dead battery CHEVROLET CAMARO 1982 Repair Guide

[x] Cancel search | Manufacturer: CHEVROLET, Model Year: 1982, Model line: CAMARO, Model: CHEVROLET CAMARO 1982Pages: 875, PDF Size: 88.64 MB

Page 138 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 138

the ground side of the circuit) and

connect the positive lead to the

positive (+) side of the circuit (to t he power source or the nearest power

source). Note that the negative voltme ter lead will always be black and

that the positive voltmeter will alwa ys be some color other than black

(usually red).

• Ohmmeter - the ohmmeter is designed to read resistance (measured in

ohms) in a circuit or component. Mo st ohmmeters will have a selector

switch which permits the measurement of different ranges of resistance

(usually the selector swit ch allows the multiplication of the meter reading

by 10, 100, 1,000 and 10,000). Some ohmmeters are "auto-ranging"

which means the meter itself will dete rmine which scale to use. Since the

meters are powered by an internal battery, the ohmmeter can be used

like a self-powered test light. When the ohmmeter is connected, current

from the ohmmeter flows through the ci rcuit or component being tested.

Since the ohmmeter's internal resi stance and voltage are known values,

the amount of current flow throug h the meter depends on the resistance

of the circuit or component being test ed. The ohmmeter can also be used

to perform a continuity test for suspected open circuits. In using the

meter for making continuity checks, do not be concerned with the actual

resistance readings. Zero resistance, or any ohm reading, indicates

continuity in the circui t. Infinite resistance indi cates an opening in the

circuit. A high resistance reading w here there should be none indicates a

problem in the circuit. Checks for s hort circuits are made in the same

manner as checks for open circuits, ex cept that the circuit must be

isolated from both power and normal gr ound. Infinite resistance indicates

no continuity, while zero resi stance indicates a dead short.

WARNING - Never use an ohmmeter to check the resistance of a component or

wire while there is volt age applied to the circuit

• Ammeter - an ammeter measures the am ount of current flowing through

a circuit in units called amperes or amps. At normal operating voltage,

most circuits have a characteristic amount of amperes, called "current

draw" which can be measured usi ng an ammeter. By referring to a

specified current draw rating, then measuring the amperes and

comparing the two values, one can det ermine what is happening within

the circuit to aid in diagnosis. An open circuit, for example, will not allow

any current to flow, so the amme ter reading will be zero. A damaged

component or circuit will have an incr eased current draw, so the reading

will be high. The ammeter is always connected in series with the circuit\

being tested. All of the current that normally flows through the circuit

must also flow through the ammeter; if there is any other path for the

current to follow, the ammeter readi ng will not be accurate. The ammeter

itself has very little resistance to curr ent flow and, therefore, will not affect

the circuit, but it will measure current draw only when the circuit is closed

and electricity is flowing. Excessive current draw can blow fuses and

drain the battery, while a reduced current draw can cause motors to run \

slowly, lights to dim and other components to not operate properly.

Page 351 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 351

alternating current developed

within the stator windings to a direct (DC) current

at the output (BAT) terminal. Three of these diodes are negative and are

mounted flush with the end frame while t he other three are positive and are

mounted into a strip called a heat sink. The positive diodes are easily identified

as the ones within small cavities or depressions.

The alternator charging system is a negative (-) ground system which consists

of an alternator, a regulat or, a charge indicator, a storage battery and wiring

connecting the components, and fuse link wire.

The alternator is belt-driven from t he engine. Energy is supplied from the

alternator/regulator system to the rotati ng field through two brushes to two slip-

rings. The slip-rings are mounted on the rotor shaft and are connected t\

o the

field coil. This energy supplied to the ro tating field from the battery is called

excitation current and is used to init ially energize the field to begin the

generation of electricity. Once the alter nator starts to generate electricity, the

excitation current comes from its ow n output rather than the battery.

The alternator produces power in the form of alternating current. The alternating

current is rectified by 6 diodes into dire ct current. The direct current is used to

charge the battery and power the rest of the electrical system.

