boot CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 48 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 48

BRAKES

BASIC OPERATING PRINCIPLES

Hydraulic systems are used to actuate t he brakes of all modern automobiles.

The system transports the power required to force the frictional surfaces of the

braking system together from the pedal to the individual brake units at each

wheel. A hydraulic system is used for two reasons.

First, fluid under pressure can be carried to all parts of an automobile by small

pipes and flexible hoses without taking up a significant amount of room or

posing routing problems.

Second, a great mechanical advantage can be given to the brake pedal end of

the system, and the foot pressure requi red to actuate the brakes can be

reduced by making the surface area of t he master cylinder pistons smaller than

that of any of the pistons in t he wheel cylinders or calipers.

The master cylinder consists of a flui d reservoir along with a double cylinder

and piston assembly. Double type master cylinders are designed to separate

the front and rear braking systems hydraulic ally in case of a leak. The master

cylinder coverts mechanical motion from t he pedal into hydraulic pressure within

the lines. This pressure is translated back into mechanical motion at th\

e wheels

by either the wheel cylinder (drum brak es) or the caliper (disc brakes).

Steel lines carry the brake fluid to a po int on the vehicle's frame near each of

the vehicle's wheels. The fluid is then ca rried to the calipers and wheel cylinders

by flexible tubes in order to allow for suspension and steering movements.

In drum brake systems, each wheel cylinde r contains two pistons, one at either

end, which push outward in opposite direct ions and force the brake shoe into

contact with the drum.

In disc brake systems, the cylinders ar e part of the calipers. At least one

cylinder in each caliper is used to fo rce the brake pads against the disc.

All pistons employ some type of seal, us ually made of rubber, to minimize fluid

leakage. A rubber dust boot seals the outer end of the cylinder against dust and

dirt. The boot fits around the outer end of the piston on disc brake calipers, and

around the brake actuating rod on wheel cylinders.

The hydraulic system operates as follows : When at rest, the entire system, from

the piston(s) in the master cylinder to t hose in the wheel cylinders or calipers, is

full of brake fluid. Upon app lication of the brake pedal, fluid trapped in front of

the master cylinder piston(s) is forced through the lines to the wheel cylinders.

Here, it forces the pistons outward, in the case of drum brakes, and inward

toward the disc, in the case of disc brakes. The motion of the pistons is

opposed by return springs mounted outside the cylinders in drum brakes, and

by spring seals, in disc brakes.

