torque CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 803 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 803

5. Pry out the inner seal and

remove the inner bearing.

6. Wipe out the grease from inside the hub.

7. Clean the wheel bearings thor oughly with solvent and check their

condition before installation. Afte r cleaning, check parts for excessive

wear and replace damaged parts.

WARNING - Do not allow the bearing to spin when blowing dry with

compressed air, as this would allow t he bearing to turn without lubrication.

8. Apply a sizable amount of lubricant to the palm of one hand. Using your

other hand, work the bearing into the lubricant so that the grease is

pushed through the rollers and out t he other side. Keep rotating the

bearing while continuing to push the lubricant through it.

9. Apply grease to the inside of t he hub and install the inner bearing in the

hub. Install a new grease seal, be careful not to damage the seal.

10. Install the disc/hub assembly onto t he steering knuckle. Install the outer

bearing, thrust washer and castle nu t. Torque the nut to 12 ft. lbs. (16

Nm) while turning the wheel.

11. Back the nut off and retighten it by hand until nearest slot aligns with the

cotter pin hole.

12. Insert a new cotter pin.

13. Mount a dial indicator onto the vehi cle so that any end-play in the hub

can be measured. Measure the end-play and record the value. End-play

should be between 0.001-0.005 in. (0.025- 0.127mm). If play exceeds this

tolerance, the wheel bearings should be replaced.

