torque CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 422 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 422

4. Drain the engine oil.

CAUTION

- Be sure that the catalytic c onverter is cool before proceeding.

5. Remove the air injection pipe at t he catalytic converter, if applicable.

6. Remove the catalytic converte r hanger bolts. Disconnect the exhaust

pipe at the manifold.

7. Remove the starter bolts, loosen t he starter brace, then lay the starter

aside.

8. Remove the front engine mount through-bolts.

9. Raise the engine enough to provide sufficient clearance for oil pan

removal.

10. Remove the oil pan bolts.

If the front crankshaft throw prohibits remo val of the pan, turn the crankshaft to

position the throw horizontally.

11. Remove the oil pan from the vehicle.

12. Remove the old RTV sealant or gasket from the oil pan and engine

block.

To install: 13. Run a

1/8 in. (3mm) bead of RTV around the oil pan sealing surface or

install a new gasket. Remember to keep the RTV on the INSIDE of the

bolt holes.

14. Install the pan and pan bolts. Torque the pan bolts to:

• 2.8L & 3.1L V6 (M6 x 1 X 16.0 bolts): 6-9 ft. lbs. (8-12 Nm)

• 2.8L & 3.1L V6 (M8 x 1.25 x 14.0 bolts ): 15-22 ft. lbs. (20-30 Nm)

• 1982-84 V8 engine (5/16-18 bolts): 165 inch lbs. (10 Nm)

• 1982-84 V8 engine (1/4-20 bolts): 80 inch lbs. (8 Nm)

• 1985 V8 engine (5/16-18 x 1.44 studs): minimum of 10 inch lbs.

• 1985 V8 engine (stud nuts): 150- 180 inch lbs. (17-20 Nm)

• 1985 V8 engine (1/4-20 x 0.56 bolts): 72-90 inch lbs. (8-10 Nm)

• 1985 V8 engine (1/4-20 x 0.50 x 0.56 studs): 72-90 inch lbs. (8-10

Nm)

• 1986-92 V8 engine (stud nuts): 150-250 inch lbs. (17-28 Nm)

• 1986-92 V8 engine (1/4-20 x 0.56 bolts): 72-130 inch lbs. (8-14

Nm)

• 1986-92 V8 engine (1/4-20 x 0.50 x 0.56 studs ): 72-130 inch lbs.

(8-14 Nm)

15. Lower the engine and install t he front engine mount through-bolts.

Torque bolts to 48 ft. lbs. (65 Nm).

16. Install the starter and starter brace, then secure using starter bolts.

17. Connect the exhaust pipe at the manifo ld. Install the catalytic converter

hanger bolts.

18. Install the air injection pipe at the catalytic converter.

19. Lower the vehicle.

20. Install the fan shroud assembly . Install the distributor cap.

21. Connect the negative battery cable at the battery and air cleaner.

Page 424 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 424

11. Clean all old RTV from the mating surfaces.

12. Install the rear gasket into the

rear main bearing cap and apply a small

amount of RTV where the gasket engages into the engine block.

13. Install the front gasket.

14. Install the side gaskets, using grease as a retainer. Apply a small amount

of RTV where the side gaskets meet the front gasket.

15. Install the oil pan.

Install the oil pan-to-timing cover bolts la st, as these holes will not align until the

other pan bolts are snug.

16. Torque the pan bolts to 53 inch lbs. (6 Nm) for 1982-1985 models and 90

inch lbs. (10 Nm) for 1986 models.

17. Lower the engine and install the fr ont mount through-bolts. Torque bolts

to 48 ft lbs. (65 Nm).