Page 57 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 57

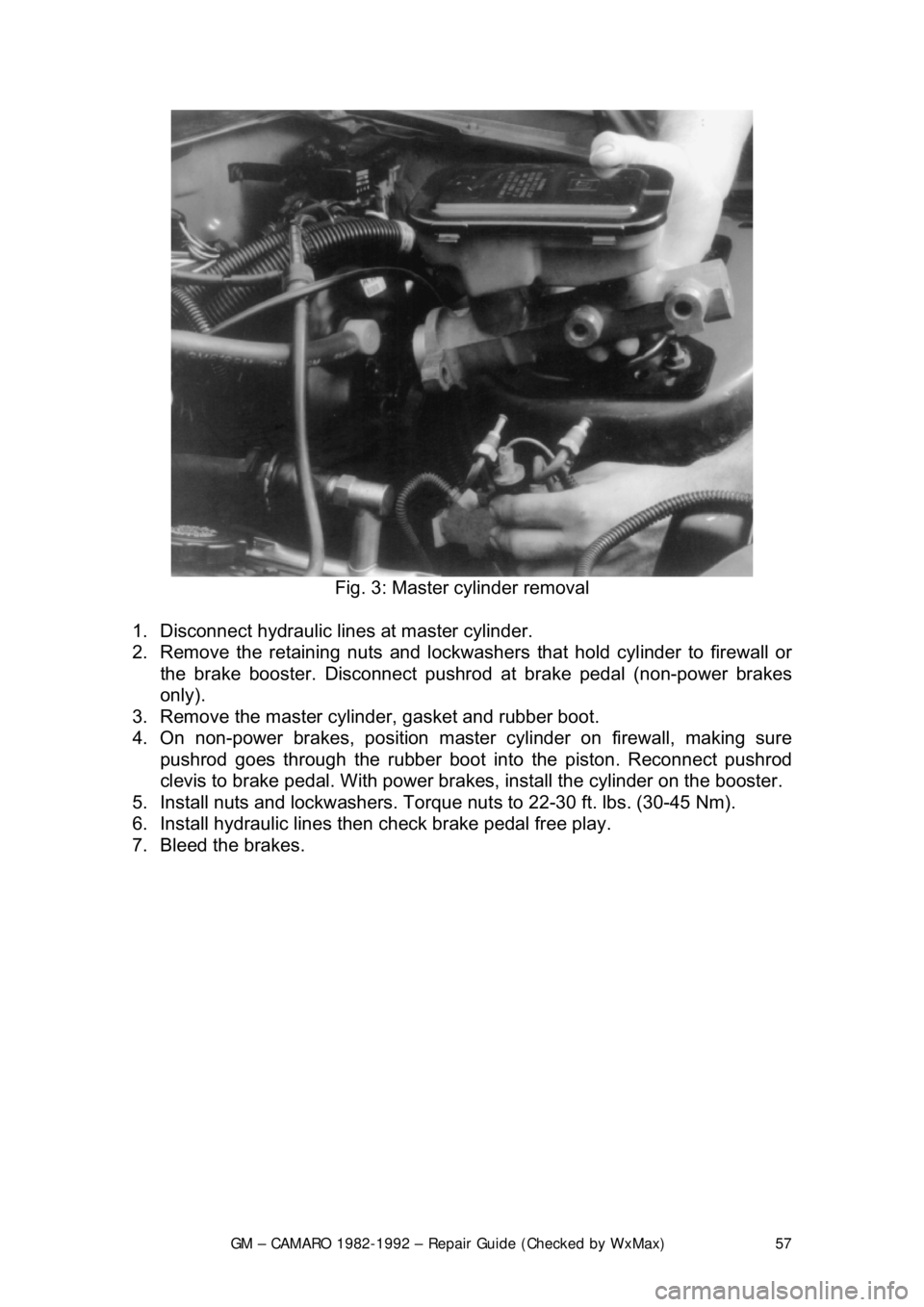

Fig. 3: Master cylinder removal

1. Disconnect hydraulic lines at master cylinder.

2. Remove the retaining nuts and lockwasher s that hold cylinder to firewall or

the brake booster. Disconnect pushrod at brake pedal (non-power brakes

only).

3. Remove the master cylinder, gasket and rubber boot.

4. On non-power brakes, position master cylinder on firewall, making sure pushrod goes through the rubber boot in to the piston. Reconnect pushrod

clevis to brake pedal. With power brakes, install the cylinder on the bo\

oster.

5. Install nuts and lockwashers. Torque nut s to 22-30 ft. lbs. (30-45 Nm).

6. Install hydraulic lines t hen check brake pedal free play.

7. Bleed the brakes.

Page 82 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 82

Avoid inhaling any dust from

any brake surface! When cleaning brake surfaces,

use a commercially available brake cleaning fluid.

1. Remove

2/3 of the brake fluid from the mast er cylinder. Raise the vehicle and

remove the wheel.

2. Place a C-clamp across the caliper, positioned on the brake pads. Tighten it

until the piston is forced into its bore.

3. Remove the C-clamp. Remove the bolt holding the brake hose to the caliper.

4. Remove the Allen head caliper mounting bolts. Inspect them for corrosion

and replace them if necessary. Remove the caliper.

To install:

5. Position the caliper with the brake pad installed and install Allen head caliper

mounting bolts. Mounting bo lt torque is 21-35 ft. lbs. (28-47 Nm.) for the

caliper.

6. Install the bolt holding the brake hos e to the caliper and tighten to 18-30 ft.

lbs. (24-40 Nm.).

7. Fill the master cylinder with brake fluid.

8. Install the wheels and lower the vehicle.

CAUTION - Before moving the vehicle, pump the brakes several times to seat

the brake pad against the rotor

OVERHAUL

Some vehicles may be equipped dual piston calipers. The procedure to

overhaul the caliper is e ssentially the same with t he exception of multiple

pistons, O-rings and dust boots.

1. Remove the caliper from the ve hicle and place on a clean workbench.

CAUTION - NEVER place your finger s in front of the pistons in an attempt to

catch or protect the pistons when applying compressed air. This could result in

personal injury!

Depending upon the vehicle, there are two different ways to remove the piston

from the caliper. Refer to the brake pad replacement procedure to make sure

you have the correct procedure for your vehicle.

2. The first method is as follows: a. Stuff a shop towel or a block of wood into the caliper to catch the piston.

b. Remove the caliper piston using co mpressed air applied into the caliper

inlet hole. Inspect the piston for scor ing, nicks, corrosion and/or worn or

damaged chrome plating. The piston mu st be replaced if any of these

conditions are found.