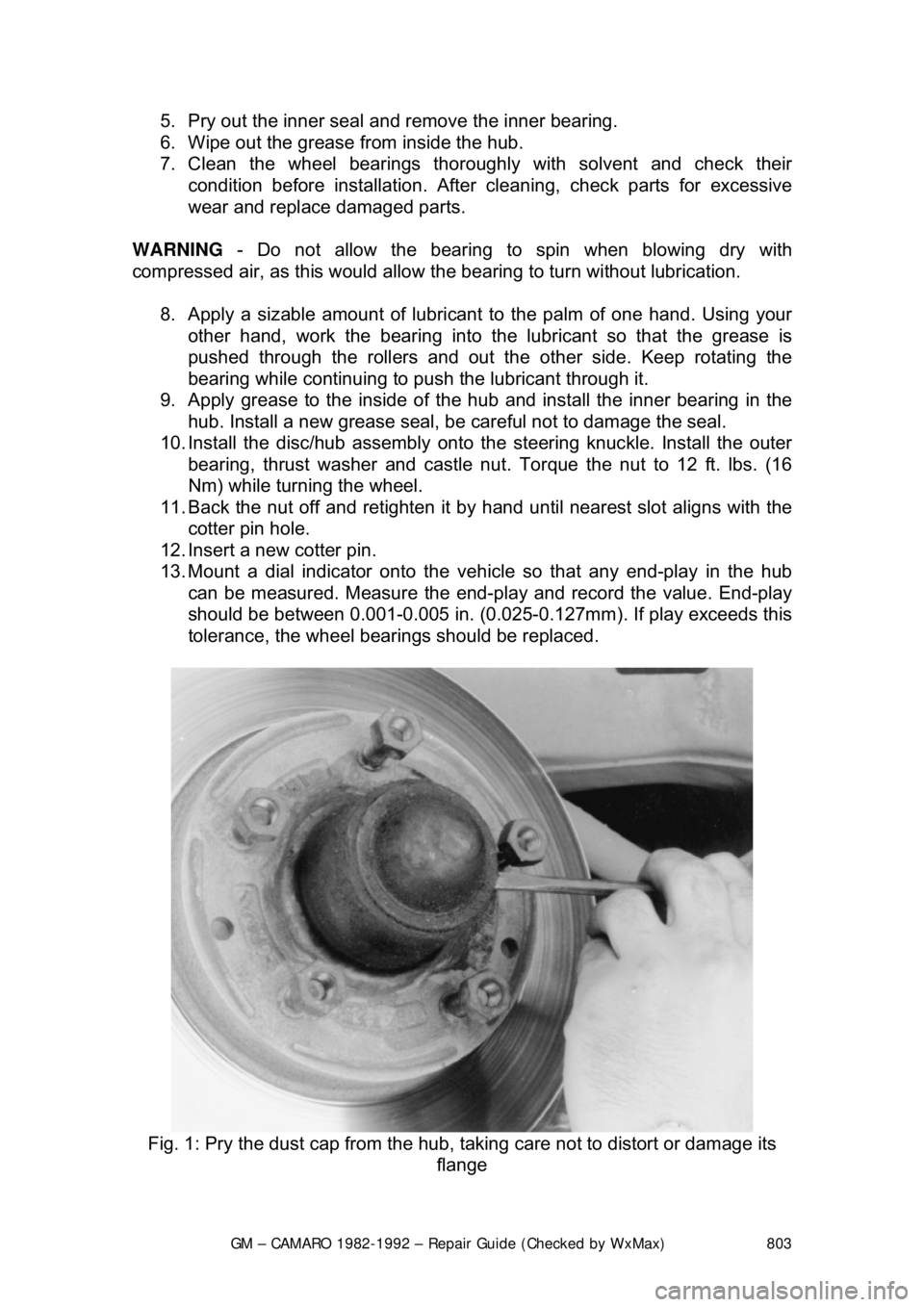

Fig. 1: Pry the dust cap fr om the hub, taking care not to distort or damage its

flange

Page 818 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 818

•

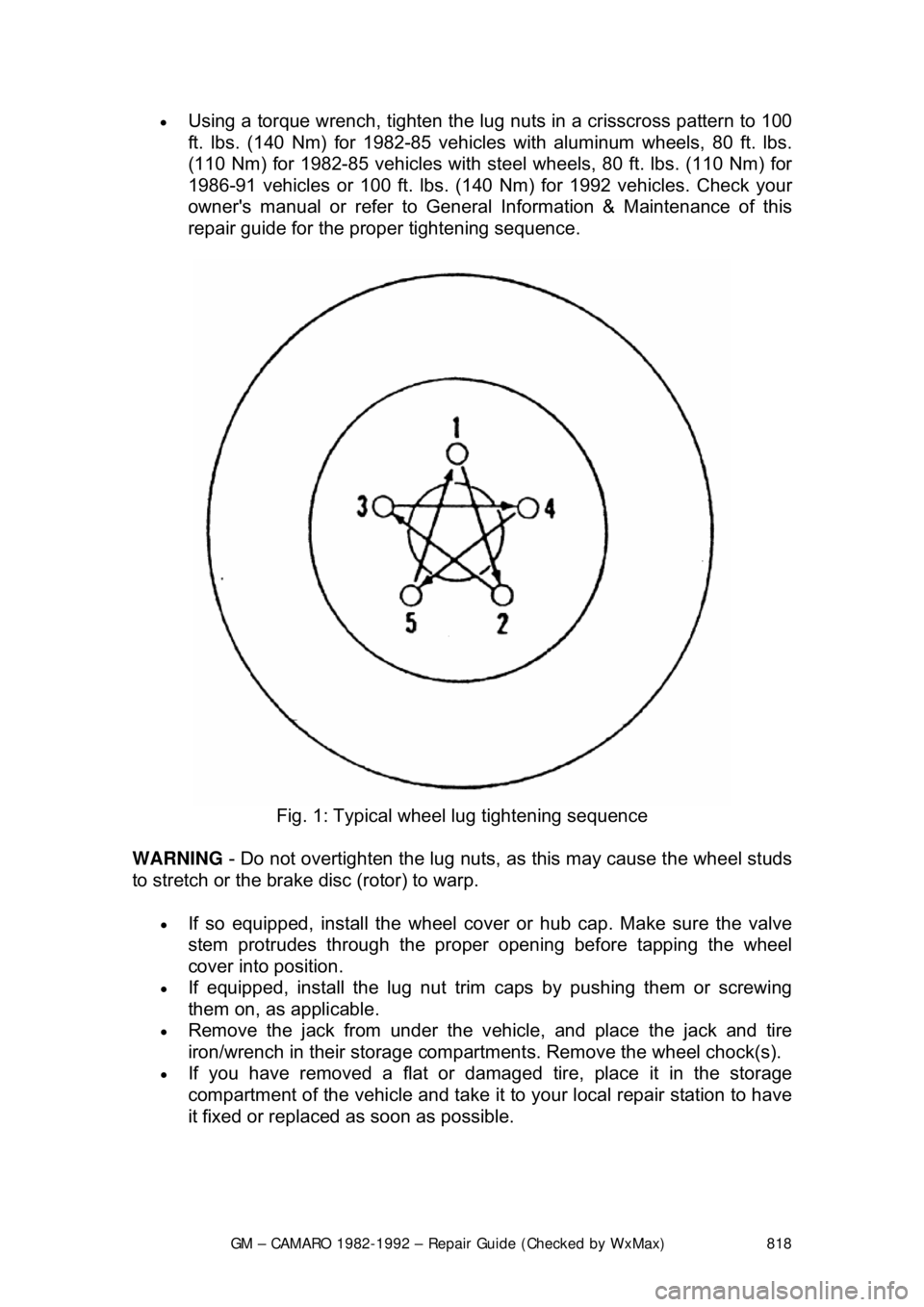

Using a torque wrench, tighten the lug nuts in a crisscross pattern to 100

ft. lbs. (140 Nm) for 1982-85 vehicles with aluminum wheels, 80 ft. lbs.

(110 Nm) for 1982-85 vehicles with st eel wheels, 80 ft. lbs. (110 Nm) for

1986-91 vehicles or 100 ft. lbs. (140 Nm) for 1992 vehicles. Check your

owner's manual or refer to General Information & Maintenance of this

repair guide for the proper tightening sequence.