When the ignition key is turned ON, current flows from the battery, through the

charging system indicator light on the in strument panel, to the voltage regulator,

and to the alternator. Since the alternat or is not producing any current, the

alternator warning light comes on. When the engine is started, the alternator

begins to produce current and turns the alte rnator light off. As the alternator

turns and produces current, the current is divided in two ways: part to the

battery(to charge the battery and power the electrical components of the

vehicle), and part is returned to the alte rnator (to enable it to increase its

output). In this situation, the alternator is receiving current from the battery and

from itself. A voltage regulat or is wired into the current supply to the alternator

to prevent it from receiving too much cu rrent which would cause it to put out too

much current. Conversely, if the voltage regulator does not allow the alternator

to receive enough current, the battery will not be fully charged and will

eventually go dead.

The battery is connected to the alternator at all times, whether the ignition key is

turned ON or not. If the battery were shorted to ground, the alternator would

also be shorted. This woul d damage the alternator. To prevent this, a fuse link

is installed in the wiring between the battery and the alternator. If the battery is

shorted, the fuse link melts, protecting the alternator.

An alternator is better that a convent ional, DC shunt generator because it is

lighter and more compact, because it is designed to supply the battery and

accessory circuits through a wide range of engine speeds, and because it

eliminates the necessary maintenance of replacing brushes and servicing

commutators.

PRECAUTIONS

Page 352 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 352

To prevent serious damage to the alte

rnator and the rest of the charging

system, the following precauti ons must be observed:

• Never reverse the battery connections.

• Booster batteries for starting must be connected properly: positive-to-

positive and negative-to-ground.

• Disconnect the battery cables before using a fast charger; the charger

has a tendency to force current through the diodes in the opposite

direction for which they were designed. This burns out the diodes.

• Never use a fast charger as a booster for starting the vehicle.

• Never disconnect the voltage regulator while the engine is running.

• Avoid long soldering times when replacing diodes or transistors.

Prolonged heat is damaging to AC alternators.

• Do not use test lamps of more t han 12 volts (V) for checking diode

continuity.

• Do not short across or ground any of the terminals on the AC alternator.

• The polarity of the battery, alter nator, and regulator must be matched

and considered before making any elec trical connections within the

system.

• Never operate the alternator on an open circuit. make sure that all

connections within the circ uit are clean and tight.

• Disconnect the battery terminals when performing any service on the

electrical system. This wil l eliminate the possibility of accidental reversal

of polarity.

• Disconnect the battery ground cable if arc welding is to be done on any

part of the car.

CHARGING SYSTEM TROUBLESHOOTING

There are many possible ways in whic h the charging system can malfunction.

Often the source of a problem is diffi cult to diagnose, requiring special

equipment and a good deal of experience. However, when the charging system

fails completely and causes the dash boar d warning light to come on or the

battery to become dead the following items may be checked:

1. The battery is known to be good and fully charged.

2. The alternator belt is in good condition and adjusted to the proper

tension.