18. Install the flywheel dust cover.

19. Install the starter assembly.

20. Connect the exhaust pipe at the manifold.

21. Tighten the exhaust pipe hanger bracket.

22. Lower the vehicle.

23. Connect the negative battery cable at the battery.

24. Fill the engine with engine oil and start engine. Check for leaks.

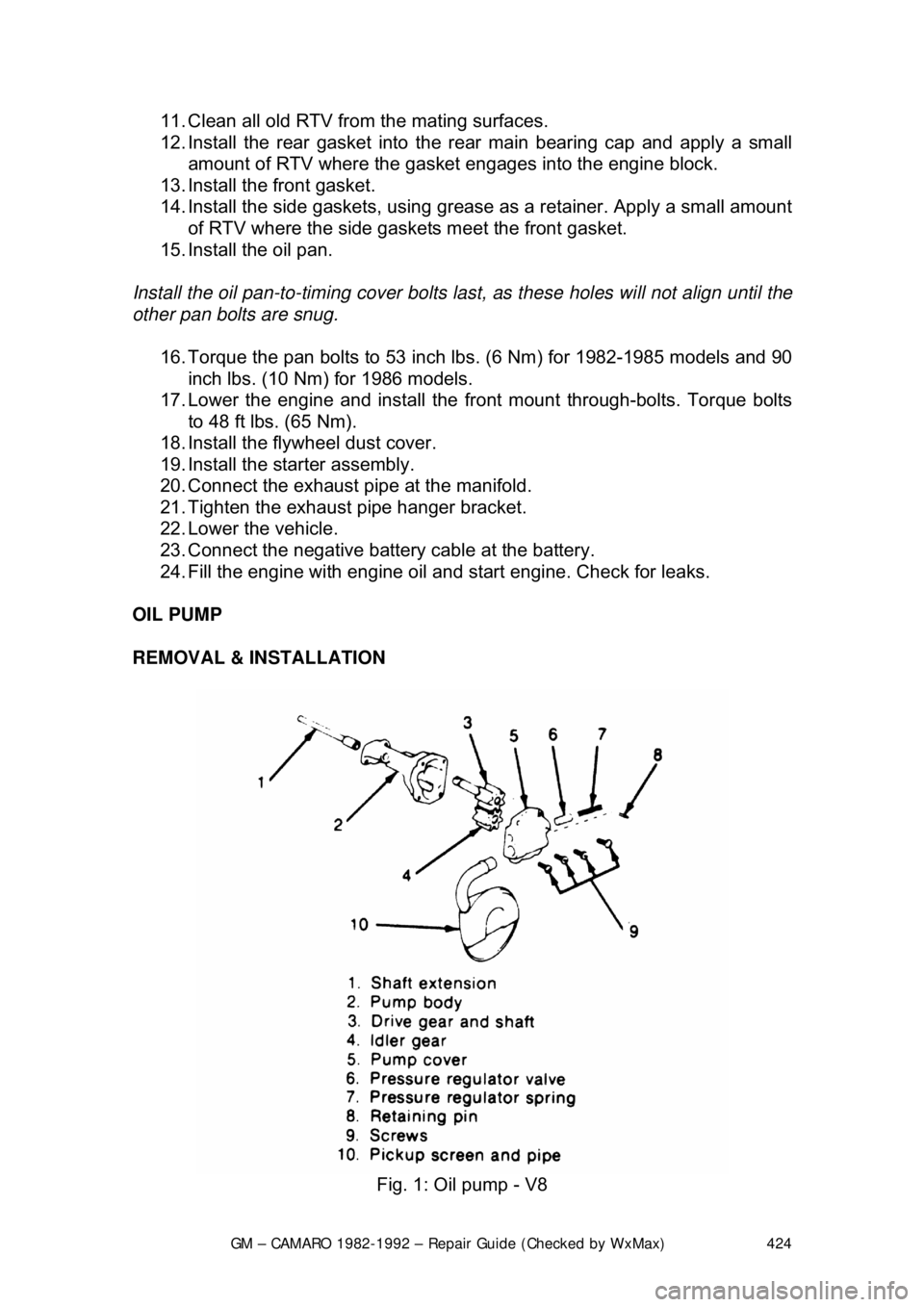

OIL PUMP

REMOVAL & INSTALLATION

Fig. 1: Oil pump - V8

Page 425 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 425

1. Drain and remove the oil pan.

CAUTION - The EPA warns that prolonged contact with used engine oil may

cause a number of skin disorders, incl uding cancer! You should make every

effort to minimize your exposure to used engine oil. Pr otective gloves should be

worn when changing the oil. Wash y our hands and any other exposed skin

areas as soon as possible after exposure to used engine oil. Soap and water, or

waterless hand cleaner should be used.

2. Remove the oil pump-to-rear main bearing cap bolt. Remove the pump

and the extension shaft.

3. Remove the cotter pin, spring and pressure regulator valve.

Place your thumb over the pressure r egulators bore before removing the cotter

pin, as the spring is under pressure.