Fig. 1: Typical wheel lug tightening sequence

WARNING - Do not overtighten the lug nuts, as this may cause the wheel studs

to stretch or the brake disc (rotor) to warp.

• If so equipped, install the wheel cover or hub cap. Make sure the valve

stem protrudes throu gh the proper opening bef ore tapping the wheel

cover into position.

• If equipped, install the lug nut trim caps by pushing them or screwing

them on, as applicable.

• Remove the jack from under the v ehicle, and place the jack and tire

iron/wrench in their storage compartment s. Remove the wheel chock(s).

• If you have removed a flat or damaged tire, place it in the storage

compartment of the vehicle and take it to your local repair station to have

it fixed or replaced as soon as possible.

Page 821 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 821

If a press is not availabl

e, start the lug stud through the bore in the hub, then

position about 4 flat washers over t he stud and thread the lug nut. Hold the

hub/rotor while tightening the lug nut, and the stud should be drawn into

position. MAKE SURE THE STUD IS FU LLY SEATED, then remove the lug nut

and washers.

7. Install the rotor and adjust the wheel bearings.

8. Install the brake caliper and pads.

9. Install the wheel, then remove the jackstands and carefully lower the

vehicle.

10. Tighten the lug nuts to the proper torque.

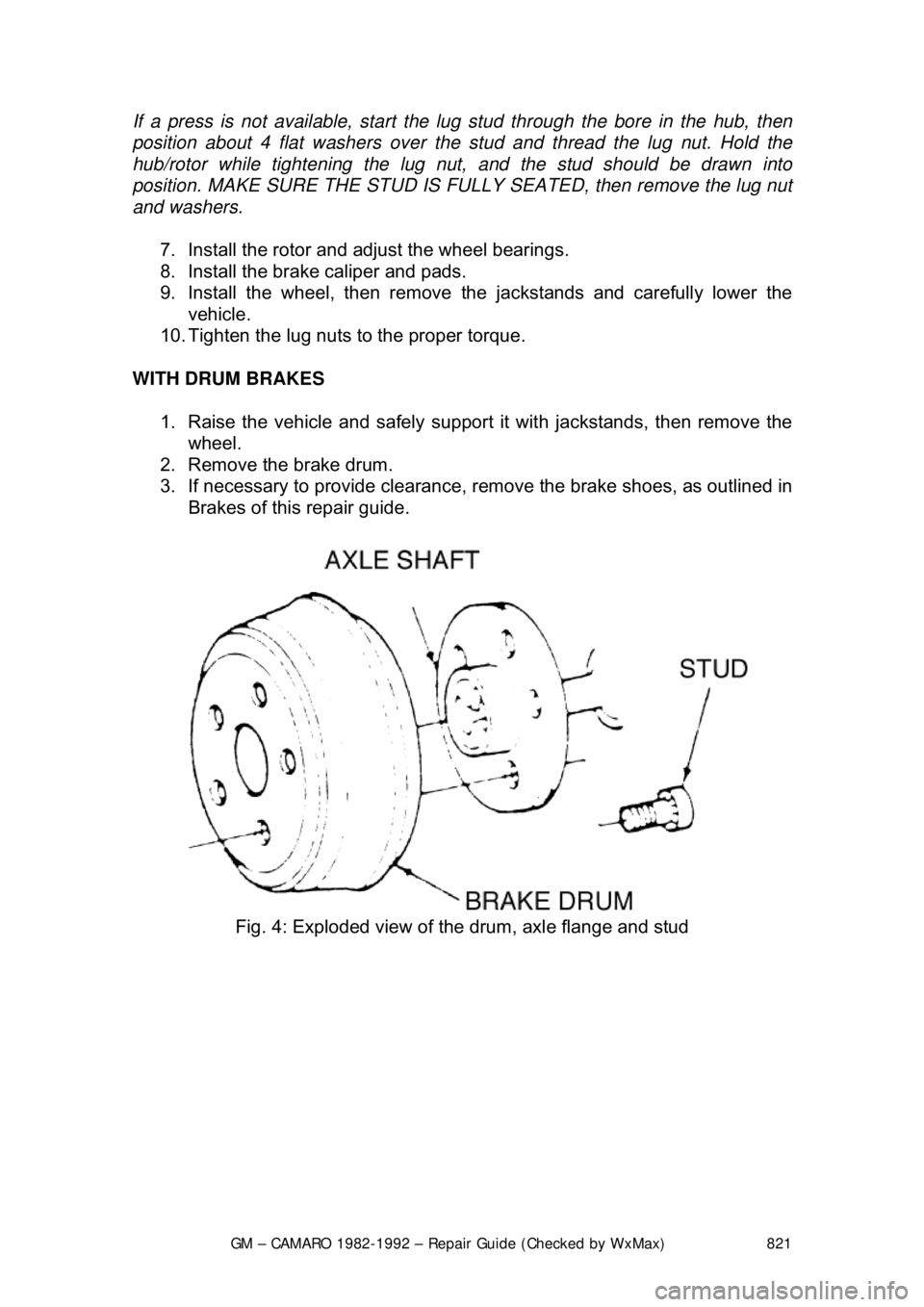

WITH DRUM BRAKES 1. Raise the vehicle and safely su pport it with jackstands, then remove the

wheel.