3. All connections in t he system are clean and tight.

REMOVAL & INSTALLATION

Page 653 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 653

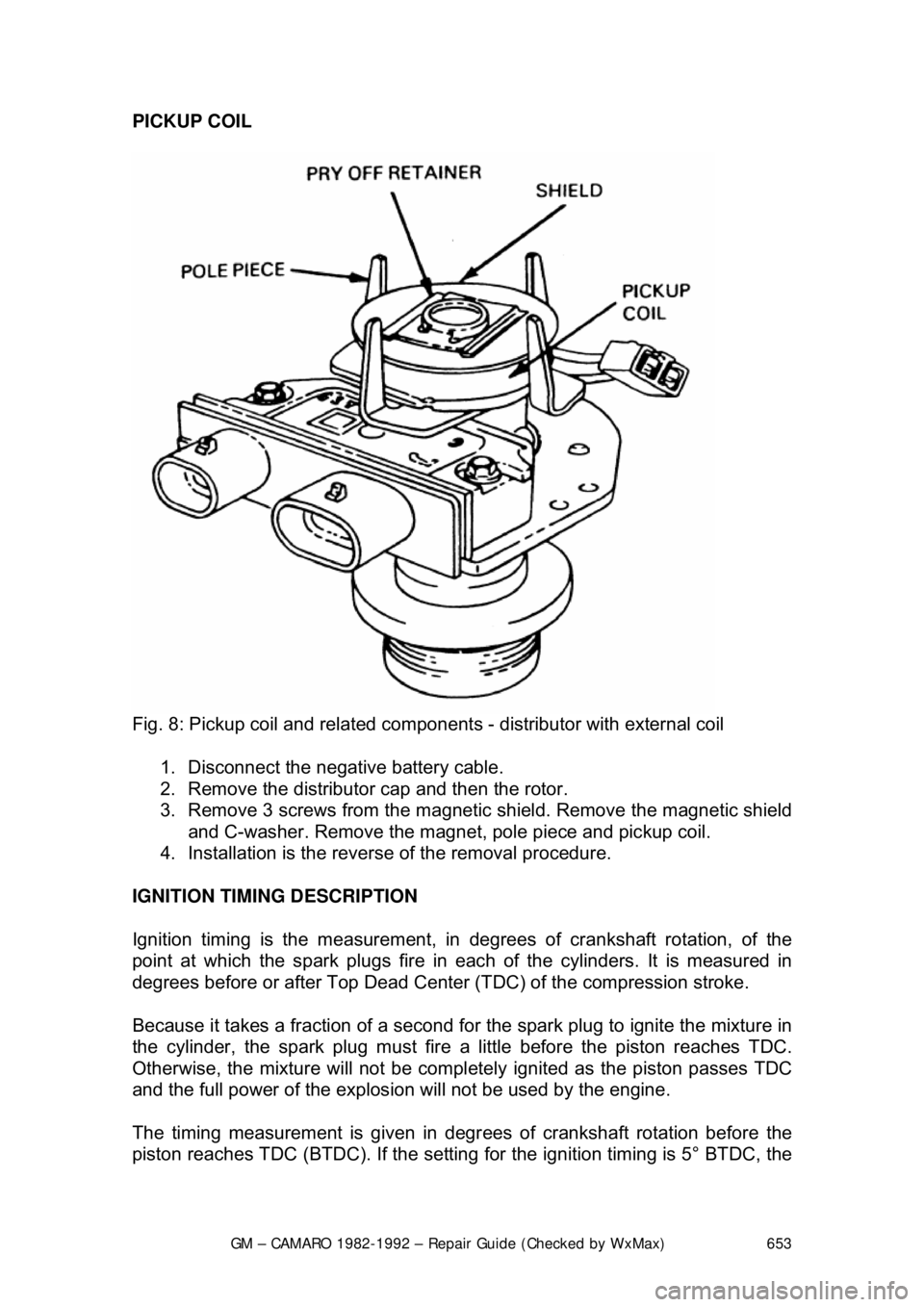

PICKUP COIL

Fig. 8: Pickup coil and related component s - distributor with external coil

1. Disconnect the negative battery cable.

2. Remove the distributor cap and then the rotor.

3. Remove 3 screws from the magnetic shield. Remove the magnetic shield

and C-washer. Remove the magnet, pole piece and pickup coil.

4. Installation is the revers e of the removal procedure.

IGNITION TIMING DESCRIPTION

Ignition timing is the measurement, in de grees of crankshaft rotation, of the

point at which the spark plugs fire in eac h of the cylinders. It is measured in

degrees before or after Top Dead Center (TDC) of the compression stroke.

Because it takes a fraction of a second for the spark plug to ignite the mixture in

the cylinder, the spark plug must fire a little before the piston reaches TDC.

Otherwise, the mixture will not be complete ly ignited as the piston passes TDC

and the full power of the explosion will not be used by the engine.

The timing measurement is given in degr ees of crankshaft rotation before the

piston reaches TDC (BTDC). If the setting fo r the ignition timing is 5° BTDC, the