Page 84 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 84

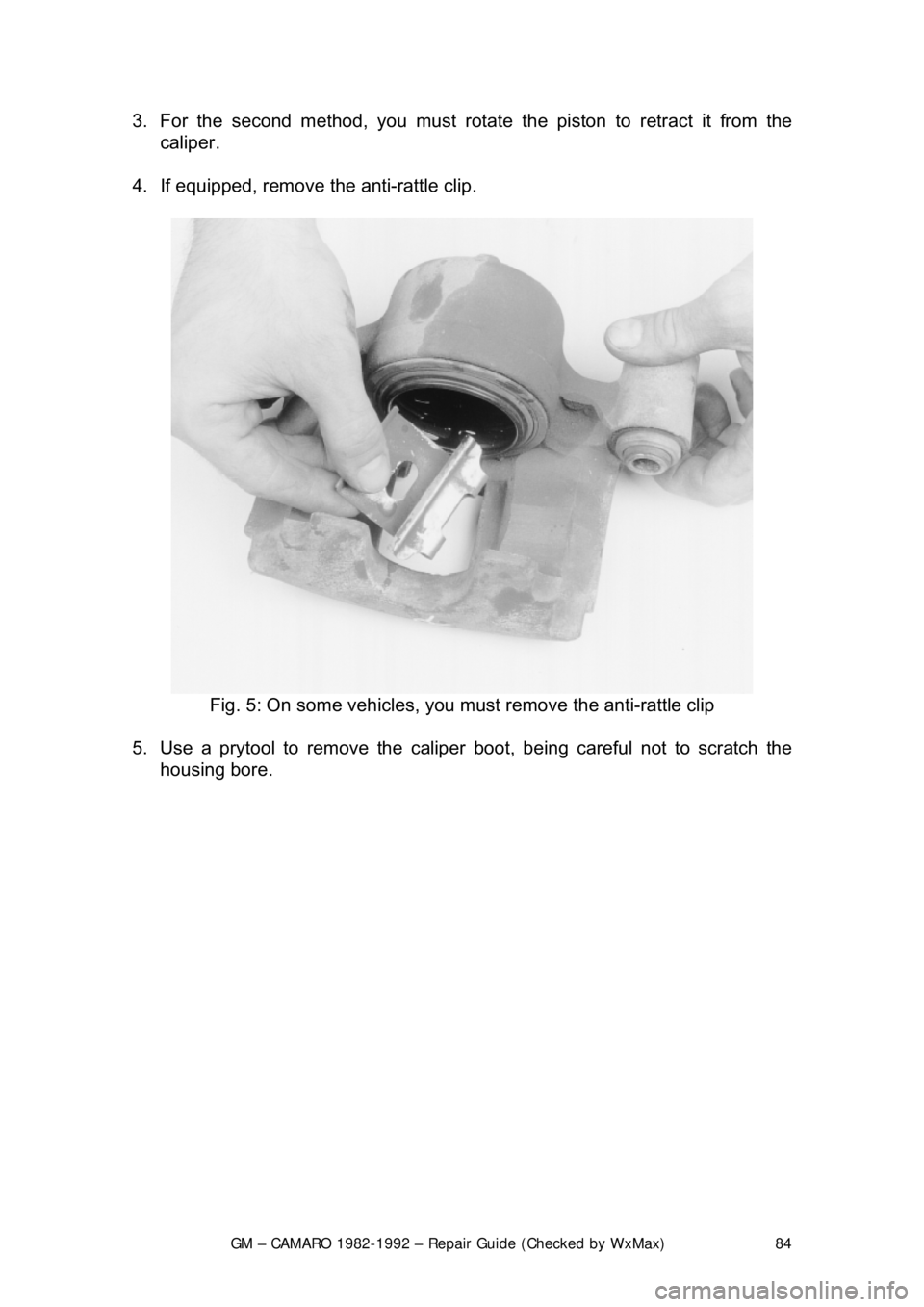

3. For the second method, you must rota

te the piston to retract it from the

caliper.

