brake light CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 49 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 49

Upon release of the brake pedal, a spri

ng located inside the master cylinder

immediately returns the master cylinder pistons to the normal position. The

pistons contain check valv es and the master cylinder has compensating ports

drilled in it. These are uncovered as the pistons reach their normal position. The

piston check valves allow fluid to flow to ward the wheel cylinders or calipers as

the pistons withdraw. Then, as the return springs force the brake pads or shoes

into the released position, the excess fluid reservoir through the compensating

ports. It is during the time the pedal is in the released position that any fluid that

has leaked out of the syst em will be replaced through the compensating ports.

Dual circuit master cylinders employ tw o pistons, located one behind the other,

in the same cylinder. The primary pist on is actuated directly by mechanical

linkage from the brake peda l through the power booster. The secondary piston

is actuated by fluid tra pped between the two pistons. If a leak develops in front

of the secondary piston, it moves forward until it bottoms against the front of the

master cylinder, and the fluid trapped betw een the pistons will operate the rear

brakes. If the rear brakes develop a l eak, the primary piston will move forward

until direct contact with the secondary pi ston takes place, and it will force the

secondary piston to actuate the front brakes. In either case, the brake pedal

moves farther when the brakes are applied, and less braking power is available.

All dual circuit systems use a switch to wa rn the driver when only half of the

brake system is operational. This switch is usually located in a valve body which

is mounted on the firewall or the frame below the master cylinder. A hydraulic

piston receives pressure from both circui ts, each circuit's pressure being applied

to one end of the piston. When the pressures are in balance, the piston remains

stationary. When one circuit has a leak, however, the greater pressure in that

circuit during application of the brakes will push the piston to one side, closing

the switch and activating the brake warning light.

In disc brake systems, this valve body also contains a metering valve and, in

some cases, a proportioning valve. The metering valve keeps pressure fro\

m

traveling to the disc brakes on the front wheels until the brake shoes on the rear

wheels have contacted the drums, ensuri ng that the front brakes will never be

used alone. The proportioning va lve controls the pressure to the rear brakes to

lessen the chance of rear wheel lo ck-up during very hard braking.

Warning lights may be tested by depressi ng the brake pedal and holding it while

opening one of the wheel cyli nder bleeder screws. If this does not cause the

light to go on, substitute a new lamp , make continuity checks, and, finally,

replace the switch as necessary.

The hydraulic system may be checked for leaks by applying pressure to the

pedal gradually and steadily. If the pedal sinks very slowly to the floor, the

system has a leak. This is not to be conf used with a springy or spongy feel due

to the compression of air within the lin es. If the system leaks, there will be a

gradual change in the position of the pedal with a constant pressure.

Check for leaks along all lines and at wheel cylinders. If no external leaks are

apparent, the problem is inside the master cylinder.

Page 50 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 50

DISC BRAKES

Instead of the traditional ex

panding brakes that press out ward against a circular

drum, disc brake systems utilize a disc (rotor) with brake pads positioned on

either side of it. An easily-seen analog y is the hand brake arrangement on a

bicycle. The pads squeeze onto the rim of the bike wheel, slowing its motion.

Automobile disc brakes use the identical principle but apply the braking effort to

a separate disc instead of the wheel.

The disc (rotor) is a casting, usually eq uipped with cooling fins between the two

braking surfaces. This enables air to ci rculate between the braking surfaces

making them less sensitive to heat bui ldup and more resistant to fade. Dirt and

water do not drastically affect braking ac tion since contaminants are thrown off

by the centrifugal action of the rotor or scraped off the by the pads. Also, the

equal clamping action of the two brake pad s tends to ensure uniform, straight

line stops. Disc brakes are inherently se lf-adjusting. There are three general

types of disc brake:

1. A fixed caliper.

2. A floating caliper.

3. A sliding caliper.

The fixed caliper design uses two pistons mounted on either side of the rotor (in

each side of the caliper). The caliper is mounted rigidly and does not move.