To install: 4. Assemble pump and extension shaft to rear main bearing cap, aligning

slot on top end of extension shaft with drive tang on lower end of

distributor driveshaft.

When assembling the driveshaft extensi on to the driveshaft, the end of the

extension nearest the washers must be inserted into the driveshaft.

5. Insert the driveshaft extension through the opening in the main bearing

cap and block until the shaft mates in to the distributor drive gear.

6. Install the pump onto t he rear main bearing cap and install the attaching

bolts. Torque the bolts to specifications:

• L4 engines: 22 ft lbs. (30 Nm)

• V6 engines: 25-35 ft lbs. (35-47 Nm)

• V8 engines: 65 ft lbs. (88 Nm)

7. Install the oil pan and fill t he crankcase with engine oil.

CRANKSHAFT DAMPER

REMOVAL & INSTALLATION

Page 428 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 428

1. Disconnect the battery ground c

able. Drain the cooling system.

2. Remove the fan shroud or the upper radiator support and drive belts.

Remove the fan and pulley from the water pump.

3. Remove the alternator upper and lower brackets, air brace with brackets,

and power steering lower bra cket (move it aside).

4. Remove the radiator lower hose and the heater hose from the water

pump. Remove the water pump bolts and the water pump.

5. If A/C equipped, remove the comp ressor and move aside. Remove the

compressor mounting bracket.

6. Remove the damper pulley retain ing bolt and the damper pulley.

7. Remove the timing gear cover bolts and the timing gear cover.

With the timing gear cover removed, use a large screwdriver to pry the oil seal

from the cover. To install the new oil se al, lubricate it with engine oil and drive it

into place.

To install: 8. Prepare the mating surfaces for reinst allation of the timing gear cover.

Coat the new gasket with RTV sealer.

9. Install the timing gear cover and timing gear cover bolts. Torque the

cover bolts to specifications:

• V6 engines (M8 x 1.25 bolts): 13-22 ft. lbs. (18-30 Nm)

• V6 engines (M10 x 1.5 bolts): 20-35 ft. lbs. (27-48 Nm)

• V8 engines (all bolts): 69-130 inch lbs. (8-14 Nm)

10. Install the damper pulley by pulli ng the damper onto the crankshaft. Use

tool J-23523 or equivalent. Install t he damper pulley retaining bolt and

torque bolts to 67-85 ft lbs. (90-110 Nm).

11. If A/C equipped, install the compressor mounting bracket and

compressor.

12. Install the water pump and the water pump bolts.

13. Install the radiator lower hose and the heater hose to the water pump.

14. Install the alternator upper and lower brackets, air brace with brackets

and the power steering lower bracket.

15. Install the fan and pull ey to the water pump. Inst all the fan shroud or the

upper radiator support and drive belts and adjust.

16. Connect the battery ground cable.

17. Fill the cooling syst em, start the engine and check for leaks.

Page 430 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 430

4. Use a new front oil pan gasket, cut

the tabs from the gasket. Replace the

crankshaft oil seal.

5. Place RTV sealer in the corners of the new oil pan gasket and the new

timing gear cover gasket.

6. Install the front cove r and install the oil pan-to -front cover screws and the

front cover-to-block screws. Torque scr ews to 90 inch lbs. (10 Nm).

7. Install the hub and pulle ys onto the crankshaft. Install the hub center bolt

and torque to 162 ft lbs. (220 Nm).