4. If equipped, remove th e anti-rattle clip.

Fig. 5: On some vehicles, you must remove the anti-rattle clip

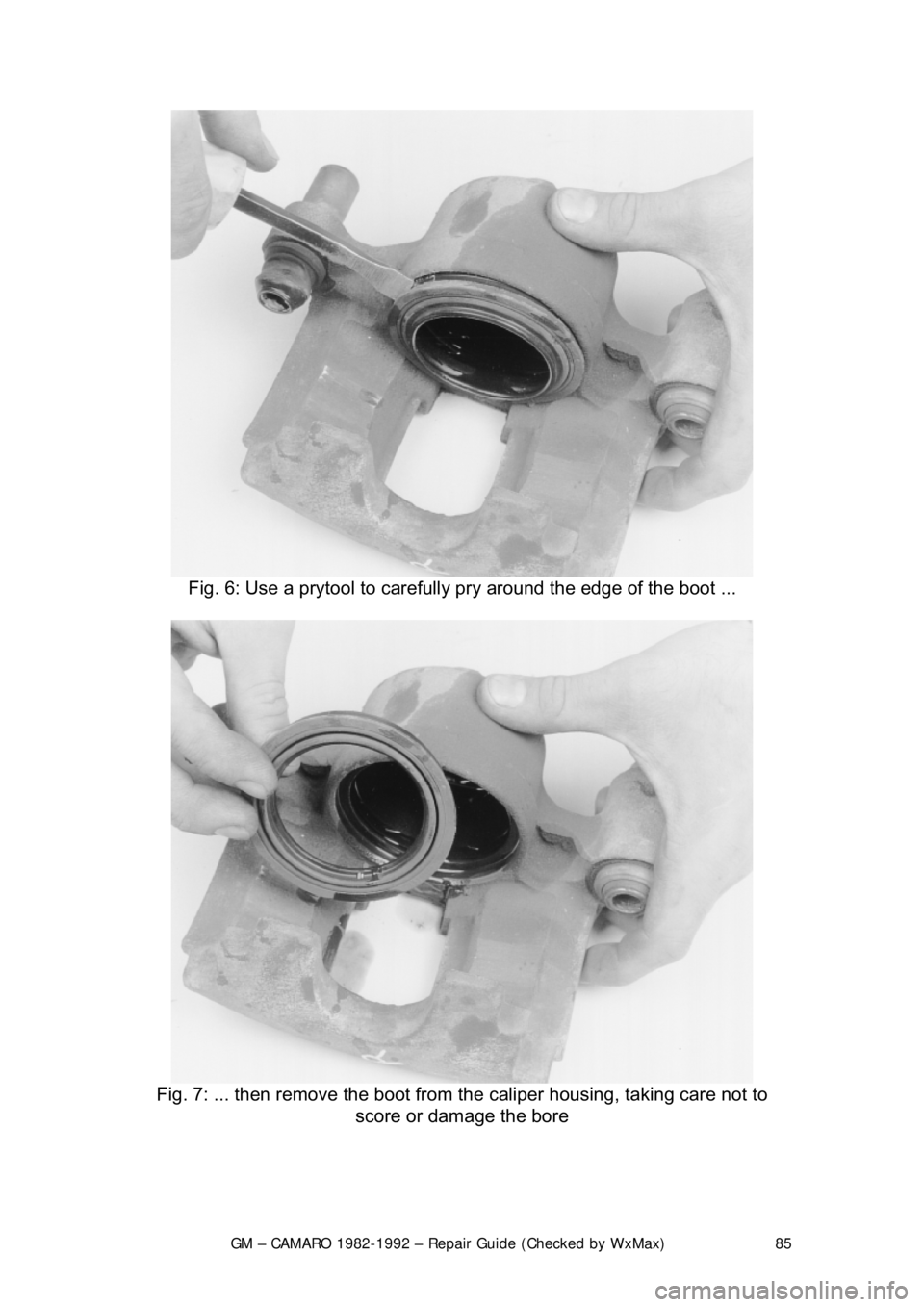

5. Use a prytool to remove the caliper boot, being careful not to scratch the

housing bore.

Page 85 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 85

Fig. 6: Use a prytool to carefully pry around the edge of the boot ...

Fig. 7: ... then remo ve the boot from the caliper housing, taking care not to

score or damage the bore

Page 86 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 86

6. Remove the piston seals from

the groove in the caliper bore.

Fig. 8: Use extreme caution when remo ving the piston seal; DO NOT scratch

the caliper bore

7. Carefully loosen the br ake bleeder valve cap and valve from the caliper

housing.

8. Inspect the caliper bores, pistons and mounting threads for scoring or excessive wear.

9. Use crocus cloth to polish out light corrosion from the piston and bore.

10. Clean all parts with denatured alcohol and dry with compressed air.

To assemble:

11. Lubricate and install th e bleeder valve and cap.

12. Install the new seals into the caliper bore grooves, making sure they are not

twisted.

13. Lubricate the piston bore.

14. Install the pistons and boots into the bores of the calipers and push to the

bottom of the bores.