2. Remove the brake drum.

3. If necessary to provide clearance, re move the brake shoes, as outlined in

Brakes of this repair guide.

Fig. 4: Exploded view of t he drum, axle flange and stud

Page 822 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 822

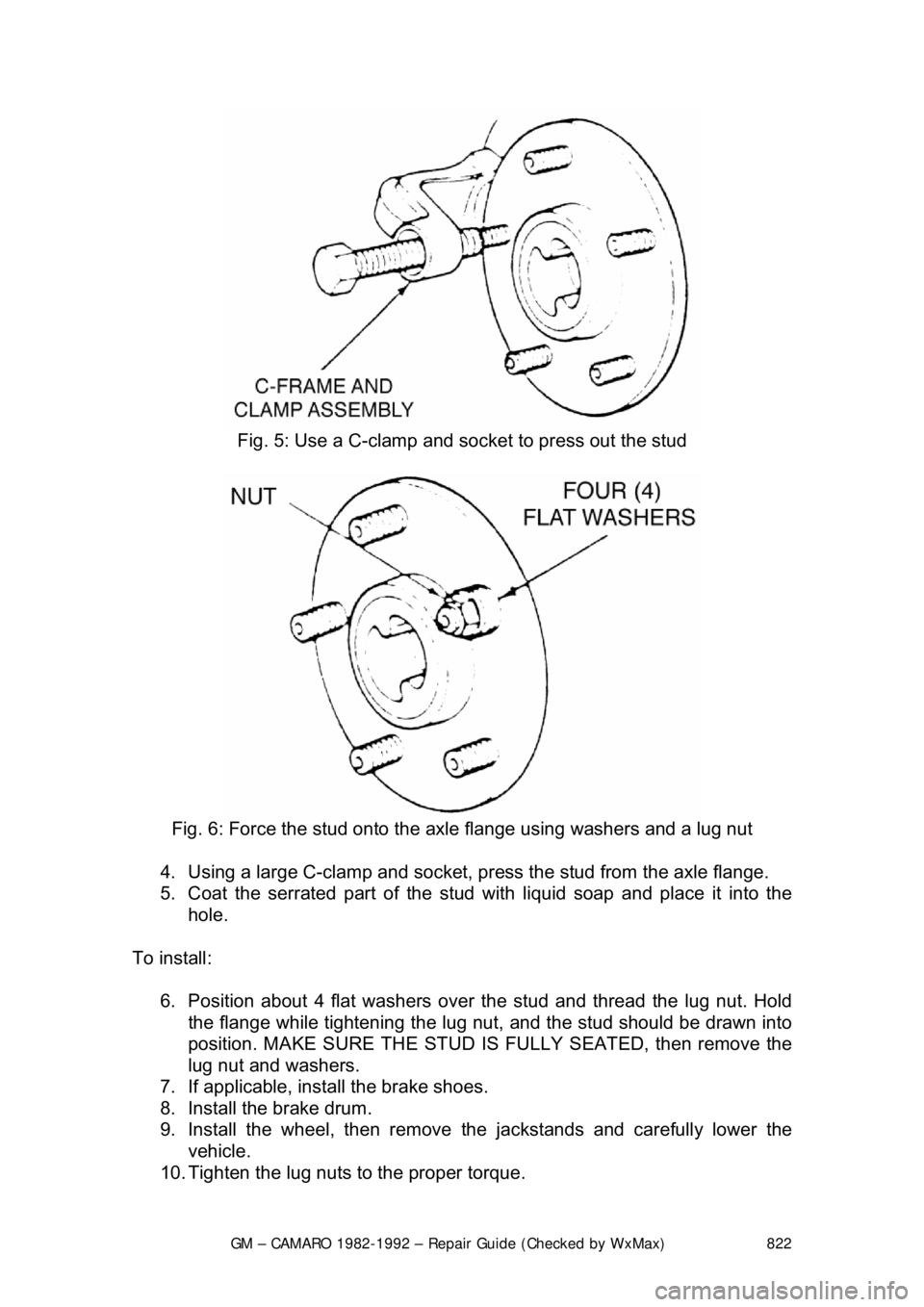

Fig. 5: Use a C-clamp and socket to press out the stud

Fig. 6: Force the stud onto the axle flange using washers and a lug nut

4. Using a large C-clamp and socket, pre ss the stud from the axle flange.

5. Coat the serrated part of the stud with liquid soap and place it into the

hole.