The sliding and floating designs are quite similar. In fact, these two types are

often lumped together. In both designs, the pad on the inside of the rotor is

moved into contact with the rotor by hy draulic force. The caliper, which is not

held in a fixed position, moves slightly, bringing the outside pad into contact with

the rotor. There are various methods of attaching floating calipers. Some pivot

at the bottom or top, and some slide on mounting bolts. In any event, the end

result is the same.

DRUM BRAKES

Drum brakes employ two brake shoes mounted on a st ationary backing plate.

These shoes are positioned inside a circul ar drum which rotates with the wheel

assembly. The shoes are held in place by springs. This allows them to slide

toward the drums (when they are applied) while keeping the linings and drums

in alignment. The shoes are actuated by a wheel cylinder which is mounted at

the top of the backing plat e. When the brakes are app lied, hydraulic pressure

forces the wheel cylinder's actuating links outward. Since these links bear

directly against the top of the brake s hoes, the tops of the shoes are then forced

against the inner side of the drum. This action forces the bottoms of the two

shoes to contact the brake drum by rotati ng the entire assembly slightly (known

as servo action). When pressure within the wheel cylinder is relaxed, return

springs pull the shoes back away from the drum.

Most modern drum brakes are designed to self-adjust themselves during

application when the vehicle is moving in reverse. This motion causes both

Page 51 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 51

shoes to rotate very slightly with the

drum, rocking an adjusting lever, thereby

causing rotation of the adjusting scr ew. Some drum brake systems are

designed to self-adjust duri ng application whenever the br akes are applied. This

on-board adjustment system reduces the need for maintenance adjustments

and keeps both the brake function and pedal feel satisfactory.

POWER BOOSTERS

Virtually all modern vehicles use a va cuum assisted power brake system to

multiply the braking force and reduce pedal effort. Since vacuum is always

available when the en gine is operating, the system is simple and efficient. A

vacuum diaphragm is located on the front of the master cylinder and assists the

driver in applying the brakes, reducing both the effort and travel he must put into

moving the brake pedal.

The vacuum diaphragm housing is normally connected to the intake manifold by

a vacuum hose. A check valve is placed at the point where the hose enters the

diaphragm housing, so that during periods of low manifold vacuum brakes

assist will not be lost.

Depressing the brake pedal closes o ff the vacuum source and allows

atmospheric pressure to enter on one side of the diaphragm. This causes the

master cylinder pistons to move and app ly the brakes. When the brake pedal is

released, vacuum is applied to both si des of the diaphragm and springs return

the diaphragm and master cylinder pist ons to the released position.

If the vacuum supply fails, the brake pedal rod will contact the end of the master

cylinder actuator rod and the system will apply the br akes without any power

assistance. The driver will notice that much higher pedal effort is needed to stop

the car and that the pedal f eels harder than usual.

VACUUM LEAK TEST

1. Operate the engine at idle without t ouching the brake pedal for at least one

minute.

2. Turn off the engine and wait one minute.

3. Test for the presence of assist va cuum by depressing the brake pedal and

releasing it several times. If vac uum is present in the system, light

application will produce less and less pedal travel. If there is no vacuum, air

is leaking into the system.

SYSTEM OPERATION TEST

1. With the engine OFF, pump the brake p edal until the supply vacuum is

entirely gone.

2. Put light, steady pressu re on the brake pedal.

3. Start the engine and let it idle. If the system is operating correctly, the brake

pedal should fall toward the floor if t he constant pressure is maintained.

