plug. If the plug you are installing is equipped

with a crush washer, seat the plug, then tighten about

1/4 turn to crush

the washer. If you are installing a t apered seat plug, tighten the plug to

specifications provided by the vehicle or plug manufacturer.

9. Apply a small amount of silicone di electric compound to the end of the

spark plug lead or inside the spark pl ug boot to prevent sticking, then

install the boot to the spark plug and pus h until it clicks into place. The

click may be felt or hear d, then gently pull back on the boot to assure

proper contact.

INSPECTION & GAPPING

Check the plugs for deposits and wear. If they are not going to be replaced,

clean the plugs thoroughly. Remember t hat any kind of deposit will decrease

the efficiency of the plug. Plugs can be cleaned on a spark plug cleaning

machine, which can sometimes be found in service stations, or you can do an

acceptable job of cleaning with a stiff br ush. If the plugs are cleaned, the

electrodes must be filed flat. Use an igni tion points file, not an emery board or

the like, which will leave deposits. The electrodes must be filed perfectly flat

with sharp edges; rounded edges reduce the s park plug voltage by as much as

50%.

Check spark plug gap before installati on. The ground electrode (the L-shaped

one connected to the body of the plug) mu st be parallel to the center electrode

and the specified size wire gauge (please refer to the Tune-Up Specifications

chart for details) must pass between t he electrodes with a slight drag.

NEVER adjust the gap on a used platinum type spark plug .

Always check the gap on new plugs as they are not always set correctly a\

t the

factory. Do not use a flat feeler g auge when measuring the gap on a used plug,

because the reading may be inaccurate. A round-wire type gapping tool is the

best way to check the gap. The co rrect gauge should pass through the

electrode gap with a slight drag. If you're in doubt, try one size smaller and one

larger. The smaller gauge should go through easily, while the larger one\

shouldn't go through at all. Wire gapping tools usually have a bending tool

attached. Use that to adjust the side electrode until the proper distance is

obtained. Absolutely never attempt to bend the center electrode. Also, be

careful not to bend the side electrode too fa r or too often as it may weaken and

break off within the engine, requiring remova l of the cylinder head to retrieve it.