15. Use a suitable driving tool to seat the boots in the housing.

Page 87 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 87

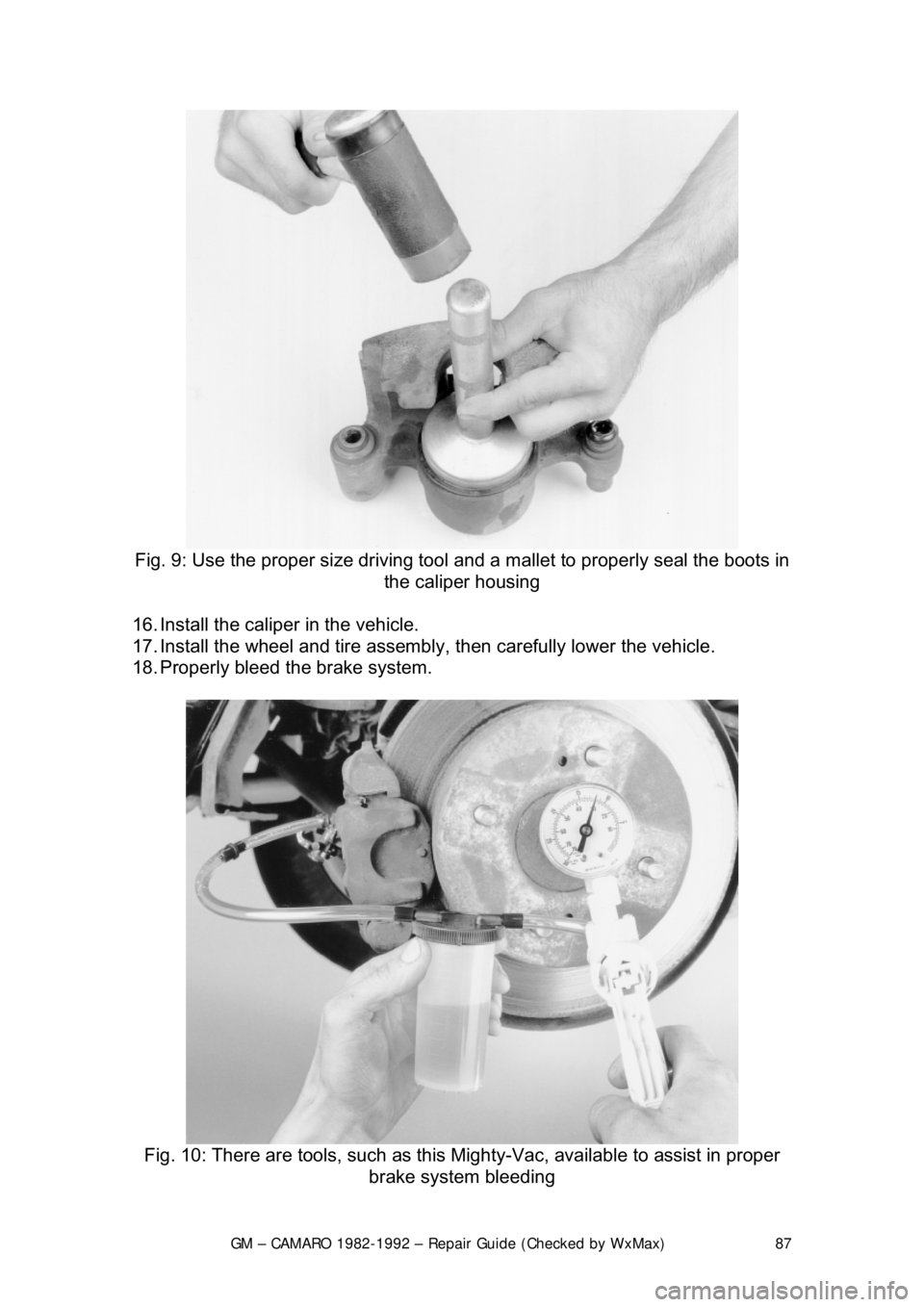

Fig. 9: Use the proper size driving tool and a mallet to properly seal the boots in

the caliper housing

16. Install the caliper in the vehicle.

17. Install the wheel and tire assembly , then carefully lower the vehicle.

18. Properly bleed t he brake system.

Fig. 10: There are tools, such as this Mighty-Vac, available to assist in proper

brake system bleeding

Page 102 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 102

CAUTION

- Brake shoes may contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

1. Raise and support the car. Remove t he wheel. Remove the brake shoes by

following the Brake Shoe R eplacement procedure.

2. Remove dirt from ar ound the wheel cylinder inle t and pilot. Disconnect the

inlet tube.

3. Using 2 awls,

1/8 in. (3mm) in diameter, or J29839, remove the wheel

cylinder retainer. Insert the awls in to the access slots between the wheel

cylinder pilot and retainer. Simultaneous ly, bend both tabs away from each

other. Remove the wheel cylinder.