To install: 6. Position about 4 flat washers over the stud and thread the lug nut. Hold

the flange while tightening the lug nut, and the stud should be drawn into

position. MAKE SURE THE STUD IS FULLY SEATED, then remove the

lug nut and washers.

7. If applicable, install the brake shoes.

8. Install the brake drum.

9. Install the wheel, then remove the jackstands and carefully lower the

vehicle.

10. Tighten the lug nuts to the proper torque.

Page 829 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 829

12. Fully tighten the lower bolts onl

y when the front suspension is on the

ground. Torque the steering knuckle-to-strut nuts to 125 ft. lbs. (170 Nm)

followed by a 120 degree turn. Do not exceed a final torque of 148 Ft.

lbs. (200 Nm).

13. Install the brake caliper

14. Install the wheel and tire assembly.

15. Lower the front of the vehicle.

16. From inside the engine compartm ent, tighten the upper strut to upper

mount nut to 44 ft. lbs. (60 Nm).

17. Have the front end aligned.

OVERHAUL

The OEM domestic struts are serviced by replacement of the entire unit. There

is no strut cartridge to replace.

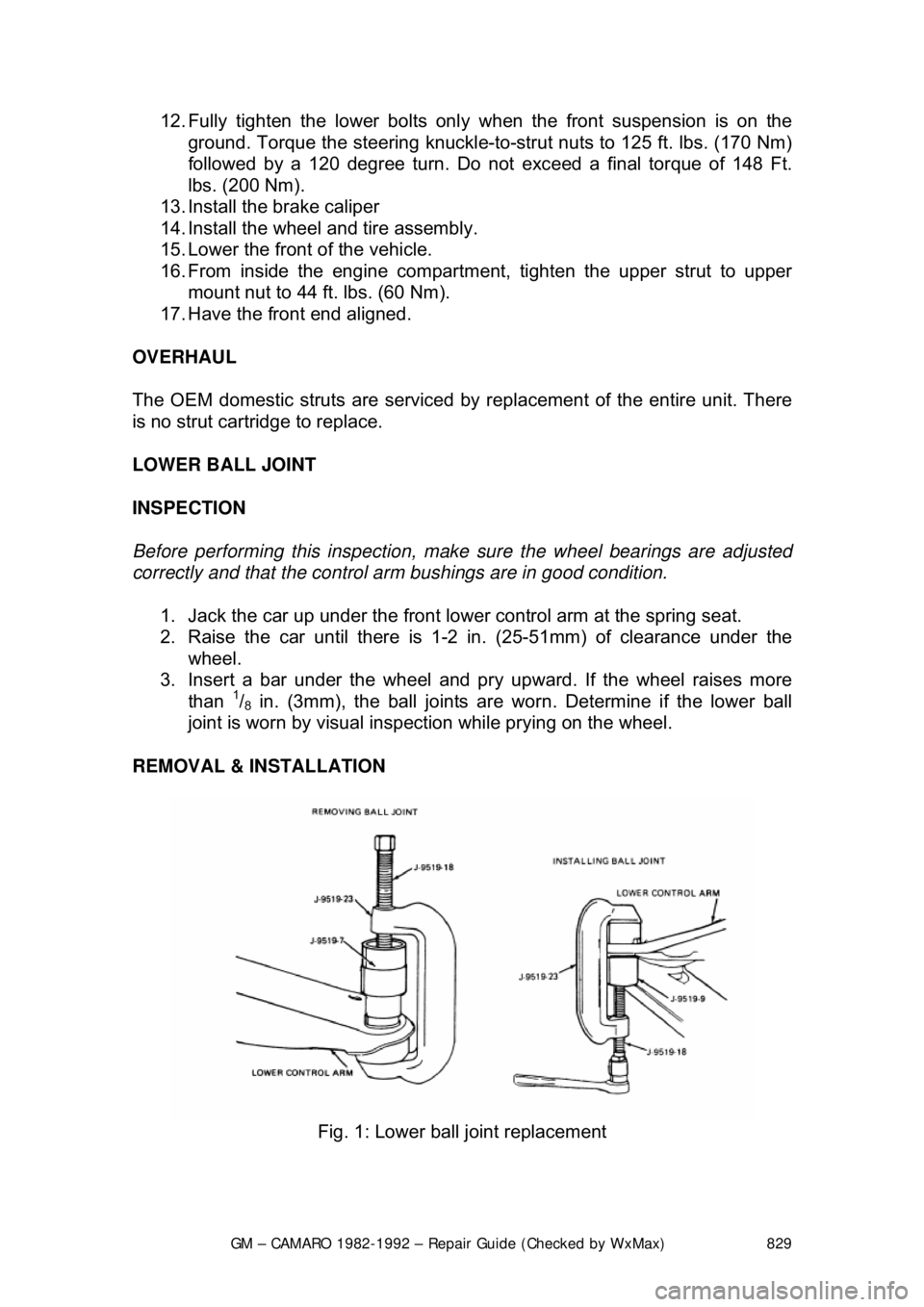

LOWER BALL JOINT

INSPECTION

Before performing this inspection, make sure the wheel bearings are adjusted

correctly and that the control arm bushings are in good condition.