Page 633 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 633

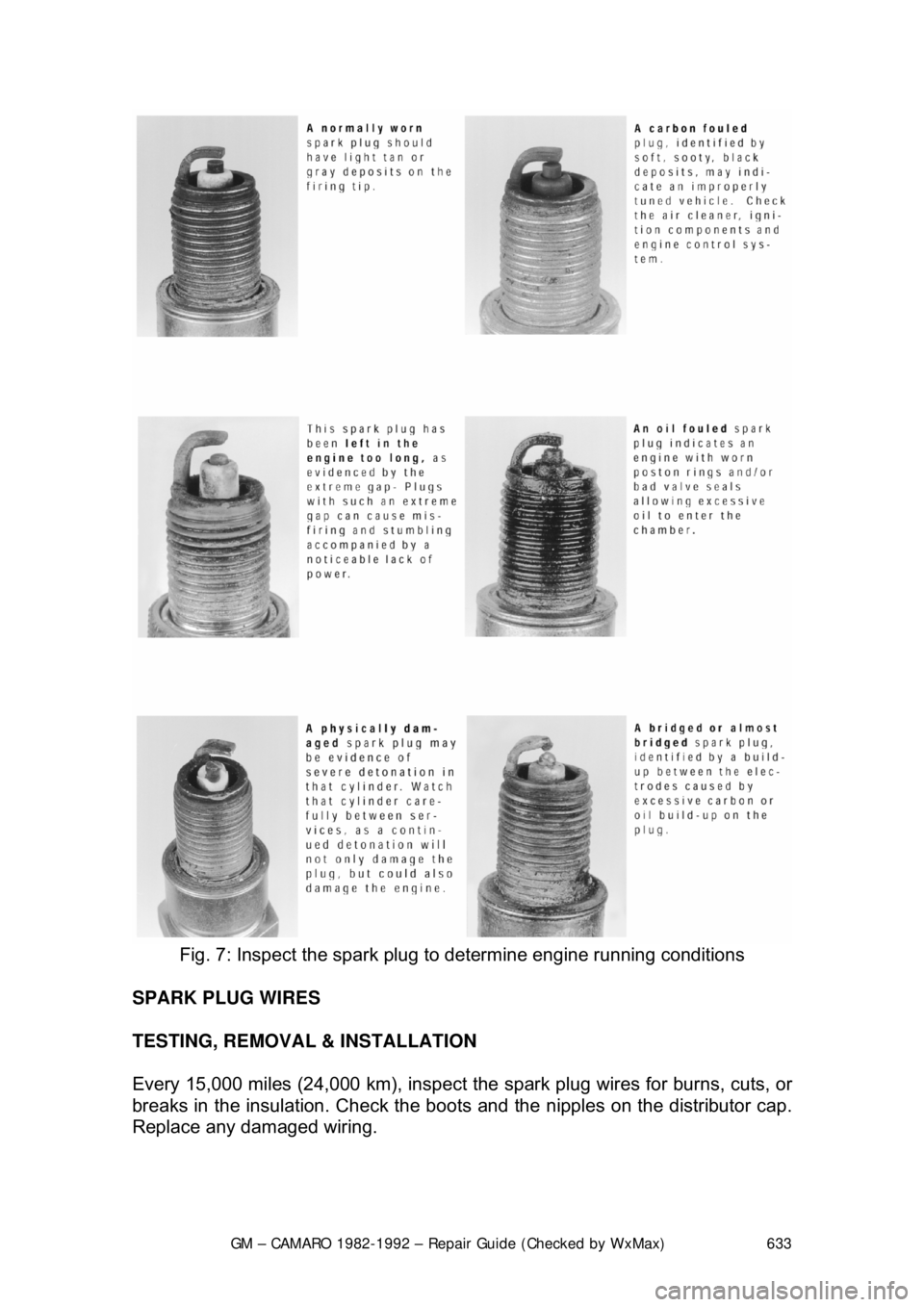

Fig. 7: Inspect the spark plug to determine engine running conditions

SPARK PLUG WIRES

TESTING, REMOVAL & INSTALLATION

Every 15,000 miles (24,000 km), inspect the spark plug wires for burns, cuts, or

breaks in the insulation. Check the boots and the nipples on the distributor cap.

Replace any damaged wiring.

Page 639 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 639

In the HEI system, as in other electr

onic ignition systems, the breaker points

have been replaced wit h an electronic switch - a tr ansistor - which is located

within the ignition module. This switching transistor pe rforms the same function

the points did in a conventi onal ignition system; it simply turns the coil's primary

current on and off at the correct time. Essentially, electronic and conventional

ignition systems operate on t he same principle.

The module which houses the switching transistor is controlled (turned on and

off) by a magnetically gener ated impulse induced in the pickup coil. When the

teeth of the rotating timer align with t he teeth of the pole piece, the induced

voltage in the pickup coil signals the elec tronic module to open the coil primary

circuit. The primary current then decreases, and a high voltage is induced in the

ignition coil secondary windings, which is then directed through the rotor and

high voltage leads (spark plug wires) to fire the spark plugs.

In essence, the pickup coil module system simply replaces the conventional

breaker points and condenser. The condenser found within the distributor is for

radio suppression purposes only and has nothing to do with the ignition

process. The ignition module automatically controls the dwell period, increasing

it with increasing en gine speed. Since dwell is co ntrolled in this manner, it

cannot be adjusted. The module itse lf is non-adjustable/non-repairable and

must be replaced if found defective.

SYSTEM PRECAUTIONS

Before proceeding with troubleshooting, ta ke note of the following precautions:

TIMING LIGHT USE

Care should be exercised when connec ting a timing light or other pick-up

equipment. Do not force anything between the boots and wiring, or through the

silicone jacket. Connections should be made in parallel using an adapter.

Inductive pickup timing lights are the bes t kind to use with the ignition systems

covered by this information.

SPARK PLUG WIRES

The plug wires used with these systems are of a different construction than

conventional wires. When replacing them, make sure you get the correct wires,

since conventional wires will not carry the voltage. Also, handle the wires

carefully to avoid cracking or splitti ng them, and NEVER pierce the wires.

TACHOMETER USE

Not all tachometers will operate or indi cate correctly when used on an HEI or

C

3I system. While some tachometers ma y give a reading, this does not

necessarily mean the reading is correct. In addition, some tachometers hook up

differently from others. If you cannot fi gure out whether or not your tachometer

will work on your car, check with the tachometer manufacturer.

Page 645 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 645

3. If no defects have been found at this

time, and you still have a problem,

then the module will have to be che cked. If you do not have access to a

module tester, the only possible alter native is a substitution test. If the

module fails the substitution test, replace it.

COMPONENT REPLACEMENT

CAUTION - When handling secondar y spark plug leads with the engine running

or starting, insulated pliers must be used and care exercised to prevent a

possible electrical shock.

HEI SYSTEM

IGNITION COIL

EXTERNALLY MOUNTED

1. Disconnect the negative battery cable.

2. Disconnect the ignition coil wire from the coil. Do so by pulling on the

boot of the wire while twisting it.

3. Disconnect the harness connecto r from the ignition coil.

4. Remove the coil mounting screws and the ignition coil. If necessary, drill

out and remove the rivets holding the coil to the bracket.

To install: 5. Place the ignition coil in position on the mounting bracket and install the

mounting screws.

6. Reconnect the harness connectors to the ignition coil. Confirm that the

harness connectors are firmly attached to the coil.

7. Install the secondary coil wire to the coil tower.

8. Connect the negative battery cable.