Page 810 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 810

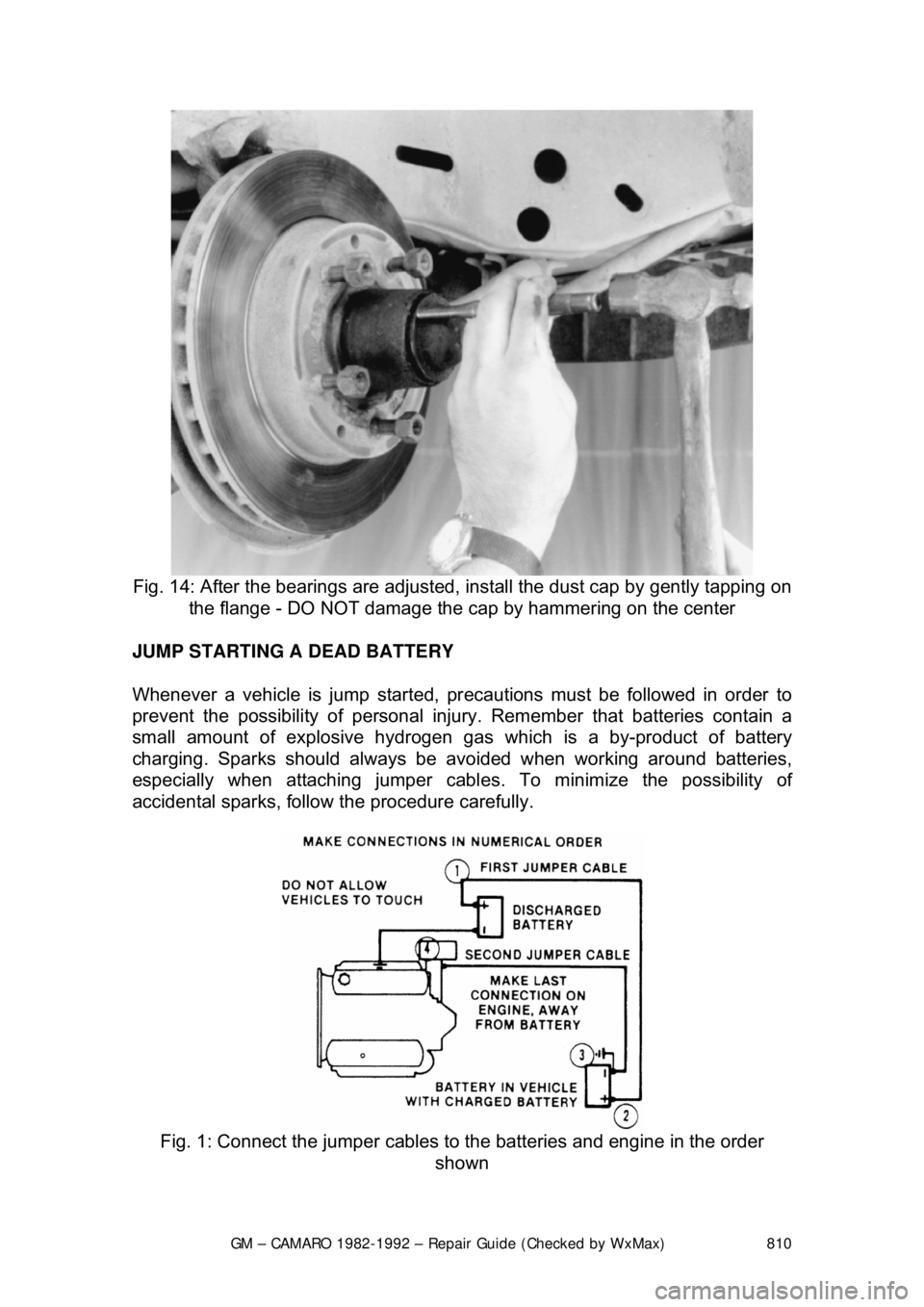

Fig. 14: After the bearings are adjusted, install the dust cap by gently tapping on