8. Install the drive belts and adjust.

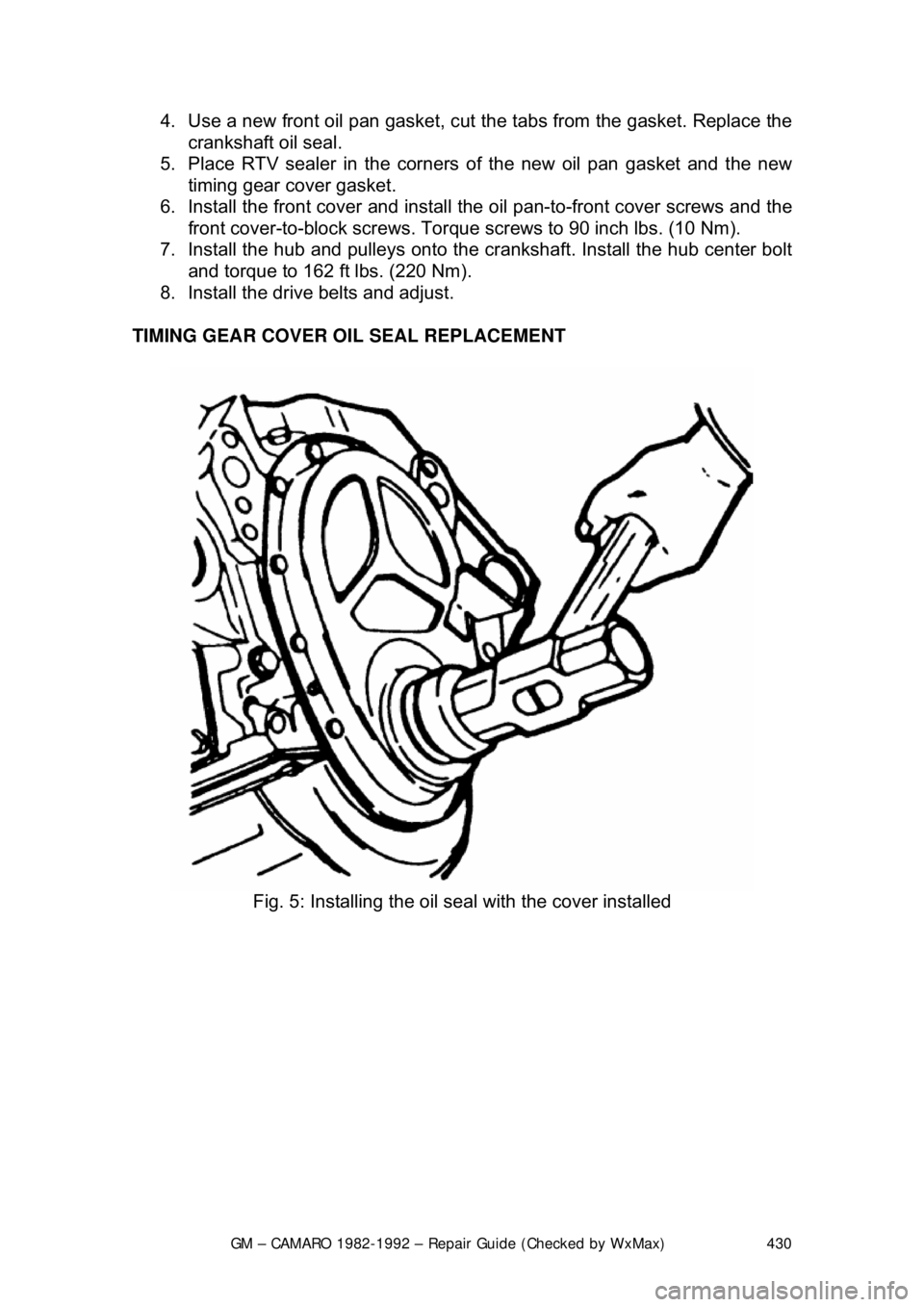

TIMING GEAR COVER OIL SEAL REPLACEMENT

Fig. 5: Installing the oil seal with the cover installed

Page 451 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 451

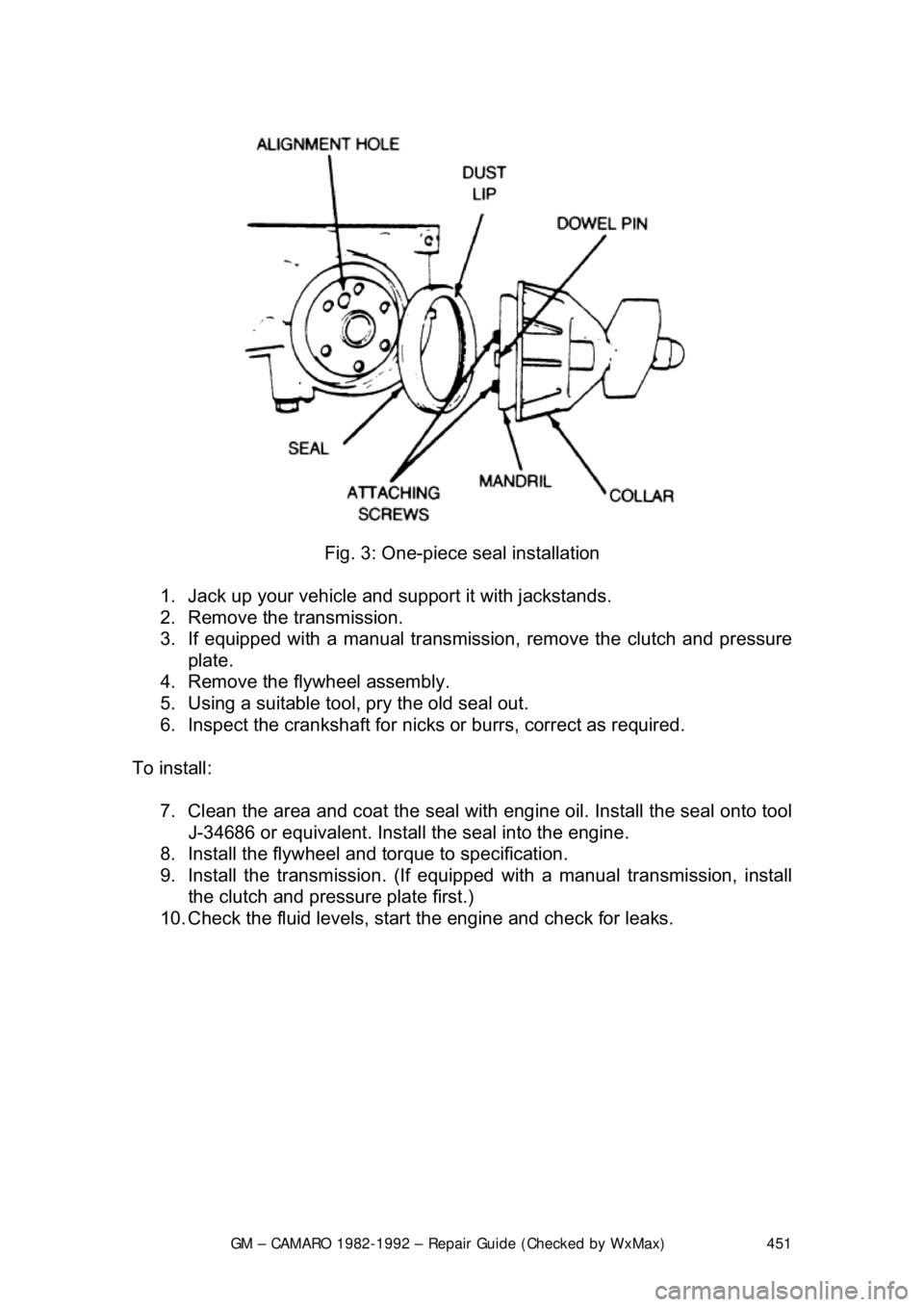

Fig. 3: One-piece seal installation

1. Jack up your vehicle and support it with jackstands.

2. Remove the transmission.

3. If equipped with a manual transmission, remove the clutch and pressure

plate.

4. Remove the flywheel assembly.

5. Using a suitable tool, pry the old seal out.

6. Inspect the crankshaft for nicks or burrs, correct as required.

To install: 7. Clean the area and coat the seal with eng ine oil. Install the seal onto tool

J-34686 or equivalent. Install the seal into the engine.

8. Install the flywheel and torque to specification.

9. Install the transmission. (If equipped with a manual transmission, install

the clutch and pressure plate first.)