To install:

4. Place wheel cylinder into position and place a block of wood between it and

the axle flange. Install a new retainer over the end of the wheel cylinder.

Using a 1

1/8 in. 12-point socket with an extensi on, drive the new retainer into

position.

5. Connect the inlet tube and torque 120-280 inch lbs. (13.6-20 Nm). Complete

installation by reversing the remova l procedure. Bleed the brakes.

OVERHAUL

Wheel cylinder overhaul kits may be available, but often at little or no savings

over a reconditioned wheel cylinder. It often makes sense with these

components to substitute a new or re conditioned part instead of attempting an

overhaul.

If no replacement is availabl e, or you would prefer to overhaul your wheel

cylinders, the following procedure may be used. When rebuilding and installing

wheel cylinders, avoid getting any cont aminants into the system. Always use

clean, new, high quality brake fluid. If di rty or improper fluid has been used, it

will be necessary to drain the entire syst em, flush the system with proper brake

fluid, replace all rubber components , then refill and bleed the system.

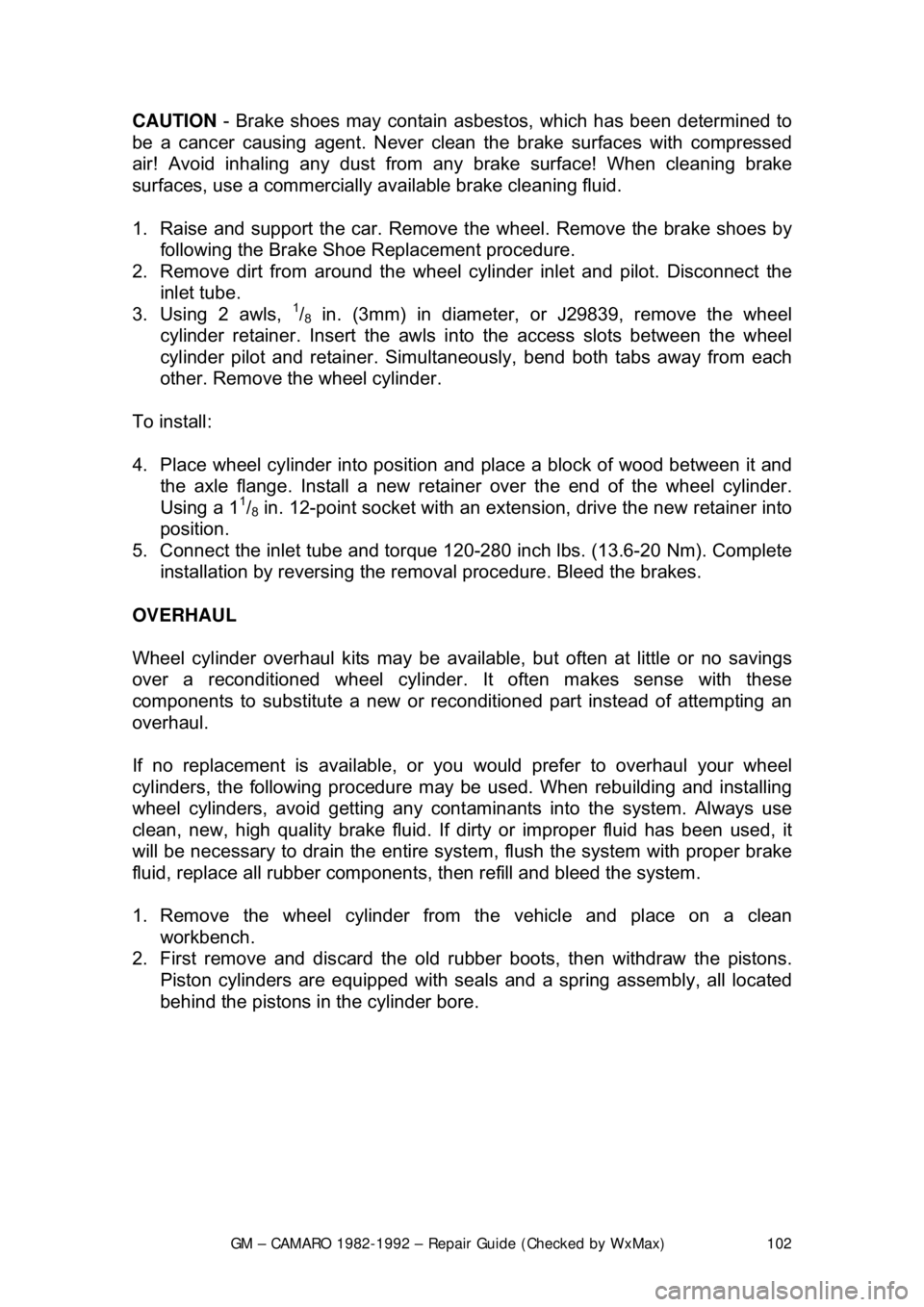

1. Remove the wheel cylinder from the vehicle and place on a clean

workbench.