1. Jack the car up under the front lower control arm at the spring seat.

2. Raise the car until t here is 1-2 in. (25-51mm) of clearance under the

wheel.

3. Insert a bar under the wheel and pr y upward. If the wheel raises more

than

1/8 in. (3mm), the ball joints are worn. Determine if the lower ball

joint is worn by visual inspec tion while prying on the wheel.

REMOVAL & INSTALLATION

Fig. 1: Lower ball joint replacement

Page 832 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 832

6. Hold the stabilizer shaft approximat

ely 55mm from the bottom of the side

rail and torque the bracket bolts to 37 ft. lbs. (50 Nm).

7. Install the bolt, nut, grommets, spacer and retainers.

8. Lower the car.

LOWER CONTROL ARM

REMOVAL & INSTALLATION 1. Raise the car and safely support on jackstands.

2. Remove the wheel and tire.

3. Remove the stabilizer link and bush ings at the lower control arm.

4. Remove the pivot bolt nuts. DO NOT re move the pivot bolts at this time.

5. Install tool J-23028 or equivalent adapter to the jack and place into

position with tool J-23028 or equival ent adapter supporting bushings.

6. Install the jackstand under the outsi de frame rail on the opposite side of

the vehicle.

7. Raise tool J-23028 or equivalent adapter enough to remove both pivot

bolts.