Page 54 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 54

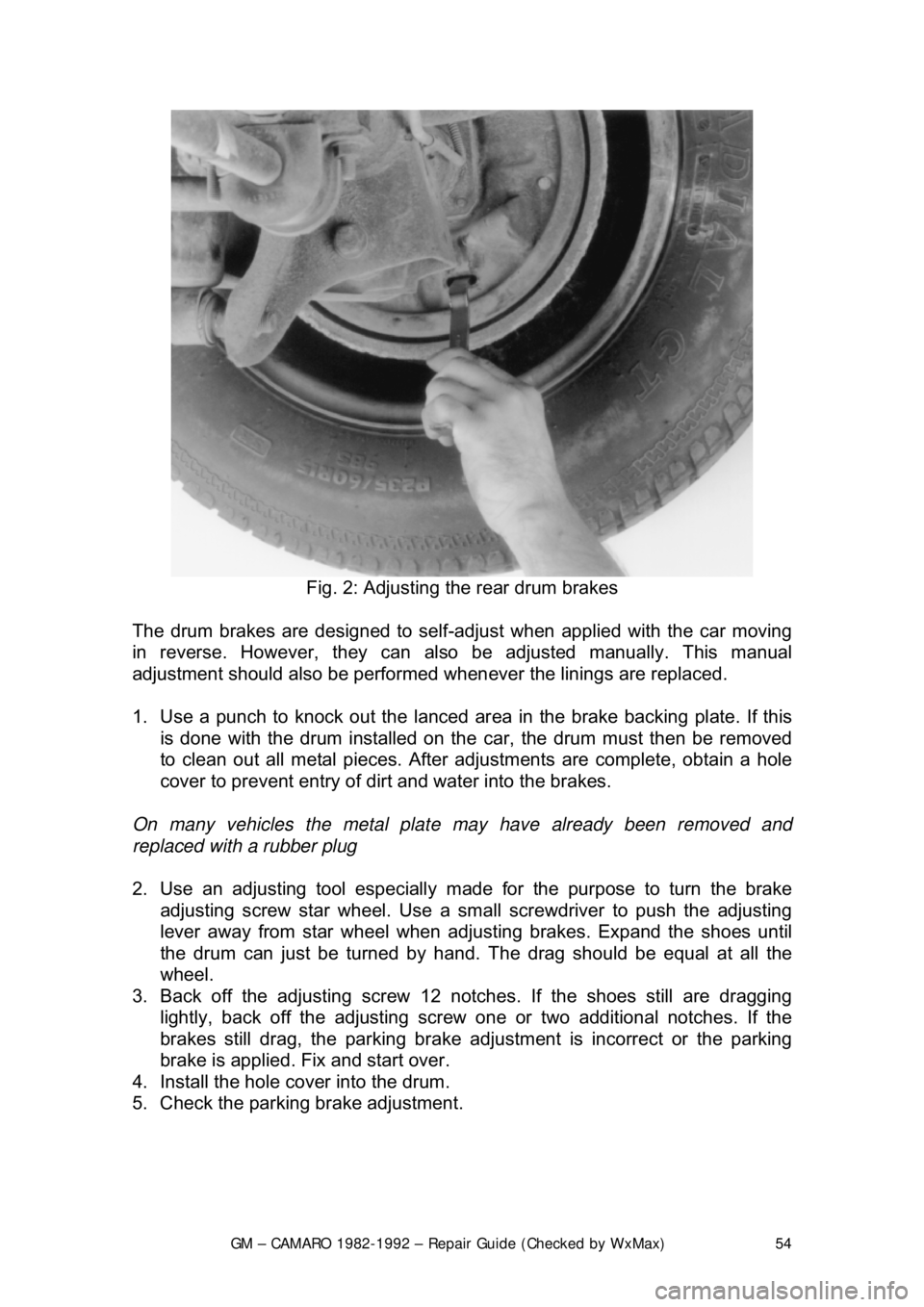

Fig. 2: Adjusting the rear drum brakes

The drum brakes are designed to self -adjust when applied with the car moving

in reverse. However, they can al so be adjusted manually. This manual

adjustment should also be performed when ever the linings are replaced.

1. Use a punch to knock out the lanced ar ea in the brake backing plate. If this

is done with the drum installed on the car, the drum must then be removed

to clean out all metal pieces. After adj ustments are complete, obtain a hole

cover to prevent entry of dirt and water into the brakes.