10. Check the fluid levels, star t the engine and check for leaks.

Page 453 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 453

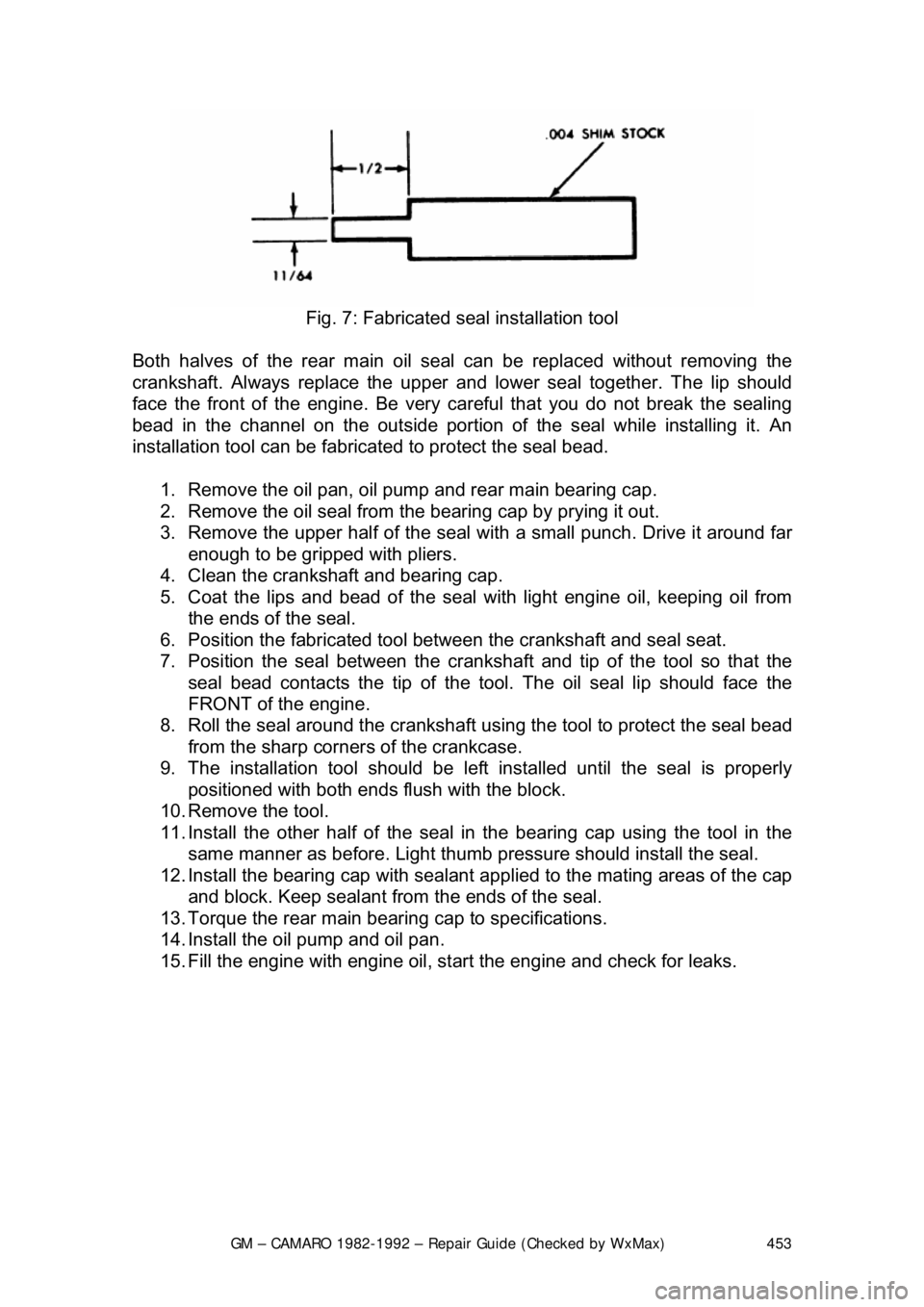

Fig. 7: Fabricated s eal installation tool

Both halves of the rear main oil s eal can be replaced without removing the

crankshaft. Always replace the upper and lower seal together. The lip should

face the front of the engine. Be very ca reful that you do not break the sealing

bead in the channel on the out side portion of the seal while installing it. An

installation tool can be fabricat ed to protect the seal bead.

1. Remove the oil pan, oil pump and rear main bearing cap.

2. Remove the oil seal from the bearing cap by prying it out.

3. Remove the upper half of the seal wit h a small punch. Drive it around far

enough to be gripped with pliers.

4. Clean the crankshaft and bearing cap.

5. Coat the lips and bead of the seal with light engine oil, keeping oil from

the ends of the seal.

6. Position the fabricated tool bet ween the crankshaft and seal seat.

7. Position the seal between the cranks haft and tip of the tool so that the

seal bead contacts the ti p of the tool. The oil seal lip should face the

FRONT of the engine.

8. Roll the seal around the crankshaft us ing the tool to protect the seal bead

from the sharp corner s of the crankcase.