the flange - DO NOT damage the c ap by hammering on the center

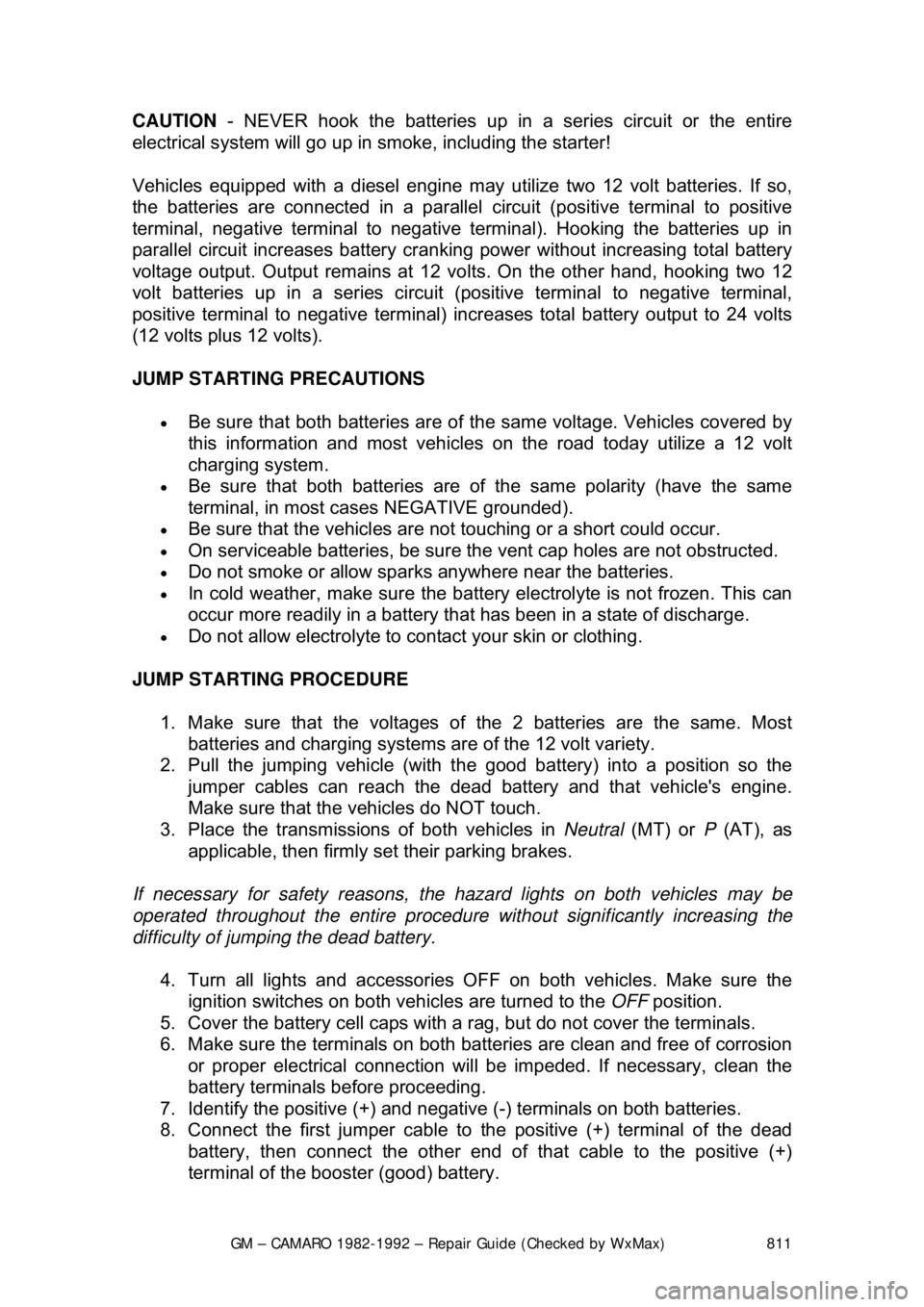

JUMP STARTING A DEAD BATTERY

Whenever a vehicle is jump started, pr ecautions must be followed in order to

prevent the possibility of personal inju ry. Remember that batteries contain a

small amount of explosive hydrogen gas which is a by-product of battery

charging. Sparks should always be av oided when working around batteries,

especially when attaching jumper cabl es. To minimize the possibility of

accidental sparks, follow the procedure carefully.

Fig. 1: Connect the jumper cables to the batteries and engine in the order

shown

Page 811 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 811

CAUTION

- NEVER hook the batteries up in a series circuit or the entire

electrical system will go up in smoke, including the starter!

Vehicles equipped with a diesel engine may utilize two 12 volt batteries. If so,

the batteries are connected in a parallel circuit (positive terminal to positive

terminal, negative terminal to negative te rminal). Hooking the batteries up in

parallel circuit increases battery cranki ng power without increasing total battery

voltage output. Output remains at 12 vo lts. On the other hand, hooking two 12

volt batteries up in a series circuit (positive terminal to negative terminal,

positive terminal to negative terminal) incr eases total battery output to 24 volts

(12 volts plus 12 volts).

JUMP STARTING PRECAUTIONS

• Be sure that both batteries are of t he same voltage. Vehicles covered by

this information and most vehicles on the road today utilize a 12 volt

charging system.