2. First remove and discard the old r ubber boots, then withdraw the pistons.

Piston cylinders are equipped with seals and a spring assembly, all located

behind the pistons in the cylinder bore.

Page 103 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 103

Fig. 4: Remove the outer boots from the wheel cylinder

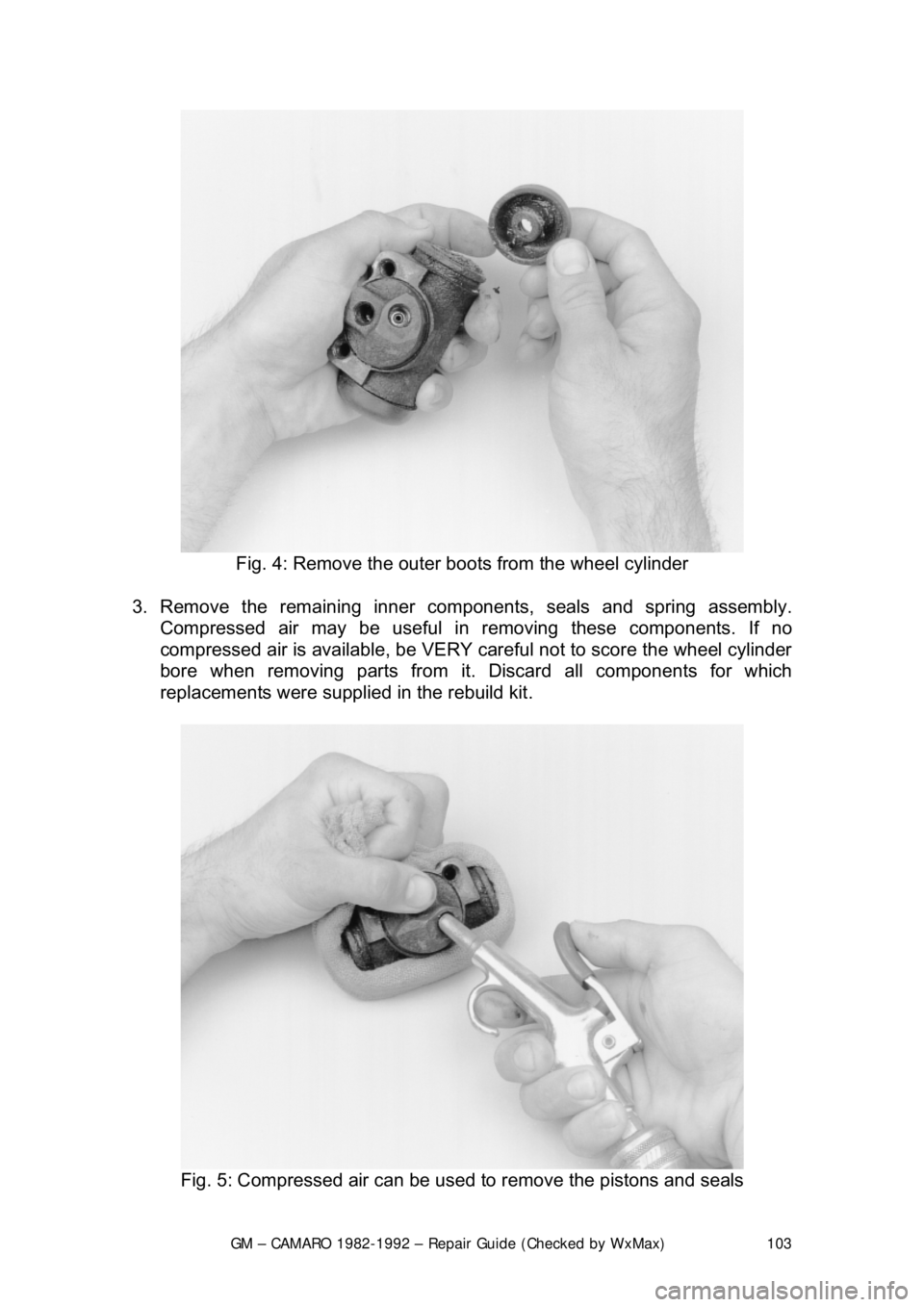

3. Remove the remaining inner com ponents, seals and spring assembly.

Compressed air may be useful in removing these components. If no

compressed air is available, be VERY careful not to score the wheel cylinder

bore when removing parts from i t. Discard all components for which

replacements were supplied in the rebuild kit.