9. The installation tool should be le ft installed until the seal is properly

positioned with both ends fl ush with the block.

10. Remove the tool.

11. Install the other half of the seal in the bearing cap using the tool in the

same manner as before. Light thumb pressure should install the seal.

12. Install the bearing cap with sealant applied to the mating areas of the cap

and block. Keep sealant from the ends of the seal.

13. Torque the rear main bear ing cap to specifications.

14. Install the oil pump and oil pan.

15. Fill the engine with engine oil, st art the engine and check for leaks.

Page 456 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 456

2. Drain the engine oil and remove the oil pan.

3. Remove the rear main bearing cap.

4. Insert packing tool J-29114-2 or equi

valent, against 1 end of the seal in

the cylinder block. Drive the old seal gently into the groove until it is

packed tight. This will vary from

1/4 in. (6mm) to 3/4 in. (19mm) depending

on the amount of pack required.

5. Repeat the procedure on t he other end of the seal.

6. Measure the amount the seal wa s driven up on one side and add

1/16 in.

(1.6mm). Using a suitable cutting tool, cut that length from the old seal

removed from the rear main beari ng cap. Repeat the procedure for the

other side. Use the rear main bear ing cap as a holding fixture when

cutting the seal.

7. Install guide tool J-29114-1 or equi valent, onto the cylinder block.

8. Using the packing tool, work the shor t pieces cut in Step 6 into the guide

tool and then pack into the cylinder block. The guide tool and packing

tool are machined to provide a built in stop. Use this procedure for both

sides. It may help to use oil on the short pieces of the rope seal when \

packing them into the cylinder block.

9. Remove the guide tool.

10. Apply Loctite® 414 or equivalent, to the seal groove in the rear main

bearing cap. Within 1 minute, insert a new seal into the groove and push

into place with tool J-29590 until the seal is flush with the block. Cut the

excess seal material with a sharp cu tting tool at the bearing cap parting

line.

11. Apply a thin film of chassis grease to the rope se al. Apply a thin film of

RTV sealant on the bearing cap mati ng surface around the seal groove.

Use the sealer sparingly.

12. Plastigage® the rear main bea ring cap as outlined in MEASURING

REAR MAIN CLEARANCE in this section and check with specification. If

out of specification, check for fr ying of the rope seal which may be

causing the cap to not seat properly.

13. Install all remaining com ponents and inspect for leaks.

FLYWHEEL AND RING GEAR

REMOVAL & INSTALLATION

The ring gear is an integral part of the flywheel and is not replaceable.

1. Remove the transmission.

2. Remove the six bolts attaching t he flywheel to the crankshaft flange.

Remove the flywheel.

3. Inspect the flywheel for cracks, and inspect the ring gear for burrs or

worn teeth. Replace the flywheel if any damage is apparent. Remove

burrs with a mill file.

4. Install the flywheel. Th e flywheel will only attach to the crankshaft in one

position, as the bolt holes are unevenly spaced. Install the bolts and

torque to specification. Tighten bolts in crisscross pattern.

Page 499 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 499

then you have wrist pin bushings in the rods. There should not be any

excessive play between the wrist pin

and the rod bushing. Normal clearance for

the wrist pin is approx. 0.001-0.002 in. (0.025mm-0.051mm).

Fig. 4: Measure the piston's outer diam eter, perpendicular to the wrist pin, with

a micrometer

Use a micrometer and measure the diamet er of the piston, perpendicular to the

wrist pin, on the skirt. Com pare the reading to its original cylinder measurement

obtained earlier. The diffe rence between the two readings is the piston-to-wall

clearance. If the clearance is within specif ications, the piston may be used as is.

If the piston is out of specification, but the bore is not, you will need a new

piston. If both are out of specificati on, you will need the cylinder rebored and

oversize pistons installed. Generally if two or more pistons/bores are out of

specification, it is best to rebore the entire block and purchase a complete set of

oversize pistons.

CONNECTING ROD

You should have the connecting rod chec ked for straightness at a machine

shop. If the connecting rod is bent, it will unevenly wear the bearing and piston,

as well as place greater stress on these components. Any bent or twisted

connecting rods must be replaced. If the rods are straight and the wrist pin

clearance is within specifications, t hen only the bearing end of the rod need be

checked. Place the connecting rod into a vi ce, with the bearing inserts in place,

install the cap to the rod and torque t he fasteners to specifications. Use a

telescoping gauge and carefully measure t he inside diameter of the bearings.