• Be sure that both batteries are of the same polarity (have the same

terminal, in most cases NEGATIVE grounded).

• Be sure that the vehicles are not touching or a short could occur.

• On serviceable batteries, be sure the v ent cap holes are not obstructed.

• Do not smoke or allow sparks anywhere near the batteries.

• In cold weather, make sure the battery electrolyte is not frozen. This can

occur more readily in a battery that has been in a state of discharge.

• Do not allow electrolyte to c ontact your skin or clothing.

JUMP STARTING PROCEDURE 1. Make sure that the voltages of the 2 batteries are the same. Most

batteries and charging systems are of the 12 volt variety.

2. Pull the jumping vehicle (with t he good battery) into a position so the

jumper cables can reach the dead battery and that vehicle's engine.

Make sure that the ve hicles do NOT touch.

3. Place the transmissions of both vehicles in Neutral (MT) or P (AT), as

applicable, then firmly set their parking brakes.

If necessary for safety reasons, the hazard lights on both vehicles may be

operated throughout the entir e procedure without significantly increasing the

difficulty of jumping the dead battery.

4. Turn all lights and accessories OFF on both vehicles. Make sure the ignition switches on both vehicles are turned to the OFF position.

5. Cover the battery cell caps with a rag, but do not cover the terminals.

6. Make sure the terminals on both batte ries are clean and free of corrosion

or proper electrical connection wil l be impeded. If necessary, clean the

battery terminals before proceeding.

7. Identify the positive (+) and negat ive (-) terminals on both batteries.

8. Connect the first jumper cable to the positive (+) terminal of the dead

battery, then connect the other end of that cable to the positive (+)

terminal of the booster (good) battery.

Page 812 of 875

GM – CAMARO 1982-1992 – Repair Guide (Checked by WxMax) 812

9. Connect one end of the other jumper

cable to the negative (-) terminal on

the booster battery and the final cable clamp to an engine bolt head,

alternator bracket or ot her solid, metallic point on the engine with the

dead battery. Try to pick a ground on the engine that is positioned away

from the battery in order to minimi ze the possibility of the 2 clamps

touching should one l oosen during the procedure. DO NOT connect this

clamp to the negative (-) term inal of the bad battery.

CAUTION - Be very careful to keep the jum per cables away from moving parts

(cooling fan, belts, etc.) on both engines.

10. Check to make sure that the c ables are routed away from any moving

parts, then start the d onor vehicle's engine. Run the engine at moderate

speed for several minutes to allow the dead battery a chance to receive

some initial charge.

11. With the donor vehicle's engine still r unning slightly above idle, try to start

the vehicle with the dead battery. Crank the engine for no more than 10 \

seconds at a time and let the starter cool for at least 20 seconds between

tries. If the vehicl e does not start in 3 tries, it is likely that something else

is also wrong or that the battery needs additional time to charge.

12. Once the vehicle is star ted, allow it to run at idle for a few seconds to

make sure that it is operating properly.

13. Turn ON the headlight s, heater blower and, if equipped, the rear

defroster of both vehicles in order to reduce the severity of voltage spikes

and subsequent risk of dam age to the vehicles' electrical systems when

the cables are disconnected. This st ep is especially important to any

vehicle equipped with computer control modules.

14. Carefully disconnect the cables in the reverse order of connection. Star\

t with the negative cable that is attached to the engine ground, then the

negative cable on the donor battery. Di sconnect the positive cable from

the donor battery and finally, disconnect the positive cable from the

formerly dead battery. Be careful when disconnecting the cables from the

positive terminals not to allow the alli gator clips to touch any metal on

either vehicle or a short and sparks will occur.

JACKING

Your vehicle was supplied with a jack for emergency road repairs. This jack is

fine for changing a flat tire or other s hort term procedures not requiring you to

go beneath the vehicle. If it is used in an emergency situation, carefully follow

the instructions provided eit her with the jack or in your owner's manual. Do not

attempt to use the jack on any portions of the vehicle other than specified by the

vehicle manufacturer. Always block the diagonally opposite wheel when using a

jack.

A more convenient way of jacking is the use of a garage or floor jack. You may

use the floor jack to raise the vehicle in the areas shown in the illustration .