On many vehicles the metal plat e may have already been removed and

replaced with a rubber plug

2. Use an adjusting tool especially m ade for the purpose to turn the brake

adjusting screw star wheel. Use a smal l screwdriver to push the adjusting

lever away from star wheel when adj usting brakes. Expand the shoes until

the drum can just be turned by hand. The drag should be equal at all the

wheel.

3. Back off the adjusting screw 12 notches. If the shoes still are dragging

lightly, back off the adjusting screw one or two additional notches. If the

brakes still drag, the par king brake adjustment is in correct or the parking

brake is applied. Fi x and start over.

4. Install the hole cover into the drum.

5. Check the parking brake adjustment.

Page 55 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 55

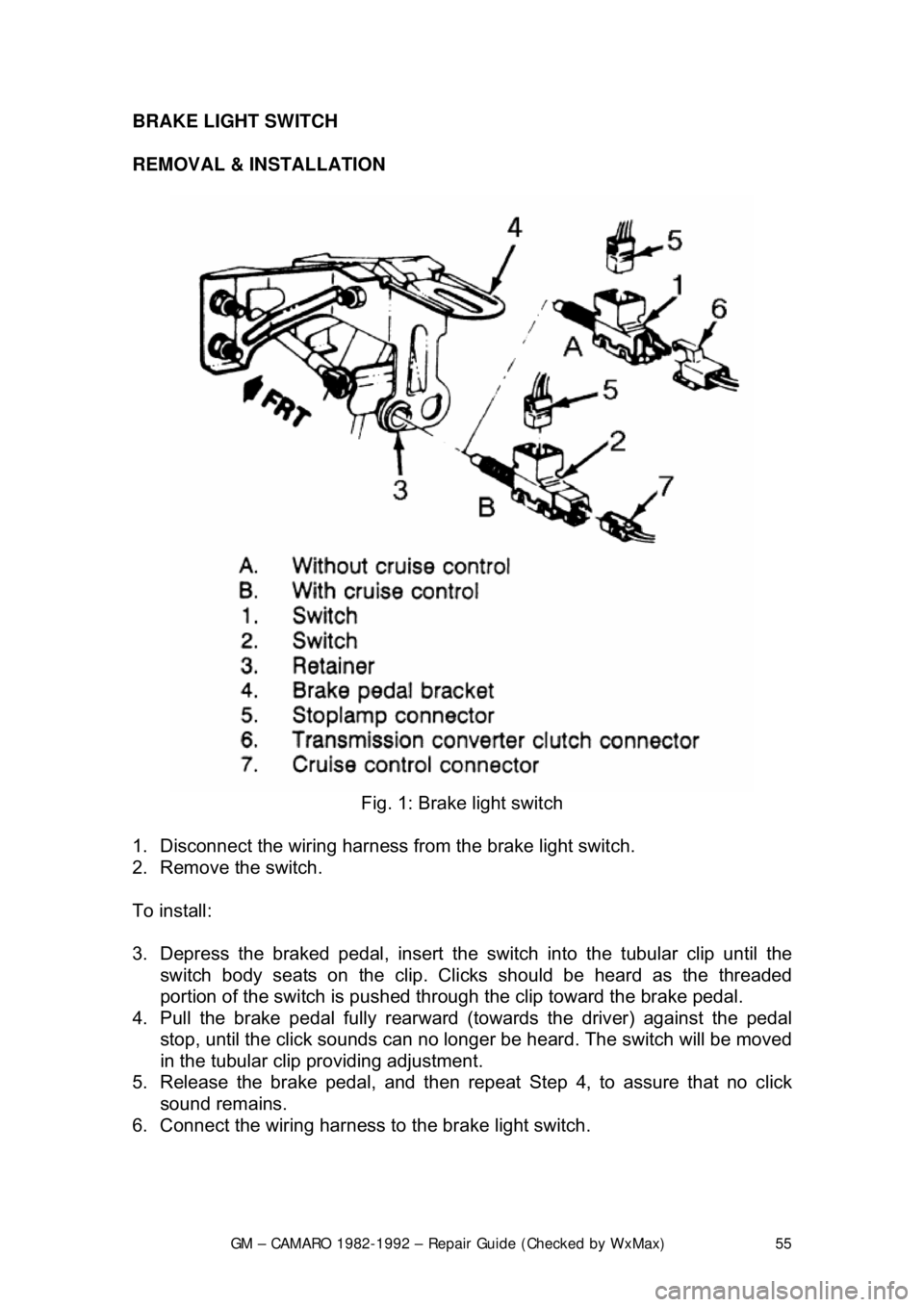

BRAKE LIGHT SWITCH

REMOVAL & INSTALLATION

Fig. 1: Brake light switch

1. Disconnect the wiring harness fr om the brake light switch.

2. Remove the switch.

To install:

3. Depress the braked pedal, insert the switch into the tubular clip until the

switch body seats on the clip. Cli cks should be heard as the threaded

portion of the switch is pushed through the clip toward the brake pedal.\

4. Pull the brake pe dal fully rearward (towards the driver) against the pedal

stop, until the click sounds can no long er be heard. The switch will be moved

in the tubular clip providing adjustment.

5. Release the brak e pedal, and then repeat Step 4, to assure that no click

sound remains.

6. Connect the wiring harness to the brake light switch.

Page 66 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 66

4. Remove nuts and lockwashers that se

cure booster to firewall and remove

booster from engine compartment.

5. Install by reversing removal procedure. Make sure to check operation of stop

lights. Allow engine vacuum to build before applying brakes.

COMBINATION VALVE

REMOVAL & INSTALLATION

This valve is not repairable and only serviced as a complete assembly.

1. Disconnect the hydraulic lines from t he valve. Plug the lines to prevent fluid

loss and dirt contamination.

2. Disconnect the electrical connection.

3. Remove the valve.

To install:

4. Position the valve.

5. Connect the electrical connection.

6. Connect the hydraulic lines to the valve.

7. Bleed the brake system.

Page 75 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 75

5. Have your assistant sl

owly depress the brake pedal. As this is done, open