Compare this reading to the rods or iginal crankshaft journal diameter

measurement. The difference is the oil clearance. If the oil clearance is not

Page 504 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 504

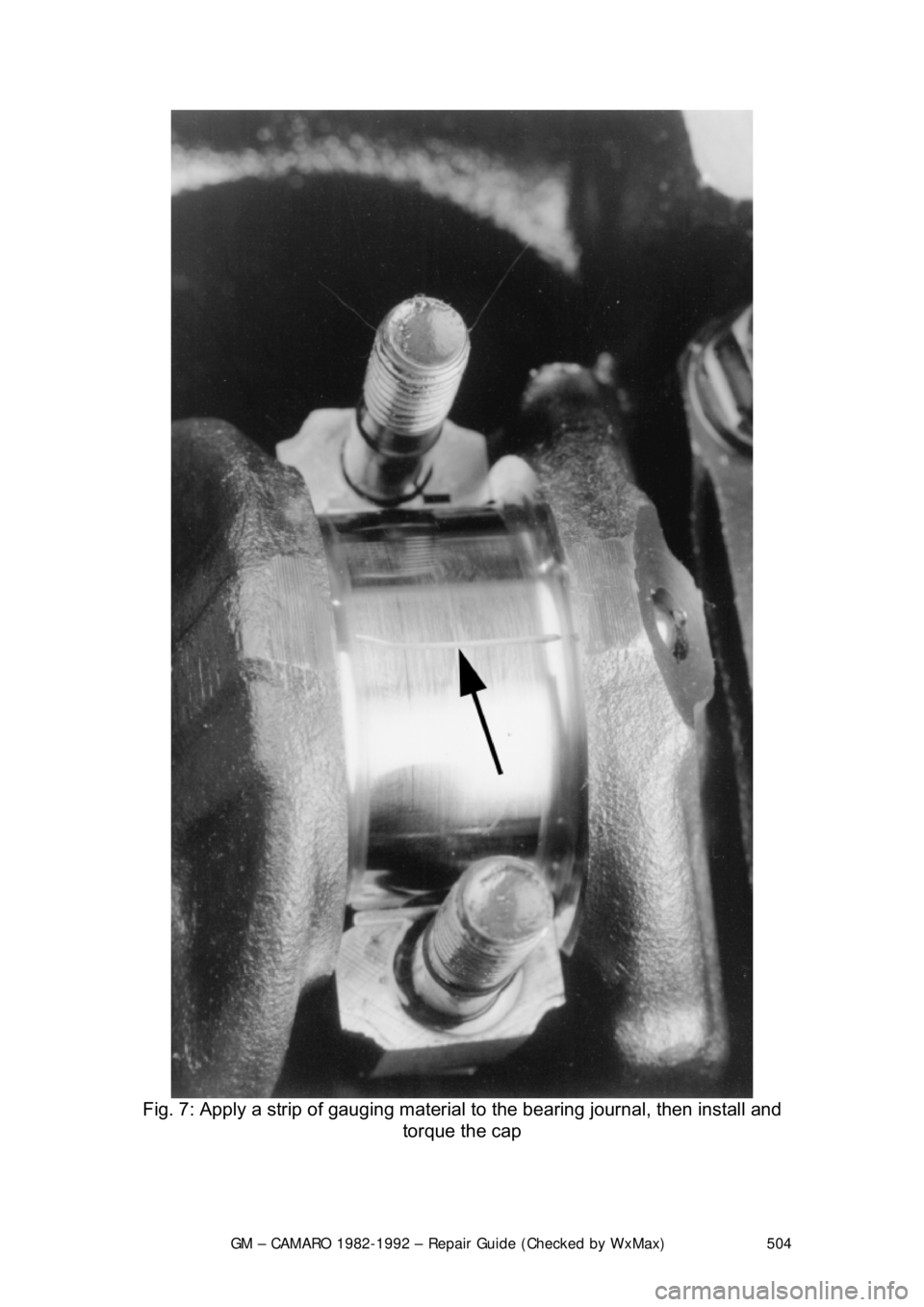

Fig. 7: Apply a strip of gauging material to the bearing journal, then install and

torque the cap