Fig. 5: Compressed air can be used to remove the pistons and seals

Page 107 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 107

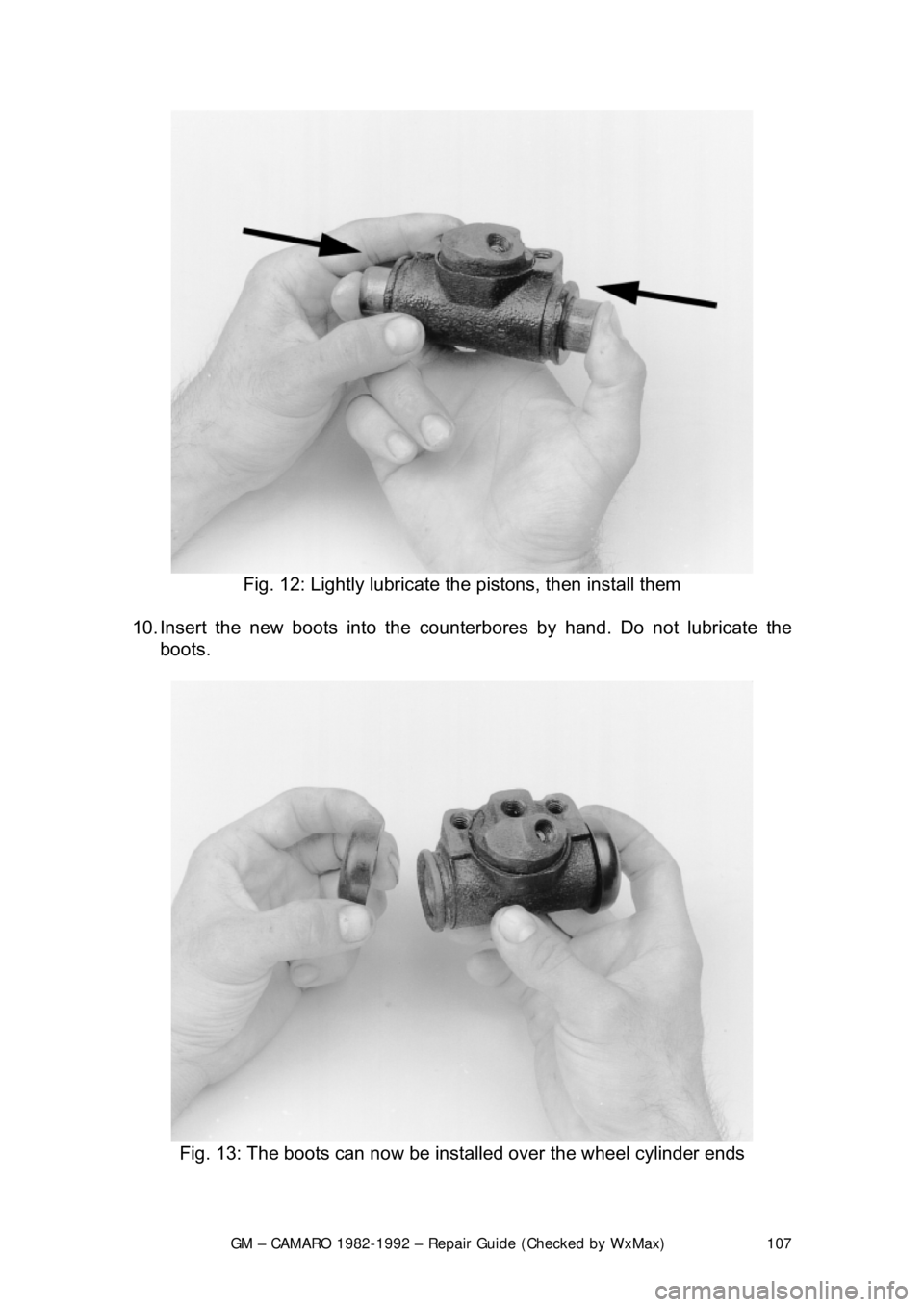

Fig. 12: Lightly lubricate t he pistons, then install them

10. Insert the new boots in to the counterbores by hand. Do not lubricate the

boots.

Fig. 13: The boots can now be installed over the wheel cylinder ends