the bleeder screw 3/4 of a turn and allow the flui d to run through the tube.

Then close the bleeder screw before the pedal reaches the end of its travel.

Have your assistant slo wly release the pedal. Rep eat this process until no

air bubbles appear in the expelled fluid.

6. Repeat the procedure on the other three br akes, checking the level of fluid in

the master cylinder reservoir often.

7. Upon completion, check the brak e pedal for sponginess and the brake

warning light for unbalanced pressure . If necessary, repeat the entire

bleeding procedure.

FRONT DISC BRAKES

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

BRAKE PADS

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

INSPECTION

The pad thickness should be inspected ever y time that the tires are removed for

rotation. The outer pad can be checked by looking in each end, which is the

point at which the highest rate of wear occurs. The inner pad can be checked by

looking down through the inspection hole in the top of the caliper. If the

thickness of the pad is worn to within 0.030 in. (0.8mm) of the rivet at either end

of the pad, all the pads should be replaced.

Always replace all pads on both front wheel s at the same time. Failure to do so

will result in uneven braking action and premature wear.

REMOVAL & INSTALLATION

Page 80 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 80

4. Remove the mounting bo

lts, if equipped with single piston caliper or the

circlip and pin, if equipped with dual piston ca liper. Inspect the bolts for

corrosion and replace as necessary.

5. Remove the caliper fr om the steering knuckle an d suspend it from the body

of the car with a length of wire. Do not allow the caliper to hang by its hose.

6. Remove the pad retaining springs and remove the pads from the caliper.

7. Remove the plastic sleeves and the rubber bushings from the mounting bolt

holes.

8. Obtain a pad replacem ent kit. Lubricate and install the new sleeves and

bushings with a light coat of silicone grease.

9. Install the retainer spring on the i nboard pad, if equipped with single piston

caliper.

A new spring should be included in the pad replacement kit.

10. Install the new inboard pad into the caliper with the wear sensor at the

leading end of the shoe duri ng forward wheel rotation.

11. Install the outboard pad into the caliper.

12. Use a large pair of slip joint plie rs to bend the outer pad ears down over the

caliper, if equipped with t he single piston caliper.