8. Lower tool J-23028 or equivalent adapter.

9. Remove the spring and insulato r tape insulator to the spring.

10. Remove the ball joint from the knuckle.

11. To install, reverse the removal procedure.

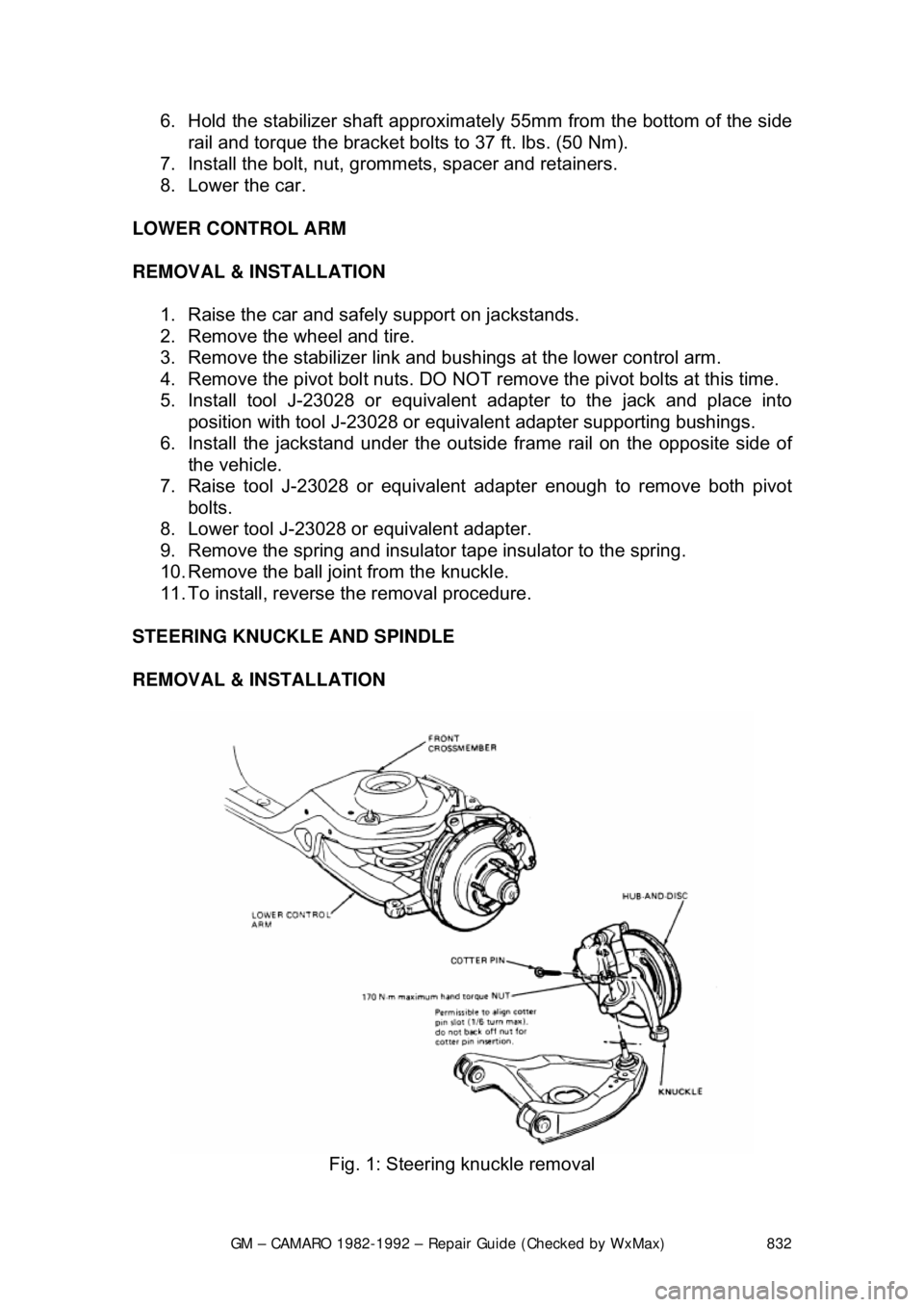

STEERING KNUCKLE AND SPINDLE

REMOVAL & INSTALLATION

Fig. 1: Steering knuckle removal

Page 841 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 841

1. Jack up the car to a convenient working height. Support the axle

assembly with jackstands.

2. Disconnect the upper s hock attaching nuts.

3. Remove the lower shock to axle mounting bolt.

4. Remove the shock absorber.

To install: 5. Position the shock into place.

6. Install the lower shoc k to axle mounting bolt. Torque to 70 ft. lbs. (95

Nm).

7. Connect the upper shock attaching nuts. Torque the upper nuts to 13 ft.

lbs. (17 Nm).

8. Lower the car.

TESTING

Visually inspect the shock absorber. If there is evidence of leakage and the

shock absorber is covered with oil, t he shock is defective and should be

replaced.

If there is no sign of excessive leakage (a small amount of weeping is normal)

bounce the car at one corner by pressi ng down on the fender or bumper and

releasing. When you have the car bouncing as much as you can, release it. The

car should stop bouncing after the first rebound. If the bouncing continues past

the center point of the bounce more t han once, the shock absorbers are worn

and should be replaced.