13. Install the calip er onto the steering knuckle. Tighten the mounting bolts to

21-35 ft. lbs. (28-47 Nm), if equipped. In stall the wheel and lower the car. Fill

the master cylinder to its proper le vel with a good quality brake fluid.

14. Pump the brake pedal slowly a nd firmly 3 times with the engine running

before attempting to move the vehicle; bleed the brakes as required.

BRAKE CALIPER

CAUTION - Some brake pads contain asbest os, which has been determined to

be a cancer causing agent. Never clean the brake surfaces with compressed

air! Avoid inhaling any dust from any brake surface! When cleaning brake

surfaces, use a commercially available brake cleaning fluid.

REMOVAL & INSTALATION

Page 93 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 93

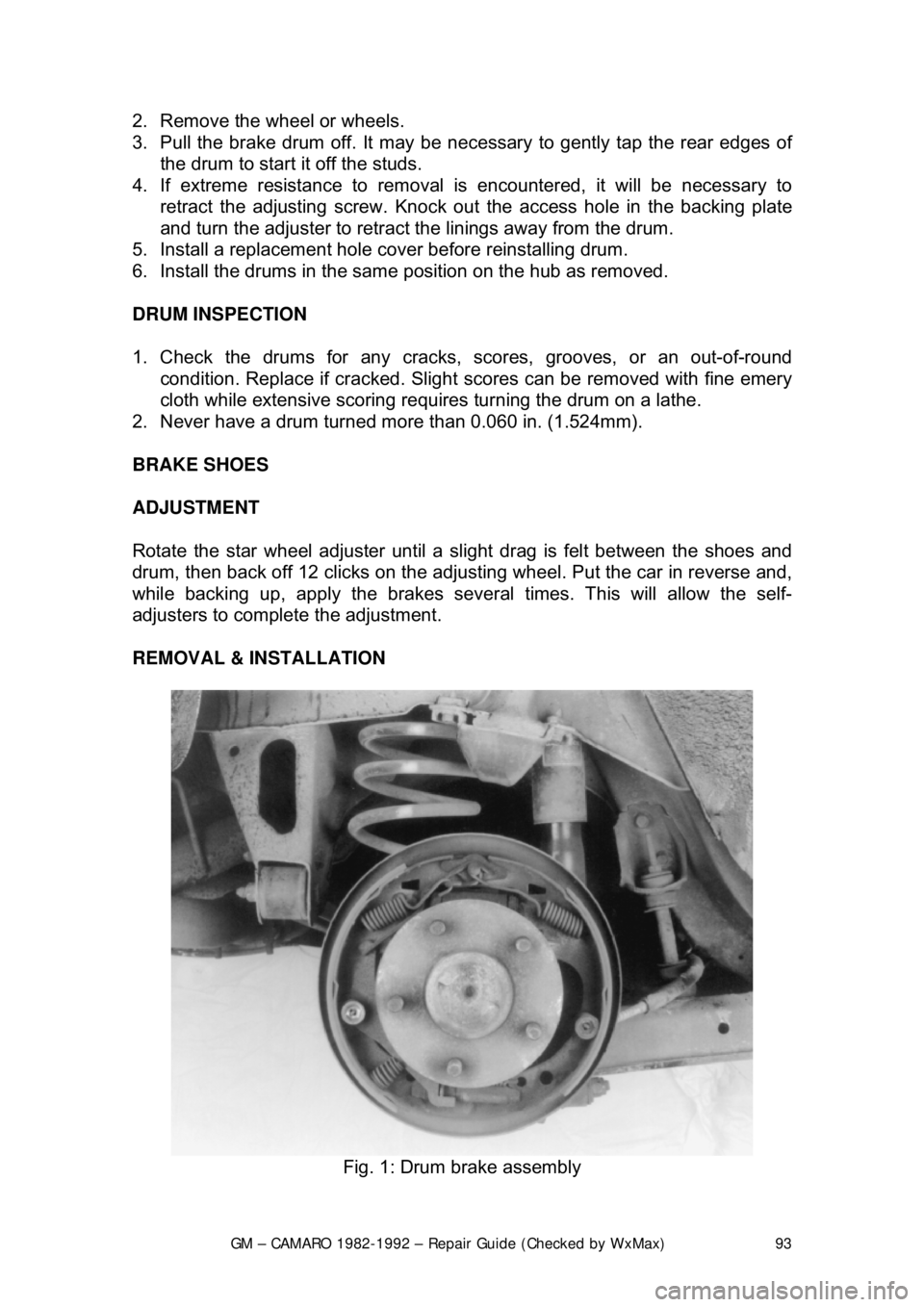

2. Remove the wheel or wheels.

3. Pull the brake drum off. It may be nec

essary to gently tap the rear edges of

the drum to start it off the studs.

4. If extreme resistance to removal is encountered, it will be necessary to

retract the adjusting screw. Knock out the access hole in the backing plate

and turn the adjuster to retract th e linings away from the drum.

5. Install a replacement hole co ver before reinstalling drum.

6. Install the drums in the same position on the hub as removed.

DRUM INSPECTION

1. Check the drums for any cracks, scores, grooves, or an out-of-round

condition. Replace if cracked. Slight scores can be removed with fine emery

cloth while extensive scoring requires turning the drum on a lathe.

2. Never have a drum turned mo re than 0.060 in. (1.524mm).

BRAKE SHOES

ADJUSTMENT

Rotate the star wheel adjuster until a sl ight drag is felt between the shoes and

drum, then back off 12 clicks on the adjusting wheel. Put the car in reverse and,

while backing up, apply the brakes seve ral times. This will allow the self-

adjusters to complete the adjustment.

REMOVAL & INSTALLATION

Fig. 1: Drum brake assembly

Page 117 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 117

5. Remove the shaft seal and washer.

6. Remove the dust boot. Be careful not to scratch the housing bore.

7. Remove the locator retainer if so