Page 842 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 842

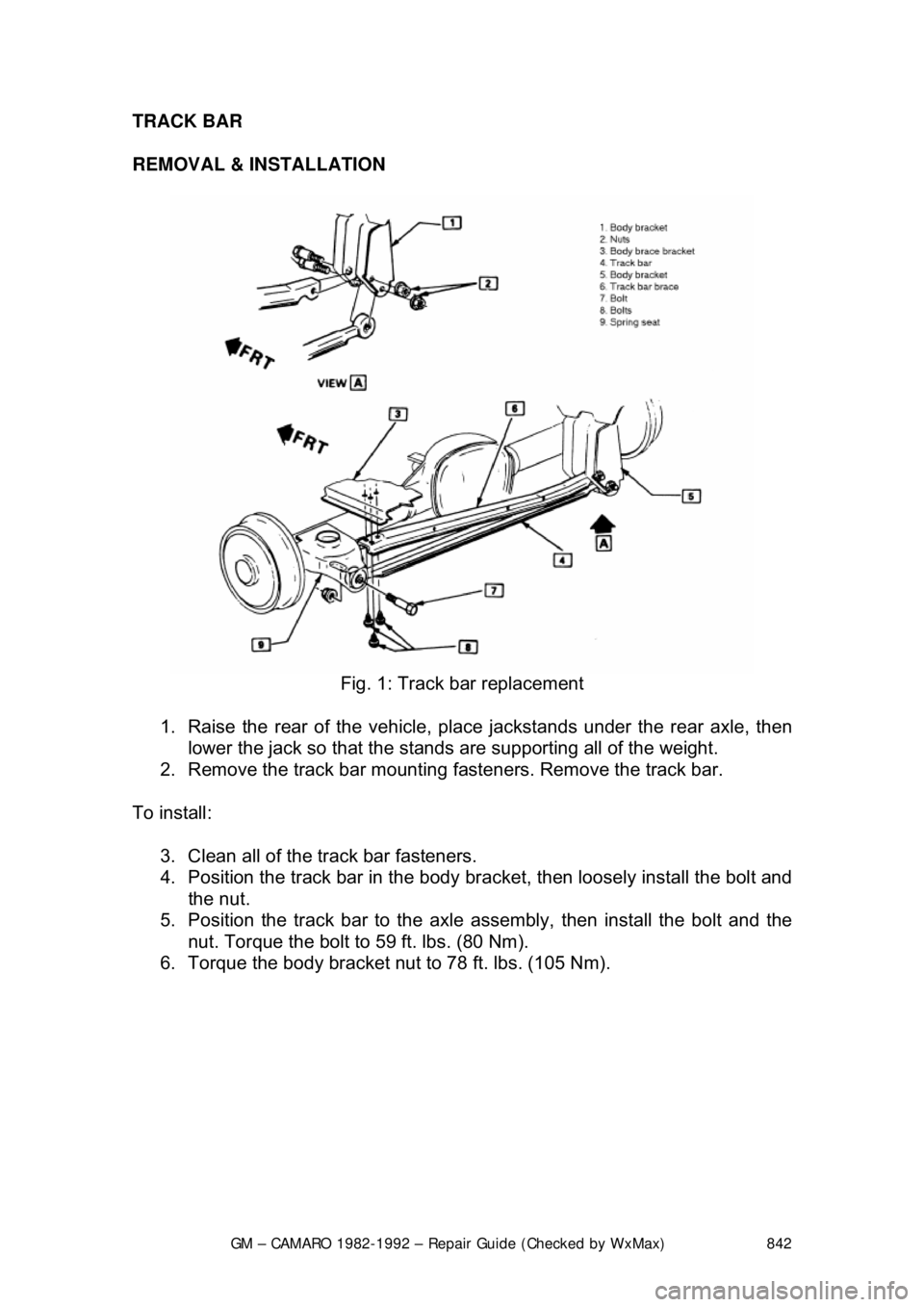

TRACK BAR

REMOVAL & INSTALLATION

Fig. 1: Track bar replacement

1. Raise the rear of the vehicle, pl ace jackstands under the rear axle, then

lower the jack so that the stands are supporting all of the weight.

2. Remove the track bar mounting fasteners. Remove the track bar.

To install: 3. Clean all of the track bar fasteners.

4. Position the track bar in the body br acket, then loosely install the bolt and

the nut.

5. Position the track bar to the axle assembly, then install the bolt and the

nut. Torque the bolt to 59 ft. lbs. (80 Nm).

6. Torque the body bracket nut to 78 ft. lbs. (105 Nm).

Page 843 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 843

TRACK BAR BRACE

REMOVAL & INSTALLATION

1. Raise the rear of the vehicle, pl ace jackstands under the rear axle, then

lower the jack so that the stands are supporting all of the weight.

2. Remove the heat shield screw s from the track bar brace.

3. Remove the three track bar brace-to-body brace screws.

4. Remove the track bar-to-body bra cket fasteners and remove the track

bar brace.

To install: 5. Place the track bar brace into position.

6. Install the track bar-to-body bracket fasteners.

7. Install the three track bar brace-to-body brace screws.

8. Install the heat shield scre ws to the track bar brace.

9. Lower the vehicle.

CONTROL ARM

REMOVAL & INSTALLATION

Remove/reinstall only one lower control ar m at a time. If both arms are removed

at the same time, the axle could roll or slip sideways, making reinstallation of

the arms very difficult.

1. Raise the rear of the vehicle, pl ace jackstands under the rear axle, then

lower the jack so that the stands are supporting all of the weight.

2. Remove the control arm attachi ng fasteners, then remove the control

arm.

3. Installation is a simple matter of bol ting the arm into place. Torque the 3

bolts at the body brace bracket to 35 ft. lbs. (47 Nm) and the nut at the

body bracket to 61 ft. lbs. (83 Nm).

TORQUE ARM

REMOVAL & INSTALLATION

The coil springs must be removed BEFORE the torque arm. If the torque arm is

removed first, vehicle damage will result. In order to proceed, the vehicle must

be supported in a manner whic h will allow the rear axle height to be adjusted

independently of the body height.

1. Remove the track bar mounting bolt at the axle assembly, then loosen

the track bar bolt at the body brace.

2. Disconnect the rear brake hose clip at the axle assembly, which will allow

additional drop of the axle.

3. Remove the lower attaching nuts from both rear shock absorbers.

4. Disconnect the shock absorbers from their lower attaching points.

Page 844 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 844

5. On models with four cylinder engines, remove the driveshaft.

6. Carefully lower the rear axle asse

mbly and remove the rear coil springs.

CAUTION - DO NOT overstretch the br ake hose when lowering the axle-

damage to the hose will result.

7. Remove the torque arm rear attaching bolts.

8. Remove the front torq ue arm outer bracket.

9. Remove the torque ar m from the vehicle.

To install: 10. Place the torque arm in position and loosely install the rear torque arm

bolts.

11. Install the front torque arm bracket and torque the nuts to 31 ft. lbs. (42

Nm).

12. Torque the rear torque arm nuts to 100 ft. lbs. (135 Nm).

13. Place the rear springs and insulators in position, then raise the rear axle

assembly until all of the weight is supported by the spring.

14. Attach the shock absorbers to the rear axle and torque the fasteners to

70 ft. lbs. (95 Nm).

15. Clean and reinstall the track bar mounting bolt at the axle. Torque the

bolt to 59 ft. lbs. (80 Nm).

16. Clean and reinstall the track bar-t o-body brace nut. Torque the nut to 78

ft. lbs. (105 Nm).

17. Install the brake line clip to the underbody.

18. On four cylinder models, reinstall the driveshaft.

19. Lower the vehicle.