equipped. Remove the piston locator if so

equipped.

8. Remove the piston seal usi ng a wooden or plastic tool.

9. Remove the bleeder screw, bolt, fi tting, and copper washer. Remove the

bracket only if it is damaged.

10. Inspect caliper bore for scoring, nicks, corrosion, and wear. Use crocus cloth

for light corrosion. Replace caliper if bore will not clean up.

To install:

11. Replace the bleeder screw, bolt, fitting, and copper washer.

12. Install the piston. Lubricate seal s and piston with brake fluid prior to

reinstallation.

13. Install the locator retainer if so equi pped. Install the piston locator if so

equipped.

14. Install the dust boot.

15. Install the shaft seal and washer.

16. Install actuator scr ew to the housing.

17. Install the nut, lever, lever seal, and anti-friction washer. It may be necessary

to rotate the parking brake lever away from the stop to install the nut. Torque

the nut 30-40 ft. lbs. (41-54 Nm) and ro tate the lever back to the stop.

18. Install the shoe dampening spri ng to the end of the piston.

It may be necessary to move the parking brake lever off the stop, extending the

piston slightly, making the dampening spring groove acce ssible. If the piston is

extended, push it back into the caliper before installing the caliper on the car.

1989-92 MODELS

1. Remove the caliper assembly. Remove the 2 collar return springs from the

actuating collar. Remove the actuator collar assembly with parts attached

out of the housing.

2. Remove the clamp rod and compliance bushing.

3. Remove the boot retainers, 2 boots and pushrod from the compliance

bushing. Discard the retainers and boots.

4. Remove the preload spring from the retainer.

5. Using compressed air directed into the brake hose port, carefully extract

piston.

CAUTION - Do not place fingers between piston and brake shoe flange, or

personal injury may occur when piston breaks free from bore. Cover caliper

assembly with a rag to prevent brake fluid from spraying when piston is

extracted

6. Inspect and clean piston and bore a ssembly for cracks or scoring.

7. Remove the piston seal.

8. Remove the bleeder valve.